#CNC router machine

Text

MadBytes Delivers Quality CNC Machine Manufacturing in Australia

MadBytes, a leading name among CNC machine manufacturers, is revolutionising the industry with their innovative and high-quality CNC machines. Known for their cutting-edge technology and exceptional customer service, MadBytes stands out as a premier CNC machine supplier.

MadBytes specialises in a wide range of CNC machines, including the highly sought-after CNC Router Machine. With an eye for precision and durability, their CNC routers are perfect for a variety of applications, from woodworking to metal fabrication. For businesses and hobbyists looking for a reliable CNC router for sale, MadBytes offers products that meet the highest standards of performance and reliability.

Our mission at MadBytes is to provide our customers with the best CNC solutions available. As one of the top CNC machine manufacturers; we are committed to innovation and excellence in every product we deliver.

What sets MadBytes apart in the competitive market of CNC machine manufacturers is their unwavering focus on quality and customer satisfaction. Every CNC router machine is designed and tested to ensure it meets stringent quality standards. This attention to detail has earned MadBytes a loyal customer base that trusts them as their go-to CNC machine supplier.

In addition to their superior products, MadBytes offers unparalleled customer support. Their team dedicates itself to ensuring a seamless experience, from helping customers choose the right CNC router for sale to providing after-sales service. This commitment to customer care is a key factor in their reputation as a leading CNC machine supplier.

MadBytes’ innovative approach to CNC technology doesn't stop at manufacturing. They are continuously researching and developing new ways to enhance their machines' capabilities, ensuring they stay ahead of the curve in the ever-evolving landscape of CNC machine manufacturers.

MadBytes is a top-tier CNC machine supplier dedicated to delivering high-quality CNC machines. With a focus on innovation and customer satisfaction, MadBytes has become a trusted name among CNC machine manufacturers. Their range of products, including the advanced CNC router machine, is designed to meet the diverse needs of their customers. For more information on MadBytes and their range of CNC machines, including the best CNC router for sale options, visit their website at madbytes.com.au. Or call us at (03) 9005 6504.

#cnc router for sale#cnc router machine#CNC machine supplier#cnc machine manufacturer#cnc machine sales#cnc mill for sale#cnc milling machine#cnc for sale#cnc router melbourne

0 notes

Text

India's largest CNC machine tools group, Sahil Machines. Leading CNC machine manufacturers offering comprehensive machining centers both in India and overseas.

Established in 1968, Sahil Alloys & Machine Tools is a CNC machine manufacturer in India that has been innovating the manufacturing and CNC sectors since day one through our brand Suraj. By driving innovation, we strive to contribute to society and bring a positive impact on the global manufacturing and CNC industries.

#cnc machine#cnc machine operator#cnc router machine#cnc machine price#cnc machine price in india#cnc milling machine#cnc router machine price

1 note

·

View note

Text

Best Cnc Router Machine In Pune

Our CNC Router Machine, which is well-designed for accuracy and productivity in woodworking and engraving applications, will empower your creative pursuits. Being a top supplier, we deliver excellent performance on a range of tasks with our state-of-the-art CNC router equipment. These machines are highly efficient and dependable, making them perfect for a variety of sectors like woodworking and signage. Examine options that put efficiency, flexibility, and precision engineering first, guaranteeing smooth routing and engraving for your unique needs. With our cutting-edge CNC router machine technology, you can streamline your creative processes and ensure exceptional quality for your projects. You can also increase productivity and shorten production times by getting exceptional results with every cut.

0 notes

Text

Uncover the Truth About CNC Router Machines for Ultimate Woodworking Reviews

Introduction

In the realm of woodworking, precision and efficiency are paramount. Craftsmen and artisans have long sought tools that not only enhance their creativity but also elevate the quality of their work. In this pursuit, Computer Numerical Control (CNC) router machines have emerged as game-changers, revolutionizing woodworking with their precision, versatility, and automation. In this article, we delve into the depths of CNC router machine reviews, exploring their attributes and benefits for woodworking enthusiasts.

