#CCUS

Text

5 notes

·

View notes

Text

0 notes

Text

𝗧𝗵𝗲 𝗖𝗮𝗿𝗯𝗼𝗻 𝗖𝗮𝗽𝘁𝘂𝗿𝗲, 𝗨𝘁𝗶𝗹𝗶𝘇𝗮𝘁𝗶𝗼𝗻, 𝗮𝗻𝗱 𝗦𝘁𝗼𝗿𝗮𝗴𝗲 (𝗖𝗖𝗨𝗦) 𝗠𝗮𝗿𝗸𝗲𝘁 𝗚𝘂𝗶𝗱𝗲: 𝗣𝗶𝗼𝗻𝗲𝗲𝗿𝗶𝗻𝗴 𝘁𝗵𝗲 𝗙𝘂𝘁𝘂𝗿𝗲 𝗼𝗳 𝗖𝗹𝗶𝗺𝗮𝘁𝗲 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀!

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲: https://www.nextmsc.com/carbon-capture-utilization-and-storage-ccus-market/request-sample

The 𝗖𝗮𝗿𝗯𝗼𝗻 𝗖𝗮𝗽𝘁𝘂𝗿𝗲, 𝗨𝘁𝗶𝗹𝗶𝘇𝗮𝘁𝗶𝗼𝗻, 𝗮𝗻𝗱 𝗦𝘁𝗼𝗿𝗮𝗴𝗲 (𝗖𝗖𝗨𝗦) 𝗠𝗮𝗿𝗸𝗲𝘁 is at the forefront of global efforts to combat climate change.

By capturing CO2 emissions and either utilizing them or storing them safely, CCUS technologies are crucial in reducing greenhouse gas emissions and advancing sustainability:

𝑪𝒍𝒊𝒎𝒂𝒕𝒆 𝑮𝒐𝒂𝒍𝒔: As nations commit to ambitious climate targets, CCUS technologies are essential in achieving net-zero emissions and mitigating the effects of climate change.

𝑰𝒏𝒏𝒐𝒗𝒂𝒕𝒊𝒗𝒆 𝑨𝒑𝒑𝒍𝒊𝒄𝒂𝒕𝒊𝒐𝒏𝒔: From enhanced oil recovery and industrial applications to direct air capture and carbon mineralization, CCUS is finding diverse and innovative uses across various sectors.

𝑰𝒏𝒗𝒆𝒔𝒕𝒎𝒆𝒏𝒕 𝒂𝒏𝒅 𝑮𝒓𝒐𝒘𝒕𝒉: Increased funding and government support are driving advancements in CCUS technologies, making them more cost-effective and scalable for widespread adoption.

𝗠𝗮𝗿𝗸𝗲𝘁 𝗢𝘂𝘁𝗹𝗼𝗼𝗸:

The CCUS market is set for significant growth as the world focuses on sustainable solutions and regulatory frameworks evolve. Companies investing in CCUS technologies will play a pivotal role in shaping the future of environmental stewardship and energy transition.

𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁: https://www.nextmsc.com/report/carbon-capture-utilization-and-storage-ccus-market

𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀

Shell PLC

Fluor Corporation

Mitsubishi Heavy Industries, Ltd.

Exxon Mobil Corporation

JGC Holdings Corporation

Let’s connect to explore the latest developments in the CCUS market and how your business can be a part of this transformative journey towards a sustainable future!

0 notes

Text

Carbon Capture, Utilization, and Storage Market worth $12.9 billion in 2030

The report "Carbon Capture, Utilization, and Storage Market by Service (Capture, Transportation, Utilization, Storage), Technology (Chemical Looping, Solvents & Sorbent, Membranes), End-Use Industry, and Region - Global Forecast to 2030", for carbon capture, utilization, and storage is expected to grow at an average CAGR of 24.0%, from USD 3.1 billion in 2023 to USD 12.9 billion in 2030. In order to minimize carbon emissions into the atmosphere, carbon capture, utilization, and storage techniques are primarily used in the oil and gas, power generation, and chemical and petrochemical sectors. Many countries all across the world have proposed deploying this technology to reduce carbon emissions and handle climate change. The market for carbon capture, utilization, and storage is being driven by government initiatives aimed at achieving net zero emissions.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=151234843

Capture service segment comprise a major share of the carbon capture, utilization, and storage market, in terms of value and volume.

