#Butterfly Valve Manufacturers

Text

Butterfly Valve Manufacturer and Supplier

Cwtvalve is one of the Best Butterfly Valve Manufacturer and Supplier company it provides the best Butterfly Valve. This valves are used in pipelines to shut-off flow of water. This types of valve are used where space is limited.

0 notes

Text

JSR Global Sales Company: Crafting Excellence in Butterfly Valve Manufacturers

In the world of industrial valves, JSR Global Sales Company stands as a paragon of innovation and quality. As leading manufacturers of butterfly valves, they have carved a niche for themselves, delivering top-notch solutions to industries worldwide.

Cutting-Edge Technology: JSR Global Sales Company's journey is marked by a commitment to technological advancement. Their butterfly valves are engineered with precision and reliability in mind, ensuring seamless fluid control in various applications and Butterfly Valve Manufacturers.

Versatile Range: JSR Global Sales Company offers a versatile range of butterfly valves, each celebrated for its unique characteristics and applications. From small-scale operations to heavy-duty industrial use, their product lineup is designed to meet diverse needs.

Customization Expertise: What sets JSR Global Sales Company apart is their ability to provide tailor-made solutions. They collaborate closely with clients to understand their specific requirements and deliver butterfly valves that meet or exceed expectations. This client-centric approach has earned them a loyal customer base.

Quality Assurance: Quality is a cornerstone of JSR Global Sales Company's operations. Stringent quality control measures and rigorous testing guarantee that every butterfly valve leaving their facility is reliable, durable, and capable of withstanding the harshest industrial conditions and Butterfly Valve.

Innovation and Sustainability: JSR Global Sales Company doesn't just excel in innovation but also prioritizes sustainability. Their eco-friendly manufacturing practices reflect their commitment to reducing environmental impact while maintaining the highest standards of performance.

Customer-Centric Approach: JSR Global Sales Company places customer satisfaction at the forefront of their business philosophy. Exceptional customer support, timely deliveries, and competitive pricing ensure a seamless experience for their clients.

In conclusion, JSR Global Sales Company's relentless pursuit of excellence has solidified its position as a reputable butterfly valve manufacturer. Their technological prowess, commitment to quality, and dedication to customer satisfaction make them the preferred choice for industries seeking top-tier fluid control solutions. For those looking to optimize their fluid management processes, JSR Global Sales Company is the name to trust in the industrial valve manufacturing industry.

0 notes

Text

TAJ HOTELS RELY ON KIRLOSKAR FOR COMFORT COOLING

Kirloskar Chillers Pvt. Ltd. is a Kirloskar Group Company, delivering futuristic solutions in the space of HVAC & R.

For decades, Taj Hotels have trusted Kirloskar chillers to deliver their commitment of an unmatched comfort cooling experience for their guests.

TAJ – A HAPPY CUSTOMER

Taj, a globally reputed world-class hotel chain famed for its unmatched royal hospitality that resonates with Indian tradition and heritage. It is one of Asia’s largest group with over 98 Hotels in 61 locations worldwide.

Kirloskar Water cooled screw chillers are installed in 18 of their hotels in India & Sri Lanka. These hotels are located in the subtropical regions where ambient temperatures are high and range from 32C to 48C throughout the year. Taj hotels are expansive structures which include amenities like guest rooms, multi-cuisine restaurants, banquet halls, meeting rooms, kitchens, fitness centers, spas and lobbies that are open 24X7 where HVAC system has to be operated for 24 hours.

Kirloskar’s Objective

to enhance the quality of air and human comfort in residential, commercial & industrial buildings

to protect food and perishables

to increase industrial productivity and efficiency

Kirloskar’s Sustainable Goals

superior operating efficiency

design flexibility

unmatched reliability

ease of maintenance

Kirloskar Chillers is the only chillers manufacturer in India having centrifugal and screw technology under one roof with the prestigious AHRI certification for the water-cooled and screw chillers.

