#EPE foam for packing

Explore tagged Tumblr posts

Text

The Indispensable Choice: Why So Many Industries Rely on EPE Foam

In the vast landscape of material science, certain substances rise to prominence due to their unique blend of properties and versatility. Expanded Polyethylene (EPE) foam stands as a prime example. Its lightweight nature, exceptional cushioning, and adaptability have made it the go-to material for a staggering array of industries worldwide. From safeguarding delicate electronics during their journey from Mumbai to New York to providing protective cradles for fragile glassware shipped from the UK to Australia, EPE foam's characteristics address critical needs across diverse sectors. This comprehensive guide will delve into the compelling reasons behind EPE foam's widespread adoption. We will explore its key attributes, supported by data and real-world examples. We will highlight its crucial role in providing "Custom EPE Foam Packaging", specialized "EPE Foam Packaging for electronics", secure "EPE Foam Packaging for glassware", and reliable "EPE Foam Packaging for fragile" items. Understanding why so many industries choose EPE foam is essential for businesses in Navi Mumbai, Thane, and Panvel, as well as those operating globally.

Unpacking the Core Advantages of EPE Foam

EPE foam's pervasive use is rooted in its exceptional combination of inherent properties:

Superior Cushioning and Shock Absorption: Its closed-cell structure effectively dissipates impact forces, providing excellent protection against shocks and vibrations.

Lightweight Nature: EPE foam adds minimal weight to products and packaging, crucial for reducing shipping costs.

Excellent Insulation Properties: It offers thermal insulation, protecting temperature-sensitive goods.

Water and Moisture Resistance: Its closed-cell structure prevents water absorption, safeguarding products from moisture damage.

Chemical Inertness: EPE foam is non-reactive with most substances, ensuring it doesn't contaminate or damage the packaged goods.

Ease of Fabrication: It can be easily cut, shaped, molded, and laminated to create "Custom EPE Foam Packaging" solutions.

Non-Abrasive Surface: It protects delicate surfaces from scratches and scuffs during handling and transit.

Cost-Effectiveness: Compared to some alternatives, EPE foam offers a balance of performance and affordability.

Recyclability: EPE foam is recyclable, aligning with growing sustainability concerns.

These core advantages collectively make EPE foam an indispensable material across numerous industries.

Industry-Specific Applications and Why EPE Foam Excels

The versatility of EPE foam allows it to cater to the specific needs of a wide range of industries:

1. Electronics Industry:

Why EPE Foam? Electronic components are often delicate and susceptible to damage from shocks, vibrations, and electrostatic discharge (ESD). EPE foam, especially anti-static varieties, provides crucial protection.

Applications: "EPE Foam Packaging for electronics" includes custom-cut inserts for circuit boards, cushioning for laptops and smartphones, and protective wraps for sensitive instruments shipped from Thane to the USA (Los Angeles, Chicago). Anti-static EPE foam prevents ESD damage, ensuring the functionality of sensitive devices.

Data: Studies indicate that inadequate packaging is a major cause of damage to electronic goods during shipping, resulting in significant financial losses (Source: Electronics industry logistics reports). EPE foam significantly mitigates this risk.

2. Glassware and Ceramics Industry:

Why EPE Foam? Glassware and ceramics are inherently fragile and prone to breakage during handling and transportation. EPE foam's excellent cushioning properties provide a secure barrier against impacts.

Applications: "EPE Foam Packaging for glassware" includes custom-molded trays for bottles and glasses, protective sleeves for ceramic items shipped from the UK (London, Birmingham) to Australia (Sydney, Melbourne). Its non-abrasive surface prevents scratches on delicate finishes.

Example: A manufacturer in Navi Mumbai shipping crystalware to the UK utilizes custom EPE foam inserts within their corrugated boxes to minimize breakage and ensure safe arrival.

3. Automotive Industry:

Why EPE Foam? Automotive parts, from delicate sensors to large body panels, require protection from scratches, dents, and vibrations during transport and assembly.

Applications: EPE foam is used for protective padding in car interiors during assembly, custom-cut dunnage for parts transportation between manufacturing plants, and protective packaging for aftermarket components. Its durability ensures parts arrive at assembly lines in perfect condition.

4. Medical and Pharmaceutical Industry:

Why EPE Foam? Medical devices and pharmaceuticals often require sterile and protective packaging. EPE foam's inert nature and cushioning properties make it suitable for various applications.

Applications: EPE foam is used for cushioning sensitive medical equipment, creating protective inserts for diagnostic kits, and providing thermal insulation for temperature-sensitive medications. Its non-reactive nature ensures the integrity of medical supplies.

5. Furniture and Home Goods Industry:

Why EPE Foam? Furniture and home goods are susceptible to scratches, dents, and corner damage during shipping and handling. EPE foam profiles, sheets, and wraps offer effective protection.

Applications: EPE foam edge protectors safeguard furniture corners, sheets provide surface protection for tabletops and upholstery, and custom-cut inserts secure fragile components during transit from Mumbai to the UK.

6. Food and Beverage Industry:

Why EPE Foam? While not for direct food contact, EPE foam provides excellent insulation for temperature-sensitive food and beverages during transport. Its water resistance is also beneficial.

Applications: EPE foam insulated containers and liners help maintain the temperature of perishable goods during shipping. Protective EPE foam packaging can also prevent damage to bottles and containers.

7. Arts and Crafts Industry:

Why EPE Foam? Delicate artwork, sculptures, and craft supplies require protection from impacts and scratches. EPE foam's non-abrasive and cushioning properties are ideal.

Applications: "EPE Foam Packaging for fragile" artwork includes custom-cut inserts to secure pieces within crates, protective wraps for sculptures, and cushioning for delicate craft materials shipped domestically within Australia (Brisbane) or internationally.

The Economic Advantages of Choosing EPE Foam

Beyond its protective qualities, EPE foam offers significant economic advantages:

Reduced Damage and Return Rates: As highlighted by data in the electronics industry, EPE foam minimizes product damage, leading to lower return rates, replacement costs, and increased customer satisfaction.

Lower Shipping Costs: Its lightweight nature reduces overall package weight, directly translating to lower shipping expenses, especially for high-volume shippers in the USA.

Efficient Packing Processes: EPE foam is easy to handle and apply, streamlining packing processes and reducing labor costs for businesses in Panvel. "Custom EPE Foam Packaging" solutions further enhance efficiency.

Durability and Reusability: While often single-use, EPE foam's durability allows for potential reuse in some applications, further extending its cost-effectiveness.

