#Capacity sorting lithium battery

Explore tagged Tumblr posts

Text

Enhancing Battery Quality Through Formation & Grading

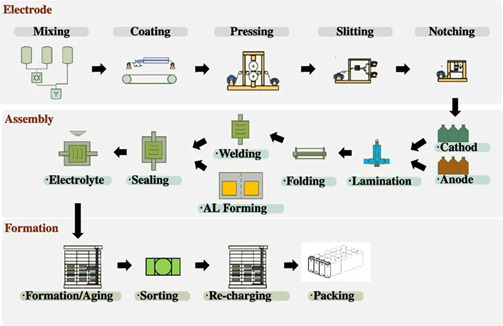

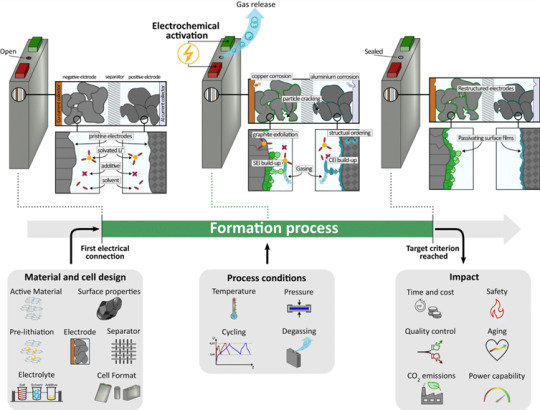

Chemical formation and capacity sorting are the two most crucial quality-control steps in the EV battery manufacturing process. They significantly affect battery performance, longevity, and safety.

Chemical Formation: Setting the Foundation

Performed using advanced battery formation equipment, this stage initiates the electrochemical life of the battery by forming a protective SEI layer on the anode. Key parameters include:

Low-current charging to stabilize reactions

Voltage control to prevent lithium plating

Temperature regulation for chemical balance

Pressure application for gas expulsion

Electrolyte refilling to compensate for loss

This step ensures structural consistency and long-term efficiency.

Battery Grading: Ensuring Performance Consistency

After formation, cells are sorted using a battery grading machine based on:

OCV at different stages

Capacity and efficiency during charge-discharge cycles

K-value to detect self-discharge

Resistance and uniformity

This ensures the lithium-ion battery production line only proceeds with top-tier cells for pack assembly.

Precision Is the Standard

Accuracy in current and voltage control is vital. With today’s battery formation equipment and grading systems offering <0.01% accuracy, EV manufacturers can confidently deliver reliable battery packs to the market.

Conclusion

When chemical formation and capacity sorting are optimized, they enable a seamless EV battery manufacturing process, guaranteeing long-term performance, safety, and customer trust.

#Chemical formation lithium battery#Capacity sorting lithium battery#Lithium-ion battery formation process#Battery cell capacity grading#Battery formation and grading#Battery chemical formation process#Lithium battery production steps

0 notes

Note

okay so i’ve never really grasped this, might as well ask now — how exactly does the cyberspace & nft stuff mine resources? i’ve heard the basics (i.e. crypto mining uses energy and what not) but i’ve never been able to understand how internet connects to real resources. could you sort of explain that (along the lines with the spam email post) in a simpler way?

ok, put very simply: it's easy for people who only interact with the internet as users to treat 'cyberspace' or 'the virtual world' as immaterial. i type something out on my phone, it lives in the screen. intuitively, it feels less real and physical than writing the same words down on a piece of paper with a pencil. this is an illusion. the internet is real and physical; digital technology is not an escape from the use of natural resources to create products. my phone, its charger, the data storage facility, a laptop: all of these things are physical objects. the internet does not exist without computers; it is a network of networks that requires real, physical devices and cables in order to store, transmit, and access all of the data we use every time we load a webpage or save a text document.

this is one of google's data centres—part of the physical network of servers and cables that google operates. these are real objects made of real materials that need to be obtained through labour and then manufactured into these products through labour. the more data we use, the more capacity the physical network must have. google operates dozens of these data centres and potentially millions of servers (there is no official number). running these facilities takes electricity, cooling technologies (servers get hot), and more human labour. now think about how many other companies exist that store or transmit data. this entire network exists physically.

when you look at a server, or a phone, or a laptop, you might be glossing over a very simple truth that many of us train ourselves not to see: these objects themselves are made of materials that have supply chains! for example, cobalt, used in (among other things) lithium-ion batteries, has a notoriously brutal supply chain relying on horrific mining practices (including child labour), particularly in the congo. lithium mining, too, is known to have a massive environmental toll; the list goes on. dangerous and exploitative working conditions, as well as the environmental costs of resource extraction, are primarily and immediately borne by those who are already most brutally oppressed under capitalism: poor workers in the global south, indigenous people, &c. this is imperialism in action. digital technologies cannot exist without resources, and tech companies (like all capitalist firms!) are profitable because they exploit labour.

all commodities require resources and labour to make and distribute. digital technology is no different. these are material objects with material histories and contexts. nothing about the internet is immaterial, from the electromagnetic waves of wi-fi communication to the devices we use to scroll tumblr. it is, in fact, only by a fantastical sleight-of-hand that we can look at and interact with these objects and still consider the internet to be anything but real resources.

394 notes

·

View notes

Text

The solution to this problem is batteries.

I don't mean "we should just hook up some lithium batteries/car batteries/some other batteries to the solar generators." (I mean. We should. But those would not fix the problem.)

Our current non-renewable power system is not designed to be run on batteries. It's designed to generate power on a cycle based on usage habits, and feed it to people on demand. It is not designed to generate power like crazy during daylight hours and still have power available at night, when the sun is not shining. It is not designed for windmills that spin heavily during the morning and evening, when the temperature change drives the wind, but move less during the day and go completely still at night.

I get that this is a non-simple logistics problem but dammit neither solar nor wind power is a new, 21st-century concept in power generation.

The battery tech we need has not been developed because there's damn little profit to be had in unlimited energy resources.

(Technically neither solar nor wind is "unlimited." They are close enough for discussion purposes. The current limits are our harvesting technology, not the source supply.)

But batteries are still extremely expensive per KW

err. sort of. They're inefficient; it takes a lot more energy to fill a battery than to just... do something with the energy. AND storage capacity vs cost is indeed not good right now. (Better than it used to be. Still not at "run your house overnight" levels.)

It doesn't matter how inefficient they are if the energy going into them is free, because it was power being generated that had nowhere to go. The problem is not "batteries won't work"; it's "power companies do not want the average suburban house to have a battery cluster the size of half a room, that gets powered up by solar/wind and runs most of the household electronics in the evening."

(I do not doubt this is not currently feasible; our current batteries could not do this safely. But I also don't doubt that we could develop ones that could... but no power company is going to support that development because it's a straight line to bankruptcy.)

Only capitalism could turn unlimited free electricity into a problem.

31K notes

·

View notes

Text

Powering the Circular Economy: The Urgency and Opportunity in Recycling EV Batteries

As the world races towards electrification, from two-wheelers to trains and grid-scale energy storage, lithium-ion batteries are taking center stage. With their unmatched performance, these batteries are not just powering vehicles—they are propelling the clean energy transition. However, with this accelerated deployment comes a pressing question: What happens when these batteries reach the end of their first life?