The first phase in the CCUS process is carbon capture, and it involves separating and extracting carbon from the effluent flue gas stream that originates from a variety of industrial sources, including power plants, petrochemical and chemical companies, iron and steel smelters, and others. Several methods are proposed to remove carbon from the flue gas effluent stream, including Direct Air Capture (DAC), Oxy-Fuel, Pre- and Post-Combustion, and Bio-Energy CCS (BECCS). Several companies use these technology all around the world to reduce their carbon footprint. Adoption of this technique appears to be more expensive since direct air capture significantly deviates from standard practices and removes carbon directly from the atmosphere rather than from industrial sources.

Chemical looping technology type to be the second dominating segment in the global carbon capture, utilization, and storage market in terms of value and volume

Chemical looping is a technique used in industries to trap CO2 during the thermal fuel conversion process. In order to create the nitrogen-free flue gas stream, which mostly consists of CO2, H2O, and reduced oxy-carbonates, a sequence of chemical processes are carried out. This extremely low chemical combination flue gas stream is subsequently sent to another operation, where carbon is removed from the residual effluent stream. This method is mostly utilized in the chemical and petrochemical, as well as oil and gas sectors, where the effluent stream's nitrogen content is considerably higher.

Oil & gas industry is the dominating end-use industry in the global carbon Capture, Utilization, and Storage market in terms of value

The carbon capture, utilization, and storage market is dominated by the oil and gas sector. This can be attributed to the industry's high initial adoption rate, which is expected to continue during the forecast period, due to the fact it is one of the main sources of atmospheric carbon emissions. The CCUS technology is being used in a number of ongoing projects, including the Century Plant in the United States, the Shute Creek Gas Processing Plant in the United States, the Uthmaniyah Gas Plant in Saudi Arabia, and the Petrobras Santos Basin Plant in Brazil, to lower carbon emissions in their respective locations.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=151234843

Asia Pacific to be the fastest-growing region in the carbon Capture, Utilization, and Storage market during the forecast period

The CCUS market is expected to grow at the fastest pace in Asia Pacific. this is mostly because of the significant improvements in technological development that Australia and China have achieved. Businesses were initially hesitant to implement CCUS as it is a capital-intensive task. However, with recent developments in environmental policies and regulations, as well as the ability to combine CCUS with hydrogen generation, companies are now actively involved in the technology's development. Governments around the Asia-Pacific region constantly encouraging their industrial sector to actively engage in the joint endeavor to reduce climate change through the establishment of tax credit programs.

Some of the key players in the global carbon capture, utilization, and storage market are such as Royal Dutch Shell (Netherlands), Fluor Corporation (US), Mitsubishi Heavy Industries, Ltd. (Japan), Exxon Mobil Corporation (US), and Linde Plc (UK), JGC Holdings (Japan), Schlumberger Ltd (US), Aker Solutions (Norway), Honeywell International (US), Equinor ASA (Norway).

#CarbonCapture#CCUS#CarbonStorage#CarbonUtilization#CleanEnergy#ClimateAction#Sustainability#NetZero#CarbonReduction#GreenTech#ClimateChange#RenewableEnergy#CarbonSequestration#Decarbonization#EnergyTransition

0 notes

Text

CCUS(建設キャリアアップシステム)の代行登録件数が、事業者・技能者併せて50件くらいになりました。まだまだですが、登録の速度は上がってきました。弊所はCCUS認定アドバイザーでもあります。許可・経審・入札と併せて、是非ご相談ください。

https://www.ccus.jp/attachments/show/ninteiad_20240701

0 notes

Text

Illinois Passes Comprehensive Law Governing Carbon Capture, Utilization and Sequestration Projects in Illinois

On May 26, the Illinois legislature passed comprehensive carbon capture, utilization, and sequestration (CCUS) legislation. CCUS involves the capture of carbon dioxide directly from ambient air or uses processes to separate carbon dioxide from industrial or energy-related sources, either for use or for underground injection for long-term storage.

