#China CNC Turning

Text

#china cnc turning#china metal parts#cnc turning#mxmparts#youtube#custom parts#china steel parts#china turned parts#cnc turned parts#turned parts

2 notes

·

View notes

Text

Components of CNC Lathe Machining

Lathe machines are commonly identified by a swing, the maximum working diameter that swings the lathe bed. A lathe swing is used to spin things that can be chopped, sanded, or drilled. Other lathe machine parameters include the length of the bed. Let’s examine the key components of a CNC Lathe Turning:

Headstock

CNC The lathe machine makes use of a headstock, which is an important component of…

View On WordPress

0 notes

Text

China Emerges as a Powerhouse in CNC and Die Casting Industries

Online Platforms Revolutionize CNC Precision Machining, Milling, Turning, and Sheet Metal Fabrication

Date: September 16, 2023

China is making significant strides in the CNC and die casting industries, solidifying its position as a key global player. Leveraging the power of online platforms, CNC precision machining, milling, turning, and custom sheet metal fabrication services have become more accessible to customers worldwide.

Within China die casting, the die casting market has experienced remarkable growth, supported by a robust manufacturing ecosystem, skilled labor, and favorable government policies. Chinese die casting companies have successfully served both domestic and international markets, with industries such as automotive, aerospace, and electronics relying on their top-quality components.

Simultaneously, the online CNC wood milling services market has witnessed a surge in demand, revolutionizing the way individuals and businesses access wood CNC services. Online platforms have simplified the process, offering convenience and efficiency to furniture makers, interior designers, and hobbyists seeking wood cutting, carving, and engraving solutions.

The rise of online CNC precision machining services has transformed the manufacturing landscape. Customers can now effortlessly upload design files and connect with CNC machining service providers through digital platforms. This technology-driven approach ensures accuracy, repeatability, and cost-effectiveness across industries such as automotive, aerospace, medical, and electronics.

In tandem, CNC milling service manufacturers are embracing the online marketplace. Equipped with advanced milling machines, software, and tooling, these companies provide a range of valuable services, including prototyping, production runs, and complex part machining. Online platforms facilitate seamless connections between customers and reliable CNC milling service providers, streamlining the manufacturing process.

Similarly, online platforms have simplified the search for CNC turning services, a crucial aspect of precision manufacturing. CNC turning involves the rotation of a workpiece while a cutting tool shapes it into the desired form. With the aid of online platforms, customers can easily connect with CNC turning service providers, catering to industries such as automotive, aerospace, and energy.

The custom sheet metal fabrication industry, vital to various sectors, has also embraced online platforms. This industry encompasses cutting, bending, welding, and assembly of sheet metal components. Online platforms enable efficient collaboration between customers and sheet metal fabrication shops, allowing customers to request quotes and actively participate in the design process.

The expansion of online services has opened up new growth opportunities in the CNC and die casting industries. Advancements in automation, machine technology, and the rising demand for customized products are driving this upward trend. However, market players must navigate challenges such as intense competition, rising raw material costs, and the need for skilled labor.

As China strengthens its position in the CNC and die casting sectors, the integration of advanced technologies and online platforms will play a crucial role. Manufacturers and service providers that embrace innovation, invest in modern machinery, and adapt to evolving customer requirements are poised to thrive in this competitive landscape.

#china die casting#CNC wood milling services#Online CNC Precision Machining#CNC Milling Service Manufacturer#CNC Turning Services#Custom Sheet Metal Fabrication

0 notes

Text

Reliable CNC Turning Services in China- EJCNC

Looking for top-notch CNC turning services? Look no further! EJCNC is your go-to solution for precision machining in China. With our state-of-the-art facilities and skilled technicians, we deliver high-quality CNC turning services that meet your exact specifications. Our experienced team is well-versed in working with various materials, including metals, plastics, and more. Whether you need small or large-scale production, we have the capabilities to handle it all.