Reduced Storage Space: Compared to bulkier alternatives, EPE foam can often be stored more efficiently, saving valuable warehouse space for businesses in London.

The Environmental Considerations of EPE Foam

While EPE foam is a petroleum-based product, it is 100% recyclable. Many manufacturers are also incorporating recycled EPE into their production processes, reducing its environmental footprint. Choosing suppliers with strong environmental policies is increasingly important for businesses in the UK and Australia with sustainability goals.

Best Searchable Keyword Variations

To optimize your online presence for individuals seeking EPE foam solutions, consider these keyword variations:

Why use EPE foam for packaging?

Benefits of EPE foam in shipping

Cost-effective foam packaging solutions

Protective foam for fragile items

Lightweight packaging material advantages

Shock-absorbing foam packaging

Custom EPE Foam Packaging suppliers

EPE Foam Packaging for electronics manufacturers

Best EPE Foam Packaging for glassware

Where to buy EPE Foam Packaging for fragile items

EPE foam applications in different industries

Recyclable EPE foam packaging options

Advantages of closed-cell polyethylene foam

EPE foam for product protection during transit

Cost savings with EPE foam packaging

Conclusion: The Undeniable Reign of EPE Foam

The widespread adoption of EPE foam across a multitude of industries is a testament to its exceptional blend of protective properties, versatility, and cost-effectiveness. From safeguarding delicate electronics and fragile glassware during international shipping to providing crucial cushioning in the automotive and medical sectors, EPE foam consistently proves its value. Its lightweight nature reduces shipping costs, its ease of fabrication allows for "Custom EPE Foam Packaging" tailored to specific needs, and its inherent cushioning minimizes damage, leading to significant savings. For businesses in Mumbai, Navi Mumbai, Thane, Panvel, the USA, the UK, and Australia seeking reliable and efficient packaging solutions for "electronics", "glassware", and other "fragile" goods, EPE foam remains the go-to material, an indispensable choice for ensuring product integrity and optimizing supply chain efficiency in a globally connected marketplace. Its continued relevance underscores its position as a cornerstone of modern packaging practices.

3 Ply Single Wall

5 Ply Double Wall

7 Ply Triple Wall

Custom Corrugated Boxes

EPE Foam Packaging

Custom Printed Boxes

#EPE foam inserts#EPE foam sheets#Buy EPE foam packaging#EPE foam suppliers#Custom foam packaging solutions#Protective foam packaging#Anti-static EPE foam packaging#EPE foam for shipping#EPE foam for packing#Die-cut EPE foam packaging#EPE foam cushioning#EPE foam manufacturers#EPE foam packaging cost#Best EPE foam packaging suppliers#EPE foam packaging for sale#EPE foam packaging USA#EPE foam packaging UK#EPE foam packaging Australia#Buy custom foam inserts online#Protective packaging for electronics supplier#Buy custom EPE foam packaging Mumbai#EPE foam inserts for electronics Navi Mumbai#Protective EPE foam for glassware Thane#Anti-static EPE foam packaging Panvel#Custom molded EPE foam USA#Lightweight EPE foam for shipping UK#Shock-absorbing EPE foam Australia#EPE foam cushioning for fragile items Mumbai#Durable EPE foam packaging Navi Mumbai#Cost-effective EPE foam Thane

1 note

·

View note

Text

NSB (Straud Legacy) Gen 9 Ep 71: Fear and Fire

The Story of a Family

Luigi had rarely been happier to get home than he was as he returned from the gym. He limped up the steps on his sore ankle, looking forward to dropping into bed with an ice pack, a nice mixed drink, and that sci-fi novel Noemi couldn’t stop raving about.

Seeing Noemi had been the only bright spot in this absolutely cursed day, and the universe had even had to go and try to ruin that! He couldn’t wait for today to be over – surely tomorrow would be better, it had to be!

Entering the downstairs foyer the first thing he heard was Chubbs, meowing plaintively. Had he forgotten to feed her? Glancing up the steps Luigi did a double take. Smoke was pouring out from under the door of his bedroom, his cat standing nearby doing her best to alert someone to the problem.

Ignoring the pain Luigi bolted up the stairs, nearly falling headfirst into his room when his ankle buckled underneath him. Catching himself on the doorframe, he continued inside to find the table on which rested Papa Jack’s urn, and the candle from Beau he’d forgotten to extinguish, ablaze.

Luigi’s heart jumped into his throat as she saw the flames engulfing Papa Jack’s remains. Without thinking he started to reach forward to grab the urn out of harm’s way but was stopped short by the intense heat radiating from the fire.

Instead, he ran back out to grab the fire extinguisher hanging in the hallway, planting his feet and venting his fear and frustration in a primal scream as he sprayed the foam in a wide arc across the blaze.

Once the fire was extinguished Luigi was left with the charred remains of ruined furniture and his papa's urn, standing like a sentinel in the middle of it all. It looked OK, but he had no way of knowing if Papa Jack's connection to the physical world had remained intact.

Luigi started to cry then, giant choking sobs that racked his entire body. He gasped out a plea to his papa, to the watcher, to anyone who could hear him to please let it be OK, to give him a sign. He didn't know how he'd live with himself if he’d destroyed his papa’s only link to the mortal realm.

Suddenly he felt a pair of strong arms wrapped around him, heard Papa Jack whisper in his ear that he was here, everything was OK.

For a long while all he could do to return the hug as if his life depended on it, his Papa rubbing his back like he used to do when Luigi was a child. Big fat tears cascaded down his cheeks as he told Papa Jack that he was so sorry, so stupid, and promised never to let anything like that happen again.

When his tears were finally spent Jack invited him to sit down and tell him everything. Luigi offloaded his tale of woe and apologized again, thanking him for coming. Papa replied that honestly, he hadn’t gotten a choice! He’d intended to visit as soon as he could when he heard Luigi’s sobs, but he’d found himself physically pulled across the barrier separating the worlds, unceremoniously deposited in the hallway of the boarding house.

After that Jack went downstairs himself to get his son that drink and the ice pack he needed more than ever after his terror fueled run.

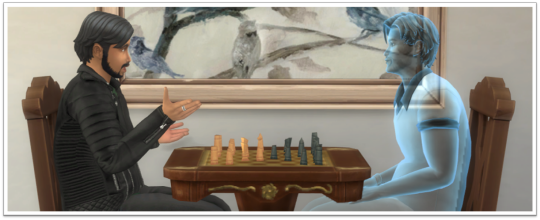

Luigi downed his glass of nectar and strapped the pack to his burning ankle but decided not to risk falling asleep on his papa. Instead, using the wall for support, he hopped to the chess table just outside his door, settling in for a relaxing game while they chatted.

