#machining parts

Text

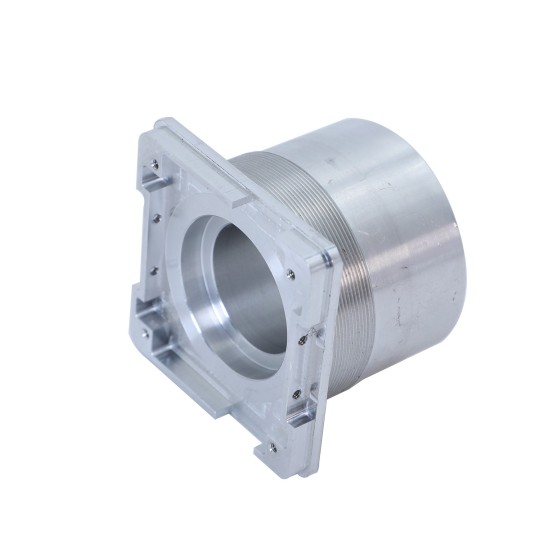

CNC turning and milling services

#design#autos#business#prototyping#cnc machining#prototype#prototype machining#rapid prototyping#precision machining#cnc turning#cnc milling#cnc precision machining#precisionmanufacturing#machining parts#cnc machining center#cnc part#cnc parts company#cnc parts factory

3 notes

·

View notes

Text

I had a vision

#deltarune#deltarune fanart#mini comic#twin runes mini#twin runes#kris dreemurr#susie deltarune#my art#art#comic#susie has the right idea#screw pulling them out#the vending machine is now a part of the FUN gang

15K notes

·

View notes

Text

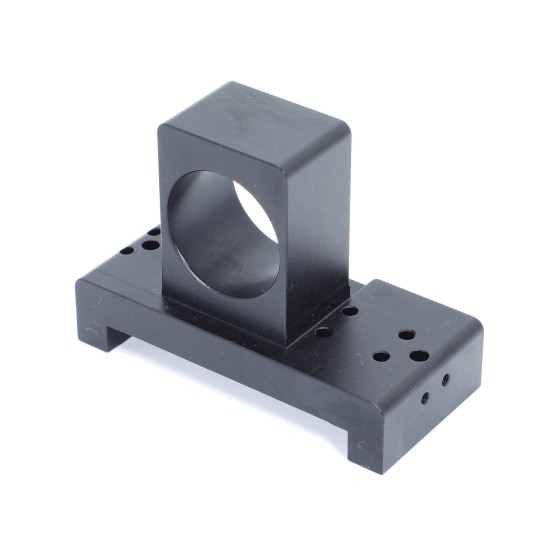

Researching Spline Connectors

Something new that we will probably have to use in our transmission design this year is a spline connector between the small sprocket and its mount to the motor.

22A Design

Last year, our motor was mounted to the chassis with a single plate seen behind the motor in the image below. On the rotor side of the motor, the small sprocket bolts onto a custom mount. The purpose of this mount is solely to offset the sprocket away from the face of the motor, so the chain can align with the large sprocket on the differential.

24A Design

For our new car, we want the motor to have two mounting plates attaching it to the chassis (we had some issues with a bent motor mount last year that I don't want to talk about). This means we will have a similar mount as seen on the rear of the motor above. But the sprocket mount on the front of the motor will double as a mount to the chassis.

My rough concept of this design is seen in the image below. Since the small sprocket mount extends further past the sprocket, it is impossible to use bolts to attach the sprocket to the mount like we did on 22A. This is why I will be investigating the use of splines for this connection.

Spline Connector

Starting on page 2252 (lol), the Machinery's Handbook linked below explains when to use splines, the basic dimensions of splines, and tolerances for these dimensions.

I just read through most of this chapter and highlighted in Adobe Acrobat the useful topics that I need to revisit if we go through with using a spline connector design.

My overall thoughts:

splines are probably the best option for mounting the small sprocket

more research is need to determine type and fit of splines for our application

we will have to outsource the machining (hopefully get it sponsored)

overall seems do-able for our timeline and level of knowledge

#solidworks#mechanical engineering#formula 1#formula e#formula one#transmission#manufacturer#machining#manufacturing#machining parts

0 notes

Text

Stainless Steel Machined Parts

Usually we all think of stainless steel as being utilised for items such as home furnishings or cutlery and earlier in the early 90's beer cans!! Well, did you actually know?? Stainless steel plays a key part as a material within the precision machining industry even more so in today's CNC machinery based processes. Whether you travel on an aeroplane or a cruise-liner you can guarantee that many of the working or exposed components have been machined from a grade of stainless steel.

