#Buy EPE foam packaging

Explore tagged Tumblr posts

Text

The Indispensable Choice: Why So Many Industries Rely on EPE Foam

In the vast landscape of material science, certain substances rise to prominence due to their unique blend of properties and versatility. Expanded Polyethylene (EPE) foam stands as a prime example. Its lightweight nature, exceptional cushioning, and adaptability have made it the go-to material for a staggering array of industries worldwide. From safeguarding delicate electronics during their journey from Mumbai to New York to providing protective cradles for fragile glassware shipped from the UK to Australia, EPE foam's characteristics address critical needs across diverse sectors. This comprehensive guide will delve into the compelling reasons behind EPE foam's widespread adoption. We will explore its key attributes, supported by data and real-world examples. We will highlight its crucial role in providing "Custom EPE Foam Packaging", specialized "EPE Foam Packaging for electronics", secure "EPE Foam Packaging for glassware", and reliable "EPE Foam Packaging for fragile" items. Understanding why so many industries choose EPE foam is essential for businesses in Navi Mumbai, Thane, and Panvel, as well as those operating globally.

Unpacking the Core Advantages of EPE Foam

EPE foam's pervasive use is rooted in its exceptional combination of inherent properties:

Superior Cushioning and Shock Absorption: Its closed-cell structure effectively dissipates impact forces, providing excellent protection against shocks and vibrations.

Lightweight Nature: EPE foam adds minimal weight to products and packaging, crucial for reducing shipping costs.

Excellent Insulation Properties: It offers thermal insulation, protecting temperature-sensitive goods.

Water and Moisture Resistance: Its closed-cell structure prevents water absorption, safeguarding products from moisture damage.

Chemical Inertness: EPE foam is non-reactive with most substances, ensuring it doesn't contaminate or damage the packaged goods.

Ease of Fabrication: It can be easily cut, shaped, molded, and laminated to create "Custom EPE Foam Packaging" solutions.

Non-Abrasive Surface: It protects delicate surfaces from scratches and scuffs during handling and transit.

Cost-Effectiveness: Compared to some alternatives, EPE foam offers a balance of performance and affordability.

Recyclability: EPE foam is recyclable, aligning with growing sustainability concerns.

These core advantages collectively make EPE foam an indispensable material across numerous industries.

Industry-Specific Applications and Why EPE Foam Excels

The versatility of EPE foam allows it to cater to the specific needs of a wide range of industries:

1. Electronics Industry:

Why EPE Foam? Electronic components are often delicate and susceptible to damage from shocks, vibrations, and electrostatic discharge (ESD). EPE foam, especially anti-static varieties, provides crucial protection.

Applications: "EPE Foam Packaging for electronics" includes custom-cut inserts for circuit boards, cushioning for laptops and smartphones, and protective wraps for sensitive instruments shipped from Thane to the USA (Los Angeles, Chicago). Anti-static EPE foam prevents ESD damage, ensuring the functionality of sensitive devices.

Data: Studies indicate that inadequate packaging is a major cause of damage to electronic goods during shipping, resulting in significant financial losses (Source: Electronics industry logistics reports). EPE foam significantly mitigates this risk.

2. Glassware and Ceramics Industry:

Why EPE Foam? Glassware and ceramics are inherently fragile and prone to breakage during handling and transportation. EPE foam's excellent cushioning properties provide a secure barrier against impacts.

Applications: "EPE Foam Packaging for glassware" includes custom-molded trays for bottles and glasses, protective sleeves for ceramic items shipped from the UK (London, Birmingham) to Australia (Sydney, Melbourne). Its non-abrasive surface prevents scratches on delicate finishes.

Example: A manufacturer in Navi Mumbai shipping crystalware to the UK utilizes custom EPE foam inserts within their corrugated boxes to minimize breakage and ensure safe arrival.

3. Automotive Industry:

Why EPE Foam? Automotive parts, from delicate sensors to large body panels, require protection from scratches, dents, and vibrations during transport and assembly.

Applications: EPE foam is used for protective padding in car interiors during assembly, custom-cut dunnage for parts transportation between manufacturing plants, and protective packaging for aftermarket components. Its durability ensures parts arrive at assembly lines in perfect condition.

4. Medical and Pharmaceutical Industry:

Why EPE Foam? Medical devices and pharmaceuticals often require sterile and protective packaging. EPE foam's inert nature and cushioning properties make it suitable for various applications.

Applications: EPE foam is used for cushioning sensitive medical equipment, creating protective inserts for diagnostic kits, and providing thermal insulation for temperature-sensitive medications. Its non-reactive nature ensures the integrity of medical supplies.

5. Furniture and Home Goods Industry:

Why EPE Foam? Furniture and home goods are susceptible to scratches, dents, and corner damage during shipping and handling. EPE foam profiles, sheets, and wraps offer effective protection.

Applications: EPE foam edge protectors safeguard furniture corners, sheets provide surface protection for tabletops and upholstery, and custom-cut inserts secure fragile components during transit from Mumbai to the UK.

6. Food and Beverage Industry:

Why EPE Foam? While not for direct food contact, EPE foam provides excellent insulation for temperature-sensitive food and beverages during transport. Its water resistance is also beneficial.

Applications: EPE foam insulated containers and liners help maintain the temperature of perishable goods during shipping. Protective EPE foam packaging can also prevent damage to bottles and containers.

7. Arts and Crafts Industry:

Why EPE Foam? Delicate artwork, sculptures, and craft supplies require protection from impacts and scratches. EPE foam's non-abrasive and cushioning properties are ideal.

Applications: "EPE Foam Packaging for fragile" artwork includes custom-cut inserts to secure pieces within crates, protective wraps for sculptures, and cushioning for delicate craft materials shipped domestically within Australia (Brisbane) or internationally.