“I’ve been very proud of your recent accomplishments” Jack began. “Tell me the latest on your lovely ladies so I don’t offer you bad advice when this fine juice loosens my tongue later.” Luigi smiled, always happy to discuss his favorite sims.

Luigi told Papa Jack all about his latest dates with Amaya and Noemi, not sure how much had come across in his nightly updates to the urn.

Jack was quiet at first, lost in thought. Finally, he told his boy “I’d say you’re incredibly lucky and unlucky. Both your girls sound great, but you’re not going to be able to keep the two of them fully satisfied indefinitely. Sooner or later, you’ll need to make a choice”.

Amaya was clearly a lot of fun, but it seemed to Jack that she and Luigi didn't "click" as well as he and Noemi. However, his responsibilities as a legacy heir meant he had to have a child. Was he prepared to do that on his own if he wanted to stay with Noemi and she refused to come out of "hiding"?

Jack went on “You have time son, but your next birthday is closer than you might realize. I suggest you put some thought towards your future.”

Luigi frowned slightly as he processed his papa's advice. Being in college it sometimes felt like he was suspended in a bubble, not as "grown-up" as his cousins with their full-time jobs and "adult" responsibilities, but that wasn't true. Time marched on, and his university days would soon be over.

He thanked his papa and pondered his next move on the board. Gazing contentedly at the ghost sitting across from him, he reflected that maybe it hadn't been that terrible of a day after all.

View The Full Story of My Not So Berry Challenge Here

#sims 4#sims 4 challenge#sims 4 legacy#sims4#sims 4 nsb#sims 4 not so berry#sims4nsbstraud#sims 4 let's play#sims 4 gameplay#sims 4 lets play

11 notes

·

View notes

Text

Klim Krios Pro Helmet

Klim produces top-tier adventure gear, so this Klim Krios Pro review aims to answer what every ADV rider wonders: does this helmet justify its reputation and price?

Koroyd forms the backbone of this helmet’s safety, with its honeycomb structure absorbing impacts and boosting airflow, while the Fidlock magnetic strap closure adds a touch of modern convenience.

The Krios Pro’s four ride modes, removable peak, and compatibility with goggles or comms gear mean it’s built for versatility, whether you’re tackling Baja dust or highway miles. I’ve logged miles in heat and rain, searching for a helmet that keeps up with every twist in the journey.

Adventure riders face tough choices in a crowded market, and every feature matters when you’re far from home. What really sets the Klim Krios Pro apart from the pack, and is it the right helmet for your next expedition?

Klim Krios Pro Weight

Klim's Krios Pro is a serious adventure motorcycling helmet, and at 540 pounds, it better be. So, let's get into the nitty-gritty.

The Pro is based on Klim's base Krios helmet and is 160 pounds dearer, but thankfully there's quite a lot to separate this one from the cheaper lid.

Klim Krios Pro — has — carbon fiber shell.

First up, this one has a full carbon fiber shell, and that's distinct from the straight Krios, which has a composite fiber shell.

This Pro is light; it weighs 1,312 grams on our scales in a size medium. But don't get carried away that spending the extra for this Pro model means there's going to be a weight saving that comes with that over the base model.

We weighed a normal Krios at 1,256 grams, and that's about 50 grams less than this Pro. There's nothing undercover or secret about the fact: Klim's stickers on the respective helmets both show that this Pro is slightly heavier than the base Krios helmet.

And let's face it, at 1,300 grams, this lid is hardly a tub of lard. It feels very light on the bike, and that feeling of mine is borne out in the customer reviews. Every person who's bought this helmet and left the review calls this helmet light.

So, if going for the Pro doesn't bring a weight advantage, what does it bring? There are several upgrades aside from the obvious aesthetic appeal of the all-carbon fiber shell.

youtube

Klim Krios Pro — includes — impact liner upgrades

One of the most spoken about differences is in the impact liner, the bit that absorbs the energy if you're unlucky enough to hit your head. The bulk of it on the Krios Pro is expanded polystyrene, or EPS, like pretty much every helmet has been since about 1954. But some of the Pro's liner is made from a new material called Koroyd.

This material consists of small extruded polymer tubes that all combine to create a compressible liner, which absorbs energy when it's impacted. Think of it like upturned drinking straws welded together in a kind of honeycomb structure.

It's lighter than polystyrene, and the fact that each tube is hollow means air can flow through those tubes to give better ventilation to the inside of the helmet. It's been used in bicycle helmets before, but this is the first bike lid that I'm aware of that uses it.

This helmet sits across the top of the shell, and it combines with the traditional EPS liner through the rest of the lid to give the impact protection that you need.

Klim Krios Pro — features — ventilation system

Moving on to ventilation, air gets to the forehead through this chunky sliding vent just above the visor, and that allows a direct flow of air.

That's the same as the straight Krios model helmet, but where the Pro takes it up a notch is in the chin venting.

The chunky, switchable vent of the Klim Krios Pro exposes a substantial inlet that's only protected by a very airy foam insert to stop any debris and bugs from getting through. Air flows more freely in this helmet than in the base model when that vent is open, and you can also close it, which isn't something you can do on the other lid.

Klim Krios Pro — uses — removable peak and visor

The removable peak is the same as the base model Krios, and it works in conjunction with the visor, which is where this Pro model has perhaps the most noticeable difference to the base model.

The standard visor on this Pro model is a straightforward, clear one, but in the box, there's this light-reactive Transitions visor.

Transitions is a coating that means the visor becomes as tinted as a race visor in strong sunlight and reverts back to being completely clear as the light fades and you're riding at night.

I think it's absolutely brilliant and really makes the Krios Pro stand out from other adventure helmets, including the straight Klim Krios, which comes with a clear visor as standard and has a permanently tinted visor in the box for when you're riding off-road.

Some of the premium kit on this Pro I could take it or leave it, but the Transitions visor is a big, big benefit over the cheaper Krios helmet. Both visors supplied with this Pro—the Transitions and the clear one—have the pins for a Pinlock, and there's a Pinlock 120 insert in the box to make sure you get clear vision regardless of the weather.

Klim Krios Pro — visor — transitions photochromic

There's only a couple of reasons I'd see for using the clear visor rather than this Transitions one, and that's that the Transitions visor does tend to react a little bit more seriously on cloudy days, and sometimes it's a bit darker than I'd like.