The Safety and Aid for the Environment in Carbon…

View On WordPress

#business#carbon capture#carbon capture utilization and sequestration (CCUS)#CCUS#Environmental Law#EPA#government#Illinois Commerce Commission#Illinois Department of Natural Resources#Illinois EPA#Illinois law#legal

0 notes

Text

That's the most significant conference in industrial gas industry in 2024. Sincerely invite you to showcase your new products related industrials gases industry at our expo. #gastank #CCUS #hydrogen #industrialgas #gases Read more, click here:> https://en.igascn.com

1 note

·

View note

Text

First set of skid-mounted CCUS-EOR circulating gas injection device

【Gas Ecosphere(www.igascn.com)】

Recently, we learned from the CCUS-EOR demonstration area of Dagang Oilfield that the first set of skid-mounted fully intelligent CCUS-EOR cycle gas injection device in China made the first show in well hole 104-1, injecting 110,000 cubic meters of carbon dioxide and recycling 133 tons of carbon dioxide, truly achieving zero carbon emissions. This move also marks a new technological breakthrough in the whole industry chain of CCUS-EOR, which is called "carbon utilization, extraction rate, carbon cycle and carbon storage".

Recently, we learned from the CCUS-EOR demonstration area of Dagang Oilfield that the first set of skid-mounted fully intelligent CCUS-EOR cycle gas injection device in China made the first show in well hole 104-1, injecting 110,000 cubic meters of carbon dioxide and recycling 133 tons of carbon dioxide, truly achieving zero carbon emissions. This move also marks a new technological breakthrough in the whole industry chain of CCUS-EOR, which is called "carbon utilization, extraction rate, carbon cycle and carbon storage".

Researchers said the device is widely used, which can be flexible layout in carbon dioxide fracturing gas, single well output jet, separation gas production system back back a variety of scenarios, dagang oilfield thus formed the CCUS-EOR industry chain medium full phase injection technology, output gas recovery and recycling technology, carbon dioxide throughput and fracturing as the main body of production technology, the whole process slow release scale resistance technology four characteristic technology, laid the technical foundation to promote the green development.

In order to solve the problem of increasing production and increasing efficiency in extremely high water content and heavy oil reservoirs, Dagang Oilfield has vigorously implemented CCUS-EOR technology since 2018. As the main implementation department, the researchers of Tongxin Bingang Petroleum Science and Technology Group are committed to tackling the problem, and have formed 18 sets of gas drive equipment and more than 10 patented technologies with specialized, fine, special and new characteristics, with an annual carbon dioxide injection capacity of 360,000 tons. According to statistics, in the past five years, 370 Wells, 160,000 tons of carbon injection, 280,000 tons of oil increase and 1.9 million cubic meters of water saving are implemented. The comprehensive oil exchange rate is 1:1.77, and the effect of oil increase and precipitation increase is outstanding.

With the large-scale implementation of carbon dioxide flooding technology, some of the gas not absorbed by the formation is released to the ground with well production. Due to the serious heterogeneity of strata in Dagang oilfield and the dispersion of measure blocks, the scattered gas recovery is faced with the reality of unstable gas source, high operating cost, no mature experience or technology for reference, so it is difficult to build a station to solve this problem. To this end, the researchers devoted themselves to research, after nearly a year of research and development, successfully developed a skid-mounted fully intelligent CCUS-EOR circulating gas injection device.

The device was first used in well hole 104-1 in CCUS-EOR demonstration area. According to the automatic purification of the gas source, the operating state was adjusted, which solved the problem of difficult recycling of scattered gas at one stroke. In the case of unattended site, the Internet of Things is used to implement remote interactive monitoring, and the emergency state can be automatically stopped. Due to the low operating costs, the 14 carbon dioxide swallowing Wells will also be injected back into the formation through this device, with an annual back injection capacity of 3.3 million cubic meters.