The Power of Precision

At the heart of CNC router machines lies their remarkable precision. These machines utilize computer-guided control systems to execute intricate designs with unparalleled accuracy. Woodworkers can effortlessly translate their digital designs into tangible masterpieces, carving out even the most intricate details flawlessly. This precision opens up a world of possibilities for creating intricate patterns, fine engravings, and complex cuts that were once considered arduous tasks.

Versatility Redefined

Gone are the days when woodworking was restricted to manual labor. CNC router machines offer an exceptional level of versatility that empowers craftsmen to experiment with various materials, techniques, and designs. From solid wood to composite materials, CNC routers can effortlessly handle a wide array of substrates, broadening the horizons of woodworking projects. This adaptability encourages artists to push the boundaries of creativity, exploring new avenues that were previously unattainable.

Automation: A Time-Saving Marvel

Woodworking, traditionally a labor-intensive craft, has been transformed by the automation capabilities of CNC router machines. These devices streamline the production process by eliminating the need for constant manual intervention. Once the design is set and the machine is programmed, it operates tirelessly, reducing production time significantly. This time-saving attribute not only increases productivity but also allows artisans to focus on design refinement and innovation.

User-Friendly Interface

While the technological aspects of CNC router machines might sound complex, manufacturers have worked diligently to make them accessible to woodworkers of all skill levels. Most modern CNC routers feature user-friendly interfaces that facilitate easy design input, manipulation, and execution. As a result, artisans with varying levels of technical expertise can harness the potential of CNC technology to bring their artistic visions to life.

Conclusion

The world of woodworking has embraced CNC router machines as invaluable tools that marry technology with craftsmanship. Their precision, versatility, automation, and user-friendly interfaces have redefined the art of woodworking, enabling artisans to elevate their creations to new heights. As technology continues to evolve, it's clear that CNC router machines will remain at the forefront of innovation in the woodworking industry, offering endless possibilities for those who dare to dream and create.

1 note

·

View note

Text

The Advantages of Purchasing CNC Router Machines from Zyena Engineers

Zyena Engineers is one of the paramount CNC Router Machine Manufacturers in Gujarat, currently. They offer the best in class machines to the customers at rates that are very considerable. Based in Surat, Gujarat, the company has expanded its wings across multiple cities.

1 note

·

View note

Text

The Benefits of Using a Laser Cutting Machine

Laser cutters are a unique tool used for cutting and engraving various materials such as wood, plastic, metal and more. Laser cutting machines provide a range of benefits, including cost savings and improved accuracy. At Ortur, we offer the best laser cutter engraver and laser cutter wood tool for metal available on the market, helping you create the best wood engraving projects. Here are just a few of the many benefits of using a laser cutting machine.

1. Accuracy & Precision: Laser cutting machines are known for their astounding accuracy and precision. When compared to traditional cutting tools, laser cutters are far more precise, producing intricate, detailed cutouts. This is especially beneficial for complex projects and intricate designs.

2. Cost Savings: One of the major benefits of using a laser cutting machine is the cost savings you can achieve. Since the cutting of materials is done with a laser, there is no need to purchase additional tools like saws or blades. This eliminates the need for additional materials, saving you time and money in the long run.

3. Safety: With a laser cutting machine, you don't have to worry about the potential hazards of traditional cutting tools. Laser cutters eliminate the need for sharp blades, meaning there is a much lower risk of injury.

0 notes

Text

What is an Air-cooled Spindle?

When using a CNC router to execute high-speed, high-intensity milling, drilling, engraving, and other mechanical operations, a spindle is a crucial and vital component. The electric spindle motor needs to be periodically cooled down to preserve performance because it rotates at a very high speed to produce the outcomes for which it is utilised. Ignoring this aspect may have serious repercussions, shorten the motor’s life, or result in component burnout.

A spindle can be cooled using either air cooling spindle or water cooling spindle. Each have advantages and disadvantages, as well as various techniques of preserving the motor when in operation. Because the air-cooled spindle uses a fan to reduce the temperature of the high-speed fan, it is thought to be less successful at cooling the motor.

