#Coil Slitting and Cutting Machine

Explore tagged Tumblr posts

Text

Top Quality Brass Coils Manufacturers in India

Top-Quality Brass Coil Manufacturers in India – Spotlight on KWM India

India has emerged as a global leader in the production of non-ferrous metals, especially brass. Among the most widely used brass products in the industrial and manufacturing sectors are brass coils manufacturers. These coils are valued for their strength, ductility, corrosion resistance, and excellent thermal and electrical conductivity. As demand grows across sectors such as electronics, construction, automotive, and plumbing, choosing a reliable and high-quality brass coil manufacturer becomes essential. One company that has consistently delivered on quality and innovation is KWM India.

Brass Coils: A Critical Industrial Material

Brass coils are produced by rolling brass sheets into a coiled form. These coils offer great flexibility in terms of dimensions and can be cut, stamped, or molded according to specific requirements. Depending on the copper-zinc ratio, brass coils can be tailored for various properties like malleability, strength, and resistance to corrosion.

Industries use brass coils in numerous applications such as:

Electrical connectors and terminals

Radiators and heat exchangers

Architectural trims and components

Plumbing fixtures and gas fittings

Decorative hardware and consumer goods

Given their widespread use, quality becomes a top priority for any business looking to source brass coils.

KWM India – A Leader in Brass Coil Manufacturing

KWM India, based in Jamnagar, Gujarat – also known as the “Brass City of India” – is one of the country’s leading manufacturers and exporters of high-quality brass coils. With years of experience and technical expertise, KWM India has built a strong reputation for delivering precision-engineered brass products that meet both Indian and international quality standards.

What makes KWM India stand out in a competitive industry is its commitment to using only the finest raw materials, combined with advanced manufacturing techniques and stringent quality control.

State-of-the-Art Infrastructure

KWM India operates modern production facilities equipped with high-capacity rolling mills, annealing furnaces, and slitting machines. These allow the company to produce brass coils in a variety of widths, thicknesses, and tempers to meet customer-specific requirements.

Whether you need soft, half-hard, or full-hard brass coils, KWM India can customize production to deliver exactly what your application demands. The company also ensures consistency in coil thickness, smooth edges, and superior surface finish — critical factors in industries where precision matters.

Uncompromising Quality Control

One of KWM India’s strongest differentiators is its dedication to quality assurance. Every batch of brass coils mnufacturers undergoes strict quality inspections, including:

Chemical composition testing

Tensile and yield strength analysis

Dimensional accuracy checks

Surface finish inspection

KWM India is also ISO-certified, reinforcing its commitment to global quality standards. Their experienced quality control team ensures that customers receive defect-free products, every time.

Focus on Sustainability and Innovation

Apart from quality, KWM India takes pride in maintaining environmentally friendly and sustainable manufacturing practices. The company implements recycling processes and energy-efficient methods, minimizing its carbon footprint while maintaining production efficiency.

KWM India is also actively investing in research and development to enhance product performance and develop new alloys that meet the evolving needs of the market.

Customer-Focused Approach

KWM India has built long-term partnerships with clients across India, the Middle East, Europe, and Southeast Asia. Their customer-centric model includes:

Competitive pricing

On-time delivery

Customized orders

Transparent communication and support

Their technical team works closely with clients to understand their exact needs and recommend the right brass coil grade and specifications for their applications.

Conclusion

With the rapid expansion of industrial sectors worldwide, the need for high-quality brass coils is on the rise. Among the top brass coil manufacturers in India, KWM India has positioned itself as a reliable, innovative, and quality-driven partner. Their combination of technical expertise, advanced infrastructure, and customer-first philosophy makes them a top choice for businesses seeking premium brass coil solutions.

Whether you are a small-scale manufacturer or a large industrial player, sourcing brass coils from KWM India ensures that you receive not just a product, but a commitment to quality, consistency, and long-term performance.

Visit:- https://www.kmwindia.com/brass-coils.html

0 notes

Text

Premier Custom Industrial Blades Manufacturer | Nanjing Metal

Your Expert Partner: Nanjing Metal - The Leading Custom Industrial Blades Manufacturer

In today's demanding industrial landscape, precision, durability, and efficiency are paramount. The quality of cutting tools, specifically industrial blades and machine knives, directly impacts production output, product quality, and operational costs. Nanjing Metal stands out as a premier Custom Industrial Blades manufacturer, dedicated to providing tailor-made cutting solutions that meet the unique challenges of various industries worldwide. With years of expertise and a commitment to excellence, we engineer blades that don't just cut – they perform reliably, time after time.

Understanding the Need for Custom Industrial Blades

Standard, off-the-shelf blades may suffice for some applications, but many industrial processes require blades with specific dimensions, geometries, edge profiles, material compositions, or coatings. As a specialized Custom Industrial Blades manufacturer, we understand that factors like the material being cut, cutting speed, machine type, and desired finish necessitate bespoke solutions. Whether you need enhanced wear resistance, superior sharpness, specific heat tolerance, or unique mounting configurations, customization is key to optimizing performance and extending blade life.

Diverse Applications Across Industries

Our custom industrial blades are engineered for a vast array of applications, serving sectors such as:

Packaging: Slitting, perforating, and cutting films, foils, paper, and cardboard.

Converting: Precision cutting in paper, film, and foil converting processes.

Food Processing: Slicing, dicing, and cutting various food products with food-grade materials.

Plastics & Rubber: Granulating, pelletizing, trimming, and cutting plastic sheets, films, and rubber components.

Textiles & Leather: Cutting fabrics, nonwovens, composites, and leather with clean, precise edges.

Printing & Binding: Trimmer knives, guillotines blades, and other cutting tools for the graphic arts industry.

Metalworking: Shearing and slitting metal sheets and coils (specific applications).

Material Expertise for Optimal Performance

The foundation of a high-performance blade lies in its material. As an experienced Custom Industrial Blades manufacturer, Nanjing Metal utilizes a wide range of premium materials, carefully selected based on the application's requirements:

Tungsten Carbide: Offers exceptional hardness and wear resistance, ideal for demanding, long-run applications.

High-Speed Steels (HSS): Provide a good balance of toughness, wear resistance, and heat resistance.

Tool Steels (D2, A2, etc.): Known for high hardness, good toughness, and excellent edge retention.

Stainless Steels: Offer corrosion resistance, crucial for food processing and medical applications.

Specialty Alloys: Custom material solutions for unique or extreme cutting environments.

The Nanjing Metal Customization Advantage

Choosing Nanjing Metal as your Custom Industrial Blades manufacturer means partnering with a team dedicated to your success. Our advantages include:

Technical Expertise: We work closely with you, analyzing your needs based on drawings, samples, or application details.

OEM & ODM Capabilities: We manufacture blades to your exact specifications (OEM) or collaborate on designing new solutions (ODM).

Advanced Manufacturing: Utilizing state-of-the-art CNC machining, grinding, and heat treatment processes for ultimate precision.

Rigorous Quality Control: Ensuring every blade meets stringent quality standards before shipment.

Tailored Solutions: Delivering blades optimized for your specific machines and cutting tasks, enhancing efficiency and reducing downtime.

Partner with the Specialist

For reliable, high-performance cutting solutions tailored precisely to your needs, trust Nanjing Metal, your expert Custom Industrial Blades manufacturer. Contact us today to discuss your requirements and discover how our custom blades can elevate your operations.

0 notes

Text

How is an ERW Pipe Made? The Step-by-Step Process of Electric Resistance Welding Pipe Manufacturing

Electric Resistance Welding (ERW) pipes are among the most commonly used types for piping solutions across a wide range of industries due to their durability, cost-effectiveness, and versatility. ERW pipes are commonly found in applications ranging from structural supports to transport pipelines for gas and oil, water supply systems, construction, and infrastructure projects. So, what goes into making these highly reliable pipes? Let's dive into the details of the ERW pipe manufacturing process.

What is an ERW Pipe?