At LOHUM, we believe that the solution lies not just in innovation, but in sustainability. Our mission is to power the world sustainably through circular energy solutions, and at the heart of that mission is battery recycling and reuse.

The Growing Challenge of EV Battery Waste

The surge in electric vehicle (EV) adoption globally is rewriting the rules of transportation. Analysts predict that by 2030, over 2 million metric tonnes of EV batteries will be retired annually, representing more than half a million vehicles per year. In India alone, where EV adoption is gaining momentum through both public and private sector support, the need for a robust ecosystem for recycling of EV batteries in India has never been more urgent.

Modern EV batteries, especially those in passenger vehicles, are expected to last between 8 to 12 years. But as this wave of first-generation EVs begins to retire, the opportunity—and responsibility—to build a closed-loop system becomes clear.

Batteries Deserve a Second Life

When a battery no longer meets the demands of high-performance EVs, it still holds considerable potential. With more than 70-80% of its capacity intact, such batteries can be refurbished or repurposed for less energy-intensive applications—such as solar energy storage, backup power, or off-grid use.

Projects like the 300 kWh second-life EV battery storage system at UC Davis in California showcase how retired vehicle batteries can serve for another 6 to 10 years in stationary roles. This model isn’t just technically viable—it is economically compelling.

At LOHUM, we are pioneering India’s most advanced second-life battery ecosystem, integrating AI-driven diagnostics, safe refurbishment, and certified performance standards to extend the battery lifecycle, reduce environmental burden, and create new market opportunities.

EV Lithium-Ion Batteries Reverse Logistics: The Hidden Backbone

Efficient recycling starts long before a battery reaches a processing facility. One of the most overlooked but vital pillars of a circular battery economy is EV lithium-ion batteries reverse logistics.

This includes the safe collection, transport, tracking, and sorting of batteries across vast geographies and complex supply chains. At LOHUM, we’ve developed a pan-India reverse logistics network, supported by smart traceability systems that ensure compliance, safety, and cost-effectiveness.

Without reverse logistics infrastructure, recycling cannot scale. With it, we unlock the flow of valuable resources and turn waste into wealth.

Revolutionizing Recycling: Beyond Black Mass

Traditional recycling processes—like pyrometallurgy—are energy intensive, costly, and environmentally taxing. They burn batteries at high temperatures (~1500°C), recovering only select metals like cobalt and nickel while losing lithium and aluminum to slag.

But there’s a smarter way.

Recent research from Worcester Polytechnic Institute reveals a new cathode recycling technique that not only maintains the integrity of the battery’s crystalline structure but also outperforms newly manufactured cathodes. By preserving engineered cathode particles and simply "topping them off" with precise elemental adjustments, this approach enhances both charge rate and lifespan.

Such innovations align with LOHUM’s proprietary recycling processes, where we extract high-purity materials through sustainable hydrometallurgy and direct cathode recycling, dramatically reducing environmental impact and production costs.

The Mineral Equation: Supply, Risk, and Opportunity

Materials like cobalt, lithium, and nickel represent nearly 50% of the cost of a lithium-ion battery. Yet their price volatility—fluctuating up to 300% in a single year—poses a major risk to battery manufacturers and OEMs.

Additionally, over 60% of the world’s cobalt is sourced from the Democratic Republic of Congo, a region fraught with ethical and environmental concerns. Relying on virgin mining alone isn’t just unsustainable—it’s unsound business.

By recycling and reusing critical minerals, LOHUM offers a viable path to reduce raw material dependency, stabilize supply chains, and improve energy security. Our process enables the recovery of up to 95% of high-value materials, reintegrating them into the battery production ecosystem.

Policy and Infrastructure: Building the Circular Future

Countries like the U.S. and China are investing heavily in battery recycling infrastructure. California is developing mandates to ensure 100% of EV batteries sold are either reused or recycled at end of life.

In India, policy is catching up with the need. With the introduction of the Battery Waste Management Rules and incentives for Extended Producer Responsibility (EPR), momentum is building. But execution demands leadership.

LOHUM is proud to partner with both government and industry to develop standards, invest in recycling R&D, and expand domestic production capacity for secondary battery materials. We are not only building facilities but shaping the framework for a sustainable, scalable recycling ecosystem in India.

Toward a Billion-Dollar Circular Opportunity

As global demand for lithium-ion batteries skyrockets, the market for battery recycling and secondary material supply is expected to approach a trillion dollars in the coming decade. For India to lead, the time to act is now.

The recycling of EV batteries in India is not a side project—it’s central to our energy independence, economic growth, and environmental stewardship. With industry leaders like LOHUM driving innovation in EV lithium-ion batteries reverse logistics and closed-loop materials recovery, India has the potential to become a global powerhouse in sustainable battery manufacturing.

At LOHUM, we don’t just see discarded batteries—we see the future. And we’re building it.

Visit us at: Li-ion Battery Repurposing Technology

Originally published on: Blogger

#lohum#critical minerals#lithium battery reusing and recycling#battery waste management#li-ion battery waste management#3 wheeler ev battery#reverse logistics for lithium-ion batteries#lithium battery waste recycling

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] 10-year battery life and world time, 100-meter water resistance, 10-year battery life, World time, Round world map dial, Telememo 30. 1/100-second stopwatch, Alarms Resin Glass, 100-meter water resistance, Case / bezel material: Resin, Resin Band, Telememo, Memory capacity: Up to 30 sets of data, with 8-character name and 16-digit telephone number. Others: Remaining memory screen, auto-sort. World time, current time in 30 cities (29 time zones), daylight saving on/off. 1/100-second stopwatch, Measuring capacity: 23:59'59.99'', Measuring modes: Elapsed time, split time, 1st-2nd place times, Countdown timer. Measuring unit: 1 second, Countdown range: 24 hours, Countdown start time setting range: 1 minute to 24 hours (1-minute increments and 1-hour increments). 3 daily alarms (with 1 snooze alarm). Hourly time signal, Full auto-calendar (to year 2099), 12/24-hour format, Regular timekeeping, Analog: 2 hands (hour, minute (hands move every 20 seconds), Digital: Hour, minute, second, am/pm, month, date, day, Accuracy: ±30 seconds per month, Approx. battery life: 10 , years on CR2025, Size of case:52.2×46.6×16.6mm, Total weight: 49 g. Batteries : 1 Lithium Metal batteries required. Is Discontinued By Manufacturer : No Product Dimensions : 10.4 x 9.6 x 6 cm; 88 g Date First Available : 14 March 2016 Manufacturer : Casio ASIN : B01CYAE6LM Item model number : AEQ-110BW-9AVDF (AD206) Country of Origin : Thailand Department : Men Manufacturer : Casio Item Weight : 88 g Item Dimensions LxWxH : 10.4 x 9.6 x 6 Centimeters Net Quantity : 1 Count Generic Name : watch [ad_2]

0 notes

Text

What is a Pure Sine Wave Inverter and Why Do We Need It?

