#steel coil slitting line

Text

Cut to Length Line Machine Manufacturer

About PrecisionCut Industries:

PrecisionCut Industries is a leading manufacturer of high-quality Cut to Length Line Machines, catering to various industries such as automotive, construction, metal processing, and more. With a strong commitment to innovation, reliability, and customer satisfaction, PrecisionCut Industries has established itself as a trusted name in the metal fabrication equipment industry.

Cut to Length Line Machines:

PrecisionCut Industries designs and manufactures a wide range of Cut to Length Line Machines, tailored to meet the specific needs of its diverse clientele. These machines are essential for transforming large metal coils into precise and accurate flat sheets of various lengths. Whether you require precision cuts for small-scale applications or heavy-duty processing for industrial projects, PrecisionCut Industries has the perfect solution to streamline your production process.

Key Features:

1. Precision Cutting: The Cut to Length Line Machines by PrecisionCut Industries are equipped with advanced cutting technology, ensuring precise and uniform cuts throughout the entire length of the metal coil.

2. High-Speed Processing: To maximize efficiency and productivity, these machines are designed to handle high-speed processing, enabling rapid conversion of metal coils into flat sheets.

3. Customizable Solutions: PrecisionCut Industries understands that each client's requirements may vary. Therefore, their Cut to Length Line Machines can be customized to accommodate different coil widths, thicknesses, and processing speeds.

4. Automated Control System: These machines come equipped with a state-of-the-art automated control system, allowing for easy operation and reducing the likelihood of errors during the production process.

5. Durability and Reliability: PrecisionCut Industries uses top-quality materials and components in their manufacturing process, ensuring the durability and longevity of their machines even under heavy-duty usage.

6. Safety Features: Safety is a top priority at PrecisionCut Industries. Their machines are designed with multiple safety features to protect operators and prevent accidents in the production environment.

#cr slitting line#manufaturinginindia#coil slitting machine#coil slitting line#steel coil slitting line#steel coil slitting machine#manufaturing

1 note

·

View note

Text

The Mission

Page One

Clarke stood on the littered sidewalk looking up at the sign. Until now this place had been a rumor, whispered in the dark: The Deacon’s Mission. By the sounds of it you had to take your bread with a little preaching. They could try, Clarke thought. He wasn’t that hungry.

Inside, a couple dozen men had their heads down folding up tables and unstacking towers of chairs into rows. Clarke spotted a large stainless steel pot, its lid ajar, the slit puffing steam. He made straight for it, his mouth hung open expectantly as he grabbed the lid.

Page Two

“They wanted to clear that away,” a hand fell on his shoulder and squeezed. “But He told me you’d come.”

The voice had that benevolence only a servant of God could muster. Clarke turned around; the Deacon’s greying hair and lined face betrayed a searing vitality.

“I’d like something to eat please… sir.” Clarke heard himself, the last and only person he addressed that way being his father.

Page Three

The Deacon released his grip and proceeded to ladle hot soup into a bowl. “The Lord needs us strong,” he proclaimed, passing it to Clarke along with a spoon.

The warm liquid snaked down his throat and coiled within his belly. It felt good. Better than he expected. Clarke went for another spoonful. Maybe he was that hungry after all.

3 notes

·

View notes

Text

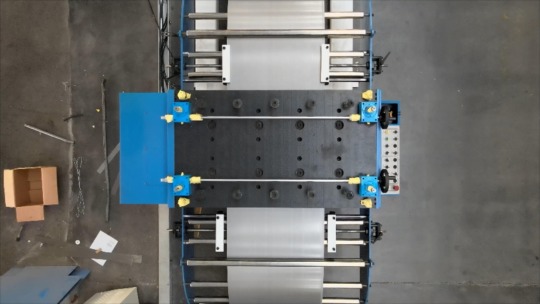

(1.0-6.0)×1650mm Automatic Slitting line

Experience unmatched precision and efficiency with our 1650mm Steel Coil Slitting and Shearing Line! This state of the art automatic slitting machine revolutionizes metal processing, offering seamless operation and superior results. Boost your production capabilities and achieve perfect cuts every time. Invest in quality, invest in Lotosslitting.

