#Cabinets Making CNC Router

Explore tagged Tumblr posts

Text

Kitchen Cabinet Door Making CNC Router Machine for Sale

CNC router machines are highly versatile and can be programmed to create a wide range of cabinet door styles, from simple and traditional to intricate and custom designs. They offer precision, consistency, and efficiency in the manufacturing process, which can be especially valuable when producing a large number of cabinet doors.A CNC router machine is a computer-controlled cutting machine that is commonly used in woodworking and cabinetry among other applications.

Cabinets Making CNC Router Description

The closet, wardrobe, cabinets, and other wooden furniture manufacturing are the most popular applications for computerized wood carving machine. Our Nesting CNC Router, ATC CNC Router, Multi-Spindles CNC Cutting Router are perfect CNC Routers for woodworking projects. Why use a wood CNC router?

Traditional woodworking workers can‘t meet the growing needs of the woodworking industry in terms of processing speed or accuracy. Wood CNC machines have the advantages of efficient use, mass production, fast speed, and high efficiency, which greatly help the manufacturers of furniture and cabinets. Moreover, The manufacturers of wooden furniture and cabinets can customize wood CNC machines according to their own economic conditions, production processes, and other actual needs. The flexibility of woodworking engraving machines brings great benefits to wood furniture manufacturers.

CNC Router Cabinet Making Machine For Sale

This CNC router cabinet making machine is a high-efficiency machine, it is controlled by Syntec CNC controller, this machine with 9kw(12HP) spindle is powerful enough for high speed cutting.And the carousel type tool magazine is driven by a servo motor, which support fast tool change and high precision tool change.

The opening machine can make maximum use of the working time of the opening machine, high processing efficiency, convenient feeding and unloading, and can avoid the droop of the drag chain. The cabinet making CNC router is suitable for kitchen cabinet making, cabinet door making, corner cabinet making, decorative cabinet making, home cabinet making, wall cabinet making, wood cabinet making, base cabinet making and other custom cabinet making in bathroom, garage, living room, and office.

This CNC router cabinets machine is with an optional Italian drilling bank for fast hole drilling. Now,The ATC CNC Nesting machine is a special equipment for customized panel furniture cutting, drilling and groove milling. It is suitable for auxiliary processing of wardrobe, cabinet, computer desk, panel furniture, office furniture, wooden speaker, wooden kitchenware, etc. Because of its automatic processing and production, time-saving, cost saving and other advantages, it is trusted by the majority of furniture manufacturing enterprises.

Cabinets Making CNC Router Applications

Woodworking Industry: Cabinet making CNC router is ideally suitable for furniture decorations, musical instruments, wooden crafts, solid wood furniture, MDF door, wood composite door, cabinet making, kitchen cabinet doors, windows, tables, etc.

Decoration Industry: Art model, wall art, screen relief engraving and cutting, decoration processing, gifts wrapping, waved plate, electrical cabinets panels, sports equipment, and other industrial wood works.

Kitchen Cabinet Door Making CNC Features

1. The 12-tool linear automatic tool magazine reduces tool changing time and improve work efficiency.

2. Its new-type heavy duty machine structure ensures strong loading capacity and stable operation.

3. Optional LNC or SYNTEC control system has strong compatibility and is easy to operate and control. It is also equipped with a handwheel to facilitate the control of movement for the CNC router.

4. The whole vacuum table is divided into 7 zones with each zone controlled by a control valve. The strong adsorption force prevents sliding or moving of the wooden panel during operation.

5. Auxiliary feeding rollers make it more convenient to load wooden boards and reduce human labor.

What is a Nesting CNC Machine?

The nesting CNC machine is a computer numerical control equipment specially designed for the production of panel furniture line. It is also known as CNC nesting machine for sale, furniture making machine, CNC router nesting near me, nesting CNC router for furniture, furniture manufacturing machine, cabinet CNC machine, kitchen cabinet door making machine, CNC machine for cabinet making, cabinet door machine for sale, etc.

Nesting CNC machine is mainly used to cut various wooden works. Generally, through the design of intelligent software, the nesting CNC routers can automatically optimize the typesetting design and generate the effect map. Besides, the nesting machine can also perform operations such as modification intuitively, and automatically generate various paths. Therefore, it can save sheets and improve sheet utilization. The nesting CNC machine is widely used in the furniture industry such as cabinet doors, wardrobe doors, solid wood doors, paint-free doors, solid wood composite doors, and suite doors. If you are a manufacturer of furniture production lines, this nesting CNC machine is definitely one of your indispensable CNC equipment.

Nesting CNC Routers VS. Wood CNC Routers

Both nesting CNC machine wood cutter and CNC woodworking engraving machine belong to wood machining equipment. They can both be used for wood CNC cutting and engraving. And from the working principle to the appearance of the CNC machine, the CNC wood engraving machine is similar to the wood nesting CNC machine. How ever, here are many differences. What are the differences between wood nesting machine for sale and wood CNC engraver for sale? It is also a big concern that many businesses have when choosing CNC routers. Next, I will make a clear explain.

Processing field Generally speaking, the main function of CNC wood router machine is CNC engraving. While the nesting CNC machine is mainly used to cut a board into different sizes. CNC nesting router machine is a special equipment for custom-made board furniture with multiple functions such as cutting, punching, carving, grooving, edge milling, and engraving.

Machine bed structure The bed structure and accessories used by the nesting machine are much higher than those of the CNC wood carving machine. Therefore, furniture CNC wood nesting machine can adapt to long-term cutting work with very fast processing speed. Although ordinary woodworking engraving machine or multi-process CNC engraver for sale can cut material, its bed structure and mechanical parts determine that it cannot carry out cutting work for a long time. Otherwise, it will cause deformation of the bed and lower mechanical precision.

Positioning cylinder Ordinary CNC engraving machines do not have positioning cylinders. However, the panel furniture needs to be punched and slotted on the front and back, the lack of positioning cylinders will lead to errors in the hole spacing. In order to ensure good processing accuracy, nesting machines are generally equipped with positioning cylinders. .

Spindle configuration Traditional wood engraving machines basically have only one spindle to cut and engrave. And there is no way to realize automatic tool changing. If you want to process complex processes, you need to manually change the tool, which wastes a lot of manpower and time. The CNC nesting cutting machine can switch between multiple cutter heads to realize the automatic tool change of three or four cutter heads, and even the carousel tool magazine. It can process both the front and back of the cabinet to punch holes.

Automation degree The nesting machine for CNC furniture can cooperate with automatic CNC systems such as feeding, unloading, and labeling to truly realize automatic production. And one person can complete the operation. At the same time, the nesting CNC machine has more detection and fault-tolerant mechanisms. In addition, the operation of such a nesting CNC equipment is very simple. Even an ordinary worker can complete the operation after simple training.

Control system The nesting CNC machine near me can continuously increase the utilization rate of the plate by cooperating with a number of designs and layout optimization software. And then it can realize automatic order unpacking and cutting. Besides, the operation method can be improved by simple CNC analysis. But our ordinary CNC woodworking engraving machine cannot complete it in time.

Dust removal effect The dust removal function of the nesting machine is much stronger than that of the CNC engraver machine, and the dust removal effect is better. To put it simply, the nesting CNC machine that the woodworking engraving machine can do can do, but the CNC engraving machine that the nesting machine can do cannot. So if you just do some hollow carving and relief cutting of door panels, you can choose woodworking engraving machine. But if you plan to make panel furniture involves cabinet body and cabinet door, please choose the best CNC nesting machine for sale.

0 notes

Text

Mastering Woodworking with a CNC Router Machine: Unlocking Precision and Efficiency

The CNC router machine for wood has emerged as an indispensable tool for modern woodworking. Whether crafting intricate designs or scaling up production, this advanced technology brings precision, speed, and creativity to the forefront. Among its many variations, the 5x10 CNC router stands out for its large working area and robust functionality. This article delves into the transformative impact of CNC router machines on woodworking and why they are a must-have in today’s workshops.