Email : [email protected]

URL : https://3t-saudi.com/

#valve#suadi#air conditioning#air compressor menards#air compressor receiver tank#air compressor market#kirloskar#butterfly valve manufacturers#REFRIGERATION COMPRESSORS

1 note

·

View note

Text

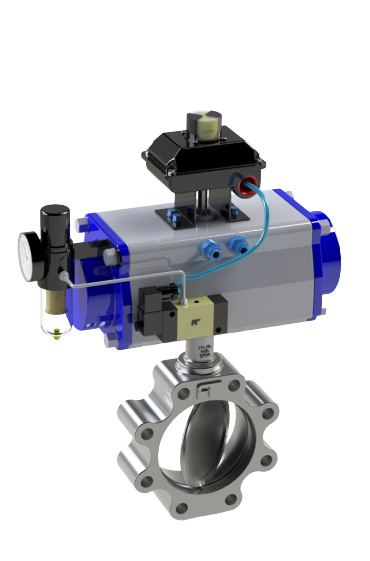

A butterfly valve insulates or regulates the flow of a fluid. This valve has a disc which is connected to a rotating shaft. When the valve is fully closed at that time the disk completely blocks the pipeline.

#butterfly valve manufacturers#Wafer butterfly valve#4 butterfly valve#6 butterfly valve#3 butterfly valve#flanged butterfly valve

0 notes

Text

Industrial dampers manufacturer in Pune

Pune, a bustling hub of industrial activity in India, is home to numerous manufacturing companies, including Parth Valve & Hoses Pvt. Ltd, a leading high-quality Industrial Dampers manufacturer. With a strong commitment to innovation, quality, and customer satisfaction, Parth Valve is the go-to choice for businesses seeking reliable and efficient solutions for their industrial needs

A Legacy of Excellence

Founded with a vision to deliver top-notch industrial solutions, Parth Valve has grown to become a prominent name in the manufacturing sector. Their extensive experience and expertise have earned them a reputation for producing some of the best Industrial Dampers manufacturer in Pune market. The company’s dedication to maintaining high standards is evident in every product they manufacture.

Industrial Dampers

Cutting-Edge Technology and Innovation

Parth Valve is at the forefront of technological innovation and is also the leading Industrial Dampers manufacturer in Pune. They utilize state-of-the-art machinery and employ advanced manufacturing techniques to ensure their products meet the highest quality standards. By continuously investing in research and development, Parth Valve stays ahead of the curve, delivering innovative solutions that cater to the evolving needs of their clients.

Industrial Dampers

Comprehensive Product Range

Parth Valve, the Industrial Dampers manufacturer in Pune, offers a wide range of Industrial Dampers designed to meet diverse industrial requirements. Their product line-up includes:

Butterfly Dampers:

Known for their compact design and efficient operation, butterfly dampers are ideal for applications requiring tight shut-off and precise flow control.

Guillotine Dampers: These dampers are perfect for isolating sections of ductwork or equipment, providing a reliable seal even in high-temperature environments.

Louver Dampers: Designed for precise airflow regulation, louver dampers are used in various industrial applications to control ventilation and exhaust systems.

Multi-Louver Dampers: These dampers offer superior control over airflow, making them suitable for complex ventilation systems in industrial settings.

Quality Assurance

Quality is at the core of Parth Valve’s manufacturing process. Each product undergoes rigorous testing and quality checks to ensure it meets the stringent industry standards. The company is ISO certified, which reflects its commitment to delivering products that are not only reliable but also durable and efficient.

Customer-Centric Approach

Parth Valve’s success can be attributed to their customer-centric approach. They work closely with clients to understand their specific needs and provide customized solutions that best fit their requirements. Their dedicated customer support team ensures that clients receive prompt assistance and support throughout their engagement with the company.

Sustainability and Environmental Responsibility

In addition to their focus on quality and innovation, Parth Valve is committed to sustainability and environmental responsibility. They implement eco-friendly manufacturing practices and strive to minimize their environmental footprint. By doing so, they contribute to a greener future while maintaining their competitive edge in the industry.