The Economic Advantages of Choosing EPE Foam

Beyond its protective qualities, EPE foam offers significant economic advantages:

Reduced Damage and Return Rates: As highlighted by data in the electronics industry, EPE foam minimizes product damage, leading to lower return rates, replacement costs, and increased customer satisfaction.

Lower Shipping Costs: Its lightweight nature reduces overall package weight, directly translating to lower shipping expenses, especially for high-volume shippers in the USA.

Efficient Packing Processes: EPE foam is easy to handle and apply, streamlining packing processes and reducing labor costs for businesses in Panvel. "Custom EPE Foam Packaging" solutions further enhance efficiency.

Durability and Reusability: While often single-use, EPE foam's durability allows for potential reuse in some applications, further extending its cost-effectiveness.

Reduced Storage Space: Compared to bulkier alternatives, EPE foam can often be stored more efficiently, saving valuable warehouse space for businesses in London.

The Environmental Considerations of EPE Foam

While EPE foam is a petroleum-based product, it is 100% recyclable. Many manufacturers are also incorporating recycled EPE into their production processes, reducing its environmental footprint. Choosing suppliers with strong environmental policies is increasingly important for businesses in the UK and Australia with sustainability goals.

Best Searchable Keyword Variations

To optimize your online presence for individuals seeking EPE foam solutions, consider these keyword variations:

Why use EPE foam for packaging?

Benefits of EPE foam in shipping

Cost-effective foam packaging solutions

Protective foam for fragile items

Lightweight packaging material advantages

Shock-absorbing foam packaging

Custom EPE Foam Packaging suppliers

EPE Foam Packaging for electronics manufacturers

Best EPE Foam Packaging for glassware

Where to buy EPE Foam Packaging for fragile items

EPE foam applications in different industries

Recyclable EPE foam packaging options

Advantages of closed-cell polyethylene foam

EPE foam for product protection during transit

Cost savings with EPE foam packaging

Conclusion: The Undeniable Reign of EPE Foam

The widespread adoption of EPE foam across a multitude of industries is a testament to its exceptional blend of protective properties, versatility, and cost-effectiveness. From safeguarding delicate electronics and fragile glassware during international shipping to providing crucial cushioning in the automotive and medical sectors, EPE foam consistently proves its value. Its lightweight nature reduces shipping costs, its ease of fabrication allows for "Custom EPE Foam Packaging" tailored to specific needs, and its inherent cushioning minimizes damage, leading to significant savings. For businesses in Mumbai, Navi Mumbai, Thane, Panvel, the USA, the UK, and Australia seeking reliable and efficient packaging solutions for "electronics", "glassware", and other "fragile" goods, EPE foam remains the go-to material, an indispensable choice for ensuring product integrity and optimizing supply chain efficiency in a globally connected marketplace. Its continued relevance underscores its position as a cornerstone of modern packaging practices.

3 Ply Single Wall

5 Ply Double Wall

7 Ply Triple Wall

Custom Corrugated Boxes

EPE Foam Packaging

Custom Printed Boxes

#EPE foam inserts#EPE foam sheets#Buy EPE foam packaging#EPE foam suppliers#Custom foam packaging solutions#Protective foam packaging#Anti-static EPE foam packaging#EPE foam for shipping#EPE foam for packing#Die-cut EPE foam packaging#EPE foam cushioning#EPE foam manufacturers#EPE foam packaging cost#Best EPE foam packaging suppliers#EPE foam packaging for sale#EPE foam packaging USA#EPE foam packaging UK#EPE foam packaging Australia#Buy custom foam inserts online#Protective packaging for electronics supplier#Buy custom EPE foam packaging Mumbai#EPE foam inserts for electronics Navi Mumbai#Protective EPE foam for glassware Thane#Anti-static EPE foam packaging Panvel#Custom molded EPE foam USA#Lightweight EPE foam for shipping UK#Shock-absorbing EPE foam Australia#EPE foam cushioning for fragile items Mumbai#Durable EPE foam packaging Navi Mumbai#Cost-effective EPE foam Thane

1 note

·

View note

Text

AusFoam: Adaptable Marvels

youtube

The Australian foam industry is an ever-evolving sector, offering versatile options for various applications. From flexible foams with different grades to sturdy foam varieties serving industries like sign writing and construction, and closed cell foams boasting buoyancy and thermal insulation properties, the foam sector is an essential component of modern manufacturing. Foams That's Very Flexible Manufactured in diverse grades, flexible foams cater to a range of needs. The industry standard code, such as 16-100, denotes the density and hardness of the foam. Higher density foams last longer but are pricier, while hardness, measured in Newtons, signifies the 'feel' of the foam. This flexibility allows for tailored solutions, from packaging to comfortable cushions. Rigid Foams Extending its reach, the foam industry supplies sturdy foam varieties crucial in sign writing, building, and construction. Versatile materials such as polystyrene (EPS and XPS), PIR, and rigid polyurethanes find applications across various industries, enhancing structural integrity and insulation. EPS, with its closed-cell and resilient nature, finds applications in thermal insulation systems, decorative surfaces, packaging, and stage sets. Closed Cell Foams Crafted from polyethylene or ethyl vinyl acetate co-polymers, closed cell foams exhibit buoyancy, waterproof properties, lightweight composition, and exceptional thermal insulation characteristics. Their applications span expansion joints, packaging, impact absorption, thermal insulation, and backing rod. These foams, resistant to common chemicals, are ideal where the need for durability and performance is paramount. Environmental Considerations and Innovation With global emphasis on sustainability, the foam industry is aligning with environmental goals. Innovations in materials and manufacturing processes, along with recycling initiatives and eco-friendly alternatives, ensure the industry's continued growth while minimizing ecological impact. In conclusion, Australia's foam industry is a versatile and innovative force, providing essential materials for diverse applications. From flexible foams to rigid and closed cell foams, these materials have become integral to daily life, showcasing the adaptability and ingenuity within the Australian manufacturing landscape. https://ausfoamversatilesolutions817.blogspot.com/2024/11/ausfoam-adaptable-marvels.html Perth foams insulation foam WA polystyrene blocks buy styrofoam sheets foam technologies closed cell foam WA Foam Supplies in Perth

1 note

·

View note

Text

Insulation Market Challenges and Opportunities in a Changing Economy

Insulation Market Growth Strategic Market Overview and Growth Projections

The global insulation market was valued at USD 56.25 billion in 2021 and is projected to reach USD 98.64 billion by 2030 at a CAGR of 6.44% from 2022 to 2030.

