#CNC Machine Monitoring Software Market Share

Explore tagged Tumblr posts

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes

Text

The Evolution of CAM (Computer-Aided Manufacturing) in Industry

Hello, engineering students and tech enthusiasts! If you’re curious about how products go from ideas to reality, let’s dive into the world of Computer-Aided Manufacturing (CAM). CAM has transformed industries, making manufacturing faster, smarter, and more precise. As your mentor, I’m excited to walk you through its evolution, from its early days to its role in today’s high-tech factories. With insights grounded in industry trends, this guide will show you why CAM is a game-changer for mechanical engineers.

The Birth of CAM: A New Era Begins

CAM started in the 1950s when computers first entered manufacturing. Early systems used punched tapes to control machines, a far cry from today’s tech. By the 1970s, Numerical Control (NC) machines evolved into Computer Numerical Control (CNC), allowing engineers to program tools with precision. A 2023 ASME report notes that these advancements cut production times by 40% in industries like aerospace. CAM was born to bridge design and production, turning digital models into physical parts with minimal human intervention.

The 1980s and 1990s: CAM Goes Mainstream

The 1980s brought CAD/CAM integration, letting engineers design and manufacture in one workflow. Software like Mastercam and CATIA emerged, enabling complex geometries for automotive and aviation parts. By the 1990s, CAM systems supported multi-axis machining, which meant machines could move in multiple directions for intricate shapes. According to a 2024 Manufacturing Technology Insights study, this boosted productivity by 25% in factories. If you’re at one of the best private engineering colleges in Odisha, like NM Institute of Engineering and Technology (NMIET), you’re likely using similar software in labs to simulate these processes, getting a taste of real-world applications.

The 2000s: Automation and Precision Take Over

The 2000s saw CAM embrace automation. Robotic arms, guided by CAM software, started handling repetitive tasks like welding and assembly. This was huge for industries like automotive, where companies like Toyota slashed production costs by 20%, per a 2023 Industry Week report. CAM also integrated with simulation tools, letting engineers test toolpaths virtually before cutting metal, reducing errors. Cloud-based CAM software, like Fusion 360, made collaboration easier, allowing teams to share designs globally. These tools are now standard in many engineering curriculums, giving students hands-on experience.

CAM Today: Industry 4.0 and Beyond

Fast forward to 2025, and CAM is at the heart of Industry 4.0. It’s now paired with AI, IoT, and additive manufacturing (3D printing). AI-powered CAM optimizes toolpaths, cutting waste by up to 15%, according to a 2024 McKinsey report. IoT connects machines to monitor performance in real-time, predicting maintenance needs. Additive manufacturing, guided by CAM, creates complex parts layer by layer, revolutionizing aerospace and medical device production. A 2024 Deloitte study predicts the global CAM market will reach $5.2 billion by 2030, driven by demand for smart manufacturing.

Students at the best private engineering colleges in Odisha are well-positioned to jump into this field. Institutes like NMIET, with modern labs and industry ties to companies like IBM, offer exposure to CNC machines and CAM software, helping you build skills employers value. The hands-on learning you get now is your ticket to thriving in this dynamic industry.

How to Prepare for a CAM Career

Want to be part of CAM’s future? Start with a strong grasp of mechanical engineering fundamentals like mechanics and materials science. Learn CAM software—Mastercam, Siemens NX, and Fusion 360 are industry favorites. A 2024 LinkedIn report found that 82% of CAM-related job postings list software proficiency as a must. Online courses on platforms like Coursera can help you master these tools.

Internships are key. Look for opportunities with manufacturers or CNC shops. A 2023 Glassdoor study showed that engineering interns with CAM experience are 30% more likely to land full-time roles. Network with professionals through ASME or LinkedIn, and attend industry events to stay updated on trends. Your college’s placement cell, especially at institutes like NMIET, might connect you with firms using CAM technologies.

Why CAM Matters for Your Future

CAM isn’t just about machines—it’s about innovation. It powers industries from automotive to healthcare, creating jobs for skilled engineers. Roles like CAM programmer or manufacturing engineer offer salaries ranging from ₹5-12 LPA in India, per 2024 Payscale data, with higher earnings as you gain experience. You could work for global giants like General Electric or local manufacturers, or even start your own CNC workshop.

Final Thoughts

The evolution of CAM has reshaped manufacturing, and it’s only getting bigger. From CNC machines to AI-driven factories, mechanical engineers are driving this revolution. Stay curious, master the tools, and seek hands-on experience. A 2024 Industry 4.0 report predicts a 25% rise in CAM-related jobs by 2030, so the opportunities are endless. Whether you’re at NMIET or another institute, use your education to dive into CAM. The future of manufacturing is in your hands—go shape it!

#best colleges in bhubaneswar#college of engineering bhubaneswar#best engineering colleges in orissa#best engineering colleges in bhubaneswar#best private engineering colleges in odisha#best engineering colleges in odisha

0 notes

Text

CNC Controller Market Size, Share & Industry Growth Analysis Report 2030

The global CNC controller market size is expected to be USD 3.23 billion in 2025 and is projected to grow at a CAGR of 4.8% from 2025-2030 to reach USD 4.08 billion by 2030. The CNC controller market is driven by the increasing demand for automation of manufacturing processes that increase precision and efficiency. The advancement in the industry 4.0 technologies, including the Internet of Things and AI, helps accelerate the usage of smart CNC systems. The economic and time-efficient production requirement and the growing automobile and aerospace industries fuel further market growth. More importantly, the rising prevalence of custom machinery and the trend toward miniaturization in electronic devices stand out among catalysts.

Driver: Increasing adoption of industrial automation in the global manufacturing sector

The primary reason for the need for industrial automation in the global manufacturing industry is due to the need for real-time data monitoring and predictive maintenance. The benefits that accrue from automation are many, including higher precision, better quality products, accuracy, safety, and consistency in the production processes. It also increases productivity and reduces operation costs, a huge advantage for automotive, aerospace, and medical equipment manufacturing industries. Probably because companies are trying to increase automation and improve their production processes, there is an expected increase in the use of advanced technologies, like CNC machines.

Restraint: High investment and long-term maintenance cost

Introducing CNC controllers is an enormous economic burden both due to the very high initial cost and the high maintenance cost. The above costs are especially challenging to SMEs characterized by limited capital. The cost of the machinery, aside from that, required infrastructure upgrades, including power supply enhancements, a dedicated workspace, and environmental controls to ensure optimal performance of CNC systems.

Once it becomes operational, the monetary obligations will only continue with maintenance and operational expenses. CNC controllers need servicing, too, to get precise and efficient commands and would therefore consider necessary periodic checks, adjustments, and replacement of key parts, including drive motors, spindles, and sensors. Software updates are necessary to improve performance, minimize cyber risks, and bring them up to current industry standards, but this usually comes at a charge in licensing or subscription fees.

Opportunity: Integration of 3D printing technology with CNC machining.

Integrating CNC controllers with 3D printing creates a significant opportunity for augmenting precision through hybrid manufacturing that combines additive and subtractive techniques. This approach would make complex parts possible, minimizing the post-processing needed, enhancing accuracy, and reducing lead times. Mass customization, reduction of material waste, and consistency with sustainability goals are also promoted. It will integrate CNC-3D printing, thus becoming the future of smart, efficient, and flexible manufacturing through real-time adaptation and seamlessness in switching between processes.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=133889642

Challenge: Integration of Modern CNC Controllers with Legacy Systems

Integrating modern CNC controllers with legacy systems will raise significant challenges to manufacturers working on older machinery. The primary problems are that legacy hardware, software, and communication protocols are not compatible with newer advanced CNC controllers that use digital communication, IoT connectivity, and real-time data exchange. This often requires costly custom interfaces and retrofitting the older machines with newer motors, drives, and sensors for compatibility.

