#Cable and Wire Harness Assembly Services

Explore tagged Tumblr posts

Text

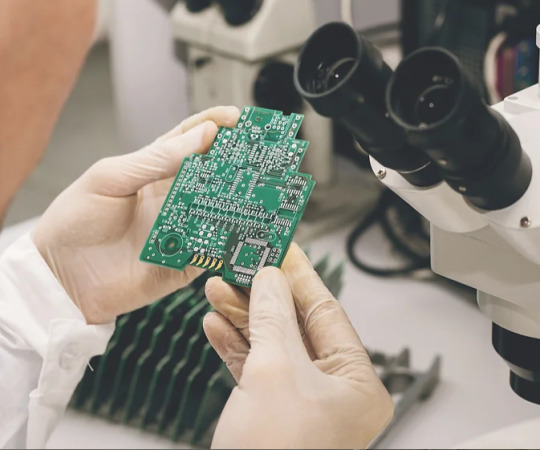

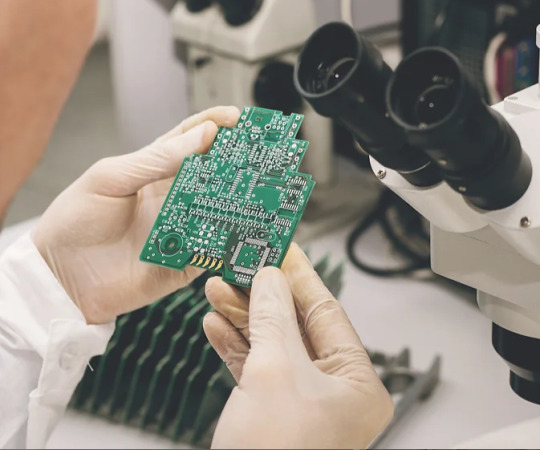

Top Contract Electronic Manufacturing Services

Discover top-tier contract electronic manufacturing services with East West Manufacturing Enterprises. Specializing in PCB assembly and complete product builds, we combine precision, quality, and efficiency to meet your manufacturing needs. Count on us for reliable solutions that ensure your products are built to the highest standards, helping you bring innovative ideas to market with confidence. Explore how our expertise can streamline your manufacturing process today!

#east west manufacturing austin#electronics manufacturers#electronics contract manufacturing#electronics manufacturing services#aerospace and defense manufacturing#defense electronics manufacturing#aftermarket services#east west electronics#integration system#system integration testing#Military Electronics Manufacturers#Electronic Contract Manufacturing Services#Contract Electronic Manufacturing Services#Cable and Wire Harness Assembly Services#Contract Electronic Manufacturing#Functional Testing Austin#Printed Circuit Board Assembly

0 notes

Text

https://www.bloglovin.com/@mefrontechnologies/understanding-wire-harnessing-a-complete

Understanding Wire Harnessing - A Complete Guide

With comprehensive wire harness services, tailored solutions, and a commitment to quality, manufacturers like us ensure that your products perform reliably and efficiently.

0 notes

Text

Life Cycle Management

Electronic Manufacturing Services Across the Product Life Cycle

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Design For Excellence (DFX)#Return Merchandise Authorisation (RMA)#BOM Analysis#PLM Agile System For Program Management#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS#Life Cycle-Management

2 notes

·

View notes

Text

Genuine Royal Enfield GT 650 Parts & Accessories – Trusted Worldwide by Smart Parts Exports

The Royal Enfield Continental GT is the epitome of modern classic motorcycling. It achieved great fame all over the world with its retro café racer styling, powerful parallel-twin engine and immense muscle. As a bike enthusiast or a motorbike shop mechanic, maintaining your Royal Enfield GT 650 demands an upkeep and that begins with genuine spare components.

At Smart Parts Exports, we take immense pride in premium motorcycle parts. With our trustful reputation Smart Parts Exports became highly sought out for authentic Royal Enfield GT 650 components. Now specializing in the export of premium GT 650 parts and GT 650 spare parts for enthusiasts and workshops, we are focused on delivering quality and timely service.

Why the Royal Enfield Continental GT Deserves Genuine Parts

The Royal Enfield Continental GT is not just another motorcycle, but rather a powerhouse on wheels. Aptly encapsulated by its 648cc twin-cylinder engine, the Royal Enfield GT 650 also embraces sporty ergonomics and agile handling which adds to its flair as a stylish motorbike.

To reap the full benefits of your investment and performance, it is advisable to only use GT 650 authentic spare parts. With genuine parts, your bike will operate properly, has a longer service life, and will continue to provide the thrilling riding experience it was designed for. Aftermarket or low end copies not only affect performance but can also be a safety hazard.

That’s where Smart Parts Exports steps in.

Your One-Stop Shop for All GT 650 Parts

Smart Parts Exports has in stock a wide and comprehensive range of GT 650 parts which include the mechanical, electrical and body cosmetic accessories. Whatever part you want, we will help you locate it quickly and reliably.