But I've never found that it's gone dark enough to be a real problem. The other reason is that you might be riding on dirt roads, and you're worried about scratching the expensive Transitions visor. It's definitely worth being more careful than usual with this visor, as a replacement Transitions visor is 150 quid, whereas it's normally 50 quid for a clear one.

But if you're planning on dirt riding, you're probably going to be looking down the route of using goggles. There's room beneath the peak on the side for the goggle strap to fit, and there's plenty of room inside the aperture for goggle frames.

And you don't even have to remove the visor to use this lid with goggles, as the strap will fit under the visor once it's been raised, although goggles will fit better if you do remove the visor first.

Klim Krios Pro — visor and peak — removal method

To remove the visor first, you undo this screw at the top of the shell, and then you rotate these buttons on the side and pull them away, which leaves space for the peak to be pulled away, and then the visor can be removed as well.

If you want to run the helmet without the peak, or "street mode" as Klim call that, you can take it off and then fit two side covers that are supplied with the lid. They go in here, and they just take up the space that would normally be taken up by the peak.

It's handy to be able to run a helmet without the peak when riding long distances on the road, as peaks can disturb the aerodynamics, but I found there wasn't too much of an issue on that score when wearing the Krios Pro with a peak.

Klim Krios Pro — fastener — Fidlock magnetic system

The final difference worth noting for the Krios Pro over the base model is the strap fastener. This one is a system called Fidlock. It clips together using magnets and can only be undone by pulling this red release tab in the correct direction.

It feels odd to someone like me, who's been riding for 20 years and is used to either D-rings or a buckle, to have something that comes apart so easily. It feels as though it shouldn't work, but try as I might, I can't work out what's actually wrong with it, other than being different to what I've always known.

And people who find helmet straps too much of a fiddle—especially D-rings, which tend to drive a lot of people mad—I think those people will absolutely love this system because it is really simple to use. It just flicks together with those magnets, and it's done up.

Klim Krios Pro — shares — essential basics with base model

So those are the main differences between the Pro and a normal Krios, and there's actually quite a lot to separate them, but they still share some really essential basics, including a very soft and comfortable interior lining. It's also been tailored to suit a dedicated Sena TenU intercom. That lining is fully removable for washing, and it runs a chin curtain here to block out drafts.

Klim Krios Pro — receives — positive customer reviews

Customer reviews for this Krios Pro helmet are really positive. People are especially complimentary about the Transitions visor and the breadth and depth of the peripheral vision they get from this helmet. Those things all get a lot of praise.

I'd agree with all of that, and I was seriously impressed with this helmet when I tested it. At 540 pounds, it's not cheap, but there are plenty of reasons why I think you'd want to stretch your budget to get one.

I hope that goes into all the detail you want about the Klim Krios Pro, but if you have anything to ask or to add, then please pop a comment below. Thanks for watching.

0 notes

Text

Cold‑Chain Reinvented: Dry Ice Packaging Market to Chill at $1.4 Billion by 2035

The global Dry Ice Packaging market is on track to expand from USD 640 million in 2024 to over USD 1.4 billion by 2035, registering a CAGR above 7% over the forecast period hallbook social network. This surge is rooted in explosive growth across pharmaceutical logistics, frozen food delivery, biotechnology, and laboratory research, each demanding ever‑more reliable cold‑chain solutions.

Market Context & Scope

While Dry Ice Packaging specifically targets insulated shippers and containers, the broader Dry Ice market itself is projected to climb from USD 1.54 billion in 2024 to USD 2.73 billion by 2032, at a 7.4% CAGR Fortune Business InsightsGlobeNewswire. Within that, packaging solutions alone were valued at USD 642.2 million in 2024 and are expected to hit USD 1.0 billion by 2030, reflecting the premium placed on safety and reliability in cold‑chain delivery DataString Consulting.

Key Growth Drivers

Pharmaceutical Cold Chain

The boom in biologics and mRNA‑based vaccines has made ultra‑cold transport non‑negotiable, embedding dry ice packaging at the heart of global vaccine distribution networks

Frozen & Perishable Foods

Direct‑to‑consumer meal kits, specialty seafood shipping, and grocery delivery all lean on extended cold‑retention systems—dry ice packaging volumes jumped 8.5% year‑over‑year in 2024 to meet online grocery demand

Biotech & Laboratory Research

Sensitive reagents, cell cultures, and diagnostic kits require controlled cooling; specialized packaging ensures temperature excursions remain within strict ±2 °C tolerances

Innovation & Sustainability Trends

Multi‑Layer Insulation: Advanced foams and vacuum panels extend hold‑times by 20–30% over traditional EPS

Modular Container Systems: Interlocking designs allow scalable payloads and faster turnaround in rental fleets

Eco‑Friendly Materials: Adoption of recyclable liners and bio‑based insulating inserts is rising in line with broader temperature‑controlled packaging trends

Digital Temperature Tracking: IoT‑enabled sensors embedded in inserts provide real‑time monitoring and automated alerts for shipments in transit

Competitive Landscape

Leading cold‑chain packaging firms are expanding their dry ice portfolios through technology partnerships and geographic expansion:

Cold Chain Technologies Inc.

Cryopak Industries Inc.

Sofrigam SA

CCL Industries Inc.

Sealed Air Corporation

These players focus on automated filling systems, sustainable design, and integrated digital monitoring to differentiate in a market where reliability is paramount.

Broader Cold‑Chain Packaging Outlook

The overall Cold‑Chain Packaging segment (including gel packs, PCM, and others) is forecast to surge from USD 4.33 billion in 2024 to USD 63.48 billion by 2029, at a ~19.8% CAGR SkyQuest. Dry ice solutions will remain a critical high‑performance niche within this expansive market.

Regional Dynamics

Asia‑Pacific dominates the Dry Ice market with a 32.5% share in 2024, driven by rapid urbanization and cold‑chain investments in China and India

North America follows, buoyed by its mature pharma sector and stringent FDA cold‑chain regulations

Future Outlook

Looking ahead, the Dry Ice Packaging market will continue to evolve around:

Smart Coatings & Inserts that actively regulate temperature via embedded phase‑change materials.

Reusable, Circular‑Economy Systems to reduce waste in high‑volume shipment corridors.

AI‑Driven Route Optimization for minimized freeze‑time losses during transit.