0 notes

Text

Rebar Processing Equipment Market

Rebar Processing Equipment Market Size, Share, Trends: Schnell Spa Leads

Integration of Advanced Technologies Enhances Efficiency and Precision in Rebar Processing

Market Overview:

The rebar processing equipment market is predicted to develop at a CAGR of XX% between 2024 and 2031, with market value rising from USD XX in 2024 to USD YY by 2031. Asia-Pacific now dominates the industry, accounting for the vast majority of worldwide sales. Key metrics include increased infrastructure development, urbanisation, and ongoing innovation in rebar processing technology.

The market is expanding rapidly, owing to a thriving construction industry, particularly in emerging nations, rising demand for prefabricated construction elements, and the growing usage of automation in construction processes. The necessity for infrastructure restoration and the shift towards sustainable construction practices are creating major growth prospects in developed nations.

DOWNLOAD FREE SAMPLE

Market Trends:

The rebar processing equipment market is seeing a considerable increase in the integration of sophisticated technologies, including automation, robotics, and digital control systems. The growing demand for more efficiency, precision, and productivity in building projects is driving this trend. Manufacturers are introducing technologies such as Computer Numerical Control (CNC) systems, which enable more precise cutting, bending, and shaping of rebars based on complex design criteria. For example, some advanced rebar bending machines now have multi-axis bending capabilities, allowing for the production of complex structures with minimal human interaction.

Furthermore, the integration of IoT (Internet of Things) technologies allows for real-time monitoring and predictive maintenance of rebar processing equipment, decreasing downtime and increasing overall operating efficiency. The trend continues with the development of software solutions that seamlessly interface with rebar processing equipment, enabling improved project planning, inventory management, and quality control. This change to more technologically advanced equipment not only improves the speed and precision of rebar processing, but it also addresses the construction industry's skilled labour problem by lowering reliance on manual processes.

Market Segmentation:

Bending machines are essential in rebar processing because they can provide the numerous forms and angles necessary in modern construction projects. The growing complexity of architectural designs and structural requirements in construction, which necessitate accurate and diversified rebar bending capabilities, has contributed to this segment's supremacy. Bending machines are required to create stirrups, hooks, and other complex shapes that are crucial to reinforced concrete constructions.

The global market for rebar bending machines was worth roughly $650 million in 2023, with forecasts predicting a consistent increase in the next few years. This expansion is being driven by the increased use of automated and CNC-controlled bending machines, which provide greater precision, speed, and efficiency than traditional human bending methods. The industry is seeing a shift towards multi-function bending machines that can cut and straighten in addition to bend, providing greater versatility and space efficiency for building sites and fabrication businesses.

Recent industrial advances have strengthened the position of bending machines in the rebar processing equipment market. In late 2023, a leading construction equipment manufacturer launched a new line of electric rebar bending machines with superior servo motor technology, promising up to 30% energy savings over hydraulic ones. Furthermore, cooperation between equipment makers and software developers is growing, resulting in the integration of Building Information Modelling (BIM) software with bending machines. This interface enables seamless data flow from design to production, eliminating errors and increasing overall project efficiency. The sector is also experiencing a rise in investment in research and development of bending technologies capable of handling greater diameter rebars and more complex bending sequences in order to meet the demands of major infrastructure projects.

Market Key Players:

Schnell Spa

Eurobend S.A.

KRB Machinery

Pedax GmbH

Toyo Kensetsu Kohki Co., Ltd.

Ellsen Bending Machine Company

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

CAM Software Market - Forecast(2024 - 2030)

CAM Software Market Overview

CAM Software Market Size is forecast to reach $4.2 billion by 2030, at a CAGR of 6.5% during 2024-2030. North America held the largest market share of 30.7% in 2020 from overall global CAM Software Market. Growth in this region is attributed to the ever increasing demand from various industry verticals including Manufacturing, Automotive, Aerospace and Defense and others. Moreover, this region is witnessing a significant growth of around 5.9% during the forecast period 2024 – 2030. Surge in demand for CAM software to facilitate and automate the manufacturing processes, has significantly boosted the market growth.

There is a noticeable shift towards cloud-based CAM solutions, driven by the need for enhanced collaboration, accessibility, and scalability across manufacturing operations. Cloud-based platforms offer manufacturers the flexibility to access CAM tools and data remotely, enabling real-time monitoring and optimization of production processes. The integration of artificial intelligence (AI) and machine learning (ML) algorithms into CAM software is gaining momentum. These technologies empower CAM systems to analyze vast amounts of manufacturing data, optimize toolpaths, and automate repetitive tasks, thereby improving efficiency and productivity. There is a growing emphasis on interoperability and compatibility among CAM software and other manufacturing systems and equipment. Seamless integration between CAM software and CAD (Computer-Aided Design) systems, CNC (Computer Numerical Control) machines, and IoT (Internet of Things) devices streamlines data exchange and enhances overall operational efficiency.

Report Coverage

The report: “CAM Software Market Report– Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the CAM Software market. By Model: 2D, 3D. By Organization Size: SME, Large Enterprises. By Pricing Model: One Time Payment, subscription By Integration: Standalone, Plug-in, Dual Capacity. By End User: Railways, Automotive, Healthcare, IT and Telecom, Power and Energy, Aerospace and Defense, Government and Public Sector, Marine, Industrial Machinery and Others. By Geography: North America (U.S, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Russia, Netherlands and Others), APAC (China, Japan India, South Korea, Australia & New Zealand, Indonesia, Malaysia, Taiwan and Others), South America (Brazil, Argentina, Chile, Colombia and others), and RoW (Middle East and Africa).

Request Sample

Key Takeaways

Enterprises are adopting SaaS which is enabling redeployment of their software tools and data. Surge in use of CAM software as it provides improved product quality has considerably proven to be effective in sharing of design information.

With the use of CAM software machinery can turn raw material into finished products and helps in making a product by generating tool paths. To automate the manufacturing process CAM uses software and computer-controlled machinery through which machine can produce parts easily.

There's a significant shift towards cloud-based CAM solutions, offering scalability, accessibility, and collaboration across diverse teams. Secondly, automation and integration are becoming paramount, with CAM software increasingly incorporating AI and machine learning capabilities to streamline manufacturing processes and enhance efficiency.

CAM Software Market Segment Analysis - By Model

The CAM software is segmented into two types by model, of which the 3D CAM software such as solid modeling, surface modeling, sculpting and others has the widest variety of applications and held the largest market share estimated to around 73.1% in 2023. The integration of 3D technology stands as a pivotal growth factor, revolutionizing design and manufacturing processes worldwide. The increasing demand for complex and intricate designs across various sectors, including aerospace, automotive, and healthcare, propels the adoption of 3D capabilities in CAM software. This demand stems from the need for enhanced precision and efficiency in product development cycles. Advancements in additive manufacturing techniques drive the expansion of 3D CAM software, facilitating seamless compatibility and optimization with 3D printing technologies. Such integration streamlines prototyping and production, fostering innovation and competitiveness within the industry.

Inquiry Before Buying

CAM Software Market Segment Analysis - By End User

Among all the other end user industries, the CAM Software Market was dominated by Automotive vertical as they held the largest market share of around 23.6% in 2023. Additionally, the Healthcare sector is witnessing a significant growth rate estimated to around a CAGR of 11.32% during the forecast period 2024 – 2030.

CAM Software Market Analysis-By Integration

The CAM software technology is segmented into three types by integration, of which the standalone has the widest variety of applications and held the largest market share estimated to around 74.1% in 2023.

