#Best Slitter Machine

Explore tagged Tumblr posts

Text

A Heavy-Duty slitter rewinder machine is an integral part of converting wide rolls into smaller widths of material with high accuracy. The heavy-duty type is meant to deal with tougher materials, processing those smoothly while maintaining the best quality.

the Heavy-Duty Slitter Rewinder Cylinder Machine cuts and rewinds materials such as paper, plastic films, laminates, and foils with unmatched precision. Krishna Engineering Works the reputed name worldwide as a manufacturer and exporter of industrial machinery-supplies the best Slitter Rewinder Machines with excellent durability, precision, and ease of operation.

#krishnaengineeringworks#slitter rewinder machine#machine#manufacturer#machinemanufacturer#industry#export#supplier#machinery#industrial#heavy duty slitter rewinder machine#packaging industry#paper machinery#paper industry

2 notes

·

View notes

Text

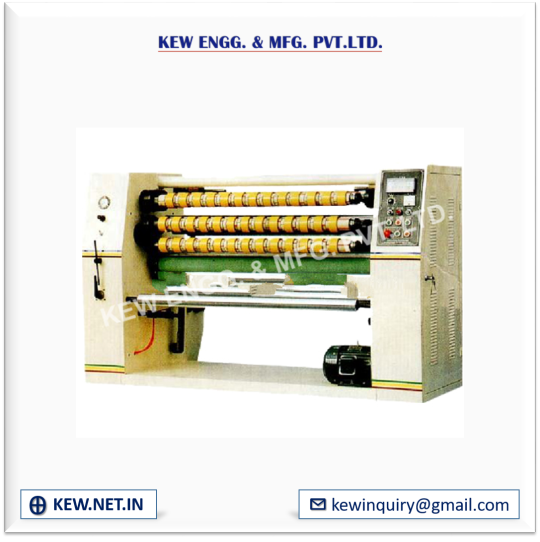

KEW ENGG. & MFG. PVT. LTD., we specialize in manufacturing cutting-edge Heavy Duty Drum Slitter Machine designed to meet diverse industrial requirements. Whether it’s for paper, plastic, textile, or packaging applications, our machines deliver unparalleled precision and durability.

#kewengg#machine#machinery#industry#machinemanufacture#industrial#exporter#supplier#manufacturer#manufacturing#Heavydutydrum#heavyduty#slittermachine#paper industry#papermachinery

2 notes

·

View notes

Text

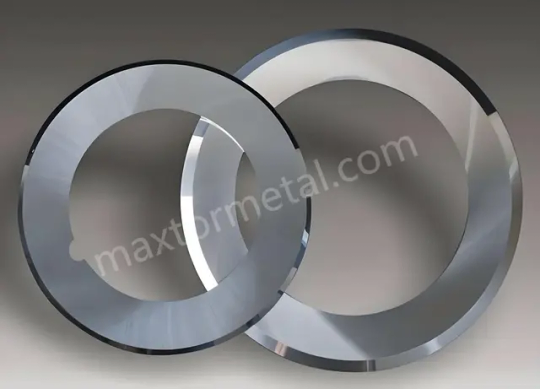

How to Maximize Slitter Blade Sharpness for Superior Cutting Performance

Summary

Maintaining the sharpness of a slitter blade is essential for achieving precise cuts, minimizing downtime, and improving operational efficiency. This article explores why sharpness retention matters, factors affecting blade longevity, advanced techniques for durability, and best practices for maintenance, ensuring your cutting tools perform at their best.

Introduction

In industrial applications, precision cutting is the cornerstone of efficiency and quality. The slitter blade, a critical component in industries like paper, metal, and plastic processing, must remain sharp to perform effectively. Dull blades lead to uneven cuts, wasted material, and costly downtime. This article delves into the technologies and strategies to retain the sharpness of slitting tools, helping you optimize performance and reduce costs.

By understanding the factors influencing blade sharpness and adopting advanced techniques, you can ensure your operations run smoothly. Let’s explore how you can keep your slitter blades sharp and effective for longer periods.