Here’s what you can expect from our inventory:

Engine Parts: Pistons, camshafts, crankshafts, cylinder heads

Brake Systems: Brake pads, discs, calipers, master cylinders

Suspension: Front forks, rear shock absorbers, fork oil seals

Body Panels: Fuel tanks, side panels, mudguards, seats

Electrical Components: Ignition coils, wiring harnesses, ECUs

Exhaust Systems: Mufflers, exhaust pipes, silencers

Accessories: Windshields, handlebars, mirrors, lights

All our GT 650 spare parts are either OEM-certified or genuine Royal Enfield products, which means you can expect excellent fit, finish, and durability.

The Smart Parts Advantage in Exporting Royal Enfield GT 650 Parts

With vast experience in the automotive export business, Smart Parts Exports has developed a very strong global network, shipping vehicle parts to over 80 countries. We sell to retail shops, garages, bike modifiers, and individual enthusiasts who expect and demand high standards.

What sets us apart?

✅ Authenticity Guaranteed: Every product we sell is 100% genuine or OEM equivalent.

✅ Affordable Pricing: Our efficient sourcing system ensures competitive prices on all GT 650 parts.

✅ Bulk Availability: Planning a restoration project or need regular parts for a workshop? We handle bulk orders with ease.

✅ International Shipping: Safe and fast global shipping to your doorstep—whether you’re in the Middle East, Europe, South America, or Africa.

✅ Customer Support: Our expert team is always ready to assist you in identifying the right GT 650 spare parts for your specific need.

Whether you're restoring an old bike or customizing your Royal Enfield Continental GT, we’re here to supply the parts that match the build quality of your machine.

Commonly Requested GT 650 Spare Parts

If you're wondering what our most frequently shipped Royal Enfield GT 650 parts are, here’s a quick look:

Clutch plates and clutch cables

Rear view mirrors and handlebar grips

Side stands and center stands

Air filters and oil filters

Headlight assemblies and turn indicators

Chain sprockets and drive chains

Whether you're carrying out routine maintenance or a full-scale rebuild, we have the parts to match your exact needs.

Serving Royal Enfield Enthusiasts Globally

From experienced mechanics to novice bike riders, any one who rides or repairs a Royal Enfield GT 650 is a customer. Lasting bonds is what we aim to build with customers through serving them with quality, timely deliveries, and no hidden pricing.

These parts of the world, Russia, UAE, Kenya, Nepal, the Philippines and many others are some of our clients important and new proven regions which mean Smart Parts Exports is a reputable name in the global auto spare parts industry.

We’ve helped riders rebuild their crashed bikes, supported workshops with urgent orders, and even supplied hard-to-find GT 650 parts for vintage restoration projects.

Contact Smart Parts Exports for Your Royal Enfield Continental GT Needs

Are you struggling to find a reliable exporter of GT 650 spare parts? Do you want the peace of mind that comes with dealing with genuine parts suppliers?

Get in touch with Smart Parts Exports today. Our team is standing by to answer your queries, provide part recommendations, and help you place your order.

From the smallest bolts to major engine components, we stock and ship everything your Royal Enfield Continental GT might need. Don’t compromise on quality—choose Smart Parts Exports for genuine Royal Enfield GT 650 parts that go the distance.

0 notes

Text

Custom Wire Harness Assembly Solutions for Every Industry

Why Wire Harness Assembly Matters

A wire harness assembly isn’t just a bunch of wires bundled together — it’s the backbone of any reliable electrical system. Whether you're powering a car, industrial machine, or electronic device, a professionally designed harness ensures safety, simplifies installation, and improves performance.

Custom Cable Harness Assembly for Unique Needs

Not every project is one-size-fits-all. At Popular Systems, we offer custom cable harness assembly solutions tailored to your design and technical requirements. From simple wire bundles to complex multi-branch harnesses, our team ensures exact fit and flawless operation.

Trusted Cable Harness Assembly Suppliers in India

As experienced cable harness assembly suppliers, we serve OEMs across automotive, energy, and appliance sectors. Our quality-tested products meet international standards and are built to withstand harsh environments and continuous operation.

Why Choose Custom Cable Manufacturers?

Working with expert custom cable manufacturers gives you full control over wire length, insulation, shielding, and connector types. This customization leads to better performance and fewer failures, which means fewer headaches down the road.

Applications We Serve

Automotive wiring harness systems

Industrial cable assemblies

Home appliance wiring

Renewable energy electrical assemblies

Electrical control panels and switchgear wiring

Quality You Can Count On

Our custom wiring harness solutions go through stringent testing for continuity, insulation resistance, and durability. We use high-grade materials and advanced assembly processes to guarantee long-term reliability.

Ready to upgrade your electrical systems? Visit Popular Systems for expert wire harness assembly and electrical sub-assembly services you can rely on.