CAM Software Market Segment Analysis - By Geography

CAM Software market in Asia-Pacific region held significant market share of 40.5% in 2023. U.S is predicted to dominate the global CAM software market during the forecast period due to the region's large presence of distributors and resellers selling CAM software. Leading market vendors are introducing advanced CAM software which support stand alone as well as plug in type for Windows and MAC operating systems to address end user needs. The increased adoption rate of industrial robotics in the United States region is driving growth in this region, and CAM adoption has multiplied in the recent past. With the introduction of industrial robots, CAM has aided in the improvement of robotics efficiency. Shifting towards automated production, an established ecosystem for manufacturing practises, and continuous R&D investments by manufacturers to drive innovation into their manufacturing processes are key factors driving growth in this region. The rising cost of labour in the United States has compelled manufacturers to use automation to reduce expenses. The risks associated with human labour are also significantly decreased with the use of CAM software.

Schedule a Call

CAM Software Market Drivers

Surge in application of CAM software in the industry verticals and adoption of Cloud

The surge in industrialization have resulted in the adoption of CAM software for precision and cost effective designing purposes. In January 2023, Open Mind Technologies unveils the HyperMill 2023 CAD/CAM software suite, featuring advanced capabilities for streamlined NC programming in 2.5D to five-axis milling applications, enhancing user productivity and efficiency. CAM software performs engineering analysis and computer numerical control code generation using 3D part modeling along with handling large assemblies. Many organizations, particularly manufacturing companies, are now taking advantage of the emerging cloud and Internet of Things (IoT) developments to make their operations operate leaner and increase sales. IoT apps are crucial to delivering updates in real time, including shipment and storage status, repair and proactive maintenance warnings, and details from the supply chain. With the CAM software the manufacturers are finding end-to-end digital thread running through the manufacturing process. The replacement of aging aircrafts with the new ones along with the demand for commercial aircrafts are the reasons due to which the major airlines are expanding globally. The newer aircrafts are equipped with latest techniques as the aircraft manufacturers are investing heavily in new computer systems. Computer aided design (CAD) and computer aided manufacturing (CAM) makes airplane design easier.

Increased Use of CAM Software for Industrial Machinery

CAM software is very useful in manufacturing, planning and control of products as it makes effective use of computer technology. Computer aided software (CAM) saves time, labor and cost by bringing automation through real time control and robotics in production processes. In recent years CAM software is facing steady growth owing to its various applications such as numerical control, computer numerical control, industrial robots, design of dies and molds for casting, design of tools and fixtures and EDM electrodes and quality control and inspection in manufacturing plants. CAM software is finding huge application in the packaging machinery as this machinery are becoming increasing complex with higher efficiency demand. This software packages provides ability to produce parts faster and provides feedback and update the CAD models. CAM software is adopted as a powerful software for advanced manufacturing tools. The increased demand for packaged foods, continuous production of machines and drugs and increasing spending on branded products have aided the growth of lean packaging operations which in turn have driven the growth of CAM software. Some of the major key players of packaging technology such as Krones, Robert Bosch, Coesia and others are focusing on the production of the smart and innovative machinery to provide enhanced services with optimum safety due to which CAM software is highly used in the designing processes.

CAM Software Market Challenges

Cost Related Issues

Considerable amount of PC processing power is required for CAM software which ultimately involves high quality components that have high cost which is a major hurdle to the broader usage of CAM technological innovation. Although the CAM software is becoming more versatile and convenient, the complexness of the application makes it more difficult for the first time users to learn it. In the manufacturing sector CNC machinery is widely used where pre-programmed computer software (CAM) is used to control the machining tools as it uses numerical code. It carriers out variety of applications such as routing, milling, punching, turning and lathing. Although the CNC machining is used in the supply chain process and adopted as a standard machinery it requires greater initial investment than machines that can be operated manually due to which it is very expensive. Most of the students rarely adopt manual machine operators as a skill which is leading to the complete loss of long preserved skills. In addition the investment in CNC machines can lead to the chances of unemployment. Many of the countries do not give proper training of manually operated lathers. In case of any damage highly skilled professional is required to solve the damage or error problem. Regular inspection with a highly skilled person is required for the maintenance and error less results.

Buy Now

CAM Software Market Landscape

Product launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the CAM Software market. CAM Software top 10 companies include Autodesk, Siemens, Dassault Systemes, BobCAD-CAM, Cimatron, Hexagon AB, HCL Technologies, GRZ Software, Open Mind Technologies, SolidCAM among others.

Acquisitions/Product Launches

In May 2023, BLM Group launched VGPNext, a cutting-edge CAD/CAM programming software for tube and wire bending machines, streamlining part program identification, job simulation, and production initiation with minimal clicks.

In September 2022, Planmeca releases a new Romexis CAD/CAM software module designed to streamline intraoral scanning and facilitate collaboration with external partners for restoration design and manufacturing, enhancing digital dentistry workflows.

#CAM Software Market#packaging machinery#CAM Software Market Size#CAM Software Market Share#CAM Software Market Analysis#CAM Software Market Revenue#CAM Software Market Trends#CAM Software Market Growth#CAM Software Market Research#CAM Software Market Outlook#CAM Software Market Forecast

0 notes

Text

Quantifying the Tangible Business Growth Driven by Digital Marketing Investments

Digital marketing has become an indispensable growth driver for today's Cyprus businesses. As consumers flock to digital channels, companies that strategically invest in online initiatives reap substantial rewards. In fact, research shows that 67% of the buying journey now occurs digitally. Strategically investing to meet customers there pays off.This article spotlights the tangible business results progressive Cyprus companies achieve through targeted digital marketing. By shining a light on the measurable return-generated across key digital channels, we present a compelling case for the smart allocation of marketing resources.Success stories of local businesses that enjoyed remarkable growth through digital efforts further crystallize its ROI.Equipped with this piece, Cyprus marketing leaders can confidently spotlight and quantify digital marketing ROI within their organizations.The presented framework for optimizing budget allocation provides an actionable template to maximize online initiatives' impact. Following the best practices outlined here allows both small enterprises and large corporations alike to drive substantial lead generation, customer acquisition, and revenue growth—ultimately improving both the top and bottom lines.In other words, done right, digital marketing delivers sales figures, profit margins, and customer loyalty numbers that merit every penny invested into it. Demonstrating ROI Across Key Digital Channels With a strategic approach, major digital marketing channels deliver quantifiable results and ROI. Consider these success stories from innovative Cyprus businesses: Paid Search - A client we work with, in the manufacturing sector increased sales 36% YoY, generating an average ROAS of $3.20 through Google Ads targeting manufacturers. Top performing keywords include “CNC machine tools” and “factory automation software” . - Another client in the tourism industry saw site traffic double (+112%) and trip package sales increase 29% YoY thanks to targeted Facebook and Instagram ads. With a $5,200 monthly ad budget, our client achieves an average CPL of $18 and ROAS of $6.50. 📈 Takeaways: Monitoring key metrics like CPL and ROAS allows businesses to optimize paid campaigns driving strong ROI. SEO - By ranking #1 for a limassol accounting service provicer, captured 68% market share. Total organic traffic rose 146% YoY, generating $846K incremental revenue. - We also work with a client's Law firm, which bumped 36% more leads via SEO including rankings for valuable commercial litigation terms. Each new organic lead converts at $312. 📈 Takeaways: Capturing high-value organic keywords directly translates to more revenues. Content Marketing & PR - Through educational content production, FXGlobe Limited Ltd captured over 50,000 new leads last year. With a 8% conversion rate, content drove 4000 new traders. - Following a PR initiative focused on sustainability values, Zoom cars saw brand awareness lift by 29%, expanding their potential car leasing customer reach. 📈 Takeaways: Owned and earned media demonstrably raise awareness and leads. Social Media Marketing - By tracking social conversions, Costa Coffee House tied 12% annual revenue growth directly to targeted social initiatives and offers. - Analyzing campaign influence on buying journeys, another client, a Jeweler store attributes $129K in sales to sponsored social advertisements over 8 months. 📈 Takeaways: When appropriately tracked and optimized, social spends can be justified by hard revenue figures. Translating Digital Marketing Impact Into Business Growth Beyond lead gen, digital done well means: Increased Customer Acquisition - Our client in the manufactoring sector (above) saw new customer acquisition rise by 29% YoY by reallocating budget to max ROI. - FXGlobe Limited LTD. (above) saw 4000 new customer additions from content efforts expand revenue by 5%. Higher Purchase Frequency - Zoom Cars (above) leveraged retargeting to increase repeat purchase rate 66%, driving higher order values. - Our Jeweler client (above) increased average order values by 28% YOY through retargeting existing buyers on social channels. Lower Churn - By offering portal access to materials, our firm Law client (above) cut client churn by 42%, improving LTV. - By providing exclusive online access to preferred clientele, our client in the tourism industry (above) reduced membership cancellations by 31% YoY. Modeling Lifetime Customer Value Shift - Businesses can quantify long-term profit increases driven by digital programs by determining the lifetime value of a customer rather than individual transactions. - For example, analysis by our tourist services client (above) showed that reducing churn by 31% amongst preferred members increased projected lifetime value by $412 per member due to their higher annual spend. Revenue/Profit Increase Success Stories - After an 18-month integrated digital marketing initiative focused on customer loyalty and retention, many banks in cyprus increased annual profit margins by 2.3%. This translates to over $1.2M in incremental bottom line profit YoY. - Following search engine visibility gains for key services terms, our accounting client (above) saw gross revenue rise by 9.4% - adding an estimated $521K compared YoY. Optimizing Spend Across Digital Marketing Funnel Allocating budget appropriately across the digital sales funnel maximizes impact: Top of Funnel (TOFU) Raise brand awareness and capture new visitors through: - Content marketing - PR outreach - Select paid social campaigns Example: Our lowyer client (above) invests 36% into thought leadership content propagation. Middle of Funnel (MOFU) Drive consideration and leads through: - SEO - Lead gen offers (eBooks, whitepapers) - Targeted paid ads (Google, Facebook) Example: FXGlobe Limited (above) allocates 43% budget to paid search, SEO, and social media. Bottom of Funnel (BOFU) Motivate action through: - Retargeting campaigns - Personalized messaging - Customer portals (for retention) Example: Zoom Cars (above) utilizes 29% budget for tailored client ads Optimization Adjust allocations dynamically based on performance data to maximize conversions across funnel stages. Conclusion The success stories and best practices presented make an ironclad case for digital marketing investment. Follow the outlined framework to showcase tangible ROI - including lead gen, customer acquisition, lifetime value expansion, and revenue growth.While every Cyprus business is unique, the message rings clear: Paying attention to digital pays off. Smart allocation of marketing resources to online channels delivers outsized returns across industries.Gone are the days when CEOs and CMOs could question the business impact derived from their digital marketing efforts. This playbook leaves no doubt - executed strategically, digital marketing must sit at the core of any high-growth Cyprus company moving forward. Read the full article

