#CNC Stone Router

Explore tagged Tumblr posts

Text

https://aaradhanatech.com/product/exchange-platform-fiber-laser-cutting-machine/

Upgrade your cutting capabilities with Aaradhana Technology's exchange platform fiber laser cutting machine. Get precise, efficient cuts every time.

#wood cnc machine price#co2 laser machine price in india#cnc router machine price#cnc wood carving machine price in india#Automatic Wood CNC Router Machine#CNC Router Engraver#CNC Stone Router

0 notes

Text

CNC Stone Router in Uttar Pradesh: Precision Cutting for Modern Stone Crafting

The stone industry in Uttar Pradesh has evolved significantly with the introduction of advanced machinery like the CNC Stone Router. This high-precision machine has revolutionized granite, marble, and composite stone cutting, enabling intricate designs, temple carvings, and architectural detailing with unmatched accuracy. Whether for monuments, flooring, or decorative art, the CNC Stone Router In Uttar Pradesh is a game-changer for manufacturers, sculptors, and construction businesses.

Why Choose a CNC Stone Router in Uttar Pradesh?

Uttar Pradesh is a hub for stone craftsmanship, particularly in cities like Agra, Lucknow, and Varanasi, where marble and granite work is in high demand. A CNC Stone Router offers several advantages:

Precision Cutting: Ensures flawless engravings, 3D carvings, and complex patterns.

Time Efficiency: Faster than manual carving, reducing production time.

Custom Designs: Ideal for temple architecture, personalized home décor, and commercial projects.

Durability: Built to handle hard stones like granite and marble with minimal wear.

Cost-Effective: Reduces labor costs and material wastage.

Applications of CNC Stone Router Machines

Monuments & Memorials – Intricate engravings for tombstones and statues.

Temple & Religious Artwork – Detailed carvings for idols, pillars, and mandirs.

Flooring & Wall Cladding – Perfectly cut tiles and decorative panels.

Furniture & Home Décor – Custom-designed tabletops, countertops, and artistic pieces.

Commercial Signage – High-precision lettering and logos on stone.

Finding the Best CNC Stone Router in Uttar Pradesh

When selecting a CNC Stone Router in Uttar Pradesh, consider:

Machine Quality: Look for robust construction and high spindle power.

Software Compatibility: Ensure it supports CAD/CAM designs.

After-Sales Support: Choose suppliers offering maintenance and training.

Budget-Friendly Options: Compare prices without compromising on performance.

Top Cities for CNC Stone Router Services in UP

Agra – Known for marble craftsmanship.

Varanasi – Hub for religious stone carvings.

Lucknow – Growing demand for architectural stonework.

Kanpur & Meerut – Industrial and commercial stone applications.

Conclusion

The CNC Stone Router in Uttar Pradesh has transformed traditional stone carving into a high-tech, efficient, and scalable industry. Whether you're a sculptor, architect, or business owner, investing in a CNC Stone Router ensures superior quality, faster production, and endless design possibilities.

For the best CNC Stone Router machines in Uttar Pradesh, connect with trusted suppliers who offer advanced technology and reliable support to elevate your stone craftsmanship.

0 notes

Text

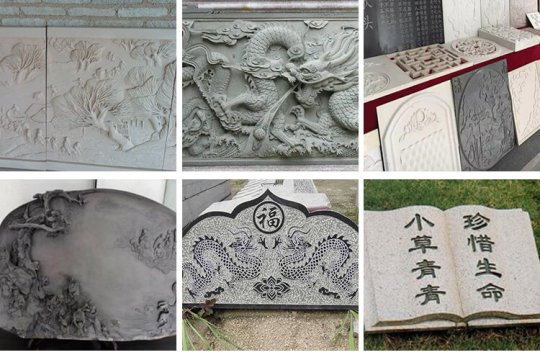

Monument & Tombstone & Gravestone Engraving Machine

CNC stone carving machine can not only emboss stone but also have other very important auxiliary functions. For instance, the stone carving machine can realize CNC stone cutting, CNC stone carving, CNC stone engraving, CNC stone scribing, and CNC stone hollowing.

Tombstone & Gravestone Engraving Machine

Stone engraving machines are tools used to carve, etch, or engrave designs, text, or images into various types of stone such as granite, marble, limestone, and soapstone. These machines utilize carbide or diamond-tipped cutting tools to precisely remove material from the stone surface, allowing for the creation of detailed and intricate stone carvings.

In the memorial industry, the creation of lasting, personalized gravestones and headstones is of utmost importance. Gravestone engraving machines play a crucial role in this process, enabling monument companies and memorial providers to efficiently and accurately engrave text, images, and intricate designs onto a variety of memorial stone materials.

Key Features of Stone Engraving Machines Include

Computer numerical control (CNC) capabilities

Many modern stone engravers are CNC-controlled, allowing for highly precise and repeatable engraving based on digital designs.

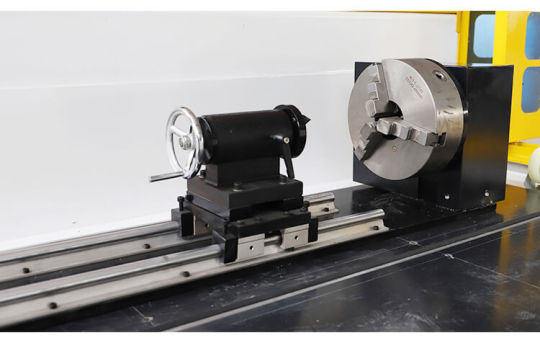

Rotary engraving

Rotary engravers use a spinning cutting tool to carve into the stone surface, enabling engraving of curved or irregular shapes.

3D engraving

More advanced machines can create 3D relief carvings by controlling the depth of the engraving.

Varying tool sizes

Machines accommodate different sized cutting tools to allow for engraving of varying levels of detail. Dust collection systems – Integrated dust collection helps keep the work area clean during the engraving process.

Gravestone Engraving Machines

These are specialized CNC (computer numerical control) engraving machines designed specifically for engraving text, images, and designs onto gravestones, headstones, and memorial markers.

Stone Engraving Machine Kits / Parts

The machines use carbide or diamond-tipped cutting tools to precisely carve the stone surface, creating a clean, high-quality engraved finish. Common materials engraved include granite, marble, limestone, and other types of memorial stone.

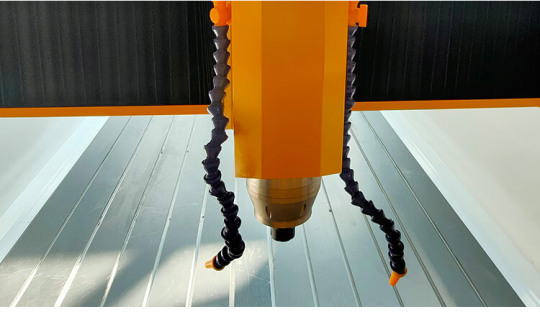

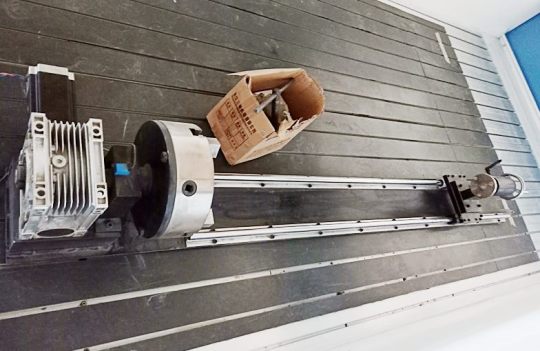

High configuration CNC stone router: Heavy-duty stone CNC machine has a T-shaped bed for seamless welding of generous square tubes, steel gantry, servo motor, 7.5kw spindle, and more advanced CNC controller. The working speed of the machine can be 10000mm/min.

Gravestone engraving machine often have a rotary engraving capability, allowing for engraving of curved surfaces.

Many models offer 3D engraving capabilities to create raised text and bas-relief carvings. The machines are programmed with specialized CAD/CAM software to translate digital designs into the engraved output.