+86-13814241007

https://lotosslitting.com/product/automatic-slitting-line/

#SlittingLineMachine#SlittingLineParts#slittinglinesProcess#slittinglinesTechnology#MetalCoilSlittingMachine#SlittingLineSetup#CoilSlittingProcess#Metalworking Machinery#IndustrialSlittingMachine#SteelCoilSlitting#SlittingMachineOperation#MetalCoil Processing#SlittingLineTroubleshooting#slitting#slitting line#slitting machine#lotosslitting#high speed slitting line#precisionengineering#youtube#slittingline#industrialmachinery#manufacturingexcellence

0 notes

Text

Steel Coil Slitting Machine Equipment Suppliers in Hyderabad

Revolutionizing Metal Processing: The Coil Slitting Machine Manufacturing Company in Hyderabad, India

Introduction:

In the ever-evolving world of metal processing, efficiency and precision play pivotal roles in meeting industry demands. Among the key players in this sector is the Coil Slitting Machine Manufacturing Company, a trailblazer in designing and producing cutting-edge machinery that revolutionizes the way metal coils are processed. Based in Hyderabad, India, this company stands out as one of the best industrial coil slitting machine suppliers in the country.

Background:

Founded with a vision to enhance productivity and streamline metal cutting processes, coil slitting machine for sale in hyderabad, India, has emerged as a frontrunner in the manufacturing industry. Specializing in the production of coil slitting machines, the company has consistently delivered innovative solutions to cater to the diverse needs of metal processing facilities worldwide.

State-of-the-Art Technology:

At the heart of the Coil Slitting Machine Manufacturing Company lies a commitment to integrating state-of-the-art technology into its products. These cutting-edge machines, available for sale in Hyderabad, are designed to slit and cut metal coils with unparalleled precision and speed. Equipped with advanced automation features, the company's machines not only increase efficiency but also reduce human error, ensuring a higher quality output.

Precision Engineering:

One of the key factors that sets the Coil Slitting Machine Manufacturing Company apart is its emphasis on precision engineering. Best industrial coil slitting machine suppliers in India, The machines produced by the company are meticulously crafted to meet the exacting standards of the metal processing industry. This precision ensures that the slitting process is carried out with utmost accuracy, resulting in consistent and high-quality end products.

Versatility in Application:

The steel coil slitting machine equipment suppliers in India understands that different industries have unique requirements when it comes to metal processing. Therefore, their machines are designed with versatility in mind. Whether it's steel, aluminum, or other metals, these machines can handle a wide range of materials, making them suitable for various industrial applications.

Efficiency and Cost-effectiveness:

In today's competitive market, efficiency and cost-effectiveness are paramount. The Coil Slitting Machine Manufacturing Company in Hyderabad recognizes this, and its machines are engineered to deliver optimal performance while minimizing operational costs. The automated features not only reduce labor requirements but also enhance the overall speed of the metal processing line, translating into increased productivity for its clients.

Commitment to Customer Satisfaction:

Beyond providing cutting-edge machinery, the Coil Slitting Machine Manufacturing Company prides itself on its commitment to customer satisfaction. The company's dedicated customer support team works closely with clients, including coil cutting machine suppliers in Hyderabad, to understand their specific needs and ensures that the machines are tailored to meet those requirements. This customer-centric approach has resulted in long-lasting relationships and a growing reputation for reliability in the industry.

Environmental Responsibility:

In an era where environmental sustainability is a global concern, the Coil Slitting Machine Manufacturing Company recognizes its responsibility to contribute positively to the environment. The company, as one of the leading coil slitting machinery exporters in India, employs eco-friendly manufacturing practices and is continually exploring ways to reduce its carbon footprint. By promoting energy efficiency in its machines, the company not only benefits its clients but also plays a role in promoting sustainable practices within the metal processing sector.

Conclusion:

As the demand for precision in metal processing continues to rise, the Coil Slitting Machine Manufacturing Company in Hyderabad, India, stands at the forefront, providing innovative solutions that redefine efficiency and quality in the industry. With its commitment to technological advancement, precision engineering, and customer satisfaction, the company is poised to shape the future of metal processing across India and beyond.