ERW stands for Electric Resistance Welding, a manufacturing process that produces a high-quality pipe by welding metal sheets or strips together using electric current. The process is highly efficient and creates a durable bond, which makes ERW pipes perfect for both structural and fluid-transport applications.

Unlike other types of welding, ERW doesn’t involve any filler materials, so the finished pipes are smoother, lighter, and have a uniform wall thickness. Here's how ERW pipes are made step-by-step.

Step 1: Raw Material Selection and Preparation

The process begins with selecting the right raw material, which is typically a strip or coil of low carbon steel. The quality and type of steel used are critical as they determine the strength, durability, and flexibility of the finished product.

Once the coil or strip is selected, it is carefully inspected for any imperfections or inconsistencies. Quality is a top priority at this stage, as any defects in the material can lead to issues during the welding process or impact the final pipe's structural integrity.

Step 2: Slitting and Uncoiling

The steel coil is then uncoiled and fed into a slitting machine, where it is cut into narrow strips based on the diameter of the pipe to be produced. This slitting process allows the material to be prepared in the exact width needed for the pipe dimensions, ensuring minimal wastage.

Once slitted, the strips are rewound into smaller coils. These coils are now ready for the forming process.

Step 3: Forming the Pipe

In this stage, the prepared steel strip is uncoiled and passed through a series of forming rollers. These rollers gradually shape the flat strip into a round, open-seam tube. The forming rollers apply precise pressure to bend the strip without cracking or damaging the material, ultimately creating a tube with a gap where the two edges of the strip meet.

Step 4: Electric Resistance Welding

The core of the ERW pipe manufacturing process lies in this step. The open seam tube is passed through a series of high-frequency electric resistance welding units. Here, an electric current is applied to the edges of the tube, causing them to heat up and reach the point of fusion.

As the edges are heated, they are pressed together using rollers, which forms a solid-state weld without adding any filler material. The pressure exerted by the rollers removes any molten material, creating a smooth and seamless weld. This electric resistance welding method produces a strong bond along the seam, making ERW pipes highly reliable.

Step 5: Sizing and Shaping

After welding, the pipe is sent through another series of rollers, known as the sizing section, which adjusts the diameter and roundness of the pipe. This step ensures that the pipe achieves its final dimensions and maintains uniformity in thickness and shape.

The sizing process is crucial for applications where consistency in diameter and wall thickness is required, such as in fluid transport systems where precise pressure ratings must be met.

Step 6: Cutting

Once the pipe has been sized and shaped, it moves along the production line to the cutting section. Here, automated cutting machines cut the continuous length of pipe into shorter, specific lengths based on customer or industry requirements.

Some ERW pipes are cut to standard lengths, while others may be customized depending on the intended application.

Step 7: Inspection and Quality Control

Quality assurance is critical in ERW pipe manufacturing, as the pipes are often used in applications where safety is paramount. After cutting, each pipe undergoes rigorous testing and inspection, including:

Ultrasonic Testing to check for any hidden defects.

X-ray Testing to ensure the weld is of high quality.

Hydrostatic Testing to verify the pipe's strength and ability to withstand pressure.

Visual Inspection for any surface defects, dents, or irregularities.

If any pipe fails to meet quality standards, it is either reworked or discarded to ensure only top-quality pipes reach the market.

Step 8: Finishing and Marking

After passing the quality control tests, the ERW pipes undergo finishing treatments, which may include deburring (smoothing sharp edges), coating (for corrosion resistance), or galvanizing if needed.

Finally, the pipes are marked with essential information, such as size, grade, manufacturer details, and any other relevant certifications or standards, ensuring traceability and compliance with industry regulations.

Final Thoughts

The ERW pipe manufacturing process is an efficient and reliable way to produce pipes that can withstand high pressures, resist corrosion, and maintain structural integrity over time. From raw material selection to final inspection, each stage of production ensures that the finished product meets high standards for quality and durability.

Whether used in construction, energy, water supply, or industrial applications, ERW pipes continue to be a popular choice for their strength, cost-effectiveness, and versatility. Understanding the process behind their manufacturing provides insight into why ERW pipes are trusted in such critical applications worldwide.

Click here for more information

0 notes

Text

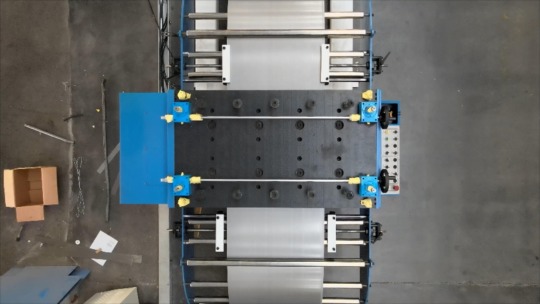

Optimizing Production with High-Precision Slitting Lines

In today's manufacturing landscape, efficiency and precision are paramount to maintaining competitiveness. Among the myriad of techniques employed to enhance production, high-precision slitting lines stand out as a pivotal solution. These systems are designed to cut large rolls of material into narrower strips with unparalleled accuracy. This article explores the significance of high-precision slitting lines, their operational mechanisms, benefits, and their role in optimizing production processes.

Understanding High-Precision Slitting Lines High-precision slitting line are specialized equipment used in the processing of various materials, including metals, plastics, and paper. The primary function of these lines is to convert wide coils of material into narrower strips or slits. This process is vital in various industries, including automotive, aerospace, packaging, and electronics. The machinery involved typically consists of unwinders, slitting blades, tension control systems, and rewinders, all designed to ensure a seamless and efficient slitting process.

The Mechanism of Operation The operation of high-precision slitting lines involves several critical steps. Initially, the material is unwound from a large coil and fed into the slitting machine. The material is then guided through a series of rotating blades, which slice it into the desired widths. Precision is achieved through advanced blade technology and computerized controls that adjust the positioning and speed of the blades according to the material specifications. After slitting, the narrower strips are wound back onto coils for storage or further processing. The entire process is designed to minimize waste and maximize efficiency, ensuring that the materials are cut to exact specifications.

Benefits of High-Precision Slitting Lines One of the most significant advantages of high-precision slitting lines is their ability to produce consistent and uniform strips. This uniformity is essential for industries where precise measurements are critical, such as in the production of automotive components or electronic devices. Additionally, these slitting lines reduce material waste by optimizing the cutting process to ensure that as much of the original coil as possible is utilized. This not only contributes to cost savings but also promotes sustainability by minimizing waste.

Another key benefit is the enhancement of production speed. High-precision slitting lines are engineered for rapid operation without compromising accuracy. This increased throughput allows manufacturers to meet high demand while maintaining quality standards. Furthermore, modern slitting lines are often equipped with automation features, reducing the need for manual intervention and lowering labor costs. Automation also enhances safety by minimizing human error in the slitting process.

Applications Across Industries High-precision slitting lines find applications across a wide array of industries. In the automotive sector, for instance, they are used to produce strips for various components, such as body panels and reinforcement materials. The aerospace industry also benefits from these lines, utilizing them for lightweight yet durable materials that are essential for aircraft performance. In packaging, high-precision slitting lines are crucial for creating customized sizes of packaging materials, ensuring that products are appropriately protected and presented. Furthermore, in electronics, precision slitting is vital for producing components that require exacting standards to function effectively.

Challenges and Considerations While high-precision slitting lines offer numerous advantages, manufacturers must also navigate challenges associated with their operation. One primary concern is the initial investment cost. High-precision equipment can be expensive, and companies must weigh this cost against potential long-term savings and efficiency gains. Additionally, maintaining the precision of slitting lines requires regular maintenance and calibration, which can further complicate operations. Training staff to operate and troubleshoot this sophisticated machinery is also essential to ensure optimal performance.

Future Trends in High-Precision Slitting As technology continues to advance, the future of high-precision slitting lines looks promising. Innovations in automation, such as artificial intelligence and machine learning, are expected to enhance the efficiency and accuracy of slitting processes further. These technologies can facilitate real-time monitoring and adjustments, ensuring that production runs smoothly without interruptions. Additionally, the development of more advanced materials and blades will likely improve cutting precision and durability, further optimizing production capabilities.

