#China clay supplier in india

Text

China Clay – A Versatile Raw Material for Everyday Products

Kaolinite is a soft, usually white and earthy clay mineral which is produced by the chemical weathering of aluminium silicates. Rocks that are rich in Kaolinite are known as Kaolin or China Clay. China Clay is also referred to as White Clay and mainly includes the composition of fine particles in the form of platelets. The clay also consists of the hydrous aluminium silicate found in rocks rich in feldspars, such as granite. The hydrothermal process under which this granite changes into a soft clay found in Kaolin deposits is called Kaolinisation. China clay has high mechanical strength and anti-cracking properties.

Kaolin was first discovered in China, and hence, it gets its name from the Kao-Ling Hill in China, where it has been mined for centuries. High grade deposits of China clay in India are found in Rajasthan, West Bengal, Orissa, Madhya Pradesh and Gujarat. Zillion Sawa Minerals Pvt. Ltd. is India's leading and reputed China clay supplier that delivers fine and premium quality at reasonable market rates!

Uses of China Clay

China clay is the main ingredient used in the manufacturing of porcelain. But nowadays, it is widely used in other industries such as paper, rubber, paints and cosmetics.

Application and Benefits of China Clay

Filler Component: China clay is used as a filler component in paints, inks, cement primers, wood primers, spray plasters and texture paints, as it has a favourable effect on finished goods. China clay has a lamellar structure that adds toughness to the coatings. Due to its property of low solubility in water, it settles slowly in water and hence, is used in water-based paints. China clay has excellent levelling and brushing characteristics and is therefore used in latex paints as well.

Adhesive Sealants: China clay gives a good rheology control to adhesive sealants. Controlling rheology means influencing the speed at which the adhesive flows, which is crucial during laminating procedures. One of the properties of China clay is a low moisture picking up characteristic, which is beneficial when using moisture sensitive adhesive sealants.

Pharmaceuticals: China clay has been used as an emulsifier or a filler in traditional medicines for years. It has excellent antibiotic, antioxidant and antifungal properties, which is beneficial to the pharmaceutical industry.

Plastic: China clay is used as filler along with other components to add smoothness to plastic products—for example, PVC cables and PE film.

Ceramics: China clay is a naturally hydrated Aluminium Silicate mineral. It has alumina, which does not swell when mixed with water. Therefore, China clay is the most crucial element for making ceramics, rubber, tiles, potteries and many other industries.

Paper: China clay has low abrasive properties, is white in colour, affordable and easily available. Thus, it is the best and primary component for a paper filler. Plus, it adds smoothness, glossiness and brightness to paper, adds strength and improves the opacity and printability of paper.

Cosmetics: China clay is added to a wide range of cosmetic products. It is added to toothpaste for a brightening effect. It is also added to many facial masks as it offers several advantages like oil absorption, preventing acne and hydrating dry skin. When applied, it leaves a gentle, cooling and satisfactory effect on the skin.

Other Uses: China clay is used in the glass manufacturing process because of its high alumina content. It also acts as an excellent pesticide, dust-control and fog removing agent. It is also used for making dinnerware!

Zillion Sawa Minerals – The Skilled China Clay Supplier in India

China clay in India was and will continue to be in demand because of the multiple advantages it offers to ease the manufacturing process of many products. Because of this reason, there are many suppliers who deliver adulterated minerals. But if you are looking for high-grade, premium quality and budget-friendly China clay in India – we are here for all your requirements!

From mining to China clay delivery, we use the best technology, fully-functional and operational machinery and a team of professional and skilled workers to deliver nothing less than high quality. We are the best China clay suppliers in India with the best prices.

Contact us today to receive a superior supply of China Clay!

1 note

·

View note

Text

#Calcium Carbonate Powder manufacturers in india#Calcium Carbonate Powder manufacturers in Alwar#Calcium Carbonate Powder manufacturers in rajasthan#Calcium Carbonate Powder exporters in india#Lime Stone#China Clay Powder#Soap Stone Powder#Natural Calcium carbonate#Dolomite Powder Manufacturers in Alwar#Dolomite Powder Suppliers in Alwar#ARAWALI SUPPLY CHAIN SOLUTIONS

1 note

·

View note

Text

The Power of Kaolin: China Clay's Impact

China clay is a natural mineral predominantly composed of kaolinite, a hydrous aluminum silicate. It is formed through the weathering of rocks rich in feldspar. One of the unique characteristics of china clay is its soft and earthy texture, which makes it ideal for numerous applications. When it comes to industrial applications, the demand for china clay, also known as kaolin, has been on the rise in recent years. China clay is a versatile and essential mineral used in various industries, including ceramics, paper, paint, rubber, and more. A.N. Enterprises is a reputable name in the realm of China Clay Suppliers in India. With several years of experience, the company has established a strong floothold in the market. They offer a wide range of china clay products tailored to meet the specific requirements of different industries.

The Versatility of China Clay

1. Ceramics Industry: China clay plays a pivotal role in the ceramics industry, where it is a fundamental ingredient in the production of porcelain and fine china. Its presence enhances the whiteness, strength, and workability of ceramic products.

