#cnc vertical turning lathe

Text

Cosmos Impex: Leading CNC Machine Tools Manufacturer & Supplier in India

Established in 1987, Cosmos Impex excels in Leading CNC Machine Tools Manufacturer & Supplier in India. We offer cutting-edge machining centers, including vertical and horizontal turning centers, 5-axis and die-mould machining centers, and imported machines from Taiwan and Japan. Our commitment to innovation, quality, and customer service ensures top performance and reliability for manufacturers across India.

#cnc machine manufacturer india#cnc machine suppliers in india#cnc machine manufacturers in vadodara#cnc machine cost in india#cnc machine manufacturer in gujarat#cnc vertical machining centers#best vmc machine in india#vertical milling machine cnc#cnc drilling tapping machine#cnc turning machine manufacturers in india#cnc vertical turning lathe#vertical turning lathe#Digital factory solution iot cnc#surface grinder machine manufacturer#surface grinding machine price#cnc lathe machine manufacturer in india#cosmos vmc#cosmos vmc 1160#cosmos vmc 800#cosmos cvm 1370 price in india#cosmos cvm 1160 price#cosmos cvm 640 price in india#cosmos cvm 800 specifications#cosmos cvm 1370#cosmos cvm 1160

0 notes

Text

CNC Turn Mill Machine Services at Yamunanagar Engineering Cluster

Revolutionize your machining processes with the Yamunanagar Engineering Cluster CNC Turn Mill Machine. Designed for maximum efficiency and versatility, this innovative machine streamlines turning and milling operations, enabling you to tackle complex tasks with ease. Engineered with state-of-the-art features and industry-leading performance, our CNC Turn Mill Machine empowers you to optimize production workflows and achieve superior precision in every project. From rapid prototyping to high-volume production, trust Yamunanagar Engineering Cluster to deliver unmatched reliability and performance with our CNC Turn Mill Machine. Redefine efficiency and unleash your machining potential with Yamunanagar Engineering Cluster.

#Precision Machining Services#cnc precision machining services#cnc vertical turning lathe#cnc turn mill machine#high Precision Machining Services

0 notes

Text

Mudar-M Metalworking Machine Tools: Precision, Innovation, and Excellence

Introduction

Mudar-M Metalworking Machine Tools, headquartered in Sofia, Bulgaria, stands at the forefront of the metalworking industry. With a rich history spanning over three decades, Mudar-M has consistently delivered cutting-edge solutions to meet the evolving needs of manufacturers, machinists, and engineers worldwide. Let's delve into the details of this remarkable company.

Origins and Founding Vision

Founded in 1990 by visionary Rakan Mhissen, Mudar-M emerged as a response to the growing demand for reliable and efficient metalworking machinery. Rakan passion for precision engineering and his unwavering commitment to customer satisfaction laid the foundation for the company's success. From its modest beginnings as a small workshop specializing in lathe repairs, Mudar-M expanded its operations, embracing technological advancements and diversifying its product range.

CNC Lathes

Mudar-M's CNC lathes are renowned for their accuracy, versatility, and robust construction. Whether it's turning intricate components for aerospace applications or creating precision parts for automotive manufacturing, these machines consistently deliver exceptional results. Features include:

- High Precision: Mudar-M CNC lathes achieve micron-level tolerances, ensuring flawless surface finishes.

- User-Friendly Controls: Intuitive interfaces allow operators to program complex machining sequences effortlessly.

- Customization Options: Customers can choose from various spindle configurations, tool changers, and automation solutions.

Vertical Lathes

Vertical lathes play a crucial role in heavy-duty machining. Mudar-M's vertical lathes excel in handling large workpieces, such as turbine components, gearboxes, and hydraulic cylinders. Key attributes include:

- Stability: The robust column design minimizes vibrations during heavy cuts.

- Swing Diameter: Mudar-M offers a range of swing diameters to accommodate diverse applications.

- Live Tooling: Some models feature live tooling for milling, drilling, and tapping operations.

Milling Machines

Mudar-M's milling machines combine precision with versatility. From 3-axis to 5-axis configurations, these machines empower manufacturers to create complex geometries efficiently. Notable features include:

- Rigidity: Sturdy construction ensures stability during high-speed machining.

- Advanced Controls: Mudar-M integrates state-of-the-art control systems for optimal performance.