Electricity has become an essential entity these days. Whether it is running office equipment, hospitals, medical devices, home appliances, or heavy machines in industries, a power supply is the most crucial factor. Voltage problems and power outages are seen as common issues.

This is the place where the inverter comes into the picture. Among different types of inverters, a pure sine wave inverter is the ideal choice among many due to its performance and the top-notch quality that it offers. In this blog, let us gain insights into the pure sine inverters and why you should utilise them.

Pure Sine Wave Inverter: A Helpful Definition

A Pure Sine Inverter recasts the direct current from the battery into an alternating current. This power is identical to the one that the power company supplies. Sine wave signifies the shape of the electrical waveform it yields. The voltage keeps on rising and dropping constantly in this sort of inverter, like the electricity you obtain from the power company.

Why Do You Need a Pure Sine Wave Inverter?

Let us comprehend why you must pick these inverters for your business, workplace or dwelling:

Improved Performance and Efficiency

Some electric appliances perform better with a pure wave supply. For instance:

Laser printers

Water pumps

Induction cooktops

Using pure wave power makes sure home appliances work efficiently and saves time and electricity.

Suitable for Medical Equipment

Households with patients or senior citizens, monitors, CPAP machines or oxygen concentrators are important, and they might need them anytime in case of emergency. These devices require reliable power.

Pure Wave inverters are crucial in cases as:

Offer peace of mind in case of any emergency

Avoids sudden shutdown or risk of damage

Make sure that it offers uninterrupted operation

Safe for Sensitive Electronics

Modern appliances such as washing machines, microwaves, laptops, refrigerators, air conditioners, TVs and other devices use complex electronic components. These electronic devices are well-designed to run on pure sine wave electricity.

If you use a square wave or a modified inverter, then you might experience:

Overheating of devices

Malfunction

Permanent damage

Noise from motors or fans

Pure Wave Inverter helps you prevent all problems and provides stable power and smooth functioning.

No Unusual Sounds

You might have noticed flickering lights or unusual sounds during power outages. This is because of the poor quality of the inverter output.

With a pure sine inverter:

Speakers produce clear sound

Audio systems work well

Fans don't make any noise

Lights don't flicker

It offers a quiet and comfortable atmosphere during power outages.

Compatible with Electric Appliances

Whether it is a smart home system or a refrigerator, a pure sine inverter will handle it. It is a future-proof investment that you will never regret in life. You don't even have to worry about compatibility problems, as it caters to your needs.

Where is a Pure Sine Wave Inverter Most Useful?

Common places where a pure sine wave inverter makes a huge difference and is useful:

In rural areas, there are frequent voltage fluctuations

Clinics where power is necessary

Homes with modern appliances

Offices with printers, networking equipment and computers

Salons that use electronic devices and tools

Solar power systems require power conversion.

Things to Know Before Purchasing a Pure Sine Inverter

Let us discuss things that you should know before purchasing a pure sine inverter:

Value vs Price

Pure Sine inverters are costly compared to modified ones, but they provide long-term value and are best if you use advanced electronic devices.

Battery Compatibility

Ensure the pure sine inverter supports your battery type- tubular, lithium-ion or lead.

Power Needs

You may calculate the total wattage of the electronic devices you wish to run. You may choose an inverter that matches your load capacity.

Quality and Brand

You may purchase from a reliable brand that provides good warranty, after-sales support and service.

Myths About Pure Sine Inverters

Let us know some myths about pure sine inverters that include:

Modified Sine Wave is Good

It might work for small electronic devices, but it can damage modern electronics.

Pure Sine Inverters are Costly

It is a long-term investment that offers comfort and safety. Prices have fallen in recent years, so you can buy an affordable pure sine wave inverter.

All Power Inverters Are the Same

Pure Sine inverters offer safety and are of the best quality.

Conclusion

A pure sine inverter is a smart and safe investment that has become a necessity in today's era. Whether you wish to protect your expensive electronics or have peace of mind during power cuts, Microtek offers the best pure sine wave inverter.

It might cost more upfront, but the advantages it provides in terms of performance, safety and durability are the best. Workplaces and houses are dependent on technology, and the need for top-notch quality power backup is crucial. If you wish to buy an inverter, go for a Microtek pure sine wave model that works like magic.

0 notes

Text

Ukraine Business Roundup — Trump wants Ukraine's 'rare earths'

The following is the Feb. 4, 2025 edition of our Ukraine Business Roundup weekly newsletter. To get the biggest news in business and tech from Ukraine directly in your inbox, subscribe here.

President Donald Trump came out on Feb. 3 saying he wanted to make a deal with Ukraine by giving the war-torn country weapons and aid in return for its “rare earths and other things.”

“We’re looking to do a deal with Ukraine, where they’re going to secure what we’re giving them with their rare earths and other things,” Trump told reporters in the Oval Office.

“I want to have security of rare earths. We’re putting in hundreds of billions of dollars. They have great rare earths. And I want security of the rare earths, and they’re willing to do it,” he said.

It’s not quite clear what exactly Trump meant by “rare earths and other things.” Ukraine is home to all sorts of highly sought-after raw materials from critical minerals to rare earth elements.

What’s more clear is why Trump wants them. China controls 70% of global rare earth mining capacity and 90% of processing capacity. Having easy access to these materials could boost the U.S.’s competitiveness — something at the top of the new president’s “America First” agenda.

For Kyiv’s part, President Volodymyr Zelensky has positioned Ukraine’s natural materials as part of a peace plan. Reports late last year said Zelensky’s team had even delayed a deal on critical materials with former President Joe Biden’s team so it could offer it to Trump in case he won the elections.

So what critical resources does Ukraine actually have and how viable are they, really? Ukraine has 20 of the world’s critical minerals and metals like titanium used in the aerospace and defense industries and lithium, an essential component of electric vehicle batteries.

Ukraine also possesses rare earth elements — under which titanium and lithium do not fall — such as cerium, yttrium, lanthanum, and neodymium. Demand for these materials has jumped in recent years as the world shifts to renewable forms of energy. Rare earth elements are crucial for making the powerful magnets used in wind turbine generators.

The issue, however, is geography. Raw materials are unevenly distributed across Ukraine and around $12 trillion has ended up in Russian-occupied territory, according to SecDev, a global digital risk and resilience firm.

And there’s the fact that a lot of these mineral deposits are underdeveloped, with the total value unknown, according to an analysis from the Kyiv School of Economics. Existing estimates put the value of Ukraine’s critical minerals anywhere between $3-$26 trillion.

Read reporter Dominic Culverwell’s full article here.

Ukrainian then-President Viktor Yanukovych in Kyiv, Ukraine, on May 17, 2010. (Sasha Mordovets/Getty Images)

Making millions off stolen Ukrainian resources

Speaking of critical resources. Oleksandr Yanukovych, the son of former Ukrainian President Viktor Yanukovych, has made billions selling coal from Russian-occupied Ukrainian territories to Turkey, independent Russian investigative outlet Important Stories reported on Feb. 4.