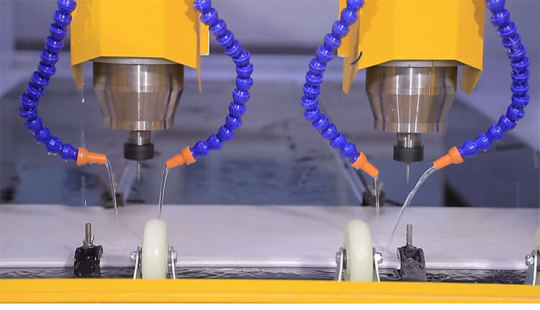

Stone Engraving Machine Kits / Parts

These machines are equipped with a High-Power Spindle that gives the machines extra torque and cutting force to effectively carve and engrave a stone. They are equipped with professional router bits and a bidirectional tool cooling system to effectively improve tool lifespan.

Integrated dust collection systems help keep the work area clean during the engraving process.

These machines allow monument companies and memorial providers to efficiently and accurately engrave gravestones to customer specifications.

The precision and detail possible with gravestone engraving machines are critical for creating high-quality, long-lasting memorial markers.

Gravestone Engraving Machine other Applications

Stone Industry

Granite, marble, quartzite, slate, sandstone, alabaster, basalt, jade, limestone, travertine, artificial stone, tombstone, headstone, cemetery, and memorial.

Kitchenware

Slate countertops, artificial quartz countertops, artificial marble table top, ceramic tile, and kitchen decorations for sink, oven, cooktop.

Decorations

Stone crafts, gifts, jewelry, wall decoration, building decoration, portrait, Buddha statue, and some exquisite stone arts.

Woodworking

Chair, door, window, bed, cabinet, kitchenware, redwood classical and antique furniture, exquisite european furniture, sculpture.

Mold Making

Copper, aluminum, building models, shoes, badge, embossed mould, biscuit, candy, chocolate mould, artificial marble, plastic, PVC, wood, foam.

Advertising

Billboard, signage, badges, logo, company plate, signs, emblem, badge, display panels, fair signs, building numbers, decoration, 3D character.

How to choose the best stone CNC machine?

The following is a brief introduction: When purchasing a marble headstone engraving machine, you should pay attention to the following points:

1.what should be considered is the power of the 3d stone carving machine. Because the hardness of the stone is relatively large, usually, the stone carving machine needs to be equipped with a larger spindle motor than the advertising engraving machine and wood engraving machine in order to carry out high-intensity work.

2.The speed adjustable range of the spindle motor of the stone cutting router, the general adjustable speed range is several thousand to 30,000 revolutions per minute, if the speed is not adjustable or the speed adjustable range is very small, then the application of this cheap stone cutting machine The range will be greatly affected because different materials must be engraved with different engraving speeds.

3.The solidity of the stone carving machine base, the material carved from stone is relatively heavy, and the CNC stone cutter is required to have a good load-bearing capacity.

4.The cooling and dust-proof system of the stone carving router machine. The stone carving process will produce high temperatures and a lot of dust, so this CNC stone machine should have good heat dissipation and dustproof functions.

5.The controller of The CNC stone router.

Controllers are generally divided into two categories: a controller is just a driver, and all calculations are done by the computer. When the engraving machine is working, the computer is in a waiting state and cannot perform typesetting. Another type of controller is controlled by a single-board computer or a single-chip computer. This kind of controller is actually a computer, so as long as the granite cutting machine starts to work, the computer can immediately perform other typesetting work, especially when engraving for a long time. The advantages are particularly obvious.

6.Screws and guide rails are also an important part of AAA. When using the marble engraving machine for a long time, good screws and guide rails are the guarantees of accuracy and performance.

7.please try carving before buying.

Regardless of the type of CNC stone machine purchased, the user should go to the manufacturer for on-site investigation or ask the manufacturer of the CNC router machine for proofing. To test whether the performance of this stone CNC carving machine can meet the demand.

STONE CNC MACHINE, STONE CNC MACHINECNC Stone Cutting & Carving Machine

STONE CNC MACHINECNC Glass Milling Drilling and Cutting Machine

STONE CNC MACHINECNC Glass Cutting Machine for Sale

CNC ROUTER, STONE CNC MACHINECNC Stone Cutting And Polishing Machine for Quartz

STONE CNC MACHINEWater Jet Cutting Machine

CNC ROUTER, STONE CNC MACHINENew CNC Bridge Saw for Granite & Marble Stone Cutting Machine

CNC ROUTER, STONE CNC MACHINEStone CNC Router Machine – Marble CNC Machine

STONE CNC MACHINEStone CNC Router Cutting & Engraving Machine

STONE CNC MACHINEMarble, Granite Tombstone 3D Stone Sculpture Machine

STONE CNC MACHINE, STONE CNC MACHINELarge Rock CNC Engraving Machine With Best Price

CNC ROUTER, STONE CNC MACHINEFive Axis Stone Bridge Cutting Machine IGS-B (Upgrade)

CNC ROUTER, STONE CNC MACHINE, STONE CNC MACHINEBridge Saw Machine 4-Axis And 5 Axis For Granite Marble

4 Axis 5 Axis Cutting Bridge Saw

5 Axis CNC Stone Cutting Bridge Saw for Granite & Marble

This stone CNC machining center can cut quartz, marble, granite, and rock slabs with a powerful saw blade. It combines a saw blade and CNC router tools to achieve multiple advanced functions. For example, cutting and milling straight and inclined edges, chamfering, cutting arc edges, polygon, edge milling, edge tracking, and other powerful functions. The 5 axis bridge saw is widely used in the stone processing plants, kitchen countertop processing, background wall profiling, and other fields.Request a Quote

Auto CNC Bridge Saw Stone Cutting Machine

CNC Bridge Saw for Marble, Quartz Stone,Tile Cutting

5 Axis CNC Bridge Saw for Quartz, Granite, Marble(2024 Upgraded)

4 +1 Axis Stone Bridge Saw for Marble Granite and Quartz

5 Axis CNC Stone Cutting Bridge Saw for Quartz Granite Marble

Automatic CNC Glass Drilling Milling Machine

Glass Milling Drilling Edge Grinding Polishing Machine

Stone Water Jet Cutting Machine

Waterjet Cutting Machine Equipment

CNC Waterjet Cutting Machine for Sale

3020 ATC Quartz Stone CNC Machining Center

CNC Stone Carving Machine

Stone CNC router is a computer numerical controlled machine tool used for CNC stone carving, CNC stone engraving, and CNC stone cutting. The stone router machine can complete functions of engraving, carving, cutting, milling, and polishing of granite, quartz, marble, tombstone, ceramic tiles, and other artificial stones. Therefore, we also call it marble CNC router, marble carving machine, granite CNC router, CNC granite cutting machine for sale, quartz stone machine, etc.

The stone engraving machine is a high-tech fully automatic computer-controlled engraving equipment capable of engraving and painting on natural stone, glass and ceramics. It can meet the requirements of personalized home decoration and tooling art design. It can be used as a decoration company, handicraft industry, stone industry , Inscription industry, ceramic company advanced carving processing equipment.Request a Quote

CNC Stone Carving Machine for Marble Granite with Rotary Axis

CNC Stone Granite Marble Carving Machine

CNC 3D Stone Carving Machine With 4th Axis Rotary

Customized 1825 CNC Stone Cutting Carving Machine

Learn More →

0 notes

Text

"Unlocking Precision and Creativity: A Comprehensive Guide to CNC Routers for Modern Makers"

In the realm of modern manufacturing and creative design, CNC routers have become indispensable tools, blending precision with creativity to produce stunning results. Whether you’re a seasoned craftsman or a newcomer eager to explore the world of CNC routing, mastering these machines can elevate your projects to new heights. This guide will delve into essential tips and techniques to help you unlock the full potential of your CNC router and achieve exceptional craftsmanship.

2 notes

·

View notes

Video

youtube

4 axis cnc stone marble granite carving machine, 4 axis stone cnc router...

0 notes

Text

Aaradhana CNC Stone Routers in Uttar Pradesh – Precision Stone Cutting Solutions

n the heart of India's stone industry, Aaradhana has emerged as a trusted name among CNC Stone Router manufacturers in Uttar Pradesh. Specializing in high-precision stone carving and engraving machines, we provide advanced solutions for granite, marble, and composite stone fabrication. Our CNC Stone Routers in Uttar Pradesh are engineered for accuracy, durability, and superior performance, making them ideal for temples, monuments, countertops, and architectural designs.

Why Choose Aaradhana CNC Stone Routers?