Conclusion In conclusion, high-precision slitting lines play a crucial role in optimizing production across various industries. Their ability to produce consistent, uniform strips while minimizing waste and enhancing speed makes them an invaluable asset in modern manufacturing. Despite the challenges associated with their operation, the benefits far outweigh the drawbacks. As technology continues to evolve, high-precision slitting lines will undoubtedly become even more integral to efficient production processes, driving innovation and competitiveness in the global market. Embracing these advanced systems is not merely an option; it is a necessity for manufacturers aiming to thrive in an increasingly demanding landscape.

0 notes

Text

what is slit coin: Jaybee Laminations

In the realm of industrial manufacturing, efficiency and precision are paramount. One of the unsung heroes contributing to this efficiency is the slit coil. Often overlooked but indispensable, slit coils play a crucial role in various industries, ranging from automotive to construction. Let's delve into what slit coils are, how they are made, and their diverse applications across different sectors.

Slit coils are long strips of metal, typically steel, that have been cut into narrower widths. This process is achieved through precision slitting machines, which meticulously slice large coils of material into smaller, more manageable strips. The width of these strips can be tailored to the specific requirements of the intended application, offering flexibility and customization.

The manufacturing process begins with the selection of high-quality raw materials, ensuring the final product meets stringent industry standards. Once the material is sourced, it undergoes a series of precision slitting operations, where it is fed through specialized machines equipped with sharp rotary knives. These knives make precise cuts along the length of the coil, dividing it into narrower strips with consistent widths.

The versatility of slit coils is evident in their widespread applications across various industries. In the automotive sector, slit coils are used in the production of components such as automotive frames, exhaust systems, and structural reinforcements. The construction industry relies on slit coils for manufacturing roofing materials, structural beams, and siding panels. Additionally, slit coils find applications in the manufacturing of appliances, HVAC systems, and agricultural equipment.

One of the key advantages of slit coils is their ability to streamline production processes. By providing material in pre-cut widths, manufacturers can eliminate the need for time-consuming manual cutting operations, thus increasing productivity and reducing waste. Furthermore, slit coils enable tighter control over material usage, optimizing resource utilization and minimizing costs.

Another benefit of slit coils is their contribution to inventory management. By stocking slit coils instead of full-width coils, manufacturers can conserve valuable warehouse space while ensuring quick access to the required materials. This just-in-time inventory strategy enhances operational efficiency and reduces overhead costs associated with inventory storage.

In addition to their practical advantages, slit coils offer aesthetic benefits as well. The precision cutting process results in clean, straight edges, enhancing the visual appeal of finished products. Whether used in architectural applications or consumer goods, slit coil-derived components exhibit a polished appearance that reflects attention to detail and quality craftsmanship.

In conclusion, slit coils represent a cornerstone of modern industrial manufacturing, offering efficiency, versatility, and precision. From automotive to construction, these narrow strips of metal play a vital role in the production of a wide range of products. By harnessing the capabilities of slit coils, manufacturers can optimize their processes, reduce costs, and deliver high-quality products that meet the demands of today's competitive market.

0 notes

Text

Steel Coil Slitting Machine Equipment Suppliers in Hyderabad

Revolutionizing Metal Processing: The Coil Slitting Machine Manufacturing Company in Hyderabad, India

Introduction:

In the ever-evolving world of metal processing, efficiency and precision play pivotal roles in meeting industry demands. Among the key players in this sector is the Coil Slitting Machine Manufacturing Company, a trailblazer in designing and producing cutting-edge machinery that revolutionizes the way metal coils are processed. Based in Hyderabad, India, this company stands out as one of the best industrial coil slitting machine suppliers in the country.

Background:

Founded with a vision to enhance productivity and streamline metal cutting processes, coil slitting machine for sale in hyderabad, India, has emerged as a frontrunner in the manufacturing industry. Specializing in the production of coil slitting machines, the company has consistently delivered innovative solutions to cater to the diverse needs of metal processing facilities worldwide.

State-of-the-Art Technology:

At the heart of the Coil Slitting Machine Manufacturing Company lies a commitment to integrating state-of-the-art technology into its products. These cutting-edge machines, available for sale in Hyderabad, are designed to slit and cut metal coils with unparalleled precision and speed. Equipped with advanced automation features, the company's machines not only increase efficiency but also reduce human error, ensuring a higher quality output.

Precision Engineering:

One of the key factors that sets the Coil Slitting Machine Manufacturing Company apart is its emphasis on precision engineering. Best industrial coil slitting machine suppliers in India, The machines produced by the company are meticulously crafted to meet the exacting standards of the metal processing industry. This precision ensures that the slitting process is carried out with utmost accuracy, resulting in consistent and high-quality end products.

Versatility in Application:

The steel coil slitting machine equipment suppliers in India understands that different industries have unique requirements when it comes to metal processing. Therefore, their machines are designed with versatility in mind. Whether it's steel, aluminum, or other metals, these machines can handle a wide range of materials, making them suitable for various industrial applications.

Efficiency and Cost-effectiveness:

In today's competitive market, efficiency and cost-effectiveness are paramount. The Coil Slitting Machine Manufacturing Company in Hyderabad recognizes this, and its machines are engineered to deliver optimal performance while minimizing operational costs. The automated features not only reduce labor requirements but also enhance the overall speed of the metal processing line, translating into increased productivity for its clients.

Commitment to Customer Satisfaction:

Beyond providing cutting-edge machinery, the Coil Slitting Machine Manufacturing Company prides itself on its commitment to customer satisfaction. The company's dedicated customer support team works closely with clients, including coil cutting machine suppliers in Hyderabad, to understand their specific needs and ensures that the machines are tailored to meet those requirements. This customer-centric approach has resulted in long-lasting relationships and a growing reputation for reliability in the industry.

Environmental Responsibility:

In an era where environmental sustainability is a global concern, the Coil Slitting Machine Manufacturing Company recognizes its responsibility to contribute positively to the environment. The company, as one of the leading coil slitting machinery exporters in India, employs eco-friendly manufacturing practices and is continually exploring ways to reduce its carbon footprint. By promoting energy efficiency in its machines, the company not only benefits its clients but also plays a role in promoting sustainable practices within the metal processing sector.

Conclusion:

As the demand for precision in metal processing continues to rise, the Coil Slitting Machine Manufacturing Company in Hyderabad, India, stands at the forefront, providing innovative solutions that redefine efficiency and quality in the industry. With its commitment to technological advancement, precision engineering, and customer satisfaction, the company is poised to shape the future of metal processing across India and beyond.

0 notes

Text

Innovative Coil Slitting Machine Makers in Hyderabad by Koneet Industries

Introduction:

At Koneet Industries, we are recognized as leading coil slitting machine manufacturers in Hyderabad. With a relentless commitment to excellence and a passion for delivering cutting-edge solutions, we have established ourselves as a trusted name in the industry. Our coil slitting machines are engineered to meet the diverse needs of various businesses, ensuring precision, efficiency, and reliability. As one of the best coil cutting machine suppliers in Hyderabad, we offer top-quality solutions.

Our Expertise:

We specialize in designing, fabricating, and supplying a wide range of coil slitting machines, and our expertise in this field is second to none. With years of experience and a team of highly skilled engineers, we have the knowledge and capability to create custom solutions that cater to your specific requirements.

Innovative Technology:

What sets us apart is our dedication to innovation. We continuously invest in research and development to integrate the latest technological advancements into our machines. This ensures that our coil slitting machines for sale in Hyderabad are at the forefront of the industry, providing our clients with a competitive edge. As a prominent coil slitting machine manufacturing company in Hyderabad, we take pride in offering state-of-the-art solutions.

Precision and Quality:

Precision and quality are the cornerstones of our manufacturing process. Every Koneet Industries coil slitting machine is crafted with meticulous attention to detail, using top-grade materials and quality control measures to guarantee flawless performance and durability.