- Tool Changers: Automatic tool changers enhance productivity.

Cylindrical Grinding Machines

For achieving precise cylindrical shapes and superior surface finishes, Mudar-M's cylindrical grinding machines are indispensable. These machines excel in applications like bearing manufacturing, toolmaking, and precision engineering. Highlights include:

- Grinding Accuracy: Mudar-M's machines maintain tight tolerances, critical for cylindrical components.

- Wheel Dressing Systems: Automatic wheel dressing ensures consistent results.

- Coolant Filtration: Efficient coolant management prolongs wheel life.

Horizontal Boring Machines

Mudar-M's horizontal boring machines tackle large-scale projects with ease. Whether it's boring engine blocks or creating intricate molds, these machines offer:

- Spindle Power: High-torque spindles handle heavy cutting loads.

- Linear Guideways: Smooth movement across axes ensures precision.

- Digital Readouts: Accurate positioning for intricate machining tasks.

Commitment to Quality

Mudar-M's success hinges on its unwavering commitment to quality. Rigorous testing, continuous research, and collaboration with industry experts ensure that every machine leaving their facility meets the highest standards. The ISO 9001 certification underscores their dedication to excellence.

Global Reach

Mudar-M ships its machines to more than 50 countries across Europe, Asia, the Middle East, and beyond. From small workshops to large manufacturing plants, their footprint extends across continents. By empowering businesses with reliable tools, Mudar-M contributes to the advancement of global manufacturing capabilities.

Conclusion

Mudar-M Metalworking Machine Tools embodies precision, innovation, and excellence. As technology evolves, the company remains steadfast in its mission: to equip the world with cutting-edge machinery, enabling manufacturers to shape the future. Whether it's a CNC lathe, a vertical mill, or a cylindrical grinder, Mudar-M's legacy continues to shape the metalworking industry, one precision cut at a time.

#metalmachining#metalworking#lathe#machinery#machinetools#engineering#manufacturing#forsale#metalwork#milling#industrial

0 notes

Video

youtube

twin spindle cnc lathe parallel vertical lathe #turning

0 notes

Text

Transforming Precision Engineering with Advanced Machinery

In the realm of precision engineering, the demand for sophisticated machinery that can deliver high accuracy and efficiency is ever-increasing. Industries spanning automotive, aerospace and manufacturing require cutting-edge solutions to meet their stringent specifications. Among the innovative solutions available, Vertical Turning Lathes (VTLs), 5-axis turnmills and special-purpose machines stand out for their exceptional capabilities.

The Revolution of Vertical Turning Lathes

Vertical Turning Lathes have revolutionized the machining landscape by offering unparalleled stability and precision in handling large, heavy workpieces. Unlike traditional horizontal lathes, VTLs position the workpiece vertically, ensuring gravity-assisted centering and minimizing deflection. This configuration is particularly advantageous for machining large-diameter components such as turbine casings and flywheels.

The design of VTLs allows for robust construction, capable of supporting massive workpieces with ease. The vertical orientation not only enhances accuracy but also simplifies the loading and unloading process, making it a preferred choice for industries requiring precise and efficient machining of substantial components.

5-Axis Turnmills: The Pinnacle of Versatility

The advent of 5-axis turnmill machines has marked a significant leap in machining technology. These machines integrate turning and milling functions into a single setup, drastically reducing the need for multiple machine setups and manual interventions. The 5-axis capability enables the machining of complex geometries with a single clamping, enhancing precision and reducing cycle times.

5-axis turnmills excel in producing intricate components that demand multi-faceted machining. By offering simultaneous control over five axes, these machines can handle the most challenging contours and shapes, making them indispensable in aerospace and medical device manufacturing. The integration of advanced CNC controls ensures seamless operation, paving the way for enhanced productivity and superior surface finishes.

Special-Purpose Machines: Tailored for Excellence

In industries where standard machinery falls short, special-purpose machines (SPMs) come into play. These machines are custom-designed to address specific manufacturing needs, delivering optimal performance and efficiency. SPMs are engineered to perform dedicated tasks, often combining multiple operations into a single machine.