#cable assembly manufacturers#wire harness assembly#cable harness assembly#custom cable manufacturers#custom wiring harness#Cable Harness#Cable assembly

0 notes

Text

Measures of Avoiding Unskilled Manufacturers for Custom Wire Harness Assembly

Cables are one of the most common products within the motive of communication and electronics industries. However, conventional cables are not always viable for really demanding and important applications. Occasionally, there will be a need for custom wire harness manufacturing services.

If so, you need cables that will be unique to your needs and the usage situation that you provide. But which cable should you use? Can cables actually be ordered from scratch? Custom cables are essential to be selected to meet a specific wiring need if you desire to do so. This blog’s area of interest is how to select wire harness manufacturing companies.

Offerings of Reputable Manufacturers of Custom Cable Assembly

Respectable custom harness assembly companies are unique in terms of the services they offer and the quality of products they deliver. For this reason, you should look into which particular services a certain business provides before deciding on it.

This is because, if warranted, a tailored wire harness is paramount given the benefits, such as the ability to distinguish a single wire easily and the added space conservation. As such, ensure that you make the right decisions in order to ensure that you achieve the expected results.

Legitimate Responsibilities of an Ideal Cable Harness Assembly Producer

Merely paying attention to services offered by the manufacturer of bespoke cable assemblies is not enough. It would also be wise to identify more specific duties of these organizations. You are limited to accepting whatever is given to you by the organization, even if this is inappropriate if you cannot identify the organization’s duties.

What is, therefore, expected of a maker of bespoke wiring harnesses? The solution is rather simple. Their duties include:

●Skilled employees ●The abundance of expertise ●Creativity and abilities ●Cost ●Service and product quality

Identifying a False Cable Harness Assembly Business

People have a basis to know what is real and what is fake by assessing certain factors. At some other times, you decide to look the other way. Among the methods for spotting fraudulent cable harness assembly firms are:

●Service prices are really low ●Unrecognized site or, conversely, poorly created web page ●Lack of attention to details ●Staff strength

The Consequence of Lower Standard

Failure to have proper custom cables causes environmental problems. Offering low-quality custom wires has considerable disadvantages. Apart from time and scarce resources being channeled to the wrong thing, substandard and low-quality bespoke cables also remain one of the easiest ways through which the environment is put in one or many dangers and incidents that cause loss of lives and property.

Conclusion

The only way to get the best is to accept the finest. Those automakers who require new wire harnesses do not know what you require, but they know your resources. Instead of utilizing the services of nonprofessional wire harness manufacturers, consult with professionals in custom wire harness manufacturing services.

0 notes

Text

China Cable Wire Harness Assembly: Why Topscom Technology is Your Best Choice

In today's fast-paced technological world, cable wire harness assemblies play a crucial role in various industries, from automotive and aerospace to consumer electronics and industrial machinery. These assemblies ensure efficient power transmission, signal connectivity, and overall system reliability. For companies looking to source high-quality cable wire harness assemblies, China has become a prominent global hub due to its advanced manufacturing capabilities and competitive pricing. Among the many providers in China, Topscom Technology stands out as a leading choice for superior China cable wire harness assembly services. https://is.gd/RIk8ag

PCB SMT assembly, China printed circuit board assembly, China PCB factory, China PCB fabrication, China PCB manufacturing, China PCB board, China PCB manufacturer, China PCB service, China PCB prototype, China PCB supplier, China PCB, PCB China, China PCB online, PCB board, China PCB assembly, PCBA China, China PCB design, PCB assembly, China PCB quote, PCBA, contract manufacturing China, China contract manufacturing, contract manufacturing, China electronic assembly, China electronic manufacturing, electronics manufacturing, electronic board manufacturers, China OEM manufacturing, OEM manufacturing, China cable wire harness assembly

0 notes

Text

Top Contract Electronic Manufacturing Services

Discover top-tier contract electronic manufacturing services with East West Manufacturing Enterprises. Specializing in PCB assembly and complete product builds, we combine precision, quality, and efficiency to meet your manufacturing needs. Count on us for reliable solutions that ensure your products are built to the highest standards, helping you bring innovative ideas to market with confidence. Explore how our expertise can streamline your manufacturing process today!

#East West Manufacturing Austin#East West Manufacturing Enterprises#East West Electronics#Fct Testing Austin#System Integration Testing Austin#Cable and Wire Harness Assembly Austin#Cable Assembly Services Austin#Wire Harness Assembly Austin#Cable Harness Assembly Austin#Printed Circuit Board Assembly Austin

0 notes

Text

Absolute Electronics Inc: Redefining Excellence in Touchless Contract Manufacturing and Cable Assembly System Integration

In today's rapidly advancing technological landscape, precision and efficiency are crucial. At Absolute Electronics Inc, we pride ourselves on being industry leaders in touchless contract manufacturing and cable assembly system integration, offering unmatched innovation and quality.