Why Sharpness Retention Matters for Slitter Blades

Sharpness plays a critical role in ensuring the efficiency and precision of industrial cutting processes. Whether you are cutting thin plastic films, thick metal sheets, or delicate paper rolls, maintaining a sharp edge on your slitter blade is essential. Let’s examine the specific impacts dull blades have on your operations:

1. Uneven Cuts

Dull blades fail to create clean, consistent edges, which can compromise the quality of the final product. For example, in the paper industry, jagged edges can lead to product rejection, affecting customer satisfaction and brand reputation. According to industry reports, manufacturers using dull blades experience up to 15% more defective products than those using well-maintained cutting tools.

2. Material Waste

Poor sharpness often results in inaccurate cuts, generating excess material waste. In industries handling expensive raw materials like aluminum or specialty polymers, this waste can represent significant financial losses. A study in a metal processing plant found that switching to precision-sharpened slitting knives reduced scrap rates by 25%, saving approximately $100,000 annually.

3. Increased Wear on Equipment

Using a dull blade requires more force to achieve the same cuts, which puts undue stress on machinery. Over time, this can lead to faster wear and tear on mechanical components, increasing maintenance costs and the risk of equipment failure. Preventive maintenance through blade sharpness retention can lower machine repair expenses by 20%.

4. Downtime for Maintenance

Frequent blade sharpening or replacement interrupts production schedules, resulting in costly downtime. In high-volume production environments, even an hour of unscheduled maintenance can translate into thousands of dollars in lost revenue. Maintaining sharper blades significantly extends service intervals, keeping your operations running smoothly.

The Competitive Edge

Maintaining sharp blades is more than just a technical necessity—it’s a strategic advantage. Companies that invest in blade sharpness retention report up to 30% better operational efficiency, giving them an edge in competitive markets.

Keep reading to explore the factors affecting sharpness and how to address them.

Key Factors Affecting Slitter Blade Sharpness

1. Blade Material

Blade composition significantly affects sharpness retention. High-grade alloys such as M2 tool steel, tungsten carbide, and ceramic composites offer excellent hardness and durability. A coated slitting blade can last twice as long as an uncoated one under similar conditions. For example, tungsten carbide-coated blades can withstand up to 500,000 cuts before requiring sharpening, compared to just 250,000 for standard steel.

2. Cutting Environment

The type of material being processed greatly influences blade wear. Harder materials like steel generate more friction and heat, which can quickly degrade blade edges. Additionally, cutting plastics or rubber often produces sticky residues that dull blades faster if not cleaned properly. Addressing these environmental factors with proper lubrication and cleaning can extend blade life by up to 40%.

3. Maintenance Practices

Inadequate blade maintenance is a major factor in premature dulling. For instance, incorrect sharpening angles can weaken the blade edge, while poor cleaning techniques may leave residues that accelerate wear. Implementing systematic maintenance schedules helps ensure consistent blade performance.

4. Innovative Blade Design

Advanced blade designs optimize edge geometry for specific applications. For example, beveled edges reduce cutting resistance and friction, improving durability. Laser-precision manufacturing techniques can achieve tolerances as fine as 0.001mm, creating sharper, more reliable blades.

Advanced Techniques to Prolong Slitter Blade Sharpness

1. Coating Technologies

Special coatings protect blade surfaces from wear and corrosion. For example, titanium nitride coatings increase surface hardness, allowing blades to retain sharpness 50% longer in high-speed operations. Similarly, diamond-like carbon coatings reduce friction, lowering operational temperatures and improving edge retention.

2. Cryogenic Treatment

Cryogenic processing aligns the internal structure of metals, enhancing their hardness and resistance to wear. Studies show that cryogenically treated industrial cutting tools last 30% longer than untreated blades in heavy-duty environments.

3. Precision Grinding and Sharpening

Grinding machines capable of maintaining a consistent edge angle ensure that the blade delivers smooth, precise cuts. Automated sharpening systems eliminate human error, providing consistent results that increase blade longevity by up to 20%.