The flexibility of SPMs allows manufacturers to achieve high throughput and consistency, particularly in mass production environments. By eliminating the need for multiple machines and setups, SPMs streamline the production process, reducing downtime and operational costs. From automated assembly lines to specialized drilling and tapping operations, SPMs are the epitome of tailored engineering solutions.

Conclusion: WIDMA – Pioneering Precision Engineering Solutions

As the demand for advanced machining solutions continues to rise, WIDMA stands at the forefront of innovation, delivering state-of-the-art machinery that meets the evolving needs of modern industries. With a strong commitment to precision engineering, WIDMA offers a comprehensive range of Vertical Turning Lathes, 5-axis turnmills and special-purpose machines designed to enhance productivity and accuracy.

WIDMA's expertise in developing customized solutions ensures that clients receive machinery tailored to their specific requirements, driving efficiency and quality in their operations. By leveraging cutting-edge technology and a deep understanding of industry challenges, WIDMA remains a trusted partner for manufacturers seeking to elevate their machining capabilities.

In conclusion, the advancements in Vertical Turning Lathes, 5-axis turnmills as well as special-purpose machines underscore the importance of precision engineering in today's competitive landscape. WIDMA's dedication to innovation and excellence positions them as a leader in delivering transformative solutions that empower industries to achieve new heights of performance and productivity.

0 notes

Text

Fair Friend Group (FFG) was established in 1979 with the founding principles of reliability, rowth,continuous advancement,best in quality,and strive for excellence.

FFG consists of three major divisions of businesses:

(1) Machine Tool Division, (2) Industry Equipment Division and (3) Green Energy Division.

Machine Tool Division is the main business. Which overall performance of all group is 50%。 Machine Tool Division of the group(FFG) was established in 1985. FFG is the original machining factory of the group. The main products during its beginning stage were Sawing Machines and Grinding Machines. Realizing the industry trend toward high automation and unmanned operations in the machine tool industry, the development in CNC Machine Tool was launched in the same year, and the brand name FEELER was established for the overseas marketing. In 1986, the first moving column vertical machining center in Taiwan was built and it was highly regarded by the market. After this success, the development of CNC Lathes was launched in order to complete the FEELER product line. The product range is contain as follow: Vertical/Horizontal turning and milling, 5-axis machining center, automatic production system and all line equipment...etc.

For any kind of query, contact us with the details below.

Call: +91 011-41608833

Website:www.mdcorpindia.com

#5axismachiningcenter,#cncmachine,#cncmachinetools,#verticalmachine,#mdcorporation,#feelergroup

0 notes

Text

Understanding the Importance of Lathe Machines in UAE's Manufacturing Sector

The UAE has rapidly emerged as a global industrial hub, thanks to its strategic location, robust infrastructure, and progressive economic policies. In this thriving environment, lathe machines have become indispensable tools in various manufacturing and industrial applications. These versatile machines are crucial for shaping, cutting, and finishing materials, making them essential for industries ranging from automotive and aerospace to construction and metalworking. This blog will delve into the significance of lathe machines in UAE, exploring their types, applications, and key considerations for selecting the right lathe machine for your needs.

The Significance of Lathe Machines

Lathe machines are fundamental to the manufacturing process, providing the precision and efficiency needed to produce high-quality components and products. They work by rotating a workpiece around a stationary cutting tool, allowing for a variety of operations such as turning, facing, threading, and drilling. This capability makes lathe machines vital for creating parts with intricate details and precise dimensions.

In the UAE, where the manufacturing sector is a critical component of the economy, lathe machines play a pivotal role in ensuring that products meet the highest standards of quality and performance. The country's focus on technological advancement and innovation further amplifies the importance of these machines, as businesses strive to enhance productivity and maintain a competitive edge.

Types of Lathe Machines

There are several types of lathe machines available, each designed for specific applications and material requirements. Understanding the different types can help businesses in the UAE choose the right machine for their specific needs.

Engine LathesEngine lathes are the most common type of lathe machines, known for their versatility and ease of use. They are suitable for a wide range of operations, including turning, facing, threading, and drilling. Engine lathes are ideal for both small-scale workshops and large manufacturing facilities, making them a popular choice in the UAE.

Turret LathesTurret lathes are designed for high-volume production and repetitive operations. They feature a turret that holds multiple cutting tools, allowing for quick tool changes and increased efficiency. This makes turret lathes suitable for industries that require mass production of identical parts, such as automotive and aerospace manufacturing.