For an in‑depth strategic roadmap and full market data, explore the comprehensive report at DataString Consulting.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] GURU Cycling Helmet, Light Weight with Superior Ventilation, Helmet For Mountain, Road Bike & Skating Helmet with Premium EPS Foam Lining, Ideal for Adults and Kids Adjustable Skating/Cycling Helmet in 9 Air Vents. Black EPS With Thick PVC Shell in Multi Patterns. Packed in Thick Transparent PVC Sheet Sealed With Head Bag Available in 6 Different Colours [ad_2]

0 notes

Text

The Ultimate Convenience: Le Regalo® 5 Piece Bake & Take Set

For anyone who loves to bake and share their homemade creations, the Le Regalo® 5 Piece Bake & Take Set is an absolute game-changer. This thoughtfully designed set not only helps you bake delicious meals but also makes it easy to store and transport them, whether you’re heading to a picnic, a potluck, or simply want to save leftovers. Let’s dive into what makes this set the perfect companion for every kitchen.

A Closer Look at the Set

The Le Regalo® 5 Piece Bake & Take Set includes two high-quality borosilicate glass casseroles, complete with tight-fitting plastic lids, and a two-tier insulated carrier. The combination of durable glass containers and a thermal-resistant carrier ensures your food stays fresh, hot, or cold while you transport it.

What’s Included:

1 Medium Casserole with Lid: A 1.7QT capacity dish ideal for side dishes or smaller meals.

1 Large Casserole with Lid: A 2.3QT capacity dish perfect for family-sized meals.

1 Two-Tier Insulated Carry Bag: With a smart dual-compartment design, this bag allows you to carry both casseroles conveniently, while its thermal insulation ensures temperature retention.

Versatile and Durable

One of the standout features of this set is its versatility. The borosilicate glass casseroles are safe to use in the oven, microwave, freezer, and dishwasher, making them perfect for preparing a variety of dishes. Whether you’re baking lasagna, casseroles, or pasta, these dishes handle it all. Plus, the BPA-free plastic lids are designed for easy storage of leftovers, ensuring that your food remains fresh in the fridge or freezer.

Easy Transport with Thermal Insulation

Transporting food can sometimes be a challenge, especially when it comes to keeping dishes at the right temperature. That’s where the insulated carrier comes in. Designed with a food-grade aluminum foil lining and EPE foam padding, this bag offers excellent thermal resistance, keeping your food warm or cold for longer periods. Whether you’re bringing a hot dish to a potluck or storing cold food for a picnic, this carrier has you covered.

Why You’ll Love the Bake & Take Set

1. Convenience at Its Best

With this set, you no longer have to worry about baking, storing, and transporting your food in multiple dishes. The two-tier insulated carrier makes it easy to bring two separate dishes, while the tight-fitting lids prevent spills and keep your food fresh during transport.

2. Durable and Long-Lasting

Made from tough borosilicate glass, the casseroles are designed to endure extreme temperatures, whether you’re baking in the oven or freezing leftovers. The plastic lids are BPA-free, ensuring they’re safe for food storage and protecting your health.

3. Perfect for Any Occasion

Whether you're hosting a gathering or going on a picnic, the Le Regalo® 5 Piece Bake & Take Set is ideal for any occasion. Bake your favorite dishes, pack them up, and enjoy a meal with family and friends, no matter where you are.

Practical Features

Durable Material: The borosilicate glass is highly durable and resistant to temperature changes, meaning you can go straight from the oven to the fridge or freezer without any worries.

Versatile Use: These dishes are not only great for baking but also for freezing, storing, and reheating leftovers.

BPA-Free Lids: Ensuring safe storage, the BPA-free lids tightly seal the casseroles to keep your food fresh and protected.

Insulated Carrier: With two compartments and thermal insulation, your food remains at the desired temperature during transport.

Ideal for Picnics, Potlucks, and More

The Le Regalo® 5 Piece Bake & Take Set makes it easy to share your favorite meals wherever you go. The two-tier design allows you to carry two dishes in one convenient carrier, making it perfect for picnics, potlucks, or family gatherings. No need to worry about your food losing its temperature or freshness during travel.

0 notes

Text

https://www.tskindustrialservices.com/industry-packing-products/top-rated-epe-foam-manufacturing-in-hosur

0 notes

Text

Food Delivery Box | Bikekit

BikeKit breaks the glass ceiling with food delivery boxes

When BikeKit introduced food delivery boxes and bags there was so much commotion in the market. Buyers were thrilled just looking at the innovation, while competitors wondered why they had not come up with such a brilliant idea! That was 2018!

Today BikeKit is a force to reckon with. An established name it manufactures home delivery boxes and bags and focuses on the requirements of the Last Mile delivery segment. With discerning and different products and services in its portfolio, BikeKit offers tangible solutions in the verticals of Delivery Solutions, Rider Wellness, and Rider Safety. In Delivery Solutions, there is a range of delivery boxes and bags to cater to various industries.

With a network that spans the globe, BikeKit offers three types of food delivery boxes such as the premium LED backlight box, the LED budget box, and the plain box. Supplying to more than 20 countries around the world the delivery boxes are a game changer and an excellent marketing and branding tool. The food delivery box is mounted on a bike however the in-built LED-backlit panels glow when the rider is out making a delivery. There is a choice of having the box in any color or size and it can have company logos and contact details printed on it so that where ever the biker goes, the box is being read too.

The plain delivery boxes are without LED panels. Modular in nature they are meant to be assembled by the customer. Available in three sizes of 42cm x 42cm, 45cm x 45 cm, and 52 cm x 52 cm, they are light in weight as UPVC and foam board have been used to make them.

BikeKit has ensured that items in the delivery box stay fresh! All the boxes are large enough to stock several orders and have high-grade EPS insulation and Hard Case Gel Packs to maintain the appropriate temperature inside the box.

Hence food can be enjoyed as it is meant to without zero complaints from a customer about food becoming warm or cold.

It is clear that sustainability is at the core of the company and it shows in its products, especially when delivering sensitive items such as food, grocery, and medicines. The company’s informed and expert designers in Dubai are making sure they only use recycled material to create boxes and bags so that they do not leave any carbon footprints. BikeKit is an environment-friendly company that cares for its business partners and mother earth.

BikeKit does a lot of research to help its customers find the best practical solution without wasting time. It will suggest the right delivery box or bag for the business. What’s more the company believes in staying connected with its customers even after the sale has been made. It has distributors around the globe that will take care of the smallest concerns that arise in the delivery boxes or bags. So, once you have handed over the order request to BikeKit you can sit back and relax.