Touchless Contract Manufacturing - A Unique Approach

In a world where contamination risks and precision are paramount, Absolute Electronics Inc has embraced a unique touchless contract manufacturing process. Our state-of-the-art facilities utilize advanced robotics and automation to handle delicate components without human interference, ensuring a higher level of cleanliness and accuracy in production. This approach not only reduces the risk of contamination but also enhances product reliability and longevity.

By adopting touchless manufacturing, we can meet the most stringent quality standards across various industries, from medical devices to aerospace applications. Our focus on automation and robotics allows us to deliver products that are precise, efficient, and built to withstand the toughest conditions.

Cable Assembly System Integration

At the heart of many modern electronic devices is the complex network of cables and wiring that powers them. Our expertise in cable assembly system integration enables us to deliver robust solutions tailored to specific client needs. Whether you require simple cable assemblies or complex wiring harnesses for intricate systems, Absolute Electronics Inc ensures that every project is handled with meticulous attention to detail.

Our cable assembly services provide seamless integration, from design to production. This results in systems that are not only functional but optimized for performance. We take pride in our ability to handle both high-volume and custom projects, always with a commitment to quality, reliability, and timely delivery.

Why Choose Absolute Electronics Inc?

Absolute Electronics Inc stands out in the industry due to our commitment to innovation, quality, and customer satisfaction. Here’s what sets us apart:

Innovative Manufacturing: We utilize cutting-edge technologies, such as touchless systems, to enhance product quality.

Customized Solutions: Whether it’s contract manufacturing or cable assembly system integration, we tailor our services to meet your specific needs.

Expert Team: Our skilled professionals bring decades of experience in electronics manufacturing and system integration.

On-Time Delivery: We understand the importance of deadlines and ensure timely project completion without compromising on quality.

At Absolute Electronics Inc, we are more than just a manufacturing company; we are a partner dedicated to your success. By combining touchless contract manufacturing with expert cable assembly system integration, we help you bring cutting-edge products to market faster and more efficiently.

0 notes

Text

Exploring the Competitive Edge of Cable Manufacturers in Vietnam

As the global market for custom cable assemblies continues to expand, the role of cable manufacturers in Vietnam has become increasingly significant. Among various companies in this field, SINNHONG ELECTRONICS CO., LIMITED stands out by offering multiple clients diversified cable assemblies. We commit to quality, speed, flexibility, and competitive pricing, all of which make our firm stand strong for new challenges in the growing market.

Solution Tailored to Diverse Needs

Our customization lies at the heart of operations. Each client might have unique requirements and we propose highly adaptable solutions. Be it a specific design, material or configuration, our team can develop custom cable assemblies that perfectly match your needs. This flexibility has earned us a pinnacle spot among cable manufacturers in Vietnam. It has allowed us to serve clients in sectors that range from automotive and industrial equipment to telecommunications and security products.

Speed and Efficiency of Production

In today's fast paced marketplaces, time is a critical factor. For quick delivery of customized cable assemblies we have adopted lean manufacturing techniques. Our customers' products are delivered sooner because of our efficient manufacturing techniques and rapid prototyping which also cut lead times. This speed is among the prime reasons that make us one of the leading choices for cable manufacturers in Vietnam. At the same time, it enables our customers to outpace their competition.

The Affordable Solution without Compromising on Quality

Operating in Vietnam also offers several advantages in terms of competitive pricing. We use our bulk purchasing power and efficient production methods to ensure practical solutions at low costs to our clients. Meanwhile, quality is never compromised at the altar of cost competitiveness, so our customers get total value for their investment. This affordability and quality are among the hallmarks of our operations and a significant reason we stand out as one of the premier cable manufacturers in Vietnam.

Responsiveness towards Dedicated Customer Support

Customer satisfaction is one of our top priorities. Our team of professionals is always ready to help with any queries and issues. We believe in long term relationships with our clients and offer the best customer service from the initial consultation to after sales service. This extra care towards the customers further strengthens our position as a reliable cable manufacturer in Vietnam.

Expansion by Strategy for Global Competitiveness

We have strategically expanded its operations to Vietnam to enhance its global competitiveness. The manufacturing facility in Dongguan and Ho Chi Minh City is spread over 3,000 square meters and has a working strength of about 100 skilled staff. Having set foot in Vietnam, we made the most of our business-friendly atmosphere, especially where the country's tariffs are low and plenty of labor is affordable. This expansion step allows us to revise our production methods for increased efficiency and maintain our leading position in this globally competitive market.

Diverse Product Portfolio

We have a massive portfolio of customized cable assemblies for our client's diversified requirements. It encompasses industrial assemblies, computer cables, telecommunication cables, and wiring harnesses for different applications. Products are well-designed and manufactured with strict adherence to the latest industry regulations and RoHS 2.0 standards. With our wide variety of offerings, we are a one-stop destination among cable producers in Vietnam.