Users frequently misunderstand which motor should be used to cool the CNC router machine. The decision will always be influenced by the elements weighing the benefits and drawbacks of water- and air-cooled spindles. Let’s examine a few elements to see if air-cooled spindles are the best option for you.

Cooling effect: It is recommended to stop an air-cooled spindle machine after 4 hours of continuous operation and give it a 30-minute rest. Air-cooled spindles can become damaged and have their service life significantly altered if they are operated for more than 4 hours. Spindles that are air-cooled cannot operate continuously without being interrupted every few hours. Because of this, the cooling effect is not as effective as in a spindle that is water-cooled.

Noise: The action of the cooling fan causes air-cooled spindles to make a lot of noise. With spindles that are cooled by water, this problem does not exist.

3. Ease of use: Compared to water-cooled spindles, which contain water tanks, pipelines, etc. that need to be cleaned and maintained on a regular basis, air-cooled spindles are simpler to use because they don’t require any additional equipment.

4. Service life: Because the cooler cannot be changed, air-cooled spindles have a shorter lifespan. As opposed to a water-cooled spindle, which can have its tank cleaned, maintained, and replaced in the event of catastrophic damage.

0 notes

Text

What is Water-cooled and Air-cooled Spindle:

People are overall a piece lost when choosing a water-cooled or air-cooled Spindle. There are several things that ought to be considered during this decision cycle.

Cooling in a water-cooled spindle is achieved by flowing water through an external guide into and out of an inside shell inside the Spindle. Subsequent to leaving the Spindle, the water is directed into a tank of water which is cooled by the incorporating air temperature.

An air-cooled spindle has a cooling turbine joined to the Spindle of the Spindle. Exactly when the pivot is turning it makes the turbine turn, bringing enveloping air into and through the internals of the Spindle. As the turbine is related directly to the Spindle of the Spindle it is turning at a comparative speed as the piece (8000–24000 rpm) which is fast! The turbine speed drawing air rapidly into the Spindle causes an ear-splitting crying upheaval, which in case you are running in your parking space at home, could upset your neighbors.

In case upheaval is an issue water-cooled is the best methodology. Moreover, the power movement speed of water is generally on numerous occasions better contrasted with air. Hence, a water-cooled Spindle will run cooler which in this manner will construct the bearing presence of the Spindle.

Not all things are horrible with an air-cooled Spindle, there is no prerequisite for fiddly water pipes and a tremendous tank of water on your shop floor which will likely be kicked over in the long run (we are dealing with this issue by making a shut circle cooling system with a radiator which will be open soon). A water-cooled Spindle is in like manner fairly more expensive than an air-cooled unit. Likewise, look at about CNC machine spindle.

Along these lines, to wrap up, if the disturbance isn’t an issue, go with an air-cooled Spindle as it’s less significantly an issue to set up, it’s more affordable and there is no tank of water on the floor. If the racket is an issue, you will require a water-cooled Spindle.

The essential differentiation between air cooled Spindle and a water-cooled Spindle is as a person:

The most extreme Spindle turning speed: air-cooled Spindle is 18000r/min, but water-cooled Spindle is 24000r/min. the higher the turning speed, the external layer of the workpiece will be more smooth at a comparatively short period of time.

The continuing to work time: air-cooled Spindle is cooled through the air, and when the Spindle keeps on working from now on, endlessly for a long time, the introduction of force dispersal will be not superb. So the air-cooled Spindle basically can keep on laboring for 6–8 hours, then, it should have a rest for a really long time, then, continue to work. In any case, the water-cooled Spindle is cooled by water, if you keep the water in the water tank cooling, the machine can work for a whole day.

A peaceful work area: air cooled Spindle is cooled by the fan, and the high turning speed same as the fan, it makes a more prominent clatter than the water Spindle.

Convenience to use: because the air-cooled Spindle has no water tank or water siphon, it is useful to use.

The worth: because of the different cooled structures, the intensity strength of the parts in the Spindle will be remarkable, so the expense is extraordinary. Air-cooled Spindle, considering everything, cost considerably more.