Viktor Yanukovych was Ukraine’s pro-Kremlin president from 2010 to 2014 before fleeing to Russia with his family in the wake of the EuroMaidan Revolution. In October 2024, reports emerged that Oleksandr Yanukovych had been granted Russian citizenship.

The company behind the coal exports, Energoresurs, is registered in Rostov-on-Don, Russia, and has exported nearly half a million tons of coal abroad between 2023 and 2024. Journalists linked Energoresurs to Oleksandr Yanukovych through his coal holdings and mining enterprises.

According to the investigation, the firm sources coal from suppliers in occupied Donbas and transports it to Turkey by rail and sea.

The coal is reportedly sold to an offshore company, Energy Union, registered in the British Virgin Islands. Energoresurs sells the coal at a significantly low price — an average of $60 per ton in 2024 — allowing the company to minimize export duties before reselling it at a higher price on international markets.

A Huless tethered drone system. (Brave1/LinkedIn)

Ukrainian drone maker attracts $1 million

Huless, a Ukrainian company developing tethered drone systems, secured over $1 million in private financing, loans, and a grant from Ukrainian Defense Tech cluster Brave1, the company said in a press release on Jan. 30.

Huless makes the Highline-T, a drone that can operate for up to four hours at heights up to 100 meters, even without GPS signals, the company says.

Unlike kamikaze or bomber drones that blow up Russian positions or vehicles, the Highline-T’s main function is to carry radio equipment that boosts the operational range of other drones and remote-controlled ground vehicles.

The tethered drone stays connected to the ground via a cable that provides constant power and data connection independent of interference from electronic warfare.

Huless plans to use the funding to expand its market presence and develop its tethered drone technology for military communications, the company said.

A bakery worker sifts flour to bake bread in Druzhkivka, Ukraine on Dec. 16, 2024. (Yelyzaveta Sekretarenko / The Kyiv Independent)

Front-line lifeline

One of the oddities of Russia’s war has been the parallel realities that coexist, almost seamlessly: on the one side are daily air raid sirens, Russian attacks, and casualties, on the other, people grabbing coffee, children going to school, businesses growing.

Nowhere are these two starkly divergent realities more clear than near the front lines.

Reporter Yelyzaveta Sekretarenko took a trip to the front-line town of Druzhkivka, located just 15 kilometers from the embattled city of Chasiv Yar to talk to the local entrepreneurs and businesses that remain despite the dangers.

In one scene in Sekretarenko’s article, taxi driver Serhiy Pohrebnyakov sits calmly behind the wheel of his car waiting for customers as explosions go off and people around begin running in different directions for cover.

Beyond the services or goods they provide — taxi rides, baked bread, and shampoo and razors for soldiers at roadside kiosks — these small businesses contribute to a semblance of normalcy in their community amid all the devastation wrought by Russia.

Read the full article here.

What else is happening

Ukraine’s inflation expected to peak by mid-2025, cool by year-end

Ukraine’s inflation rate is set to peak at 15% by mid-2025 before dropping to 8.4% by year’s end, Ukraine’s Central Bank said on Jan. 31. Poor harvests and higher wages amid labor shortages are currently driving the rising inflation, according to the bank. Inflation in Ukraine accelerated to 12% year-on-year in December 2024, surpassing the bank’s earlier projections. After peaking in the middle of the year and cooling to 8.4% by year’s end, the bank expects inflation to reach a target 5% in 2025.

Ukraine’s parcel delivery giant Nova Poshta invests $43 million to expand network in 2024

Ukraine’s largest private delivery company Nova Poshta invested Hr 1.8 billion ($43 million) to expand its Ukrainian network in 2024, a 35% increase from 2023, the company said on social media. The company opened 1,747 new branches across Ukraine and installed 8,410 self-service delivery package lockers in 2024, bringing the total number of its service points across the country to 37,210.

Nearly 100 companies in Ukraine quietly change Russian ownership in 6 months, monitoring service reports

Within the last six months, 93 companies in Ukraine have removed signs of Russian ownership and continue to do business in the country, despite a moratorium on altering the registration of companies with Russian owners, the monitoring service Opendatabot reported. The monitoring service also found that some of these companies have participated in the Ukrainian public procurement tenders.

Ukraine announces privatization auction of country’s largest electromagnetic switch manufacturer

Ukraine’s State Property Fund announced an auction to privatize the state-owned Radiorele plant in Kharkiv — the country’s largest switching equipment manufacturer, the fund said on Feb. 3. Radiorele produces low-current, miniature, electromagnetic switches, and relays, which are used to control voltage, current, and temperature in electrical systems. The plant has been put up for auction in the past but has so far been unable to attract a buyer. The auction, which is for a 100% stake in the plant, will be held on Feb. 4. Its starting price is Hr 234.4 million ($5.6 million), which includes debts for the last six months.

Ukrainian bakery chain Lviv Croissants opens first French location in Cannes

Ukrainian cafe chain Lviv Croissants opened its first restaurant in Cannes, France, making it the fifth country outside of Ukraine where it now operates, the company said in a press release on Feb. 3. Lviv Croissants said it chose Cannes as its first French location “because of the impressive tourist flow and high prospects for the gastronomic business.”

Subscribe to the Newsletter

Ukraine Business Roundup

<span data-sanitized-id="ukraine-business-roundup-info" data-sanitized-class="ukraineBusinessRoundup__info"></span> <button data-sanitized-id="ukraine-business-roundup-subscribe-btn" data-sanitized-class="ukraineBusinessRoundup__form_button"> <span data-sanitized-class="ukraineBusinessRoundup__form_label">Subscribe</span> </button> </div>

0 notes

Text

[ad_1] Transportable power storage techniques have turn out to be important to many purposes as we speak, starting from outside purposes to residence backup energy techniques. If you select the fitting system, it may possibly present dependable power when and the place you want it. With the fitting assets, resembling Goneo, an trade chief in moveable power storage, this information will assist clarify the significance of constructing the fitting alternative when looking for your subsequent power resolution. Why Transportable Power Storage Is Not Seychelles Versatility for Fashionable Life Transportable power storage techniques are nice for tenting journeys, powering small home equipment, or offering backup energy throughout outages. Comfort vs Sustainability The answer lies in techniques resembling these offered by Goneo, which combine renewable power sources so you possibly can swap on dependable power and make the planet greener. Issues to Hold in Thoughts Whereas Deciding on a Transportable Power Storage System Capability and Energy Output Decide your power wants. Select a system with adequate capability to run your gadgets and home equipment. Goneo’s moveable power storage options have high-capacity batteries able to powering a number of gadgets directly. Battery Sort and Sturdiness Lithium-ion batteries are light-weight, extra sturdy, and longer-lasting. That, nonetheless, is commonplace in high-end fashions like those who Goneo has to provide. Portability and Design Take into consideration dimension and weight, particularly should you want a system for touring or outside use. Portability —with a compact and light-weight design}. Charging Choices Test for charging choices like photo voltaic panel capabilities, AC retailers, or automobile chargers. Goneo Options shines with its vary of charging choices. Security Options Make sure the system has overcharge, overcurrent, and short-circuit safety for secure and dependable operation. High Options to Think about for Transportable Power Storage Excessive Power Effectivity The facility-hungry system provides you essentially the most prolonged attainable utilization of your battery. Consumer-Pleasant Interface Select fashions that supply easy-to-read shows and intuitive controls. Photo voltaic Compatibility For individuals who care in regards to the setting, a tool ought to be able to photo voltaic charging. The Goneo is a conveyable system with built-in photo voltaic panels. A number of Output Ports A medley of USB, DC, and AC ports accommodates a variety of gadgets and home equipment. Why Goneo Stands Out Goneo is an enterprise that makes high-quality moveable power storage merchandise. Goneo’s moveable power storage techniques are characterised by the next: Lasts a very long time: Superb for long-term use. Compact design: Superb for residence and outside purposes. Security: Trust realizing you might be not risking something when in operation. Since then, Goneo has advanced, providing options that handle a variety of power necessities, making it a go-to alternative for purchasers worldwide. How one can Choose the Proper Transportable Power Storage for Your Wants Assess Your Wants To get began, decide the system's major use: Are you planning to make use of it open air? Is it an emergency backup, or do you need to energy instruments and home equipment? Evaluate Fashions Analyze options that range in capability, bodily dimensions, and additional companies. Discover Goneo’s vast varieties and discover your good match. Think about Funds and Guarantee Choose a system inside your value vary that isn’t skimping on high quality. Guarantee choices are crucial, too. Conclusion When selecting the best moveable power storage resolution, contemplate capability, portability, security, and different options. Options like Goneo’s moveable power storage techniques are high-performing and dependable, making them splendid for residence and outside use.