What is a CNC Router Machine for Wood?

A CNC (Computer Numerical Control) router machine for wood is a sophisticated device that automates cutting, engraving, and carving processes. By using computer-aided designs (CAD), it translates digital plans into precise physical creations. This machine eliminates the challenges of manual craftsmanship, ensuring flawless results even for the most complex patterns.

Key Benefits:

Unmatched Accuracy: Create intricate details with pinpoint precision.

Time-Saving: Reduce production times significantly without compromising quality.

Versatility: Handle diverse projects, from furniture making to decorative carvings.

Consistency: Deliver identical results across multiple pieces, perfect for bulk production.

Exploring the 5x10 CNC Router

The 5x10 CNC router is a preferred choice for professionals who handle large-scale projects or work with oversized wooden sheets. Its generous 5-foot by 10-foot workspace allows for seamless execution of expansive designs, such as furniture panels, doors, and signage.

Features of the 5x10 CNC Router:

Ample Work Area: Ideal for cutting and engraving large materials without the need for piecing.

Precision Mechanics: Designed to maintain accuracy over extended working hours.

Tool Flexibility: Compatible with various attachments for added functionality, such as automated tool changers or multiple spindles.

This model is particularly useful in industries where size and detail matter, such as interior design and furniture manufacturing.

Applications of CNC Router Machines in Woodworking

CNC router machines have diverse applications across various woodworking domains, including:

Furniture Production: Create tables, chairs, cabinets, and other custom pieces with intricate designs.

Interior Décor: Produce unique wooden wall panels, decorative moldings, and ceiling details.

Architectural Designs: Craft custom doors, frames, and staircases with precision.

Artisanal Creations: Design engraved artwork, personalized gifts, and one-of-a-kind decorative items.

Sign Making: Build durable and aesthetically pleasing wooden signs with precision engravings.

Why Choose a CNC Router Machine for Wood?

Ease of Use: With user-friendly software and automated processes, CNC routers make complex projects manageable.

Material Optimization: Reduce waste with precise cutting and carving.

Scalable Production: Adaptable for one-off creations or large-scale manufacturing.

Cost Efficiency: While an initial investment is required, long-term savings are achieved through reduced material waste and increased productivity.

Conclusion

The CNC router machine for wood is a technological marvel that combines precision, versatility, and efficiency to revolutionize woodworking. Its ability to automate complex tasks while maintaining artistic integrity makes it an invaluable asset for both seasoned professionals and hobbyists. The 5x10 CNC router, with its expansive workspace, is especially suited for tackling large and detailed projects. Whether you aim to craft fine furniture or intricate designs, investing in a CNC router ensures that your woodworking ventures achieve excellence with every cut and carve.

2 notes

·

View notes

Text

Top CNC Router In Ahmedabad, India | CNC Routers for Woodworking & Sign Making – Success Technologies

Ahmedabad's premier CNC Router Wood Engraving Machine manufacturer, delivering innovative and efficient machinery. Transform your woodworking experience with our premium range of products.

Success Technologies is proud to be recognized as a top CNC Router manufacturer in Ahmedabad, India, offering high-performance CNC Router machines designed for a wide range of applications.

Our CNC Routers are engineered to deliver precise, high-speed cutting, engraving, and milling solutions across industries like woodworking and the sign industry. If you're searching for reliable and cost-effective CNC Routers in Ahmedabad, Success Technologies has the perfect solution for your needs.

What is a CNC Router?

A CNC Router (Computer Numerical Control Router) is an advanced cutting machine that automates the cutting, drilling, carving, and engraving processes using computer software. Unlike traditional machines, CNC Routers can perform highly detailed tasks with exceptional speed and repeatability.

They are widely used in industries such as:

Woodworking: for crafting furniture, cabinets, decorative items, and more.

Sign making: for creating complex signboards, logos, and 3D signage.

Plastics and composites: for engraving and cutting materials like acrylic, PVC, and MDF.

Why Choose a CNC Router for Woodworking?

The woodworking industry demands machines that can work with softwoods, hardwoods, MDF, plywood, and more, without compromising on finish quality. A WoodWorking CNC Router Machine provides:

Precision: Accurate cuts and carvings, ensuring repeatable designs.

Versatility: Ability to handle various woodworking tasks including furniture making, door design, carving, and cabinetry.

Productivity: Automated operations reduce manual effort and save time.

Customization: Ideal for producing one-off or custom designs at scale.

At Success Technologies, our CNC Routers are designed specifically for woodworking professionals, combining durability with user-friendly controls.

CNC Router for Sign Industry

If you're in the business of sign making, investing in a CNC Router for the sign industry is essential. Signboards, architectural lettering, 3D logos, and backlit signs require fine detailing and consistency, which traditional manual tools can't provide.

Our CNC Router machines can process materials like:

Acrylic

PVC

Aluminum composite panels (ACP)

MDF

Whether you’re a small sign shop or a large-scale signage production company, our CNC Routers provide the speed, accuracy, and reliability you need to scale your operations.

Features of Success Technologies CNC Routers

As a reputed CNC Router manufacturer and supplier in India, we ensure our machines come equipped with top-of-the-line features:

Heavy-Duty Frame: The machine's robust structure ensures vibration-free operation and high-precision performance even during continuous, high-speed operations.

High-Speed Spindle: Our CNC Router machines are equipped with powerful spindles capable of operating at high RPMs, making them ideal for intricate cuts and engravings.

User-Friendly Interface: We provide machines with intuitive software interfaces and controllers, making them easy to operate even for beginners.

Customizable Sizes: From small table-top CNC Routers to large industrial-scale machines, we can customize machines based on your workspace and project needs.

Dust Collection System: Efficient dust collection keeps the workspace clean and protects components from debris, especially critical in woodworking environments.

Applications of CNC Routers

Success Technologies’ CNC Routers serve a wide range of applications across industries:

Wood carving

Sign Board manufacturing

Interior and exterior decor

Furniture production

Architectural millwork

Nameplates and number boards

Acrylic and plastic fabrication

Our CNC Router machines are designed to handle different materials with ease, including wood, plastic, foam, and metal.

CNC Router Machine Price in Ahmedabad, India

One of the common queries we receive is about the CNC Router machine price in Ahmedabad, India. While prices vary depending on the size, features, and customization, Success Technologies offers competitive pricing without compromising on quality.

Our CNC Routers are available in a wide range of models to suit every budget and requirement — from startups and workshops to large manufacturing units.

Reach out to us for a personalized quote and know the best CNC Router machine price in India tailored for your specific application.

Why Choose Success Technologies?

Made in India Excellence: We take pride in being a leading CNC Router Manufacturer in Ahmedabad and contributing to the "Make in India" movement. All our machines are designed and built in-house using globally sourced components.

Experience and Expertise: With years of experience in manufacturing and support, our team understands your unique needs and provides tailored solutions.

Pan India Support: As a top CNC Router Supplier in India, we provide installation, training, and technical support across all major cities.

After-Sales Service: Our relationship doesn’t end at the sale. We provide comprehensive after-sales support and maintenance services to ensure your machine performs optimally throughout its lifespan.

CNC Routers in Ahmedabad – Local Trust, Global Standards

Ahmedabad is fast becoming a hub for machinery manufacturing, and Success Technologies is at the forefront as one of the most trusted CNC Router machine manufacturers in Ahmedabad.

Whether you're a business owner looking to enhance your manufacturing capabilities or a startup exploring CNC possibilities, Success Technologies has the right machine for you.