CAD-CAM software further enables the capability to manufacture stainless steel components to the highest specification.

Today's common methods of machining stainless steel components can be one of many including turning, milling, drilling and boring using state-of-the-art CNC Machinery. In the aerospace industry close tolerance, complex parts are required and are produced using 5-Axis milling machines along with Multi-Axis CNC mill/turning machines. CAD-CAM software further enables the capability to manufacture stainless steel components to the highest specification.

Why Stainless Steel??

Well, this material combines a number of excellent properties. Firstly, stainless steel has great corrosion resistance making it appealing for applications that are exposed to bad weather and moisture. Secondly, It offers greater strength than materials such as mild steel and aluminium and can be further enhanced with heatreatment processes. As you guessed it, it makes for a great choice for aerospace components.

Thanks for taking the time to read this article and we hope it has given you some valuable insight into stainless steel machined parts.

Thank you!!

0 notes

Text

Non-standard precision machining/Precision manufacturing machining/milling machine machining surface charm

machining

#precision parts#precision machining manufacturer#non standard precision machining#cnc turning#cnc swiss#precision machining#machining parts#shaft

1 note

·

View note

Text

Precision CNC machining service for defence, automotive, medical, government, mining, aerospace, electronics and telecommunication industries.

#machinery#cnc machined components#electronic components#spareparts#manufacturer#factory#cnc machining#machining parts#precision machining#machinist