4. Custom Blade Design

Tailored blade solutions enhance performance for specific applications. For example, rotary knives designed for textile cutting may feature serrated edges to minimize wear while ensuring clean cuts. Custom designs reduce maintenance frequency and improve process efficiency.

Maintenance Best Practices to Retain Blade Sharpness

Routine care and attention can drastically extend the lifespan of your slitting knives.

1. Routine Inspections

Perform regular checks for visible damage, including nicks, burrs, or uneven wear. An inspection log helps identify patterns and predict when blades require sharpening or replacement.

2. Proper Cleaning

Use non-abrasive tools and solvents to remove residues after each use. For example, a specialty blade-cleaning solution can reduce buildup by 50%, minimizing the risk of dulling.

3. Lubrication

Choose a lubricant that matches the cutting environment. For example, water-based lubricants are effective for heat-sensitive applications, while oil-based options are ideal for heavy-duty metal cutting. Proper lubrication reduces friction, extending blade life by 15%-25%.

4. Correct Storage

Preventing physical damage during storage is crucial. Blades should be kept in dry, temperature-controlled environments, and protective covers should always be used.

5. Operator Training

Ensure operators understand proper blade handling techniques, such as avoiding direct contact with edges and correctly aligning blades during installation. Trained staff are less likely to cause accidental damage, reducing blade replacements by up to 10%.

By adopting these best practices, you can ensure peak performance from your cutting tools.

How Our Slitter Blades Stand Out in Sharpness Retention

At [Your Company Name], we prioritize precision and durability in every slitter blade we manufacture. Here’s why our products excel:

Superior Materials: Our blades are crafted from premium alloys and coated with cutting-edge technologies to ensure unmatched sharpness retention.

Advanced Manufacturing: We use precision grinding and laser cutting to create blades tailored to your specific needs.

Proven Performance: Our blades have helped clients reduce downtime by 40% and improve product quality consistently.

Client Testimonial:

“We switched to Metal’s industrial cutting tools, and the difference was night and day. Less waste, smoother cuts, and longer blade life!” – Operations Manager, Packaging Industry

Our commitment to quality ensures that your cutting operations remain seamless and efficient.

Contact us today to learn how we can optimize your cutting processes.

Conclusion and Call to Action

Sharpness retention is the cornerstone of efficient and cost-effective cutting operations. By understanding the factors that affect slitter blade performance, leveraging advanced technologies, and following best maintenance practices, you can enhance blade durability and reduce operational costs.

Ready to upgrade your cutting tools? Discover how our advanced solutions can revolutionize your operations. Custom Industrial Blades Manufacturer in China and Custom Industrial Blades Supplier in China. Contact us today!

1 note

·

View note

Text

CONPAPTEX EQUIPMENTS delights in high-performance solutions at par with the world of modern manufacturing pace.

#conpaptex#machine#manufacturing#exporter#supplier#industrial#slitterrewinder#rewindermachine#machinery#highperformance

1 note

·

View note

Text

Pelican Rotoflex's 'Make in India' innovations at drupa 2024

Rajkot-based Pelican Rotoflex highlighted the ‘Make in India’ theme at drupa 2024, showcasing its Solomark 6450 ELS rotogravure press technology and the Acrostar turret slitter at the printing expo held in Düsseldorf from 28 May to 7 June.

“We did not run the full press but displayed a demo unit that showcased all the features of the Solomark 6450. We highlighted various features of the machine, including the semi-floatation dryer and the highly efficient ventilation module. The efficiency of this press is fantastic. There is a servo control damper for recycling air, which reduces energy consumption,” said Yash Shrimanker of Pelican Rotoflex.

The Solomark 6450 rotogravure printing press has been designed for a wide range of print substrates, including new eco-friendly substrates. It features easy operation, quick changeover with multiple trolley options, and aims to reduce wastage. “As margins are shrinking and the industry is becoming competitive, customers are ready to invest in quality machinery that can help them reduce costs. At Pelican, we provide the best solutions to help reduce wastage, ink consumption, and save power. And the best part is, our presses are made in India,” Shrimanker added.