2. Paper Industry: In the paper industry, china clay is used as a filler material, improving the smoothness and printability of paper products. It also reduces the usage of costly wood pulp and enhances the paper's brightness.

3. Paint Industry: China clay acts as an extender in the paint industry, enhancing opacity and reducing the overall cost of paint production. It also provides excellent coverage and texture to various paint formulations.

4. Rubber Industry: In the rubber industry, china clay is used as a reinforcing filler, which enhances the strength and elasticity of rubber products. It is particularly crucial in manufacturing tires and various rubber components.

The Role of A.N. Enterprises in the China Clay Supply Chain

A.N. Enterprises is a renowned name in the field of China clay supply. Established with a vision to deliver quality minerals to industries, they have made a significant mark in the market. Their commitment to excellence, ethical business practices, and customer-centric approach sets them apart from others.

Why Choose A.N. Enterprises?

1. Quality Assurance: We take pride in providing the highest quality of china clay to their clients. They source their minerals from trusted locations and conduct rigorous quality checks to ensure consistency and purity.

2. Wide Product Range: The company offers an extensive range of china clay products, catering to diverse industrial requirements. Whether you need it for ceramics, paper, paint, or rubber, we have got you covered.

3. Timely Delivery: Understanding the importance of timely supplies, we ensure that their customers receive their orders promptly. Their well-organized logistics network enables smooth and efficient deliveries.

4. Customer Support: We take pride in its excellent customer support team, always ready to address queries and provide assistance. Their customer-centric approach fosters long-lasting relationships.

How to Place an Order with A.N. Enterprises?

Ordering china clay from us is a straightforward process. Customers can contact their sales team through their website or give them a call directly. Their team of experts will guide you through the available products and help you choose the right one for your specific needs.

Looking to source high-quality China clay for your business needs? Look no further! At A.N. Enterprises, we are dedicated to providing top-notch china clay products that cater to various industries. Whether you are in the ceramics, paper, paint, rubber, or cosmetics sector, our diverse range of china clay will meet your specific requirements. Contact us today to discuss your needs and get a quote tailored to your project.

0 notes

Text

Innovative Solutions for Industry Needs: The Role of Clay Powder

China clay, also known as kaolin, is a fine, white clay formed by the decomposition of rocks rich in kaolinite minerals. For centuries, it has been a critical raw material in a wide range of industries due to its unique properties. Today, China clay powder manufacturers play a crucial role in providing high-quality kaolin to various sectors, including ceramics, paints, paper, and rubber. Among these manufacturers, Sudarshan Group has carved a niche for itself with its focus on quality, innovation, and sustainability.

Understanding China Clay Powder

China clay powder is primarily composed of kaolinite, a hydrated aluminosilicate mineral. It has excellent physical and chemical properties, including high whiteness, low shrink-swell capacity, and low plasticity, which makes it highly sought after in various industrial applications. The extraction and processing of China clay involve a series of steps, including mining, beneficiation, and refining to achieve the desired quality and particle size.

The versatility of China clay powder is unmatched, and it is used in multiple industries for different purposes. In the ceramics industry, it is a key ingredient in the production of porcelain and fine china. In the paper industry, kaolin is used as a coating material to improve the brightness and smoothness of the paper. Its role in paints and coatings is crucial, where it acts as a filler to enhance the opacity and durability of the product.

The high demand for China clay powder, both domestically and globally, has led to the emergence of several manufacturers who specialize in mining and processing this valuable resource. However, not all manufacturers offer the same quality, and this is where Sudarshan comes into the picture.

The Role of China Clay Powder in Various Industries

China clay powder’s utility across different industries has made it an indispensable raw material. Let's look at its key applications:

1. Ceramics Industry

China clay powder is an essential component in the ceramics industry. Its high melting point and excellent binding properties make it ideal for producing high-quality ceramic products, including tiles, porcelain, and sanitary ware. The fine particle size of kaolin ensures smoothness and durability, which are key factors in the production of premium ceramic items.

2. Paper Industry

In the paper industry, China clay powder is used as a filler and coating material. It improves the smoothness and printability of paper, enhancing the brightness and reducing ink absorption. This results in high-quality paper products used in printing, packaging, and other applications. With the increasing demand for high-performance paper products, the need for premium-quality kaolin is growing rapidly.

3. Paints and Coatings

China clay powder plays a crucial role in the paints and coatings industry, where it is used as an extender. Kaolin improves the opacity and gloss of paints while reducing production costs. It also enhances the durability and resistance of coatings to weathering, making it a popular choice in the formulation of both decorative and industrial paints.

4. Rubber Industry

In the rubber industry, China clay powder is used as a reinforcing agent. It improves the strength, elasticity, and resistance of rubber products. Kaolin also helps in reducing shrinkage during the vulcanization process, ensuring the production of high-quality rubber products.

A Trusted Name in China Clay Powder Manufacturing

In a competitive market where the quality of raw materials can make or break a product, Sudarshan Group has earned a stellar reputation as one of the leading China clay powder. With over three decades of experience in mining and processing minerals, the company has established itself as a reliable supplier of premium-quality China clay powder.