1. Unmatched Precision & Customization

Aaradhana’s CNC Stone Routers in Uttar Pradesh use advanced servo motors and high-speed spindles to deliver intricate carvings with micron-level accuracy. Whether you need floral patterns, religious motifs, or 3D sculptures, our machines ensure flawless execution.

2. Robust Build for Heavy-Duty Performance

Designed for Uttar Pradesh’s thriving stone industry, our routers feature:

Reinforced steel frames for vibration-free operation

Diamond-tipped tools for smooth granite/marble cutting

Dust-proof systems to enhance machine longevity

3. Smart Automation & User-Friendly Controls

Aaradhana integrates IoT-enabled controls and CAD/CAM compatibility, allowing operators to upload designs seamlessly. Our CNC Stone Routers In Uttar Pradesh support:

3D/4D engraving

Batch production mode

Auto-tool changers

4. Affordable & Low-Maintenance Solutions

Compared to imported machines, Aaradhana offers cost-effective CNC Stone Routers in Uttar Pradesh with:

Local service support

Energy-efficient operations

Easy-to-replace spare parts

Applications of Aaradhana CNC Stone Routers

Temple & Monument Carving: Perfect for intricate deity statues and heritage designs.

Kitchen Countertops: Precision-cut edges for marble/granite slabs.

Architectural Cladding: Custom patterns for flooring and wall panels.

Signage & Memorials: Detailed lettering and portraits.

Serving Uttar Pradesh’s Stone Hub

Uttar Pradesh, home to Agra, Varanasi, and Lucknow, has a booming demand for stone craftsmanship. Aaradhana’s CNC Stone Routers in Uttar Pradesh empower local artisans and factories to: ✔ Boost productivity by 5X compared to manual carving ✔ Reduce material wastage with optimized cutting paths ✔ Expand business with high-quality, export-ready products

Future-Ready Stone Technology

Aaradhana is pioneering AI-assisted design libraries and cloud-based monitoring for its CNC Stone Routers in Uttar Pradesh. We aim to make stone fabrication smarter, faster, and more sustainable.

Partner with Aaradhana Today!

As a leading CNC Stone Router manufacturer in Uttar Pradesh, Aaradhana combines Indian engineering excellence with global standards. Our machines come with training, warranty, and 24/7 technical support.

0 notes

Text

Stone CNC Engraving Tombstone Headstone Machine

A stone CNC machine is an automatic power tool with computer numerical controller for hobbyists and industrial manufacturer to make custom stone machining for artwork, decorations, souvenirs, gifts, crafts, tombstones and home improvement. It is capable of carving, engraving, cutting, polishing for basalt, granite, quartzite, limestone, marble, onyx, jade, travertine, alabaster, sandstone, slate, soapstone.

CNC Tombstone Headstone Carving Machine

CNC stone craving machine offer great design flexibility. They can reproduce intricate patterns, decorative motifs, personalized messages, and even photo-realistic images with high accuracy. The software used in conjunction with the machine allows for precise control over the depth, width, and intricacy of the engravings.

CNC machines automate the engraving process, reducing the need for manual labor and increasing overall efficiency. Once the design is programmed, the machine can work autonomously, reducing production time and ensuring consistent quality.

A CNC stone engraving machine for tombstones and headstones is a specialized device used in the monument and memorial industry. These machines are designed to precisely engrave or carve designs, text, and other features onto stone surfaces like granite or marble.

CNC Tombstone Engraving Machine for Sale

Because the machine is a CNC stone engraver machine, in order to make the machine bear the weight of the stone, we adopted a T-type heavy machinery structure and the gantry is made of tubular steel, so this CNC tombstone engraver machine can bearing more than 2000kgs materials.and the Thick Aluminum & Hard PVC T-Slot Table makes the machine can easily fix the stone on the work table.

This stone CNC machine is equipped with an advanced 5.5kw water-cooled spindle, which can be controlled by a program, and the frequency range is from 6000 to 24000 RPM. It can meet the requirements of stone carving, cutting, lettering, polishing, and other operations. This ensures that this granite cutting tool can maintain high work efficiency

This Stone CNC Router utilizes brushless microstepper motors. These motors require no regular maintenance — therefore the machine can work efficiently. At the same time this CNC tombstone machining machine come standard with 5.5kw high frequency water cooling spindle, this spindle produces low noise and high cutting precision.

Even if you are a person who has never used CNC stone router machine, you can quickly learn how to operate this CNC tombstone machining machine.it has Automatic tool calibration which can easily and accurateily “Z” zero position for single and multiple tool changes.You can use the DSP hand controller to control this machine without connecting to the computer.

High Quality Cnc Granite Cutting Tools Engraving Machine

This Stone CNC Machine adopts an advanced machine tool construction concept and unique heavy-duty mechanical structure make our granite cutting tools not easy to deform and have excellent load-bearing capacity. At the same time, in order to improve the accuracy of stone relief, we have specially designed Zaxis, which not only improves the accuracy but also solves the problem of ball screw or Zaxis belt breaking. In terms of power, This stone design machine uses a motor with excellent performance to work, which ensures the accuracy and high speed of the stone design machine at work. This also makes granite router bits of granite cutting tools have greater momentum.

Advanced Stone CNC Machine Granite Cutting Tools

To make the service life of the stone CNC machine longer, The stone CNC machine has selected the advanced waterproof and dustproof system for the X Y Zaxis, which can protect all parts and reduce the number of product failures. The spindle adopts the famous water-cooled brushless spindle (5.5KW Powerful Water Cooling Spindle), which has the characteristics of strong cutting ability, low noise, and long working hours. At the same time, the stone design machine adopts Taiwan Hiwin square rail, XY axis German helical rack, and pinion, Z-axis high precision TBI ball screw, which are all durable stone CNC machine accessories and granite cutting tools.

Multifunctional Marble Granite Cutting Tools Machine

Our stone CNC cutting Machine is a stone design machine that can carry out multi-functional engraving on stone and can engrave a variety of stones, such as marble, granite, sapphire, quartz. And this stone CNC machine equipped with the advanced Mach 3 operating system, which can be used with all industry-standard CAD/CAM software to cut, drill, engrave and engrave the stone. It has a wide range of applications and can be used for carving memorial boards, furniture, bas-reliefs, tombstones, stone countertops, and other stone products. This granite letter cutting machine is a granite cutting tool machine very suitable for small and medium-sized stone processing plants.

Applications

Applicable Materials:

Headstone, memorial stone, granite tombstone, natural marble, granite, bluestone, sandstone, artificial stone, milestone, ceramic tile, jade, crystal, glass, plastic, wood, bamboo and so on, it can do 3D embossment, line carving, bevelling and laser engraving.

Applicable Industries:

Stone Industry: Headstone, memorial stone, granite tombstone, natural marble, granite, bluestone, sandstone, artificial stone, milestone, ceramic tile, jade, etc.

Kitchen Ware Industry: Man-made marble cabinet table surface.

Artwork Decoration Industry: Wood crafts, gift box, jewelry box and other exquisite art crafts.

Mold Industry: Engraving copper, aluminum, and other metal molds; Building models, shoes, badge, embossed mould, biscuit, candy, chocolate mould; Artificial marble, plastic sheeting, PVC, wood, foam and other non-metallic mold.

Advertising Industry: Billboard, signage, badges, logo, company plate, signs, emblem, badge, display panels, fair signs, building numbers, signs of decoration, literal hole cutting etc.; 3D character cutting, acrylic cutting, LED/neon channel, lightbox;

The laser head is available for engraving and cutting nonmetal materials, such as acrylic,color plates,ABS board,rubber,plastic,cloth toys,leather ,wool, crystal, glass, ceramic tile, jade, bamboo products, wood products.

Features and A dvantages of the Stone CNC Router

Automatic leveling function: It can correct the concave, convex, and uneven slope of any stone surface. The software automatically generates a new program based on the floating of the stone surface, which conforms to the surface characteristics of the stone.

Stable table structure: The table adopts a high-quality steel structure and double beam design. And its gantry and work surface are respectively supported by reinforced beams. Therefore, the stone carving machine has the advantages of bearing load, no deformation, and high stability.

Super cutting ability: The stone carving machine has the features of greater torque force, smoother operation, precise and powerful cutting point. And Y-axis uses the dual-motor synchronous drive.