Welcome to https://igascn.com for more news of industrial gas globally.

0 notes

Text

We come to work in order to find solutions

Simon Kronenberg (42), CEO of Holcim Central Europe West, talks about transparent milestones on the way to net zero, new technologies for capturing and storing CO2 and the fact that concrete - the most commonly used building material - has an impressive recycling rate.

The global building materials group Holcim[1] is perceived by the public as not very environmentally friendly. You have been working for the company for 16 years – how has it changed for the better during this time?

Simon Kronenberg: As a manufacturing industry, our industry is energy and resource intensive, especially the production of cement. Thie latter in turn is the binding agent for producing concrete. We have therefore invested heavily in sustainability since the 1990s. In recent years, we have achieved a lot, particularly in decarbonization and promoting the circular economy, and as a driving force in the domestic market, we have made a significant contribution to solving social challenges such as resource scarcity or climate change. Sustainability is now an integral part of our business.

Can you back this up with facts and figures?

SK: Let's take the CO2 reduction per ton of cement as an example: here we have saved over 35% to date and are still at 520 kilos of CO2 net. Our goal in Switzerland by 2030 is to save 380 kilos of CO2, another 25%. In addition, we are constantly developing new materials that are CO2-reduced, reusable and 100% recyclable. For example: “carbon pre-stressed concrete”, concrete elements with prestressed carbon reinforcement. Depending on the construction, the high-performance, extremely thin concrete slabs enable significant material savings and reduce the CO2 footprint by up to 75%. With products such as Airium[2], a mineral insulation material, we also contribute to the sustainability of the use of buildings.

What about recycling?

SK: The building materials industry offers huge potential for recycling waste – and we are doing our part. To give you an idea of the magnitude: we recycle around 4 million tons of various types of waste every year, such as excavation, concrete and mixed demolition, and industrial waste.

What role does concrete play in this?

SK: Concrete is the most important building material of our time, it enables our modern infrastructure. If you consider that we use more than 60 million tons of building material in Switzerland every year - almost 40 million tons of which are concrete - this material must be recycled in the interests of sustainability. We Swiss are considered the world champions of PET recycling; this value is 82%. However, the recycling rate for concrete is already 85%. And by ensuring high quality, especially with the preparation of the dismantled concrete and its later use, concrete can be recycled almost infinitely.

Holcim Switzerland published an environmental report last year and set clear interim goals for 2030 - which ones?

SK: We are aware of our social responsibility and know that time is of the essence. Last year we published our environmental goals and discussed them intensively with our partners. The publication consists of eight domains of action with clearly defined milestones, for example in the areas of decarbonization, circular economy, sustainable logistics, renewable energy or “carbon capture, utilisation and storage”, or CCUS in short[3]. This is how we reduce CO2 from the quarry to the construction site or by recycling building materials. The greatest potential for CO2 reduction lies in reducing the clinker share in the cement. But it is also a fact that, in addition to conventional technologies, we need to develop and implement innovative approaches such as CCUS in order to get to net zero.

On the capture, use and storage of CO2: Where does Holcim Switzerland stand regarding CCUS?

SK: We are developing around ten pilot projects in different phases, and at group level there are over fifty. By 2030, we want to capture around 20,000 tons of CO2 per year in our cement plants in this country. The goal is to either transform this CO2 into a product or store it in a storage facility. The prerequisites for the successful implementation of such projects are, in particular, the legal framework, the required domestic storage capacity, access to foreign storage facilities and the acceptance of the population.

Can you give concrete examples of how CO2 can be integrated into a product?

SK: There are already various CO2 applications, for example as carbon dioxide in mineral water or for the chemical industry. As far as concrete is concerned, we now have a system with which we can fumigate 100,000 tons of demolished concrete with CO2 and thus store around 10 kilos of CO2 per cubic meter of concrete. This product is called ECOPact RECARB.[4]

Keyword: resource-saving products: what are the innovations ECOPact and Susteno developed by Holcim Switzerland?