CNC LathesComputer Numerical Control (CNC) lathes represent the pinnacle of modern manufacturing technology. These machines are controlled by computer programs, allowing for precise and automated operations. CNC lathes are capable of producing complex parts with minimal human intervention, making them ideal for high-precision industries. In the UAE, where technological innovation is a key focus, CNC lathes are widely used in advanced manufacturing applications.

Toolroom LathesToolroom lathes are precision machines designed for toolmaking and intricate work. They offer high accuracy and are typically used in tool rooms for creating fixtures, jigs, and other tools. These lathes are essential for industries that require precision engineering and high-quality tooling.

Bench LathesBench lathes are smaller, compact machines designed for light-duty work. They are commonly used in small workshops, educational institutions, and hobbyist applications. Despite their size, bench lathes offer significant capabilities and are suitable for a variety of tasks.

Vertical LathesVertical lathes, also known as vertical turning centers, are designed for handling large, heavy workpieces. The workpiece is mounted vertically, allowing for easier manipulation and machining of large components. These lathes are used in industries such as aerospace and heavy machinery manufacturing.

Applications of Lathe Machines in UAE

Lathe machines are employed in a wide range of industries across the UAE, each benefiting from the precision, versatility, and efficiency these machines offer. Some of the key applications include:

Automotive IndustryThe automotive industry relies heavily on lathe machines for manufacturing engine components, transmission parts, and various other critical elements. The precision of lathe machines ensures that these parts meet stringent quality standards, contributing to the overall performance and safety of vehicles.

Aerospace IndustryIn the aerospace sector, lathe machines are used to produce high-precision components such as turbine blades, aircraft frames, and landing gear parts. The ability to create intricate and accurate parts is crucial for maintaining the safety and reliability of aircraft.

Construction IndustryThe construction industry uses lathe machines for fabricating structural components, machinery parts, and tools. These machines enable the production of custom parts that fit specific requirements, ensuring the integrity and functionality of construction projects.

Oil and Gas IndustryThe oil and gas industry in the UAE utilizes lathe machines for creating components used in drilling, extraction, and refining processes. The harsh environments and demanding conditions of this industry require parts that are durable and precisely engineered.

Metalworking IndustryLathe machines are central to the metalworking industry, where they are used to shape, cut, and finish various metal products. From creating metal furniture to producing intricate art pieces, lathe machines enable metalworkers to achieve their desired results with high precision.

Education and TrainingEducational institutions and training centers in the UAE use lathe machines to teach students and apprentices the fundamentals of machining and manufacturing. These machines provide hands-on experience and practical skills that are essential for future engineers and technicians.

Key Considerations for Choosing a Lathe Machine

Selecting the right lathe machine involves evaluating several factors to ensure it meets your specific needs. Here are some key considerations to keep in mind:

Type of WorkpieceConsider the size, material, and complexity of the workpieces you will be machining. Different lathe machines are suited to different types of work, so choose a machine that can handle your specific requirements.

Precision and AccuracyEvaluate the precision and accuracy required for your applications. CNC lathes offer the highest level of precision and are ideal for industries that demand intricate and accurate parts.

Production VolumeDetermine the volume of production and the speed at which you need to operate. For high-volume production, turret lathes or CNC lathes with automated capabilities may be the best choice.

BudgetConsider your budget when selecting a lathe machine. While it's important to invest in high-quality equipment, there are options available at different price points to suit various budgets. Weigh the features and capabilities against the cost to find the best value for your investment.

Space and LayoutAssess the available space in your facility and the layout of your workshop. Choose a lathe machine that fits within your workspace and integrates seamlessly into your production process.

Support and MaintenanceEnsure that the machine you choose comes with adequate support and maintenance options. Reliable maintenance services and readily available spare parts are essential for minimizing downtime and ensuring long-term performance.

Future NeedsConsider your future needs and potential growth. Investing in a machine with capabilities that can accommodate future requirements can save you from having to purchase new equipment as your business expands.

Conclusion

Lathe machines in UAE's manufacturing and industrial sectors, providing the precision, versatility, and efficiency needed to produce high-quality components and products. From the automotive and aerospace industries to construction and metalworking, these machines play a crucial role in ensuring that products meet stringent quality standards and performance requirements.