Tailored Solutions:

We understand that no two businesses are the same, which is why we offer tailored solutions to meet your unique needs. Whether you require a standard model or a customized machine, our team will work closely with you to ensure that the final product aligns perfectly with your requirements.

Client-Centric Approach:

At Koneet Industries, we prioritize our clients. Our commitment to customer satisfaction is unwavering. We provide exceptional pre-sales and after-sales support, including installation, training, and maintenance services. Your success is our success.

Industry Applications:

Our coil slitting machines find applications in a wide range of industries, including metal processing, steel manufacturing, automotive, and more. No matter the sector, our machines are designed to boost efficiency and productivity. As one of the best industrial coil slitting machine suppliers in Hyderabad and steel coil slitting machine equipment suppliers in Hyderabad, we are your trusted partner.

Conclusion:

When it comes to innovative coil slitting machines in Hyderabad, Koneet Industries is your trusted partner. Our dedication to excellence, cutting-edge technology, precision engineering, and customer-centric approach set us apart in the industry. Contact us today to discuss your coil slitting machine requirements and discover how we can help elevate your operations. We also serve as coil slitting machinery exporters in Hyderabad and provide coil slitting machine supplies in India, in addition to being prominent coil slitting machine manufacturers in India.

For more information please visit www.koneetindustries.com

0 notes

Text

A Cut Above the Rest: Stainless Steel Slit Coils Explained

In the world of manufacturing and industry, precision and quality are paramount. One of the unsung heroes of many industrial processes is the stainless steel slit coil. These coils play a crucial role in a wide range of applications, from construction to automotive manufacturing, and their importance cannot be overstated. In this article, we'll dive into the world of stainless steel slit coils, explaining what they are, how they are made, and why they are considered a cut above the rest.

What Are Stainless Steel Slit Coils?

Stainless steel slit coils are long, narrow strips of stainless steel that are precisely cut from larger rolls or coils. The term "slitting" refers to the process of cutting these coils into narrower widths while ensuring uniformity and precision. These slit coils are often used in situations where standard-sized sheets or plates are not suitable or cost-effective.

The Manufacturing Process

1. Selection of Stainless Steel: The process begins with the selection of the appropriate grade of stainless steel based on the desired characteristics, such as corrosion resistance, strength, and ductility.

2. Uncoiling: A large roll or Stainless steel slits coils is uncoiled, and it becomes the primary material for creating slit coils.

3. Slitting: The uncoiled stainless steel is fed through a slitting machine, which precisely cuts it into narrower strips of the desired width. This process demands a high level of accuracy to ensure consistent strip dimensions.

4. Edge Trimming: The edges of the slit coils are often trimmed to remove any irregularities and ensure smooth, straight edges.

5. Coiling: The resulting slit coils are recoiled into smaller rolls, making them easier to handle and transport.

Why Stainless Steel Slit Coils Are a Cut Above the Rest

1. Precision: The slitting process is incredibly precise, allowing for the production of strips with consistent widths. This precision is essential in industries where uniformity is critical.

2. Cost Efficiency: Stainless steel slit coils can be more cost-effective than purchasing full sheets or larger coils, especially when smaller quantities or specific dimensions are required.

3. Versatility: These coils find applications in a wide range of industries, including construction, automotive manufacturing, appliances, and more.

4. Customization: Slit coils can be customized to meet the unique needs of various industries, making them a versatile solution for diverse applications.

Stainless steel slit coils are an essential component in many industries, enabling the efficient production of high-quality products while maintaining cost-effectiveness. Their precision, versatility, and customization options make them a preferred choice for manufacturers who demand excellence in their processes.

Whether you're in the construction business, the automotive industry, or any other field that relies on stainless steel components, it's clear that these slit coils are truly a cut above the rest. Their role in ensuring the quality and reliability of your products cannot be underestimated.

So, the next time you encounter a stainless steel product, remember the precision and versatility of the slit coil – a humble yet crucial part of the manufacturing world.

#Stainless Steel Coil Manufacturers#Stainless Steel Circle Suppliers#Stainless Steel Circle Distributors#Stainless Steel Circle Wholesalers

0 notes

Text

The sheet coil slitting machine is widely applied in steel furniture, electrical cabinets, elevator, etc. industries, which can be combined with laser cutting, cnc panel bender, Robert loading and unloading system, which can realize the 24 hours unmanned processing and the electricity consumption only need 1 degree/hour. This sheet metal coil line machine is the complete solution for coil sheets. Including a de-coiling system, levelling system, thick turret punching and slitting system.If you need the higher productivity, less electric consumption and less cost on materials and labors. REMCOR sheet metal slitting machine is your best choice. Contact us and get steel coil slitting machine price now!

REMCOR coil-sheet fed punching or shearing line is a fully automated punching solution for metallic coils. Which can realize the 24 hours unmanned production. It is capable of handling coils of 300 – 1500 mm in width, up to 9 ton in weight.

Features of Coil-Fed Punching Machine

24 hours unmanned processing, From the de-coiling, feeding, leveling, feeding, thick turret punching, slitting the whole process can be done with our system continuously. Realize the real 24 hours unmanned processing. The traditional processing needs different systems and a numeral labor to handle the machine together with loading and unloading. Different devices have different beats and lead a lot of waste on labors.

Higher productivity, only need to monitor the system, can realize the 24 hours continuous automatic manufacturing. Continous processing from the raw coil material to the final profile, there is no waste of time in loading and blanking compared with traditional forming lines. 2 times faster than traditional technologies.

Higher Flexibility, Multiple combination with standard die bases and diverse die tools, one-to-one correspondence between products and molds. Shorter mold changing time.

More chances for automation, It is available for combining with laser cutting system, panel bender system, and Robert loading and unloading system, which can leave more space for automation. With punching station unworking, and the other station working, it is equivalent to a leveling line, can provide plates for turret punching, single platform laser cutting machines, automatic panel benders, etc.

Parameter Details of Coil-Fed Punching Machine

Feeding system

1000mm/ Precision Ball Screw

Die base

2 sets of standard thick turret plug-in box molds 4 sets of Remcor standard mold bases

Punch frequency

200cp/min

Die changing trolley

2

Number of servo axes

8+1+2

Material width

300-1000mm

Feed roller

2sets

Correction roller

Up 5/Down 4

Output speed

16m/min

Coil weight

7T/8T

Coil inner hole

φ508mm

Coil outer hole

φ1300mm

Rack expansion

Hydraulic

Max thickness

2mm

Forth

300KN

Maximum punching

90*180mm

Number of modules

There are 8 stations in B and 4 stations in D, which can hold 4 large squares or 8 small squares

Punching accuracy

±0.1mm

Diagonal accuracy

±0.5mm

Coil loading - Trolley - Decoiler

The Coil-sheet fed system starts with loading. The process can automatically change from one material to another in under 2 minutes. The hydraulic expansion is applied in decoiling station. After the decoiling station, the strip is straightened and the coiling tensions are removed.

Levelling station

The levelling station principle is using upper and down rolls to staigthen the strip. After this station the tensions for the strip are removed. The rolls and drive motors will be choosen according to the material thickness. The straightener settings can be imported from the controller system, we also add the manual wheel for the special condition

Punching unit

The levelling station principle is using upper and down rolls to staigthen the strip. After this station the tensions for the strip are removed. The rolls and drive motors will be choosen according to the material thickness. The straightener settings can be imported from the controller system, we also add the manual wheel for the special condition

FAQ of Coil-Fed Punching Machine

1. How can I know if your system workable for my factory

Our metallic coil-sheet feed punching line is widely applied in steel furniture industry, the electric cabinets. the elevator shells, the kitchen and bathroom facilities, etc. Pls kindly share with your profile drawings and material type, width, thickness, weight. We will offer you suitable proposals

2. Can I come to your factory to check the real working process?

Yes and before travelling, pls also kindly share with us your profiles drawings, material type and thickness and weight. We welcome the global business partners to visit us.