Meet your good moveable power storage resolution. Take a look at Goneo’s product choice as we speak and expertise the benefits of reliable, eco-friendly energy inside attain. [ad_2] Supply hyperlink

0 notes

Text

In the digital age, laptops have become indispensable tools for work, education, and entertainment. With millions of laptops in use worldwide, there's an increasing need to consider the fate of these devices when they reach the end of their lifespan. One aspect often overlooked is the disposal of scrap laptop batteries, which contain valuable materials and pose environmental risks if not handled properly. At Waste Material, we specialize in the responsible collection and recycling of scrap laptop batteries, ensuring that this e-waste is processed in a sustainable manner.

Why Scrap Laptop Batteries Matter

Laptop batteries are typically made from lithium-ion cells, which have a limited lifespan. Over time, they degrade, lose capacity, and eventually stop working. When a laptop battery is no longer functional, it becomes e-waste. Many people are unaware that disposing of these batteries in regular trash can lead to serious environmental hazards. Here’s why:

Toxic Components: Laptop batteries contain heavy metals such as lithium, cobalt, and nickel, which are harmful to the environment if they leak into the soil or water. Improper disposal can lead to contamination of natural resources, affecting wildlife and human health.

Fire Hazards: Lithium-ion batteries are known to be a fire hazard if damaged. When improperly discarded, they can catch fire, posing risks to waste management facilities and even endangering lives.

Valuable Metals: Despite their hazards, scrap laptop batteries also contain precious metals like cobalt and lithium, which are in high demand for producing new batteries and electronic devices. Recycling these metals reduces the need for mining, preserving natural resources and reducing the environmental footprint of the tech industry.

The Importance of Recycling Scrap Laptop Batteries

At Waste Material, we understand the potential hidden in scrap laptop batteries. By recycling these batteries, we can help recover valuable materials while preventing environmental damage. Here are some key reasons why recycling your old laptop batteries with us is important:

Resource Recovery: By recycling, we can extract valuable metals such as cobalt, lithium, nickel, and copper, which can be reused in manufacturing new batteries or other products. This reduces the demand for raw materials, minimizing the need for destructive mining practices.

Environmental Protection: Discarding laptop batteries improperly can lead to soil and water contamination, which can affect local ecosystems and human populations. Recycling prevents these toxic substances from entering landfills and polluting the environment.

Energy Savings: Extracting metals from recycled batteries requires significantly less energy compared to mining and processing raw materials. By recycling scrap laptop batteries, we can contribute to energy savings, reducing greenhouse gas emissions.

How Waste Material Handles Scrap Laptop Batteries

At Waste Material, we offer a streamlined process to ensure that your scrap laptop batteries are handled responsibly:

Collection: We provide convenient drop-off points and scheduled pick-ups for businesses and individuals to dispose of their scrap laptop batteries.

Sorting: Once collected, the batteries are sorted based on their chemical composition and condition. This allows us to determine the most effective recycling method for each battery type.

Recycling: Our advanced recycling processes safely extract valuable metals while neutralizing harmful substances. We adhere to strict environmental regulations, ensuring that no hazardous waste is released during the recycling process.

Certification: After processing, we provide certification to businesses, confirming that their e-waste has been handled responsibly and sustainably.

Partner with Waste Material for Sustainable Recycling

Whether you're an individual looking to dispose of an old laptop battery or a business with a bulk of e-waste, Waste Material is your trusted partner for eco-friendly recycling. Our commitment to sustainability ensures that scrap laptop batteries are not only safely disposed of but also contribute to a greener future through material recovery.

Conclusion

Scrap laptop batteries may seem like small, inconsequential items, but they hold significant potential for both environmental harm and resource recovery. By choosing Waste Material to recycle your laptop batteries, you play a role in reducing e-waste, conserving natural resources, and protecting the planet. Let’s work together towards a more sustainable future—one battery at a time.

0 notes

Text

How Lithium-ion Battery Packs Are Assembled: Techniques, Testing & Key Challenges?

The manufacturing of lithium-ion battery packs is a crucial step in delivering high-performance, reliable power solutions. It involves combining individual lithium-ion cells into functional battery modules, integrated with safety and monitoring systems.

These battery packs power a range of modern applications, including electric vehicles (EVs), renewable energy storage systems, and portable electronics.

Key Stages in Lithium-ion Battery Pack Manufacturing

1. Battery Cell Sorting and Grouping

Selection: Match cells with similar internal resistance, voltage, and capacity.

Grouping: Uniform cell groups promote balanced performance and longevity.

Testing: Evaluate cell capacity, voltage drop, and charge/discharge cycles.

2. Cell Assembly and Spot Welding

Fixture Placement: Accurately arrange cells using designated tools.

Spot Welding: Use automatic battery welding machines for strong, clean joints.

Quality Inspection: Check weld integrity to avoid electrical faults.

3. Battery Module Assembly

Module Connection: Configure cells in series or parallel for target voltage/capacity.

BMS Integration: Install a Battery Management System (BMS) to monitor temperature, voltage, and current flow.

4. Battery Pack Testing and Quality Control

Functional Testing: Validate module safety, performance, and reliability.

Leakage Testing: Ensure airtight, leak-free construction.

Visual Inspection: Spot physical defects or structural inconsistencies.

Challenges and Considerations in Battery Pack Manufacturing

Cell Consistency: Inconsistent cells can destabilize battery module performance.

Welding Quality: Poor welds may lead to short circuits and thermal hazards.

BMS Configuration: A well-calibrated BMS ensures safe energy management.

Compliance: Must meet global safety standards like UN 38.3, UL 2580, ISO 26262.