The latest Global Insulation Market by straits research provides an in-depth analysis of the Insulation Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global Insulation Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the Insulation Market are

BASF

Bayer

Dow Chemical Company

GAF Materials Corp.

Huntsman International LLC

Johns Manville

Cellofoam North America Inc.

Rockwool International A/S

DuPont

Owens Corning

Atlas Roofing Corp.

Saint-Gobain S.A.

Kingspan Group

BASF

Knauf Insulation

Get Free Request Sample Report @ https://straitsresearch.com/report/insulation-market/request-sample

The Insulation Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global Insulation Market: Segmentation

The Insulation Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

Product Outlook

Glass Wool

Mineral Wool

EPS

XPS

CMS Fibers

Calcium Silicate

Aerogel

Cellulose

PIR

Phenolic Foam

Polyurethane

End-use Outlook

Construction ( Residential, Non-Residential & Commercial)

Industrial

HVAC & OEM

Transportation ( Automotive, Marine, Aerospace)

Appliances

Furniture/Bedding

Packaging

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/insulation-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the Insulation Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the Insulation Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the Insulation Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the Insulation Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

0 notes

Text

Where Can Foam Inserts Be Found

Foam inserts are widely used across various industries for their versatility, cushioning properties, and protective qualities. They can be found in several places, catering to different needs and applications. Here are some of the most common sources where foam inserts can be found:

1. Packaging and Shipping Stores

Foam inserts are extensively used in packaging and shipping to protect fragile and valuable items. Stores specializing in packaging materials, such as Uline, Staples, and local packaging supply stores, often carry a variety of foam inserts. These stores offer different types of foam, including polyethylene, polyurethane, and expanded polystyrene (EPS) inserts, tailored to specific protection needs.

2. Custom Foam Manufacturers

For specific requirements, custom foam manufacturers provide tailored solutions. Companies like Foam Factory, MyCaseBuilder, and Pelican specialize in creating custom foam inserts designed to fit unique shapes and sizes. These manufacturers use advanced cutting technologies, such as CNC routing and waterjet cutting, to produce precise inserts that meet exact specifications.

3. Electronics and Appliance Stores

Electronics and appliance stores often use foam inserts to protect delicate items like televisions, computers and other electronic devices. Retailers like Best Buy, Apple, and other electronics stores include foam inserts in their packaging to ensure safe transportation of products. Additionally, these stores might sell protective cases with pre-cut foam inserts for various devices.

4. Tool and Hardware Stores

Foam inserts are commonly used in toolboxes and carrying cases to organize and protect tools. Stores like Home Depot, Lowe’s, and specialized tool retailers provide foam inserts for tool organization. These inserts can be custom-cut or pre-cut to fit specific tools, ensuring they remain secure and undamaged during transport and storage.

5. Outdoor and Sporting Goods Stores

Foam inserts play a crucial role in protecting equipment in outdoor and sporting activities. Stores like Cabela’s, Bass Pro Shops, and REI offer foam inserts for items such as firearms, cameras, and sporting gear. These inserts help secure and protect equipment from impacts and environmental elements.

6. Online Retailers

Online marketplaces like Amazon, eBay, and Alibaba offer a wide range of foam inserts for various applications. These platforms provide access to a broad selection of pre-made and customizable foam inserts, allowing consumers to find the perfect fit for their needs. Online retailers also offer reviews and ratings, helping buyers make informed decisions.

7. Medical and Scientific Equipment Suppliers

In the medical and scientific fields, foam insert sare used to protect sensitive instruments and equipment. Suppliers like Fisher Scientific and McKesson provide foam inserts for medical devices, laboratory equipment, and diagnostic tools, ensuring these critical items are safeguarded during transport and storage.

In summary, foam inserts are available in a wide range of places, each catering to specific needs. Whether for packaging, custom applications, electronics, tools, sporting goods, online purchases, or medical equipment, foam inserts provide essential protection and organization across various industries.

0 notes

Text

FoamFlex: Adaptable Marvels

youtube

The Australian foam industry is a dynamic force, providing a wide array of solutions for various applications. From adaptable foam types with different grades to sturdy foam varieties serving industries like sign writing and construction, and dense cellular materials boasting buoyancy and thermal insulation properties, the foam sector is a cornerstone of modern manufacturing. Foams That's Very Flexible Manufactured in varying grades, adaptable foam types cater to various requirements. The industry standard code, such as 16-100, denotes the density and hardness of the foam. Higher density foams last longer but are pricier, while hardness, measured in Newtons, signifies the 'feel' of the foam. This versatility allows for customized answers, from packaging to comfortable cushions. Rigid Foams The foam industry extends its reach by providing sturdy foam varieties, which are crucial in sign writing, building, and construction. Materials like polystyrene (EPS and XPS), PIR, and rigid polyurethanes serve diverse industries, enhancing structural integrity and insulation. EPS, with its closed-cell and resilient nature, finds applications in thermal insulation systems, decorative surfaces, packaging, and stage sets. Closed Cell Foams Polyethylene or ethyl vinyl acetate co-polymers are used to craft dense cellular materials, which exhibit buoyancy, waterproof properties, lightweight composition, and exceptional thermal insulation characteristics. Their applications span expansion joints, packaging, impact absorption, thermal insulation, and backing rod. These foams, resistant to common chemicals, are ideal where the need for durability and performance is paramount. Environmental Considerations and Innovation With global emphasis on sustainability, the foam industry is aligning with environmental goals. Innovations in materials and manufacturing processes, along with recycling initiatives and eco-friendly alternatives, ensure the industry's continued growth while minimizing ecological impact. In conclusion, Australia's foam industry is known for its adaptability and innovation, providing essential materials for diverse applications. From adaptable foam types to rigid and closed cell foams, these materials have become integral to daily life, showcasing the adaptability and ingenuity within the Australian manufacturing landscape. https://ausfoamadaptablemarvels491.blogspot.com/2024/04/foamflex-adaptable-marvels_074291422.html foam WA insulation foam WA Polystyrene WA buy styrofoam sheets EPS Perth closed cell foam WA https://www.tumblr.com/gerardgallagherlot/746707936421756928 https://carrestorationakronoh392.blogspot.com/2024/04/what-is-chiropractic-mission-hills-ks.html https://www.tumblr.com/androfergiespaces/746704821851226112 https://massagecareertrainingglendale629.blogspot.com/2024/04/laguna-hills-persian-rug-restoration.html https://www.tumblr.com/juliannacastroverde/746705997735804928