Talking about drupa, Shrimanker said the show was great and they received some genuine inquiries during the expo. “We had many overseas visitors who were impressed not only by our Solomark 6450 but also the our converting equipment. Our displays and presentation evoked extremely positive response and appreciation from our visitors,” he stated.

Shrimanker also commented on the potential of the Indian packaging market, stating, “To be honest, the Indian market is where the big growth is. We expect the Indian packaging market to be robust for many years to come. A lot of global companies and investors are looking to invest in India. The biggest thing is, the name of 'Made in India' products is now getting due recognition globally.”

Pelican’s new state-of-the-art manufacturing plant, set up on a sprawling estate of 24 acres in 2020, is located about 25 kilometers from the city of Rajkot in Gujarat.

0 notes

Text

How to Find the Best Deals on Dennis Lawn Mowers For Sale?

Dennis Lawn Mower For Sale, Dennis is the leading British manufacturer of innovative professional fine turf maintenance equipment. Dennis helps groundsmen, greenkeepers and gardeners the world over to create their ultimate natural turf surface. Dennis offer a wide range of cylinder mowers and grounds maintenance equipment that enable groundsmen, greenkeepers and gardeners to create their perfect surface. Dennis manufacture walk behind cylinder mowers for the discerning professional, featuring interchangeable cassettes which give the option to fit 12 different heads including scarifiers, verticutters, brushes, spikers and slitters in 15 seconds. Dennis machines are used at high profile International stadia around the world, many top football, cricket, golf and bowling clubs as well as local authorities, schools, colleges and universities.

#Dennis Lawn Mower For Sale#Dennis Mowers#Dennis Mower#Dennis Lawn Mower#Dennis Mowers UK#Dennis Lawn Mowers#Dennis Lawn Mowers For Sale

0 notes

Text

"When in 1956, after the capitulation of Monsieur Guy Mollet to the settlers in Algeria, the Front de Libération Nationale, in a famous leaflet, stated that colonialism only loosens its hold when the knife is at its throat, no Algerian really found these terms too violent. The leaflet only expressed what every Algerian felt at heart: colonialism is not a thinking machine, nor a body endowed with reasoning faculties. It is violence in its natural state, and it will only yield when confronted with greater violence. At the decisive moment, the colonialist bourgeoisie, which up till then has remained inactive, comes into the field. It introduces that new idea which is in proper parlance a creation of the colonial situation: non-violence. In its simplest form this non-violence signifies to the intellectual and economic elite of the colonized country that the bourgeoisie has the same interests as they and that it is therefore urgent and indispensable to come to terms for the public good. Nonviolence is an attempt to settle the colonial problem around a green baize table, before any regrettable act has been performed or irreparable gesture made, before any blood has been shed. But if the masses, without, waiting for the chairs to be arranged around the baize table, listen to their own voice and begin committing outrages and setting fire to buildings, the elite and the nationalist bourgeois parties will be seen rushing to the colonialists to exclaim, “This is very serious! We do not know how it will end; we must find a solution–some sort of compromise.” This idea of compromise is very important in the phenomenon of decolonization, for it is very far from being a simple one. Compromise involves the colonial system and the young nationalist bourgeoisie at one and the same time. The partisans of the colonial system discover that the masses may destroy everything. Blown-up bridges, ravaged farms, repressions, and fighting harshly disrupt the economy. Compromise is equally attractive to the nationalist bourgeoisie, who since they are not clearly aware of the possible consequences of the rising storm, are genuinely afraid of being swept away by this huge hurricane and never stop saying to the settlers: “We are still capable of stopping the slaughter; the masses still have confidence in us; act quickly if you do not want to put everything in jeopardy.” One step more, and the leader of the nationalist party keeps his distance with regard to that violence. He loudly proclaims that he has nothing to do with these Mau-Mau, these terrorists, these throat-slitters. At best, he shuts himself off in a no man’s land between the terrorists and the settlers and willingly offers his services as go-between; that is to say, that as the settlers cannot discuss terms with these Mau-Mau, he himself will be quite willing to begin negotiations. Thus it is that the rear guard of the national struggle, that very party of people who have never ceased to be on the other side in the fight, find themselves somersaulted into the van of negotiations and compromise–precisely because that party has taken very good care never to break contact with colonialism." -Franz Fanon, "The Wretched of the Earth"