Conclusion

From cell sorting to final testing, every stage in lithium-ion battery pack assembly ensures the product is safe, efficient, and ready for deployment. When done correctly, this process delivers durable energy solutions for EVs, solar systems, and industrial battery applications.

#lithium-ion battery pack assembly#battery pack manufacturing process#lithium battery pack testing#battery pack assembly techniques#battery module assembly

0 notes

Text

Battery Internal Resistance Tester: A Key Tool Ensuring Energy Security in Modern Society

Batteries are indispensable energy sources widely used in various electronic devices and transportation. However, ensuring the safety and stability of batteries remains a focal point for both the public and professionals. To guarantee high safety and reliability throughout their usage, the battery internal resistance tester has emerged as a crucial tool, safeguarding battery performance. The battery internal resistance tester evaluates the health of batteries by measuring their internal resistance. Elevated internal resistance may indicate aging or potential failure risks, making timely detection essential for preventing hazards. With its high precision and convenience, the battery internal resistance tester is extensively applied in electric vehicles, smartphones, laptops, and more, playing a pivotal role in battery safety management. The battery internal resistance tester effectively measures the voltage and internal resistance at both terminals of rechargeable batteries, assessing their capacity and technical state. Users can select different testing functions as per their needs, including resistance testing, voltage testing, and capacity estimation. The results of resistance testing are crucial during the pairing of new battery packs to ensure consistent internal resistance matching. Extensive testing confirms that the internal resistance of batteries increases with decreasing capacity. This indicates that as batteries age and their capacity diminishes, their internal resistance correspondingly rises. These test results facilitate the identification of deteriorating battery performance by comparing internal resistance values across battery sets or tracking changes in individual cell resistance. Monitoring changes in individual cell resistance enables the assessment of battery aging, thereby facilitating effective battery maintenance. During battery operation, issues such as overcurrent or short circuits can be detected using the battery internal resistance tester, ensuring early identification of safety risks and prompt preventive measures. Typically, the tester consists of essential components: the testing circuit, data acquisition unit, display screen, and power module. The testing circuit is critical for performing tests, often designed using instruments like digital multimeters or oscilloscopes. The data acquisition unit converts and processes test results into digital signals, employing microcontrollers or microchips. The display screen provides test results and operational prompts, while the power module ensures stable power supply to the entire instrument. By utilizing the battery internal resistance tester, industries and consumers alike can enhance battery safety, reliability, and longevity, thereby supporting sustainable energy practices in modern society. Battery Tester LS5562 AL3 Shanghai LISUN LS5562 series of high-voltage, high-precision battery internal resistance testers are special designed to meet battery industry test requirements, and it is developed for the testing of low-resistance and large-scale lithium battery packs and high-speed assembly line sorting. With many years of technical advantages in the field of impedance testing, the LS5562 series come with highest test resolution to reach 0.1uΩ and voltage resolution up to 10uV. The instrument have equipped with RS232C and HANDLER as standard interfaces, which can easily set up an automated test system. Technical Specification: • Included 4.3-inch LCD screen display, battery internal resistance R and voltage V are displayed at the same time; • Minimum resolution 0.1uΩ, 10uV; • High precision, good stability, the fastest test speed up to 100 times/second; • Test lead contact check function; • Built-in comparator function, 10-level sorting; • Equipped HANDLER sorting interface to achieve automatic online function; • Standard RS232 communication interface (Optional: RS485), support SCPI and Modbus (RTU) two communication modes; • The test conditions are automatically saved, with 50 groups inside the instrument and 500 groups of setting files in the U disk • Invention patent, no need to install software, it can upload test results to the computer directly. Application: • Deficiency of alkaline batteries and lead battery measurement and life assessment • UPS detection • Factory inspection of batteries • High -precision lithium battery internal resistance and voltage detection • High -speed mass production random inspection of buttons • Measurement of fuel cell group • Test of high -voltage battery packs such as electric vehicle lithium batteries • Multi -section series high -voltage lithium battery internal resistance and voltage measurement • Measurement of hydrogen fuel cell resistance and voltage • The supporting automatic sorting machine performs battery internal resistance+voltage automatic test • The deterioration state and life evaluation of the battery • ESR test of super capacitance (low internal resistance capacitor) Read the full article

0 notes

Text

LiFePO4 Battery 12v 100ah: The Key To Enhanced Performance In Electric Vehicles

With the current changes in the working environment, it has become more common to change traditional Lead-Acid batteries to a state-of-the-art lithium iron phosphate LiFePO4 forklift battery. This shift is quite a step up from the productivity and safety point of view as well as from the point of view of performance. Therefore, for organizations that may be interested in this sort of transition, it is rather important to understand the nature of LiFePO4 forklift batteries and the particular strengths of a LiFePO4 Battery 12v 100ah. This is what you need to know about making this crucial transition.

Why Choose LiFePO4 Forklift Batteries?

A LiFePO4 forklift battery is emerging as a new trend in the materials handling industry. Despite the differences in construction and chemical composition from regular lead acid batteries, LiFePO4 batteries deliver considerably higher energy density, they cycle more times, and can be charged much faster. These benefits are manifested in elevated levels of productivity and minimum time loss for the companies.

Perhaps, the most important benefit associated with the use of LiFePO4 forklift batteries is the b the former is safer in use than the latter. Another advantage, which consists of higher stability of LiFePO4 chemistry compared to other types of lithium-ion chemistry, reduces the risk of thermal runaway and increases safety during the operation of the battery pack. Also, these batteries cause less pollution to the environment as compared to lead-acid batteries which require dangerous materials and disposal processes.

Understanding the LiFePO4 Battery 12v 100ah

All in all, the LiFePO4 Battery 12v 100ah is highly suitable for different forklift applications. Its content is a particular setting to give a stable and steady power supply, which is useful in different industrial settings. The cell label 12v 100ah describes a battery of 12 volts nominal voltage and 100 Ah of capacity, which is suitable for long operation.

This battery has some advantages over lead-acid batteries. The LiFePO4 Battery 12v 100ah is superior to the lead-acid batteries in the following aspects. So it provides more power per pound than any other battery technology currently available for improving the agility and productivity of your forklift. In addition, it has a longevity of over 2,000 charge cycles and this implies that it will require frequent replacements as its costs are thoroughly evaluated.

Key Benefits of Transitioning

Extended Runtime and Efficiency: Compared to traditional forklift batteries, a LiFePO4 forklift battery offers longer runtime between charges to support sustained operative shifts and minimize recharging frequency. This rounds up to greater efficiency leading to better productivity and total cost of ownership.

Faster Charging Times: The LiFePO4 Battery 12v 100ah takes less time to charge as compared to other forms of batteries like lead-acid batteries. This aspect means that your forklifts will have minimal time attached to the charging process and will instead stay longer in use effectively increasing the organizational procedures’ productivity.

Low Maintenance Requirements: LiFePO4 batteries are known to be a low-maintenance type of battery, unlike lead-acid batteries. Another advantage is that commercial vehicle starting batteries or deep cycle batteries do not need refilling or equalization charges; thus battery management is easy and cheap.