Conclusion

Parth Valve & Manufacturing Co. is the best choice for Industrial Dampers manufacturer in Pune. Their unwavering commitment to quality, innovation, and customer satisfaction has earned them a stellar reputation. As industries continue to evolve, Parth Valve is well-equipped to meet the challenges of the future, providing top-tier solutions that drive efficiency and reliability in industrial operations.

For more information on Parth Valve’s products and services, visit their website or contact their customer support team. With Parth Valve, you can be assured of the best in Industrial Dampers technology and unparalleled service.

#Industrial Dampers in Pune#Industrial Dampers#Importance of industrial dampers#Pune#a bustling hub of industrial activity in India#is home to numerous manufacturing companies#including Parth Valve & Hoses Pvt. Ltd#a leading high-quality Industrial Dampers manufacturer. With a strong commitment to innovation#quality#and customer satisfaction#Parth Valve is the go-to choice for businesses seeking reliable and efficient solutions for their industrial needs#A Legacy of Excellence#Founded with a vision to deliver top-notch industrial solutions#Parth Valve has grown to become a prominent name in the manufacturing sector. Their extensive experience and expertise have earned them a r#Cutting-Edge Technology and Innovation#Parth Valve is at the forefront of technological innovation and is also the leading Industrial Dampers manufacturer in Pune. They utilize s#Parth Valve stays ahead of the curve#delivering innovative solutions that cater to the evolving needs of their clients.#Comprehensive Product Range#Parth Valve#the Industrial Dampers manufacturer in Pune#offers a wide range of Industrial Dampers designed to meet diverse industrial requirements. Their product line-up includes:#Butterfly Dampers:#Known for their compact design and efficient operation#butterfly dampers are ideal for applications requiring tight shut-off and precise flow control.#Guillotine Dampers: These dampers are perfect for isolating sections of ductwork or equipment#providing a reliable seal even in high-temperature environments.#Louver Dampers: Designed for precise airflow regulation#louver dampers are used in various industrial applications to control ventilation and exhaust systems.#Multi-Louver Dampers: These dampers offer superior control over airflow

0 notes

Text

#butterfly valves manufacturers#butterfly valves#butterfly valves suppliers#bf valve price#butterfly valves exporter#Specte valves & Instruments Pvt. Ltd.

0 notes

Text

Why Butterfly Valve Manufacturers in India are Gaining Global Recognition

One of the primary reasons behind the global recognition of butterfly valve manufacturers in India is their cost-effectiveness. India benefits from lower labor costs compared to many Western countries, allowing manufacturers to produce high-quality valves at competitive prices.

0 notes

Text

The Benefits of Using a Sanitary Butterfly Valve for Food Production

In the dynamic and meticulously regulated food production industry, maintaining high standards of hygiene, efficiency, and reliability is paramount. A critical component that significantly contributes to these standards is the sanitary butterfly valve. Designed specifically for hygienic applications, these valves offer numerous advantages over traditional valve types. Freture Techno Pvt. Ltd., a leading butterfly valve manufacturer based in Mumbai, India, excels in providing top-quality sanitary butterfly valves tailored to meet the stringent demands of the food industry.

Understanding Sanitary Butterfly Valves

Sanitary butterfly valves are a type of quarter-turn valve, designed with a disk that rotates to allow, regulate, or halt the flow of fluids. The “sanitary” aspect refers to their construction and materials, which ensure they meet the rigorous cleanliness standards required in food production. Typically made from stainless steel, these valves are designed to minimize crevices and cavities where contaminants could accumulate, making them easy to clean and maintain.

Key Benefits of Sanitary Butterfly Valves in Food Production

Hygiene and Cleanability

The primary advantage of sanitary butterfly valves is their superior hygiene. Made from high-grade stainless steel, these valves are resistant to corrosion and are designed with smooth surfaces that prevent the buildup of bacteria, mold, and other contaminants. The absence of internal pockets and crevices ensures thorough cleaning, reducing the risk of contamination in food products. This cleanability is essential for maintaining the safety and quality of food products, complying with food safety regulations, and achieving certifications such as HACCP (Hazard Analysis and Critical Control Points) and ISO 22000.