We offer:

In-stock models for quick delivery

Custom design options

On-site installation and training

Post-sale support and maintenance

CNC Router Machine – Manufacturers & Suppliers in India

Success Technologies is proud to be listed among the top Double Head WoodWorking CNC Router Machines And suppliers in India. Our focus on innovation, quality, and customer satisfaction sets us apart from others in the industry.

When it comes to buying the best CNC Router in Ahmedabad, India, Success Technologies stands as a trusted name for high-quality, performance-driven machines. Whether you need a CNC Router for woodworking or a sign making machine, we have solutions tailored to your needs.

Our goal is to help Indian manufacturers grow with world-class machines that deliver speed, precision, and profitability.

📞 Ready to Boost Your Productivity?

Get in touch with Success Technologies today!

✅ Explore our range of CNC Router Machines in Ahmedabad

✅ Know the latest CNC Router machine price in India

✅ Request a demo or quote tailored to your needs

✅ Partner with a reliable CNC Router manufacturer and supplier in India

Let Success Technologies be your partner in precision manufacturing!

For more information: https://www.successlaser.com/ Contact us: 9998961184 E-mail ID: [email protected] Location: 97, Barcelona Industrial Estate, Odhav Rd, Odhav, Kathwada, Ahmedabad, Gujarat 382415

#CNC Router#CNC Router for Wood#CNC Router for Sign Industry#CNC Machine#CNC Router Manufacturer#Woodworking Machine#Sign Making Machine#CNC Router Machine#CNC Router India#CNC Router Supplier#CNC Router Machine in Ahmedabad#CNC Router Machine - Manufacturers & Suppliers in India#CNC Router machine price in india

0 notes

Text

Why Pursue a Certificate III in Cabinet Making? Your Path to a Skilled Trade Career

If you enjoy working with wood, have an eye for detail, and want a hands-on career, earning a Certificate III in Cabinet Making could be your perfect next step. This nationally recognized qualification provides the essential skills needed to become a professional cabinet maker or furniture builder. Whether you're starting your trade journey or looking to formalize your experience, Prisms Education offers comprehensive training to help you succeed in this rewarding industry.

In this blog, we’ll explore what a Certificate III in Cabinet Making involves, the career opportunities it unlocks, and why studying with Prisms Education gives you a competitive edge.

What Is a Certificate III in Cabinet Making?

A Certificate III in Cabinet Making (typically MSF31122 under the Australian qualifications framework) is a vocational course that teaches the fundamentals of:

Designing and constructing cabinets, furniture, and joinery

Working with timber, veneers, laminates, and other materials

Reading and interpreting technical drawings

Using hand and power tools safely

Installing fitted furniture and built-in cabinetry

This qualification combines classroom learning with hands-on workshop training, ensuring graduates are job-ready.

Benefits of Completing a Certificate III in Cabinet Making

1. High Demand for Skilled Cabinet Makers

The construction and renovation industry always needs qualified tradespeople. With a Certificate III in Cabinet Making, you can work in:

Custom furniture workshops

Kitchen and bathroom manufacturing

Commercial joinery businesses

Self-employed contracting

2. Hands-On, Creative Work

If you enjoy craftsmanship and seeing tangible results, cabinet making is a fulfilling career. You’ll transform raw materials into beautiful, functional pieces.

3. Pathway to Further Qualifications

After completing your Certificate III in Cabinet Making, you can advance to:

Diploma of Furniture Design and Technology

Specialist roles in high-end furniture making

Starting your own business

4. Strong Earning Potential

Experienced cabinet makers can earn between 55,000−55,000−85,000 per year, with higher incomes for those running their own workshops.

What Will You Learn in a Certificate III in Cabinet Making?

The course covers essential skills, including:

✅ Material Selection – Understanding different woods, composites, and finishes. ✅ Machinery & Tool Use – Operating saws, routers, sanders, and CNC machines safely. ✅ Construction Techniques – Joinery, laminating, and assembly methods. ✅ Installation & Repair – Fitting cabinets and furniture in homes and businesses. ✅ Workplace Safety – Complying with industry regulations.

At Prisms Education, the training is delivered by experienced tradespeople who provide real-world insights.

Why Study with Prisms Education?

Not all training providers offer the same level of support and practical learning. Here’s why Prisms Education stands out:

�� Industry-Experienced Trainers – Learn from professionals who’ve worked in cabinet making. 🔹 Modern Workshop Facilities – Get hands-on practice with professional-grade tools. 🔹 Job Placement Assistance – Gain connections with employers in the trade. 🔹 Flexible Study Options – Choose full-time, part-time, or apprenticeship pathways.

Whether you're a beginner or upskilling, Prisms Education ensures you graduate with confidence.

Career Opportunities After Certification

With a Certificate III in Cabinet Making, you can pursue roles such as:

Cabinet Maker – Building kitchens, wardrobes, and custom furniture.

Joiner – Specializing in doors, windows, and architectural woodwork.

Furniture Manufacturer – Crafting bespoke or production-line pieces.

Shop Fitter – Creating retail displays and commercial interiors.

Many graduates also start their own businesses or move into supervisory roles.

How to Enroll in a Certificate III in Cabinet Making

Entry Requirements

Most courses require:

Basic literacy and numeracy skills

A passion for woodworking (no prior experience needed for beginners)

Safety awareness when handling tools

Course Duration

Full-time: 12–18 months

Apprenticeship pathway: 3–4 years (earning while you learn)

Funding & Support

Government funding or subsidies may be available—check with Prisms Education for eligibility.

Final Thoughts

A Certificate III in Cabinet Making is more than just a qualification—it’s your ticket to a stable, creative, and hands-on career. With strong industry demand and diverse job opportunities, skilled cabinet makers will always be valued.

If you’re ready to turn your passion for woodworking into a profession, Prisms Education provides the training, tools, and support to help you succeed.

#Certificate III in Carpentry#Diploma of Building and Construction#certificate iii in cabinet making#Certificate iii in brick and block laying#Certificate iii in wall and floor tiling

0 notes

Text

This set includes two Roman Classical rail and stile bits, each sized at 1/2" x 1-5/8". The Roman Classical profile features elegant and timeless detailing, adding a touch of sophistication to woodworking projects such as cabinet doors, frames, and panels. Crafted from high-quality materials, these bits ensure clean and precise cuts, facilitating the seamless joining of rail and stile components to create sturdy and visually appealing mortise and tenon joints. The precision-ground cutting edges and flute geometry guarantee smooth operation and less tear-out, resulting in professional-quality finishes with every use.

0 notes

Text

The Ultimate Guide to Customized Furniture Tools: Creating Your Dream Pieces

Customized furniture has become increasingly popular in recent years, as homeowners and businesses seek unique and personalized pieces that reflect their individual style. However, creating customized furniture requires specialized tools and expertise. In this comprehensive guide, we'll explore the world of customized furniture tools, discussing the different types of tools available, their uses, and benefits. Whether you're a DIY enthusiast, a professional furniture maker, or simply looking to create your dream pieces, this article will provide you with valuable insights and inspiration.

Types of Customized Furniture Tools

Customized furniture tools can be broadly categorized into several groups, including:

Hand Tools: These are manual tools used for various tasks such as cutting, shaping, and assembling. Examples include hand saws, chisels, and clamps.

Power Tools: These are electric or gas-powered tools used for tasks such as cutting, drilling, and sanding. Examples include table saws, drill presses, and sanders.

Specialized Tools: These are tools specifically designed for customized furniture making, such as jigs, templates, and molding machines.

CNC Machines: These are computer-controlled machines used for precision cutting, drilling, and shaping. Examples include CNC routers, CNC mills, and CNC lathes.

Benefits of Customized Furniture Tools

Using customized furniture tools can have numerous benefits, including:

Increased Precision: Customized tools enable you to create pieces with precise measurements and angles, ensuring a professional finish.

Improved Efficiency: Specialized tools can save you time and effort, allowing you to complete projects faster and more efficiently.