0 notes

Text

PP Tray Manufacturer - Brothers Packaging

Your One-Stop Shop for Packaging Solutions

Brothers Packaging is a trusted company for all your packaging needs, based in Ahmedabad, Gujarat, India. We are a renowned manufacturer and supplier of a comprehensive range of high-quality packaging products, designed to keep your items safe and secure.

Our Variety of Packaging Solutions:

PP Trays: These lightweight and durable trays, made from polypropylene plastic, are perfect for packaging a variety of products. They are ideal for food items, delicate electronics, and much more. They are also reusable and can be folded for easy storage.

PP Boxes: Made from strong and sturdy polypropylene, our PP boxes offer excellent protection for your products during transport and storage. They come in various sizes and can be customized to fit your specific needs.

ESD Packaging Solutions: For those of you dealing with electronic components that are sensitive to electrostatic discharge (ESD), we offer specialized packaging solutions to prevent damage.

Customized PP Sheets: We understand that every business has unique packaging requirements. That's why we provide the option of customized PP sheets, which can be cut and shaped to your exact specifications.

HDPE Crates with Fabrication: High-density polyethylene (HDPE) crates are known for their strength and durability. We can fabricate these crates to include compartments, lids, and other features to meet your specific needs.

Inserts and Separators: Keep your products organized and protected with our inserts and separators. These can be made from various materials, such as cardboard or foam, to provide additional cushioning and prevent items from shifting during transport.

EPE/EVA Foam with Fabrication: EPE (expanded polyethylene) and EVA (ethylene vinyl acetate) foam are lightweight and provide excellent shock absorption. We can fabricate these foams into custom shapes to perfectly fit your products.

Pallet Lid Sleeves (PLS): These sleeves offer an extra layer of protection for your palletized goods during storage and transportation.

Consumable Packaging: We offer a variety of consumable packaging materials, such as tapes, strapping, and void fill, to ensure your products arrive safely at their destination.

Internal Material Handling Fabricated Trolleys: Move your products around your warehouse or facility efficiently with our custom-made fabricated trolleys.

PP Box Files: Keep your documents and files organized and protected with our durable PP box files.

Committed to Quality and Customer Satisfaction

At Brothers Packaging, we are committed to offering our customers with highest quality products and exceptional service. We use only the highest quality materials in our manufacturing process, and our team of experts is dedicated to creating packaging solutions that meet your specific needs and budget. Contact us today to learn more about our various types of packaging products and how we can help you keep your products safe and secure. Buy Now: https://www.brotherspackaging.in/, or call: +918446036105

#tray pp#pp tray#buy tray pp#pp tray price#pp tray manufacturer#pp tray supplier#pp tray manufacturer in Ahmedabad#pp tray in gujarat

0 notes

Link

EPE SHEETS - Expanded polyethylene is commonly known as EPE foam. The various goods and activities requires safeguarding and protection. The EPE foam sheets are flexible coverings used in order to secure the goods. Whenever you buy a product, it is usually covered with a thermocol type layer; this very layer is made of EPE foam sheets, particularly used for packaging. In today’s time, there in an unimaginable demand for these sheets. Various companies are working solely towards the fulfillment of this particular demand of the manufacturers, shop owners and even the individuals.

1 note

·

View note

Text

FoamFlex: Adaptable Marvels

youtube

Australia's foam industry is an ever-evolving sector, offering versatile options for various applications. From adaptable foam types with different grades to rigid foams serving industries like sign writing and construction, and closed cell foams boasting buoyancy and thermal insulation properties, the foam sector is a cornerstone of modern manufacturing. Flexible Foams Manufactured in varying grades, adaptable foam types cater to a range of needs. The industry standard code, such as 16-100, denotes the density and hardness of the foam. Foams with higher density have a longer lifespan but come at a higher cost, while hardness, measured in Newtons, signifies the 'feel' of the foam. This flexibility allows for tailored solutions, from packaging to comfortable cushions. Rigid Foams The foam industry extends its reach by providing rigid foams, which are crucial in sign writing, building, and construction. Versatile materials such as polystyrene (EPS and XPS), PIR, and rigid polyurethanes find applications across various industries, enhancing structural integrity and insulation. The closed-cell and resilient nature of EPS make it suitable for thermal insulation systems, decorative surfaces, packaging, and even stage sets. Closed Cell Foams Crafted from polyethylene or ethyl vinyl acetate co-polymers, closed cell foams exhibit buoyancy, waterproof properties, lightweight composition, and exceptional thermal insulation characteristics. Their applications span expansion joints, packaging, impact absorption, thermal insulation, and backing rod. These foams, resistant to common chemicals, are ideal where the need for durability and performance is paramount. Environmental Considerations and Innovation With the growing focus on global sustainability, the foam industry is aligning with environmental goals. Materials and manufacturing processes are evolving, and recycling initiatives, along with the introduction of eco-friendly alternatives, ensure the industry's continued growth while minimizing ecological impact. In conclusion, the foam sector in Australia is known for its adaptability and innovation, offering essential materials for diverse applications. From adaptable foam types to rigid and closed cell foams, these materials have become integral to daily life, showcasing the adaptability and ingenuity within the Australian manufacturing landscape. https://foamflexadaptablemarvels189.blogspot.com/2024/10/foamflex-adaptable-marvels.html Perth foams insulation foam WA polystyrene blocks buy styrofoam sheets foam technologies closed cell foam WA Future Foams https://sydneyroofingtakeonclimate754.blogspot.com/ https://sydneyroofingtakeonclimate754.blogspot.com/2024/10/sydney-roofing-take-on-climate.html https://www.tumblr.com/windmillsbright/765100954187104256 https://www.tumblr.com/androfergiespaces/765094004046053376 https://autobodyrepairshopsakronoh220.blogspot.com/2024/10/fitness-gymnastics-sherman-oaks.html