3. What's your system punching process, and are they same as turret punching?

Our system Punching is done by tools set in two traversing tool cassettes, with the punching stroke done by a single ram plate. The dies quantity for our punching unit is at least 6 stations more than turret punching. And our system support the customerized square dies. The system starts with the raw coil material, which is different as turret which need to be cut-to-length square sheets that have been processed. The completly efficiency for our system is much higher than turret punch.

0 notes

Text

Cut to Length Line

Title: Understanding the Cut to Length Line: Streamlining Material Processing

Introduction:

Introduce the concept of a Cut to Length Line and its significance in the manufacturing and metal processing industries. Highlight the benefits of using Cut to Length Lines for efficient and precise material cutting.

What is a Cut to Length Line?

Define a Cut to Length Line and provide an overview of its components and functionalities. Explain how it differs from other metal processing equipment, such as slitting lines or shearing machines.

Key Components and Functions of a Cut to Length Line:

Decoiler: Describe the purpose and operation of the decoiler, which unwinds and feeds the coil into the line. Straightener: Explain the role of the straightener in removing coil-set and ensuring flat material for accurate cutting. Leveler: Discuss the function of the leveler in flattening and removing any residual stresses in the material. Shear: Highlight the cutting mechanism of the shear and its ability to make precise cuts at programmed lengths. Stacker: Describe the stacking system that neatly collects and organizes the cut-to-length sheets or plates.

Material Types and Applications:

Explore the different types of materials that can be processed using a Cut to Length Line, such as steel, aluminum, and stainless steel. Discuss the wide range of applications for cut-to-length sheets, including automotive, construction, and appliance manufacturing.

Advantages of Cut to Length Lines:

Discuss the benefits of using Cut to Length Lines, such as increased efficiency, reduced waste, and improved accuracy. Highlight how these lines can optimize production by eliminating the need for manual cutting and trimming processes.

Factors to Consider When Choosing a Cut to Length Line:

Discuss key factors to consider when selecting a Cut to Length Line, such as material thickness and width capacity, line speed, and automation features. Mention additional considerations like space requirements, maintenance, and operator training.

Maintenance and Safety:

Provide guidelines for regular maintenance and upkeep of a Cut to Length Line to ensure its smooth operation and longevity. Emphasize the importance of safety protocols and training for operators working with the equipment.

Conclusion:

Summarize the key points discussed throughout the blog post, emphasizing the advantages and applications of Cut to Length Lines. Highlight how these lines streamline material processing and contribute to increased productivity and quality in manufacturing operations.

Remember to include relevant visuals, such as images or videos, to enhance the clarity and engagement of your blog post.

#coil slitting machine#cr slitting line#steel coil slitting line#coil slitting line#manufaturinginindia#steel coil slitting machine

0 notes

Text

Valgo Group is proud to present our state-of-the-art CR Slitting Line Machine. Designed and manufactured with utmost precision, our machine sets the industry standard for quality and efficiency.

With advanced features and cutting-edge technology, it delivers unparalleled performance in slitting and processing CR coils.

Experience seamless operation, exceptional accuracy, and maximum productivity with Valgo Group CR Slitting Line Machine. Trust in our expertise and join the league of satisfied customers who have elevated their metal processing capabilities with our top-of-the-line solution.

Take your business to new heights with Valgo Group CR Slitting Line Machine - where precision meets excellence.

0 notes

Text

Only her - Spencer Reid (smut)

Just a small drabble to get you guys (and myself) through the weekend. Also its @playboysbunny wedding day, so, I dedicate this to you my fellow Spencer lover. Enjoy my loves. xxx

Summary: Some sweet lovemaking in the early morning hours.

Warnings: 18+, smut, unprotected sex, breeding kink, oral (f), fluff

Pairing: Spencer Reid x fem!reader

Heat engulfed her, danced along her naked limbs, stroking the marks her body was covered in. Spencer had his front pressed against her side, curls tickling her throat, clinging to her like a baby needing to feel his mother close. The invisible bond that kept them chained together strengthened with every rising of the sun, keeping them bound to one another.

The day had just begun, the sun was painting the horizon in a deep red, allowing (y/n) to linger for a moment or two. Another case would keep them on their toes, would force them apart as they would protect the ones in need. But in this very moment only their time together counted, they couldn’t afford to worry about the what if’s, not when every day could be their last.

Mornings like these were rare for the couple, though not unwelcomed. (Y/n) loved to feel Spencer near, breathing calmly into the crook of her neck, not plagued by nightmares or reminders of the past days, though content and safe. Both needed to feel one another after tiring cases, needing to know that at the end of the day they would still have their significant other wrapped around their frame.

Carefully she let go of him, stretching her body to shake off her tiredness before she pulled his shirt over her head. Her naked feet tapped against the cold floor, carrying her into their kitchen, towards the coffee machine she called her best friend. Spencer groaned as he followed her, eyes still half closed to hold onto the all too comforting warmth sleep had brought upon him.

“Morning,” he pulled her in for a kiss, tongue running along her lower lip. But (y/n) gently pushed him away, mumbling something along the lines of “morning breath”. He felt needy, wanting to run his fingers up her sides, to explore the soft skin he would shower in kisses at any given chance.

A shriek bled from her lips as Spencer picked her up and placed her on their kitchen island, standing between her thighs, staring down onto her shirt covered chest. The shirt acted like a film of dust covering the spine of an expensive book to keep its secrets hidden from nosy eyes, like a butterfly flapping its wings to rise into the air above.

“I need to feel you, can I?” Spencer’s hands moved up her thighs, creeping closer to her heat, eyes trained onto her exposed cunt, the glistening wetness he wanted to feast from. (Y/n) nodded her head, eyes fluttering close to fully focus on the feeling of his plush lips kissing her skin.

As if he was working a case, he began to eat her out, his hands were experienced enough to pin her down onto the tabletop, shoulders keeping her thighs spread for him to linger down there. He didn’t hesitate once, ran through the routine that would push (y/n) over the edge in no time.

“Fuck, Spence’, feels so good.” Her lips moved, though her brain couldn’t catch up with the words that flooded from them. Pleasure dampened her brain, covering it like a wet towel wanting to cool down burn marks left on her skin. Her orgasm began to crawl closer as if it was rainwater that kept crashing down to the floor, rising from the ground.

His tongue brushed through her slit, scooping up drops of her arousal, while his thumb rubbed her clit. It was easy, oh so easy, to pleasure her, to coax the most sinful sounds out of her mouth. She was perfect for him, not just behind closed doors, but in those intimate moments, Spencer found himself reminded once again, that she was his salvation, his saving grace.

“Look at me when you cum.” The vibrations from his words trembled on her skin, eyes struggling to find his as the coil inside her began to tighten. A cry left her, back struggling not to arch her off the island, but his hands kept her pinned down.

(Y/n)’s orgasm clashed through her, danced through her limbs, shaking every single one of her bones. Her pants filled the kitchen, drowning out the sound of her coffee brewing in the distance, even managing to distract her from the heavenly scent that began to wrap itself around the couple.

“Thank you,” a chuckle left her, hands combing through his locks as Spencer began to stretch back, towering over her. His bulge twitched against his boxers, begging her to touch him, to pump him with her nimble fingers before he would dive into her tightness.

But Spencer was too impatient, couldn’t wait any longer, he had to feel her, had to pound into her as he would do on most nights and mornings.

“I love you,” he pulled her in for a kiss, upper body momentarily leaving the hard surface. (Y/n)’s reply got swallowed by the moan that clawed through her, walls clamping down on his cock.

“Fuck, you’re going to be the death of me.” Spencer kept her pressed to his body, hips jerking against hers, forcing his cock into her tightness with every thrust. Their bodies danced together, swayed back and forth in the most intimate way one could imagine.