Enhanced Creativity: Customized tools provide the flexibility to experiment with new designs and techniques, unlocking your creative potential.

Better Quality: Using high-quality, customized tools ensures that your pieces are built to last, with a focus on durability and craftsmanship.

Top Customized Furniture Tools for DIY Enthusiasts and Professionals

Here are some of the top customized furniture tools that every DIY enthusiast and professional should consider:

Festool Domino Joiner: A versatile and precise tool for creating strong and accurate joints.

Incra IBox: A comprehensive tool for creating precise boxes and cabinets.

Woodpeckers Coping Sled: A specialized tool for creating intricate and precise coping cuts.

CNC Shark HD: A high-performance CNC machine for precision cutting, drilling, and shaping.

Kreg Jig: A popular and versatile tool for creating strong and accurate joints.

Best Practices for Choosing the Right Customized Furniture Tools

When choosing customized furniture tools, consider the following best practices:

Assess Your Needs: Identify the specific tasks and projects you'll be working on, and choose tools that cater to those needs.

Research and Compare: Research different tools and brands, comparing features, prices, and customer reviews.

Consider Quality and Durability: Invest in high-quality tools that are built to last, ensuring a professional finish and minimizing maintenance.

Seek Expert Advice: Consult with experienced furniture makers or industry experts to gain valuable insights and recommendations.

Budget Wisely: Set a budget and stick to it, prioritizing essential tools and upgrading as needed.

Conclusion

Customized furniture tools are essential for creating unique and personalized pieces that reflect your individual style. By understanding the different types of tools available, their uses, and benefits, you can unlock your creative potential and take your furniture making to the next level. Remember to choose the right tools for your needs, prioritize quality and durability, and seek expert advice to ensure a professional finish.

For related information click:- Amazearchitectures.in

Architecture in Kannur

0 notes

Text

Cadolino Woodworking CNC Guide for Beginners

Woodworking has evolved significantly with modern technology, and CNC (Computer Numerical Control) machines have revolutionized the craft. Whether you’re a hobbyist or a professional looking to refine your skills, CNC woodworking can help you achieve precision and efficiency. In this guide, we’ll explore the basics of CNC woodworking and how you can get started.

What is CNC Woodworking?

CNC woodworking involves the use of a computer-controlled machine to carve, cut, engrave, and shape wood with incredible precision. Unlike traditional woodworking tools, CNC routers follow programmed instructions to create intricate designs and detailed cuts automatically.

Why Use CNC for Woodworking?

Precision & Consistency – CNC machines allow for repeatable, high-accuracy cuts, eliminating human error.

Efficiency – Automated cutting reduces time spent on complex designs.

Versatility – CNC machines can handle various woodworking projects, from furniture making to intricate carvings.

Creativity – Easily turn digital designs into real wood products without extensive manual labor.

Essential CNC Woodworking Tools

To get started with CNC woodworking, you’ll need:

CNC Router – The main machine that executes programmed cuts.

Computer & Software – Programs like VCarve, Fusion 360, or Easel to design and generate cutting paths.

Cutting Bits – Various router bits for carving, cutting, and engraving.

Workholding Clamps – Secure your wood material for accurate cutting.

Dust Collection System – Keeps your workspace clean and safe.

Getting Started with CNC Woodworking

Choose a CNC Machine – Entry-level models like Shapeoko or X-Carve are great for beginners, while professional-grade options include ShopBot and Axiom.

Learn CNC Software – Familiarize yourself with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to create digital designs.

Prepare Your Wood – Select quality wood, secure it properly, and ensure the cutting surface is even.

Set Up Toolpaths – Use your software to determine how the CNC will cut your design.

Run a Test Cut – Always test on scrap material before finalizing your design.

Finish & Assemble – After cutting, sand, stain, and assemble your project for a professional look.

Common CNC Woodworking Projects

Custom furniture pieces

Decorative wall art

Personalized signage

Cabinet and drawer parts

Wooden toys and sculptures

Tips for Success

Start simple – Begin with basic designs before advancing to complex projects.

Double-check settings – Verify spindle speed, feed rate, and toolpath before cutting.

Keep your machine maintained – Regular cleaning and calibration ensure longevity and precision.

Join CNC woodworking communities – Learn from forums, online courses, and woodworking groups.

Conclusion

CNC woodworking opens up endless possibilities for creativity and efficiency. Whether you’re making custom furniture or intricate carvings, mastering CNC technology can take your woodworking skills to the next level. At Cadolino Woodworking, we embrace CNC technology to bring high-quality, custom wood designs to life.

#CNCWoodworking#CNCProjects#CNCRouter#Woodworking#DIYCrafts#WoodworkingProjects#CNCDesign#WoodworkingTools#CNCMachine#WoodworkingLife

1 note

·

View note

Text

What Is Melamine Particle Board? Comparison with Plywood and MDF

How Are Melamine Particle Board Manufactured?

Melamine particle board are crafted through a process involving melamine resin, initially an organic compound that undergoes polymerization to become a robust and durable plastic material. Essentially, melamine is a chemical compound derived from an organic base and acts as a trimer of cyanamide.

Melamine Laminate is typically resistant to stain, heat, and fire. It’s moisture and scratch-resistant and can be found in many colors, patterns, sizes, and thicknesses making it ideal for particleboard, plywood, or MDF applications. Melamine is more like small pieces of wood (particleboard) glued and pressed together and covered with a plasticized coating.

Uses of Melamine

The term "melamine" finds extensive application not only in cabinet construction but also in various other industrial sectors unrelated to construction.

For instance, melamine laminate serves as a key material not only in crafting woodworks such as shelves and cabinets but also in the resin utilized for Formica and other laminated countertops commonly found in kitchens.

Moreover, melamine is widely employed in the manufacture of floor tiles. Melamine tile floors offer enhanced glossiness, scratch resistance, reduced susceptibility to staining, and easier maintenance compared to porcelain or stone alternatives. Importantly, they also tend to be more cost-effective.

Given the glossy finish of melamine-coated boards and their ability to resist surface scratches, melamine proves to be an excellent material for the production of whiteboards.

Advantages of Melamine Wood

Melamine engineered products are often more budget-friendly while maintaining reliability.

Melamine boards boast a consistent surface that is highly durable and resistant to scratches, stains, heat, and fire.

The waterproof nature of typical melamine surfaces allows for easy cleaning with soap and water.

Many prefer the absence of wood grain in melamine boards, especially those seeking solid-colored cabinets, as melamine is readily available pre-finished in various colors.

It offers a smooth finish, ready for use with minimal construction waste.

Cutting melamine is relatively straightforward with the right equipment, such as a saw with a scoring unit or CNC routers, which help prevent chipping. Proper material support during cutting reduces the risk of breakage.

Disadvantages of Melamine Board

Melamine boards are prone to bending and warping under heavier loads.

Due to its composite composition, melamine material tends to be heavy.

Melamine boards are manufactured using glues that can emit Volatile Organic Compounds (VOCs), which, according to the United States Environmental Protection Agency, may have adverse health effects in both the short and long term.

Comparing Melamine with Plywood

Melamine board offers distinct advantages when compared to plywood. While plywood board is known for its strength and natural wood grain appearance, melamine board provides a cost-effective alternative with increased durability and moisture resistance. It offers a wide range of attractive finishes, allowing for diverse design options.

Moreover, melamine board demands minimal upkeep and exhibits lower susceptibility to warping or delamination when contrasted with plywood. These attributes have propelled melamine board to become a preferred option in furniture production, especially when factors like durability, cost-effectiveness, and aesthetic appeal are pivotal. Although plywood possesses its own strengths, the benefits of melamine board render it an enticing choice for furniture designers and manufacturers aiming for a versatile and pragmatic material.

Comparing Melamine with MDF

Fiberboards, particularly MDF board (Medium Density Fiberboard), offer a cost-effective option for those looking to outfit modern kitchens, bathrooms, and interior furniture.