0 notes

Text

Top 5 Materials Used in Packaging Fitments

When you are designing a box, it’s equally important to look at the inner packaging fitments. These inserts or “things that go inside the box” are just as crucial as the outer box design. While the outer box packaging makes the solid first impression, it’s inner fitments are shouldering the responsibility for delivering the inside good with stability and security. They are ones which create a long lasting impact!

The quality of materials used in the fitments is the key differentiating factor in box quality. Poor choice of fitments can result in damaged products and flimsy boxes. Are you wondering, “What material should I use for the next box I need for my corporate event?”

We’ve got you! We have put together a list of the top five materials for inner packaging fitments. These materials have been rated on four key parameters:

Sustainability

Pricing

Strength

Customization

Let’s begin, shall we?

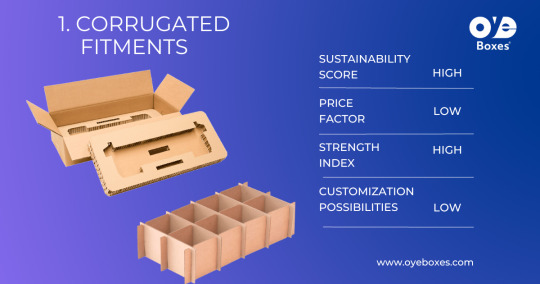

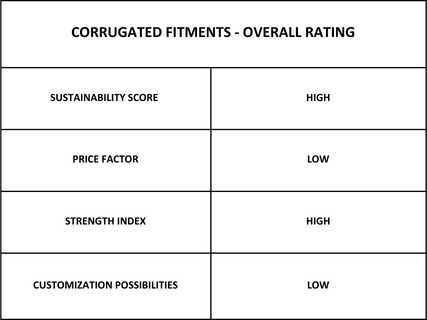

1. Corrugated Fitments:

Corrugated Fitments are the most commonly used materials in manufacturing of fitments and inserts. Depending on the use case, either 3 ply or 5 ply fitment sheets are used. Corrugated fitments are made of recycled materials and score high in terms of sustainability. They are usually 30% less expensive as compared to other materials, however you may have to buy them in larger quantities.

Corrugated fitments, inserts, and dividers provide a lot of sturdiness to the contents and can withstand rough transportation as well. They are ideal for products such as glass jars, machine parts, etc.

They have their limitations with respect to colour availability, however they can be offset printed for larger quantities or digitally printed for shorter quantities.

Here’s the rating chart for Corrugated fitments.

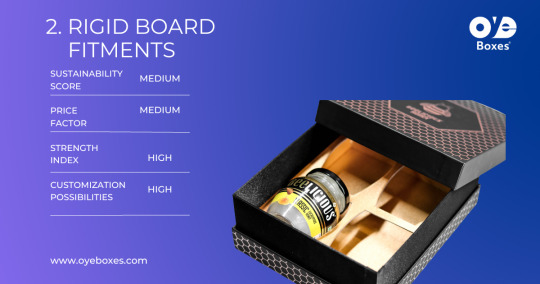

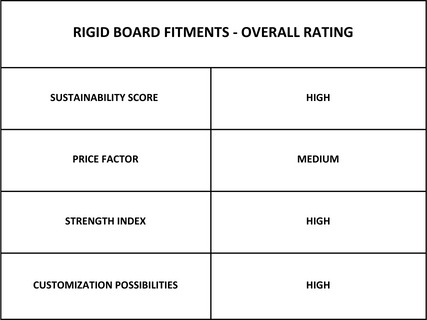

2. Rigid Board Fitments:

Rigid board fitments are an extremely popular choice when manufacturing fitments for packaging. Rigid fitments are frequently used in packaging for cosmetics, FMCG, jewelry, and other luxury items. Many times they are also used in conjunction with XLPE or EPE foam fitments.

Rigid board, commonly known in India as Putha Board, is made of recycled pulp and scores high in the sustainability index.

The price of rigid board fitments is slightly higher that of corrugated sheets. However, the strength and stability they provide is worth the higher price point. If we choose the appropriate thickness of board for making the fitments, then a very superior level of strength and stability can be achieved in the packaging.

The best part about rigid board fitments is that they are completely customizable. Any type of printed or colour sheets can be pasted on top of these rigid fitments.

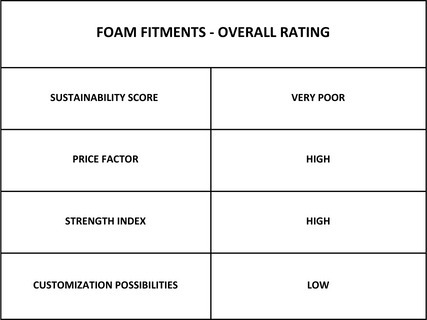

3. Foam Fitments :

Foam based fitments are widely used in packaging of glass, machine tools, and other high-value items. Currently, two of the most commonly available foam fitments are —- XLPE foam or EPE foam.