0 notes

Text

Industrial Automation: Revolutionizing Manufacturing Processes

Introduction:

In the realm of manufacturing, the rapid advancement of technology has brought about a significant transformation known as industrial automation. This revolution has fundamentally changed the way industries operate, boosting efficiency, productivity, and quality while reducing costs. In this blog post, we will delve into the intricacies of industrial automation, exploring its various components, benefits, challenges, and future prospects.

What is Industrial Automation?

Industrial automation refers to the utilization of advanced technologies and control systems to streamline manufacturing processes and replace manual labor with machinery and software. It encompasses a wide range of applications, including robotics, programmable logic controllers (PLCs), computer numerical control (CNC) systems, and artificial intelligence (AI).

Components of Industrial Automation:

a) Robotics: Robots play a crucial role in industrial automation, performing tasks with precision, speed, and consistency. They can handle repetitive tasks, work in hazardous environments, and operate around the clock, thus optimizing production processes.

b) Programmable Logic Controllers (PLCs): PLCs are computerized control systems that automate electromechanical processes. They monitor sensors, make decisions based on predefined programs, and control actuators to ensure seamless operation. PLCs offer flexibility, reliability, and real-time monitoring capabilities.

c) Computer Numerical Control (CNC) Systems: CNC systems control and automate machinery in manufacturing processes. By integrating computers with machine tools, they enable precise and complex operations such as cutting, milling, and drilling. CNC systems enhance accuracy, reduce waste, and facilitate customization.

d) Artificial Intelligence (AI): AI technologies, such as machine learning and computer vision, are increasingly being incorporated into industrial automation. They enable machines to learn, adapt, and make decisions based on data analysis, enhancing efficiency, predictive maintenance, and product quality.

Benefits of Industrial Automation:

a) Increased Productivity: Automation minimizes manual errors, reduces production time, and enables continuous operation, leading to enhanced productivity and output.

b) Improved Quality Control: Automation systems ensure consistency, precision, and adherence to predefined standards, resulting in higher product quality and fewer defects.

c) Enhanced Workplace Safety: Automation reduces the need for human intervention in hazardous environments, minimizing the risk of accidents and injuries.

d) Cost Reduction: While the initial investment in automation systems can be significant, the long-term benefits include reduced labor costs, improved resource utilization, and minimized wastage.

e) Scalability and Flexibility: Automation allows for easy scalability and rapid adaptation to changing production demands, enabling manufacturers to respond quickly to market needs.

Challenges in Implementing Industrial Automation:

a) Initial Investment: The cost of acquiring and implementing automation technologies can be a barrier for some industries, requiring careful financial planning and analysis.

b) Workforce Adaptation: The transition to automation necessitates upskilling and retraining the existing workforce to effectively operate, maintain, and repair automated systems.

c) Cybersecurity Risks: As automation relies heavily on interconnected systems and data exchange, robust cybersecurity measures are crucial to protect against potential threats.

d) Ethical Considerations: The increasing integration of AI raises ethical concerns related to job displacement, privacy, and the responsible use of automation technologies.

Future Trends and Outlook:

a) Collaborative Robotics: The integration of humans and robots working together in a shared workspace is gaining prominence, enabling efficient collaboration and leveraging the strengths of both.

b) Internet of Things (IoT): IoT connectivity allows for seamless data exchange between machines, facilitating predictive maintenance, remote monitoring, and optimization of production processes.

c) Edge Computing: Edge computing brings processing power closer to the data source, enabling real-time analysis, reduced latency, and improved operational efficiency in industrial automation.

d) Artificial Intelligence Advancements: AI algorithms are expected to become more sophisticated, enabling machines to handle complex tasks, make autonomous decisions, and further optimize manufacturing operations.

Conclusion:

Industrial automation continues to reshape the manufacturing landscape, driving improvements in productivity, quality, and safety. By leveraging advanced technologies such as robotics, PLCs, CNC systems, and AI, industries are able to streamline processes, reduce costs, and stay competitive in a rapidly evolving market. While challenges exist, careful planning, upskilling, and robust cybersecurity measures can pave the way for a successful implementation of industrial automation. Looking ahead, the future holds exciting possibilities as collaborative robotics, IoT, edge computing, and AI advancements continue to push the boundaries of industrial automation. Reach out to Ipcs Erode to know more.

0 notes

Text

Wholesale & Distribution Erp Sage Enterprise Administration & Bi Montreal Canada

NetSuite offers organizations with an built-in system of cloud functions that helps them run their enterprise.... Complete integration with manufacturing, stock, buying, gross sales, and finance provides a 360-degree understanding of all buyer exercise sage x3 food and beverage. Sage X3 helps organizations keep up with demand through real-time stock monitoring and status tracking. GetApp offers free software discovery and choice sources for professionals like you.

The mid-market ERP publishers, then again, corresponding to Infor or Epicor, are probably to offer significantly better worth for the mid-market producers. They present self-contained solutions and have industry-specific last-mile functionality built in for a quantity of manufacturing verticals similar to Industrial Automation or Machinery. Their products are technical to supply the needed flexibility for a lot larger manufacturing organizations.

