#Component Decapsulation

Explore tagged Tumblr posts

Text

Unveiling the Inner Workings of Electronics: A Comprehensive Guide to Component Decapsulation

Within the intricate realm of electronics, each element assumes a critical role in determining the system's overall performance and longevity. Gaining profound insights into these components, and comprehending their functionalities and internal arrangements, becomes paramount for the maintenance and advancement of our electronic devices. A fundamental procedure that enables us to delve into the intricacies of electronic components is known as decapsulation.

For more info visit - https://nisene.tumblr.com/post/724076418631434240/the-anatomy-of-electronics-a-guide-to-component

0 notes

Text

Gi, Gn, and Gb interfaces

GPRS (General Packet Radio Service) is a mobile data communication technology that allows users to connect to the internet and other data networks using their mobile phones. To understand how GPRS works, it's important to familiarize oneself with the various interfaces involved. These interfaces act as the communication gateways between different components of the GPRS network. Let's explore three key interfaces: Gi, Gn, and Gb.

Gi Interface The Gi interface serves as the connection point between the GPRS network and external packet-switched data networks such as the internet or ISDN. It's also where the IP address of a device is mapped to an external network address. Key functions at this interface include protocol encapsulation/decapsulation, address translation, and authentication. Since GPRS can support a variety of data networks, the Gi interface is more of a reference point than a standardized interface.

Gn Interface The Gn interface connects different SGSNs within the same PLMN. This interface supports the transmission of user data and signaling information, and is crucial for mobility management. The TCP/IP protocol is used for communication over the Gn interface. For IP-based backbones, the Gn (and Gp) interface employs the GPRS Tunneling Protocol (GTP).

Gb Interface The Gb interface connects the SGSN to the BSS. Through this interface, the SGSN communicates with the BSS and mobile stations to handle packet data transfer, mobility management, and session management. This interface is essential for GPRS network operation. It supports both signaling and traffic information transmission. Frame Relay networks can be used for traffic control between the SGSN and BSS, providing flexibility in network configuration. The Gb interface also supports mobility management functions such as attachment/detachment, security, routing, and activation/deactivation of data connections.

Source: What is Gi, Gn, Gb interface?

0 notes

Text

Mastering PCB Reverse Engineering: A Comprehensive Guide

Circuit boards that have been printed (PCBs) are the foundation of modern electronics. They are everywhere, from your smartphone to your home appliances. PCB reverse engineering is a vital process that allows engineers and hobbyists to understand and replicate these crucial components. In this guide, we'll dive into PCB reverse engineering, exploring its significance, methods, and practical applications.

What is PCB Reverse Engineering?

Reverse engineering a printed circuit board is dissecting it to determine its layout and purpose. The goal is to recreate the board's schematics, layout, and connections. This process of pcb reverse engineering is crucial for repairing, improving, or replicating existing electronic devices. By examining how components are connected, engineers can troubleshoot issues or design compatible replacements.

Why is PCB Reverse Engineering Important?

PCB reverse engineering serves several purposes. It helps in:

Repairs and Maintenance: By understanding the layout and connections, technicians can fix malfunctioning devices.

Legacy Systems: Many older systems have outdated or unavailable documentation. Reverse engineering aids in the upkeep and modernization of these systems.

Security Analysis: It is used to identify vulnerabilities and improve the security of electronic systems.

Innovation: Engineers can learn from existing designs and develop improved versions or entirely new devices.

Methods of PCB Reverse Engineering

There are several methods of pcb reverse engineering. Here are the most common techniques:

1. Visual Inspection

The simplest method involves visually inspecting the PCB. Using a magnifying glass or microscope, you can examine the components and their connections. This method is often the first step in understanding the board's layout.

2. Circuit Tracing

Tracing a circuit entails navigating the PCB's electrical routes. By using tools like continuity testers or multimeters, you can map out the connections between different components. This technique is useful for creating a basic schematic of the circuit.