This material is composed of numerous wood fibers mixed with wax and resin under high pressure and temperature conditions.

Fiberboards available in the market are classified based on their densities, which are determined by the levels of temperature and pressure during manufacturing. Consequently, HDF (High Density Fiberboard) requires higher levels of pressure and temperature compared to MDF.

In summary, MDF falls in between HDF and particleboard in terms of density, with particleboard having the lowest density and exhibiting larger wood grains.

Comparing Melamine with solid wood, plywood, or fiberboards is a complex task.

Melamine is a popular plastic material widely used by modern cabinet builders. It can be applied as a laminate onto substrates such as plywood or particleboard, or it can be incorporated into the construction of kitchen cabinets, particularly when combined with MDF or particleboard. These substrates, made from wood chips, are used to form High Pressure Laminate (HPL) or Thermally Fused Laminate (TFL). Consequently, direct comparisons between melamine and MDF or particleboard can be challenging.

One of the key advantages of melamine is its durability and high resistance to scratches, along with its extensive range of colors and patterns. This versatility makes melamine fused with plywood arguably one of the most sustainable options for cabinetry.

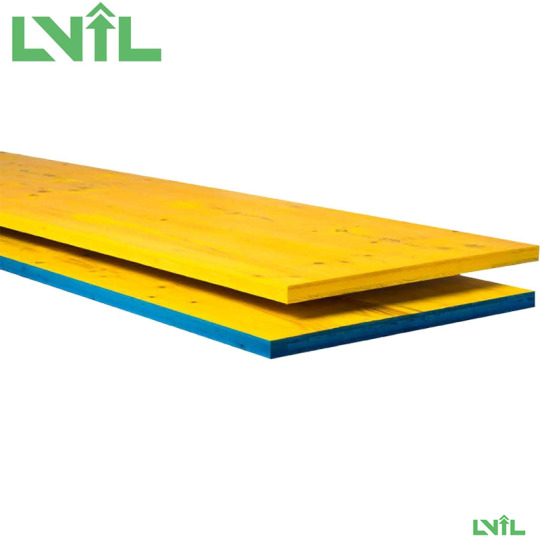

Previous:The Benefits and Safety of LVL Scaffold Planks in Construction

Next:LVL vs. Solid Wood Window Frames: Choosing the Right

0 notes

Text

CNC Wood Router

Do you have a thought to DIY or buy a reliable CNC Wood Router? Browse the 2024 new Wood Router buyer’s guide as follows, we’ll provide you with the competitive Wood Routers of 2024 with expert customer service to satisfied your requirements.

What is a CNC Wood Router? CNC Wood Router is a wood router machine controlled by the computer. It can process 2D/3D, milling, carving (relief, plane engraving, hollow carving, 3D carving), cutting, slotting and drilling of most popular wood materials and other soft materials, including woodworking crafts, wood carving, wooden marks, wooden toys, wooden gifts, cabinet making, wooden door making, wooden modelling, production of wooden furniture such as wardrobe.

The main structure of CNC Wood Router includes spindle, bed, gantry, servo motor and actuator, CNC operating system, CNC software, rack guide, screw, worktable, power supply, limit switch and so on.

CNC Wood Router is also known as wood CNC machine, woodworking CNC router, wood CNC router, CNC wood carving machine, wood CNC cutter, CNC wood milling machine, wood CNC table, CNC wood table, CNC wood router machine, CNC woodcarver, CNC wood engraver, CNC woodcutter, CNC wood cutting machine, c and c wood router, CNC woodworking machine, CNC wood engraver, wood c and c machine.

ATC CNC ROUTER SERIES

ATC CNC router is the first choice for enterprises with large production volume. According to the different tool changing methods, automatic tool changing engraving machines can be subdivided into linear ATC CNC machine and disc ATC engraving machines.Compared with the traditional manual tool change production method, this type of ATC CNC engraving machine has an independent tool magazine with different tool bits.Request a Quote

Small CNC Machine for Small Business

IGW-ATC 1325(PRO)ATC CNC Machine

ATC CNC Wood Router Table Kit

Wood CNC Router and Laser Engraver Combo

4×8 Wood CNC Router for Sale

Linear ATC CNC Router with Oscillating Knife Cutting

3d Atc Auto Tool Changer Wood Woodworking Machine

Wood CNC Router Rotation Head With Rotation Table

ATC CNC ROUTER SERIES

ATC CNC router is the first choice for enterprises with large production volume. According to the different tool changing methods, automatic tool changing engraving machines can be subdivided into linear ATC CNC machine and disc ATC engraving machines.Compared with the traditional manual tool change production method, this type of ATC CNC engraving machine has an independent tool magazine with different tool bits.Request a Quote

Small CNC Machine for Small Business

IGW-ATC 1325(PRO)ATC CNC Machine

ATC CNC Wood Router Table Kit

Wood CNC Router and Laser Engraver Combo

4×8 Wood CNC Router for Sale

Linear ATC CNC Router with Oscillating Knife Cutting

3d Atc Auto Tool Changer Wood Woodworking Machine

Wood CNC Router Rotation Head With Rotation Table

ATC CNC ROUTER, CNC ROUTER MACHINE, CNC WOOD ROUTERCNC Wood Router Machine

CNC ROUTER, CNC WOOD ROUTERBest Wood CNC Machine for Small Business

CNC WOOD ROUTERBest CNC Router Machines for Woodworking

CNC WOOD ROUTERLatest 1325 Wood CNC Machine 4×8

CNC WOOD ROUTERCNC Wood Router Manufacturers and Supplier

ATC CNC ROUTER, CNC ROUTER MACHINE, CNC WOOD ROUTERCNC Wood Carving Machine

3 AXIS CNC ROUTER, CNC WOOD ROUTER3 Axis CNC Router with automatic tool changer

HOT3 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER3 Axis ATC CNC Router with Automatic Tool Changer for Wood Furniture5.00 out of 5

HOT3 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERWood 3 Axis 4*8 CNC Router Machine for Sale

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERMulti Use 4 Axis Woodworking CNC Router with Rotary Axis

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER4 Axis CNC Wood Engraving Machine with Spindle Swing 180 Degree

READ MOREQUICK VIEW3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERRotary Spindle 4 Axis CNC Wood Engraving Machine with Auto Tool Change

0 notes

Text

Why CNC Machines Are Essential for Modern Woodworking - Squickmon's Perspective

CNC machines have revolutionized the woodworking industry by providing efficiency and precision that traditional equipment just cannot match. CNC technology can transform your approach to woodworking, regardless of your level of experience or type of work: hobbyist, skilled craftsmen, or large production team member.

What Are CNC Machines?

Computer-controlled movements are used by CNC (Computer Numerical Control) machines, such as routers, mills, and lathes, to precisely cut, carve, and shape wood. They work with digital design files, which guarantees correct and consistent outcomes each and every time.

Why Use CNC Machines?

1. Precision and Accuracy: CNC machines are great at producing finely detailed cuts and removing human mistakes, all while guaranteeing superior quality.

2. Efficiency and Productivity: These devices boost output and speed project completion by automating tool changes, accelerating manufacturing, and operating constantly.

3. Versatility and Flexibility: CNC machines can perform a wide range of tasks with ease, enabling endless inventiveness, from simple furniture items to intricate architectural elements.

4. Waste Reduction and Material Optimisation: CNC machines reduce waste and maximise material utilisation, which makes them economical and eco-friendly.

Streamlining Production with CNC

Automated Operation: CNC Plasma Cutters handle repetitive tasks, freeing up woodworkers to focus on design and supervision, reducing errors and rework.

Batch Production: Produce identical or similar parts in large quantities with consistent quality, ideal for items like chair legs or cabinet doors.