Sage X3 helps your company comply by providing a convenient and environment friendly approach to gather and monitor related process data and eliminating guide procedures throughout the manufacturing process. With the rising variety of food safety incidents, a mock recall is nothing short of obligatory for producers critical about food safety. Tailor behaviour, user experiences and automate enterprise processes and operations easily. At the identical time, customers expect consistency whilst provide, demand, and the marketplace itself adjustments. It's difficult to stay in management, hold costs down, and retain flexibility for reacting to these modifications, however you can overcome it with the right resolution. Addressing these challenges will assist you determine if your business is compliant, accountable, ready for recalls, and capable of keep constant product quality.

I like the function and performance improvement course of that the supplier uses and believe this ERP suite is reasonably priced and enough for the million and billion dollar firms. A single cloud ERP resolution sage x3 food and beverage for fast-growing, mid-market companies to scale and compete with out the complexity and value. A confirmed ERP software program resolution to help distributors and producers run effectively.

Have the opportunity to standardize your unique recipe processes as a lot as a global scale with Ross. New Westminster, BC, September 5, (T-Net)--The Answer Company, a number one business management software program & expertise consulting firm, has been named one of many fastest-growing companies in B.C. Manufacturing resource planning software, generally referred to as material necessities planning or as MRP II software program, is the core know-how that sets manufacturing applications other than other kinds of enterprise software.

Better planning and monitoring leads to operations that generate less waste and less scrap, reducing environmental influence for those companies. Additionally, as more documentation is saved electronically, it reduces waste paper and cuts paper prices sage x3 food and beverage. Specialists in a single perform, similar to materials costing, may value the function depth of best-of-breed options designed for his or her perform.

Minimum of 1-year experience working machines such as lathes and milling machines (non-CNC) in a heavy manufacturing setting. We will be succesful of visibility and transparency across all vegetation for company, lowering the time for shut, as properly as sharing supplies and ingredients which would possibly be shared. Trace is a huge win for our Quality group for audits and any product tracing that's required, which a really nice time saver. EVERYTHING (Acctng,CRM,Orders,Inv/WMS,Purch,Ecom) on a single cloud enterprise suite from an moral, U.S. primarily based small business advocate. A higher method to handle your entire business, at a lower price and on a global scale.

And it is in fact essential to think about foreign money trade charges, as a end result of it's not unusual for importers to be incurring costs in two or more currencies. For foreign money conversion, assuming you haven't hedged currencies, the guidelines say to use the exchange price on the date of receipt of the goods. There are many strict laws to follow in phrases of the distribution of food and drink merchandise. Compliance with these rules is necessary to ensure the products’ freshness and high quality.

0 notes

Text

U.S Outdoors Advertising Market 2022 - Global Industry Analysis 2022-2030#

"https://tealfeed.com/car-sharing-europe-market-2022-global-wzw73 https://tealfeed.com/distributed-power-generation-systems-us-market-8wmn6 https://tealfeed.com/extensometers-europe-market-size-incredible-possibilities-od7dd https://tealfeed.com/conversion-rate-optimization-cro-software-us-azeoz https://tealfeed.com/non-relational-databases-europe-market-2022-mnzbs https://tealfeed.com/white-shrimp-us-market-growing-rapidly-gbree https://tealfeed.com/fertility-drug-europe-market-demand-future-qlixr https://tealfeed.com/sandalwood-us-market-current-business-trends-7pbxm https://tealfeed.com/waterjet-cutting-machine-europe-market-2022-zhkah https://tealfeed.com/extruded-aluminium-us-market-witness-huge-vegr4 https://tealfeed.com/luxury-car-rental-europe-market-2022-wsad0 https://tealfeed.com/commercial-led-lighting-solution-us-market-6wkuw https://tealfeed.com/express-delivery-europe-market-2022-continues-mty9r https://tealfeed.com/poultry-processing-software-us-market-advancing-ml1dz https://tealfeed.com/foot-traffic-customer-location-intelligence-solution-p6y5c https://tealfeed.com/rfp-software-us-market-continues-rapid-6pqbz https://tealfeed.com/tpe-tourniquet-europe-market-2022-comprehensive-ycu4t https://tealfeed.com/pruritus-therapeutics-us-market-2030-merck-1kpfs https://tealfeed.com/e-discovery-europe-market-2022-huge-szeqn https://tealfeed.com/aircraft-insulation-materials-us-market-2022-qtfvq https://tealfeed.com/proppant-europe-market-2022-analysis-trends-vfj9e https://tealfeed.com/agricultural-films-bonding-us-market-upcoming-fpniy https://tealfeed.com/cnc-machine-cnc-machine-tools-europe-iojdx https://tealfeed.com/business-process-management-bpm-paas-us-972qh https://tealfeed.com/blood-filter-europe-market-size-historical-hxwiz https://tealfeed.com/calcium-fluoride-us-market-covid19-omicron-4wm1l https://tealfeed.com/touch-panels-europe-market-2022-thriving-izwag https://tealfeed.com/rod-ends-us-market-size-growth-1vwma https://tealfeed.com/eyeglasses-frames-europe-market-2022-2030-nsvnq https://tealfeed.com/fertilizer-mixtures-us-market-2022-booming-c2uhm https://tealfeed.com/video-making-software-europe-market-report-m380b https://tealfeed.com/expanders-us-market-2022-explained-effective-dkbap https://tealfeed.com/electronic-ink-screen-products-europe-market-xrj3j https://tealfeed.com/mobile-racks-us-market-trends-2022-narxf https://tealfeed.com/europe-maritime-analytics-industry-future-demand-dr7kf https://tealfeed.com/counter-otc-analgesics-us-market-global-wthrv https://tealfeed.com/solar-charge-controllers-europe-market-expected-pzfmx https://tealfeed.com/us-ladys-sexy-lingeries-market-size-9jday https://tealfeed.com/customer-experience-monitoring-europe-market-2022-b7dcv https://tealfeed.com/reflective-sunglasses-us-market-size-share-gcg3p https://tealfeed.com/acid-steam-cleaning-system-europe-market-iwe8s https://tealfeed.com/digital-diagnostics-us-marketcovid-19-industry-4h0fj https://tealfeed.com/stock-option-plan-administration-software-europe-aqerp https://tealfeed.com/energy-measuring-devices-us-market-witness-5uzwk https://tealfeed.com/copper-indium-gallium-selenide-cigs-cis-nzlpt https://tealfeed.com/art-collection-software-us-market-2022-gbdc5 https://tealfeed.com/jet-skiing-equipment-europe-market-trends-q0llj https://tealfeed.com/us-fluorinated-polymer-market-2022-current-0tjp2 https://tealfeed.com/inductive-absolute-encoders-europe-market-growth-fby0b https://tealfeed.com/s-trioxane-us-market-share-size-h0nvt https://tealfeed.com/water-hardness-test-strips-europe-market-fkycn https://tealfeed.com/copper-coil-us-market-2022-demand-luqyz https://tealfeed.com/textile-recycling-europe-market-future-scope-z6nsr https://tealfeed.com/ultrasonic-beam-sensor-us-market-2022-pi1dp https://tealfeed.com/ethernet-adapter-europe-market-2022-new-7q6mp https://tealfeed.com/ambulatory-surgery-centre-us-market-huge-nmwdv

0 notes

Text

#CNC Machine Monitoring Software Market#CNC Machine Monitoring Software Market Share#CNC Machine Monitoring Software Market Forecast

0 notes

Text

Global Super Precision Bearing Market Outlook, Industry Analysis and Prospect 2026