As expected, they don’t score well on the sustainability scale. They are harmful to the environment since they are non-biodegradable. But, they are the most sturdy and safe fitment option out there.

And, since they are the most sturdy option available in the market, their price is always on the higher side. We would like to highlight that XLPE foam fitments are 40% more expensive than EPE foam fitments.

Lastly, the customisation of these fitments is very expensive. They generally are available in few colour options – white, black, pink and blue. In order to customise them further, they need a layer of paper or paperboard on top of them.

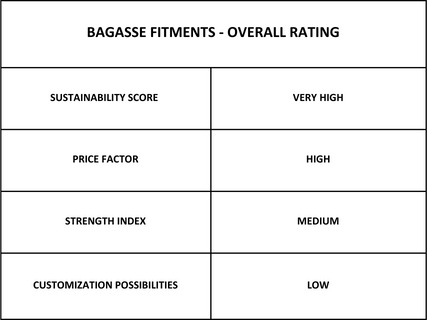

4. Bagasse Fitments

Bagasse is a dry fibrous residue that is generated after extraction of sugar from sugarcane. Nowadays, Bagasse is being used extensively in the making paper moulded fitments and dividers for various packaging applications.

You might be aware of bagasse plates and other recyclable cutlery that are widely used today. Bagasse fitments or inserts are slowly starting to trend in the packaging industry as well.

Bagasse is probably the most eco-friendly material amongst the entire list of fitments mentioned here. It is 100% recyclable. However, the costs associated with making a bagasse mould and then manufacturing these fitments is on the higher end when compared to other paper-based or plastic fitments.

Customization of colours in bagasse fitments is extremely difficult and require extremely large quantities to justify the expense. From a durability standpoint, bagasse fitments are sturdy enough to withstand pressure, however not as strong when compared to foam or rigid board fitments.

5. Paper Fitments :

Paper or paperboard fitments are the most pocket friendly fitment option (Probably 25% cheaper than rigid board). These are easy to source and manufacture. Paper fitments are generally made of recycled paper. But, it’s important to remember that they do not provide as much stability as other material options.

The parameter where paper fitments beats the competition is customization. All sorts of customizations are possible with paper fitments, including offset printing, digital printing, foiling, and embossing. So if you are looking for something really unique and tailored to your brand, then paper fitments might be your best bet.

#rigidboxpackaging#rigidboxpackagingfitments#packagingfitments#boxpackaging#CorrugatedFitments#RigidBoardFitments#FoamFitments#BagasseFitments#PaperFitments#luxuryboxpackaging

0 notes

Text

Compress EPE using an EPE foam densifier, then use PE plastic particles to create new plastic items.

With the growing global emphasis on environmental preservation and sustainable growth, using PE (polyethylene) plastic particles in the production of novel plastic items has emerged as a promising avenue for innovation. This program contributes positively to the creation of a green, low-carbon society by lowering environmental impact and plastic pollution in addition to reducing reliance on finite resources.

PE plastic is a typical plastic material that is used extensively in a variety of industries, including construction, automotive, packaging, and so forth. It has good processability, toughness, and durability. However, resource waste and plastic pollution are getting worse as more and more things are made of plastic, and new solutions are desperately needed.

Polyethylene (PE) recycled plastic particles, which have numerous uses, are obtained by the recycling and repurposing of old PE plastic goods. Some typical uses for PE recycled plastic particles are as follows:

Packaging materials: PE recycled plastic particles can be used to make various packaging materials, such as plastic bags, plastic films, foam packaging, etc. These packaging materials have good flexibility and durability and are suitable for packaging and protection in food, daily necessities, medicine and other fields.

construction supplies: Recycled PE plastic particles can be used to create a variety of construction supplies, including wall panels, flooring, and insulation. These building materials are ideal for a variety of applications in construction and interior design projects since they are lightweight, wear-resistant, waterproof, and heat-insulating.

Home furnishings: Recycled PE plastic particles can be utilized to create a variety of home furnishings, including storage boxes, trash cans, and furniture. These everyday household goods are appropriate for regular usage in homes and businesses because of their good toughness and durability.

Usually, trash is compressed using a PE foam densifier before PE plastic particles are made. One way to improve granulation efficiency is to use high-density compressed materials. The GREEMAX PE foam densifier is an appropriate compression device because of its high compression ratio of up to 90:1. In addition to growing its business, GREENMAX has started a venture to buy back EPE foam ingots. To aid in the construction of its own facilities, INTCO Recycling GREENMAX has started producing PE plastic particles in addition to EPS particles.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Description: Good ventilate function with 24 air holes,and good protective performance cause it was specially designed for the endurance racing athlete. The thickened inner EPS shock-release system was put in, and use the inner frame to enhance the strength. Compatible for road bike,for man and women. Passed CE/SGS Certification. Past the safety test. Specification: Model: SV9 X Material: PC + EPS + Carbon fiber frame Head circumference: 58-62cm/22.83-24.41 Foam density: 96g/L Weight: 260g Air vents number: 24 Package Includes: 1 Piece Bike Helmet Note: Due to the light and screen setting difference, the items color may be slightly different from the pictures. Please allow slight dimension difference due to different manual measurement. The thickened inner EPS shock-release system was put in, and use the inner frame to enhance the strength. Compatible for road bike,for man and women. Kindly refer the product description before buying the product. Package Includes:1 Piece Bike Helmet [ad_2]