SK: ECOPact is our sustainable and resource-efficient concrete product family. Susteno[5] is the world's first cement that consists of 20% recycled material. We are very pleased with how the sales volumes of these products are developing. This shows that the demand is there. We have set ourselves the goal of having converted around 50% of our portfolio to these resource-saving products by 2030.

How essential is digitalisation for achieving your sustainability goals?

SK: Of central importance, in three main aspects: on the customer side or in construction, it is important that we go as paperless as possible and use new technologies such as 3D printing or prefabrication. The second big topic is logistics, in order to plan and deliver more sustainably. The last important point is the digitalization of our production – both in terms of automation and innovation. Our cement plant in Untersiggenthal[6] is a pilot for the group-wide “Plant of Tomorrow” project, which aims to make cement production more efficient and sustainable. As part of this project, for example, we use fully autonomous, electric tippers, so-called e-dumpers, in the quarry or special drones for maintenance work at high altitudes.

Despite all the measures, the cement and concrete industry remains resource-intensive. Why can their net zero vision still be achieved?

SK: We are confident about our successes to date and our comprehensive innovation projects, particularly to reduce CO2 and promote the circular economy. We also see increasing demand for sustainable building solutions and resource-saving products. As already explained, in order to achieve our goals we also need CCUS technologies, which we are working hard to implement. Switzerland currently has to handle around 36 million tons of CO2 annually. For this we need new approaches such as capturing, using or storing CO2.

What is the level of social awareness when it comes to the topic of sustainable building?

SK: We are on the right track. In order to create further awareness in society, we promote public discussions about sustainable building solutions. We also strengthen collaboration and knowledge transfer between different actors: from research institutes to architects to developers. At the same time, we seek dialogue with startups.

The vision of Holcim Switzerland is: “By 2050 we will produce climate-neutral and fully recyclable building materials.” Can you reach net zero faster?

SK: That is our ambition. Not only are we on schedule, we are often one step ahead. In Switzerland we are in the fortunate position of having extremely competent and motivated employees who are passionate about making our vision a reality. We come to work in order to find solutions. But we can't do it alone. Net zero is possible if all of us have a common vision, and collaborate with all partners across the region and use industrial synergies.

Source

Norman Bandi, “Wir kommen zur Arbeit, um Lösungen zu finden», in Neue Zürcher Zeitung, 3-09-2023; https://www.nzz.ch/themen-dossiers/zukunft-bauen/wir-kommen-zur-arbeit-um-loesungen-zu-finden-ld.1754051

[1] Holcim (Schweiz) AG, based in Zurich, is one of Switzerland's leading providers of innovative and sustainable construction solutions in the areas of building construction, civil engineering and infrastructure. The company produces concrete, gravel and cement at 55 locations across Switzerland and recycles demolition materials into resource-saving products. Sustainability is at the centre of business activities. Holcim Switzerland is a subsidiary of the globally active Holcim Ltd and employs around 1,200 people in 3 cement plants, 16 gravel plants, 36 concrete plants and several recycling centres.

[2] Airium® is a versatile mineral insulating foam that offers a solution to make buildings sustainable and energy-efficient in use. Today, it is available in 9 countries worldwide for both new build and renovation projects to ensure an ideal thermal comfort, be it for cold temperatures or heat waves. With Airium®, we are accelerating the uptake of insulation in both developed and emerging economies. It can be used in a simple way for many applications: from sub-screed floor insulation to the filling of concrete blocks to roof terraces, attics or lightweight void filling. It is composed mostly of air (up to 95%), water, a cementitious base binder and several additives in small proportions. It is then mixed in a special machine to create the insulating foam at the exact density required. https://www.airium.com/about

[3] CCUS involves the capture of CO2, generally from large point sources like power generation or industrial facilities that use either fossil fuels or biomass as fuel. If not being used on-site, the captured CO2 is compressed and transported by pipeline, ship, rail or truck to be used in a range of applications, or injected into deep geological formations such as depleted oil and gas reservoirs or saline aquifers. https://www.iea.org/energy-system/carbon-capture-utilisation-and-storage