1 note

·

View note

Link

Krishna Engineering Works is Manufacturing, Exporting and Supplying standard quality of many types of slitter rewinder machine like Plastic, Paper, Flexible Packaging, PVC, Aluminium Foil, Stretch Film, LDPE Film, BOPP Film, BOPP Tape, OPP, METPET, Pet Film, OPA, Non-Woven Fabric, Paper Board, Adhesive Tape, Film Ribbon, Textile Cloth, Nylon Fabric, Micro Tape, Coated Paper, Ice Cream Cup Paper, Fax Roll, Laminated Film, Cling Film, Duct Tape, Mask Tape, Rubber, Tarpaulin, Tube, etc.

#Paper Slitter Rewinder Machine#Paper And Board Slitter Machine#Paper And Board Slitter Rewinder Machine#Slitter Machine#Slitter Rewinder Machine#Best Slitter Machine#Slitter Machine Manufacturer#Slitter Rewinder Machine Manufacturer#Paper Slitting And Rewinding Machine#Mini Bopp Tape Slitting Machine#Roll Slitting Machine for Sale

0 notes

Link

We “Krishna Engineering Works” are biggest manufacturer exporter & supplier of all types of slitter rewinder machine. We are engaged in supplying a wide range of Slitter Rewinder Machine of Metallized Film. machines are developed and designed for Metallized films with high quality equipment, high grade raw material in compliance with industry laid norms. For more information visit our website: krishnaengineeringworks.com

#Slitter rewinder machine#slitting machine#slitter rewinder at best price#slitter manufacturer#slitter machine manufacturer

2 notes

·

View notes

Link

KEW ENGG MFG PVT LTD is biggest manufacturer, exporter & supplier of easy stackable film slitter rewinder machine. Featuring and functioning like, slitting line, High quality on levelling, High cutting accuracy, and High productivity. For more information visit our website: kew.net.in

1 note

·

View note

Text

Krishna Engineering Works has a solution that best fits your manufacturing unit or enterprise. Know more about its latest machines from Krishna Engineering Works. Upgrade your paper-making productivity and establish your company as an industry leader in the long term.

heavy duty type slitter drum rewinder machine can process all kinds of paper of any GSM thickness. In our heavy duty series paper slitting rewinding machine, the rewinding diameter can be achieved up to 1200mm.

#krishnaengineeringworks#machine#manufacturer#machinery#industry#export#supplier#industrial#machinemanufacturer#slitterrewindermachine#heavydutyslitterrewindermachine#slittingrewindingmachine#paperindustry#papermachinery

1 note

·

View note

Link

KEW ENGG MFG PVT LTD is biggest manufacturer, exporter & supplier of Deep Freeze Film Slitter Rewinder Machine at best price. We are manufacturing, exporting & supplying all types of slitter rewinder for deep freeze film including EVA, LDPE, MDPE & HDPE. For more information about products and inquiry please visit our official website “kew.net.in” or contact us at [email protected]

#Paper slitter rewinder machine#slitter rewinder machine#slitter rewinder machine manufacturer#deep freeze film slitter rewinder machine at best price#slitter rewinder manufacturers

5 notes

·

View notes

Link

Con Pap Tex is biggest manufacturer, exporter & supplier of all types of textile machineries like slitter, printing machine. Shaft winder slitter rewinder machine is the design incorporate the three motor control system & unwind pneumatic brake with load cell feed brake Digital Edge/line guiding to achieve high speed correction.