Longer service life: Use stainless steel sink, protection plate, and other parts to fully protect the transmission parts and electrical components.��So that the CNC stone engraving machine has a long service life. Advanced professional control system: It can be compatible with Type3 / Artcam / Castmate / pro-e / Ug / Cad / IIIustrator / Wentai / Jingdiao and other software.

0 notes

Text

Carbide Bit: The Ultimate Guide for Precision Cutting and Drilling

In this article we'll go over everything you should learn about carbide bits, including their definitions, their types and benefits, as well as applications and how to pick the best one.

What is a carbide bit?

The carbide bit is an instrument for cutting or drilling constructed from tungsten carbide, which is a metal compound that is renowned for its extraordinary hardness and resistance to heat. Tungsten carbide is typically combined with cobalt in order to create a composite that is substantially more durable than steel, making it suitable for hard materials such as hardened steel, ceramics, cast iron, and composites.

In contrast to regular high-speed steel (HSS) bits, carbide bits keep their sharpness for longer and run at higher speeds without deteriorating.

Types of Carbide Bits

Carbide bits are available in a variety of designs, each designed to suit specific applications and materials. The most popular types are

1. Carbide Drill Bits

For precision drilling in ceramics, metals, as well as stone. These are great for CNC production drilling and machining.

2. Carbide Burrs

Rotary files are used to shape grinding, shaping, and deburring surfaces of metal. Available in various shapes such as ball, cylinder flame, cone, and cylinder.

3. Carbide End Mills

Milling machines use milling to cut slots, contours, and forms within hard materials.

4. Carbide Router Bits

Commonly employed in woodworking for shaping, trimming, and sizing.

5. Carbide Nail Drill Bits

In beauty salons, they are popular for doing manicures and pedicures. These bits are employed by electric nail drills to form and tidy nails.

Key Advantages of Using Carbide Bits

Carbide bits provide a variety of advantages over traditional HSS or steel bits:

1. Extreme Hardness

Tungsten carbide is about twice as rigid as steel and can withstand extreme loads without deforming.

2. Superior Heat Resistance

Carbide bits are efficient in dispersing heat, which allows for high-speed operation without losing control of the process.

3. Longer Tool Life

Due to their toughness and wear resistance, the carbide bits last longer, which reduces the number of times they need to be replaced.

4. Precision and Clean Cuts

They make cleaner, more precise cuts that have no burrs or edge fraying.

5. Cost Efficiency Over Time

Although they are more expensive initially, however, the durability and performance of carbide bits typically results in less overall cost for tools.

Common Applications of Carbide Bits

Carbide bits are utilized in many industries, including

Metalworking

Drilling, cutting, and shaping stainless steel, aluminum, steel, and titanium.

Woodworking

Cutting, shaping, and engraving using router bits.

Construction

In hammer drills, it is used to cut through concrete, stone, and masonry.

Cosmetics

Electric nail drills are equipped with carbide bits for secure and efficient nail treatment.

CNC Machining

Automated turning and milling of metal components that are complex within manufacturing settings.

How to Choose the Right Carbide Bit

The choice of the right carbide bit is dependent on the specific needs of your application:

1. Material Being Cut

Make use of carbide bits that are coated for high-friction or abrasive materials.

Pick non-coated pieces for non-ferrous metallics and plastics.

2. Bit Geometry

The flute design can affect cutting speed and removal of chips.

Point angle influences entry speed and accuracy.

3. Bit Size and Shank Type

Check compatibility with your tool or machine, whether it's a hand drill, CNC, or rotary tool.

4. Coating Type

TiN (Titanium Nitride): Increases hardness and longevity.

TiAlN (Titanium Aluminum Nitride): Better for applications with high temperatures.

Diamond Coated is ideal for composites, ceramics, and PCB fabrication.

Tips for Using Carbide Bits Effectively

To increase the performance and longevity of your carbide bits

Use the proper speeds and feed rates determined by the material's hardness.

Use coolant or cutting fluid to help reduce the amount of heat that builds up.

Avoid pressure from the side Carbide is hard, but it is also brittle.

Make sure to clean the part often to avoid buildup of residue.

It is important to store HTML0 in a safe way to avoid damage caused by accidental drops or collisions.

Carbide Bit vs. HSS Bit What's the difference?

Feature

Carbide Bit

HSS Bit

Hardness

Extremely difficult to work with

Less challenging

Heat Resistance

Very high

Moderate

Cost

Costs of upfront costs that are higher

Lower initial cost

Durability

Longer lifespan

Wears out more quickly

Cutting Speed

Higher

Lower

Best Use Case

Hard materials, long runs

General use, soft materials

Frequently Asked Questions (FAQs)

Q1. Are carbide pieces soft?

While carbide is extremely tough, however, it may become brittle when pressure is applied to it or misused. Always handle it with care and employ the correct methods.

Q2. Can I sharpen carbide bits?

Yes, carbide bits can be sharpened with diamond wheels or sharpening tools made by professionals.

Q3. Do carbide bits work to be used in DIY projects?

Absolutely. Many DIYers utilize carbide bits for metalworking, woodworking, or precision drilling due to their excellent quality and long-lasting nature.

Q4. What is the difference between carbide-tipped and solid carbide?

Solid carbide bits are composed entirely of tungsten carbide.

Carbide-tipped bits are only equipped with the cutting edge, which is made of carbide. The remainder of the body is constructed from steel.

Final Thoughts

Carbide bits are a great investment in precision, performance, and durability. No matter if you're a professional machinist or a contractor, or even a hobbyist, the right carbide bits can dramatically improve your results as well as reduce the amount of time you have to change your tool.

When selecting carbide bits, take into consideration the application, the material coating, the material, and the geometric shape of the bit to ensure maximum performance. With proper use and care, carbide bits could be among the most cost-effective tools you can have in your production line or workshop.

0 notes

Text

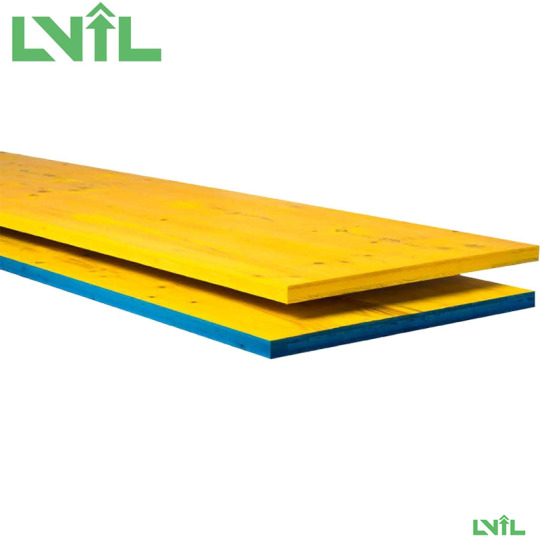

What Is Melamine Particle Board? Comparison with Plywood and MDF

How Are Melamine Particle Board Manufactured?

Melamine particle board are crafted through a process involving melamine resin, initially an organic compound that undergoes polymerization to become a robust and durable plastic material. Essentially, melamine is a chemical compound derived from an organic base and acts as a trimer of cyanamide.

Melamine Laminate is typically resistant to stain, heat, and fire. It’s moisture and scratch-resistant and can be found in many colors, patterns, sizes, and thicknesses making it ideal for particleboard, plywood, or MDF applications. Melamine is more like small pieces of wood (particleboard) glued and pressed together and covered with a plasticized coating.

Uses of Melamine

The term "melamine" finds extensive application not only in cabinet construction but also in various other industrial sectors unrelated to construction.

For instance, melamine laminate serves as a key material not only in crafting woodworks such as shelves and cabinets but also in the resin utilized for Formica and other laminated countertops commonly found in kitchens.

Moreover, melamine is widely employed in the manufacture of floor tiles. Melamine tile floors offer enhanced glossiness, scratch resistance, reduced susceptibility to staining, and easier maintenance compared to porcelain or stone alternatives. Importantly, they also tend to be more cost-effective.

Given the glossy finish of melamine-coated boards and their ability to resist surface scratches, melamine proves to be an excellent material for the production of whiteboards.

Advantages of Melamine Wood

Melamine engineered products are often more budget-friendly while maintaining reliability.

Melamine boards boast a consistent surface that is highly durable and resistant to scratches, stains, heat, and fire.

The waterproof nature of typical melamine surfaces allows for easy cleaning with soap and water.