Working environment: water cooling spindles can not be used in places where there is little water or freezing. Expecting that the weather patterns are endlessly freezing, it is frightful to the water-cooled Spindle. Differentiated and water cooling Spindle, air cooling Spindle is more useful, and has fewer limitations of the environment.

The water cooling Spindle embraces the water cycle to cool the Spindle, so the cooling influence is marvelous. There is basically no upheaval and high extended life. Moreover, there is fairly badly designed because it needs to present the water siphon. For the air-cooling Spindle, no need water siphon, so it is very useful. Nevertheless, the uproar is greater than the water-cooling Spindle and the cost is higher.

For air-cooled Spindles and water-cooled spindles, each partakes in its advantage and damage. Additionally have some familiarity with CNC router machine.

0 notes

Text

Increases Productivity With Top Custom CNC Machine

MadBytes, a prominent name in the realm of manufacturing innovation, is proud to announce its expansion into CNC machine manufacturing. Renowned for its cutting-edge technology and unwavering commitment to excellence, MadBytes is poised to revolutionise the industry with its new offerings.

With a focus on precision engineering and advanced technology, MadBytes is set to become a frontrunner in the realm of CNC machine manufacturers. The company's expertise extends to various sectors, including CNC woodworking machines, Co2 laser CNC machines, and CNC router machines. By leveraging its years of experience and technical prowess, MadBytes aims to deliver superior-quality machines that cater to the diverse needs of its clientele.

We are thrilled to embark on this new journey as CNC machine manufacturers, Our expansion into this domain is a testament to our relentless pursuit of innovation and our dedication to providing cutting-edge solutions to our customers.

MadBytes' CNC woodworking machines are engineered for precision, offering unparalleled accuracy and efficiency in woodworking operations. Whether it's crafting intricate designs or executing large-scale projects, MadBytes' CNC woodworking machines deliver exceptional results every time.

Moreover, MadBytes' Co2 laser CNC machines redefine precision cutting with their advanced laser technology. From intricate patterns to intricate cuts, these machines offer unmatched versatility and precision, making them indispensable tools for various industries.

Additionally, MadBytes' CNC router machines are designed to meet the demands of modern manufacturing processes. With their robust construction and intuitive controls, these machines offer unparalleled performance and reliability, empowering businesses to achieve greater efficiency and productivity.

As MadBytes ventures into the realm of CNC machine manufacturing, it remains committed to its core values of quality, innovation, and customer satisfaction. With a dedicated team of engineers and technicians, MadBytes is poised to set new standards of excellence in the industry.

MadBytes is a leading provider of innovative manufacturing solutions, specialising in CNC machine manufacturing. With a focus on quality and innovation, MadBytes aims to empower businesses with cutting-edge technology and unparalleled expertise. For more information about MadBytes and its range of CNC machines, visit https://madbytes.com.au/ or call us at (03) 9005 6504.

0 notes

Text

Air-Cooled or Water-Cooled, Which Is Better?

A spindle is the critical part of any CNC router, which administrators use to perform rapid processing, penetrating, etching, and other such procedure on their benchtop CNC plant. In any case, as the electric shaft pivots at a fast to convey such outcomes, it should be chilled off to keep up with execution. Disregarding this issue can prompt grave ramifications for the machine shop and the particular CNC machine — — from diminished help life to finish burnout of the part.

Air cooling and water cooling are two of the most well-known cooling frameworks that come to play in such circumstances. Yet, which of these procedures is more proficient and powerful? Furthermore, which one would it be a good idea for you to pick? We should examine.

A head-to-head comparison

Coming up next is a rundown of a few key factors that separate air-cooled shafts from water-cooled shafts. Continue to peruse to figure out which axle is an ideal choice for you.

Cooling effect. As the name shows, the air-cooled CNC machine spindle utilizes a fan that emanates air, what capabilities as a liquid to scatter heat. Additionally, the water-cooled CNC spindle utilizes water dissemination to chill off the spindle.

Water-cooled spindle are viewed as more successful in temperature guideline as their temperature doesn’t ordinarily surpass 40 degrees after water dissemination.