Meeting the Challenges of the Industry

The China clay powder manufacturing industry faces several challenges, including fluctuating demand, environmental concerns, and competition from alternative materials. However, companies like Sudarshan Group have risen to these challenges by focusing on quality, sustainability, and innovation.

By investing in advanced technologies and maintaining strong relationships with customers, it continues to lead the way in providing high-quality China clay powder. The company’s emphasis on sustainable mining practices and its commitment to minimizing the environmental impact of its operations make it a model for other manufacturers to follow.

Conclusion

China clay powder is a versatile raw material that plays a pivotal role in various industries, from ceramics and paper to paints and rubber. As the demand for high-quality kaolin continues to grow, manufacturers like Sudarshan Group are leading the way by offering premium-grade products that meet the needs of diverse industries.

With a focus on quality, sustainability, and innovation, Sudarshan Group has established itself as a trusted name in the China clay industry. Its commitment to delivering consistent, high-performance products ensures that the company will remain a key player in the global kaolin market for years to come.

0 notes

Text

Kaolin Clay Manufacturers: Trends, Innovations, and Market Leaders

Kaolin clay, also known as China clay, is a versatile mineral used in various industries, including the production of sanitaryware. In this article, we'll delve into the world of kaolin clay manufacturers, highlighting trends, innovations, and key market leaders such as The Sharad Group. Whether you're a supplier, manufacturer, or simply curious about kaolin clay, this article will provide valuable insights. Let's explore the fascinating landscape of kaolin clay manufacturing!

Introduction to Kaolin Clay

Kaolin clay has been a cornerstone in the manufacturing industry for centuries. Its unique properties make it an essential ingredient in the production of ceramics, paints, paper, and especially sanitaryware. But what makes kaolin clay so special? And who are the key players in this market? Let's dig deeper into the world of kaolin clay manufacturers and uncover the trends and innovations shaping this industry.

What is Kaolin Clay?

Kaolin clay, often referred to as China clay, is a soft white clay that is primarily composed of the mineral kaolinite. It forms from the weathering of aluminum silicate minerals like feldspar. Imagine it as the flour in the cake batter of the ceramic industry—an essential ingredient that ensures the final product's quality and durability. Its fine particle size and ability to remain white after firing make it a favorite in many applications.

Uses of Kaolin Clay in Sanitaryware

When it comes to sanitaryware, kaolin clay plays a crucial role. It's used to manufacture items like toilets, sinks, and bathtubs. But why is kaolin clay preferred?

High Plasticity: Kaolin clay can be easily molded into various shapes, which is vital for creating intricate sanitaryware designs.

Strength and Durability: Products made from kaolin clay are strong and can withstand significant wear and tear.

Smooth Surface Finish: It ensures a smooth, glossy finish, which is not only aesthetically pleasing but also easy to clean.

Kaolin Clay Manufacturing Process

The process of manufacturing kaolin clay involves several steps to ensure its purity and quality:

Mining: Kaolin is extracted from open-pit mines.

Blunging: The clay is mixed with water to form a slurry.

Screening: The slurry is screened to remove impurities.

Centrifuging: This step further refines the clay by removing sand and other coarse particles.

Drying: The refined slurry is dried to produce a fine powder.

Calcination: In some cases, the clay is heated to enhance its properties.

Each step in this process is meticulously monitored to ensure the highest quality of kaolin clay.

Global Market Trends

The global kaolin clay market is experiencing significant growth, driven by its increasing use in various industries. Here are some key trends:

Rising Demand in Emerging Markets: Countries like China and India are witnessing a surge in demand due to their booming construction and manufacturing sectors.

Technological Advancements: Innovations in mining and processing technologies are improving the quality and efficiency of kaolin clay production.

Environmental Regulations: Stricter environmental regulations are pushing manufacturers to adopt sustainable practices.

Innovations in Kaolin Clay Production

Innovation is the heartbeat of any thriving industry, and kaolin clay manufacturing is no exception. Recent advancements include:

Enhanced Purification Techniques: New methods are being developed to remove impurities more efficiently, resulting in higher-quality kaolin.

Nanotechnology: Incorporating nanotechnology in kaolin production can improve its properties and expand its applications.

Sustainable Practices: Companies are investing in eco-friendly mining and processing techniques to reduce their environmental impact.

The Sharad Group: A Market Leader

The Sharad Group stands out as a leading mineral processing company. Based in India, The Sharad Group has carved a niche for itself in the mineral processing industry. Here's why they are a market leader:

Cutting-Edge Technology: The Sharad Group employs the latest technologies in kaolin processing, ensuring top-notch quality.

Sustainable Practices: They are committed to eco-friendly mining and processing techniques, minimizing their environmental footprint.

Customer-Centric Approach: With a focus on customer satisfaction, The Sharad Group offers tailored solutions to meet specific industry requirements.

Quality Control and Standards

Maintaining high quality is paramount in the kaolin clay industry. Manufacturers adhere to stringent quality control measures, including:

Regular Testing: Kaolin samples are regularly tested for purity, particle size, and other critical parameters.

Certification: Leading manufacturers often hold certifications like ISO to ensure their products meet international standards.

Customer Feedback: Continuous feedback from customers helps manufacturers improve and innovate their products.