By understanding the different types of lathe machines and their applications, businesses in the UAE can make informed decisions when selecting the right equipment for their needs. Whether you require an engine lathe for general-purpose machining, a CNC lathe for high-precision work, or a vertical lathe for handling large workpieces, there is a lathe machine that can meet your specific requirements.

Investing in the right lathe machine will enhance your productivity, ensure the quality of your work, and contribute to the success of your projects in the UAE. As industries in the UAE continue to grow and evolve, the role of lathe machines will remain crucial in driving innovation and maintaining high standards of manufacturing excellence.

Read More Fastener Insertion Machines in UAE

0 notes

Text

Types of CNC Machines | SBV Engineering Works Coimbatore

There are several types of CNC machines, each designed for specific applications:

CNC Milling Machines: Used for cutting and drilling materials along multiple axes. They are ideal for producing complex parts with high precision.

CNC Lathes: Rotate the workpiece against cutting tools to create symmetrical objects. Commonly used for producing cylindrical parts.

CNC Routers: Similar to milling machines but typically used for cutting softer materials like wood, plastics, and composites.

CNC Plasma Cutters: Use a plasma torch to cut through conductive materials like steel and aluminum.

CNC Laser Cutters: Employ a laser beam to cut or engrave materials with high precision, suitable for delicate tasks and intricate designs.

CNC Electrical Discharge Machines (EDM): Use electrical sparks to shape hard materials like metal.

Our machines are:

CNC Vertical Machine

CNC Turning Machine

VMC Machine

Horizontal Boring Machine

Radial Drilling Machine

See more about our machines and services: https://www.sbvengineering.com/

#cncmachine#horizontal millingandboringmachine#cncturningmachinejobwork#cncmachinejobwork#cnccompany#cncverticalmachining#cncmachineshop#cncmachiningjobwork#VMCmachinejobwork

0 notes

Text

Streamlining Production with Innovative CNC Milling Solutions

Computer Numerical Control (CNC) milling and turning are integral components of the modern manufacturing industry. These processes leverage computer systems and machine tools to create precise parts and components, thus enabling efficient, high-volume production. In this article, we will explore the fundamentals of CNC milling and turning their differences, and how they work together to streamline production.

Understanding CNC Milling

CNC milling is a machining process that utilizes computerized controls to remove layers of material from a workpiece. There are various types of CNC milling machines, including vertical, horizontal, and benchtop models, each suited to specific manufacturing tasks. The CNC milling process involves three primary phases: design creation, program input, and execution. This technology is used across a wide array of industries, including automotive, aerospace, and consumer products, for its remarkable precision and flexibility.

Understanding CNC Turning

CNC turning, on the other hand, involves the rotation of the workpiece while a cutting tool moves in a linear motion. This process is typically performed using lathes or turning centers, and it's known for its ability to deliver precise, fast, and repeatable results. Like milling, the CNC turning process also involves design creation, program input, and execution. Industries such as healthcare, electronics, and construction are leveraging CNC turning for producing intricate and detailed components.

Comparing CNC Milling and Turning

While both CNC milling and turning are critical manufacturing techniques, they differ in their operation, applications, and the types of parts they produce. Milling machines are preferred for flat or irregular surfaces, while turning machines are used for cylindrical parts. The choice between milling and turning hinges largely on the part's complexity, volume, and material. In general, milling is best suited for intricate parts that require multiple cuts and angles, whereas turning can deliver high precision on simpler components.

The Future of CNC Milling and Turning

Technological advancements are continually reshaping the realm of CNC milling and turning. Innovations like 3D printing and AI-assisted manufacturing are making CNC processes faster, more accurate, and more adaptable. These advancements are poised to boost manufacturing efficiency and precision, propelling the industry into a future of unprecedented productivity. In Canada, CNC milling and turning are rapidly evolving, with industries embracing the technology to enhance their production capabilities.

Conclusion

In conclusion, both CNC milling and CNC turning are essential components of modern manufacturing in Canada. Whether it's CNC milling Canada industries rely on for precision parts or CNC turning Canada companies leverage for cylindrical components, these techniques play a pivotal role in delivering high-quality products across a multitude of sectors. As technological innovation continues to drive advancements in these processes, the future of CNC milling and turning in Canada is undoubtedly bright and full of potential.