As one of the leaders of cable manufacturers in Vietnam, SINNHONG ELECTRONICS CO., LIMITED insists on providing customer-made quality, speed, cost, and customer service to secure the leading position in the global cable assembly market.

0 notes

Text

Avalon Technologies Limited Is a Top EMS Industries In India

We Provide Services and Solutions Like:

Design

Engineering

NPI

Volume Production

Life Cycle Management

System Integration

PCB Assembly

Cable & Wire Harness

Sheet Metal

Aerospace Metal

Machining

Magnetics

Plastics

Supply Chain & Logistics

2 notes

·

View notes

Text

How Do Wire Harness Manufacturers Ensure Quality Control

In the context of the widespread application of modern industrial and electronic equipment, the quality of wire harnesses directly affects the stability and safety of equipment. As a professional wire harness manufacturer, we are well aware of the importance of ensuring the quality of wire harnesses and have taken a series of strict measures to ensure the accuracy and reliability of our products. In this article, we will introduce in detail how we pass 23 strict tests before leaving the factory and follow international standards to ensure the quality of wire harnesses.

Strict quality control process

Raw material testing

Our quality control starts with the most basic raw materials. All raw materials entering the warehouse must undergo strict testing to ensure that they meet the standards we set. Only qualified materials can be put into production.

2. Wire conductivity test

Conductivity is one of the important criteria for testing the quality of wire harnesses. We conduct conductivity tests on each batch of wires to ensure that their conductivity is excellent.

3. Wire mechanical strength test

Wires must have a certain mechanical strength to cope with various application environments. We use a tensile testing machine to test the tensile strength of the wires to avoid failure of the wire harnesses due to mechanical damage.

4. High and low-temperature performance test

Wire harnesses must maintain stable performance in different environments. We conduct high-temperature and low-temperature tests to test the performance of the wire under extreme temperature conditions.

5. Anti-aging performance test

The anti-aging performance of the wire is related to its service life. We evaluate the anti-aging ability of the wire through accelerated aging tests.

6. Insulation performance test

Ensuring the insulation performance of the wire harness is the key to preventing short circuits and leakage. We use professional equipment to test the insulation performance of the wire.

7. Corrosion resistance test

8. Cable crimping test

The wire harness involves a large number of crimping processes during the assembly process. We inspect each crimp to ensure that the crimping is firm and does not loosen or fall off.

9. Wire harness welding test

The welding quality of the wire harness directly affects its electrical performance and mechanical strength. We use X-ray microscopes to perform non-destructive testing on the welding points to ensure that the welding quality meets the standards.

10. Wire harness forming test

The wire harness forming must meet the specification standards. We use special equipment to test the size of the formed wire harness to ensure the accuracy of the wire harness size.

11. Electrical test

To ensure that the electrical connection of the wire harness is normal, we conduct a full inspection of the formed wire harness to test its continuity and resistance value.

12. Bending resistance test

The wire harness needs to be bent many times during use. We use the bending resistance test to test the stability of the wire harness during bending.

13. Wear resistance test

The wire harness needs to have good wear resistance. We use a wear resistance test to ensure that the wire harness is not easily damaged during friction.

14. Waterproof performance test

The wire harness needs to have good waterproof performance when used in a humid environment. We use a waterproof test to test the performance of the wire harness after being immersed in water.

15. Flame retardant performance test

To ensure the safety of the wire harness under fire conditions, we conduct a flame retardant performance test on the wire to ensure that it meets the flame retardant standard.

16. Connector performance test

The performance of the connector directly affects the connection reliability of the wire harness. We perform plug-in and pull-out tests on each connector to ensure that it has good contact and no poor contact.

17. EMIRFI shielding performance test

In an environment where electromagnetic interference(EMI)and radio frequency interference(RFI)are frequent, the wire harness must have good shielding performance. We use special instruments to test the EMIRFI shielding effect of the wire harness.

18. Wire harness weight detection

The weight of the wire harness must meet the design requirements. We use a precision electronic scale to weigh the finished wire harness to ensure that it meets the standards.

19. Appearance inspection

20. Packaging inspection

The wire harness must be well protected during transportation. We inspect the packaging to ensure that the packaging materials and methods meet the requirements.

21. Label inspection

Each wire harness must have a clear label. We check the wire harness label to ensure that its content is accurate and the font is clear.

22. Environmental testing

The wire harness material must meet environmental requirements. We use professional testing agencies to test the environmental performance of wire harness materials and meet international environmental standards such as RoHS.

23. Factory inspection

All qualified wire harnesses are subject to final factory inspection. We conduct comprehensive inspections on wire harnesses through random sampling to ensure that the products are 100%qualified.