1 note

·

View note

Text

Get Plastic Moulding In China at Affordable Price

Supplybase Solutions offers sourcing and supply chain management services, as well as plastic moulding in China. We provide affordable prices, quick lead times, and premium plastic moulding goods. We offer regular updates about the development of your product's import at every stage of production thanks to our staff' availability in both China and the UK. Go to our website to learn more.

#Plastic Moulding China#chinese product suppliers#cnc spare parts suppliers#Machine Part Suppliers uk#Machined Parts China#Mechanical Components Supplier#Diamond Tools Flooring#turned parts supplier

0 notes

Video

youtube

China CNC machining service: CNC turning parts factory - Tuofa

What is CNC turning?

0 notes

Text

"Don't spank me anymore... Wake up! Lan Zhan, wake up..."

...................is this .....is this a safe word?

Like, if there's some form of BDSM etiquette in ancient fantasy China, Wangxian certainly don't know about it. But the incense burner serves as a pretty awesome metaphor for a roleplay fantasy or CNC scene, letting them (and readers) explore CNC dynamics without turning into a dry "how to" guide.

The dream in question is the one where Wei Wuxian fucks Bichen* and gets spanked. Towards the end, Wei Wuxian gets pushed a little too far, breaks character, and says "wake up" to Lan Wangji.

If Lan Wangji didn't actually know it was fantasy (a dream, but also CNC roleplay), "wake up" wouldn't work any better than "stop."** But sure enough, Wei Wuxian says "wake up," and he stops spanking him, they finish up quickly, wake up, snuggle, and talk*** about it.

Because "wake up" is a safe word! Or at least it functions like one in this scene, in a way that lets MXTX portray good CNC dynamics in a fun way.

*Fucking Bichen serves a purpose beyond just outlandish porn! It's intentionally ridiculous, impossible, and Wei Wuxian would never do it in real life. MXTX put it right before the book's most egregious CNC scene, specifically to show that it's all a fucking fantasy.

**Compare with their first encounter, where the poor confused top does stop to ask: "Are you actually begging for mercy or are you... doing this on purpose... ?"

***talk is a strong word for it, but there's clearly some boundaries being negotiated.

25 notes

·

View notes

Text

youtube

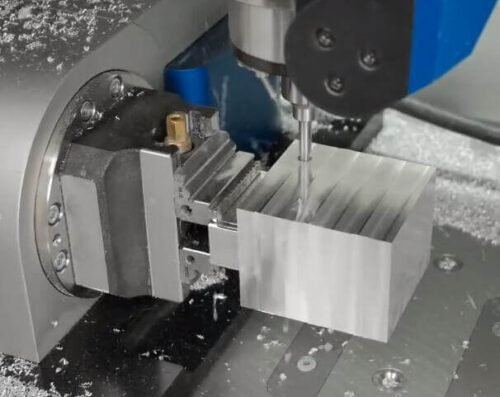

Precision cnc turning milling aluminum parts

We are specialize in cnc machining stainless aluminum cnc turning part, cnc turning milling machining parts, cnc turning parts manufacture, cnc turning milling parts, cnc turning parts aluminum, cnc turning and milling products, cnc stainless steel turning parts, cnc lathe with polygon turning etc

------------------------------------------------------

0 notes

Text

Cross recessed countersunkhead machine screw DIN7987

Stainless steel series is our hot-selling series.

We supply all kinds of general fasteners,including screws,nuts,washers,bolts...

Just try us,you will be pleasantly surprised!

UNIFIXS is an international trade enterprise combined with factory, specializing in the manufacturing of screws, anchors, rods, precision turning parts with stainless steel, carbon steel and low alloy steel. Which is located in Haiyan, It is only 100 kilometers away from shanghai and ningbo port. As China Cross recessed countersunkhead machine screw DIN7987 Suppliers and wholesale Cross recessed countersunkhead machine screw DIN7987 Company, we both have our screw, anchors and CNC machining factory, which enable us to supply different markets with an annual production capacity of over 10000 tons. And our product are mainly exported to over 30 countries such as Panama, Columbia, Peru, Germany, Poland, Japan, Spain, Italy, Australia, Russia and etc.