Ease of Maintenance

Sanitary butterfly valves are known for their simplicity in design, which translates to easier maintenance and lower downtime. The disk and seal design allows for quick disassembly, inspection, and cleaning without the need for specialized tools or extensive training. This ease of maintenance ensures that production lines can be quickly brought back online after routine checks or unexpected issues, maintaining consistent productivity and minimizing operational costs.

Efficient Flow Control

These valves offer precise flow control, essential for processes requiring exact dosing and mixing of ingredients. The ability to finely adjust the flow rate ensures consistent product quality and optimizes the use of raw materials. Sanitary butterfly valves provide a reliable seal in both the open and closed positions, reducing the risk of leaks and ensuring the integrity of the production process.

Durability and Longevity

Constructed from robust materials like stainless steel, sanitary butterfly valves are designed to withstand the demanding conditions of food production, including exposure to various temperatures, pressures, and cleaning agents. This durability translates to a longer lifespan, reducing the frequency of valve replacements and providing a better return on investment over time.

Cost-Effectiveness

Despite their high performance, sanitary butterfly valves are often more cost-effective than other types of valves. Their straightforward design and minimal moving parts mean they are less expensive to manufacture, purchase, and maintain. This cost-efficiency makes them an attractive option for food producers looking to optimize their budget without compromising on quality or performance.

Versatility

Sanitary butterfly valves are highly versatile and can be used in a wide range of applications within the food industry. Whether it's for the production of beverages, dairy products, or processed foods, these valves can handle various types of liquids and semi-liquids. Their adaptability to different production processes makes them an indispensable component in a modern food manufacturing facility.

Applications in Food Production

Sanitary butterfly valves are used across various stages of food production:

Ingredient Handling: Ensuring precise control over the addition of liquids and semi-liquids.

Mixing and Blending: Providing consistent flow rates for uniform mixing.

Pasteurization: Withstanding high temperatures and maintaining sterility.

Bottling and Packaging: Ensuring clean and efficient transfer of products into packaging.

Compliance with Industry Standards

Freture Techno Pvt. Ltd. manufactures sanitary butterfly valves that comply with international standards, including FDA, 3A, and EHEDG. This compliance ensures that their valves meet the highest quality and safety requirements, providing peace of mind to food producers.

Innovation and Customization

Freture Techno Pvt. Ltd. stands out not only for its adherence to quality standards but also for its innovative approach and customization capabilities. Recognizing that each food production facility may have unique requirements, the company offers customized solutions tailored to specific needs. This bespoke approach ensures that their sanitary butterfly valves integrate seamlessly into existing systems, enhancing efficiency and performance.

Sustainable Manufacturing

In addition to their functional benefits, sanitary butterfly valves from Freture Techno Pvt. Ltd. are manufactured with a focus on sustainability. The company employs eco-friendly manufacturing processes and materials, reflecting a commitment to environmental responsibility. By choosing these valves, food producers can align their operational practices with broader sustainability goals, appealing to eco-conscious consumers and stakeholders.

Real-World Success Stories

Numerous food production companies have experienced significant improvements in their operations after integrating sanitary butterfly valves from Freture Techno Pvt. Ltd. These success stories highlight reduced contamination risks, lower maintenance costs, and enhanced product quality. For instance, a dairy processing plant reported a 20% increase in productivity and a notable reduction in product recalls due to improved hygiene and reliability of the valves.

Conclusion

The role of sanitary butterfly valves in food production cannot be overstated. Their benefits, ranging from superior hygiene and ease of maintenance to precise flow control and cost-effectiveness, make them an indispensable component in the industry. Companies like Freture Techno Pvt. Ltd. are at the forefront of manufacturing these essential valves, providing high-quality, reliable solutions that meet the rigorous demands of modern food production.

As the food industry continues to evolve, the importance of maintaining stringent hygiene standards and operational efficiency remains paramount. Sanitary butterfly valves offer a robust solution to these challenges, ensuring that food products are safe, high-quality, and produced efficiently. By investing in these valves, food producers can not only enhance their production processes but also ensure compliance with international standards, ultimately leading to greater consumer trust and satisfaction.