#food delivery box

1 note

·

View note

Text

Difficulties and Remedies in Reusing Styrofoam for Home Appliance Packaging

The packing of household appliances frequently uses Styrofoam. It can safeguard the security of household appliances while being transported and stored because of its superior cushioning, light weight, and impact resistance. But just as quickly as consumer gadgets and home appliances are becoming more and more in demand, so is the quantity of waste foam packaging produces. Because EPS is difficult to decompose, improper processing and recycling will result in significant environmental impact. The recycling problems with foam plastics found in household appliance packaging, as well as current recycling models and solutions, will be covered in this article.

Styrofoam is ineffective for storage and transportation because it is heavy despite being incredibly light. Due to its low density and light weight, foam requires more space and costs more to ship. Because recycling foam plastics has low economic rewards and large transportation expenses, many recyclers are not very enthused about it.

Despite its difficulty, styrofoam can be readily recycled provided the proper recycling tools are used. The most widely utilized piece of machinery in North America is the styrofoam densifier, which is mostly used to recycle the packaging from styrofoam appliances. The GREENMAX styrofoam densifier has a compression ratio of up to 90:1. The reason for this foam densifier's popularity is its increased compression ratio.Compression treatment is a basic first recycling step for large foam plastics. Compressing foam plastics with specialized equipment lowers their volume and lowers storage and shipping expenses. Reusing the foam plastic packaging used for household appliances is a crucial step in combating plastic pollution. With the aid of foam densifiers, legislative assistance, and technological advancement, it is possible to recycle foam despite the difficulties involved in doing so. Future foam plastic recycling rates can be greatly raised, environmental pollution can be decreased, and the circular economy can be fostered with the help of numerous parties working together.

0 notes

Text

What Commonly Used Injection Molding Materials Have: An Insight into Their Properties and Applications.

Injection molding is a widely utilized manufacturing process that involves injecting molten material into a mold to create a wide array of products. The choice of material is crucial as it influences the properties, cost, and applications of the final product.

Here, we delve into some of the most used injection molding materials, exploring their characteristics and common applications.

1. Polypropylene (PP)

Characteristics:

Polypropylene is a type of plastic that is very versatile. It is lightweight, resists chemicals well, and can handle repeated stress without breaking. This makes it perfect for uses that need to be durable.

Applications:

PP is often used in packaging, car parts, everyday products, and medical devices. Repeated bending makes it great for items like living hinges that need to bend a lot.

2.Acrylonitrile Butadiene Styrene (ABS)

Characteristics:

ABS is a type of plastic made by mixing styrene and acrylonitrile with polybutadiene. This makes it very strong, tough, and keeps its shape well.

Applications:

ABS is commonly used in car parts, electronic cases, everyday items, and toys. Its strength and easy shaping also make it popular for 3D printing.

3. Polyethylene (PE)

Characteristics:

Polyethylene comes in different types like HDPE and LDPE. It resists chemicals, insulates electricity, and is flexible. HDPE is harder and more rigid, while LDPE is softer, more flexible, and melts at a lower temperature.

Applications:

PE is used for many items like containers, bottles, plastic bags, and toys. It is also great for medical and food packaging because it is safe and non-reactive.

4. Polycarbonate (PC)

Characteristics:

Polycarbonate is a strong type of plastic known for being tough and clear. It can be shaped easily and is used in many ways.

Applications:

Polycarbonate is often used in eyeglass lenses, medical tools, car parts, and electronics. Its clearness and strength make it perfect for things that need to be strong and easy to see through.

5. Polystyrene (PS)

Characteristics:

Polystyrene is a type of man-made plastic that comes in two types: solid and foam. It is light, stiff, and cheap to make.

Applications:

PS is used in things like disposable utensils, plastic models, CD cases, and foam packaging. The foam kind, called expanded polystyrene (EPS), is common in insulation and packing materials.

6. Nylon (Polyamide - PA)

Characteristics:

Nylon is a man-made material that is strong and flexible. It can handle being pulled hard, resist wear and tear, and is good with heat and chemicals.

Applications:

Nylon is used in cars, machines, everyday items, and clothes. It is tough and strong, perfect for parts that get a lot of use and pressure.

7.Polyethylene Terephthalate (PET)

Characteristics:

PET is a thermoplastic polymer resin of the polyester family. It is known for its strength, thermostability, and resistance to moisture.

Applications:

PET is widely used in beverage bottles, food packaging, and synthetic fibers. Its recyclability makes it a popular choice for environmentally conscious manufacturers.

Different materials used in injection molding have special qualities that suit various needs. For example, polypropylene is versatile and tough, while polycarbonate is strong and clear. Knowing these traits helps manufacturers pick the best material for their specific use, ensuring good performance, cost-efficiency, and eco-friendliness. As technology and materials improve, more options for injection molding become available, opening new possibilities for innovation in manufacturing.

There are 7 Most Common Injection Moulding Gate Types - Choosing a Gate for Your Project

An injection molding gate is a specially designed opening that controls how molten plastic flows into the mold. Its main job is to manage the amount and direction of the plastic as it fills the mold. There are different kinds of gates, such as edge gates, sub gates, and direct sprue gates, each with its own unique features and uses. We will look at these types more closely below.

Most common types of injection moulding gate:

Edge Gates

Tunnel / Submarine (Sub) Gates

Cashew Gates

Sprue or Direct Gates

Fan Gates

Diaphragm Gates

Pin Gates

Inject moulding is a prototyping tool made by HLH Rapid. Before beginning production, our engineers choose the ideal gate for your design and build bespoke moulds and parts based on your CAD drawings. Simply use our site contact form to send us your CAD designs and project specifics, including quantity, material, and any surface finishing. In a span of 24 to 48 hours, our staff will furnish an estimate.

Do you want to learn about Injection Molding or need a Free Quote? Submit your CAD drawings and project details, including quantity, material, and surface finish, through our site contact form. Our team will send you a quote within 24-48 hours.

0 notes

Text

Art of Packaging: Transforming Sheets into Essential Packing Materials

Introduction:

Packaging plays a pivotal role in safeguarding products during transit, ensuring they reach their destination intact and in pristine condition. Among the myriad of materials used for packaging, sheets stand out as versatile assets. What may seem like a simple sheet of material holds the potential to be molded, folded, and transformed into a variety of Packing materials from sheets, each serving a unique purpose. In this blog, we delve into the world of packing materials derived from sheets, exploring their versatility, benefits, and sustainable potential.