3. Decapsulation and Microscopy

For detailed analysis, especially in the case of integrated circuits (ICs), decapsulation and microscopy are used. An IC's covering layers must be removed during decapsulation in order to access its interior circuitry. Then, you can use microscopy to look at the circuit's minute features.

4. Software Tools

Reverse engineering can be substantially improved by using contemporary software technologies. Programs like KiCad and Eagle allow you to create digital schematics and layouts from your findings. These tools can also simulate the circuit to ensure accuracy.

Practical Applications of PCB Reverse Engineering

Reverse engineering of PCBs has several applications:

Product Development: Companies use reverse engineering to improve or modify existing products.

Educational Purposes: It helps students and hobbyists understand complex electronic systems.

Competitive Analysis: Businesses analyze competitors' products to understand their design and functionality.

PCB reverse engineering is a powerful technique that opens up numerous possibilities in electronics. Whether you're repairing an old device, analyzing security vulnerabilities, or innovating new technology, understanding how PCBs work is crucial. By mastering pcb reverse engineering, you can unlock the secrets of electronic designs and drive advancements in technology. For anyone involved in electronics, PCB reverse engineering is an invaluable skill. Embrace it to enhance your understanding, solve complex problems, and push the boundaries of what's possible.

0 notes

Link

Global IC Trading Group is one of the best independent and authorized wholesalers of electrical and electronics Components and have invested too heavily in a detailed inspection process with state of the art equipment, including X-Ray, XRF, and Decapsulation.

0 notes

Text

Services offered by GreenTree Electronics

GreenTree Electronics LTD. is a leading independent distributor of electronic components and provides Authentication and Testing of electronic components and value-added services. GreenTree has a Service License Agreement with White Horse Laboratories for testing and authentication electronic components.

Quality Inspection: This service includes - Microscopy Inspection, Electrical Measurement, Marking Permanency, Dimensions Measurement, Compliance to Order and Datasheet, Storing and packaging.

Testing and Authentication: GreenTree Electronics offers a firm-form warranty to customers by testing and authenticating electronic components in a test laboratory.Testing- Documentation and Packaging Inspection (DPI), Microscope External Visual Inspection (EVI), Remarking and Resurfacing Tests (MPT and RTS), X-ray Florescence (XRF) Material Analysis, X-ray Analysis, Solderability Testing, Heated Chemical Testing (HCT), Decapsulation and Die Analysis, Comprehensive and Electrical Testing, Functional Testing.

Obsolete Electronics Components: GreenTree Electronics provide authenticated, reliable, and genuine obsolete electronic components with complete authentication and traceability tests according to customer requirement.

Excess Inventory: GreenTree Electronics offers inventory management programs to fulfill specific requirements. They suggest professional management of obsolete and excess components to improve the supply chain process.

Engineering consult: GreenTree Electronics offers free engineering consult to help customers choose the most suitable programmable device by taking under consideration the Cost, I/O’s, Power consumption, integrated blocks, Footprint, Speed, and operational temperature grade.

0 notes

Text

Description of the 600 bottles per hour for 5 gallon water filling line

Basically, the 5 gallon water filling line, as the name implies produces 5 gallon barreled drinking water. This unique type of water filling line come in various types which include the 80 bottles per hour type, 150 bottles per hour type, 300 bottles per hour type, 450 bottles per hour type, 600 bottles per hour type, and the 900 bottles per hour type.

Here, our focus will be on the 600 bottles per hour type gallon water filling machine.

Let’s get started!

The 600 bottles per hour type integrates the bottle cleaner, filler and sealer in one unit.

Cleaning: To achieve the purpose of multiple injections, washing and sterilization by means of liquid washing and bleaching are applied during the bottle cleaning process. However, wash solution can also be applied.

Filling: The filling phase follows after the bottles are properly cleaned and made ready to receive the content.

Sealing or capping: The sealer can seal the barrel caps is aseptic and healthy, this line can also automatically perform washing, sterilization, filling, capping, counting and unloading of the products. It is a new kind of auto-producing line barreled of water, which incorporates integrates high tech mechanisms and technology.

