#CNC Lathe Machining

Text

youtube

CNC Lathe Machining, a pinnacle of precision engineering, transforms raw materials into finely crafted components. At the forefront of technological innovation, our CNC Lathe Machining service at China Ming Xiao Manufacturing is dedicated to shaping your ideas into reality. From intricate details to seamless finishes, our advanced machinery ensures unparalleled accuracy, making us the go-to choice for those who demand precision in every turn. Elevate your projects with the excellence of CNC Lathe Machining – where precision meets craftsmanship.

#CNCMachining #PrecisionParts #GlobalManufacturing #cnclathemachining #customparts

#CNC Lathe Machining#CNC Lathe Turning#CNC Turning#mxmparts#china metal parts#china supplier#turned parts#custom parts#china turned parts#cnc turned parts#china steel parts#Youtube

0 notes

Text

Milling graphite on the machine increases the efficiency and quality of processing.

2 notes

·

View notes

Text

Cnc Torna

Talaşlı imalat

Fason üretim

2 notes

·

View notes

Text

I'm the lathe queen

15 notes

·

View notes

Text

How do you process carbon fiber brake discs?#carbonfiber #brakedisc #cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnclaser #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

5 notes

·

View notes

Text

Powermatic

Powermatic is a well-known brand of woodworking machinery that has been producing high-quality tools and machines since 1921. The company is known for its wide range of products, including table saws, bandsaws, jointers, planers, lathes, and dust collection systems. Woodworking professionals and enthusiasts around the world trust Powermatic machines due to their precision and accuracy.

One of the key features that sets Powermatic machinery apart from others is the use of cast iron in their construction. This material provides stability and durability to their machines, making them reliable and long-lasting.

Powermatic machinery is designed with safety in mind. They incorporate various safety features in their machines such as blade guards and safety switches to prevent accidents in the workshop.

Overall, Powermatic is a reputable brand that offers high-quality woodworking machinery. Their precision, durability, and safety features make them a popular choice for both professional woodworkers and hobbyists alike.

Powermatic product line

Powermatic is a renowned brand that specializes in crafting top-quality woodworking machinery and tools. The brand offers a diverse product line that caters to the varying needs of woodworkers, from novice hobbyists to seasoned professionals.

Table Saws - Powermatic's table saws are engineered for precision, power, and durability. The brand offers cabinet saws designed for heavy-duty use, featuring large table surfaces and robust motors. Contractor saws are more portable and suitable for job site use, while hybrid saws combine features of both cabinet and contractor saws.

Bandsaws - Powermatic's bandsaws are designed to make accurate cuts in wood and other materials. They come in different sizes, from benchtop models suitable for small jobs to floor models capable of handling larger wood pieces. Powermatic's bandsaws are renowned for their precision, ease of use, and smooth operation.

Planers - Powermatic's planers are designed to smooth rough lumber and make it usable for woodworking projects. The brand offers a variety of sizes, with larger models capable of handling wide boards and thick wood pieces. Powermatic's planers are known for their precision and user-friendliness.

Jointers - Powermatic's jointers are used to straighten and flatten wood surfaces. They come in benchtop and floor models, with larger ones capable of handling wider wood pieces. Powermatic's jointers are known for their accuracy and ease of use.

Sanders - Powermatic's sanders include both belt and drum sanders, designed to make sanding jobs quick and straightforward. They come in different sizes, with larger models capable of handling more substantial wood pieces. Powermatic's sanders are renowned for their accuracy, speed, and ease of use.

Dust Collectors - Powermatic's dust collectors are designed to ensure workspace cleanliness and safety by removing dust and debris from the air. They come in different sizes, with larger models capable of handling multiple machines at once. Powermatic's dust collectors are known for their efficiency and reliability.

Lathes - Powermatic's lathes are used for turning wood and other materials. They come in benchtop and floor models, with larger ones capable of handling more significant wood pieces. Powermatic lathes are known for their precision and ease of use.