The Foundation: Cardboard Sheets

Cardboard sheets are the unsung heroes of packaging. Sturdy yet flexible, they serve as the foundation for various packing materials. From corrugated cardboard used in shipping boxes to flat cardboard sheets utilized as dividers and protective layers, their versatility knows no bounds. These sheets can be easily customized to fit any product, providing cushioning and support while minimizing the risk of damage during transportation.

Bubble Wrap: More Than Just a Popping Sensation

Who can resist the satisfying pop of bubble wrap? But beyond its entertainment value, bubble wrap is an effective packing material derived from sheets. By laminating two sheets and trapping air pockets between them, bubble wrap creates a cushioning layer that absorbs shocks and vibrations. Whether wrapping fragile items or filling void spaces within packages, bubble wrap offers unparalleled protection while remaining lightweight and cost-effective.

Foam Sheets: Soft Yet Protective

Foam sheets, made from materials such as polyethylene or polyurethane, are prized for their soft yet resilient nature. These sheets can be cut to size and used to cushion delicate items, providing a protective barrier against impacts and abrasions. From electronics to glassware, foam sheets conform to the shape of the product, ensuring a snug fit that minimizes movement during transit. Additionally, foam sheets are reusable and recyclable, making them an eco-friendly choice for sustainable packaging solutions.

Packing Peanuts: Lightweight Fillers

Packing peanuts, often overlooked, are another ingenious creation derived from sheets. These lightweight fillers, typically made from expanded polystyrene (EPS) foam, excel at filling void spaces within packages. By interlocking and conforming to the contours of the product, packing peanuts prevent shifting and settling during shipping, maintaining product integrity throughout the journey. Despite their lightweight nature, packing peanuts offer impressive shock absorption capabilities, safeguarding even the most fragile items.

Paper Cushioning: Sustainable and Versatile

In an era of heightened environmental consciousness, paper-based Packing materials from sheets have emerged as sustainable alternatives to traditional plastics. Paper sheets, whether crumpled, shredded, or folded, provide excellent cushioning and void-fill properties while being biodegradable and recyclable. From kraft paper to newsprint, these sheets offer versatility and eco-friendliness without compromising on performance.

Conclusion:

From cardboard to foam, sheets serve as the building blocks of a diverse array of packing materials, each designed to protect and preserve products during transit. Whether it's safeguarding fragile glassware or cushioning sensitive electronics, these materials play a crucial role in ensuring that goods arrive safely at their destination. Moreover, with sustainability at the forefront of packaging innovations, the versatility and eco-friendly attributes of sheet-based packing materials make them indispensable assets in the modern packaging landscape. As we continue to seek innovative solutions for safer, more sustainable packaging, the humble sheet remains a timeless cornerstone of the art of packaging.

0 notes

Text

UNICASE is your one-stop shop for all equipment protection and storage needs

We, at UNICASE, offer a comprehensive assortment of hard protection cases ranging from plastic carry cases, presentation cases, camera carry cases, instrument cases, industrial carry cases and long or gun and rifle cases to fit a variety of usages.

In addition, we also provide the extra option to have the interior of the case customized with various kinds of foam inserts and foam packing materials, UNICASE adds unique value to all your protection requirements.

Based on your protection needs, UNICASE offers the following product categories to choose from :

♦ Heavy duty waterproof hard carry cases

♦ Heavy duty waterproof long and gun hard carry cases

♦ Medium duty non waterproof carry cases

UNICASE stands apart from others

Our experience in the market and with our customers, adds value, not only in providing quality products to our customers along with quality service, but also we bear a sense of urgency from the perspective of customer needs.

With a large house stocking facility and state of the art foam cutting capability, UNICASE is strongly positioned as one of the top leading Protective Hard Cases and Foam packing suppliers. UNICASE protective plastic carry cases come with optimally designed, appealing interior and exteriors made up of best quality high grade polypropylene, and TSU resin’s providing highest level of protection and durability.

UNICASE understands the value of Product Quality

UNICASE robust and long-lasting Heavy duty waterproof hard carry cases are capable of withstanding any obstacle posed by hard handling and harsh environmental conditions. Majority of our cases for extreme duty equipment have ingress protection level of IP67. UNICASE carry case product offerings are comparable or better in design and pricing as compared to PELICAN, B&W, SKB, NANUK and other brands.

UNICASE Heavy duty waterproof long gun hard carry cases are most suitable to securely carry long musical instruments, rifles, and guns. These cases are most suitable for military and outdoor protection needs.

UNICASE Medium duty Non waterproof cases come in a wide range of sizes to suit a multitude of uses, including consumer products storage, instrument sales kits, demonstration kits, presentation exhibitions, and sales & marketing kits.

Since UNICASE understands the industry need to protect and secure all types of sensitive equipment’s, camera equipment’s, drones and accessories, military equipment’s, demo kits, valuable exhibit items, presentation kits, etc. UNICASE is branded one of top among very few protective hard cases and storage/ transit carry case suppliers, which provide unique foam packing solutions for the carry case interiors to give your products high levels of protection along with most optimised and professional product arrangement. The foam packaging solutions offered by UNICASE include variety of foam insert choices like EPE, PU, and XLPE material as per customer’s products and protection needs.

UNICASE Product Ranges

UNICASE Waterproof and non-waterproof protective hard cases are extensively used, and not limited to the following segments:

♦ Plastic hard carry cases for Camera’s and related accessories

♦ Heavy duty hard carry cases for drones and related accessories

♦ Waterproof hard carry cases for videography equipment’s

♦ Equipment cases for Military / Défense Applications

♦ Plastic carry cases for industrial devices and OEM’s

♦ Protective hard carry cases for all kinds of testing and calibration equipment’s

♦ Waterproof hard carry cases for medical equipment’s, devices and kits

♦ Robust and heavy-duty plastic hard carry cases for the aerospace/ aviation industry

♦ Instrument plastic hard carry case for unmanned aerial vehicle systems (UAV)

♦ Heavy duty hard carry cases for Industrial equipment’s

♦ Protective hard plastic carry cases for sensitive instruments

♦ Plastic carry cases for demo and marketing kits

♦ Protective hard plastic carry cases for delicate artifacts and valuable gift items

♦ Equipment cases toolbox and tool kits for all purpose.

To know more: https://www.unicase.in/

1 note

·

View note

Text

styrofoam balls in decorative crafts

Styrofoam balls are commonly used in decorative crafts due to their lightweight and versatile nature. Here are some ways Styrofoam balls can be incorporated into decorative crafts:

Wreaths and Garlands: Styrofoam balls can be used as decorative elements in wreaths and garlands. They can be painted, covered with fabric or ribbon, and attached to the base to add texture, color, and visual interest. Styrofoam balls can also be used as fillers between other embellishments in wreaths and garlands.