0 notes

Text

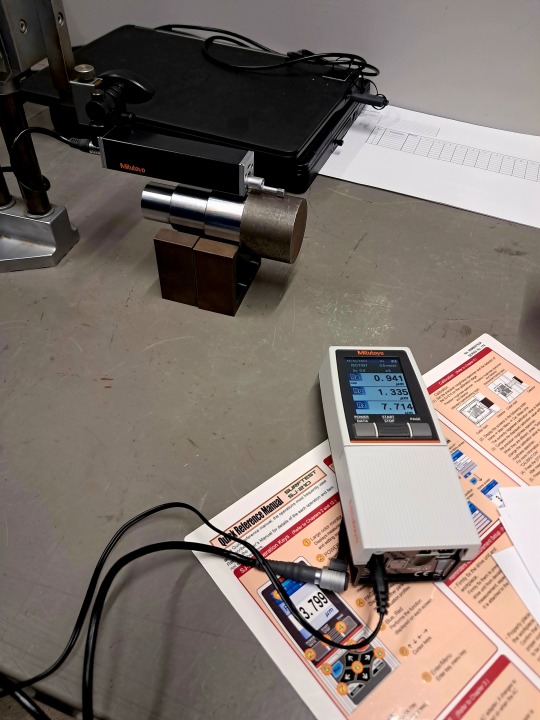

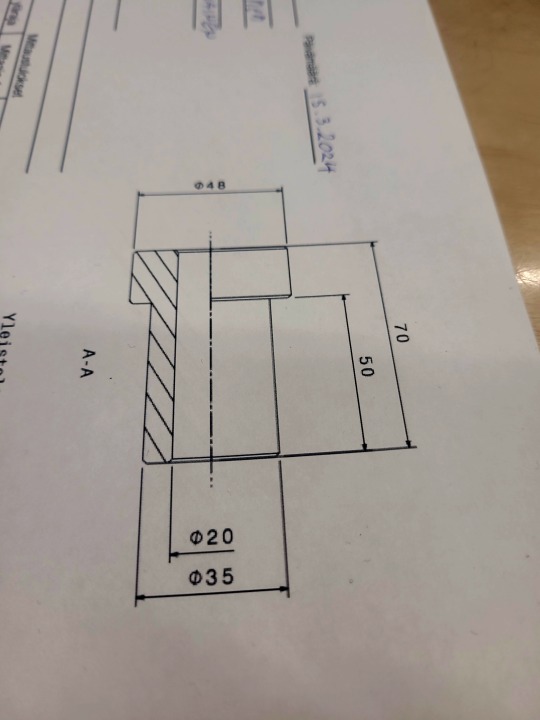

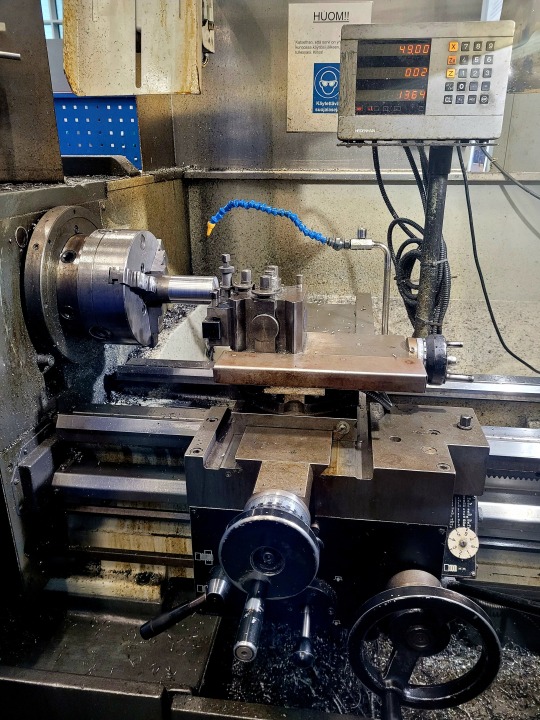

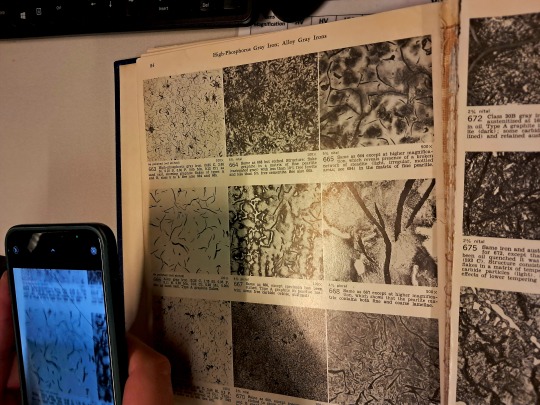

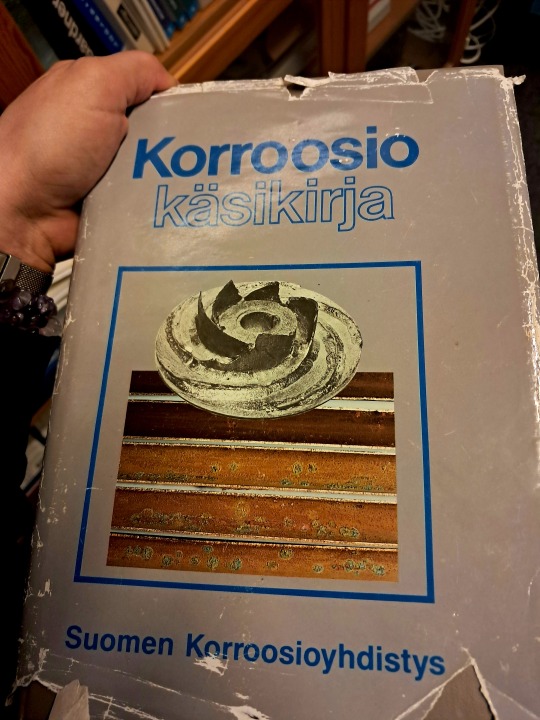

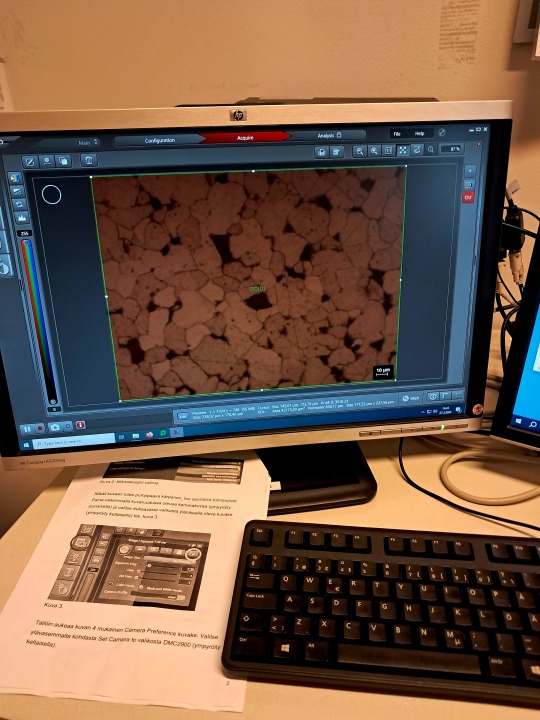

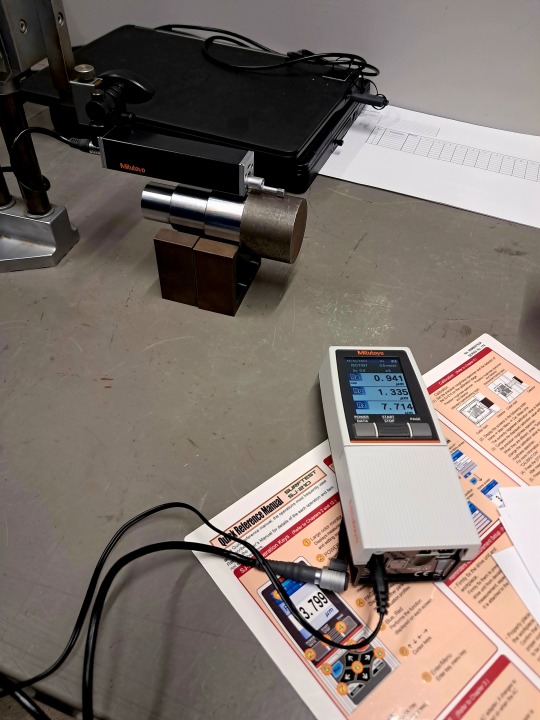