0 notes

Text

FoamFlex: Adaptable Marvels

youtube

The Australian foam industry is an ever-evolving sector, offering a wide array of solutions for various applications. From adaptable foam types with different grades to sturdy foam varieties serving industries like sign writing and construction, and dense cellular materials boasting buoyancy and thermal insulation properties, the foam sector is an essential component of modern manufacturing. Flexible Foams Manufactured in varying grades, adaptable foam types cater to a range of needs. The industry standard code, such as 16-100, denotes the density and hardness of the foam. Foams with higher density have a longer lifespan but come at a higher cost, while hardness, measured in Newtons, signifies the 'feel' of the foam. This flexibility allows for tailored solutions, from packaging to comfortable cushions. Rigid Foams The foam industry extends its reach by providing sturdy foam varieties, which are crucial in sign writing, building, and construction. Materials like polystyrene (EPS and XPS), PIR, and rigid polyurethanes serve diverse industries, enhancing structural integrity and insulation. EPS, with its closed-cell and resilient nature, finds applications in thermal insulation systems, decorative surfaces, packaging, and stage sets. Closed Cell Foams Crafted from polyethylene or ethyl vinyl acetate co-polymers, dense cellular materials exhibit buoyancy, waterproof properties, lightweight composition, and exceptional thermal insulation characteristics. They find applications in expansion joints, packaging, impact absorption, thermal insulation, and even as backing rod. These foams, resistant to common chemicals, are ideal where durability and performance are crucial. Environmental Considerations and Innovation With global emphasis on sustainability, the foam industry is aligning with environmental goals. Innovations in materials and manufacturing processes, along with recycling initiatives and eco-friendly alternatives, ensure the industry's continued growth while minimizing ecological impact. In conclusion, the foam sector in Australia is a versatile and innovative force, offering essential materials for diverse applications. From adaptable foam types to rigid and closed cell foams, these materials have become integral to daily life, showcasing the adaptability and ingenuity within the Australian manufacturing landscape. https://ausfoamadaptablemarvels491.blogspot.com/2024/04/foamflex-adaptable-marvels.html foam in Perth insulation foam WA Polystyrene WA buy styrofoam sheets EPS Perth closed cell foam WA https://massagecareertrainingglendale629.blogspot.com/2024/04/laguna-hills-persian-rug-restoration.html https://www.tumblr.com/juliannacastroverde/746705997735804928 https://llltforpainrelief547.blogspot.com/2024/04/lllt-for-pain-relief.html https://fountainvalleypersianrugrepair.blogspot.com/2024/04/westwood-persian-rug-restoration.html https://www.tumblr.com/philbentonblog/746699582159896576

0 notes

Text

Inserts and Cushion for Packaging Market Growing factors analyzed by growing players - DS Smith Plc, UFP Technologies, Inc., AFP Inc., Reflex packaging Inc.

In today’s world, the root of packaging lies in the safety of a product during its transportation or the time before product purchase or consumption. Numerous packaging options today offer enhanced aesthetic values to the product from varied industries with inserts & cushion to emerge as one of the protective packaging solution that adheres to the basic property of protection. Inserts & cushion are separators that protect the fragile product from any damage due to sudden impact, shaking or vibration during shipment between manufacturers, distributors, retailers, and consumers. Manufacturers of inserts & cushion readily prefer foaming material such as expanded polystyrene (EPS), expanded polypropylene (EPP) and expanded polyethylene (EPE) which are injected into molds, heated with steam, causing them to swell and thus solidified into the desired shape. Inserts & cushion are applied in safe shipping of electronic products such as computers, transistor, registers, etc. as well as in transit of sensitive products such as glass, ceramics, porcelain, etc.

Global Inserts & Cushion for Packaging Market: Drivers & Restraints

Changing consumer lifestyle with growing per capita income is fueling the demand for consumer products across the globe. Applications of inserts & cushion packaging results into the protection of goods as well as safe delivery. Inserts & Cushion for Packaging Market is expected to witness healthy investments in the protective packaging market, particularly in developing countries. However, recycling of scrapped inserts & cushion packaging products being dumped remains a critical challenge for manufacturers across the globe. Growing consumption of inserts & cushion has badly affected the environment as these becomes useless after their packaging use. Continuous dumping of such inserts & cushion is forcing the regulatory bodies to induce harsh recycling protocols for the market players.

Segmentation Overview

Inserts & cushion packaging is in high demand for safe shipping of electronic products as well as also in e-commerce packaging industry. Based on the product type, foam packaging type is expected to dominate the inserts & cushion packaging market over the forecast period. By material type, expanded polystyrene (EPS) has excellent insulating properties and can widely be shaped to almost any need.

Make an Enquiry Before Buying – https://www.transparencymarketresearch.com/sample/sample.php?flag=EB&rep_id=25724

Regional Overview:

Geographically, the inserts & cushion for packaging market is segmented into seven regions, namely North America, Latin America, Western Europe, Eastern Europe, Asia Pacific Excluding Japan (APEJ), Japan and the Middle East and Africa (MEA).

Among the regions, the inserts & cushion for packaging market is presently being dominated by the regions which show a quantitative demand in consumer goods, particularly made from the e-commerce portals. North America and European countries are likely to grow linearly over the forecast period as the market for protective packaging are well established in this region. Asia Pacific region, especially the developing economies such as India & China are expected to emerge as the most lucrative market for the growth of inserts & cushion over the coming years, as a result of the rise in disposable incomes and the booming consumer products industry. Likewise, Latin America and MEA are likely to create opportunities for the inserts & cushion manufacturers over the forecast period. Overall, the global inserts & cushion packaging market is estimated to grow at a healthy CAGR over the forecast period.

Ask for References – https://www.transparencymarketresearch.com/sample/sample.php?flag=ARF&rep_id=25724

Key Players:

Some of the key players that operate in the inserts & cushion packaging market across the globe are DS Smith Plc, UFP Technologies, Inc., AFP Inc., Reflex packaging Inc., Salazar Packaging, Plastifoam Company and Green Packaging Group.

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

The report has been compiled through extensive primary research (through interviews, surveys, and observations of seasoned analysts) and secondary research (which entails reputable paid sources, trade journals, and industry body databases). The report also features a complete qualitative and quantitative assessment by analyzing data gathered from industry analysts and market participants across key points in the industry’s value chain.

A separate analysis of prevailing trends in the parent market, macro- and micro-economic indicators, and regulations and mandates is included under the purview of the study. By doing so, the report projects the attractiveness of each major segment over the forecast period.