Discover the best-in-class CNC milling and turning solutions in Canada. Experience precision like never before with our CNC milling Canada and CNC turning Canada services. Contact us today!

0 notes

Text

CNC Lathe Machine Manufacturer in India

For our cherished customers, we offer the finest prices on CNC lathe machines at Indian Trade Birds. Our company is a top producer, supplier, exporter, and retailer of CNC lathes, routers, laser cutting machines, milling machines, wood cutting machines, CNC rotary die making machines, CNC wood routers, CNC automatic tables, industrial CNC turning machines, flat bed lathes, automatic vertical lathes, fully automatic CNC stone carving machines, and CNC sculpture machines—all of which we offer for sale. As a result, the products are priced lower and profit margins are higher. Our clients really value the machine we provided them with because of its durable build and low maintenance requirements. With the maximal pressure field, the material is modeled into a solid compact sheet or flakes of ingredients as the volume declines.

For more details clicks here - https://www.indiantradebird.com/product/cnc-lathe-machine

0 notes

Text

Ptuj Acquires New Turning Lathes and Refurbished Wheelset Press

SŽ – VIT’s wheel machining service at the shop in Ptuj recently got a boost by acquiring a new CNC vertical carousel lathe and a new CNC horizontal lathe, which are crucial tools in this line of work, facilitating high precision and quality reconditioning of wheelsets.

The lathes are used to process axles and monoblocs, and bring a number of advantages and improvements to our production…

View On WordPress

0 notes

Text

Best CNC Machines in India | Cosmos Impex India Pvt Ltd

Cosmos Impex India Pvt Ltd is a leading CNC machine manufacturer in Gujarat, specializing in advanced CNC vertical turning lathes. Renowned for precision and reliability, their machines cater to diverse industrial needs, making them a top choice in the region. Trust Cosmos Impex for cutting-edge CNC solutions in Gujarat.

#cnc machine manufacturer india#cnc machine suppliers in india#cnc machine companies in india#cnc machine manufacturer in gujarat#best cnc machines in india

0 notes

Text

Yamunanagar Engineering Cluster CNC Turn Mill Machine

Experience precision machining like never before with the Yamunanagar Engineering Cluster CNC Turn Mill Machine. Engineered to perfection, this advanced machine seamlessly integrates turning and milling operations, offering unparalleled accuracy and efficiency in one compact unit. Crafted with cutting-edge technology and precision components, our CNC Turn Mill Machine delivers exceptional results across a wide range of materials and applications. Whether you're shaping intricate parts or optimizing production processes, trust Yamunanagar Engineering Cluster to elevate your machining capabilities to new heights.

#Precision Machining Services#cnc precision machining services#cnc vertical turning lathe#cnc turn mill machine#high Precision Machining Services

0 notes

Text

Mudar-M Metalworking Machine Tools: Precision, Innovation, and Excellence

Introduction

Mudar-M Metalworking Machine Tools, headquartered in Sofia, Bulgaria, stands at the forefront of the metalworking industry. With a rich history spanning over three decades, Mudar-M has consistently delivered cutting-edge solutions to meet the evolving needs of manufacturers, machinists, and engineers worldwide. Let's delve into the details of this remarkable company.

Origins and Founding Vision

Founded in 1990 by visionary Rakan Mhissen, Mudar-M emerged as a response to the growing demand for reliable and efficient metalworking machinery. Rakan passion for precision engineering and his unwavering commitment to customer satisfaction laid the foundation for the company's success. From its modest beginnings as a small workshop specializing in lathe repairs, Mudar-M expanded its operations, embracing technological advancements and diversifying its product range.

CNC Lathes

Mudar-M's CNC lathes are renowned for their accuracy, versatility, and robust construction. Whether it's turning intricate components for aerospace applications or creating precision parts for automotive manufacturing, these machines consistently deliver exceptional results. Features include:

- High Precision: Mudar-M CNC lathes achieve micron-level tolerances, ensuring flawless surface finishes.

- User-Friendly Controls: Intuitive interfaces allow operators to program complex machining sequences effortlessly.

- Customization Options: Customers can choose from various spindle configurations, tool changers, and automation solutions.