Super Precision Bearing Market in Italy - Manufacturing and Consumption, Outlook and Forecast 2020-2026 A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. Super precision bearings are high-precision bearings that are designed for use in machine-tool spindles and other precision applications. Also Read: https://icrowdnewswire.com/2021/01/18/aircraft-refurbishing-market-2021-key-players-global-trend-industry-size-share-price-and-opportunities-forecast-to-2026/ This report contains market size and forecasts of Super Precision Bearing in Germany, including the following market information: Italy Super Precision Bearing Market Revenue, 2015-2020, 2021-2026, ($ millions) Italy Super Precision Bearing Market Consumption, 2015-2020, 2021-2026, (M Units) Italy Super Precision Bearing Production Capacity, 2015-2020, 2021-2026, (M Units) Top Five Competitors in Italy Super Precision Bearing Market 2019 (%) Also Read: https://icrowdnewswire.com/2021/01/12/hair-styling-products-market-2020-global-key-vendors-analysis-revenue-trends-amp-forecast-to-2026/ The global Super Precision Bearing market was valued at 865.6 million in 2019 and is projected to reach US$ 1024.6 million by 2026, at a CAGR of 4.3% during the forecast period. While the Super Precision Bearing market size in Italy was US$ XX million in 2019, and it is expected to reach US$ XX million by the end of 2026, with a CAGR of XX% during 2020-2026. Also Read: https://icrowdnewswire.com/2021/01/05/high-availability-software-market-share-size-future-demand-global-research-top-leading-player-emerging-trends-region-by-forecast-to-2025/ MARKET MONITOR GLOBAL, INC (MMG) has surveyed the Super Precision Bearing manufacturers, suppliers, distributors and industry experts on the impacts of the COVID-19 pandemic on businesses, with top challenges including ingredients and raw material delays, component and packaging shortages, reduced/cancelled orders from clients and consumers, and closures of production lines in some impacted areas. This report also analyses and evaluates the COVID-19 impact on Super Precision Bearing production and consumption in Germany Total Market by Segment: Italy Super Precision Bearing Market, By Type, 2015-2020, 2021-2026 ($ millions) & (M Units) Italy Super Precision Bearing Market Segment Percentages, By Type, 2019 (%) Angular Contact Ball Bearings Cylindrical Roller Bearings Double Direction Angular Contact Thrust Ball Bearings Axial-Radial Cylindrical Roller Bearings Others Also Read: https://icrowdnewswire.com/2021/01/20/digital-fault-recorder-2021-market-segmentation-application-technology-amp-market-analysis-research-report-to-2026/ Italy Super Precision Bearing Market, By Application, 2015-2020, 2021-2026 ($ millions) & (M Units) Italy Super Precision Bearing Market Segment Percentages, By Application, 2019 (%) Machine Tools Medical and Dental Aviation & Defense Precision Equipment Others Also Read: https://icrowdnewswire.com/2021/01/12/cnc-automatic-lathes-market-global-industry-analysis-size-share-trends-growth-and-forecast-2021-2026/ Competitor Analysis The report also provides analysis of leading market participants including: Total Super Precision Bearing Market Competitors Revenues in Germany, by Players 2015-2020 (Estimated), ($ millions) Total Super Precision Bearing Market Competitors Revenues Share in Germany, by Players 2019 (%) Total Italy Super Precision Bearing Market Competitors Sales, by Players 2015-2020 (Estimated), (M Units) Total Italy Super Precision Bearing Market Competitors Sales Market Share by Players 2019 ($ millions) Further, the report presents profiles of competitors in the market, including the following: Schaeffler Nachi-Fujikoshi NSK SKF Koyo Timken ZYS C&U Group ZWZ About Us: Wise Guy Reports is part of the Wise Guy Research Consultants Pvt. Ltd. and offers premium progressive statistical surveying, market research reports, analysis & forecast data for industries and governments around the globe. Contact Us: NORAH TRENT

0 notes

Photo

Dell XPS 15 9500 Laptop, Price, Specification, Drivers

Dell XPS 15 Laptop has a more vivid. And it has 38.01 cm with 4 sides narrow. As well as, It has 16:10 Infinity Edge display that is deliver 100% Adobe RGB color in amazing detail.

The processor is the 10th generation, Intel Core i7-10750H

Video Card is NVIDIA GeForce GTX 1650 Ti 4GB GDDR6

Hard Drive is 1TB M.2 PCIe NVMe Solid-State Drive

Memory is 32GB, DDR4, 2933 MHz, 2x16G

The display is 39.6 cm

Operating System is Windows 10 Pro - 64bit.

Price of Dell XPS 15

Intel Core i7 512GB / 16GB is $ 2,545.87 / € 2,184.10 / £ 1,961.53 Rs 1,90,495.77

Intel Core i7 1TB / 32GB is $2,918.54 / € 2,506.31 / £ 2,250.12 / Rs 2,18,495.76

Buy Amazon.com

Drivers of Dell XPS 15 9500

After all, you can download the driver of Dell XPS 15 9500

Configuration of Dell XPS 15 9500

Processor

After all, You can configure the processor as the 10th Generation, Intel Core i7-10750H [12MB cache, 5.0 GHz, 6 cores].

OS

Operating System is Windows 10 Pro 64bit - English

Video Card

NVIDIA GeForce GTX 1650 Ti 4GB GDDR6

Display

15.6 inches FHD+ [1920 x 1200] InfinityEdge, Of course Non-Touch Anti-Glare 500-Nit Display. 15.6 inches UHD+ [3840 x 2400] InfinityEdge, As well as, Touch Anti-Reflective 500-Nit Display.

Memory

16GB DDR4, 2933 MHz, 2x8G. 32GB DDR4, 2933 MHz, 2x16G.

Hard Drive

512GB M.2 PCIe NVMe Solid State Drive. 1TB M.2 PCIe NVMe Solid State Drive.

Color

The color is Platinum Silver with Black Carbon Fiber Palmrest.

Microsoft

There is no Microsoft Office License but 30 days of the trial offer.

Security

After all, The Security Software is McAfee Live Safe for 12 months.

Warranty

Of course, there is a Warranty of One year premium support plus and onsite services.

Damage Protection

After all, There is none accidental damage protection.

Keyboard

After all, The keyboard is Black Backlit, which is US/International with Fingerprint Reader

Slots and Ports

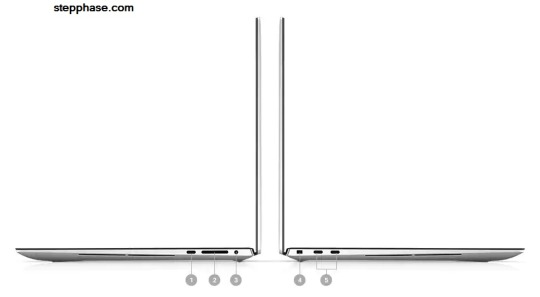

2x Thunderbolt 3 with the display port and the power delivery

1x USB-C 3.1 with the display port and the power delivery

1x Full size SD card reader v6.0

Combo jack 1x 3.5mm microphone/headphone

1x Wedge shaped lock slot

1x USB-c to USB-A v3.0 & HDMI v2.0 adapter ships standard

Weight & Dimension of Dell XPS 15

Weight is 1.83 kg [4 lbs] of non-touch / 2.05 kg [4.5 lbs] of touch

Height is 0.71 - 0.46 inch

Width is 13.57 inch

Depth is 9.06 inch

Camera

Of course, It has a 720p at 30 fps HD camera with a Dual array microphones

Speakers and Audio

After all, It has Studio quality tuning with a Waves with a MaxxAudio Pro and Waves Nx 3D audio.

As well as, It also has a Quad-speaker design with a 2.5W x 2 woofers and a 1.5W x 2 tweeters = 8W total peak output.

Also, a 3.5mm microphone/headphone combo jack that is featuring waves Nx 3D audio with head tracking.

As well as, Dual microphone array optimized with a Waves MaxxVoice supporting VoIP - Microsoft Cortana capable.