Julong Bridge, Yongfu Community, Yuantong Street, Haiyan County, Jiaxing City, Zhejiang Province (Buildings 1 and 2 of Haiyan Qi Anrui Precision Machinery Co., Ltd.)

+86-0573-86572400 / +86-15167379148

[email protected]/[email protected]

1 note

·

View note

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

1 note

·

View note

Text

CNC lathe turning offers several advantages over manual turning

CNC lathe turning is a precise and efficient machining process used to shape cylindrical workpieces using a lathe machine controlled by computer numerical control (CNC). Here’s a step-by-step overview of the CNC lathe turning process:

Workpiece Preparation: The process begins with selecting a raw material, usually a cylindrical bar or rod made of metal, plastic, or other materials. The workpiece…

View On WordPress

#CNC Lathe Turning#CNC Lathe Turning China#CNC Lathe Turning manufacturer#CNC Lathe Turning process#CNC Lathe Turning supplier

1 note

·

View note

Text

Top Aluminum CNC Machining Service in China

Aluminum CNC machining is a procedure that uses computer numerical control (CNC) machines to produce accurate and complicated Aluminum components. With technological improvements, the demand for high-quality Aluminum parts has skyrocketed. As a result, several Chinese enterprises are providing aluminium CNC machining services to suit the expanding demand.

China has quickly emerged as a top provider of CNC machining services because to its trained labor, superior technology, and cost-effective solutions. This has made it a popular choice for businesses wishing to outsource their CNC machining requirements. Aluminum CNC machining services provide a numerous benefits, including quick turnaround times, competitive pricing, and high-quality goods.

Our Aluminum CNC Machining Capabilities

We specialise in a variety of Aluminum CNC machining services, such as milling, turning, drilling, tapping, and more. Whether you need prototypes, small batches, or large-scale production runs, we can handle projects of any size or complexity. Our staff uses cutting-edge CNC machining equipment to enable quick turnarounds without sacrificing quality.

Benefits of Aluminum CNC Machining

Aluminum is regarded as being lightweight, sturdy, and corrosion-resistant, making it an excellent material for a variety of applications. Aluminium CNC machining allows you to make parts and components that are robust, reliable, and visually appealing. Additionally, aluminum is a cost-effective option that offers excellent thermal conductivity, making it suitable for various industries.

One of the primary benefits of choosing aluminium CNC machining services in China is the country's extensive network of suppliers and manufacturers. This provides organisations with access to a diverse choice of aluminium materials and machining techniques, guaranteeing that they can discover the optimum solution for their individual requirements. Furthermore, Chinese manufacturers are known for their meticulous attention to detail and precision, which ensures that the finished items satisfy the highest standards.

Another advantage of using Aluminum CNC machining Service is cost reduction. The country's competitive labor market and lower production costs result in lower prices for customers. China offers a cost-effective manufacturing choice without sacrificing quality.

In conclusion, Aluminum CNC Machining Service in China offers high-quality precision machining for aluminum parts. With state-of-the-art equipment and experienced technicians, we can produce custom aluminum components with tight tolerances and excellent surface finishes. Whether you need prototypes or large production runs, our CNC machining service can meet your specific requirements efficiently and cost-effectively. Trust us to deliver top-notch aluminum parts that meet your exact specifications and exceed your expectations.

0 notes

Text

What brand of CNC Maternal Row Rower is good (which one is the best of Sichuan mother row CNC cutting machine)

Due to the improvement of new power devices and thermal imagination technology, the current inverter is getting more and more loose, HB-5B, the size is getting smaller and smaller, and the power density is getting higher and higher, but it is necessary to strengthen research on how to control key technologies such as temperature rise.