[4] ECOPact+ and ECOPact RECARB are concretes based on Holcim Susteno 4, an ecologically mature, high-quality cement. Using the latest technologies, a solution was developed to reuse the fine fraction of the processed mixed granules as part of the new cement. This innovative development conserves natural resources, saves landfill space and reduces CO2 emissions by partially replacing cement clinker. https://www.holcimpartner.ch/de/produkte/beton/ecopactplus

[5] Susteno is the world’s first resource-saving cement with 20 percent recycled construction and demolition materials (CDM) inside. Susteno is made possible by processing and upcycling materials from demolition projects, resulting in a cement that closes the loop on CDM to build new from the old and preserve nature. The quality requirements of the recycled aggregates for the production of Susteno are very high, including strict acceptance criteria regarding the size and humility of the granulates, as well as chemical and mineral requirements and components that need to be excluded. The strict quality management includes testing of the cement and concrete beyond the standard, ensuring an efficient and high-quality cement that can be used in all building construction applications. https://www.holcim.com/what-we-do/our-building-solutions/cement/susteno

[6] Untersiggenthal is a municipality in the district of Baden in the canton of Aargau in Switzerland, located in the Limmat Valley (German: Limmattal).

0 notes

Photo

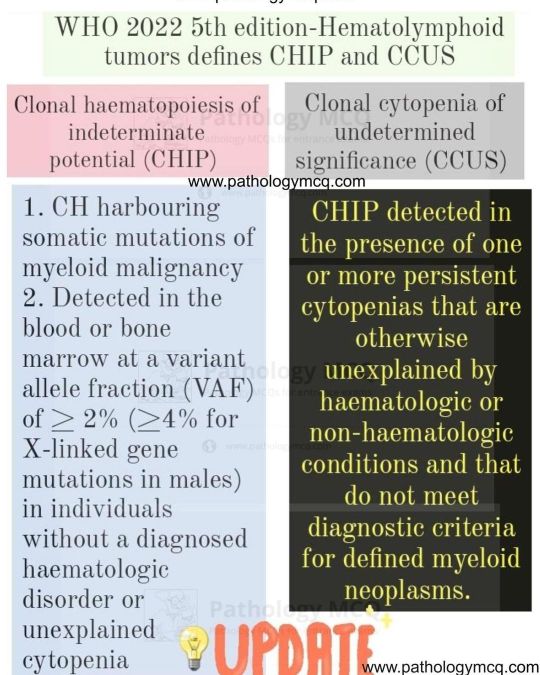

UPDATE!! 2022 5th edition of Hematolymphoid tumors - Has defined CHIP and CCUS #chip #ccus #mds #dmhematopathology #inisshematopathology #pathologymcq #pathologists #hematology #hematologists #hematopathology #leukemias #leukemia #acuteleukemia #acutemyeloidleukemia #pathboards https://www.instagram.com/p/CouaWgxJ4to/?igshid=NGJjMDIxMWI=

#chip#ccus#mds#dmhematopathology#inisshematopathology#pathologymcq#pathologists#hematology#hematologists#hematopathology#leukemias#leukemia#acuteleukemia#acutemyeloidleukemia#pathboards

0 notes

Text

Whats a 7 ft tall ghoul bodyguard for if not piggybacks

#fallout#fallout 3#fo3#lone wanderer#fallout oc#charon#fallout charon#ghoul#fallout ghoul#art'd#i think ccus a bit too small in this image but whatever

1K notes

·

View notes

Text

0 notes

Text

ni-pah

#sonic#sonic the hedgehog#shadow the hedgehog#amy rose#shadamy#wanted to redraw an older drawing ccus it's uggo. also inuyasha fandom veterans know the referenc

195 notes

·

View notes

Text

Some more sketches from the last month!

Posting here by the request of @cilil - traditional joke about Melkor being maidenless. Also a design showcase.