Freture Techno Pvt. Ltd., with its expertise and commitment to quality, stands as a trusted partner for food producers seeking reliable and innovative sanitary butterfly valves. Based in Mumbai, India, the company continues to lead the way in delivering exceptional products that drive the success of food production facilities worldwide.

1 note

·

View note

Text

butterfly valve manufacturer in ahmedabad

We are leading butterfly valve manufacturer in Ahmedabad, India. A butterfly valve is used to regulate flow in a pipeline. It is made up of a butterfly-like disc-shaped closure element that spins on a spindle to regulate fluid flow. Butterfly valves are popular due to their compact design and widely used in a variety of industries including HVAC systems and water treatment.

#butterfly valve#butterfly valve manufacturer#butterfly valve supplier#butterfly valve in Ahmedabad#butterfly valve manufacturer in Ahmedabad#butterfly valve supplier in India

0 notes

Text

Top Features of Butterfly Valve Gearbox

Various water treatment and chemical processing plants often have control flow of liquids and gases passing through the pipelines. A well-known tool termed butterfly valve gearbox helps them regulate and manage the flow of the fluids. Viral Industries is a leading manufacturer of butterfly valve gearboxes, and they are designed to meet the exciting demands of the business industry. In this blog, we have mentioned the top-quality features of butterfly valve gearboxes.

0 notes

Text

Nishaaircon : Exploring the Features of MS Spigot

Nishaaircon air conditioning system, equipped with advanced technology to ensure optimal cooling performance. Our product features the latest MS Spigot technology, guaranteeing efficient airflow and temperature control. Stay cool and comfortable all year round with Nishaaircon.

Click Here: https://nishaaircon.com/ms-spigot

#jet diffuser manufacturers in delhi#aluminum circular diffuser#jet nozzle diffuser#ms spigot#gi single butterfly flap#aluminium toilet exhaust valves suppliers in delhi#spot diffuser manufacturers in delhi#double flap butterfly damper#aluminum round diffuser in delhi#jet nozzle eye ball tips

0 notes

Text

The fully automatic valve production workshop is very cruel to the workers.

1 note

·

View note

Text

Unveiling the Precision of Casting Butterfly Valves: A Comprehensive Overview

Introduction: In the intricate realm of industrial valves, the casting butterfly valve stands out as a pivotal component in fluid control systems. Known for its simplicity, reliability, and efficiency, this valve plays a crucial role in regulating the flow of liquids and gases. In this article, we delve into the fascinating world of casting butterfly valves, exploring their design, functionality, applications, and the intricate casting process that brings them to life.

I. Understanding Butterfly Valves: Before we delve into the casting process, it's essential to grasp the fundamentals of butterfly valves. Butterfly valves are quarter-turn rotational motion valves, typically used to control the flow of fluids in pipelines. They consist of a disc mounted on a rotating shaft, situated in the pipe's diameter. When the valve is fully open, the disc aligns with the flow, allowing for minimal obstruction.

II. Anatomy of a Casting Butterfly Valve: A casting butterfly valve comprises several key components, each contributing to its efficient operation. These include the body, disc, stem, seat, and actuator. The body serves as the outer shell, housing the internal components, while the disc, often called the "butterfly," controls the flow. The stem connects the disc to the actuator, facilitating the rotational movement. The seat provides a tight seal when the valve is closed, preventing leakage.

III. Casting Process Overview: The casting process is a critical step in the manufacturing of butterfly valves, determining their structural integrity and performance. The primary materials used in casting butterfly valves are metals such as stainless steel, cast iron, and aluminium. The casting process involves the following key steps:

Pattern Creation: The process begins with the creation of a pattern, which is a replica of the final valve's shape and size. This pattern can be made from wood, plastic, or metal and serves as a template for the casting Mold.

Mold Formation: The pattern is used to create a Mold, usually made from sand or other refractory materials. The Mold is designed to accommodate the molten metal and create the desired shape of the valve.