“You feel so good, so pretty wrapped around my cock.” His words left her heart pounding, shaking in pleasure, ready to burst into the morning atmosphere. Clouds of fog were covering the city, keeping the lovers hidden in their shadow, allowing them to let their sounds claw through them without any shame.

Spencer was burning her from inside out, a fire she found herself worshipping, a fire she didn’t find herself fleeting from, though chasing it with her mind set on its flames that would consume every part of her body. It was annihilating her, an insanity both found comfort in as time seemed to stand still.

“Wish I could stay buried in your cunt.” Spencer spoke with his eyes closed, desperate to chase the high he needed to make it through another day filled with murder and despair. Only (y/n) could take away his sorrows, only (y/n) could make him feel like he was loved and cherished, only (y/n) could save him.

With his hand fisting her hair he pulled her in for a kiss, forcing his tongue into her mouth, not giving her any chance to move away from him. Her breaths fell short, no longer able to pump any air through her burning lungs, the ache shot shudders right down her clit, making her walls flutter in pleasure. She squeezed his cock with every pump of his, teasing him, wondering how long he could drag out his spiel.

“Spence, I want you to-” his tip hit her sweet spot, cutting her words short for a second. Her moan left her, like a prayer, like a call in the middle of the night, begging whoever was out there to care for her. “I want you to fill me up, please.”

The words left his cock twitching in anticipation. Every now and then they’ve talked about taking the next step, to try for a baby, without any pressure nor expectations chasing them.

But hearing her say those words pushed him into a mindset he had never found himself in before. Pictures of (y/n) with a round belly filled his mind, the skin that would stretch as she would carry his child, thoughts that threatened to hurl him straight off the edge.

“Yeah? Want me to breed you, to fill your tight cunt?” His raspy voice met her skin like a snowflake tumbling to the ground, making earth freeze for a second. (Y/n) moaned his name as her body began to shake, her second orgasm of the morning rocked through her, walls clamping down on his cock like a vice.

Spencer kept on fucking her, slamming into her over and over again till he felt her fall limp in his grasp, only then he allowed his body to let go. His cum filled her, painted her walls white with heavy, hot ropes.

“Fuck, are you okay?” Spencer murmured against her hairline, smiling as she wordlessly nodded her head, legs wrapped around his waist to keep him close. Both would stay like this for a few more moments, basking in one another’s company, hoping that the day would stay calm and quiet, just like their morning.

Follow my sideblog @little-diableswriting for taglist reblogs

422 notes

·

View notes

Text

Steel Coil Slitting Machine Equipment Suppliers in Hyderabad

Revolutionizing Metal Processing: The Coil Slitting Machine Manufacturing Company in Hyderabad, India

Introduction:

In the ever-evolving world of metal processing, efficiency and precision play pivotal roles in meeting industry demands. Among the key players in this sector is the Coil Slitting Machine Manufacturing Company, a trailblazer in designing and producing cutting-edge machinery that revolutionizes the way metal coils are processed. Based in Hyderabad, India, this company stands out as one of the best industrial coil slitting machine suppliers in the country.

Background:

Founded with a vision to enhance productivity and streamline metal cutting processes, coil slitting machine for sale in hyderabad, India, has emerged as a frontrunner in the manufacturing industry. Specializing in the production of coil slitting machines, the company has consistently delivered innovative solutions to cater to the diverse needs of metal processing facilities worldwide.

State-of-the-Art Technology:

At the heart of the Coil Slitting Machine Manufacturing Company lies a commitment to integrating state-of-the-art technology into its products. These cutting-edge machines, available for sale in Hyderabad, are designed to slit and cut metal coils with unparalleled precision and speed. Equipped with advanced automation features, the company's machines not only increase efficiency but also reduce human error, ensuring a higher quality output.

Precision Engineering:

One of the key factors that sets the Coil Slitting Machine Manufacturing Company apart is its emphasis on precision engineering. Best industrial coil slitting machine suppliers in India, The machines produced by the company are meticulously crafted to meet the exacting standards of the metal processing industry. This precision ensures that the slitting process is carried out with utmost accuracy, resulting in consistent and high-quality end products.

Versatility in Application:

The steel coil slitting machine equipment suppliers in India understands that different industries have unique requirements when it comes to metal processing. Therefore, their machines are designed with versatility in mind. Whether it's steel, aluminum, or other metals, these machines can handle a wide range of materials, making them suitable for various industrial applications.

Efficiency and Cost-effectiveness:

In today's competitive market, efficiency and cost-effectiveness are paramount. The Coil Slitting Machine Manufacturing Company in Hyderabad recognizes this, and its machines are engineered to deliver optimal performance while minimizing operational costs. The automated features not only reduce labor requirements but also enhance the overall speed of the metal processing line, translating into increased productivity for its clients.

Commitment to Customer Satisfaction:

Beyond providing cutting-edge machinery, the Coil Slitting Machine Manufacturing Company prides itself on its commitment to customer satisfaction. The company's dedicated customer support team works closely with clients, including coil cutting machine suppliers in Hyderabad, to understand their specific needs and ensures that the machines are tailored to meet those requirements. This customer-centric approach has resulted in long-lasting relationships and a growing reputation for reliability in the industry.

Environmental Responsibility:

In an era where environmental sustainability is a global concern, the Coil Slitting Machine Manufacturing Company recognizes its responsibility to contribute positively to the environment. The company, as one of the leading coil slitting machinery exporters in India, employs eco-friendly manufacturing practices and is continually exploring ways to reduce its carbon footprint. By promoting energy efficiency in its machines, the company not only benefits its clients but also plays a role in promoting sustainable practices within the metal processing sector.

Conclusion:

As the demand for precision in metal processing continues to rise, the Coil Slitting Machine Manufacturing Company in Hyderabad, India, stands at the forefront, providing innovative solutions that redefine efficiency and quality in the industry. With its commitment to technological advancement, precision engineering, and customer satisfaction, the company is poised to shape the future of metal processing across India and beyond.

0 notes

Text

☯🐍LUKADRIEN HEADCANONS🐍☯

It all started when Luka got his first tattoo. Juleka livestreamed it on Instagram and Adrien watched as much as he could of it while in the back of Father’s Mercedes, purposely ignoring Nathalie’s pointed stare. No doubt she would tell Father he was watching videos of his friends “partaking in delinquent behaviour”, but Adrien couldn’t blame her. It was her job, after all.

That aside, Adrien found himself both entranced and horrified as the artist carefully outlined the shape of a serpent in black ink up and down Luka’s right forearm, wiping away the excess ink before starting anew. It must hurt like hell, but Luka talked through it easily, humming a melody he’d been writing with his sister like the needle in his arm was hardly a bother.

Even after he’d been rushed out of the Mercedes and onto the runway, Adrien couldn’t stop thinking about it. How calm and collected Luka had been. How intricate the scales of the onyx snake had been against the paleness of his skin. How the tattoo would look after a few days of healing.

Adrien desperately wanted to find out. And thankfully, a week or so later, he got his chance.

“Dude, you gotta show Adrien. He’s been dying to see it, bro!” Nino calls out from beside him, waving Luka over from where he’d just parked his bike. Marinette had organized a collège graduation picnic and thankfully, the invitation that she’d sent home with Adrien had “mandatory for class attendance” printed on it in big, red letters.

“Yes, please!” Adrien responds, practically skipping in place as Luka saunters over and stretches out his hand. Adrien’s eyes grow wide as he takes in the snake’s coils that twist from his elbow to his wrist. The pattern on the snake’s scales is so familiar that Adrien is sure he’s seen this type of snake before, from the hood of its neck to its elongated fangs.

“Did it hurt?” Alix asks, buzzing with excitement. She’d already proudly announced that she’s booked her first tattoo for her upcoming sixteenth birthday next week.

“A little.” Luka shrugs, smiling downwards as Adrien forgets all of his manners and gently turns Luka’s arm around so he can see the other side. “The elbow was the worst part. Once he got away from the bone, it wasn’t so bad at all.”