Hanging Decorations: Styrofoam balls can be transformed into hanging decorations by stringing them together with beads, ribbons, or strings. They can be painted, glittered, or wrapped with yarn to create eye-catching ornaments for parties, weddings, or home decor.

Pom-Poms: Styrofoam balls can be covered with yarn or fabric, transforming them into fluffy pom-poms. These pom-poms can be used as decorative elements in various crafts, such as wreaths, mobiles, or as accents on gift wrapping.

Centerpieces: Styrofoam balls can be incorporated into centerpieces for parties, weddings, or special occasions. They can be painted, decorated with sequins or beads, and arranged with flowers, foliage, or other decorative elements to create visually appealing table decorations.

Christmas Ornaments: Styrofoam balls are widely used in Christmas ornament crafts. They can be painted, glittered, or covered with fabric or paper to create personalized ornaments. Styrofoam balls can also be used as a base for attaching other decorative elements like ribbons, buttons, or small figurines.

Mobiles and Chandeliers: Styrofoam balls can be suspended from strings or wires to create mobiles or chandeliers. They can be decorated with paint, glitter, or other materials to add visual interest and movement to the hanging decoration.

Party Decorations: Styrofoam balls can be used in various party decorations, such as themed props, centerpieces, or hanging decorations. They can be transformed into elements like balloons, planets, or clouds, depending on the theme of the party.

These are just a few examples of how Styrofoam balls can be made by hot wire foam cutter and used in decorative crafts. The lightweight and customizable nature of Styrofoam balls make them a popular choice for adding texture, dimension, and creativity to a wide range of craft projects.

0 notes

Text

youtube

EPE Sheet Production line machine Laxmi Enterprises [email protected]

Polyethylene foam sheet(film),also named as pearl cotton, is a kind of new-type packing material with the features of dampproof, shockproof, sound insulation, heat preservation and good plasticity . It is an ideal substitute of traditional packing materials and used widely in the packing of electronic product, commodity, glass, pottery, electrical household appliances, spraying, furniture, hardware product, toy, etc.

#Polyethylene foam sheet(film)#also named as pearl cotton#is a kind of new-type packing material with the features of dampproof#shockproof#sound insulation#heat preservation and good plasticity . It is an ideal substitute of traditional packing materials and used widely in the packing of electr#commodity#glass#pottery#electrical household appliances#spraying#furniture#hardware product#toy#etc.#Youtube

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] GURU Cycling Helmet, Light Weight with Superior Ventilation, Helmet For Mountain, Road Bike & Skating Helmet with Premium EPS Foam Lining, Ideal for Adults and Kids Adjustable Skating/Cycling Helmet in 9 Air Vents. White EPS With Thick PVC Shell in Multi Patterns. Packed in Thick Transparent PVC Sheet Sealed With Head Bag Available in 4 Different Colours [ad_2]

0 notes

Text

The Ultimate Convenience: Le Regalo® 5 Piece Bake & Take Set

For anyone who loves to bake and share their homemade creations, the Le Regalo® 5 Piece Bake & Take Set is an absolute game-changer. This thoughtfully designed set not only helps you bake delicious meals but also makes it easy to store and transport them, whether you’re heading to a picnic, a potluck, or simply want to save leftovers. Let’s dive into what makes this set the perfect companion for every kitchen.

A Closer Look at the Set

The Le Regalo® 5 Piece Bake & Take Set includes two high-quality borosilicate glass casseroles, complete with tight-fitting plastic lids, and a two-tier insulated carrier. The combination of durable glass containers and a thermal-resistant carrier ensures your food stays fresh, hot, or cold while you transport it.

What’s Included:

1 Medium Casserole with Lid: A 1.7QT capacity dish ideal for side dishes or smaller meals.

1 Large Casserole with Lid: A 2.3QT capacity dish perfect for family-sized meals.

1 Two-Tier Insulated Carry Bag: With a smart dual-compartment design, this bag allows you to carry both casseroles conveniently, while its thermal insulation ensures temperature retention.

Versatile and Durable

One of the standout features of this set is its versatility. The borosilicate glass casseroles are safe to use in the oven, microwave, freezer, and dishwasher, making them perfect for preparing a variety of dishes. Whether you’re baking lasagna, casseroles, or pasta, these dishes handle it all. Plus, the BPA-free plastic lids are designed for easy storage of leftovers, ensuring that your food remains fresh in the fridge or freezer.

Easy Transport with Thermal Insulation

Transporting food can sometimes be a challenge, especially when it comes to keeping dishes at the right temperature. That’s where the insulated carrier comes in. Designed with a food-grade aluminum foil lining and EPE foam padding, this bag offers excellent thermal resistance, keeping your food warm or cold for longer periods. Whether you’re bringing a hot dish to a potluck or storing cold food for a picnic, this carrier has you covered.

Why You’ll Love the Bake & Take Set

1. Convenience at Its Best

With this set, you no longer have to worry about baking, storing, and transporting your food in multiple dishes. The two-tier insulated carrier makes it easy to bring two separate dishes, while the tight-fitting lids prevent spills and keep your food fresh during transport.

2. Durable and Long-Lasting

Made from tough borosilicate glass, the casseroles are designed to endure extreme temperatures, whether you’re baking in the oven or freezing leftovers. The plastic lids are BPA-free, ensuring they’re safe for food storage and protecting your health.

3. Perfect for Any Occasion

Whether you’re hosting a gathering or going on a picnic, the Le Regalo® 5 Piece Bake & Take Set is ideal for any occasion. Bake your favorite dishes, pack them up, and enjoy a meal with family and friends, no matter where you are.

Practical Features

Durable Material: The borosilicate glass is highly durable and resistant to temperature changes, meaning you can go straight from the oven to the fridge or freezer without any worries.

Versatile Use: These dishes are not only great for baking but also for freezing, storing, and reheating leftovers.

BPA-Free Lids: Ensuring safe storage, the BPA-free lids tightly seal the casseroles to keep your food fresh and protected.

Insulated Carrier: With two compartments and thermal insulation, your food remains at the desired temperature during transport.

Ideal for Picnics, Potlucks, and More

The Le Regalo® 5 Piece Bake & Take Set makes it easy to share your favorite meals wherever you go. The two-tier design allows you to carry two dishes in one convenient carrier, making it perfect for picnics, potlucks, or family gatherings. No need to worry about your food losing its temperature or freshness during travel.

0 notes