Just-In-Time Manufacturing: Components are produced as needed, reducing inventory costs and enhancing flexibility.

Integration with CAD/CAM Software: Design files can be easily created and modified, accelerating prototyping and production planning.

Diverse Woodworking Tasks with CNC

Cutting and Profiling: CNC routers excel at making straight cuts, curved shapes, and intricate designs with precision.

Carving and Engraving: Create detailed patterns and artistic designs with CNC mills and routers.

Joinery and Assembly: Achieve perfect joints like dovetails and mortise and tenon with automated accuracy.

3D Sculpting and Modeling: Bring digital designs to life with detailed 3D sculptures and reliefs.

Conclusion

In the field of woodworking, CNC machines are cutting-edge because they improve accuracy, increase output, and foster creativity. Embrace CNC technology to elevate your craft and achieve remarkable results. For high-quality CNC equipment, trust Squickmon's Engineering & Automation, a leader in the industry with over 15 years of expertise.

Unlock the future of woodworking with CNC machines and experience unparalleled precision and efficiency!

Check Out: Reasons to Use CNC Machines in Woodworking - Squickmon's

#CNCPlsmaTableManufacturer.#cnc plasma#cnc plasma table manufacturer#plasma table#cnc plasma table#woodworking

0 notes

Text

Explore the Power of CNC Router Machine for Cutting & Engraving Manufacturing | Success Technologies

Manufacturing, precision, speed, and automation are vital for delivering high-quality products consistently. One of the most revolutionary tools in this arena is the CNC Router Machine. From woodworking to plastics, metal fabrication, signage, and furniture production, CNC Routers have become indispensable across industries. If you're looking for a reliable solution for cutting and engraving tasks, a CNC Router offers unmatched efficiency and quality.

What is a CNC Router Machine?

Wood, plastics, foams, composites, and even soft metals can all be carved, engraved, and cut with a CNC router machine, also known as a computer numerical control router. The machine is managed by CAD/CAM software, which ensures that complex and consistent patterns are produced with little human error.

The Role of CNC Router Machines in Modern Manufacturing

CNC Router Machines play a critical role in boosting manufacturing productivity and quality. Whether you're a craftsman, a small business, or a large-scale industrial manufacturer, the integration of a CNC Router can take your production capabilities to the next level.

Some key applications include:

Woodworking: Creating decorative designs, furniture, cabinetry, and artistic Woodcrafts.

Signage: Precise engraving and cutting of signboards from materials like acrylic, MDF, and PVC.

Plastic and Foam Cutting: Smooth and accurate shaping of plastic components and foam inserts.

Aluminum and Soft Metal Machining: Ideal for light-duty cutting and engraving in soft metals.

Panel Processing: In cabinet and furniture making, CNC Routers ensure speed and quality in panel processing.

Benefits of Using a CNC Router

1. High Precision and Repeatability: With a CNC Router Machine, every cut, groove, or engraving is performed with digital accuracy. Whether it's a single piece or a bulk order, the results remain consistent and flawless.

2. Increased Productivity: Automated operation means less downtime and higher output. Complex jobs that would take hours manually can be completed in minutes, allowing businesses to meet tight deadlines without compromising on quality.

3. Reduced Waste: Because the machine follows pre-programmed paths, material usage is optimized, leading to less wastage and lower raw material costs.

4. Versatility: From simple 2D designs to intricate 3D carving, CNC Routers can handle a wide range of tasks across various materials.

5. Lower Labor Costs: Once programmed, a CNC Router requires minimal supervision, which reduces the need for skilled manual labor and lowers operational costs in the long run.

CNC Router Machine in Ahmedabad—A Hub of Quality Manufacturing

Ahmedabad, Gujarat, is rapidly becoming a powerhouse for advanced manufacturing in India. With increasing demand for automation and precision tools, the region is now home to several top-tier CNC Router machine manufacturers and suppliers. Companies like Success Technologies are leading the way by offering world-class CNC router solutions tailored to the Indian market needs.

Whether you're searching for a CNC Router Machine in Ahmedabad for your woodworking factory or want to expand into plastic fabrication, you'll find a comprehensive range of machines and services right here.

Why Choose Success Technologies?

At Success Technologies, we specialize in providing high-performance CNC routers in Ahmedabad, Gujarat, that are engineered for reliability, precision, and long-lasting durability. As a trusted CNC router manufacturer and supplier in India, we bring you a wide array of machines designed to cater to every industrial requirement.

Here’s what sets us apart:

Custom Machine Design: We recognize the uniqueness of every business. To create machines that meet your unique demands, whether they be for Metal Engraving, woodworking, or advertising, our team works directly with clients.

Advanced Features: Our CNC Router Machines come equipped with high-speed spindles, rigid gantry structures, automatic tool changers, and intelligent control systems to ensure smooth operation.

After-Sales Support: Success Technologies provides extensive after-sales support, including training, installation, and maintenance, ensuring maximum uptime for your business.

Affordable Pricing: Searching for an affordable CNC router machine price in India? We provide the best return on your investment with competitive pricing without compromising quality.

CNC Router Machine Manufacturers & Suppliers in India – The Competitive Edge

The Indian manufacturing market is witnessing a boom in automation and smart machinery. As one of the emerging global hubs, India offers high-quality CNC Router solutions that compete with international standards—at a fraction of the cost.

By partnering with a trusted CNC Router Machine Manufacturer in India like Success Technologies, businesses can tap into state-of-the-art technology, robust machine design, and ongoing technical support.

From small businesses to large industrial units, CNC Routers are proving to be game changers. Indian-made machines, especially those from Ahmedabad-based CNC Router manufacturers, are known for their durability, efficiency, and cost-effectiveness.

CNC Router Machine for Woodworking – Revolutionizing the Craft

The woodworking industry has undergone a massive transformation with the advent of CNC Router technology. Gone are the days of time-consuming manual carving. Today, furniture designers and carpenters rely on CNC Router Machine for Woodworking to produce flawless, detailed, and repeatable designs with minimal effort.

Common applications in woodworking include:

Intricate furniture components

Custom cabinetry

Decorative wall panels

Wooden signboards

Artistic carvings

With a CNC Router, the creative possibilities are endless, and you get the consistency and scalability that traditional methods cannot provide.

Factors to Consider When Buying a CNC Router

If you're considering purchasing a CNC Router Machine, keep these points in mind:

Material Type: Identify the materials you'll be working with (wood, plastic, aluminum, etc.)

Size and Bed Area: Choose a machine that matches the size of your workpieces.

Spindle Power: Ensure the spindle is powerful enough for your intended applications.

Software Compatibility: Check if the machine supports your preferred CAD/CAM software.

After-Sales Service: Select a manufacturer who offers excellent technical assistance and training.

CNC Router Machines – A Smart Investment for the Future

CNC technology adoption has become essential, never optional. Manufacturers need to adopt automation in order to stay ahead of the increasingly competitive global market. In addition to increasing output and quality, a CNC router machine makes it easier to fulfill complex designs and customized requests.

Whether you're a startup, SME, or large-scale manufacturer, investing in a CNC Router in Ahmedabad from Success Technologies is a step toward a smarter, more efficient future.

🔧 Get the Best CNC Router Machine at Success Technologies!

Are you looking to purchase a high-performance, affordable, and dependable CNC router machine in India? Join forces with Success Technologies, one of Ahmedabad, Gujarat's leading manufacturers and suppliers of CNC router machines. We provide a large selection of equipment designed for metal cutting, woodworking, signs, and other applications.