0 notes

Text

0 notes

Text

Lowongan Kerja Terbaru di PT Pratama Steel Pekanbaru Agustus 2023

SMITH JANKERMAN Lowongan Kerja Terbaru di PT Pratama Steel Pekanbaru Agustus 2023 – PT Pratama Steel adalah sebuah sebuah usaha sebagai penyedia stainless steel, material plat, dengan produk antara lain; Cutting Line (Shearing), Circle, Coil, Slitting dan lainnya. PT Pratama Steel berlokasi di Jl. Riau Ujung No. 199 A-B Tampan Kota Pekanbaru.Saat ini kami Pratama Steel Pekanbaru sedang membuka http://dlvr.it/Sv75lx

0 notes

Text

0 notes

Text

The sheet coil slitting machine is widely applied in steel furniture, electrical cabinets, elevator, etc. industries, which can be combined with laser cutting, cnc panel bender, Robert loading and unloading system, which can realize the 24 hours unmanned processing and the electricity consumption only need 1 degree/hour. This sheet metal coil line machine is the complete solution for coil sheets. Including a de-coiling system, levelling system, thick turret punching and slitting system.If you need the higher productivity, less electric consumption and less cost on materials and labors. REMCOR sheet metal slitting machine is your best choice. Contact us and get steel coil slitting machine price now!

REMCOR coil-sheet fed punching or shearing line is a fully automated punching solution for metallic coils. Which can realize the 24 hours unmanned production. It is capable of handling coils of 300 – 1500 mm in width, up to 9 ton in weight.

Features of Coil-Fed Punching Machine

24 hours unmanned processing, From the de-coiling, feeding, leveling, feeding, thick turret punching, slitting the whole process can be done with our system continuously. Realize the real 24 hours unmanned processing. The traditional processing needs different systems and a numeral labor to handle the machine together with loading and unloading. Different devices have different beats and lead a lot of waste on labors.

Higher productivity, only need to monitor the system, can realize the 24 hours continuous automatic manufacturing. Continous processing from the raw coil material to the final profile, there is no waste of time in loading and blanking compared with traditional forming lines. 2 times faster than traditional technologies.

Higher Flexibility, Multiple combination with standard die bases and diverse die tools, one-to-one correspondence between products and molds. Shorter mold changing time.

More chances for automation, It is available for combining with laser cutting system, panel bender system, and Robert loading and unloading system, which can leave more space for automation. With punching station unworking, and the other station working, it is equivalent to a leveling line, can provide plates for turret punching, single platform laser cutting machines, automatic panel benders, etc.

Parameter Details of Coil-Fed Punching Machine

Feeding system

1000mm/ Precision Ball Screw

Die base

2 sets of standard thick turret plug-in box molds 4 sets of Remcor standard mold bases

Punch frequency

200cp/min

Die changing trolley

2

Number of servo axes

8+1+2

Material width

300-1000mm

Feed roller

2sets

Correction roller

Up 5/Down 4

Output speed

16m/min

Coil weight

7T/8T

Coil inner hole

φ508mm

Coil outer hole

φ1300mm

Rack expansion

Hydraulic

Max thickness

2mm

Forth

300KN

Maximum punching

90*180mm

Number of modules

There are 8 stations in B and 4 stations in D, which can hold 4 large squares or 8 small squares

Punching accuracy

±0.1mm

Diagonal accuracy

±0.5mm

Coil loading - Trolley - Decoiler

The Coil-sheet fed system starts with loading. The process can automatically change from one material to another in under 2 minutes. The hydraulic expansion is applied in decoiling station. After the decoiling station, the strip is straightened and the coiling tensions are removed.

Levelling station

The levelling station principle is using upper and down rolls to staigthen the strip. After this station the tensions for the strip are removed. The rolls and drive motors will be choosen according to the material thickness. The straightener settings can be imported from the controller system, we also add the manual wheel for the special condition

Punching unit

The levelling station principle is using upper and down rolls to staigthen the strip. After this station the tensions for the strip are removed. The rolls and drive motors will be choosen according to the material thickness. The straightener settings can be imported from the controller system, we also add the manual wheel for the special condition

FAQ of Coil-Fed Punching Machine

1. How can I know if your system workable for my factory

Our metallic coil-sheet feed punching line is widely applied in steel furniture industry, the electric cabinets. the elevator shells, the kitchen and bathroom facilities, etc. Pls kindly share with your profile drawings and material type, width, thickness, weight. We will offer you suitable proposals

2. Can I come to your factory to check the real working process?

Yes and before travelling, pls also kindly share with us your profiles drawings, material type and thickness and weight. We welcome the global business partners to visit us.