Characteristics

1) The machine has the advantages of complete function, compact structure, new design and high level of automation

2) The operation of imported computer control system and touch screen is equipped, whose key components are imported from Germany, Taiwan, American assembly. It is a new type electric integrated drinking water machine equipment.

3) According to customer's requirement, we will change the modification design based on the existing machine.

The automatic 5 gallon water filling line is designed and made by our company with advanced technology and improved by ourselves according to market situations. It is one of the most advanced filling equipment in the world. With advanced technology, reliable performances, scientific process flow, good food hygiene conditions, the equipment is an ideal filling machine for manufacturers in various industries, especially drinking water industry.

The main parts of the machine are made of superior stainless steel and others are made of non-toxic materials and articles. The electrical and pneumatic systems consist of high quality components such as which work together to ensure low failure rate and high reliability of the machine.

Now, let’s look at the description of semi-automatic barrel brusher

20 Liter Water Jar Washer For 5 Gallon Water Filling Machine

1. This semi-automatic decapper and washer is the corollary equipment of the 5 gallon barrel drinking water production line. It is used for decapsulation and thoroughly washing the gallon before the filling activity is commenced. This helps to increase efficiency and quite suitable for the relatively smaller capacity types such as the 150 gallon per hour type.

2. The machine is made of high quality stainless steel which makes it corrosion resistant, and relatively easy to clean.

3. The main part of the machine which come in contact with the liquid is made of high quality stainless steel, corrosion resistant, easy to clean.

0 notes

Text

Original Post from Rapid7 Author: Tod Beardsley

Rapid7 researcher Andreas Galauner has discovered two vulnerabilities affecting the TwinCAT PLC environment. The first, CVE-2019-5637 describes a denial-of-service (DoS) condition resulting from a divide-by-zero error CWE-369 when processing a malformed UDP packet, and has a CVSSv3 base score of 7.5. The second, CVE-2019-5636, describes a DoS condition by removing a routing table after processing an empty UDP packet, and has a CVSSv3 base score of 5.3.

Credit

These issues were discovered by Andreas Galauner of Rapid7 and reported in accordance with Rapid7’s vulnerability disclosure policy.

TwinCAT product description

TwinCAT is a PLC runtime developed by the company Beckhoff. It runs on top of Windows and extends the Windows kernel with real-time capabilities, a number of network protocol stacks for industrial fieldbuses, a runtime for programming languages defined in IEC 61131-3, and additional components for motion control.

This runtime is used to perform typical industrial control tasks for use in machines or other industrial processes. Different fieldbuses like EtherCAT, Profinet, CANopen, EtherNet/IP, etc. can be used to attach I/O devices like sensors, actuator or motor controllers, and even other PLCs for periodic data exchange.

Current runtime versions can be installed on Windows 7 or Windows 10 LTSC. These full versions can run on any Windows-compatible machine and turn it into a PLC. However, Beckhoff offers specially designed industrial PCs for use with its software as well. There is a Windows CE-based variant available as a lightweight embedded alternative for use on Beckhoff’s industrial PCs if a full Windows OS isn’t required.

The following bugs were verified on the following versions of the TwinCAT runtime, which were the latest available from Beckhoff:

Version 3.1.4022.30 running two Beckhoff CX2030 and CX5140 industrial PCs using their OEM Windows 10 LTSC 1607 image

Version 3.1.4022.29 running on a Beckhoff CX5140 industrial PC on Windows CE

R7-2019-32.1: Profinet DCP DoS (CVE-2019-5637)

Exploitation of TwinCAT CVE-2019-5637

When the TwinCAT environment is configured to be a Profinet controller or device, the Profinet protocol stack is running on the PLC and needs to reply to “Discovery and Configuration Protocol” (DCP) requests, a part of the Profinet protocol suite. It is, as the name suggests, used for initial device discovery and configuration of certain parameters like the station name, network address, and netmask. It is usually done during initial setup of the devices but isn’t disabled after that.