Improved Safety: The nature of LiFePO4 technology has fewer inherent dangers relating to heat and chemical leakage due to the additional measure of stability that is offered by the technology. This added factor of safety in the workplace is important for the protection of both the employees and property.

Implementing the Transition

Changing forklift batteries to LiFePO4 demands effective planning and analysis of different factors. To start with, one cast takes stock of the existing battery infrastructure and the requirements for battery operation. Assess whether your current equipment is compatible with LiFePO4 batteries, and ascertain that your chargers are compatible with lithium-ion chemistry.

It is also important to engage the services of an experienced supplier or consultant who can advise on the same. They can give useful tips about the advantages of the LiFePO4 Battery 12v 100ah for your types of usage and help to change your charging or maintaining processes.

Conclusion

The transition to LiFePO4 forklift batteries is therefore a major new development in material handling. Thus, by adopting the advantages of LiFePO4, namely higher efficiency, safety, and low maintenance, companies can enhance their operations’ performance. The LiFePO4 Battery 12v 100ah is, therefore, exemplary in every way and can be viewed as a perfect solution to meet today’s industrial digital requirements.

This is why the transition from one phase to the other requires a lot of planning to guarantee that your business benefits a lot from this technological advancement.

#LiFePO4 Forklift Battery#Marine Lithium Cranking Battery#lithium rv battery#LiFePO4 Battery 12v 100ah

0 notes

Text

Home Energy Storage Alleviates Urban Power Shortage Problem

According to forecasts, compared with 2022, the global installed capacity of home energy storage systems will increase by 27%. This will benefit from the continued recovery of the global economy. Special incentive policies for energy storage, and clean energy owners’ continued desire for consumption.

After experiencing a challenging year, Benrong Group will accelerate the development of the global household energy storage market in 2023. Focus on the home energy storage track with excellent products and a new brand. Through market layout, the business penetrates into more application scenarios. Control the cost structure, sort out key processes and establish a support system around core business. Not only must we conquer cities and territories, but we must also seize market share.

Based on a clear strategic direction, Benrong New Energy has expanded its strategic cooperation with the Hong Kong-listed company Huaxun. On February 17, Lin Xianqi, Chairman of Hong Kong Huaxun, and his delegation visited Benrong New Energy. Conducted in-depth discussions on the policy of continued cooperation with Benrong and future product structure layout.

Qiu Kaijian, chairman of Benrong New Energy, said that the home energy storage market has broad prospects. The global home energy storage market will be worth US$7.5 billion in 2022, including US$1.337 billion in China. Not only that, it will reach US$26.4 billion and US$4.6 billion in 2027.

The current global energy crisis is becoming increasingly severe.

As a major energy consumer, China has no time to delay in strengthening the development of energy storage. As a part of the energy storage field, household energy storage is also crucial to its development. With the continuous advancement of energy storage products such as lithium batteries, and the continuous improvement of national policies. I believe that more and more energy storage products will come to the fore and improve people’s quality of life. Benrong New Energy not only upgraded and put into large-scale production, but also successfully launched the company's business growth flywheel. It not only effectively drives the company's product upgrades and brand upgrades, but also demonstrates the company's strength.

Benrong smart home energy storage not only adopts an integrated design, but is also exquisite, beautiful and easy to install. It can supply power to residences, public facilities, small places, etc. Smart home energy storage systems are similar to energy storage power stations, and their operation relieves urban power supply pressure. In the future, we hope to become a company that solves the country’s carbon-neutral electricity target.

During low power consumption periods, home energy storage systems can recharge themselves to prepare for power outages. Not only used as an emergency power source, but also home energy storage relieves electricity pressure and saves household expenses. Committed to solving the problem of continuous power supply for the 1.6 billion people around the world who lack electricity.

1 note

·

View note

Text

Powering the Future Sustainably: How LOHUM is Closing the Battery Loop with Repurposing and Reverse Logistics

In the fast-evolving era of electrified mobility, lithium-ion batteries have become the lifeblood of innovation. From scooters to electric cars, buses, commercial trucks, trains, and even aircraft, Li-ion batteries are driving the global transition towards cleaner, smarter transportation. But while this technological shift helps reduce emissions, it also brings a new kind of challenge: What happens to these batteries once they reach the end of their first life?

With over 2 million metric tonnes of used lithium-ion batteries projected to be retired annually by 2030, the world is facing a critical inflection point. The rise in electric vehicles (EVs), solar energy storage, and consumer electronics means that an unprecedented volume of used batteries will soon require responsible handling. At LOHUM, we see this as a defining opportunity—to not just manage battery waste, but to mine value from it. Our mission is to power the world sustainably through world-class battery repurposing and recycling solutions.

A Circular Opportunity: Rethinking Battery End-of-Life

Today, less than 5% of lithium-ion batteries are recycled globally. Much of the battery waste ends up in landfills or is stored indefinitely, awaiting infrastructure improvements or economic justification for recycling. Yet lithium-ion batteries are anything but waste—they are repositories of critical materials like lithium, cobalt, and nickel, and represent a latent opportunity for resource recovery and circular manufacturing.

According to analysts, more than half a million EV battery packs could be retired each year by the end of this decade. That’s not a problem—it’s a reservoir of potential. With Li-ion Battery Repurposing Technology, LOHUM is unlocking this potential, transforming retired batteries into high-performance, second-life energy storage solutions.

Repurposing, Not Just Recycling: The LOHUM Way

Recycling batteries is essential, but it's only part of the answer. At LOHUM, we believe in maximizing the usable life of every battery before it reaches the recycling stage. Our proprietary Li-ion Battery Repurposing Technology enables us to identify, extract, and refurbish healthy battery modules from retired EV battery packs. These refurbished modules are then used in applications such as renewable energy storage, backup systems, telecom towers, and grid balancing.

One battery, many lives—that’s the circular principle we live by.

Studies show that EV batteries typically reach end-of-life when they lose around 20% of their original capacity. But even with 80% capacity, these batteries can serve for an additional 6 to 10 years in stationary applications. That’s years of valuable, sustainable use that would otherwise be lost in traditional recycling streams. By extending battery life, we not only reduce demand for new materials but also dramatically cut down the carbon footprint associated with manufacturing.

The Reverse Logistics Revolution

Central to this sustainable model is the development of efficient reverse logistics for lithium-ion batteries. Unlike traditional supply chains that flow in a single direction—from manufacturer to consumer—reverse logistics creates a two-way street. It ensures that batteries, once retired, find their way back into the value chain through reuse, remanufacturing, or material recovery.

At LOHUM, we've built one of the most advanced and scalable reverse logistics networks in South Asia, enabling seamless collection, diagnosis, sorting, and repurposing of end-of-life batteries. This infrastructure is key to managing the growing influx of retired batteries as EV adoption accelerates.

Why does reverse logistics matter?

Environmental Impact: Proper logistics ensure batteries don’t end up in landfills, where they pose a serious ecological threat.

Resource Efficiency: It enables recovery of valuable materials and avoids the environmental damage caused by mining.

Economic Value: It provides manufacturers and consumers a reliable, cost-effective way to manage battery lifecycles, while creating circular revenue streams.