Features also Measse (the OC, not the canon one it is a long story).

79 notes

·

View notes

Text

Happy Holidays from Pneu-Con and friends!!

#happy holidays#merry christmas#pneu con#oc#ccu#robot girl#robotgirl#controller girl#suggestive#comicoal#thecomicoalman#virgin killer sweater#christmas#christmas eve#kepali is so gay for her i cant even blame her

142 notes

·

View notes

Text

For The Team

Ithan Holstrom x Reader

Masterlist - Join My Taglist!

Fandom: Crescent City

Summary: Ithan's new girlfriend is about to experience her first sunball game since she started dating one of the players, but they might have to establish some new traditions first

Word Count: 1,533

Category: Fluff, Humor

Putting work into an AI program without permission is illegal. You do not have my permission. Do not do it.

I scanned the crowd anxiously, looking for any sign of my boyfriend. I was hoping to catch him before he went into the locker room, but there were so many people here for the first sunball game of the season that it was impossible to pick him out in the crowd, despite his height.

Something needed to be done about that.

I hopped up on the first rock I found, going onto my tiptoes for the best possible view. I could see better, but there were still so many people I couldn't pick out my boyfriend. I huffed, then decided to change tactics.

I weaved through the crowd of people until I got to the slightly less crowded tunnel to the locker room. Technically, nobody but players were allowed to come down this way, but right now I didn't care.

"Hey!"

I turned, a little worried I'd have to defend my presence to somebody, only to find my beaming boyfriend Ithan Holstrom heading my way.

"You're not allowed to be back here," he teased. I beamed back at him, rushing to close the short distance between us. Ithan wrapped his arms around my waist as soon as I was close enough, pulling me to him and kissing me deeply. I ran my hands through his hair as he moved me back until I gently hit the wall. I could've stayed like that forever, but after a few long moments, he pulled back.

"Sorry. I hate to cut this short, but I kinda need to go get ready for my game."

"I get it," I said, leaning up to kiss him again all the same. I pulled away more quickly than the first time, giving him a bright smile as I did. "For luck."

Ithan laughed, leaning in to rest his forehead against mine. He had an absolutely beaming smile on his face, which made my heart race.

"Are you excited?" I asked. "First game of the season and all?"

"Of course. I always am. But I'm even more excited that you're at this one."

I smiled. Ithan and I had just started dating a few months ago, and we'd met not long before that. This would be my first sunball game as his girlfriend, and I couldn't wait to cheer him on louder than anyone else in the crowd.

"Me too. You're gonna crush the other team."

"Thanks."

We shared a smile, and I let my hand come up to cup his jaw, lightly stroking my thumb across his cheek. He leaned into the touch, but after a few moments, he sighed.

"I need to go." I frowned, and he gave me a forehead kiss before taking a step away. "I do have a little surprise for you though. Stay here, I'll be right back."

I leaned against the wall as he turned and ducked into the locker room, biting my lip and trying not to give in to how giddy Ithan made me feel. As promised, he was back a second later with a bundle of red fabric in one hand. He grinned my favorite million-watt smile as he held it out to me.

"What's this?" I asked, laughing a little as I took it from him. I held it out in front of me and found myself holding Ithan's jersey, the color he wouldn't be wearing today.

"I thought you could wear it," he explained, rubbing at the back of his neck. "For luck."

"Of course I'll wear it! I love it." I beamed at him, then glanced quickly up and down the hallway. We were alone, at least for now, so I wasted no time whipping off my shirt and putting the jersey on in its place. When I looked at my boyfriend again, I saw him staring at me in awe, his mouth hanging slightly open. "You might wanna close your mouth, babe."

Ithan huffed a laugh, meeting my eyes with clear, shining love in his.

"Have I mentioned lately how much I absolutely love you?"

"Actually, yes," I laughed. "But I can always stand to hear it again."

"Well, I absolutely love you. And I'm so sorry, but I really do have to go now. My teammates are already giving me shit for being late when I left the first time."