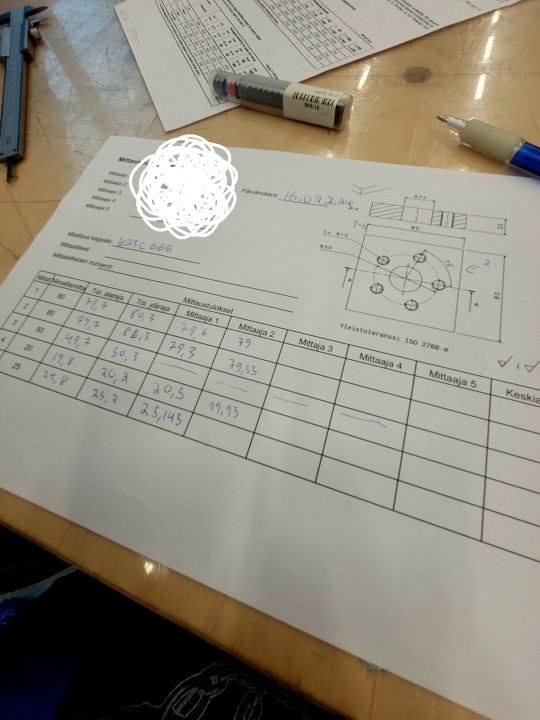

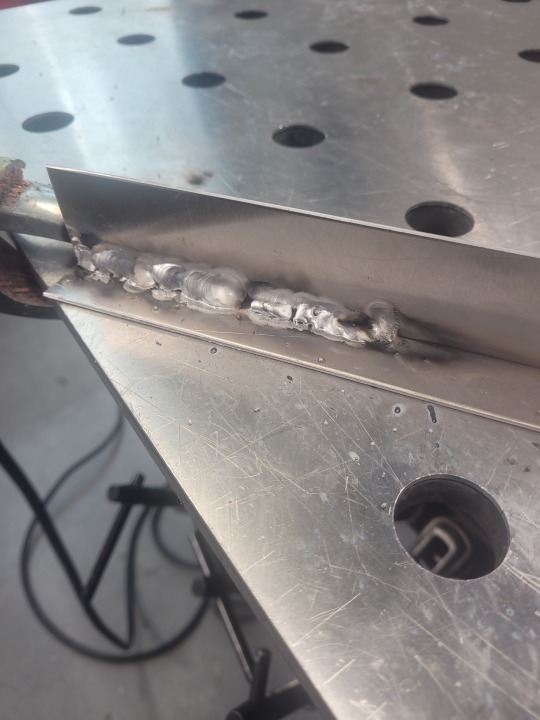

29.3.2024.

Nyt tuntuu, että oon saanut vähän paremman otteen opiskelusta tänä keväänä. Olen aika kovasti tosin joutunut karsimaan sosiaalista elämää, jotta pysyisin ajantasalla kaikissa aineissa.