The Science Behind Sustainable Battery Recycling

While repurposing offers a powerful bridge to a second life, batteries will eventually need to be recycled. Traditional pyrometallurgical recycling techniques—essentially high-heat smelting—recover some materials like cobalt and nickel but at a high environmental cost and low lithium recovery rates. These processes also generate toxic emissions and are energy-intensive.

LOHUM is innovating beyond these limitations. Our advanced hydrometallurgical processes and material re-refinement systems allow for the recovery of lithium, cobalt, nickel, and manganese with high purity and significantly lower emissions. Additionally, we are actively exploring direct recycling techniques where cathode compounds are rejuvenated without breaking them down entirely—preserving material value and reducing reprocessing energy.

New research even suggests that cathode materials from recycled batteries can outperform virgin cathodes. Increased porosity, improved lithium-ion flow, and reduced microcracking all contribute to longer cycle life and faster charging—turning yesterday’s batteries into tomorrow’s performance stars.

Policy Momentum & Global Responsibility

Forward-looking governments are recognizing the critical role battery recycling will play in achieving climate targets. California, for instance, is working to ensure 100% of EV batteries sold in the state are either reused or recycled at end-of-life. The European Union and India are exploring Extended Producer Responsibility (EPR) mandates to ensure accountability and sustainability across the battery value chain.

As one of the few companies delivering integrated battery lifecycle solutions, LOHUM is aligning with this global shift. We are not only recovering materials but also creating a reliable, domestic supply of battery-grade minerals—critical for national energy security and industrial growth.

The Future is Circular—and LOHUM is Leading the Charge

The battery industry is on the cusp of a trillion-dollar revolution. With rising demand for EVs and renewable energy storage, the world needs solutions that are scalable, sustainable, and socially responsible.

At LOHUM, we are proud to be pioneers in this transformation—building a vertically integrated ecosystem that covers everything from reverse logistics and repurposing to responsible recycling and material re-manufacturing. Our work ensures that no battery is wasted, and every gram of material is used to its fullest potential.

Because when batteries live longer, our planet does too.

#critical minerals#lohum#battery waste management#lithium battery reusing and recycling#li-ion battery waste management#3 wheeler ev battery#reverse logistics for lithium-ion batteries#lithium battery waste recycling

0 notes

Text

Powering the Future Responsibly: The Role of Solar Battery Recycling

Introduction:

As the world seeks sustainable and clean energy solutions to combat climate change, solar energy has emerged as a prominent renewable power source. Solar panels, also known as photovoltaic (PV) panels, harness the sun's energy to generate electricity. To enhance the efficiency and reliability of solar power systems, many installations are equipped with recycle solar batteries. These batteries store excess energy produced by solar panels for use during periods of low sunlight or at night, ensuring a consistent energy supply. However, like all technologies, solar batteries have a limited lifespan and eventually reach the end of their operational life. To ensure a sustainable energy future, responsible recycling of solar batteries is vital. This article explores the role of solar battery recycling, its significance in powering the future responsibly, the recycling process, and the environmental benefits it brings.

The Growing Importance of Solar Battery Recycling:

Solar batteries play a crucial role in maximizing the potential of solar energy by storing excess electricity for later use. They enhance the reliability and grid integration of solar power systems, enabling the supply of electricity even when the sun is not shining. However, as solar batteries age, their capacity and performance diminish. Proper recycling at the end of their life cycle is necessary to prevent environmental harm and recover valuable materials.

The Significance of Solar Battery Recycling:

a. Environmental Impact:

The recycling of solar batteries offers numerous environmental benefits that contribute to sustainable waste management and resource conservation:

Waste Reduction: Recycling solar batteries diverts them from landfills, reducing the burden on waste disposal sites and minimizing potential environmental pollution.

Resource Conservation: Valuable materials like lithium, cobalt, nickel, and other metals can be extracted during the recycling process, reducing the need for new raw materials and energy-intensive extraction methods.

Hazardous Material Management: Solar batteries may contain hazardous substances, such as lithium and lead-acid, which need proper handling and disposal to prevent environmental contamination.

Lower Emissions: Recycling solar batteries requires less energy and emits fewer greenhouse gases compared to extracting and manufacturing new materials.

b. Circular Economy:

Emphasizing solar battery recycling aligns with the principles of a circular economy, where resources are used and recovered in a closed-loop system. By reclaiming valuable materials from decommissioned batteries, the recycling process helps create a more sustainable and circular supply chain.

c. Energy Independence:

Recycling solar batteries contributes to energy independence by reducing the reliance on foreign sources of critical materials. Recovering these materials domestically promotes a secure and resilient energy infrastructure.

The Solar Battery Recycling Process:

The recycling process for solar batteries involves several key steps to ensure the safe and efficient recovery of materials:

a. Collection: Decommissioned solar batteries are collected from various sources, including residential, commercial, and utility-scale installations. Proper collection mechanisms are crucial to ensure that the batteries reach recycling facilities.

b. Testing and Sorting: Upon arrival at the recycling facility, solar batteries undergo testing to determine their condition and performance. Batteries are then sorted based on their chemistry and type to facilitate the subsequent recycling process.

c. Discharge and Transportation: To ensure safety during transportation and recycling, solar batteries are discharged of any remaining energy before being transported to the recycling facility.

d. Shredding and Smelting: The batteries are shredded into smaller pieces to expose the internal components. The shredded materials then undergo smelting or hydrometallurgical processes to recover valuable metals.

e. Material Recovery: During the recycling process, valuable metals like lithium, cobalt, and nickel are extracted for reuse in the manufacturing of new batteries or other products.

f. Hazardous Material Management: Proper handling and disposal of hazardous substances, such as lithium and lead-acid, are essential to prevent environmental contamination.

g. Residue Management: The remaining materials after recycling are managed responsibly, with a focus on minimizing waste generation and maximizing resource recovery.

Challenges in Solar Battery Recycling:

Despite its significant benefits, solar battery recycling faces several challenges:

a. Lack of Awareness: Many individuals and businesses are unaware of the importance of solar battery recycling, leading to improper disposal and lost opportunities for material recovery.

b. Collection and Transportation: Establishing efficient collection and transportation networks is crucial to ensure a steady supply of solar batteries to recycling centers.

c. Technology Diversity: Solar batteries come in various chemistries and types, each requiring specific recycling processes. Developing adaptable and efficient recycling methods for diverse batteries is essential.

d. Cost Considerations: The recycling process can be expensive, particularly for certain types of batteries. Financial incentives and policies may be required to encourage more businesses and consumers to recycle their batteries.

Conclusion:

The role of solar battery recycling in powering the future responsibly cannot be overstated. By responsibly managing the end-of-life phase of solar batteries, we can reduce waste, conserve resources, and minimize the environmental impact of renewable energy systems. Governments, industries, and individuals must collaborate to invest in recycling infrastructure, promote responsible disposal practices, and implement policies that incentivize solar battery recycling. Through collective efforts, we can unlock the full potential of solar energy while contributing to a cleaner, more sustainable, and resilient energy future for generations to come.

0 notes