Sustainability Practices

Sustainability is not just a buzzword; it's a necessity. Kaolin clay manufacturers are increasingly adopting sustainable practices to protect the environment. These include:

Recycling Water: Using closed-loop systems to recycle water used in the manufacturing process.

Reducing Carbon Footprint: Investing in energy-efficient technologies and renewable energy sources.

Land Rehabilitation: Restoring mined land to its natural state to preserve biodiversity.

Challenges Facing the Industry

Like any industry, kaolin clay manufacturing faces its share of challenges:

Environmental Regulations: Stricter regulations can increase production costs.

Resource Depletion: Finding new kaolin deposits is becoming increasingly challenging.

Market Competition: Intense competition from other mineral alternatives can impact market share.

Future Prospects

Despite these challenges, the future looks bright for the kaolin clay industry. The increasing demand for high-quality kaolin in various industries, coupled with technological advancements, promises sustained growth. Moreover, the focus on sustainability and innovation will drive the industry forward.

Conclusion

Kaolin clay is more than just a mineral; it's a cornerstone of the manufacturing industry, especially in the sanitaryware sector. With market leaders like The Sharad Group at the forefront, the industry is poised for continued growth and innovation. Whether you're a kaolin clay manufacturer, supplier, or simply an enthusiast, staying informed about the latest trends and innovations is crucial.

0 notes

Text

The Evolution and Significance of AAC Block Machine Manufacturers

In recent years, the construction industry has been undergoing a significant transformation, with a strong shift towards more sustainable, efficient, and cost-effective building solutions. One of the standout innovations has been the development and widespread adoption of Autoclaved Aerated Concrete (AAC) blocks. The demand for AAC blocks has consequently spurred a parallel growth in the sector of AAC block machine manufacturers. These manufacturers are crucial in the production of AAC blocks, providing the necessary machinery and technology to produce these lightweight, insulative, and environmentally friendly building materials.

Understanding AAC Block Machinery

AAC block machinery is involved in the entire production process of AAC blocks, from raw material preparation to the final output. The key components of an AAC block production line include raw material processing equipment, mixing equipment, cutting machines, and autoclaves. The technology involved in these machines is highly specialized, focusing on precision and efficiency to ensure that the AAC blocks meet the required standards of quality and sustainability.

Global Leaders and Innovations

Globally, several key players dominate the AAC block machinery sector. Companies based in Germany, China, and the United States have been at the forefront, driven by continuous innovations in machine efficiency, automation, and the integration of advanced technologies such as IoT and artificial intelligence. These technologies not only enhance the production process but also improve the quality control mechanisms throughout the manufacturing cycle.

The Role of AAC Block Machine Manufacturers in India

India, with its booming construction industry and increasing focus on sustainable practices, presents a huge market for AAC blocks. Indian manufacturers of AAC block machines have risen to the challenge, adapting global technologies to local conditions and requirements. These manufacturers are not just machinery suppliers but solution providers, often helping with the setup of entire AAC block production plants and providing after-sales services and technical support.

Key Challenges and Opportunities

Challenges:

High Initial Investment: The primary challenge for many manufacturers and their clients is the high capital investment required for setting up AAC block production units.

Technical Expertise: Manufacturing AAC block machinery requires high technical expertise and constant innovation to keep up with global standards and evolving construction practices.

Market Penetration: Especially in regions where traditional building materials like clay bricks still dominate, convincing the construction industry to switch to AAC blocks involves extensive marketing and education efforts.

Opportunities:

Rising Demand for Sustainable Building Materials: With increasing environmental awareness and stricter regulations on energy efficiency in buildings, the demand for AAC blocks is expected to grow, thus driving the demand for related machinery.

Government Initiatives: In countries like India, government initiatives aimed at improving housing facilities and promoting sustainable construction practices offer a lucrative opportunity for AAC block machine manufacturers.

Export Potential: Established manufacturers in countries with advanced technology can tap into emerging markets in Asia, Africa, and South America, where construction industries are booming.

Technological Trends Influencing AAC Block Machinery

The future of AAC block machinery is likely to be shaped by several technological trends:

Automation: Enhanced automation in the production process reduces manual labor and improves the efficiency and safety of the production line.

Customization: As different markets have varying requirements, the ability of manufacturers to customize machinery to suit specific needs will be a competitive advantage.

Sustainability Features: Incorporating features that reduce energy consumption during the AAC block manufacturing process and utilizing renewable energy sources will enhance the appeal of these machines.

Case Studies: Success Stories

Several success stories highlight the impact of innovative AAC block machine manufacturers:

A German company has pioneered fully automated AAC block production lines that have reduced production times and increased output by 50%.

An Indian manufacturer has developed a compact AAC block machine specifically designed for small and medium-sized enterprises, significantly reducing the entry barrier for new players in the industry.

Conclusion

AAC block machine manufacturers are pivotal in the ecosystem of sustainable construction. With their ability to innovate and adapt to both global and local conditions, these manufacturers not only support the green building movement but also contribute significantly to the modernization of the construction industry. As the world continues to push for more sustainable building solutions, the role of AAC block machine manufacturers will become increasingly central, making them key players in the global effort towards more environmentally friendly and economically feasible construction practices.