For more information: https://www.successlaser.com/ Contact us: 9998961184E-mail ID: [email protected] Location: 97, Barcelona Industrial Estate, Odhav Rd, Odhav, Kathwada, Ahmedabad, Gujarat 382415

#CNC Router#CNC Router Machine#CNC Router Manufacturer#CNC Router India#CNC Router Supplier#CNC Router Machine in Ahmedabad#CNC Router Machine - Manufacturers & Suppliers in India#CNC Router machine price in india#CNC Router machine manufacturers#CNC Routers in Ahmedabad#Gujarat#CNC Router Machine For Woodworking

0 notes

Text

The Evolution of Panel Saw CNC Machines

Introduction:

In the realm of woodworking and industrial manufacturing, precision, efficiency, and versatility are paramount. Over the years, the integration of Computer Numerical Control (CNC) technology has revolutionized various manufacturing processes, including woodworking. One significant advancement in this domain is the Panel Saw CNC machine. These machines have not only simplified the process of cutting large panels but have also ushered in a new era of precision and productivity in the woodworking industry.

Understanding Panel Saw CNC Machines:

Panel Saw CNC machines are sophisticated pieces of equipment designed for precise and efficient cutting of large panels such as plywood, particleboard, MDF (Medium-Density Fiberboard), and other engineered wood products. These machines utilize CNC technology, which involves the automation of cutting processes based on digital designs and instructions.

Key Features and Components:

Panel Saw CNC machines come equipped with several essential features and components to ensure accurate and efficient operation:

Cutting Head: The cutting head of a Panel Saw CNC machine holds the cutting tool, which could be a circular saw blade, a router, or a combination of both. These cutting tools are capable of making various cuts, including rip cuts, cross cuts, and angled cuts, depending on the requirements of the project.

CNC Control System: At the heart of every Panel Saw CNC machine lies its control system, comprising software and hardware components. The CNC software interprets digital design files (such as CAD drawings) and translates them into precise cutting instructions. Operators can input parameters such as cutting dimensions, tool paths, and cutting speeds through user-friendly interfaces.

Precision Drive Mechanism: To ensure accuracy in cutting, Panel Saw CNC machines are equipped with precision drive mechanisms. These mechanisms control the movement of the cutting head along the X, Y, and Z axes with high precision, allowing for intricate cuts and tight tolerances.

Material Handling System: Many Panel Saw CNC machines feature integrated material handling systems to streamline the loading and unloading of large panels. These systems can automatically feed panels into the cutting area and remove finished pieces, reducing manual labor and increasing efficiency.

Benefits of Panel Saw CNC Machines:

The adoption of Panel Saw CNC machines offers numerous benefits to woodworking businesses and manufacturers:

Precision: CNC technology ensures consistent and precise cuts, resulting in high-quality finished products with tight tolerances and minimal waste.

Efficiency: By automating the cutting process, Panel Saw CNC machines significantly reduce production times compared to manual methods. This increased efficiency translates to higher productivity and lower labor costs.

Versatility: Panel Saw CNC machines can handle a wide range of panel materials and cutting tasks, making them suitable for diverse woodworking applications, from cabinet making to furniture manufacturing.

Scalability: With the ability to process large volumes of panels quickly and accurately, Panel Saw CNC machines enable woodworking businesses to scale their production capacity to meet growing demand.

Applications:

Panel Saw CNC machines find applications across various industries and woodworking sectors, including:

Cabinet Making: Precisely cut panels for constructing cabinets, shelves, and other storage solutions.

Furniture Manufacturing: Produce components such as tabletops, side panels, and drawer fronts with high precision and efficiency.

Architectural Millwork: Fabricate custom moldings, trim pieces, and architectural details for residential and commercial projects.

Sign Making: Create intricate designs and lettering on wood panels for signage and displays.

Conclusion:

Panel Saw CNC machines represent a significant advancement in the woodworking industry, combining the precision of CNC technology with the efficiency of panel cutting operations. By automating processes, enhancing precision, and increasing productivity, these machines empower woodworking businesses to deliver high-quality products while remaining competitive in today’s market. As technology continues to evolve, Panel Saw CNC machines are poised to play an increasingly integral role in modern woodworking and manufacturing processes.

0 notes

Text

Precision Woodworking Redefined The Transformative Technology of CNC Wood Router Machines

In the ever-evolving world of woodworking, the marriage of technology and craftsmanship has given rise to groundbreaking tools, and at the forefront of this revolution is the CNC wood router machine. This Computer Numerical Control (CNC) marvel has become an indispensable asset to woodworkers, artisans, and manufacturers alike, offering unparalleled precision, versatility, and efficiency. In this article, we will explore the key features, capabilities, and applications that make CNC wood router machine a game-changer in the realm of woodworking.

Understanding CNC Wood Router Machines:

CNC wood router machines represent a leap forward in woodworking technology. These automated devices are designed to cut, carve, and shape wood with an exceptional level of precision. The defining feature of CNC technology is the ability to follow digital instructions, allowing woodworkers to create intricate designs and execute complex patterns with ease. This technological advancement has transformed the traditional woodworking landscape, offering a more efficient and precise alternative to manual methods.

Key Features and Capabilities:

Digital Precision: At the core of CNC wood router machines is their ability to execute digital designs with unparalleled precision. The machine precisely follows the programmed instructions, resulting in intricate and accurate cuts that would be challenging to achieve consistently with manual methods.

Automation: CNC wood routers operate in an automated fashion, reducing the need for constant manual intervention. Once the design is programmed, the machine can execute the tasks autonomously, freeing up the woodworker to focus on other aspects of the project.

Versatility: These machines are highly versatile and can be adapted to work with a variety of materials beyond wood, including plastics, composites, and soft metals. This flexibility makes CNC wood routers suitable for a wide range of applications in diverse industries.

Efficiency and Speed: CNC wood router machines significantly enhance efficiency and speed in the woodworking process. The automation of tasks, coupled with the precision of the cutting process, results in quicker project turnaround times, making these machines invaluable for both small-scale workshops and large-scale manufacturing facilities.

Applications of CNC Wood Router Machines:

Furniture Manufacturing: CNC wood routers are a cornerstone in the production of furniture, allowing for the precise cutting and shaping of components. This technology ensures consistency in design and quality, contributing to the overall craftsmanship of the finished pieces.

Cabinet Making: In cabinetry, CNC wood router machines excel in creating intricate joinery, custom moldings, and precisely fitted components. The ability to replicate designs consistently enhances the efficiency of cabinet-making processes.

Sign Making: The signage industry benefits from the precision of CNC wood routers in creating detailed and eye-catching signs. These machines are capable of carving intricate letters and designs with ease, catering to the demands of the visual communication sector.

Artistic Woodworking: Artists and designers leverage CNC wood routers to bring their creative visions to life. The precision and versatility of these machines allow for the creation of complex and artistic patterns, contributing to the fusion of technology and creativity in woodworking.

Conclusion:

CNC wood router machines have redefined precision woodworking, offering woodworkers a powerful tool to bring their designs to life with accuracy and efficiency. As technology continues to advance, these machines are likely to play an increasingly vital role in shaping the future of woodworking, providing endless possibilities for innovation and creativity in the hands of skilled craftsmen.

0 notes

Link

0 notes

Text

4 Axis 3 Axis CNC Router Machine for Woodworking 2d 3D Engraving

Woodworking cnc router

A woodworking CNC router is a computer numerical control (CNC) machine specifically designed for woodworking applications. It is a versatile and precision tool that automates the cutting, carving, engraving, and shaping of wood and wood-based materials.

A CNC wood router machine is an automatic table kit for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories. The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines. The most commonly used CNC wood router tables include 2ft by 3ft, 2ft by 4ft, 4ft by 4ft, 4ft by 6ft, 4ft by 8ft, 5ft by 10ft, and 6ft by 12ft. A wood router is applied in most popular woodworking plans and projects such as cabinet making, door making, sign making, arts & crafts, furniture making, and home decorations.