Follow international standards

We strictly follow international quality management system standards including ISO 9001 and IATF 16949, as well as international certification standards such as UL, CSA, CE, and RoHS.Through these standards, we ensure that each product meets the high-quality requirements of the global market.

As a professional wire harness manufacturer, we ensure the excellent quality and stable performance of our products through a series of strict quality control measures and 23 specific tests. We always adhere to quality as the basis for providing customers with high-quality and high-reliability wire harness products. In future development, we will continue to maintain rigorous quality control standards and strive to provide customers with the best quality wire harness solutions.

0 notes

Text

Wire Harness Assembly: A Key Solution by Bhagyadeep Cables

Wire harness assemblies are the backbone of modern electrical systems, providing a structured and organized way to connect and transmit electrical power and signals across various components. From automotive and industrial machinery to home appliances and telecommunications, wire harness assemblies play a crucial role in ensuring the reliability, efficiency, and safety of electrical systems. Bhagyadeep Cables, a leading manufacturer of wire harness assemblies in India, is renowned for its high-quality products, innovative solutions, and customer-centric approach.

What is a Wire Harness Assembly?

A wire harness assembly, also known as a cable harness or wiring assembly, is a systematically arranged bundle of wires, cables, and connectors that transmits electrical power and signals in electrical and electronic equipment. The assembly provides several key benefits, including:

Simplified Installation: By bundling wires and cables into a single unit, wire harness assemblies make installation easier and more efficient, reducing assembly time and labor costs.

Improved Safety and Reliability: Wire harness assemblies protect wires and cables from external factors such as moisture, heat, abrasion, and vibrations, enhancing the overall safety and reliability of the electrical system.

Space Optimization: A well-organized wire harness assembly helps in saving space and reducing clutter, especially in compact and densely packed applications like automobiles and industrial machinery.

Cost-Effective Solutions: Wire harness assemblies help reduce material costs by minimizing the use of unnecessary wiring, reducing labor, and enhancing system performance.

Types of Wire Harness Assemblies Offered by Bhagyadeep Cables

Bhagyadeep Cables offers a diverse range of wire harness assemblies designed to meet the specific requirements of various industries and applications:

Automotive Wire Harness Assemblies: These assemblies are designed to meet the stringent requirements of the automotive industry, providing reliable connections for various systems such as lighting, engine management, infotainment, safety systems, and more. Bhagyadeep Cables manufactures automotive harnesses that are durable, resistant to heat and chemicals, and capable of withstanding harsh environments.

Industrial Wire Harness Assemblies: Used in heavy machinery, industrial equipment, and automation systems, these harnesses provide secure and efficient connections for electrical and electronic components. Bhagyadeep Cables ensures that its industrial harnesses meet high standards of safety, durability, and performance.

Telecommunication Wire Harness Assemblies: For telecommunications infrastructure, these harnesses are designed to offer reliable and stable connections for data transmission, fiber optics, and network equipment. Bhagyadeep Cables’ telecom harnesses are engineered to provide optimal signal integrity and protection against interference.

Home Appliance Wire Harness Assemblies: In home appliances such as refrigerators, washing machines, air conditioners, and microwaves, wire harness assemblies provide organized and safe electrical connections. Bhagyadeep Cables manufactures high-quality harnesses that comply with safety regulations and offer long-lasting performance.

Custom Wire Harness Assemblies: Bhagyadeep Cables also offers customized solutions tailored to meet the unique needs of clients across different industries. This includes custom wire lengths, connector types, cable colors, labeling, and specific insulation materials.

Why Choose Bhagyadeep Cables for Wire Harness Assemblies?

Bhagyadeep Cables has established itself as a trusted name in the wire harness assembly industry by offering exceptional quality, innovation, and customer service. Here are the reasons to choose Bhagyadeep Cables for your wire harness needs:

Superior Quality and Reliability: Bhagyadeep Cables is committed to producing wire harness assemblies of the highest quality. All products undergo rigorous quality checks and testing to ensure they meet or exceed industry standards, such as ISO, RoHS, and UL certifications.

Advanced Manufacturing Capabilities: Equipped with state-of-the-art manufacturing facilities and automated machinery, Bhagyadeep Cables ensures precision, consistency, and efficiency in the production of wire harness assemblies. This results in high-quality products that meet diverse customer requirements.

Customization and Flexibility: Understanding that different industries have unique needs, Bhagyadeep Cables offers fully customizable wire harness solutions. The company’s experienced engineering team works closely with clients to design and manufacture harnesses that meet specific technical specifications.

Expertise and Experience: With years of experience in the cable and wiring industry, Bhagyadeep Cables possesses deep expertise in wire harness assembly design and production. The company’s skilled professionals are adept at understanding customer needs and providing solutions that enhance performance and reliability.

On-Time Delivery and Support: Bhagyadeep Cables prides itself on its efficient supply chain and logistics management. The company ensures timely delivery of products while maintaining the highest standards of customer service and technical support.