0 notes

Text

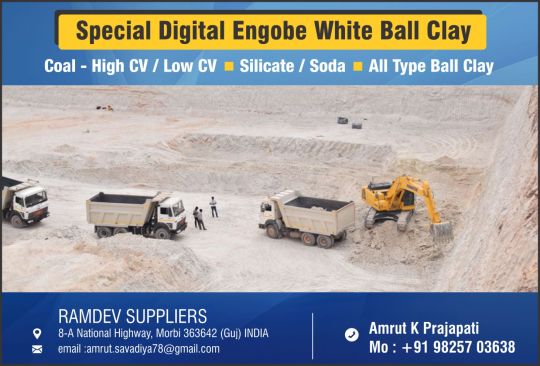

Ceramic Raw Material for tiles and sanitarywares, Ceramic India

Ceramic Raw Material for tiles and sanitarywares, Ceramic India

Ramdev Suppliers

Ceramic Raw Material, Ceramic Machinery Spare & Parts, Raw Material & Chemicals, Ceramic Roller & Grinding Media, China Clay, Digital Ink, Ceramic Color, Frit & Zinc Oxide, Refractories, Feldspar (Soda & Potash), Quartz, ceramic india

#ceramic#raw#materials#machinery#spareparts#chemical#roller#grinding#chinaclay#digitalink#color#frit#zincoxide#refractory#feldspar#sodapotash#tiles#sanitarywares#india#morbi#gujarat

0 notes

Text

Roofing Market Challenges and Opportunities (2024-2033)

Roofing Market is projected to achieve a value of USD 197.6 Billion in 2023, with a linear behavior in the market growth it is forecasted to achieve a value of USD 342.8 Billion by 2033 with a CAGR of 5.0% during the forecast period 2024-2033. deployment models, competitive analysis, operator case studies, opportunities, future trends, value chains, ecosystem player profiles, and strategies included. The report also presents a SWOT analysis and forecast for Roofing investments from 2024 to 2033.

Click the link to get a sample copy of the report: https://wemarketresearch.com/sample-request/roofing-market/1345

Top Companies in the Roofing Market:

Owens Corning (U.S.)

Duro-Last Roofing

(U.S.)

BASF SE (Germany)

3M (U.S.), Dow (U.S.)

DuPont (U.S.)

Braas Monier Building Group (Luxembourg)

Sika AG (Switzerland),

Atlas Roofing Corporation (U.S.)

Innospec (U.S.)

ADEKA CORPORATION (Japan)

Dorf Ketal Chemicals (I) Pvt. Ltd. (U.S.)

PMC Specialties Group (U.S.)

Afton Chemical (U.S.)

The Lubrizol Corporation (U.S.)

Clariant (Switzerland)

ANXESS (Germany)

Mayzo, Inc. (U.S.)

Solvay (Belgium)

Akzo Nobel N.V. (Netherlands),

Arkema (France)

Eastman Chemical Company (U.S.)

Global Roofing Market Segments:

Market, By Type

Materials

Chemicals

Market, By Roofing Type

Flat Roof

Slope Roof

Market, By Application

Residential

Commercial

Non-Residential

Market, By Product

Asphalt Shingles

Concrete and Clay Tile Roof

Metal Roofs

Elastomers and Plastic Roofs

Tile Roofs

Bituminous Roof

Others

Market Trends And Opportunities:

The development of the building industry is directly correlated with the demand for roofing materials. Rooftop materials are becoming more and more necessary as global urbanization and infrastructure development continue. In addition, roofing plays a vital role in the construction sector by shielding buildings from the weather and preserving their structural integrity.

In construction, a weatherproof barrier is created over the top of a building using roofing materials such metal sheets, membranes, shingles, and tiles. This barrier shields the interior of the structure and its occupants by keeping out water, snow, and debris. Additionally, a structure's visual appeal and energy efficiency can both be enhanced by the roofing industry. To guarantee the permanency of roofing, proper installation and maintenance are crucial.

Growth Strategy of Key Vendors:

To reserve and increase their market share, the major suppliers in the global roofing market are concentrating on a number of growth tactics. Product innovation, technology breakthroughs, tactical alliances, and mergers and acquisitions are some of these tactics.

To keep ahead of the competition and satisfy changing client expectations, these vendors are always reinventing their product offerings and implementing cutting-edge technologies. Furthermore, they can broaden their customer base and strengthen their overall industry position by expanding their geographic reach and diversifying their product line through strategic alliances and acquisitions. The objectives of these growth strategies are to propel firm expansion, boost market penetration, and maintain industry competitiveness over the long run.

Regional Analysis for Roofing Market:

For a comprehensive understanding of market dynamics, the global Roofing market is analysed across key geographies namely North America, Europe, China, Japan, Southeast Asia, India, Central & South America. Each of these regions is analyzed based on market research findings for the key countries in the region for a macro-level understanding of the market.

Important sections of the TOC

Economic Impact Variables on Roofing Market: Illuminates the consequences of environmental, political and economic fluctuations, and explains changes in customer and consumer requirements. We also provide a detailed report of Roofing on the technology risks and advancements in the global market.