Chasis

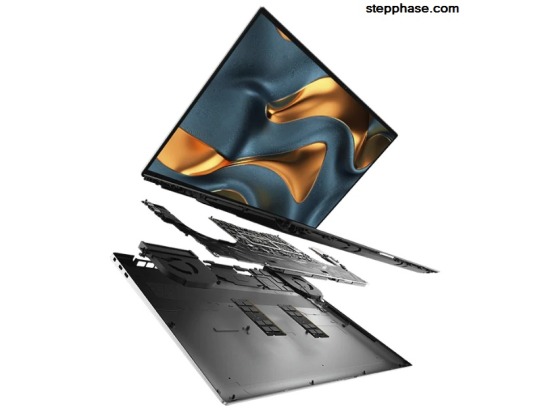

CNC machined aluminum in platinum silver with a carbon fiber composite palm rest in black.

Corning Gorilla Glass 6 on the touch panel.

Wireless

After all, It has a Killer Wi-Fi 6 AX1650 [2x2] and Bluetooth 5.1

Primary Battery

As well as, it has a 6 cell battery with 86 WHr Integrated.

Regulatory

The Regulatory Model is P91F, Regulatory type is P91F001, Energy star is 7.1, EPEAT is 2018 Silver registered for specific country participation and also rating. You can see www.epeat.net Hg-Free / Arsenic-Free PVC/BFC free but not PSU.

Features of Dell XPS 15

Operating system

Of course, You will get the Windows 10 Pro that features and improvements with a smooth and versatile PC experience that you will definitely like it.

Slots and Ports

Full-size SD card reader v6.0

1x USB-C 3.1 Port with display port and power delivery

3.5 mm microphone/headphone that is combo jack

Wedge-shaped lock slot

2x Thunderbolt 3 with a display port and power delivery

XPS 15 9500

Weight and Dimension

weight is 1.83 kg of non-touch / 2.05 kg of touch Height is 18 mm Width is 344 mm Depth is 230 mm

Eco wise

Of course, It is Energy Star certified.

Recycle: It's 90% of parts can be reused or recycled and its white bamboo packaging trays are 100% recyclable.

Material: Of course, It is free of materials like mercury, lead, cadmium, phthalates. Also, PVC/BFR free and EPEAT registered.

Sea: After all, 25% of materials consist of ocean plastics collected and 75% are made from recycled plastics.

Display

It has a top camera placement with a 16:10 display. As well as, it features edge to edge view with 922K pixels on UHD+ productivity.

Of course, You can take advantage of HDR content's superior dynamic range with a Dolby Vision. As well as, it can deliver colors on the SDR PC display. After all, Dolby Vision delivers highlights 40 times brighter, And blacks 10 times darker. Also has a VESA certified Display HDR 400 display on a 4K+ panel enables 16 million colors.

It has a 4K Ultra HD+ display that offers accuracy for computing needs. As well as, you can see details of a pixel in photos.

It is also equipped with a 100% Adobe RGB and a 94% DCI-P3 color gamut, also UHD+ display delivers saturated color on a 1650:1 contrast ratio that allows the darkest dark and brightest brights. After all, it has a 500-nit brightness clarity in bright light.

Of course, it has an Eyesafe display that reduces blue light and vivid color. It has a panel for intelligently manages light energy at the source.

Creations

It has 10th Generation Intel Core processors that bring you desktop-caliber creativity to the laptop. Of course, it is enough to edit, capture, and share your creations so faster.

It has GeForce GTX 1650 Ti graphics that is enough to accelerate the creative apps.

It also has a Dell Power Manager with adaptive performance.

1TB Solid State Drive storage and a 32GB of memory. Of course, it is damn faster that users will love it.

Creator

Of course, It is equipped with creative tools that are better and faster.

It has an Intel 10th Generation, 8 core, 16 threads i7 processor that is enough for the workload.

Of course, NVIDIA's graphics are rendering of high-resolution graphics and videos accelerates with performance.

It also has a full SD card slot that imports RAW images without delay.

It has a 100% Adobe RGB display, so that can let you edit photos with confidence.

After all, It has massive flash storage.

It also has multiple Thunderbolt 3 ports.

XPS 15

Masterful

Light and Cool: The aerospace industry made black palm rest, carbon fiber to minimize weight and maximum strength.

It also has stainless steel logos which is a laser cut-out.

The screen is Superior: It has a Corning Gorilla Glass 6, that is so strong as well as scratch resistance and impact.

It has a 14% larger touchpad, also it displays is 5% larger. As well as, larger keycaps because of edge to edge keyboard.

Diamond cuts: It is scratch resistant surface, superior, prevent damage if you unplugging and plugging.

Password: You can log in in two different ways. first is an Infrared camera that can recognize your face and unlock. And second is the fingerprint reader power button so that can let you log in.

Easier open: After all, The twin coil press-fit hinge is design to maximize its screen and enable 4 side Infinity Edge. Which is easier to open and it is stable.

webcam: It has a 2.25 mm webcam with a 4 element lens that delivers sharp video even in dim lighting. As well as, it improves video quality and reduce noise.

Sound

As well as, It has an immersive 3D soundscape with Waves Nx 3D Audio and quad-speaker design.

After all, It has top-mounted mics that allow talking from 14 ft away.

Accessories of Dell XPS 15

XPS 15 9500

1_Dell UltraSharp 27 USB-C Monitor - U2719DC

2_Dell Premier Sleeve 15 - PE1521VX

3_Dell Notebook Power Bank Plus, USB-C 65WH - PW7018LC

4_Dell Premier Wireless Mouse and Keyboard - KM717

5_Dell Thunderbolt Dock - WD19TB

Of course, You can contact us to let us know if we are missing something on our page. After all, We cannot guarantee, if anything is wrong on this page. I hope you like it and Thank you for your visit.

#Stepphase #technologies #technology #tech #technews #techworld #techtrends #smartphone #apple #techupdates #futuretechnology #newtech #techgeek #technologynews #technologythesedays #smarttechnology #technologylover #technologytrends #technologyblog #gadgets #smartphone #gadget #marketing #digital #india #technologyisawesome #amazing #repost

0 notes

Text

Global CAD/CAM Software Market 2019 - Industry Analysis, Size, Share, Key Players, Applications, Strategies and Forecast to 2025

Global CAD/CAM Software Industry

New Market Study On “2019-2023 CAD/CAM Software Market Global Key Player, Demand, Growth, Opportunities and Analysis Forecast” Added to Wise Guy Reports Database

Market Overview

CAM software, which is also known as computer-aided manufacturing software converts computer-aided design models into data that is used by machines on the store floor. CAD/CAM Software helps manufacturing businesses optimize the procedure of transforming components and raw materials into complete products. computer-aided manufacturing software provides data on how different equipment should perform manufacturing operations, such as milling, cutting, and roughing. CAD/CAM Software is generally leveraged by production managers to plan, create, and execute production operations.

Try Sample of Global CAD/CAM Software Market @ https://www.wiseguyreports.com/sample-request/2959550-global-cad-cam-software-detailed-analysis-report-2018-2023

These tools are also used by shop floor employees to utilize the equipment in a safe and efficient manner. CAD/CAM Software is generally utilized in integration with product lifecycle management tools. Sometimes, organizations may also require to integrate their CAD/CAM Software with other solutions used in product manufacturing, such as manufacturing execution systems and ERP systems. These solutions include features to convert and import critical CAD models and help to generate data in formats that can be understood and utilized by machines.

CAD/CAM Software enables store floor workers to monitor and control different manufacturing equipment. Also, these tools include different features that can improve production efficiency and reduce the generation of waste during product manufacturing. CAD/CAM Software supports some standard operations and enables users to customize some of the operations. These tools provide business with proper schedules and workflows for different types of manufacturing procedures. The report on the global CAD/CAM Software studies the present market trends, developments, and dynamics and analyses the market growth for the forecast period 2018 to 2023.