Vertical Lathes

Vertical lathes play a crucial role in heavy-duty machining. Mudar-M's vertical lathes excel in handling large workpieces, such as turbine components, gearboxes, and hydraulic cylinders. Key attributes include:

- Stability: The robust column design minimizes vibrations during heavy cuts.

- Swing Diameter: Mudar-M offers a range of swing diameters to accommodate diverse applications.

- Live Tooling: Some models feature live tooling for milling, drilling, and tapping operations.

Milling Machines

Mudar-M's milling machines combine precision with versatility. From 3-axis to 5-axis configurations, these machines empower manufacturers to create complex geometries efficiently. Notable features include:

- Rigidity: Sturdy construction ensures stability during high-speed machining.

- Advanced Controls: Mudar-M integrates state-of-the-art control systems for optimal performance.

- Tool Changers: Automatic tool changers enhance productivity.

Cylindrical Grinding Machines

For achieving precise cylindrical shapes and superior surface finishes, Mudar-M's cylindrical grinding machines are indispensable. These machines excel in applications like bearing manufacturing, toolmaking, and precision engineering. Highlights include:

- Grinding Accuracy: Mudar-M's machines maintain tight tolerances, critical for cylindrical components.

- Wheel Dressing Systems: Automatic wheel dressing ensures consistent results.

- Coolant Filtration: Efficient coolant management prolongs wheel life.

Horizontal Boring Machines

Mudar-M's horizontal boring machines tackle large-scale projects with ease. Whether it's boring engine blocks or creating intricate molds, these machines offer:

- Spindle Power: High-torque spindles handle heavy cutting loads.

- Linear Guideways: Smooth movement across axes ensures precision.

- Digital Readouts: Accurate positioning for intricate machining tasks.

Commitment to Quality

Mudar-M's success hinges on its unwavering commitment to quality. Rigorous testing, continuous research, and collaboration with industry experts ensure that every machine leaving their facility meets the highest standards. The ISO 9001 certification underscores their dedication to excellence.

Global Reach

Mudar-M ships its machines to more than 50 countries across Europe, Asia, the Middle East, and beyond. From small workshops to large manufacturing plants, their footprint extends across continents. By empowering businesses with reliable tools, Mudar-M contributes to the advancement of global manufacturing capabilities.

interested in more details? Contact us now: Email: [email protected] | [email protected] WhatsApp: +359878840661 | +359878840660

Conclusion

Mudar-M Metalworking Machine Tools embodies precision, innovation, and excellence. As technology evolves, the company remains steadfast in its mission: to equip the world with cutting-edge machinery, enabling manufacturers to shape the future. Whether it's a CNC lathe, a vertical mill, or a cylindrical grinder, Mudar-M's legacy continues to shape the metalworking industry, one precision cut at a time.

#metalmachining#metalworking#lathe#machinery#machinetools#engineering#manufacturing#forsale#metalwork#milling#industrial

0 notes

Text

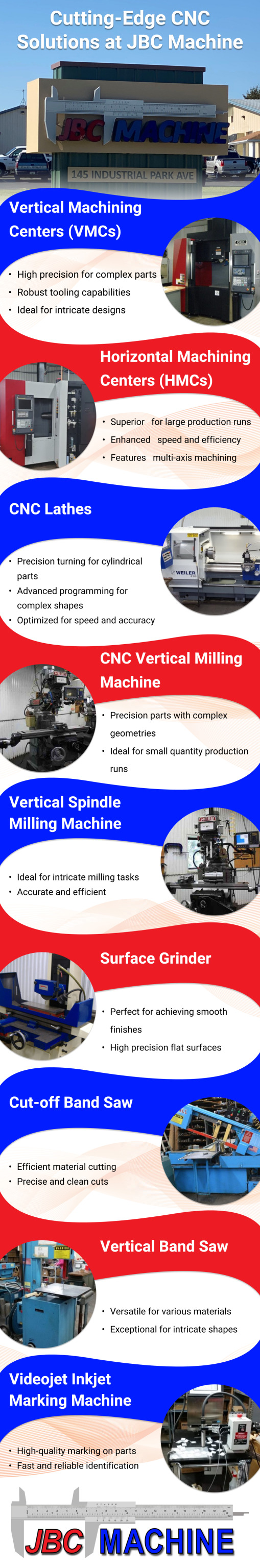

Precision CNC Machining & Custom Engineering Solutions at JBC Machine

https://jbcmachine.com/ - JBC Machine, Inc. offers advanced machining solutions with Vertical and Horizontal Machining Centers for precision and complex designs, ideal for intricate parts and large runs. Our CNC Lathes and Milling Machines excel in turning and milling precision parts, optimized for speed and accuracy. The facility also includes a Surface Grinder, Cut-off, and Vertical Band Saws for precise finishes and shapes, alongside a Videojet Inkjet Marking Machine for fast, reliable part identification. Call JBC Machine Inc. at 920-779-4075 for custom machining services.