Pouring Molten Metal: Once the mold is prepared, molten metal is poured into it. The choice of metal depends on the valve's intended use and the specific requirements of the application.

Cooling and Solidification: After pouring, the molten metal cools and solidifies within the mold, taking the shape of the valve. This phase is crucial in determining the valve's structural integrity and ensuring that it meets the specified dimensional tolerances.

Removal of Casting: Once the metal has solidified, the casting is removed from the mold. This can involve breaking the mold or using other methods, depending on the casting material and design.

IV. Advantages of Casting Butterfly Valves: Casting butterfly valves offer several advantages that contribute to their widespread use in various industries:

Cost-Effective: The casting process is generally more cost-effective than other manufacturing methods, making butterfly valves an economical choice for many applications.

Versatility: Casting allows for the production of butterfly valves in a variety of materials, providing versatility to meet the demands of different industries and applications.

Complex Shapes: The casting process enables the creation of intricate and complex shapes, allowing for the design of butterfly valves with optimal flow characteristics.

Durability: Cast materials are often known for their durability and resistance to wear and corrosion, ensuring a long and reliable service life for butterfly valves.

V. Applications of Casting Butterfly Valves: Casting butterfly valves find application in a diverse range of industries and processes, owing to their versatility and efficiency. Some notable applications include:

Water Treatment: Butterfly valves are commonly used in water treatment plants to regulate the flow of water and other fluids.

Oil and Gas: In the oil and gas industry, casting butterfly valves play a crucial role in controlling the flow of crude oil, natural gas, and various process fluids.

Chemical Processing: The chemical industry utilizes butterfly valves for handling and controlling the flow of chemicals in various manufacturing processes.

HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems often incorporate casting butterfly valves for precise control of airflow and temperature.

VI. Challenges in Casting Butterfly Valves: While casting butterfly valves offer numerous advantages, there are also challenges associated with the casting process. These challenges include:

Dimensional Accuracy: Achieving precise dimensional accuracy in the casting process can be challenging, leading to the need for meticulous quality control measures.

Porosity: Porosity, or the presence of small voids or air pockets in the casting, can affect the structural integrity of the valve. Proper casting techniques and quality control are essential to minimize porosity.

Surface Finish: The casting process may result in a rough surface finish, requiring additional machining or surface treatment to meet the desired specifications.

Conclusion: In the intricate dance of fluid control systems, casting butterfly valves emerge as reliable performers, offering a delicate balance of simplicity and efficiency. From the precision of the casting process to the diverse applications across industries, these valves play a crucial role in ensuring the seamless flow of liquids and gases. As technology advances, the casting process continues to evolve, promising even greater precision and reliability in the world of butterfly valves.

Source: https://bit.ly/4bL7hwCTop of Form

0 notes

Text

Description:

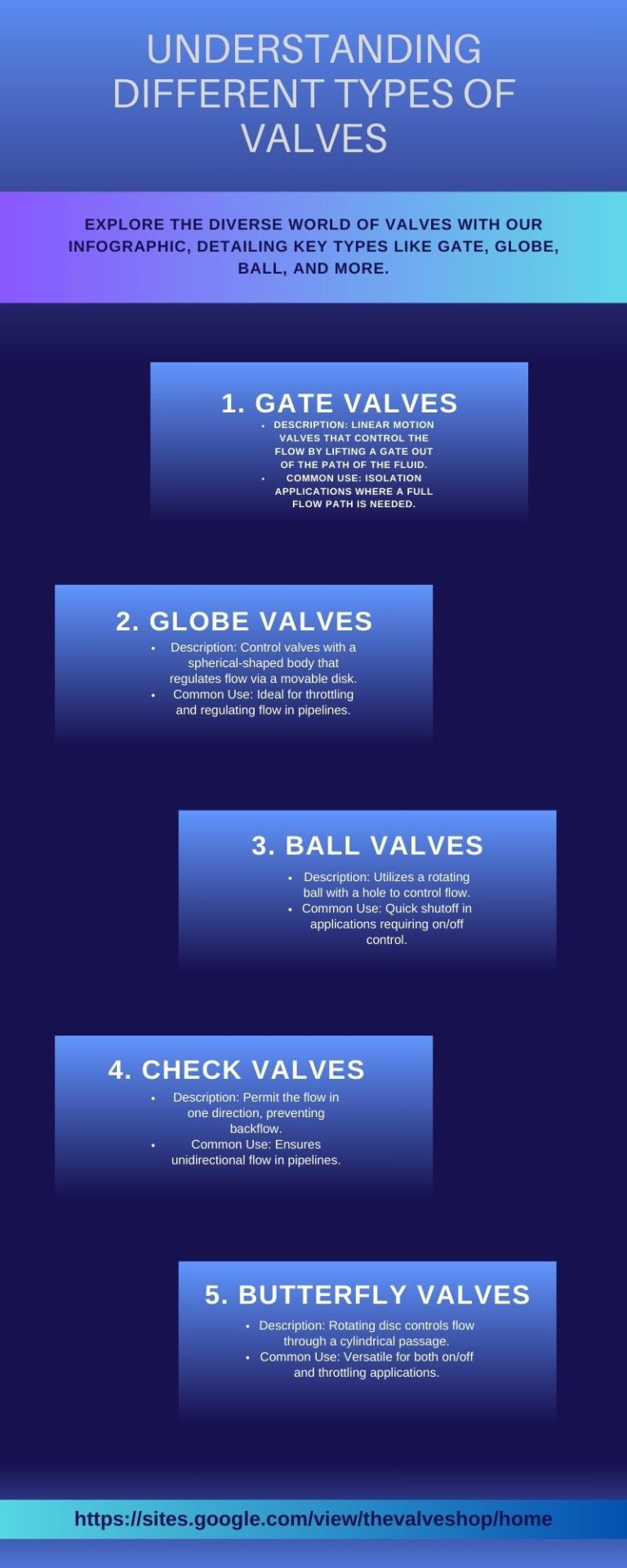

Understanding Different Types of Valves provides a comprehensive overview of key valve varieties crucial in fluid control systems. Gate valves, with linear motion, excel in isolation, while globe valves offer nuanced regulation. Ball valves ensure swift on/off control, check valves maintain unidirectional flow, and butterfly valves offer versatile usage. Each valve type caters to specific needs, from precise throttling to rapid shutoff, impacting industries like oil, water treatment, and manufacturing. This infographic empowers decision-makers to select the right valve for optimal system performance, emphasizing the importance of evaluating specific application requirements. Explore this informative guide to enhance your knowledge of these essential components shaping fluid dynamics across various sectors.

Gate Valves:

Gate valves are essential linear motion devices that manage the flow of fluid by lifting a gate obstructing the path. These valves are particularly valuable in applications where a full and unobstructed flow path is required. The operation of gate valves involves raising the gate to permit flow and lowering it to block the passage of fluid. This on/off functionality makes gate valves suitable for isolation purposes, allowing for efficient control of liquid or gas flow.

Globe Valves:

Globe valves are characterized by their spherical-shaped bodies and a movable disk that regulates the flow. Unlike gate valves, globe valves provide more nuanced control over fluid flow, making them ideal for applications that require throttling and precise regulation. The design of the globe valve allows for fine-tuning the flow rate by adjusting the position of the disk, offering versatility in managing the movement of liquids or gases through a pipeline.

Ball Valves:

Ball valves utilize a rotating ball with a hole to control the flow of fluids. These valves are particularly advantageous for applications requiring quick shutoff or on/off control. The simplicity of their design, consisting of a spherical closure element, ensures a reliable and efficient operation. Ball valves find extensive use in various industries where rapid control and shutoff are critical, providing a durable solution for managing the flow of liquids or gases.

Check Valves:

Check valves, also known as non-return or one-way valves, permit fluid flow in only one direction while preventing backflow. These valves play a crucial role in ensuring unidirectional flow within pipelines. The design of check valves typically includes a mechanism that allows the flow to open the valve while preventing reverse flow. This feature is vital in preventing the contamination of systems and maintaining the desired direction of fluid movement, making check valves essential components in a wide range of piping applications.