3 Axis Woodworking CNC Router Carving Machine

The CNC wood router on this page mainly refers to the 3 axis CNC router machine for CNC woodworking. The spindle of the CNC wood router carries the CNC router bits to move along the X, Y, and Z axes. As one type of the most commonly used wood CNC machine, it can cut, carve, engrave, mill, punch various types of wood boards. So it is also called CNC wood carving machine, CNC wood cutting machine, or CNC wood engraving machine.

The 3 axis CNC router has outstanding features, such as low cost, simple operation, multiple functions, and easy maintenance. So it is considered as an entry-level wood CNC machine in the CNC woodworking industry. And it is quite popular with users at home and abroad. The CNC wood cutting machine mainly performs some plane processing on wooden panels. If you are just doing flat machining on some plates, this 3 axis CNC router is definitely your ideal choice. For example, engrave patterns on or cut shapes out from a wood board.

Simply put, the 3 axis CNC wood carving machine works like a printer in terms of working principle.

The CNC router software (CAD) designs the engraving patterns and cutting paths to turn your ideas into electronic files. And the design and working path information is automatically transferred to the controller by the computer. Then the other type of CNC router software (CAM) turns the electronic files into G-codes. Such G-codes can drive the servo or stepper motor to work and control the CNC wood engraving machine spindle to move along the X, Y, and Z axes. So it can complete cutting, engraving, or carving work of multiple materials fixed on the working table.

Of course, sometimes, you have other machining requirements such as carving three-dimensional workpieces, curved surface machining of complex workpieces. To meet these demands, we also have CNC routers for woodworking with the rotating spindle, rotary device, automatic tool charge, or multiple spindles. You can choose one CNC wood cutting machine among them that can best suit your requirements.

3 Axis Woodworking CNC Router Machine with ATC

ATC CNC router is the first choice for enterprises with large production volume. Compared with the traditional manual tool change production method, this type of wood CNC machine has an independent tool magazine with different tool bits. It can automatically change the required tools by computer program control without stopping work during processing. And this CNC wood router can complete a series of cutting, hollowing, grooving, punching, milling grooves, milling planes and other different processing needs. Therefore, both the processing quality and processing efficiency have been greatly improved.

According to the different tool changing methods, the ATC CNC engraving machine can be subdivided into linear ATC CNC and disc ATC CNC machines. Then we are talking about the linear ATC CNC Machine. This type machine uses a straight-line tool change device, and the tool change device can be installed in different positions according to the specific needs of the user.

Firstly, the in-line tool magazine can be placed behind the bed. This conventional in-line tool changer engraving machine is cost-effective and can meet a variety of processing requirements for complex work pieces without high procurement costs. Secondly, the in-line tool magazine can also be placed under the gantry. This type of linear engraving machine does not need to go to the back of the bed to change tools, so the tool change speed is faster and the wear on the guide rail can be reduced, and the service life of the machine is relatively longer. It is worth mentioning that the number of tools in the in-line tool magazine can be customized according to the specific processing needs of the user.

4 Axes Woodworking CNC Router

4 axis CNC router is quite good at processing 3D workpieces. It generally falls into two types. The first type described hereunder is equipped with a rotating spindle that can swing by 180°. It can engrave 3D patterns and drill holes on side surfaces of wood, MDF, acrylic, foam, rubber, and other materials. For example, 3D letters, signs, reliefs, and sculptures.

In a broad sense, a 4 Axis CNC Router machine refers to a CNC machine whose processing path include X, Y, Z, and A axis. And we are going to talk about a 4 axis machine whose spindle can swing left and right. Because the spindle of this type of CNC can swing left and right, the spindle can approach the work piece from multiple different angles and efficiently process three effective processing surfaces. This CNC machine can realize not only the plane engraving, but also the 3d carving of irregular work pieces.

And this type of wood CNC machine is suitable for common work piece, three-dimensional work piece, complex work piece and irregular graphics processing. In addition, this type of CNC engraving machine makes full use of the geometric configuration of the tool, controls the angle of the force, reduces the vibration of the force, prolongs the life of the tool, enhances the stability of the processing, and improves the processing accuracy. With the advantages of complete functions, wide processing range and high processing accuracy, more and more users choose the 4 axis machines for 3D Wood Carving. If you have similar three-dimensional work pieces, this CNC Wood Router will be your ideal choice.

4 axis cnc router woodworking machine with ATC

CNC wood machining center with 4th rotary axis is designed for 2D/3D popular woodworking, including wood furniture, wood cabinets, wood doors, wood decorations, stair spindles, wood balusters, roman columns, table legs, baseball bats. Now the best CNC wood machining center for sale at affordable price.

CNC Router Woodworking Machine Applications

This unit is a type of heavy duty CNC machine with wider machining range, like wood, MDF, aluminum, plastic, foam, etc .

By using STM1325-R1, you’ll find plenty of room for creativity: anything you can draw, it can cut. This machine can cut well with tremendous edge cuts because it adopts the same motion control as the larger machines. It can also runs with hand-held control system (DSP controller) that makes it easy to use.

1. Advertising: It can carve and cut all kinds of signs, trade mark, name plates, badge, decorative gift, embossed medal, certificate, souvenir, photo frame, furniture decoration.

2. Woodworking: It can be used for solid wood furniture, mahogany furniture, MDF paint door, solid wood door, composite door, cupboard door and window, bed side cabinet, folding screen.

3. Art Work: It can make wooden craft, mural art of wood, artwork, embossed, jewelry, cosmetics package, musical instrument.

4. Soft Metal Milling & Cutting: It can process aluminum front panel, popcan, aluminum honey comb panel, train car and air craft interior decoration, bronze medal, copper mold.

5. Electronics: It can engrave electronic component, integrated circuit, electronic plastic case, electronic product model, circuit board, electronic light box, computer and mobile phone key board, and a variety of electronic products.

Features and Aspects of Woodworking Cnc Routers

Computer Control: Woodworking CNC routers are controlled by a computer or a CNC controller that interprets design files and generates toolpaths. This allows for precise and repeatable woodworking processes.

CAD/CAM Software: Users design their projects with computer-aided design (CAD) or computer-aided manufacturing (CAM) software. The design files are then imported into the CNC router’s control software.

Versatile Cutting and Carving: CNC routers can perform a wide range of woodworking tasks, including cutting, carving, engraving, drilling, and 2D/3D shaping. They can create intricate designs and detailed patterns.

Spindle or Router Bit: CNC routers typically have a spindle or router bit that rotates at high speeds to cut or shape the wood. The choice of router bit and its speed affects the type of cuts and finishes the machine can achieve.

Table Size: Woodworking CNC routers come in various sizes, with different table dimensions. The choice of size depends on the type and size of projects you plan to undertake.

Tool Changer: Some advanced CNC routers have automatic tool changers, which allow the machine to switch between different router bits without manual intervention. This feature is beneficial for complex projects that require multiple tool types.

Dust Collection System: To maintain a clean and safe working environment, many woodworking CNC routers have dust collection systems that capture and remove wood chips and dust generated during the machining process.

Material Compatibility: CNC routers can work with a variety of wood and wood-based materials, such as hardwoods, softwoods, plywood, MDF (medium-density fiberboard), and more.

Precision and Accuracy: CNC routers offer high precision and accuracy, ensuring that the final products meet design specifications.

Safety Features: Some woodworking CNC routers are equipped with safety features such as emergency stops and protective enclosures to ensure operator safety.

User-Friendly Interface: Many CNC routers have user-friendly interfaces that make it easy to set up and run jobs.

Woodworking CNC routers are a valuable addition to woodworking shops, allowing for the production of intricate and customized wood products with efficiency and precision. When using a CNC router, it’s essential to receive proper training, follow safety guidelines, and maintain the machine regularly to ensure its optimal performance.

1 note

·

View note

Video

youtube

Heavy Duty 4*9ft Wood Router Furniture Cabinet ATC Making Cnc Router Carving Machine

0 notes