Compliance with Safety and Environmental Standards: Bhagyadeep Cables is committed to safety, quality, and sustainability. The company’s wire harness assemblies are manufactured following strict quality control measures and environmental guidelines, ensuring a safe and eco-friendly product range.

Applications of Bhagyadeep Cables’ Wire Harness Assemblies

Bhagyadeep Cables’ wire harness assemblies find application in a wide range of industries:

Automotive: Used in passenger cars, commercial vehicles, electric vehicles (EVs), and two-wheelers for connecting electrical and electronic components.

Industrial Automation: Provides reliable and safe connections for control panels, industrial robots, and automation systems.

Aerospace and Defense: Offers high-performance wire harness assemblies for aircraft, satellites, and defense equipment that require precision and reliability.

Consumer Electronics: Supports the efficient functioning of various electronic devices, including computers, home appliances, and entertainment systems.

Renewable Energy: Used in solar panels, wind turbines, and other renewable energy systems to ensure efficient and reliable power transmission.

Conclusion

As a leading manufacturer of wire harness assemblies in India, Bhagyadeep Cables delivers top-notch solutions that cater to a wide array of industries and applications. With a strong focus on quality, innovation, customization, and customer satisfaction, Bhagyadeep Cables is your trusted partner for all wire harness assembly needs. Whether you require standard or custom wire harness solutions, Bhagyadeep Cables offers products that ensure reliability, efficiency, and safety in your electrical systems. Trust Bhagyadeep Cables for all your wire harness requirements and experience the difference in quality and service.

0 notes

Text

Looking for reliable wire harness assembly services? At Popular Systems, we specialize in designing and manufacturing custom wiring harness solutions for various industries, including automotive, industrial, and electronics.

Our expertise includes automotive wiring harness connectors, ensuring secure and efficient connections for vehicle electrical systems. As one of the leading cable loom manufacturers, we provide durable and high-performance wiring harness solutions tailored to meet specific requirements.

Visit our website to learn more: Popular Systems – Wiring Harness

0 notes

Text

What is EPlan? An Overview of Its Functionality and Applications

EPlan is a powerful software solution designed for electrical engineering, offering a comprehensive suite of tools to automate and optimize the design process of electrical control systems, fluid power systems, and cable harnesses. Developed by EPlan Software & Service GmbH & Co. KG, it is widely used across various industries, including automotive, energy, manufacturing, and building automation, to create detailed schematics, wiring diagrams, and documentation with high precision and efficiency. Lets understand what is EPlan, its application, functionalities, and many more in details.

Functionality of EPlan

EPlan’s core functionality revolves around its ability to streamline the planning, designing, and documenting of complex electrical systems. Here’s a closer look at some of its key features:

1. Schematic Design

EPlan allows engineers to create detailed electrical schematics that serve as the blueprint for control systems. The software offers a wide range of symbol libraries, predefined templates, and automated functions that significantly reduce the time and effort needed to produce accurate and standardized schematics. These schematics can include wiring diagrams, panel layouts, and PLC (Programmable Logic Controller) configurations.

2. Automation and Standardization

One of the standout features of EPlan is its capacity to automate repetitive tasks. By using macros and standard libraries, users can automate the generation of common circuit elements and configurations, ensuring consistency across projects and reducing the potential for errors. This automation not only speeds up the design process but also allows for easy updates and modifications to existing designs.

3. Interdisciplinary Integration

EPlan supports interdisciplinary collaboration, integrating with other engineering tools and software platforms. This capability is crucial in environments where electrical, mechanical, and fluid power systems must be designed in harmony. EPlan facilitates the exchange of data between different departments, ensuring that all aspects of a project are aligned and that any changes in one area are reflected across the board.

4. 3D Design and Visualization

EPlan includes robust 3D design tools that allow users to visualize their electrical systems within a three-dimensional space. This feature is particularly useful for panel building and cabinet layout, enabling engineers to see how components will fit together in the real world. The 3D visualization also helps in identifying potential issues, such as spatial conflicts or incorrect placements, before the manufacturing stage.

5. Project Management and Documentation

EPlan excels in project management and documentation. The software automatically generates comprehensive documentation for each project, including part lists, terminal diagrams, and assembly instructions. This documentation is essential for manufacturing, installation, and maintenance, ensuring that all stakeholders have access to the necessary information at every stage of the project.

6. Data Consistency and Reusability

With EPlan, data consistency is maintained throughout the project lifecycle. The software’s centralized database ensures that all project data is stored in a single location, reducing the risk of discrepancies. Additionally, EPlan’s data management capabilities allow users to reuse design elements and modules across different projects, enhancing efficiency and promoting best practices.

Applications of EPlan

EPlan’s versatility makes it applicable across a broad range of industries and use cases. Some of the primary applications include:

1. Industrial Automation

In industrial automation, EPlan is used to design the electrical systems that control machinery and production lines. The software’s ability to integrate with PLC programming tools and its support for creating detailed wiring diagrams make it invaluable in this sector. Engineers can design, simulate, and document the control systems that keep factories running smoothly.