Uusia aineita tullut ja ollaan niissä pureuduttu aika perusasioihin. Materiaali-ja hitsaustekniikassa ollaan tutustuttu labrojen kautta ihan itse hitsaustekniilkaan ja materiaalitekniikassa tutkittu mikroskooppisesti metallin rakenteita jne. Valmistustekniikassa on taas tutustuttu erilaisiin metallin työstömenetelmiin. (sorvaus, poraus, jyrsintä, laserleikkaus).

Haastavana uutuutena tuli myös statiikka, jossa kyllä olen kovalla opiskelulla pysynyt ihan hyvin kärryillä. 🥳 Katotaan hyytyykö hymy sitte lujuusopissa 😱

Lisäksi meillä on meneillään johdantoprojekti. Eli eka pikku projektityö. Siitä voin kertoa lisää kevään lopulla.

Alla vähän kuvia koululta...

#konejametalli#konetekniikka#insinööriopinnot#physics#machining parts#student#metropolia#Metropolia Ammattikorkeakoulu#engineering

0 notes

Text

5 Facts You Should Know About Machined Parts

Machined parts are integral components in manufacturing and engineering processes, contributing to the creation of precise and intricate components used in various industries. Understanding the critical aspects of machined parts is essential for design, production, and quality control professionals. This article will elaborate broadly on the five crucial facts about machining parts in Texas, shedding light on their significance and the considerations involved in their production.

Machining Processes and Techniques:

Machining is a manufacturing technique that removes material from a workpiece to gain the desired shape, size, and surface finish. Several machines are employed, each suited for specific applications. Standard machining parts techniques include milling, turning, drilling, grinding, and electrical discharge machining (EDM).

Milling: Comprises rotating cutting tools to remove material from a stationary workpiece.

Turning: The workpiece rotates, and a cutting tool removes material to create cylindrical shapes.

Drilling: Creates holes in the workpiece using a rotating drill bit.

Grinding: Achieves high-precision surface finishes through abrasive cutting.

EDM: Uses electrical discharges for intricate and precise shaping of conductive materials.

The choice of machining process depends on factors such as material properties, part geometry, and production volume.

Materials for Machining Parts:

Turned components can be produced from various materials, including metals, plastics, and composites. Typical metals used in machining include aluminium, steel, stainless steel, and titanium. Each material has distinct properties that impact the machining process, such as hardness, thermal conductivity, and machinability. For example, aluminium is known for its excellent machinability, making it suitable for applications where lightweight and corrosion resistance is essential.

The preference for materials is a critical element of machining, as it directly influences the tool selection, cutting speeds, and overall machining strategy.

Tolerances and Precision:

One of the defining characteristics of machining parts in Texas is the high level of precision that can be achieved. Tolerances relate to the allowable deviation from a specified dimension, and machining processes can achieve tight tolerances, often measured in micrometers. Precision is crucial in aerospace, automotive, and medical industries, where components must fit together seamlessly and meet strict performance criteria.

Achieving precise tolerances requires careful planning, tool selection, and monitoring of machining parameters to ensure consistent and accurate results.

CNC Machining:

Computer Numerical Control (CNC) machining has revolutionized the production of machined parts. CNC machines use computer agendas to control the movement of cutting tools and workpieces, enabling highly automated and precise machining. This technology creates complex shapes and intricate details efficiently and repeatably.

CNC machining offers advantages such as increased productivity, minimizing human error, and the ability to produce prototypes and small batches quickly. The versatility of CNC machining components makes it a cornerstone of modern manufacturing.

Surface Finishes and Treatments:

Machining components often undergo additional processes to achieve specific surface finishes or enhance their properties. Depending on the application requirements, surface finishes can range from rough to mirror-like. Procedures such as polishing, anodizing, plating, and coating are commonly employed to improve aesthetics, corrosion resistance, and wear resistance.

Polishing: Enhances surface smoothness and appearance.

Anodizing: Forms a protective oxide layer on the surface of aluminium parts.

Plating: Deposits a metal layer onto the surface for improved corrosion resistance.

Coating: Applies a protective layer to enhance properties such as hardness or lubricity.

These additional treatments are crucial for ensuring that machined parts meet the functional and aesthetic standards of the final product.