Forecasts based on macro- and micro-economy: ensuring price, revenue and volume EV charging service forecasts for the market. It also includes, in addition to forecasting growth, revenue and import volume for the region, with revenue forecasting for the Roofing application, along with revenue forecasting by cost, revenue and type.

Marketing Strategy Analysis: In this section, Roofing analysis aims at niche positioning and provides information regarding target audience, new strategies and pricing strategies. We provide a comprehensive Roofing marketing station analysis that investigates the problem. Marketing channel development trends, direct marketing as well as indirect marketing.

Business Intelligence: The Roofing companies studied in this section are also assessed by key business, gross margin, price, sales, revenue, product category, applications and specifications, Roofing competitors, and manufacturing base.

Directly Buy a Copy of this Roofing Market research report at@https://wemarketresearch.com/purchase/roofing-market/1345?license=single

Why to buy this Report?

The report provides valuable insights into market trends, growth opportunities, and competitive landscapes. By reading a technology report, businesses and investors can gain a better understanding of the market they are operating in or considering entering, and make more informed decisions based on data and analysis.

The report reports provide detailed information on competitors' strengths, weaknesses, and strategies, which can help businesses identify potential threats and opportunities in the market.

The report provides insights into emerging technologies and trends, which can help businesses stay up-to-date with the latest developments and make informed decisions about where to invest their resources.

About We Market Research:

WE MARKET RESEARCH is an established market analytics and research firm with a domain experience sprawling across different industries. We have been working on multi-county market studies right from our inception. Over the time, from our existence, we have gained laurels for our deep rooted market studies and insightful analysis of different markets.

Contact Us:

Mr. Robbin Joseph

Corporate Sales, USA

We Market Research

USA: +1-724-618-3925

Websites: https://wemarketresearch.com/

Email: [email protected]

0 notes

Text

Supplier of Spray Dryer in Hyderabad

Supplier of Spray Dryer in Hyderabad

Drytech Engineering System, an ISO 9001:2015 certified firm based in Ahmedabad, India, stands at the forefront of innovative drying solutions.

Our diverse product range includes Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, Dust Collector Systems, and more.

Premium Quality Spray Dryers:

As prominent Spray Dryer Manufacturers in India, Drytech Engineering System offers cutting-edge spray dryers that adhere to international standards.

Our extensive line of spray dryers is tailored to meet diverse customer requirements, handling applications ranging from heat-sensitive items like enzymes and blood to flavors and normal products.

Spray Dryer Design Excellence:

Our reputation as one of India's leading Spray Dryer Manufacturers is attributed to the quality and cost-effectiveness of our spray dryer designs.

Engineered for efficiency and versatility, our plants cater to industries such as food processing, medicine, ceramics, and more.

Types of Spray Dryers:

Nozzle Spray Dryers

Rotary Atomizer Spray Dryers

Features:

Efficiency in manufacturing adhering to industry standards.

Stable device operation with a pleasant operator experience.

Cost-effective service and repair solutions.

Swift setup with minimal lead time.

Full automation capabilities tailored to customer demands using a PLC/DCS based system.

Certification options such as CE/ATEX/GOST-R based on customer requirements.

Strong thermal performance resulting in low fuel costs.

Compact footprint meeting factory requirements.

Applications:

Dyestuffs

Pigments

Food processing

Starch

Detergents

Pharmaceutical

Herbal Extracts

Food Flavors

Ceramics & China Clay

Servicing Hyderabad, Telangana:

Drytech Engineering System is your trusted Manufacturer and Supplier of Spray Dryer in Hyderabad, Telangana. We cater to locations like Hyderabad, Warangal, Nizamabad, Khammam, Karimnagar, Ramagundam, Mahbubnagar, Nalgonda, Siddipet, Miryalaguda, Suryapet, Jagtial, Bhongir, Kamareddy, Mancherial, Wanaparthy, and Jangaon.

Read the full article

#Ahmedabad#Exporter#Gujarat#India#Manufacturer#SprayDryerinHyderabad#Supplier#SupplierofSprayDryer#SupplierofSprayDryerinHaydrabad

0 notes

Text

China clay powder suppliers and manufacturer in India | Shree Vasudev minerals and chemicals

The company, which places a strong emphasis on manufacturing excellence, is known for producing China clay powder and upholding strict quality control standards all the way through the manufacturing process.

0 notes

Text

Best Manufacturers & suppliers of Industrial Minerals

FillerBoy Pvt. Ltd is one of the leading companies in India in terms of supplying industrial minerals and mineral powders. The entire team is dedicated to serving industry-standard materials at an extremely competitive price point to all our customers. Our journey started in 2004, with a dream of being the pioneer of the mineral industry.

We typically deal with products like dolomite, calcite, china clay, soapstone, quartz, feldspar, calcined clay, manganese, hydrated lime, and other industrial minerals. Customization of mineral products is our key. We deliver mineral powders according to the need of the customers. Our team build-up is entirely dependent on fulfilling the customer's needs as that is our utmost priority.

0 notes

Photo

Zillion Sawa Minerals Pvt. Ltd. is a leading supplier of quality China clay in India, offering high-grade China clay for diverse industrial applications.