3. What's your system punching process, and are they same as turret punching?

Our system Punching is done by tools set in two traversing tool cassettes, with the punching stroke done by a single ram plate. The dies quantity for our punching unit is at least 6 stations more than turret punching. And our system support the customerized square dies. The system starts with the raw coil material, which is different as turret which need to be cut-to-length square sheets that have been processed. The completly efficiency for our system is much higher than turret punch.

0 notes

Text

Coil Slitting Line Machine: Enhancing Precision and Efficiency in Metal Processing

The coil slitting line machine is a cutting-edge solution that revolutionizes the process of slitting coils into narrower strips with precision and efficiency. This advanced machine offers numerous benefits for industries that require precise metal processing, such as steel service centers, automotive manufacturers, and construction companies. Let's explore the features and advantages of the coil slitting line machine.

Precision Slitting:

The coil slitting line machine ensures accurate and consistent slitting of coils into narrower strips. With adjustable cutting parameters and advanced control systems, this machine enables precise control over strip width, thickness, and edge quality. Manufacturers can achieve tight tolerances and uniform strip dimensions, ensuring the highest level of precision in metal processing.

High Efficiency:

The coil slitting line machine significantly improves production efficiency by automating the slitting process. It eliminates manual handling, reduces setup time, and enhances overall productivity. This machine can handle a wide range of coil materials, including stainless steel, aluminum, and galvanized steel, enabling manufacturers to efficiently process different metal coils for various applications.

Versatility and Customization:

Coil slitting line machines offer versatility and customization options to meet specific industry requirements. They can accommodate different coil widths, thicknesses, and weights, providing flexibility for diverse metal processing needs. By adjusting the slitting parameters, manufacturers can tailor the machine to their desired strip specifications, ensuring precise and customized results.

Minimized Material Waste:

Efficient material utilization is essential for cost-effective metal processing. The coil slitting line machine optimizes material usage by minimizing waste. It accurately slits coils, reducing scrap and maximizing material yield. This feature not only enhances profitability but also promotes sustainability by minimizing environmental impact.

Enhanced Safety:

Safety is a paramount concern in metal processing operations. Coil slitting line machines are equipped with safety features to ensure operator well-being. Emergency stop buttons, protective enclosures, and safety interlocks contribute to a safe working environment. Additionally, automated processes minimize direct operator involvement, reducing the risk of injuries.

0 notes

Text

Cut to Length Line Machine Manufacturer

Title: Enhancing Precision and Efficiency: The Role of Cut to Length Line Machine Manufacturers

Introduction: In the dynamic world of manufacturing, precision and efficiency are paramount to meet the demands of modern industries. Cut to length (CTL) line machines play a crucial role in producing accurately sized and shaped metal sheets, catering to diverse applications across sectors. This blog explores the significance of Cut to Length Line Machine Manufacturers, their contributions to the manufacturing industry, and the key features that make these machines indispensable.

Understanding Cut to Length Line Machines:A Cut to Length Line Machine is an advanced industrial equipment designed to process coilsof various metals, including steel, aluminum, and stainless steel. These machines can uncoil the metal coil, level it, and cut it into precise lengths and widths as per the required specifications. They are widely used in industries such as automotive, construction, appliance manufacturing, and metal fabrication.

The Importance of Precision: One of the primary advantages of Cut to Length Line Machines is their ability to achieve exceptional precision. Manufacturers rely on these machines to consistently produce metal sheets with precise dimensions, ensuring compatibility with downstream processes and reducing material wastage. Precision is especially critical when industries demand tight tolerances and strict quality control measures.

Customization for Diverse Applications: A reputable Cut to Length Line Machine Manufacturer understands the diversity of manufacturing needs. As such, they offer a range of customization options to meet specific requirements. From adjustable cutting lengths to variable sheet widths and advanced control systems, these machines can be tailored to match the unique demands of various industries.

High-Speed Production: Time is money in the manufacturing world, and Cut to Length Line Machines are designed with efficiency in mind. These machines can process coils at impressive speeds, significantly increasing productivity and shortening production cycles. The ability to handle high volumes of material swiftly makes these machines invaluable for large-scale manufacturing operations.