The minimum width of the model on the CNC bending busbar machine is 0mm (currently). Due to this restriction, the bending processing part of the bending processing inside the workpiece shall not be less than 0mm, otherwise the hole must be expanded or considering the modeling of the model. Low, low -mode production efficiency; expansion of hole expansion affects the appearance. What brand of CNC Maternal Ranking Dispeller is good

It can monitor various operating status of the line in real time, such as power supply, power outage, shortage, grounding, short -circuit, short circuit, overcurrent, etc., quickly confirm the changes and places of the operating state of the monitored line. When the operating status of the line delivery, power outage, missing phase, grounding, short circuit, flow, overcurrent, etc., the line signal collector detects the changing signals. Various signals of change are emitted by wireless devices in a coding manner. As a receiving terminal, the duty personnel are informed by the computer after the computer processing, the screen display and other methods. The operating state of the monitoring line occurs and confirm the location of the change.

What brand of CNC parent row row row machines is good for the third trick: to check and repair the dynamic equipment of the bus motor motor to ensure its normal work. The motor to stifle the technical status of the equipment, which is voting for the normal preliminary work of the motor. The effectiveness. Therefore, the motor's controlling equipment should be set in a dull, ventilated and easy -to -operate orientation, and eliminate the dust from time to time. It is often check whether the contactor contact, coil iron core, various wiring screws, etc. It is not active to make it satisfied with the satisfactory technical situation, so it is guaranteed that the motor does not encounter difficulty work without being burned and eliminated.

The operator should operate in accordance with the bus processing machine operation manual, and must not operate the damage and damage of the composition of the personnel, equipment. The mold and accessories of the bus processor must be intact. Familiar with the structure, performance and operation method of the machine. Or dismantle the mold, it must be stopped by the person who familiarize the machine according to the rules of the rules. When the machine starts, do not put the hand or part of the body between the upper and lower molds to avoid accidents. In the end The degree, the blade of the blade becomes blunt, should be grinded or changed in time. Persist in oil cleaning and the oil circuit is unobstructed. Each class adds lubricating oil to each unit motion component. When normal phenomenon, you must stop and check immediately. Turn off the work button of each unit when not working, and turn off the power switch on the operation disk

System difficulty. The bus is uneven and accumulated at the change of direction; spiral patterns and unevenness of the pavement machine appear at the direction of the bare line; the oblique winding is not performed, and the strange number of winding is performed. What brand of CNC Maternal Ranking Dispeller is good

Qu Daokui: The development of various new technologies of the Internet, the Internet of Things, cloud computing, big data, and robots has already possessed the conditions to support the new industrial revolution. China is not behind in these fields. In terms of cost, the cost of labor has increased several times in these 10 years, but the cost of using robots has decreased by more than 50%in 10 years; from the perspective of investment, robots also have extensive application conditions. The manufacturing industry is increasingly developed towards intelligent, unmanned, and digitalized, labor force has been transferred to modern service industries, and industries and people need to transform and upgrade. Robotics intervene in the manufacturing industry, liberate industry workers from monotonous repeated labor, and restore the dignity of producers. In 2014, Xintong built a digital intelligent manufacturing plant using robots to produce robots. Everything was automated: automated stereo warehouse storage parts, industrial robotics were assembled and sprayed, and automated testing was finally performed. In the next step, Shinatong will copy this production line to all parts of the country.

0 notes

Text

The ability to shorten the lead time needed to obtain mechanical components for manufacturing projects is one of the main advantages of supply base solutions. The availability of the appropriate mechanical components and Diamond Tools Flooring at the appropriate time to satisfy market needs is dependent on supply base solutions. Go to our website to learn more.

#Diamond Tools Flooring#cnc spare parts suppliers#Machine Part Suppliers uk#Plastic Moulding China#Machined Parts China#Mechanical Components Supplier#turned parts supplier

0 notes

Text

Subtractive Manufacturing Mastery: CNC's Role in Rapid Prototyping

Many innovators and manufacturers turn to rapid prototyping to speed up product development. Through subtractive manufacturing, these professionals can streamline their time to market without compromising the strength and quality of their parts. This fast-evolving technology delivers CNC machined parts and helps businesses cut manufacturing and development costs.