JBC Machine, Inc.

145 Industrial Park Avenue, Hortonville, WI 54944

Phone: (920) 779-4075

E-mail: [email protected]

https://jbcmachine.com/

#CNC Plastic Machining#Plastic Machining#Aluminum Machining Custom Machine Shop#CNC Shaft Machining#Custom Machine Shop#CNC Drilling#CNC Drilling Services

0 notes

Text

Trends and Predictions for Vertical Turning Lathes and 5-Axis Turnmills

The manufacturing world is always evolving, driven by new technologies and the constant demand for more efficient and precise production methods. Computer Numerical Control (CNC) machining stands at the forefront of this evolution.

Among the many advancements in this field, Vertical Turning Lathes and 5-axis turnmills are notable for their impact on the industry. This blog explores the future trends and predictions for these technologies for special-purpose machines and their role in modern manufacturing.

What are Vertical Turning Lathes and 5-Axis Turnmills?

Before discussing the trends, it's important to understand these machines. A Vertical Turning Lathe (VTL) is a type of lathe where the main spindle is oriented vertically, which is beneficial for handling large, heavy workpieces. On the other hand, a 5-axis turnmill combines the capabilities of a turning center and a milling center in one machine, allowing complex shapes to be manufactured with high precision.

is a type of lathe where the main spindle is oriented vertically, which is beneficial for handling large, heavy workpieces. On the other hand, a 5-axis turnmill combines the capabilities of a turning center and a milling center in one machine, allowing complex shapes to be manufactured with high precision.

Trends and Predictions

Increased Automation: One of the key trends in CNC machining is the move toward greater automation. Vertical Turning Lathes and 5-axis turnmills are integrating more with automated loading and unloading systems. This speeds up the manufacturing process and reduces the likelihood of errors and improves safety by minimizing human interaction with the machines.

Enhanced Precision: As industries like aerospace and medical devices demand ever higher precision, machines' capabilities need to keep up. Advances in software and hardware are making it possible for Vertical Turning Lathes and 5-axis turnmills to achieve even greater accuracy, thereby producing parts that meet strict specifications without additional finishing processes.

Complexity Made Simple: 5-axis turnmills have a significant advantage in handling complex shapes. With improvements in CNC technology, these machines can produce intricate and detailed parts more efficiently than ever. This capability makes them invaluable in industries where complexity and precision are critical.

Special-purpose Machines

As manufacturing challenges grow, the role of special-purpose machines in CNC machining becomes more significant. These machines are designed for specific tasks and can offer solutions that general-purpose machines cannot. For instance, they might be optimized for ultra-high precision or designed to handle particular materials or part sizes. The future will likely see an increase in the deployment of these machines as manufacturers seek tailored solutions to meet unique production needs.

The Role of WIDMA in Shaping the Future

WIDMA, a manufacturing and machining technology leader, is at the forefront of the trends discussed. Their expertise in developing advanced CNC machines, including Vertical Turning Lathes and 5-axis turnmills, positions them well to drive innovation in the industry. WIDMA's commitment to research and development ensures that it remains at the cutting edge, providing machines that are not only highly efficient but also versatile and capable of meeting the demands of modern manufacturing.

By focusing on customization and incorporating the latest technologies into their machines, WIDMA helps customers stay competitive in a rapidly changing industry. Their approach to embracing sustainable practices and promoting automation further underscores their role as a key player in the future of CNC machining.

Conclusion

The future of CNC machining looks promising with continuous advancements in technology such as Vertical Turning Lathes and 5-axis turnmills. As these machines become more automated, precise, and capable of handling complex and varied tasks, they will play an increasingly important role in manufacturing.

0 notes