Quality Control and Safety: Top Cut to Length Line Machine Manufacturers prioritize quality control and safety. They adhere to international standards to ensure the machines meet the highest quality benchmarks. Additionally, safety features are integrated into the machine's design to protect operators and prevent accidents during operation.

Technological Advancements: Innovations in manufacturing technology are continuously evolving, and reputable manufacturers stay at the forefront of these advancements. Advanced Cut to Length Line Machines are equipped with cutting-edge automation, precision measurement systems, and intuitive user interfaces, making them user-friendly and efficient.

Streamlining Workflow and Cost Savings: By investing in high-quality Cut to Length Line Machines, manufacturers can streamline their production workflow and achieve significant cost savings in the long run. The reduction in material waste, improved efficiency, and consistent output contribute to a more sustainable and profitable manufacturing process.

Conclusion: Cut to Length Line Machine Manufacturers play a vital role in enhancing the precision, efficiency, and overall productivity of modern manufacturing industries. Their dedication to quality, innovation, and customization empowers businesses to meet the ever-changing demands of the market. As manufacturing technologies continue to evolve, these machines will remain a cornerstone of efficient metal sheet processing, shaping industries and driving progress across the globe.

#coil slitting line#cr slitting line#steel coil slitting line#coil slitting machine#steel coil slitting machine#manufaturinginindia#manufaturing

0 notes

Text

Coils Shearing “Sheets” - Mitwalli Steel Products Factory Co.We have latest technology of slitting lines with high efficiency & capabilities which put us in front of our competitors in terms of wide range slitted coils in thicknesses in different widths. Also Recoiling Service is provided, supervised by skillful, trained technicians, the shearing lines are highly automated to manufacture several varieties of sheets that."

#Mitwalli Steel Products#Steel Product Factory#Steel Manufacturing#Steel Manufacturing Industry#Steel Product Company

1 note

·

View note

Text

narrow coil (3.01650)mm slitting line Experience the cutting-edge technology and superior performance of our Narrow Coil (3.01650mm) Slitting Line, designed to meet the highest standards in metal processing. Trust Lotosslitting Company to provide you with the precision and efficiency you need for your industrial machinery and steel processing requirements.

+86-13814241007

#PrecisionEngineering#MetalForming#SlittingLine#Lotosslitting#IndustrialMachinery#SteelProcessing#ManufacturingExcellence#SlittingLineMachine#SlittingLineParts#slittinglinesProcess#slittinglinesTechnology#slitting#slitting machine#slitting line#high speed slitting line#youtube

0 notes

Text

600 Joints 2-7/8 Structural Pipe in Good Condition

youtube

Watch video on YouTube here: https://youtu.be/tlZzddeQ3FU https://inventory.freeoilfieldquote.com/product/600-joints-2-78-structural-pipe-for-sale

Name: 600 Joints 2-7/8 Structural Pipe For Sale

Code: 32588937

Type: Standard

Brand: Unknown

Category: Pipe/Rods/Collars

subcategory: Line Pipe Structural (Steel)

Price: $75.50

Unit: Each (Each)

In Stock: Yes

Location: Midland, Texas

Condition: Good

Available Quantity: 1

• 600 Joints 2-7/8 Structural Pipe For Sale

Line Pipe Structural (Steel) is a hollow section most commonly constructed from hot rolled metal coils. The coils are slit to the proper width for the section being manufactured and then formed into the final shape needed. Once the size is formed and the seams are welded together the tube is cut to the desired length to make a single piece of tubing. Structural piping is offered in round, rectangular and square shapes.

Structural steel tubes are relatively low in cost, has a high strength-to-weight ratio and is easily welded, formed, punched, and drilled. Its hollow shape protects and conceals wires, pipes, moving parts and it can be left exposed. Additionally it can offer a lightweight alternative to solid steel products such as I-Beams and Wide Flange. Infra-Metals offers many different sizes, lengths and specifications for Structural Tubing.