1 note

·

View note

Text

Kaolin Clay: A Versatile Wonder of India

Kaolin clay, a natural mineral with a rich history dating back centuries, has found its way into various industries, including cosmetics, pharmaceuticals, agriculture, and ceramics. A.N. Enterprises stands at the forefront as a prominent supplier and manufacturer of high-quality Kaolin clay in India. Its versatility and wide-ranging applications have made it an invaluable resource in various industries, from cosmetics to agriculture. Their commitment to quality, custom solutions, and environmental responsibility sets them apart in the market, making them the preferred choice for businesses seeking high-quality kaolin clay. Kaolin clay provides a multitude of benefits, from enhancing the quality of skincare products and pharmaceuticals to promoting sustainable agriculture and enabling the production of high-quality ceramics.

Understanding Kaolin Clay

Kaolin clay, often referred to as China clay or white clay, is a soft, white mineral primarily composed of the mineral kaolinite. It is named after the Chinese region of Kao-Ling, where it was first discovered. This versatile clay boasts a plethora of qualities that make it indispensable across a wide range of industries.

Cosmetics and Skincare: Kaolin clay is a common ingredient in skincare and cosmetic products due to its gentle exfoliating properties and its ability to absorb excess oil. It is often used in face masks, cleansers, and powders to promote healthy and radiant skin.

Pharmaceuticals: In the pharmaceutical industry, kaolin clay is utilized as an ingredient in various formulations, including antacids and diarrhea medications. Its high adsorption capacity makes it an excellent choice for binding toxins and relieving digestive discomfort.

Agriculture: Farmers and horticulturists value kaolin clay for its role in pest control. When applied as a natural pesticide, it acts as a barrier that deters insects and protects crops from damage.

Ceramics and Pottery: Kaolin clay is the foundation of porcelain and fine china. Its unique properties, including high plasticity and white firing color, make it an essential component in the production of ceramics, tiles, and pottery.

A.N. Enterprises: A Trusted Kaolin Clay Supplier

A.N. Enterprises, headquartered in India, has emerged as a trusted name in the kaolin clay industry. With years of experience and a commitment to quality, this company has established itself as a frontrunner in providing high-grade kaolin clay products. Here's why we are the go-to choice for many businesses:

Quality Assurance: We place utmost importance on product quality. Their kaolin clay is sourced from premium deposits and subjected to rigorous quality control procedures to ensure purity and consistency.

Variety of Grades: Recognizing that different industries have distinct requirements, we offer a range of kaolin clay grades tailored to meet specific needs. Whether you need it for cosmetics, pharmaceuticals, agriculture, or ceramics, they have a suitable product.

Custom Solutions: We work closely with clients to understand their unique demands. They offer customized kaolin clay solutions, ensuring that every customer gets the right product for their application.

Environmental Responsibility: We are committed to sustainable practices and environmental responsibility. They mine and process kaolin clay with a focus on minimizing their environmental footprint, making them a responsible choice for eco-conscious businesses.

Reliable Supply: With a well-established distribution network, we ensure a consistent and reliable supply of kaolin clay to meet their customers' demands, even on a large scale.

If you're ready to harness the incredible potential of kaolin clay for your business needs, look no further than A.N. Enterprises. Contact us today to discuss your requirements, explore our range of premium kaolin clay products, and discover how our expertise can elevate your projects. Your journey towards quality and excellence begins with a simple click or call. Reach out to us now to get started. Your success is our priority!

0 notes

Text

Sudarshan Group: Leading the Way as China Clay Powder Manufacturers

Introduction

China clay, also known as kaolin, is a soft white clay mineral that finds extensive use in various industries due to its exceptional properties. From ceramics and paper to cosmetics and pharmaceuticals, the applications of china clay are diverse and significant. When it comes to sourcing high-quality china clay powder, Sudarshan Group emerges as a prominent player in the market. In this blog, we will explore why we stand out as a leader among China Clay Powder Manufacturers, offering top-notch products and unparalleled customer satisfaction.

About Sudarshan Group

Sudarshan Group has been a key player in the industrial mineral industry since its inception in [year]. With a commitment to excellence and a vision to cater to the evolving needs of their customers, We has expanded its operations and product portfolio over the years. As one of India's leading industrial mineral suppliers, we have earned a reputation for reliability, innovation, and sustainability.

Uncompromising Quality

At Sudarshan Group, quality is at the core of everything we do. Our china clay powder is sourced from the finest deposits, ensuring that only the purest and highest-grade raw materials are used in the manufacturing process. Advanced processing techniques and rigorous quality control measures guarantee that the final product meets the stringent international standards of purity and consistency.

Diverse Applications

China clay powder's versatility has earned it a prominent place in multiple industries, making it an indispensable material for countless applications. Sudarshan Group's china clay powder caters to the following industries:

Ceramics: In the ceramics industry, china clay is a fundamental component in the production of porcelain, tiles, and sanitaryware. It imparts strength, texture, and plasticity to ceramic products.

Paper and Pulp: As a coating and filler agent, china clay improves the printability and brightness of paper products, making it ideal for high-quality printing papers and glossy magazines.

Cosmetics and Personal Care: In cosmetics, china clay powder is used in products such as face masks, scrubs, and foundations, owing to its absorbent and gentle exfoliating properties.