The Bottom Line

Turned components are fundamental in manufacturing and pivotal in creating precise and intricate components across diverse industries. Understanding the various machining processes, material considerations, tolerances, the impact of CNC machining, and post-machining treatments is crucial for professionals involved in designing and producing these components. The ability to make high-precision machined parts is a critical factor in the success of industries that demand accuracy, reliability, and performance in their end products.

#machining parts#machine parts manufacturer texas#machining parts texas#turned components#machining components

0 notes

Text

Professional manufacturer customized Actuating shaft #cusn

0 notes

Text

tsum events really are just the best, huh

#art#twisted wonderland#twisted wonderland spoilers#tsumsted wonderland#to be fair this is from mal's card story so it's more...event-adjacent#i-it still counts right#poor malleus tsum is having such a time#first it blows up the kitchen and then it almost gets spin-cycle'd to tsum-death#the poor little guy just wanted to help with the party! it was trying its BEST 😭#and instead it accidentally recreated every other tuesday from my college days#i am so genuinely delighted to read two entire chapters of malleus bragging about knowing how to use household appliances#(he knows what he's doing! he READ the MANUAL)#(you know that manual has copious notes covering the margins in perfect copperplate)#and the callback to his dorm ssr story. perfect.#we all knew this was going to end in malleus punching a washing machine into smithereens#i'm disappointed that the next part is probably just going to be a fun party or whatever#and not malleus showing off how close he is to finally mastering the toaster#twst please where is my spinoff game where we have to help a dragon fae prince learn how to do household tasks#i have an indescribable need to see malleus attempt to use a vacuum#he is very enthusiastic and also very stupid and we love him for it

4K notes

·

View notes

Text

CNC plastic machining

#design#autos#business#prototyping#cnc machining#prototype#prototype machining#rapid prototyping#precision machining#machining parts#cnc precision machining#cnc plastic machining#plastic machining#plastic cnc

2 notes

·

View notes

Text

Production of connector lamp hardware accessories

0 notes

Text

Really funny that Colin insists that Alice shouldn't give the computers a personality JUST MOMENTS AFTER he claimed that the computers are fucking with him and him specifically due to their hateful and capricious nature

#i mean part of that is just how you feel working in IT i guess#but its funnier that he wants to pretend nothing weird is going on while also expressing his undying hatred for these sentient machines lol#tmagp#tmagp spoilers#tmagp 3#the magnus protocol#colin becher#also lets not gloss over the jmj error. and the sassy beeps when it refuses to run. you know they are getting salty cooped up in there

4K notes

·

View notes

Text

[ID: A colored, simple, three panel comic of teen Gojo Satoru and Megumi Fushiguro.

Panel one: Megumi sits on a stool, feet hanging barely half way down, as Gojo kneels in front of them bandaging their arm and holding their hand. Megumi has Gojo's sunglasses and is labeled "gojo put the sunglasses on them to keep Megumi's hair out of wounds." Gojo says "You got pretty close this time, Gumi! Want my help taming Nue next time?"

Second panel: Megumi from the waist up, looking at her bandaged arm and saying "No. I'm alright Dad." A small cartoon Megumi realizes what they said and goes "wait..."

Third panel: Gojo has a closed eyes smile and says "Okay, Gumi" but is labeled "Trying very very very very hard to play it cool." Multiple loud and ugly crying cartoon Gojo's reflect his real feelings in the background. /End ID]

They proceed to never talk about it again

#jjk#jujutsu kaisen#gojo satoru#megumi fushiguro#fanart#art by this machine#daily doodle:#058#I LOVE DRAWING DADJO AND MINIGUMI SO MUCH RN#Gotta make cute fluff before the manga ends and I have a void in my heart#dadjo#minigumi#i need to make a tag for these little comics#hmmmm#nah#did i accidentally color megumi's eyes blue in that one panel ? yeah....... their pupils are drawn with the line art and i was doing some#fun lineart colors and fucked it up and then forgot and now i'm too lazy to fix it#favorite part of this: megumi is holding gojo's thumb in the first panel#and megumi's outfit is somewhat based off of tojii's#best of this machine#comic by this machine

1K notes

·

View notes

Text

you know what gets me is when f1 drivers take their balaclavas off at the end of a race and the imprints are visible on their face and it looks like the panels on a robot. something about humans extracting themselves from a machine they just spent hours merged with and seeing the marks left by its touch

#guards! play gasoline by halsey#i need to hear the ''you're part of a machine you are not a human being'' line#f1

2K notes

·

View notes