Notes: Sales Price: $75.50 Per Joint

from Oilfield Equipment Manager https://rignetwork.wordpress.com/2022/12/22/600-joints-2-7-8-structural-pipe-in-good-condition/

0 notes

Text

Steel Coil Slitting Machine Equipment Suppliers in Hyderabad

Revolutionizing Metal Processing: The Coil Slitting Machine Manufacturing Company in Hyderabad, India

Introduction:

In the ever-evolving world of metal processing, efficiency and precision play pivotal roles in meeting industry demands. Among the key players in this sector is the Coil Slitting Machine Manufacturing Company, a trailblazer in designing and producing cutting-edge machinery that revolutionizes the way metal coils are processed. Based in Hyderabad, India, this company stands out as one of the best industrial coil slitting machine suppliers in the country.

Background:

Founded with a vision to enhance productivity and streamline metal cutting processes, coil slitting machine for sale in hyderabad, India, has emerged as a frontrunner in the manufacturing industry. Specializing in the production of coil slitting machines, the company has consistently delivered innovative solutions to cater to the diverse needs of metal processing facilities worldwide.

State-of-the-Art Technology:

At the heart of the Coil Slitting Machine Manufacturing Company lies a commitment to integrating state-of-the-art technology into its products. These cutting-edge machines, available for sale in Hyderabad, are designed to slit and cut metal coils with unparalleled precision and speed. Equipped with advanced automation features, the company's machines not only increase efficiency but also reduce human error, ensuring a higher quality output.

Precision Engineering:

One of the key factors that sets the Coil Slitting Machine Manufacturing Company apart is its emphasis on precision engineering. Best industrial coil slitting machine suppliers in India, The machines produced by the company are meticulously crafted to meet the exacting standards of the metal processing industry. This precision ensures that the slitting process is carried out with utmost accuracy, resulting in consistent and high-quality end products.

Versatility in Application:

The steel coil slitting machine equipment suppliers in India understands that different industries have unique requirements when it comes to metal processing. Therefore, their machines are designed with versatility in mind. Whether it's steel, aluminum, or other metals, these machines can handle a wide range of materials, making them suitable for various industrial applications.

Efficiency and Cost-effectiveness:

In today's competitive market, efficiency and cost-effectiveness are paramount. The Coil Slitting Machine Manufacturing Company in Hyderabad recognizes this, and its machines are engineered to deliver optimal performance while minimizing operational costs. The automated features not only reduce labor requirements but also enhance the overall speed of the metal processing line, translating into increased productivity for its clients.

Commitment to Customer Satisfaction:

Beyond providing cutting-edge machinery, the Coil Slitting Machine Manufacturing Company prides itself on its commitment to customer satisfaction. The company's dedicated customer support team works closely with clients, including coil cutting machine suppliers in Hyderabad, to understand their specific needs and ensures that the machines are tailored to meet those requirements. This customer-centric approach has resulted in long-lasting relationships and a growing reputation for reliability in the industry.

Environmental Responsibility:

In an era where environmental sustainability is a global concern, the Coil Slitting Machine Manufacturing Company recognizes its responsibility to contribute positively to the environment. The company, as one of the leading coil slitting machinery exporters in India, employs eco-friendly manufacturing practices and is continually exploring ways to reduce its carbon footprint. By promoting energy efficiency in its machines, the company not only benefits its clients but also plays a role in promoting sustainable practices within the metal processing sector.

Conclusion:

As the demand for precision in metal processing continues to rise, the Coil Slitting Machine Manufacturing Company in Hyderabad, India, stands at the forefront, providing innovative solutions that redefine efficiency and quality in the industry. With its commitment to technological advancement, precision engineering, and customer satisfaction, the company is poised to shape the future of metal processing across India and beyond.

0 notes

Text

0 notes

Text

Lowongan Kerja Terbaru di Pratama Steel Pekanbaru Mei 2023

SMITH JANKERMAN Lowongan Kerja Terbaru di Pratama Steel Pekanbaru Mei 2023 – Pratama Steel adalah sebuah sebuah usaha sebagai penyedia stainless steel, material plat, dengan produk antara lain; Cutting Line (Shearing), Circle, Coil, Slitting dan lainnya. Pratama Steel berlokasi di Jl. Riau Ujung No. 199 A-B Sampung Gudang SMS, Tampan Kota Pekanbaru.Saat ini kami Pratama Steel Pekanbaru sedang http://dlvr.it/Spcph9

0 notes