Many prefer the absence of wood grain in melamine boards, especially those seeking solid-colored cabinets, as melamine is readily available pre-finished in various colors.

It offers a smooth finish, ready for use with minimal construction waste.

Cutting melamine is relatively straightforward with the right equipment, such as a saw with a scoring unit or CNC routers, which help prevent chipping. Proper material support during cutting reduces the risk of breakage.

Disadvantages of Melamine Board

Melamine boards are prone to bending and warping under heavier loads.

Due to its composite composition, melamine material tends to be heavy.

Melamine boards are manufactured using glues that can emit Volatile Organic Compounds (VOCs), which, according to the United States Environmental Protection Agency, may have adverse health effects in both the short and long term.

Comparing Melamine with Plywood

Melamine board offers distinct advantages when compared to plywood. While plywood board is known for its strength and natural wood grain appearance, melamine board provides a cost-effective alternative with increased durability and moisture resistance. It offers a wide range of attractive finishes, allowing for diverse design options.

Moreover, melamine board demands minimal upkeep and exhibits lower susceptibility to warping or delamination when contrasted with plywood. These attributes have propelled melamine board to become a preferred option in furniture production, especially when factors like durability, cost-effectiveness, and aesthetic appeal are pivotal. Although plywood possesses its own strengths, the benefits of melamine board render it an enticing choice for furniture designers and manufacturers aiming for a versatile and pragmatic material.

Comparing Melamine with MDF

Fiberboards, particularly MDF board (Medium Density Fiberboard), offer a cost-effective option for those looking to outfit modern kitchens, bathrooms, and interior furniture.

This material is composed of numerous wood fibers mixed with wax and resin under high pressure and temperature conditions.

Fiberboards available in the market are classified based on their densities, which are determined by the levels of temperature and pressure during manufacturing. Consequently, HDF (High Density Fiberboard) requires higher levels of pressure and temperature compared to MDF.

In summary, MDF falls in between HDF and particleboard in terms of density, with particleboard having the lowest density and exhibiting larger wood grains.

Comparing Melamine with solid wood, plywood, or fiberboards is a complex task.

Melamine is a popular plastic material widely used by modern cabinet builders. It can be applied as a laminate onto substrates such as plywood or particleboard, or it can be incorporated into the construction of kitchen cabinets, particularly when combined with MDF or particleboard. These substrates, made from wood chips, are used to form High Pressure Laminate (HPL) or Thermally Fused Laminate (TFL). Consequently, direct comparisons between melamine and MDF or particleboard can be challenging.

One of the key advantages of melamine is its durability and high resistance to scratches, along with its extensive range of colors and patterns. This versatility makes melamine fused with plywood arguably one of the most sustainable options for cabinetry.

Previous:The Benefits and Safety of LVL Scaffold Planks in Construction

Next:LVL vs. Solid Wood Window Frames: Choosing the Right

0 notes

Text

Stone CNC Machine for Perfect Finishes

In the world of stone carving and machining, precision is everything. Whether it's creating intricate sculptures, countertops, or architectural features, a stone CNC machine is the key to achieving flawless results. These machines bring cutting-edge technology into traditional stonework, making processes faster, more efficient, and highly accurate. Using a stone CNC machine can improve the quality of your work, and investing in a CNC machine can greatly improve your business.

What is a Stone CNC Machine?

Stone CNC machine is a computer-controlled system that is designed to cut, carve, and engrave stone with precision. CNC stands for Computer Numerical Control, meaning the machine follows precise instructions given by computer software to perform specific tasks. This automation allows for a level of accuracy that manual methods simply cannot match.

Stone CNC machines come in various types, including routers and mills, with some models offering 3, 4, or even 5-axis capabilities. These machines can work with a variety of materials, including granite, marble, limestone, and even synthetic stones, to create everything from simple engravings to complex, three-dimensional sculptures.

The Advantages of Using a Stone CNC Machine

1. Precision and Accuracy

The most obvious benefit of using a stone CNC machine is the precision it offers. Manual carving, engraving, or cutting stone can be incredibly challenging and time-consuming, especially when aiming for high levels of detail. With a CNC machine, your designs are created with millimeter accuracy, ensuring consistent results with every project. This is especially useful for businesses that require repetitive tasks, such as cutting countertops or engraving gravestones.

The ability to work with complex 3D designs also sets CNC machines apart from traditional methods. Whether you're creating intricate patterns or highly detailed stone sculptures, the CNC machine can bring your vision to life without compromising on quality.

2. Increased Efficiency and Productivity

The automation of a stone CNC machine means faster production times and higher output. Once you input your design into the system, the machine does the rest. This significantly reduces the time spent on manual labor, allowing your business to take on more projects and increase revenue.

Moreover, CNC machines often operate 24/7 with minimal supervision. Once set up, they can continue to work on multiple pieces simultaneously, maximizing productivity and keeping costs low.

3. Cost-Effective in the Long Run

While the initial cost of purchasing a stone CNC machine might seem high, it is a sound investment for businesses looking to scale. The automation process reduces labor costs, lowers material wastage, and improves production efficiency. Over time, these savings will far outweigh the initial purchase price.

Additionally, the precision of CNC machines helps minimize errors during production. With less rework and waste, you’ll save money in the long term. The machines also require minimal maintenance, further reducing operational costs.

4. Versatility Across Various Applications

Stone CNC machines are incredibly versatile, making them useful in a variety of industries. Whether you're in the construction, monument, or artistic stone carving sector, these machines can handle it all. Some of the most common applications include:

Monument and Tombstone Engraving: Whether it's a traditional or contemporary design, CNC machines offer the precision needed for memorial stone engraving.

Countertop Fabrication: With the ability to cut and shape granite, marble, and other hard stones, CNC machines are perfect for creating countertops with intricate designs.

Architectural Features: From columns to ornate stone carvings, CNC machines can carve intricate architectural features that are both functional and aesthetically pleasing.

Sculpture and Artwork: Artists and sculptors can use CNC machines to create highly detailed sculptures and relief carvings, offering a level of artistry that manual tools simply cannot replicate.

Key Features to Look for in a Stone CNC Machine

When selecting a stone CNC machine, it's crucial to evaluate several factors to ensure you choose the right one for your business. The number of axes is an essential consideration. Stone CNC machines come in 3-axis, 4-axis, or 5-axis CNC stone machining center. A 3-axis machine is suitable for basic cutting, engraving, and carving tasks. For more complex shapes and deeper carvings, a 4-axis machine offers additional rotational capabilities. However, if you're looking for maximum flexibility and the ability to work on all sides of the stone, a 5-axis machine is ideal for creating intricate 3D shapes with precision.

Additionally, the software compatibility of the machine plays a significant role in its functionality. Machines that work with popular CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) programs, such as AutoCAD, Rhino, and Mastercam, allow for seamless design-to-production workflows, ensuring the accuracy of your designs. The quality of cutting tools is also vital for achieving smooth, precise cuts. Look for machines that are compatible with diamond-tipped tools to guarantee high-quality finishes on your stone materials.

Machine Stability and Durability for High-Precision Work

The stability of the CNC machine is critical for precise stone cutting and carving. A solid, stable frame made from durable materials like steel or cast iron ensures minimal vibration during operation. This reduces errors and ensures smoother, more accurate cuts. Stone CNC machines are subjected to significant forces during operation, so choosing a machine with a sturdy construction will not only enhance cutting precision but also extend the longevity of the machine. Machine stability is a key factor in producing consistent, high-quality results across various stone projects.

Maintenance and Care for Your CNC Stone Machine

While stone CNC machines are generally low-maintenance, it’s important to follow a regular maintenance routine to ensure longevity and optimal performance. Here are some tips:

Regular Cleaning: Stone cutting generates dust and debris, which can clog up the machine. Clean the machine regularly to keep it running smoothly.

Lubrication: Ensure the moving parts of the machine are well-lubricated to prevent friction and wear over time.

Check for Wear and Tear: Regularly inspect the machine for any signs of wear, especially on cutting tools. Replacing worn-out parts will ensure the machine continues to produce high-quality results.

Calibration: Periodically recalibrate the CNC machine to ensure it maintains its accuracy and precision.