“It looks so cool,” Adrien gushes, unable to contain himself. His nose is practically centimetres away from Luka’s skin so as to soak in every little detail. “I wish I could get something like this done.”

Luka continues to indulge him, despite Alix’s teasing glance in their direction. “What’s stopping you?”

Adrien snorts and stares in wonder at the snake’s slitted eyes. “Father. He’d kill me if I ever got a tattoo.”

“I doubt he’d kill his best model,” Luka responds, smiling as Adrien shakes his head and prods the little tongue of the serpent with the tip of his finger.

“Well, maybe not kill me. But he’d lock me away in my room until I was thirty five.”

“Dude, that’s abusive,” Nino says. Beside him, Alix agrees.

“It’s Father’s way of showing me he cares.” Adrien sighs and thanks Luka for letting him see the tattoo. Luka assures him that he can look at it anytime he wants.

And, of course, that’s how the plan begins.

Six months pass and Luka and Adrien are closer than they’ve ever been, thanks in part to Juleka’s burgeoning modelling career. They cross paths frequently, which means he sees Luka almost as much and begins to spend his free time with him whenever he can under the pretense of practicing his angles with Juleka and his piano skills with Luka.

Nathalie has given him exactly four hours of free time at the Couffaine’s on his day off, so long as the Gorilla is present to make sure he doesn’t “partake in any delinquent behaviour”. Adrien is an expert at eluding the massive hulk of a man and within minutes of arriving, Adrien, Luka and Juleka are meeting up with Rose, Nino and Alix for what would be the wildest, best kept secret plan in the world.

Why? Because Adrien was getting a tattoo. A tiny one. Very discreet. But a symbol of defiance and teenage rebellion nonetheless.

The whole ragtag group piles into the same studio that Luka and Alix had gotten their tattoos. White walls reflect the bright pink neon sign that takes up the majority of the side wall, adding an ambiance that simmers with excitement as house music thuds through the speakers. Adrien signs his life away with shaking fingers and gives his friends a thumbs up before sitting down on the leather lounger. Luka follows him into the smaller workspace and distracts Adrien by talking about the merits of the 5/4 time signature as the artist carefully sterilizes his equipment and applies a stencil onto the pale strip of skin just inside the swell of his hip bone. Adrien had picked this part of his body specifically; even in swimming briefs, no one would be able to see it. He would have to be completely bare in order for anyone to accidentally spot the tattoo, which makes it the perfect location for a clandestine symbol of his secret life.

The machine buzzes to life and Adrien prepares himself, gritting his teeth.

“Why did you pick this for your first tattoo?” Luka asks, wincing as Adrien grabs his hand and squeezes the life out of it. Adrien has been tossed around the city like a ragdoll countless times as Chat Noir, but this? This is the worst pain he’s ever experienced by far.

“Ghhh—oh my god.” Adrien heaves and tries to keep still as the artist completes the outline of the circle.

“Just breathe.” Luka begins to massage his arm with his other hand, rubbing smooth circles into Adrien’s tensed muscles. “It’ll be over before you know it.”

Adrien garbles something unintelligible and lets his head fall back against the headrest with a thunk. “How...did...you...?”

“I just did.” Luka shrugs and smiles encouragingly. “You get used to the feeling after a while.”

“I am never getting used to this.” Adrien groans vehemently, pushing the words from his lips in one shaky breath. Luka isn’t wrong though; after a minute or two of trying not to cry like an infant, Adrien’s hip hurts so badly that the pain begins to plateau into a five alarm burning bee sting. “Is it almost over?”

“He’s just finishing the spot,” Luka replies, leaning over to get a better look. Adrien opens his eyes, which is a horrible mistake. Between Luka’s constant presence beside him and his friend’s face mere centimetres from his belly button, Adrien finally thinks of something else that cuts through the haze.

“Y-yeah?” Adrien stammers and hopes Luka thinks it’s still from the pain. In actuality, the last six months of Adrien’s infatuation with Luka’s tattoo and, in turn, Luka himself has all flashed before his eyes in a matter of seconds.

“All finished,” the artist says, taking one last swipe with his towel before putting his tools away. Luka beams and congratulates him on being so brave, but all Adrien can think about is how his friend’s ample praise makes him melt like butter.

“Do you want to see?” Luka takes the mirror and holds it up to the tattoo. Red and raw, the yin and yang symbol shines like a beacon of Adrien’s duality. He’s the hero of destruction to Ladybug’s creation; he’s a flawless model with a secret dark side.

“I love it,” Adrien breathes, the immediate pain already fading. The artist dresses the wound and Adrien listens to the aftercare instructions with half an ear — he’s far too busy committing the experience to memory.

If Luka wants his hand back, he doesn’t ask, even as they exit the room together. Adrien’s too lost in the clouds to even realize, but the rest of his friends aren’t. They’ll tease Luka about it later, but the blue haired boy doesn’t seem to care.

A week later, Adrien proudly shows off his secret tattoo to his secret tattoo posse — he can’t risk anyone else knowing about it in case it gets leaked to the press — and beams when Luka tells him it looks beautiful.

He doesn’t tell Adrien he wasn’t talking about the tattoo.

SEE ALL OF MY LGBTQ+ HEADCANONS HERE!

336 notes

·

View notes

Text

Love Host - Ch. 6

SUMMARY: A prequel to my fic, “Good Boy.” Takes place during the final scene of the game and the journey home afterwards. Miles becomes the host and the Walrider intends to consummate their bond. No beta. Read at your own risk.

RATING: E (for tentacle sex / xenophilia)

PAIRING: Walmiles (WalriderxMiles)

WORD COUNT: 3,616

READ ON AO3: Here

A/N: Miles experiments with the Walrider’s cloaking abilities. 😋 Waylon makes contact and the journalist finally gets the thanks he deserves. It's an emotional exchange to say the least.

Happy Valentine’s Day y’all!! 🖤 💗 🖤

——————————————————————————————————————————————————————————————————–

When insistent claws latch onto his hips, yanking him off-balance, Miles squeaks, an emasculate high-pitched sound that he hates himself for.

His mismatched hands fly around the machine’s neck to steady himself, tumbling into his partner's chest, his leaking dick pressing against a dark, chiseled abdomen. The man holds his position there, too dizzy with arousal to trust moving himself, the sensation growing stronger now that he's lost his bearings.

Miles won't say it out loud, but he likes being manhandled. The coveted shocks of pain remind him that he and the Walrider are both solid and alive (at least in some capacity) and the brunette loosens his grip to stroke along the cords of the machine’s neck, his touches alternating between light and firm.

"I … I want to fuck myself on you," the host confesses into the hinge of the creature's jaw, where the juncture of an ear would be. "With those tentacles of yours," the brunette adds for clarification, a flood of embarrassment serrating his voice, making it tricky to vocalize.

Miles is shaking again, just from sharing this dirty little secret (which wasn't much of a secret to begin with) because in truth, he's been meaning to do this ever since their first night at home in his apartment.

The Walrider's eyes stretch owlishly at first, invigorated by the rush of adrenaline coursing through it's host, the revelation causing the man's heartbeat to quicken, the blood roaring in his veins.

Rapturous claws squeeze harder onto sharp hip bones, slotting their bodies together,it's mystical, silvery gaze pinched into fine-cut slits as a fabricated tongue licks at the human's neck, caressing over a thumping pulse point. The manmade demon matches the frantic vibrato it finds with a deep and bassy growl, a thick reverberation that trickles down into a purr against soft, porcelain skin.

Out of the corner of his eye, Miles can see dark tentacles phase into existence around them, a commune of phantoms ready and eager to carry out his wishes.

Miles hisses through his teeth, bucking his hips as tendrils stroke along his back in gentle, sanguine coils, his stomach muscles pulled taut as he bends into an appreciative arch.

The brunette considers letting his partner take control, to get lost in the thrall, but he can't, not yet. There's something he has to take care of first.

The journalist anchors himself around the Walrider’s neck, bringing two pale fingers to his lips, wetting them with his tongue.