Most extreme rotational speed. An air-cooled spindle can clock a rotational speed of 18,000 rpm. Interestingly, a water-cooled spindle works at 24,000 RPM. Subsequently, water-cooled spindle can accomplish the errand in a more limited time.

Noise generation. Because of the activity of the cooling fans, air-cooled spindle can produce a great deal of clamor. Conversely, water-cooled spindle offer silent activity.

Convenience. Since air-cooled spindle don’t come outfitted with water tanks or siphoning apparatus, they are more advantageous to utilize, set up, and preload than water-cooled axles.

Cutting performance. Air cooling offers more noteworthy force, which adds to a strong cutting power. This component improves an air-cooled shaft than the presentation of a water-cooled shaft.

Durability. The help life of a water-cooled shaft is longer than that of the air-cooled shaft — given that the administrator takes satisfactory consideration to keep up with it. With routine upkeep exercises, like evolving water, utilizing a modern water cooler, and so forth, you can expand the CNC machine’s administration life.

Accuracy. Water-cooled spindles convey more noteworthy precision, with hub and outspread runout being under 0.003 mm. Tragically, an air-cooled shaft comes up short, plainly, in offering such an elevated degree of precision.

Operating environment. The water-cooling technique faces two principal hindrances as to the workplace. Initial, a water-cooled spindles requires a nonstop water supply, siphon, and other such hardware. Because of this prerequisite, it will in general consume more space.

Besides, a water-cooled spindle can’t offer ideal execution in climatic limits, particularly when the temperature decreases.

Then again, air-cooled spindle are less prohibitive and can be utilized in many areas paying little mind to outside factors.

Proceeded with work time. Water cooling would be more reasonable than air cooling for cutting and etching projects that will run for longer lengths. This is on the grounds that water-cooling spindle work at exceptionally high velocities while keeping a greatest temperature of 40 degrees after each watering cycle.

Cost. Air-cooled spindles that offer presentation equivalent to that of water-cooled spindle are many times more costly. The simplicity of operability and the way that an air-cooled shaft could work in all conditions are a couple of different variables that drive up the expense of the hardware.

Best practices for air-cooled spindle

These are a couple of tips on keeping up with your air-cooled spindle:

• Guarantee that the air entering the electric air-cooled spindle is perfect and dry.

• Administrators should oil seal the fundamental shaft when the air-cooled axle isn’t being used.

Best Practices for water-cooled spindle

The following are a couple of tips on keeping up with your water-cooled spindle:

• Make certain to change the cooling water frequently.

• As often as possible clean the water tank, pipes, delta/outlet, and different components through which the water passes to eliminate any blockages.

• Seal the shaft involving oil as a grease on the off chance that it will be down and out for an impressive period.

• Evaluate the water quality at the site and set up filtration or water mellowing units, as the need should arise.

• In a perfect world, water-cooled shafts ought to work in surrounding temperatures. Be that as it may, try not to have it when the fever plunges under zero degrees.

• After the gig is finished, channel all the water out of the framework.

Because of the many benefits of a water-cooled spindle, as recorded above, it would be reasonable to involve it for different applications, like 4-hub CNC routers, multi-head CNC router machine, or some other hardware having various rotational tomahawks. Nonetheless, one must likewise consider factors like the nearby temperature and space accessibility to survey in the event that a water-cooled spindle is a solid match. Assuming such contemplations change the assessment, you can extend your financial plan to oblige an air-cooled spindle all things being equal!

1 note

·

View note

Text

CNC Routers offer exceptional repeatability for large-scale production runs and cut the operational cost, as the CNC Router machine reduces the waste pieces. Omni CNC has many such CNC Routers for Sale that reduce waste and cut cost. For more information visit our website.