Mortisers - Powermatic mortises are used to make precise mortises in wood. They come in benchtop and floor models, with larger ones capable of handling larger wood pieces. Powermatic's mortises are renowned for their accuracy and user-friendliness.

Drill Presses - Powermatic's drill presses are used to drill accurate holes in wood and metal. They come in benchtop and floor models, with larger ones capable of handling larger wood pieces. Powermatic's drill presses are known for their precision and ease of use.

CNC Machines - Powermatic's CNC machines are used for computer-controlled manufacturing processes. They come in different sizes, with larger ones capable of handling larger wood and other materials. Powermatic's CNC machines are known for their precision and efficiency.

In conclusion, Powermatic's product line is designed to cater to the needs of woodworkers at all levels, offering high-quality woodworking machinery and tools that are durable, efficient, and user-friendly.

#powermatic#CNC Machines#Drill Presses#Mortisers#Lathes#Dust Collectors#Sanders#Jointers#Planers#Bandsaws#Table Saws

2 notes

·

View notes

Video

youtube

Auto CNC Groove Lathe Machine for PEM Hex Blind Standoff Self Clinching Rivet Nut Cabinet Metal Sheet Fasteners.

Whatsapp: +86 13431255254

#youtube#CNC Lathe machine#groove cutting machine#self clinching rivet nut#standoff rivet nut machine#cold forging#standoff rivet nut groove cutting machine#hex blind rivet nut#fasteners#auto cnc lathe machine#metal sheet rivet nut#rivet nut manufacturer#rivet nut supplier#self clinching rivet nut price#standoff self clinching nut#cnc machine#groove cutting machine supplier

2 notes

·

View notes

Video

youtube

CNC Metal Lathe: Mastering Precision Machining Techniques for Beginners

#youtube#cnclathe cnclathemachine CNC Metal Lathe: Mastering Precision Machining Techniques for Beginners

0 notes

Text

Used Cnc Machines

Explore our range of high-quality used CNC machines at The Equipment Hub. We offer a comprehensive selection of used CNC machines, including mills, lathes, and routers, all rigorously tested to ensure they meet our high standards for performance and reliability. Whether you’re looking to expand your workshop or replace old equipment, our used CNC machines provide exceptional value and efficiency. Visit The Equipment Hub to view our inventory and find the perfect CNC machine to suit your needs. Enhance your operations with our trusted, pre-owned machinery and achieve outstanding results at a great price.

0 notes

Text

Graphite CNC machines provide high processing speed and increase efficiency.

2 notes

·

View notes

Text

Cosmos Impex: Leading CNC Machine Tools Manufacturer & Supplier in India

Established in 1987, Cosmos Impex excels in Leading CNC Machine Tools Manufacturer & Supplier in India. We offer cutting-edge machining centers, including vertical and horizontal turning centers, 5-axis and die-mould machining centers, and imported machines from Taiwan and Japan. Our commitment to innovation, quality, and customer service ensures top performance and reliability for manufacturers across India.

#cnc machine manufacturer india#cnc machine suppliers in india#cnc machine manufacturers in vadodara#cnc machine cost in india#cnc machine manufacturer in gujarat#cnc vertical machining centers#best vmc machine in india#vertical milling machine cnc#cnc drilling tapping machine#cnc turning machine manufacturers in india#cnc vertical turning lathe#vertical turning lathe#Digital factory solution iot cnc#surface grinder machine manufacturer#surface grinding machine price#cnc lathe machine manufacturer in india#cosmos vmc#cosmos vmc 1160#cosmos vmc 800#cosmos cvm 1370 price in india#cosmos cvm 1160 price#cosmos cvm 640 price in india#cosmos cvm 800 specifications#cosmos cvm 1370#cosmos cvm 1160

0 notes

Text

Copper mold sample test made by CNC milling machine. #copper #cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #aluminum #instagram #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