Conclusion

Stone CNC machine can revolutionize the way you approach stone carving, cutting, and engraving. The precision, efficiency, and versatility it offers can drastically improve your production capabilities and the quality of your work. Whether you’re creating complex sculptures, countertops, or architectural features, a CNC machine can help you achieve perfect finishes with minimal effort.

If you're in the market for a stone CNC machine, it's essential to choose a machine that suits your specific needs and budget. Look for key features like the number of axes, software compatibility, and cutting tools to make the best decision for your business.

By incorporating a stone CNC machine into your production process, you can stay ahead of the competition, improve your workflow, and deliver top-notch stonework to your clients every time.

FAQ

1. How accurate are stone CNC machines? Stone CNC machines are incredibly accurate, capable of producing cuts and carvings down to millimeter precision. This level of detail ensures high-quality results, especially for intricate designs.

2. What types of stone can a CNC machine cut? CNC machines can cut a variety of stones, including granite, marble, limestone, and sandstone. They are also capable of working with synthetic stones and composites.

3. How long does it take to complete a project with a CNC stone machine? The time required for a project depends on its complexity and size. However, CNC machines can complete tasks much faster than manual methods, improving production time significantly.

4. Do CNC stone machines require a lot of maintenance? CNC stone machines are relatively low-maintenance. Regular cleaning, lubrication, and tool replacement are all that’s needed to ensure the machine runs efficiently.

5. Can I use the same CNC machine for both cutting and engraving stone? Yes, many stone CNC machines are versatile enough to handle both cutting and engraving tasks. Ensure that your machine has the appropriate tooling and software to perform both functions.

0 notes

Text

Showcasing Creativity: The Craft of Custom Sign Makers

In a world brimming with visual competition, custom signs have emerged as more than just a medium for communication; they’re works of art. Behind these striking pieces of craftsmanship are skilled custom sign makers who blend creativity, technical expertise, and an understanding of branding to produce signage that commands attention.

The Evolution of Sign Making

Signage has been around for centuries, evolving from simple stone carvings to sophisticated digital displays. However, custom sign makers focus on a more personalized approach, creating pieces tailored to the unique needs and identity of their clients. From hand-painted wooden boards to neon-lit marvels, the craft has transformed into a dynamic intersection of tradition and innovation.

The Creative Process Behind Custom Signs

Every custom sign starts as an idea. Here’s a glimpse into the creative process:

Client Consultation: Understanding the client’s brand, audience, and vision is crucial. Whether it’s a cozy café or a cutting-edge tech firm, the design needs to resonate with its target audience.

Concept Development: Using design software and sketches, sign makers bring ideas to life. Colors, fonts, shapes, and materials are selected to align with the brand’s identity.

Material Selection: Modern sign makers have a plethora of materials at their disposal, from rustic wood to sleek acrylic, vibrant LEDs, and durable metals.

Fabrication: This is where the magic happens. Advanced tools like CNC routers, laser cutters, and 3D printers often complement traditional handcrafting techniques to create the final product.

Installation: A well-made sign is only as impactful as its placement. Sign makers ensure optimal positioning and durability for maximum visibility.

The Role of Creativity

Custom sign makers are more than technicians; they are artists. They combine typography, color theory, spatial awareness, and artistic flair to design signs that leave lasting impressions. Creativity plays a vital role in:

Brand Differentiation: A unique sign helps businesses stand out in crowded marketplaces.

Storytelling: Effective signage tells a brand’s story at a glance, fostering an emotional connection with viewers.

Aesthetic Appeal: From minimalist elegance to bold statements, custom signs contribute to the overall ambiance of a space.

The Impact of Custom Signs

Well-crafted custom signs are investments that deliver measurable benefits:

Enhanced Visibility: An eye-catching sign draws customers to your door, increasing foot traffic.

Brand Reinforcement: Consistent, well-designed signage strengthens brand recognition.

Longevity: High-quality custom signs often outlast generic, mass-produced alternatives, making them cost-effective in the long run.

Challenges and Opportunities

The craft of sign making isn’t without its challenges. Balancing creativity with functionality, meeting tight deadlines, and staying within budget constraints can be demanding. However, advancements in technology, such as augmented reality (AR) for design visualization and sustainable materials, are opening new doors for innovation.

Why Custom Signs Matter

In today’s competitive landscape, a cookie-cutter approach simply doesn’t cut it. Custom signs enable businesses to communicate their uniqueness, create memorable first impressions, and establish a strong visual presence. They transform spaces, guide customers, and bring a brand’s identity to life.

Conclusion

Custom sign makers are unsung heroes of the creative industry. Their work goes beyond crafting functional signage; they produce masterpieces that inspire and communicate. Whether it’s a small business looking for its first storefront sign or a global corporation rebranding its image, custom sign makers turn visions into reality.

Next time you pass by a stunning piece of signage, take a moment to appreciate the artistry and craftsmanship behind it—it’s more than just a sign; it’s a story

0 notes

Text

Are you a dynamic professional with a passion for sales and coordination? Unistar Industries, a leader in CNC router production, is looking for a dedicated Sales Coordinator to join our team. You’ll manage client interactions, streamline sales processes, and support our sales team in achieving targets. If you have strong organizational skills and a background in sales, this is your opportunity to grow with us. Apply now and take the next step in your career!

0 notes

Text

Stone CNC Router Machine

In the world of stone fabrication, precision, efficiency, and versatility are key. At GK Laser Enterprises, we understand that our clients need advanced technology to stay ahead in the competitive market. That's why we're proud to introduce our Stone CNC Router Machines – a game-changer in the stone-cutting industry.

What is a Stone CNC Router Machine? A Stone CNC (Computer Numerical Control) Router Machine is a state-of-the-art tool used for cutting, carving, engraving, and shaping stone materials. Unlike traditional methods, which rely heavily on manual labor and hand tools, CNC routers utilize computer-aided design (CAD) and computer-aided manufacturing (CAM) to perform intricate tasks with unmatched precision and efficiency.

How Does It Work? The magic of a Stone CNC Router Machine lies in its advanced software and robust hardware. Here's a step-by-step overview of how it operates:

Design Creation: The process begins with creating a digital design using CAD software. This design is a precise blueprint of the desired outcome, whether it's a detailed engraving or a complex cut.

Programming: The CAD design is then converted into a CAM file, which contains the instructions for the CNC machine. This file is uploaded to the CNC router's computer.

Setup: The stone material is securely placed on the machine's worktable. The CNC router is equipped with various cutting tools, which are selected based on the type of stone and the specific task.

Execution: Once everything is set, the machine executes the programmed instructions with high-speed precision. The router's spindle moves along the X, Y, and Z axes, following the design's path and performing cuts, carvings, or engravings.

Finishing: After the machining process is complete, the stone piece may require some finishing touches, such as polishing or additional detailing, to achieve the desired look.

Why Choose a Stone CNC Router Machine?

Unmatched Precision One of the most significant advantages of Stone CNC Router Machines is their ability to achieve unparalleled precision. Whether you're working on intricate patterns, detailed engravings, or complex shapes, the accuracy of CNC technology ensures that each piece is crafted to perfection. This level of precision is nearly impossible to achieve with manual methods.

Increased Efficiency Time is money in any industry, and stone fabrication is no exception. Stone CNC Router Machines significantly reduce the time required for cutting and shaping stone materials. Automated processes mean faster turnaround times, allowing you to complete projects more quickly and take on more clients.

Versatility Stone CNC Router Machines are incredibly versatile. They can work with a wide range of stone materials, including granite, marble, limestone, and more. This versatility opens up a world of possibilities for creating customized stone products, from countertops and flooring to intricate sculptures and architectural elements.

Cost-Effectiveness While the initial investment in a Stone CNC Router Machine may seem substantial, the long-term benefits far outweigh the costs. Reduced labor expenses, faster project completion, and minimal material wastage all contribute to significant cost savings over time. Additionally, the machine's precision minimizes the risk of errors, further reducing expenses.

Applications of Stone CNC Router Machines Stone CNC Router Machines have revolutionized various industries by offering precise and efficient solutions for stone fabrication. Some of the key applications include:

Countertops and Flooring The demand for customized stone countertops and flooring is on the rise. Stone CNC Router Machines allow for the creation of unique designs, precise cutouts for sinks and fixtures, and seamless edges, making them a favorite choice for kitchen and bathroom installations.