0 notes

Text

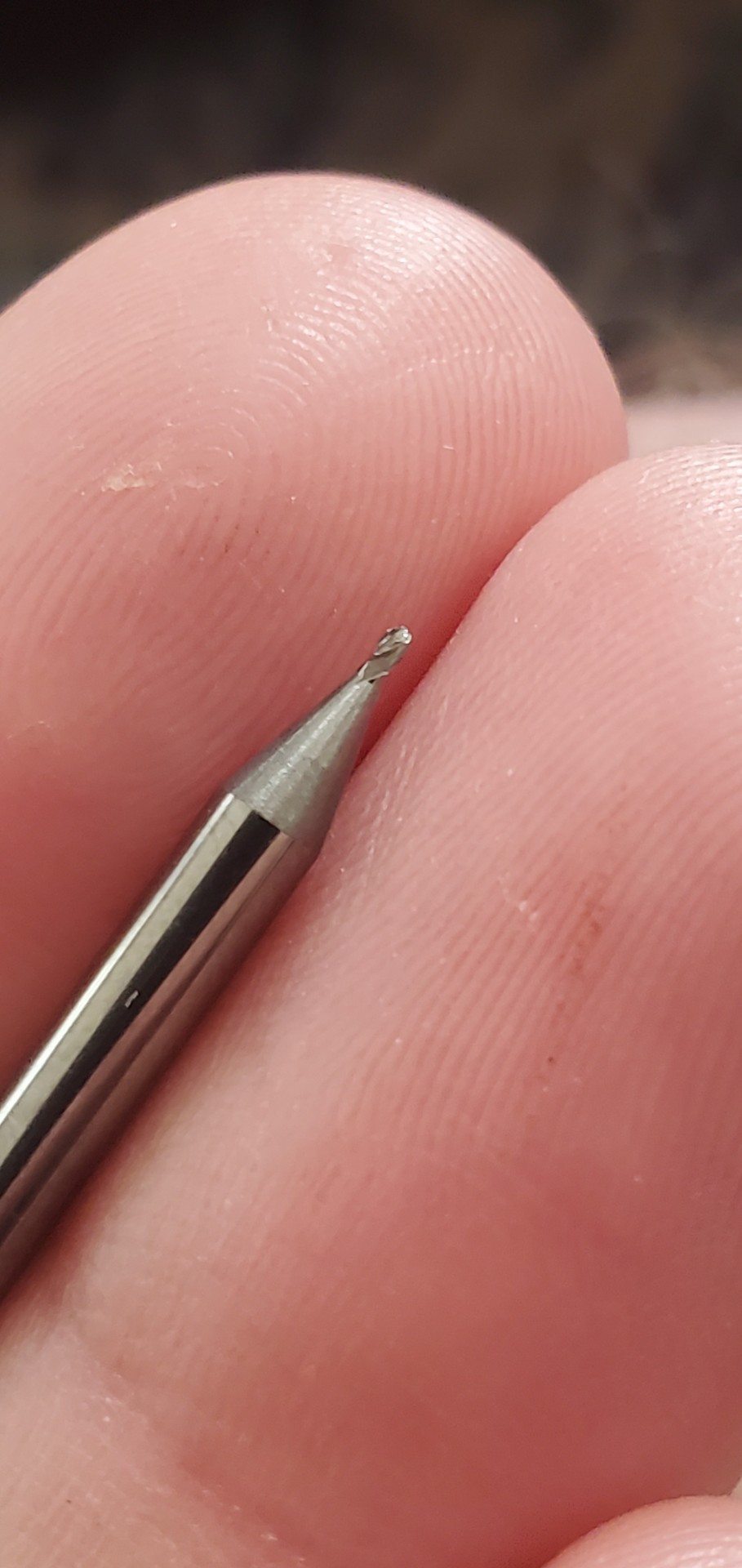

When the aluminum mold requires...

EXTREME DETAIL!

5 notes

·

View notes

Text

CNC wood carving router machine manufacturers Chennai,CNC Engraving Machine Dealers in Chennai - Hiwin CNC Router

2 notes

·

View notes

Text

Manual Tool Changer Spindle | Hiteco Spindle

Looking for a powerful CNC router machine? Our Hiteco spindle equipped router is the perfect tool for precision cutting and engraving. Get yours today!

Visit Now - https://www.kuvamtechnologies.com/manual-tool-change-spindle/

0 notes