4 notes

·

View notes

Text

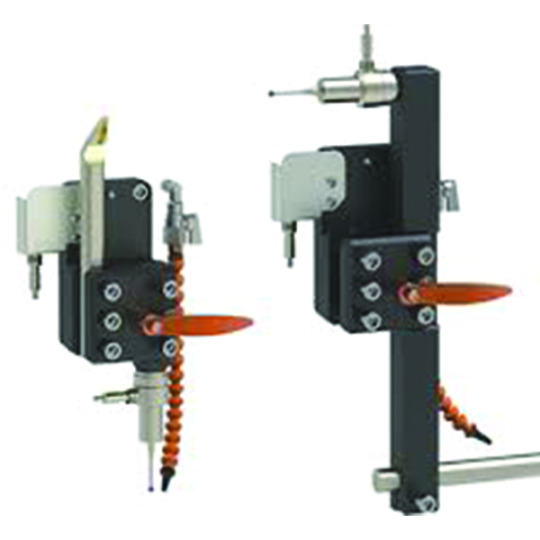

Difference Between Centre Lathe and (Capstan or Turret) Lathe

The capstan and turret lathe serve similar functions in machining processes. They both allow for efficient and precise turning of workpieces by holding and rotating them while cutting tools shape the material.

Read More

0 notes

Text

Why Your Wheel Repair Shop Needs a Diamond Cut CNC Lathe Machine?

Good quality equipment is essential for a successful wheel repair shop. Reliable machinery ensures efficient operations, leading to quicker turnaround times and satisfied customers. High-quality equipment also contributes to the precision and accuracy of repairs, ensuring consistent results and customer satisfaction. Additionally, durable machinery reduces downtime and maintenance costs, allowing the business to operate smoothly and profitably. Investing in good quality equipment is crucial for maintaining a reputable and competitive wheel repair shop.

One such indispensable tool for your shop is the Diamond Cut CNC Lathe Machine. Choosing a top-notch machine ensures unparalleled precision, efficiency, and reliability in wheel refurbishment. With advanced technology and automated operation, it delivers consistent and flawless results, enhancing the quality of your repairs and elevating customer satisfaction. Investing in a high-quality machine not only streamlines your operations but also positions your shop as a leader in the industry.

Here's Why Your Repair Shop Needs This Cutting-Edge Technology:

Precise Performance: With advanced computer-controlled technology, it ensures precise cuts and finishes, resulting in impeccable wheel restoration. Whether you're dealing with alloy, steel, or even chrome wheels, the CNC precision of this machine guarantees consistent and flawless results, elevating the quality of your repairs to new heights.

Versatility and Efficiency: From simple spoke patterns to intricate alloys, these machines can accommodate various wheel types with ease. Moreover, their automated operation streamlines the refurbishment process, reducing manual labor and increasing efficiency. With faster turnaround times and consistent performance, your shop can handle more jobs and satisfy more customers.

Enhanced Customer Satisfaction: By delivering impeccable results with precision-cut finishes, you'll earn the trust and loyalty of clients seeking superior wheel repairs. The ability to restore wheels to factory-like conditions enhances customer satisfaction, leading to positive reviews, referrals, and repeat business.

In conclusion, a Diamond Cut CNC Lathe Machine is a must-have asset for any wheel repair shop looking to excel in the industry. With its precision performance, versatility, enhanced customer satisfaction, and competitive edge, this advanced technology elevates the quality of your repairs and sets your shop apart from the competition. By investing in a good quality machine, you're not just upgrading your equipment; you're investing in the future success of your wheel repair business.

#Diamond Cut CNC Lathe Machine#Cheap Garage Equipment USA#wheel repair machines#CNC Diamond Lathe Cut Systems

0 notes

Text

In the world of manufacturing and machining, CNC (Computer Numerical Control) machines are essential for precision and efficiency. They enable complex parts and components to be produced with high accuracy and minimal manual intervention. However, investing in new CNC machines can be a significant financial burden, especially for small to medium-sized enterprises (SMEs) or startups. This is where used CNC machines come into play. At The Equipment Hub, we offer a wide selection of used CNC machines that provide high performance and value without the hefty price tag. In this blog, we'll explore why used CNC machines are a smart investment, what to consider when purchasing them, and how The Equipment Hub can help you find the right machine for your needs.

0 notes