Architectural Elements From intricate moldings and columns to decorative facades and wall panels, Stone CNC Router Machines bring architectural visions to life. Their ability to produce detailed and complex designs makes them indispensable in the construction and interior design industries.

Sculptures and Artworks Artists and sculptors have embraced Stone CNC Router Machines for their ability to translate digital designs into tangible masterpieces. The precision and versatility of CNC technology enable the creation of detailed sculptures, engravings, and artistic installations.

Memorials and Gravestones The memorial industry relies on Stone CNC Router Machines to create personalized gravestones and monuments. The ability to engrave intricate designs, text, and images ensures that each memorial piece is a unique and lasting tribute.

Why Choose GK Laser Enterprises? At GK Laser Enterprises, we are committed to providing our clients with the best tools and technology for their stone fabrication needs. Our Stone CNC Router Machines are designed to deliver exceptional performance, reliability, and precision. Here are some reasons to choose us:

Cutting-Edge Technology: Our CNC routers are equipped with the latest advancements in CNC technology, ensuring top-notch performance and precision. Custom Solutions: We understand that every project is unique. That's why we offer customizable CNC router solutions to meet your specific requirements. Expert Support: Our team of experts is always ready to provide support, from installation and training to maintenance and troubleshooting. Quality Assurance: We stand behind the quality of our machines, offering warranties and comprehensive service packages for peace of mind.

Conclusion The Stone CNC Router Machine is a revolutionary tool that has transformed the stone fabrication industry. With its precision, efficiency, and versatility, it offers countless benefits for businesses in various sectors. At GK Laser Enterprises, we are proud to provide top-of-the-line Stone CNC Router Machines that empower our clients to achieve their creative and operational goals. Discover the power of precision with our CNC routers and take your stone fabrication projects to the next level. Contact us to learn more about how our advanced Stone CNC Router Machines can enhance your business and meet your specific needs.

0 notes

Text

1325 CNC Wood Cutting Machine 4×8

The CNC wood cutting machine is also known as cnc wood cutting machine,CNC nesting machine, cnc router machine for wood, cnc machine for wood cutting, cnc machine wood cutting , CNC machine for cabinet making, cabinet door cutting machine for sale, etc.CNC wood cutting machines have revolutionized woodworking by automating and streamlining the cutting process. They are widely used in various woodworking applications, including furniture manufacturing, cabinetry, woodworking workshops, and architectural millwork.

Our 1325 CNC machine is one of our popular and best-selling machines. It is good at cutting, carving, engraving, drilling, routing, grooving, and pocketing of wood, MDF, acrylic, PVC, plastic, foam, stone, soft metal, and other materials.

CNC Wood Cutting Machine 4×8

This 1325 cnc wood cutting machine can change 12 different tools automatically. It is very suitable for the people who do complex work and change different tools frequently. This machine is provided with a push device and can push materials after cutting or engraving.

High Precision Cutting Best Selling CNC Machine For 4×8 Small CNC Machine

The 4×8 CNC machine XYZ axis Taiwan Hiwin square rail makes the gantry and spindle moving at high speed with high precision. CNC kit 4×8 adopts Hiwin square rail with high rigidity and very durable. XY axis German Helical rack and pinion are directly coupled to the stepper motor and pinion. This 4×8 CNC router cheap configuration ensures that the accuracy is less than ±0.03mm when the max 4×8 work table speed is 20,000mm/min.

Stable, Stronger And More Durable Structural Design Of CNC Machine Table 4×8

The Heavy structure adopts thicken steel square which improves the stability of wood CNC 4×8. This Stronger structure is necessary for cutting solid materials such as hardwood. During the 4×8 wood CNC machine cutting and carving process, the XYZ axis remains stationary against external cutting forces.

Long Time Operation With High-Power Stepper Motor Of Cheap CNC Router

Stepper motor and driver do not require regular maintenance. This not only reduces maintenance downtime but also spindle is able to run normally for a long time. Coupled with the fast working speed, the CNC machine 4×8 efficiency is greatly improved.

Compatible With Any Advanced Software For 4×8 CNC Wood Router

Software including Vectric Aspire, Type3, Ucancam, Artcam, AlphaCam, Powermill, Solidworks is run on the system of CNC table 4×8. You can use the CNC wood router 4×8 quickly without wasting the cost of training labor. This is simple and efficient for you.

Features CNC Wood Cutting Machine

1. Heavy duty frame. The frame is longer and much stronger than normal CNC routers.

2.Taiwan 1000w SYNTEC servo motor with Japan SHIMPO reducer. It adopts full closed loop and has brake function on Z axis. It provides constant position feedback, bigger power and smooth contentious motion.

3. Linear type tool change magazine under gantry. It can change 12 different tools fast.

4. Y axis adopts #30 Taiwan square linear guide. While X and Z axis adopt #25 square linear guide. 2M helical rack is used to ensure the high-speed and stable operation of the machine, and also ensure a higher processing accuracy.

5. ATC air cooling spindle. Max. speed can be 24000RPM. With ISO30 tool holder, it can use 20mm bits at max.

What can a 4X8 CNC Router do?

A 4X8 CNC Router is the ideal wood cutting and carving machine that imparts excellent efficacy in manufacturing doors, furniture designs, etc.

It runs on the CAD software that enables a user to cut detailed designs with utmost precision on a preferred material. The process of producing complex designs manually demands a lot of time and other resources. Just opposite, this wonder machine can perform carving and cutting in three axes to come up with the design you want.

Usually, it is cumbersome for manual processes to offer such precision and they incur huge material loss as well. With the aid of the driving software, you can convert complicated designs into a reality with the aid of 4X8 CNC Router.

Heavy duty CNC router is good for complex processes and long time work, such as:

Wood door, furniture making; MDF, Poly wood cutting;

Hardwood engraving & carving;

Big scale woodworking;

Soft metal, plastic, acrylic, foam engraving & cutting, etc.;

Automatic Wood CNC Router Cutting & Engraving Machine

A CNC wood router is an automatic machine tool for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories. The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines.

Here is our collection of most popular CNC machines for woodworking, from single-spindle to multi-spindle kits, from small footprint to large format tables, from desktop to gantry styles, from hobby to industrial models, from primary 3 axis to professional 5 axis, from entry-level for beginners to high-end ATC series for experts, all types of CNC wood routers are available.Just discover what you need, plan your budget, compare features and costs, find and buy the best one to start or upgrade your woodworking business.

0 notes

Text

CNC Lathe Machine Manufacturer in India

For our cherished customers, we offer the finest prices on CNC lathe machines at Indian Trade Birds. Our company is a top producer, supplier, exporter, and retailer of CNC lathes, routers, laser cutting machines, milling machines, wood cutting machines, CNC rotary die making machines, CNC wood routers, CNC automatic tables, industrial CNC turning machines, flat bed lathes, automatic vertical lathes, fully automatic CNC stone carving machines, and CNC sculpture machines—all of which we offer for sale. As a result, the products are priced lower and profit margins are higher. Our clients really value the machine we provided them with because of its durable build and low maintenance requirements. With the maximal pressure field, the material is modeled into a solid compact sheet or flakes of ingredients as the volume declines.

For more details clicks here - https://www.indiantradebird.com/product/cnc-lathe-machine

0 notes

Text

CNC Foam Router for Professional Foam Shaping and Design

In the world of professional foam shaping and design, precision is key. From creating intricate sculptures to producing custom packaging solutions, foam is used in a wide variety of industries, and the demand for precision-cut foam continues to rise. The solution to this demand lies in the CNC foam router—a state-of-the-art tool that revolutionizes foam cutting, carving, and shaping.

Use a rotary cutting tool (router bit) to carve and shape foam. Suitable for detailed 3D carving, engraving, and milling. Can handle a wider range of foam types, including polyurethane and polyethylene.A CNC foam cutter is a specialized type of CNC machine designed to cut and shape foam materials with high precision and efficiency. These machines are commonly used in various industries, including packaging, prototyping, model making, insulation, and more.

What is a CNC Foam Router?

CNC foam router is a specialized machine that uses computer numerical control (CNC) technology to cut, carve, and shape foam materials with remarkable accuracy. These routers are designed to work with various types of foam, including expanded polystyrene (EPS), polyethylene (PE), polyurethane (PU), and more. CNC foam router machine is a specialized type of CNC machine designed for cutting, shaping, and carving foam materials. These machines are widely used in industries such as packaging, prototyping, model making, and even in the production of theater and movie props.