Subtractive manufacturing is set to drive the growth of the rapid prototyping market by 14.9% from 2022 to 2031, with the aerospace industry likely being the largest contributor. Moreover, the increased availability of CNC machining services in China should encourage more industries to adopt and benefit from this rapid prototyping solution. Continue reading to learn more about CNC machining’s role in rapid prototyping.

A great way to make physical models

CNC machining is a subtractive manufacturing solution that helps manufacturers, product engineers, production planners, and designers make a tangible model, prototype, or sample of their product. These professionals can save time and money by using CNC machined parts to test and review their products in the real world.

Subtractive manufacturing creates a prototype by removing material from a block or billet of metal or plastic. That said, the process is fully automatic and computer-controlled, making it more reliable and capable of delivering results faster than hand-carving and other manual processes. Some service providers can even reduce lead times to 4 business days with CNC machining.

Ensuring accurate, high-quality parts

Rapid prototyping with CNC machining delivers robust, high-precision parts, especially when service providers apply industry-standard tolerances. The best CNC machined parts are controlled to DIN-2768-1 Medium for plastics and Fine for metals to ensure accurate-to-CAD results. In addition, manufacturers use the latest and proven equipment and tools, such as sink and wire EDMs, CNC mills, and surface grinding machines, to deliver CNC milling and turning solutions.

How it benefits rapid prototyping

CNC machining supports rapid prototyping because of the following reasons:

Quick and repeatable, making it ideal for low-volume manufacturing.

Delivers on high tolerance and precise specifications.

Service providers offer a wide range of rapid prototyping materials.

Master CNC machining with the experts

Learn more about subtractive manufacturing and get high-quality CNC machined parts from the experts at HLH Proto. The rapid prototyping and low-volume manufacturing company has extensive experience in providing custom solutions to various industries, including automotive, aerospace, electronics, industrial automation, robotics, oil and gas, and medical. Request a quote now to see how they can help your next project!

0 notes

Video

vimeo

TH MAchine Tools 2024 Corporate Vid Full Length from Byron Lippiatt on Vimeo.

At TH Machine Tools, business is about building relationships that last. Focusing on quality, we are confident to put our name on the machines we sell.

We specialize in new, used and reconditioned machines for fabrication, manufacturing, and engineering. Our vast portfolio includes conventional press brakes, guillotines, plate rolls, metal workers, lathes, mills, drills, band saws, welding machines and much more.

We also keep a finger on the pulse of the industry by constantly expanding our horizons with top CNC brands for our range of CNC fibre laser cutters, plasma cutters, machining centres, turning centres, press brakes and guillotines.

At TH Machine Tools we understand the need for affordable products of the best possible quality. Which is why our suppliers are carefully selected from across Europe, the East and America, namely: HURCO from the USA; SYIL from China; Sahinler, Isitan, LFSS and Bekamak from Turkey. And our own TH Machine Tools brand from China and Taiwan, ensuring quality, affordability, service, backup and spares.

We are based in Hartbeespoort and our 3000m3 warehouse offers a workshop area equipped with overhead cranes, loading bays, spares and tooling storage areas, an engineering shop, toolroom, boilermaker shop, offices and a large showroom area.

Our carefully selected staff, bring their unique contribution to unify and consolidate a well-defined work force, through love, care and dedication, assuring professional service and a long-term commitment to our customers.

TH Machine Tools is constantly evolving and adapting to the market needs and requirements, remaining consistent, rooted in faith, have withstood all the storms over the past 30 years, and still pursuing our goal to supply the industry with reliable new and used machines.

From Cape Town to Zimbabwe, Thabazimbi to Mozambique, Free State to Windhoek, you will find our name tag on quality machines across the continent.

TH Machine Tools – For Machines That Work!

0 notes