"Watch me get myself ready for you, in the mirror," Miles tells his partner, reaching down to press slick fingers inside himself.

The ambient tentacles withdraw from around their host, lingering just beyond his reach, giving Miles space to stretch out the tight ring of muscle hidden between his legs.

The claws hooked to his sides roam down, grasping around the flesh of his ass cheeks, stretching them further apart, seeking a wider angle of the human's core as the host grinds down against his fingers.

"Mnn, so how's the view," Miles asks in a sordid tease, "Like what you see?"

The Walrider growls in blatant accord, praising it's host with kisses. It's long tongue skirts against the human's lips and Miles groans once the appendage slips inside his mouth to tangle with his own.

When the machine pulls back, it's to dip twin claws into the man's mouth, mimicking it’s host’s actions as it so often does, their presence tenuous and sharp, but that doesn't stop the journalist from lapping at them greedily, satisfied only when they're left sopping with spit.

Those decidedly sharp digits leave him to trail downward and Miles feels a trickle of fear in his gut, knowing their intent, but it's overshadowed by the swell of heady anticipation.

One such dagger-like point slides inside to join his own blunt fingers, raising the number of foreign objects in his ass to three. Their phalanges twist against each other, pushing in at different momentums, a friction of textures that curl against his sweet spot, making Miles moan, long and deep, his head tilted back.

"I– I am going to take mine out …," Miles pants, feeling a little less full as he does, the Walrider following his movements, permitting just the keen edge of a sharpened nail to remain inside.

"No, wait," the brunette says, growing tense, eyes screwed shut. "It's … OK, you can keep yours in. Add the other one … please."

A second claw moves with cautious, calculated increments, minimizing the potential for error should it inadvertently damage it's host by implementing them too quickly.

"That's it," Miles groans appreciatively, panting breaths aimed toward the ceiling when those claws insert themselves up to the knuckle,"do … do that thing you showed me. Make them disappear."

The Walrider obliges, cloaking it's claws in fractals of light, their appearance practically invisible.

"How does that look? Can … can you see," Miles asks, peering over his shoulder to get a glimpse of himself in the mirror.

He's greeted by the sight of his gaping hole, probed and violated by strange translucent shapes, a mirage of movement, mercurial and oily.

With a predominantly red face, Miles swiftly turns back around.

"Haha, y-yeah, you can definitely s-see," he comments dryly, trying to steady the horrible stutter invading his voice.

That had affected him more than it should have and Miles can't get the image out of his mind, not even when he closes his eyes. The Walrider nudges it's dark, vaulted cheeks against its host, coaxing him open with smooth, languid preparations and the human finds he is hastily approaching his limit.

"You can t-take them out-t. I-I … I am ready, " the brunettes says, his intermittent breaths coming in quick, little rasps.

The Walrider ignores him, thrusting its claws inside its pliant host more vigorously than before, loving the way the human shudders with barely restrained pleasure.

"H-hey! Y-you're – you're not listening," Miles whines, his grimace of anger at war with the arousal on his face," If… if you don't stop … I am … I am going to come."

The machine doesn't understand why it's host is so opposed to the idea. How could an orgasm be such a bad thing, especially since the resourceful bioweapon could provide the man with several more in swift, consecutive order? That is, if his stubborn mortal lover would allow it.

Miles continues to whimper, squirming around in protest of the Walrider's defiance, making it more difficult for his partner to maneuver without the risk of hurting him. It was hardly any reason to be irate, but the reporter felt something akin to shame, ineptitude, at having circled the brink without so much as a single hand stroke to his aching dick.

Soon enough, thanks to all the insolent tossing and turning, his delicate insides are injured, catching the wrong side of a sharpened nail against soft tissue. The human jolts, having felt the sting of discomfort like an electric current and the Walrider pulls free of the assailed heat before it can cause any more devastating wounds.

Miles deflates in surrender, head resting on the machine’s shoulder. His hips jerk forward, desperate for contact, needing to be filled again, whining for the return of those diligent claws rather than their absence, the bloody hypocrite.

A tentacle squirms into his mouth and even in his delirious state, Miles knows enough to slick it with saliva. The tendril doesn't linger once the task is done, relocating to where the human wants it the most, claws on either side of his ass keeping him spread. The phallus slides in much easier than it had during their past experiences, thoroughly coated in improvised lube.

Miles cries out, too loud for the thin motel walls, enough for the adjacent rooms to hear him. He slaps a hand over his mouth to keep his moans in check, remembering that there were other people around that might complain about the noise. At least he had enough foresight to leave the, 'do not disturb,' placard on the doorknob and if it really came down to it, the Walrider could turn them both invisible if their love making became raucous enough to warrant a room inspection

"Let me ride you," Miles says, meeting the Walriders' mystical eyes, cupping a stygian check in his palm.

The machine gives a subsequent growl and the man in his lap starts off with a few experimental thrusts, setting the pace as he rocks up and down, his whole body tingling with heat.

The Walrider’s fastidious growl falls an octave lower as it nips at the man's neck, marking the smooth, unblemished skin with a series of love bites. Miles sucks in a breath, groaning as teeth pierce into him, razing his delicate flesh into a gleam of red jewels.

"Oh god, it fucks me up so good when you do that," the host rasps, still reeling from the aftershocks of being suckled and bruised, clutching tightly to the Walrider's sinewy shoulders.

The machine offers a knowing, possessive grumble, hot mechanized steam blowing over the abused spot like simulated breath. Just as well, the machine enjoyed branding it's host, pleased that both sides of the human’s neck now matched, indented with teeth marks, one pink and healing while the other was glistening and raw.

These facets were no less a symbol of their bond and to further signify this, talons rake down the expanse of his back, leaving branching rows of crimson streaks in their wake, an impression of folded wings dragged across his spine.

The Walrider flips the man around, the brunette now facing forward, the two pressed back to chest because it’s the human’s turn to watch them in the mirror, to behold the unseen force parting him down the middle, fucking his ass ragged.

His research papers are falling to the floor, his laptop will soon meet the same fate if he's not careful, but Miles can’t say he cares too much about that, not when more tentacles wrap around him until he’s consumed, smothered, overindulged

The Walrider bites at his ear, a guttural purr making Miles’ head spin, innocuous tentacles claiming every outstanding limb he has to offer, stroking and squeezing him to completion. The man can't speak with a tentacle in his mouth, not coherently anyway, gagged, but no less vocal, his whole body trembling as he spurts his release all over the reflective surface of the mirror and he’s too far gone to think about how obscene that is.

The reporter crumbles against the Walrider's chest, head resting against his partner’s collarbone, entirely spent. His tightly clenched hands finally let go of the death grip he held on the sheets, his unwound body growing incredibly heavy.

The apparition withdraws it’s tentacles, choosing to hold the human with it’s claws alone, nuzzling the nape of an abused neck, buried in the sweaty strands of midnight colored hair.

Miles watches in the mirror as the Walrider lifts the shroud, unmasking itself, happy to see the demon's shadowy form grace his vision once more, the miasma swarming as it curls around him in a comforting embrace, as easy as breathing.

Succumbing to his euphoric haze, Miles stumbles upon the insane notion that the machine might just love him in return.

------------------

That following morning, Waylon contacts Miles through an encrypted email.

Inside the message is a series of numbers divided by periods and semicolons, a blueprint of latitude and longitude as well as a specific time to meet.

The prearranged destination turns out to be a normal enough looking place – a rustic small-town with a few shops parsed with suburban homes, street lamps and trees.

His Audi is parked along the sidewalk, outside of a hardware store, having gotten there early to stake out the surrounding area. There’s not many people about, not even a token jogger out for a run and the few contemporary cars strewn across the block probably belonged to employees of the adjacent businesses.

Miles takes a sip of his coffee, the styrofoam cup a remnant of the motel’s continental breakfast.

OK then. All quiet on the western front.

He doesn't have too much longer to sight-see, the ring of a nearby payphone commanding his attention and the brunette has the distinct impression the call is intended for him.