The CNC foam router operates based on pre-programmed instructions from CAD (computer-aided design) software. This allows operators to create highly detailed designs and shapes in foam quickly and consistently. The process is automated, reducing the chances of human error and ensuring uniformity across multiple pieces.

Types of CNC Foam Cutter

4 Axis Foam CNC Router

The 4-axis CNC Router machine refers to the computer numerical control equipment including X, Y, Z, and additional rotation axis. It has 3 straight coordinates and 1 rotating coordinate. 4-axis CNC Router engraving machines are usually equipped with rotating axes or rocking spindles, so they can contact the workpiece from different angles and effectively work, so as to realize the 3D processing of cylindrical, curved and circular surfaces.

4 axis CNC router is quite good at processing 3D workpieces. It generally falls into two types. The first type described hereunder is equipped with a rotating spindle that can swing by 180°. It can engrave 3D patterns and drill holes on side surfaces of wood, MDF, acrylic, foam, rubber, and other materials. For example, 3D letters, signs, reliefs, and sculptures.

5 Axis CNC Foam Router

The 5 axis CNC Router machine, also known as the 5 axis CNC machining center, is equipped with a 3D CNC system.Designed as a 5 axis CNC processing solution with high cost-effectiveness, it refers to the machine's capacity to move tools or parts on five different axes for complex surface processing. As a piece of advanced CNC equipment, the 5 axis CNC machining center or CNC router is crafted especially for complex curved surfaces. It finds extensive application in industries like aviation, aerospace, automotive, military, scientific research, precision instruments, high-precision medical equipment, etc. Also, it can handle a wide variety of materials such as wood, metals, stones, plastic, styrofoam, composites, and so on.

Features of a CNC Foam Cutting Machine

Key Advantages of CNC Foam Cutting Machine

One of the primary benefits of a CNC foam router is its precision and accuracy. Unlike traditional manual cutting methods, which can lead to inconsistencies and material waste, CNC foam routers provide highly precise cuts. This ensures that foam materials are cut to exact specifications, minimizing waste and producing uniform, high-quality results.

In addition to precision, CNC foam routers are highly customizable. They can easily accommodate a wide range of intricate designs, from basic geometric shapes to more elaborate, complex patterns. With CAD software, designers can create any shape or pattern, which is then executed with exact precision by the router. This flexibility makes the CNC foam router ideal for a variety of custom applications, including sculptures, packaging, and prototypes.

Efficiency and Automation

Another major advantage of CNC foam routers is their versatility. These machines can handle different types of foam, from rigid materials like polyurethane and PVC to softer options like polystyrene. This makes CNC foam routers suitable for diverse industries, from packaging and architectural modeling to artistic sculpture and prototypes.

Speed and efficiency are also key benefits of CNC foam routers. Unlike traditional manual cutting methods, which can be slow and labor-intensive, CNC machines work quickly and continuously, cutting large volumes of foam in a fraction of the time. This makes them ideal for businesses with high-volume production needs, helping to meet tight deadlines.

Additionally, automation is a major selling point. Once the design is input into the system, the CNC foam router takes over the cutting process, reducing the need for skilled labor and minimizing human error. This automation increases productivity, reduces mistakes, and frees up resources for other tasks, significantly enhancing operational efficiency.

Applications of CNC Foam Milling

Common Applications of CNC Foam Milling

CNC foam routers offer remarkable versatility, making them ideal for various industries. In foam sculptures and artwork, artists and designers use these machines to craft intricate, detailed designs for art installations and commercial displays. From simple shapes to complex textures, CNC foam routers excel in transforming creative concepts into tangible pieces with precision.

In the packaging industry, CNC foam routers are used to create custom foam inserts for the safe transport of fragile items, such as electronics, medical devices, and automotive parts. By carving foam to exact specifications, these routers ensure products are securely packaged, minimizing the risk of damage during transit. Similarly, CNC foam routers play a significant role in prototypes and models, where engineers and designers rely on foam to create accurate initial product models before progressing to more expensive materials.

Expanding Industries for CNC Foam Routers

CNC foam routers are also widely used in architectural models, where architects rely on them to create detailed foam models of buildings and landscapes. Foam is a cost-effective material, and CNC routers can efficiently turn 3D digital designs into physical models, which are essential for presentations and design development.

In advertising and signage, CNC foam routers carve custom shapes, letters, and logos from foam, which are then painted for use in eye-catching displays, signs, and banners. The ability to create bold and intricate designs makes these routers ideal for large-scale advertising projects. Additionally, in the entertainment industry, CNC foam routers are employed for set design, crafting foam props, stage sets, and scenery. These routers allow designers to construct realistic environments for theater, film, and television productions.

Why Choose a CNC Foam Cutting for Your Business?

There are numerous reasons why investing in a CNC foam router is a wise decision for your business. Here are some of the most compelling reasons:

Increased Productivity:CNC foam routers dramatically improve productivity. With automation, the router can work continuously without requiring breaks, unlike manual labor. This not only speeds up the production process but also allows your business to handle more orders in less time, increasing overall throughput.

High-Quality Results:Because CNC foam routers offer extreme precision, the quality of the final product is significantly higher. Whether you're cutting a foam model, creating packaging inserts, or producing intricate sculptures, the results will be uniform and exact. Consistent quality across every product is essential for customer satisfaction and long-term business success.

Cost-Effectiveness:Although the initial cost of a CNC foam router may seem high, the long-term savings are considerable. These machines reduce labor costs, material waste, and production time, which translates into significant cost savings. Additionally, CNC foam routers can help companies meet tight deadlines, avoiding costly delays.

Flexibility and Customization:The customization potential offered by CNC foam routers is unparalleled. From prototypes to large-scale production, CNC foam routers can be programmed to cut any design imaginable. The flexibility to produce both large quantities of identical parts and unique one-off items makes the CNC foam router an indispensable tool in many industries.

Reduced Labor Requirements:Manual foam cutting can be labor-intensive and physically demanding. CNC foam routers reduce the need for skilled manual labor, allowing operators to focus on machine operation, design programming, and oversight. The automation process also reduces human error, ensuring that each cut is accurate.

Choosing the Right Machine

Selecting the right CNC foam router for your business involves considering several factors, including:

Machine Size and Cutting Area:The size of the foam you plan to work with will determine the size of the CNC foam router you need. Larger machines are capable of cutting larger sheets of foam, while smaller machines are suitable for more intricate designs and smaller foam pieces.

Cutting Capabilities:Different CNC foam routers have different cutting capabilities. Some may be better suited for simple, straight cuts, while others are equipped to handle more complex designs, including curves and 3D shapes. Consider your business's specific needs when selecting a machine.

Software Compatibility:Most CNC foam routers are compatible with popular CAD/CAM software. Make sure the machine you choose integrates well with the software you use for design and programming.

Cost and Budget:CNC foam routers vary in price depending on their size, features, and brand. Make sure to assess your business's budget and weigh the potential return on investment when selecting a machine. While the initial investment may be high, the long-term benefits in terms of productivity and quality will justify the cost.

Technological Advancements in CNC Foam Cutter Machines

Integration with CAD/CAM Software

Modern 3D CNC foam router machines are often integrated with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. This integration allows for seamless design and manufacturing processes, reducing errors and improving overall efficiency.

Automation and Robotics

The incorporation of automation and robotics into CNC machining has further enhanced productivity. Automated 3D CNC foam router machines can perform multiple tasks without human intervention, increasing throughput and reducing the risk of human error.

IoT and Industry 4.0

The advent of the Internet of Things (IoT) and Industry 4.0 has brought about significant changes in CNC machining. Machines are now connected to networks, allowing for real-time monitoring, predictive maintenance, and improved decision-making processes.

Conclusion

CNC foam router is an indispensable tool for businesses in industries that require precision foam cutting and shaping. From custom packaging to artistic sculptures and prototypes, CNC foam routers offer unmatched precision, speed, and versatility. By automating the foam cutting process, these machines not only enhance productivity but also reduce material waste and labor costs, allowing businesses to scale efficiently.

Investing in a CNC foam router is a smart decision for any company looking to stay competitive in the rapidly evolving foam industry. Whether you're cutting foam for practical applications or creating detailed artistic designs, a CNC foam router will give you the flexibility and control to meet the demands of your customers and grow your business.

0 notes