Major Companies, ABB Robotics, ALMA, Bentley Systems Europe B.V., BobCAD-CAM, Breton - Natural & Compound Stone Division, CNC Software, Edgecam, FIDIA, Gie-Tec GmbH, Haco Atlantic Inc., Hexagon PPM, imes-icore GmbH, LANG, Lantek Sheet Metal Solutions S.L., LVD, Manusoft Technologies, Mazak, MECANUMERIC, MTC Software, PTC, RADAN, Seron, TDM Systems, TopSolid, Vero International Software, WICAM TECHNISCHE SOFTWARE, ZWSOFTMarket Segmentation

This report segments the overall CAD/CAM Software market based on Software Type, operating Systems. The market report covers the historical information from the year 2013 to 2017 and generates future growth predictions for the period 2018 to 2023. As a Detailed Analysis report, it provides in-depth insight into the internal market analysis and provides investment opinion for the new market entrants and emerging players in the global CAD/CAM Software market.

Based on product type, the global CAD/CAM Software market has been segmented into-

CAD/CAM Software Market, by Software Type 3D Software 2D Software 2D/3D Software Real-time Software

Based on the operating system, the global CAD/CAM Software market has been segmented into-

Windows Mac OS Linux Android Web Browser

Based on applications, the global CAD/CAM Software market has been segmented into-

Industrial Design Architectural Design Graphic Design Business Training Others

Regional Overview

The global CAD/CAM Software market has been analysed at different levels, including company-level, country-level, regional-level, and global-level analysis. Based on this analysis, the present market trends, opportunities, challenges, and growth prospects have been drawn. All these factors will help emerging market participants and new market entrants to understand the overall structure and scope of the CAD/CAM Software market. The regional analysis has been conducted considering different critical factors, including regional product demand, regional market dynamics, regional market trends, distribution channels, software development strategies, capabilities, and revenue structures of different market participants operating in these regional markets. North America, Europe, Asia Pacific, and the Middle East and Africa are the major regions that are responsible for driving the growth of CAD/CAM Software market and are mentioned in the market report.

Industry News

3D Systems has declared that two prominent German industrial tool manufacturers utilizing Cimatron has reportedly integrated 3D Systems' CAD/CAM software to overcome manufacturing and production challenges more successfully and in a fast manner. Cimatron software, a dedicated design and manufacturing firm for tooling, has claimed to draw renewed interest from consumers in Germany because of its capacity to design, develop, and deliver molds faster, retain data integrity between design and manufacturing, and its outstanding EDM programming and electrode composition application.

For any query @ https://www.wiseguyreports.com/enquiry/2959550-global-cad-cam-software-detailed-analysis-report-2018-2023 Table of Contents Global CAD/CAM Software Detailed Analysis Report 2018-2023 Chapter One CAD/CAM Software Market Overview Chapter Two CAD/CAM Software by Regions 2013-2018 Chapter Three CAD/CAM Software by Players 2013-2018 Chapter Four CAD/CAM Software by Consumer 2013-2018 Chapter Five Global Top Players Profile 5.1 ABB Robotics 5.2 ALMA 5.3 Bentley Systems Europe B.V. 5.4 BobCAD-CAM 5.5 Breton - Natural & Compound Stone Division 5.6 CNC Software 5.7 Edgecam 5.8 FIDIA 5.9 Gie-Tec GmbH 5.10 Haco Atlantic Inc. 5.11 Hexagon PPM 5.12 imes-icore GmbH 5.13 LANG 5.14 Lantek Sheet Metal Solutions S.L. 5.15 LVD 5.16 Manusoft Technologies 5.17 Mazak 5.18 MECANUMERIC 5.19 MTC Software 5.20 PTC 5.21 RADAN 5.22 Seron 5.23 TDM Systems 5.24 TopSolid 5.25 Vero International Software 5.26 WICAM TECHNISCHE SOFTWARE 5.27 ZWSOFT

Chapter Six Industry Chain and Supply Chain Chapter Seven Global CAD/CAM Software Market Size (Sales and Revenue) Forecast (2018-2023) Chapter Eight Development Trend and Research Conclusion Chapter Nine Methodology and Data Source

For more information or any query mail at [email protected]

Also Read: Global CAD/CAM Software Market Size, Status and Forecast 2018-2025

NOTE : Our team is studying Covid-19 and its impact on various industry verticals and wherever required we will be considering Covid-19 footprints for a better analysis of markets and industries. Cordially get in touch for more details.

0 notes

Text

Pressure Switch Market Latest Industry Trends, Forecast, Revenue, Share, Competitive Analysis, Demand and Opportunities By 2023

The global pressure switch market is projected to reach USD 2.09 billion by 2023, at a CAGR of 4.39%, from an estimated USD 1.69 billion in 2018. The growth of the pressure switch market is mainly driven by the increasing focus on process automation and increasing demand for pressure switches in the transportation sector for various applications such as automotive, railways, and airplanes.

Asia Pacific is estimated to be the fastest growing market for pressure switches, during the forecast period. The region has been segmented, by country, into China, Japan, India, South Korea, and the Rest of Asia Pacific. The pressure switch market in the region is primarily driven by the growth in various industries such as manufacturing, mining, oil & gas, textiles, and automation. In 2017, the region manufactured more than 44 million vehicles. Moreover, the government of India also plan to increase the contribution toward its manufacturing sector to reach 25% by 2025, which is likely to drive the pressure switch market in the region.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=52557932

The pressure switch market, by type, is segmented into electromechanical and solid-state. The solid-state pressure switch segment is estimated to be the fastest growing market, during the forecast period. The use of these switches results in higher level of precision and longer life cycle, broad frequency response, better accuracy, high resistance to shock and vibration, and improved capability to handle a wide range of system pressure. Also, the increase in technological advancements for better product functionality is further expected to create the demand for solid-state pressure switches.

The report segments the pressure switch market, by pressure range, into below 100 bar, 100–400 bar, and above 400 bar. The below 100 bar segment is estimated to be the fastest growing market, during the forecast period. These switches are mostly used in hydraulic power units, material handling machinery, railway, CNC machines, compressors/boilers, food & beverage equipment, and generators. Low cost of pressure switches coupled with multifunctionality is likely to drive the pressure switch market in the below 100 bar segment.

Browse Research Report Summary With Complete TOC @ https://www.marketsandmarkets.com/Market-Reports/pressure-switch-market-52557932.html

The pressure switch market, by application, is segmented into HVAC, monitoring & control, safety & alarm systems, and hydraulics & pneumatics. The HAVC segment is estimated to be the fastest growing market for pressure switches during the forecast period. Pressure switches in the HVAC system monitor air filters, control air and fire protection flaps, monitor flows in ventilation ducts, and protect heat exchangers from frost. All such factors are expected to drive the pressure switch market in HVAC segment.

The pressure switch market, by end-user, is segmented into automotive & transportation, process & manufacturing industry, and commercial. The automotive & transportation segment is estimated to be the fastest growing market for pressure switches during the forecast period. The automotive & transportation sector includes the use of pressure switches for railways, automobiles, and electric vehicle among others. The rising automobile and electric vehicles production and investments in railways sector is likely to drive the pressure switch market in automotive & transportation segment during the forecast period.

Request for sample pages of the report @ https://www.marketsandmarkets.com/requestsampleNew.asp?id=52557932

Pressure switches in the HVAC system monitor air filters, control air and fire protection flaps, monitor flows in ventilation ducts, and protect heat exchangers from frost. All such factors are expected to drive the pressure switch market in HVAC segment.

Browse more research reports:

Diesel Power Engine Market by Operation (Standby, Prime, and Peak Shaving), Rated Power (Up To 0.5 MW, 0.5–1 MW, 1–2 MW, 2–5 MW, and Above 5 MW), End-User (Industrial, Commercial, Residential), and Region - Global Forecast to 2022