Get a Customised Report - https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=25724

About Transparency Market Research

Transparency Market Research is a global market research reports company providing business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact Us:

Rohit Bhisey

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Blog: https://tmrblog.com

Email: [email protected]

0 notes

Text

Market Future Scope and Growth Factors of Global Insulated Packaging Market

The insulated packaging market is expected to witness market growth at a rate of approximately 6.20% in the forecast period of 2021 to 2028.

An international INSULATED PACKAGING market analysis report provides market potential for each geographical region based on the growth rate, macroeconomic parameters, consumer buying patterns, their preferences for particular product and market demand and supply scenarios. The report is a precious resource which provides current as well as upcoming technical and financial details of the Materials and packaging industry to 2028. It studies a choice of parameters throughout the report which analyses the market status in detail. This marketing report covers all the market shares and approaches of the major competitors or the key players in the market. Thus, INSULATED PACKAGING business report is an ultimate solution for businesses if they want to stay ahead of the competition in today's fast moving business environment. Businesses have started adopting a market research report solution for sound decision making and superior management of goods and services. To get detailed market insights and to have market place clearly into the focus, INSULATED PACKAGING business report has to be there in the picture. This market document is mainly delivered to the users in the form of PDF or spreadsheet. However, PPT format can also be offered depending on the client’s requirement. Each of the topics covered in the report is studied very well to get clear idea about all the factors that are influencing the market growth. The competitive landscape part of the first class INSULATED PACKAGING report gives a clear insight into the market share analysis of key industry players.

Insulated Packaging Market Scope and Market Size

The insulated packaging market is segmented on the basis of material, packaging type, packaging form and end use. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target markets.

on the basis of material, the insulated packaging market is segmented into expanded polystyrene foam (EPS), polyurethane (PUR) foam, wood, glass, cupboard, others. Others are further segmented into insulating cement, vacuum insulated panel, expanded silica, radiant barrier films and mineral fiber.

On the basis of packaging type, the insulated packaging market is segmented into box and container, flexible blanket, bags, wraps and other.

On the basis of packaging form, the insulated packaging market is segmented into rigid, flexible and semi-rigid.

On the basis of end use, the insulated packaging market is segmented into food and beverages, industrial, healthcare, fast moving customer goods, cosmetic, pharmaceutical and others.

Get the free sample copy of complete report here:

Market Analysis and Insights: Global Insulated Packaging Market

The insulated packaging market is expected to witness market growth at a rate of approximately 6.20% in the forecast period of 2021 to 2028. Data Bridge Market Research report on insulated packaging market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecast period while providing their impacts on the market’s growth. The rise in disposable income of people in developing nations is escalating the growth of insulated packaging market.

Insulation material refers to a material or combination of different materials possessing low thermal conductivity in order to resist the flow of heat. The major issue faced during the transportation of temperature sensible products is thermal abuse which could be prevented with the utilization of insulated materials for packaging. The products of industries such as pharmaceutical, healthcare, food and beverages, cosmetics and chemicals may be subjected to pressure during transportation, vibration and extreme conditions. These materials help in preventing spoilage and maintaining product specifications. This is extensively used for keeping products refrigerated, frozen and warm.

The increase in use of these packaging materials in industries including pharmaceutical and electronics and the rising demand especially from healthcare sector for temperature-controlled pharmaceutical products and medical devices as these products are sensitive to temperature acting as the major factors driving the insulated packaging market. The surge in number of e-commerce websites for food and beverages and medicines raising the need for delivery of perishable goods with no wastage and high rate of insulated packaging adoption by online grocery stores globally accelerate the insulated packaging market growth. The technological advancement in protective packaging leading to the usage of various materials including cotton and wool insulation which provide bio-based approach for reducing carbon emissions and increase in research and development activities to develop sustainable packaging solutions influence the insulated packaging market. Additionally, pandemic-led consumer behavioral change, increase in demand for temperature-sensitive goods, rise in urban population, expansion of e-commerce industry and surge in disposable income of people positively affect the insulated packaging market. Furthermore, innovations in packaging solutions, growth in pharmaceuticals sector and high growth potential in developing countries extend profitable opportunities to the insulated packaging market players in the forecast period of 2021 to 2028.

Global Insulated Packaging Market Country Level Analysis

The countries covered in the global insulated packaging market report are the U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Insulated Packaging Market Share Analysis

The insulated packaging market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to insulate packaging market.

Key Players in insulated packaging market

The major players covered in the insulated packaging market report are Amcor Limited, American Aerogel, Cryopak, Davis Core & Pad Company, DS Smith, DuPont, Huhtamaki, Innovative Energy Inc., MARKO FOAM PRODUCTS, Providence Packaging, Sonoco Products Company, The Wool Packaging Company Limited, TP Solutions, Pelican BioThermal, ShipItCold, Topa Thermal Packaging, TP3 Global, Polar Thermal Packaging Ltd., Insulated Products Corporation, Therapak LLC among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

MAJOR TOC OF THE REPORT

Chapter One: Introduction

Chapter Two: Market Segmentation

Chapter Three: Market Overview

Chapter Four: Executive Summary

Chapter Five: Premium Insights

Chapter Six: insulated packaging market

Get full Access of report

Get Toc of Report:

Browse Related Reports@

Global Chromatography Columns Market – Industry Trends and Forecast to 2029

Global Orthopedic Surgical Robots Market – Industry Trends and Forecast to 2029

The Global Insulin Storage Device Market

Global Surgery Device Market – Industry Trends and Forecast to 2027

Global DNA Markers Market – Industry Trends and Forecast to 2028

Global Neurorehabilitation Gaming Systems Market – Industry Trends and Forecast to 2028

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#Insulated Packaging Market#Insulated Packaging Market scope#Insulated Packaging Market share#Insulated Packaging Market trend#Insulated Packaging Market analysis

0 notes