Pharmaceuticals: China clay is utilized in the pharmaceutical industry as an excipient in tablet formulations and suspensions.

Paints and Coatings: It acts as a key extender in paints, enhancing their opacity, texture, and rheological properties.

Rubber and Plastics: China clay powder is used as a filler in rubber and plastic products, enhancing their mechanical properties and reducing production costs.

Customized Solutions

We understand that each industry and application has unique requirements. As a customer-centric organization, we offer tailor-made solutions, providing china clay powder with specific particle size distributions, brightness levels, and rheological characteristics. This personalized approach allows our clients to optimize their processes and achieve superior results.

Commitment to Sustainability

Sudarshan Group acknowledges its responsibility towards the environment and the communities it operates in. We embrace sustainable practices throughout operations, from responsible mining to waste management and reclamation. By adhering to eco-friendly methods, We aim to minimize its environmental impact and contribute to a greener, more sustainable future.

Reliable Supply Chain

As reliable china clay powder manufacturers, Sudarshan Group boasts a well-established and efficient supply chain. We ensure a steady and uninterrupted flow of products to meet the demands of their clients. With a robust logistics and distribution network, we guarantee timely deliveries to customers across the globe.

Conclusion

Sudarshan Group has earned its reputation as a leading manufacturer of china clay powder through its unwavering commitment to quality, innovation, and sustainability. Our top-notch products find applications in diverse industries, catering to the ever-changing demands of the market. As a customer-centric organization, We offer customized solutions and technical support, making them the preferred choice for businesses seeking reliable and high-quality china clay powder. For all your china clay powder needs, Sudarshan Group stands ready to provide innovative solutions and superior products that drive your success.

0 notes

Text

Are there any China Clay Manufacturers in India

China clay, also known as kaolin, is a fine white clay that is widely used in the manufacturing of ceramics, paper, paint, rubber, and other products. India is one of the leading producers of China clay, with several manufacturers operating across the country. In this blog, we will discuss the benefits of Synergy Chemical Industries as China clay manufacturers in India.

Abundant Raw Material Supply: India has abundant deposits of China clay, which is a key factor in the growth of the industry. This has enabled manufacturers to set up large-scale production units and cater to the growing demand for China clay.

Cost-Effective Production: The cost of production of China clay in India is relatively low compared to other countries, making it an attractive destination for manufacturers. This is due to the availability of low-cost raw materials, labour, and energy.

Skilled Labour Force: India has a large pool of skilled labour, which is essential for the production of high-quality China clay. The country’s vast experience in the ceramic industry has allowed manufacturers to develop a highly skilled workforce that can meet the demands of the market.

Government Support: The Indian government has been supportive of the China clay industry, providing various incentives and tax benefits to manufacturers. This has encouraged the growth of the industry and has helped manufacturers to expand their operations.

Diversified Market: India has a large domestic market for China clay, which provides a steady demand for the product. Additionally, the country exports a significant amount of China clay to other countries, providing manufacturers with a diversified market.

Strong Infrastructure: India has a strong infrastructure, which is essential for the transportation and storage of China clay. The country has a well-developed road and rail network, along with several ports and airports, which makes it easy to transport the product both domestically and internationally.

Technological Advancements: China clay manufacturers in India have access to the latest technology, which allows them to produce high-quality products that meet the demands of the market. This has helped the industry to stay competitive and meet the changing demands of the market.

Environmental Sustainability: China clay manufacturers in India are committed to reducing their carbon footprint and preserving the environment. They use eco-friendly processes in their production, minimize waste, and implement sustainable practices to minimize their impact on the environment.

Quality Control: India has strict quality control regulations that ensure the production of high-quality China clay. Manufacturers are required to comply with these regulations to ensure that their products meet international standards.

Research and Development: China clay manufacturers in India invest heavily in research and development, which has helped the industry to stay ahead of the competition. The focus on innovation and technology has allowed manufacturers to produce new and improved products that cater to the changing needs of the market.

Conclusion In conclusion, china clay suppliers in India have several advantages that have helped the industry to grow and become one of the leading producers of the product. These advantages include abundant raw material supply, cost-effective production, skilled labour force, government support, diversified market, strong infrastructure, and technological advancements. With the growing demand for China clay, the industry is expected to continue its growth and become an even more important player in the global market.

#hydrated lime supplier#lime manufacturers in india#lime powder manufacturer in india#quick lime manufacturers in india#rajasthan lime manufacturer

0 notes

Text

Best Talc powder for Talc-filled compounds

Talc powder for Talc-filled compounds powder is a versatile ingredient that has numerous uses in the cosmetic industry. It is good at absorbing moisture, making it ideal for products such as body powders. Talc is also a good filler, so it can be used in face and body powders to create a smooth, even finish. In addition, talc powder makes an excellent base material for color cosmetics such as eye shadows and powder blushers. Ashirwad Minerals offers a wide range of China Clay Powder. Our products are perfect for increasing the strength of the material in which they are mixed. We are one of the leading suppliers of these products in India. This range of products is also called Hydrated Aluminium Silicate.

Visit Us: https://www.ashirwadtalc.com/cosmetics-industry.php

0 notes