"I know." I leaned in to give him one last kiss, my chest practically exploding with love for the male in front of me. I pulled back, beaming at him as I started backing down the hallway, towards the stands where our friends would be saving a seat for me. "I'll meet you on the field after your win!"

Ithan huffed a laugh. "I can't wait!"

I winked and blew him a kiss, then turned to finally head off to my seat. I was practically floating on cloud nine as I made my way through my fellow students to a spot in the front row.

"Finally!" My friends laughed as I squeezed in next to them. "What took you so long?"

"I know what took her so long. She was wishing Ithan good luck!"

Heat rose to my face and I looked down, fighting a smile, which was more than enough to confirm my friends' suspicions. They started laughing, teasing me good-naturedly, but thankfully the players took the field before they could really dig in.

The first sunball game of the season had officially begun.

I was fairly new to sunball in general, but that didn't stop me from screaming and cheering like a maniac for every second of the game. Ithan had given me a crash course on the rules when we watched a pro game a few weeks ago, and I picked up more and more as the game went on. I screamed every time we scored, every time we needed to disrupt the focus of the other team, and every time the refs made a bad call (or at least, one we didn't like). By the end of the game, my voice was almost gone, but it had been worth it.

We'd won.

As the last seconds ticked off the clock, I screamed with everything I had left, my voice breaking as I roared with the rest of the crowd. I wasted no time running down out of the bleachers with the rest of my friends in celebration, a whirlwind of people and emotions crashing like a wave onto the grass. The other team sulked off, giving us space to spread out and lose our minds.

I immediately started scanning for Ithan, trying to find him like I had before the game began amidst a now even rowdier crowd. And like last time, he found me, wrapping his arms around me tightly from behind and burying his face in my neck.

I laughed, not needing to turn around to know it was him. He kissed my cheek, then gave me enough space to face him, both of us beaming like fools.

"You won!" I cried, deliriously happy with him. His answering smile was as bright as the sun as he leaned in and kissed me for all he was worth.

I wrapped my arms around his neck, tangling them in his hair and deepening the kiss like we'd done outside the locker room. I heard some wolf whistles and shouts from our friends, but Ithan and I ignored them both. When we finally pulled apart, our eyes never left each other's, bright smiles still on both our faces.

"You're my good luck charm," Ithan declared. I laughed again and shook my head a little.

"What are you talking about?"

"All our scouting reports said we had no shot at winning this game. They destroyed us last season. The only difference today was I had you in the stands."

Warmth bloomed in my chest as I beamed up at my boyfriend.

"Well, I'm happy I could help." I paused, thinking for a minute, then fixed Ithan with a wicked grin. "...Does that mean we have to keep our pre-game ritual the same every time now?"

He matched my grin with one of his own. "Actually yeah, I'm pretty sure it does. It'd be bad luck to change things now, and I don't want to sacrifice the team's season."

"Oh, of course not. I need to make out with you in the locker room tunnel before every game from now on. For the sake of the team."

"For the sake of the team."

Ithan and I shared a smirk before his teammates and the rest of our friends got sick of letting us have our moment, instead pounding Ithan on the back in congratulations and shouting with the rest of us. My boyfriend just wrapped an arm around my waist and held me close as we let ourselves get swept up in the excitement of the rest of the crowd.

As we finally headed off the field together almost half an hour later, most of us headed for an immediate celebration party, Ithan leaned in and whispered just loud enough for me to hear, and no one else.

"So what's the final verdict on your first real sunball game?"

"I loved it. I'm now fully obsessed." I paused, turning to meet his eyes and give him a mischievous grin. "And I can't wait for the next game."

****************

Everything Taglist: @rosecentury @kmc1989

#crescent city#ithan holstrom#crescent city fanfiction#ithan holstrom x reader#ithan holstrom fanfiction#crescent city x reader#crescent city oneshot#crescent city imagine#ithan holstrom imagine#ithan holstrom oneshot#sunball#ccu#a house of earth and blood#a house of sky and breath#a house of flame and shadow#sarah j maas#sjm#lunathion#crescent city university#sports

72 notes

·

View notes