2. Energy and Power Distribution

EPlan is widely used in the energy sector for the design and management of power distribution systems. The software helps engineers create detailed plans for substations, switchgear, and other critical infrastructure components. EPlan’s robust documentation features ensure that all aspects of power distribution are accurately captured and easily accessible for maintenance and troubleshooting.

3. Automotive Industry

In the automotive industry, EPlan is employed to design and document the electrical systems of vehicles, including wiring harnesses, control units, and sensor networks. The software’s ability to handle complex systems and its support for 3D visualization are particularly beneficial in this context, allowing engineers to ensure that every component fits and functions as intended.

4. Building Automation

EPlan is also used in building automation to design and manage the electrical systems that control lighting, HVAC (Heating, Ventilation, and Air Conditioning), and security systems. The software’s integration capabilities ensure that these systems can be designed in conjunction with other building systems, leading to more efficient and effective building management solutions.

Conclusion

EPlan is a comprehensive tool that significantly enhances the efficiency and accuracy of electrical engineering projects. Its rich feature set, combined with its ability to integrate with other systems and disciplines, makes it a vital resource for engineers across various industries. Whether it’s automating repetitive tasks, managing complex data, or ensuring interdisciplinary collaboration, EPlan provides the functionality needed to meet the challenges of modern electrical design.

0 notes

Text

Cable/Wire Harness Assembly

In today’s technologically advanced world, the demand for reliable and efficient cable assemblies and wire harnesses spans across numerous industries. From automotive to aerospace, consumer electronics to industrial machinery, these components are vital for the functionality and reliability of countless devices and systems. At inYantra, we specialize in providing top-tier cable and wire harness assembly services that meet the specific needs of our customers across a wide range of industries.

Our Commitment to Excellence

At inYantra, we adhere to the highest standards of quality and workmanship. Our cable and wire harness assemblies are manufactured following the IPC/WHMA-A-620 workmanship standards, ensuring that every product we deliver is built to perform reliably under various conditions. We understand that every application has unique requirements, and our facility is equipped to manufacture both power and signal cable assemblies to your exact specifications.

Comprehensive Cable & Wire Harness Assembly Services

Our cable and wire harness assembly services are designed to cater to diverse industry needs. We offer a wide range of services that ensure precision, quality, and reliability in every assembly we produce.

Single Core Wires and Multi-Core Cables

Whether your project requires single core wires or complex multi-core cables, we have the expertise and capabilities to meet your needs. Our team is skilled in handling a variety of materials and configurations, ensuring that each assembly is tailored to your exact specifications.

Automated Wire Processing

We utilize advanced automated wire processing technologies, including cut, strip, crimp, and tinning processes. This automation ensures consistent quality and precision across all assemblies, reducing the potential for errors and enhancing overall efficiency.

Crimp Force Monitoring

As part of our commitment to quality, we incorporate crimp force monitoring as a standard practice in our assembly processes. This ensures that all crimps are secure and meet the required standards, providing reliable electrical connections in every product.

100% Electrical Testing

Quality assurance is paramount at inYantra. That’s why we perform 100% electrical testing on all our cable and wire harness assemblies. This rigorous testing process ensures that every assembly meets the required electrical performance standards before it leaves our facility.

IPC/WHMA-A-620 Standards

We adhere strictly to the IPC/WHMA-A-620 standards, which are the industry benchmarks for cable and wire harness assemblies. These standards cover all aspects of assembly, from materials to workmanship, ensuring that our products are of the highest quality.

Design for Manufacturability (DFM) Assistance

Our team provides Design for Manufacturability (DFM) assistance, helping you optimize your designs for production. This ensures that your cable and wire harness assemblies are not only functional but also cost-effective and efficient to produce.

Global Sourcing and Vertical Integration

We offer global sourcing for Approved Vendor List (AVL) and alternative components, giving you access to high-quality materials from trusted suppliers worldwide. Additionally, our vertical integration opportunities allow you to leverage our group manufacturing capabilities in raw cable production, further enhancing the efficiency and cost-effectiveness of your projects.

Industries We Serve

Our cable and wire harness assemblies are used in a variety of end-use applications across multiple industries. Whether you’re in the automotive, aerospace, telecommunications, medical, or industrial sector, inYantra has the expertise to deliver the solutions you need.

Conclusion

At inYantra, we take pride in delivering high-quality cable and wire harness assemblies that meet the stringent requirements of our diverse customer base. Our commitment to following industry standards, combined with our advanced manufacturing capabilities and global sourcing strategies, ensures that we can provide reliable, cost-effective solutions for your cable and wire harness needs. Trust inYantra to be your partner in delivering excellence in every assembly.

1 note

·

View note