Butterfly Valves:

Butterfly valves feature a rotating disc within a cylindrical passage to control the flow of fluids. These valves offer versatility, serving both on/off and throttling applications. The quarter-turn motion of the disc allows for quick and efficient control of the flow, making butterfly valves a popular choice in situations where precise regulation is necessary. Their compact design and ease of operation contribute to their widespread use in various industries, including water treatment, HVAC systems, and chemical processing.

Visit:

0 notes

Text

Why Butterfly Valve Manufacturers in India are Gaining Global Recognition

Butterfly valves are critical components in a wide range of industries, including oil and gas, water treatment, chemical processing, and HVAC systems. Their versatility, reliability, and cost-effectiveness make them indispensable for regulating fluid flow. In recent years, butterfly valve manufacturers in India have been gaining significant recognition on the global stage. This article explores the factors driving this trend and highlights the contributions of companies like Cair Euromatic to the industry.

Cost-Effectiveness and Competitive Pricing

One of the primary reasons behind the global recognition of butterfly valve manufacturers in India is their cost-effectiveness. India benefits from lower labor costs compared to many Western countries, allowing manufacturers to produce high-quality valves at competitive prices. This affordability has made Indian-made butterfly valves attractive to international buyers looking for cost-effective solutions without compromising on quality.

High-Quality Standards and Certification

Indian manufacturers prioritize quality and adhere to stringent standards to ensure the reliability and durability of their products. Many companies are certified to international quality management standards such as ISO 9001, ISO 14001, and OHSAS 18001. These certifications signify a commitment to excellence and provide assurance to customers worldwide about the quality of Indian-made butterfly valves.

Technological Advancements and Innovation

Indian butterfly valve manufacturers are increasingly investing in research and development to incorporate advanced technologies into their products. From smart valves with remote monitoring capabilities to energy-efficient designs, these innovations enhance the performance, reliability, and functionality of butterfly valves. This focus on innovation has positioned Indian manufacturers as leaders in the global market.

Customization Capabilities and Versatility

Another key factor driving the global recognition of butterfly valve manufacturers in India is their ability to offer customized solutions tailored to the specific requirements of customers. Whether it's size, material, or design specifications, Indian manufacturers can accommodate a wide range of customization requests. This versatility ensures that Indian-made butterfly valves can meet the diverse needs of different industries and applications.

Cair Euromatic: Setting Industry Standards

Cair Euromatic is a leading name in the Indian butterfly valve manufacturing industry, known for its commitment to quality, innovation, and customer satisfaction.

Cutting-Edge Technology

We integrates cutting-edge technology into its butterfly valves to ensure optimal performance and efficiency. The company leverages advanced manufacturing processes and materials to deliver products that meet the highest standards of quality and reliability.

Uncompromised Quality

Quality is at the core of our operations. The company follows strict quality control measures at every stage of the manufacturing process to ensure that its butterfly valves meet or exceed international standards. Our valves are known for their durability, longevity, and consistent performance in demanding applications.

Customer-Centric Approach

We prioritizes customer satisfaction and strives to exceed expectations at every touchpoint. The company offers comprehensive support services, including technical assistance, customization options, and after-sales support, to ensure a seamless experience for its customers.

Conclusion

The global recognition of butterfly valve manufacturers in India can be attributed to several factors, including cost-effectiveness, high-quality standards, technological advancements, customization capabilities, and a customer-centric approach. Cair Euromatic exemplify these qualities, driving the industry forward and setting new standards for excellence. As the demand for butterfly valves continues to grow worldwide, Indian manufacturers are well-positioned to meet the needs of diverse industries and emerge as leaders in the global market.

0 notes

Text

Butterfly Valves Suppliers in UAE - TradersFind

Find butterfly valves suppliers & manufacturers in UAE. Connect with top companies that offers the best-quality butterfly valves. Contact us!

0 notes