#Slitter rewinder machine#slitter rewinder machine manufacturer#shaft winder slitter rewinder machine#shaft winder at best price#all types of slitter manufacturer#slitter at best price

1 note

·

View note

Link

Krishna Engineering Works is biggest manufacturer, exporter and supplier of PP Slitter Rewinder Machine at best price and standard quality. Slitting of all types of material like Plastic, Paper, Flexible Packaging, PVC, Aluminium Foil, Stretch Film, LDPE Film, BOPP Film. For any types of inquiry of Slitter machine and spare parts please visit our website: [email protected]

#Slitter Rewinder Machine Manufacturer#PP Slitter Rewinder Machien Manufacturer#Sliiter Rewinder Machine at best price#Slitter Rewinder Machine Exporter

1 note

·

View note

Text

Kolkata's AB Polypacks adds a new rotogravure press

AB Polypacks, a West Bengal-headquartered one-stop shop for a wide range of flexible packaging solutions, recently added a 9-color Solomark ELS 6450 rotogravure press from Pelican Rotoflex to its portfolio. The company had earlier added a turret slitter from Pelican.

With its manufacturing facility spread over 1.5 lakh square feet of land in Howrah near Kolkata, the company, which started its journey in 2006, provides a wide range of flexible packaging solutions, including collation shrink films, shrink labels, wrap-around labels, laminates, and all kinds of pouches, under one roof.

The Solomark 6450 has a maximum web width of up to 1300 mm, with a web tension range of 60 to 400N and a reel diameter of 1000 mm. Chinmay Kumar, co-founder of AB Polypacks, emphasized its high energy efficiency with lower power consumption and less waste. “It is user-friendly with better operational ease with better print quality and higher productivity,” he said.

According to Kumar, the machines present in the plant's arsenal for printing, lamination, blown films, shrink labels, and pouching are what set the company apart from its counterparts.

The printing unit, apart from the new Solomark 6450, is equipped with four more high-speed rotogravure printing presses. It has expertise in a diverse range of materials, ranging from polyester and PVC to PET-G, shrink film, BOPP film, foil, and paper.

The blown polyethylene film unit at the plant has a production capacity of 10,000 metric tonnes per annum. The company says it takes pride in manufacturing the best quality three-layer collation shrink film and poly films of a wide variety for lamination.

Speaking about the blown film unit, Kumar said, “Our W&H Optimex extruder provides excellent mechanical strength, and a completely automated machine provides precise operations. The thickness controller ensures easy downgauging and reduces micron variation with minimum wastage.” The major suppliers of plastic granules to the plant are HPL, IOCL, Dow Chemicals, and Borouge.

To provide high-quality packaging material, the manufacturing unit is equipped with fully automatic corona treatment machines such as Nordmeccanica. It is a combi line in which simultaneously solventless and base facility can be utilized.

The pouching unit manufactures various types such as three-sided sealed pouches, central seal pouches, stand-up pouches, pillow pouches, spout pouches, shaped pouches, and various customized pouches as per requirements.

With the entire gamut of flexible packaging solutions under one roof, the company offers its products to the food packaging, liquid packaging, healthcare, and agriculture sectors, the household and personal care sectors, and the spices industry as well.

“High barrier properties along with high aroma retention properties of our packaging material make us the supplier of choice to most of the spices brands in the country,” he said. Multinational brands such as Coca-Cola, Pepsico, Hindustan Unilever, Britannia, Parle Agro, Haldiram’s, Pidilite Industries, etc., form part of the company's key client portfolio.

On the sustainability front, Kumar aims to make solar power the primary renewable source of energy for AB Polypacks by the year 2025. “Through the integration of new technology and machinery, we are wholeheartedly embracing sustainability.” According to Kumar, the company works to reduce waste and energy consumption in the manufacturing process, thereby doing its bit to produce more responsible packaging solutions.

0 notes

Link

KEW ENGG MFG PVT LTD is biggest manufacturer of all types of Slitter Rewinder Machine at best price and standard quality. Metalized BOPP Film Slitter rewinder machine is our high sealing products in market. Heavy duty slitting rewinding machine for all types of High Barrier Metalized BOPP Film, Metallized BOPP Film with high quality equipment.

#Slitter Rewinder Machine manufacturer#BOPP Film Slitter Rewinder Machine Manufacturer#Slitting Machine at best price

0 notes