Device discovery is performed by sending an “Ident Request” UDP broadcast Ethernet frame to the special MAC Address 01:0e:cf:00:00:00. Along with a transaction ID to associate possible replies from other stations with the request, the service ID and type of the action to be performed, and some additional payload for the requested action, it also contains a field called “ResponseDelay.” This field is used to control a delay of the responses sent by the stations answering to the identification request packet. Without this delay and hundreds of devices on a network, the resulting load caused by all stations sending replies out could cause network congestion and lead to dropped responses, or even negatively impact the exchange of important process data.

Impact of TwinCAT CVE-2019-5637

When setting this “ResponseDelay” field to 0, a divide by zero exception is raised on all Beckhoff PLCs that have a Profinet controller or device configured and bound to the network card that received the malicious identification request. The result is an error message on the Desktop informing you about the exception and a crash of the complete PLC runtime, including a stop of all PLC programs and fieldbus activity, which results in a complete halt of the controlled process. After a short while, the TwinCAT runtime gets restarted but remains in CONFIG mode. A manual mode change back from CONFIG into RUN mode is possible after the runtime automatically recovered back into CONFIG mode—or, alternatively, users can configure devices ahead of time to boot directly into RUN mode after a restart.

When trying to find out what exactly that field does, we came across this bug report from the company Hilscher, which specializes in fieldbus communication controllers and the accompanying software stacks implementing all kinds of industrial protocols.

The delay after which the identification response is sent out depends on the two lowermost bytes of the MAC address of the device modulo the delay factor from the packet multiplied by some constant. The modulo operation would explain the division by zero exception in case of a value of 0 for this field in the packet. However, this was not confirmed by disassembling the relevant code from Beckhoff.

R7-2019-32.2: ADS discovery DoS (CVE-2019-5636)

Exploitation of TwinCAT CVE-2019-5636

TwinCAT relies heavily on a protocol called ADS, which is developed by Beckhoff. ADS is used for internal communication between different components in the same runtime, but it can also be tunneled over different other protocols and media like RS232/485 serial ports, EtherCAT, or plain TCP/IP.

ADS itself uses AMS Net IDs and ports that are similar to TCP/IP ports and addresses and packets can be sent from one component to another one. Beckhoff uses a Visual Studio plugin as its development environment. This environment also uses ADS to communicate with all the different subsystems on the runtime to configure them and upload code.

All ADS traffic crossing the boundary of the services running on the PLC itself is usually encapsulated in TCP/IP packets and sent to other machines. The runtime contains a component called the ADS router, described in the vendor’s documentation. It listens on a TCP port and accepts AMS packets.

After parsing the packets, the PLC consults a local routing table to determine whether that host is supposed to be able to talk to local PLC components using ADS. If a route to the host that received the AMS/TCP packet from exists, the packet is decapsulated and forwarded to the addressed component on the local PLC. All traffic coming into the router from local ADS components is encapsulated in TCP again and sent out to the IP address associated with the destination AMS Net ID through its routing table.

To initially find devices, a proprietary companion protocol of ADS from Beckhoff can be used. It uses UDP broadcast packets for device discovery and modifications of the aforementioned routing tables. The handler thread executes recvfrom to receive a UDP packet in its runloop, after which it is parsed and an appropriate response is sent back. The receive loop, however, just exits when recvfrom returns 0. For TCP sockets, a recv call can return -1, 0, or n, whereas -1 is returned during an error condition (or when the socket is non-blocking and no data has been received in the meantime), 0 is returned when the opposing side closed the TCP connection, and n is returned when data has been received and n denoting how much. When a TCP connection is handled, the handler thread can usually safely perform local cleanup and exit once the remote connection is closed. UDP, on the other hand, has no concept of a connection. In the case of recvfrom, a return value of 0 means that a UDP packet was received but it was completely empty, which is a valid case for a UDP socket.

Impact of TwinCAT CVE-2019-5636

When sending an empty packet to UDP port 48899 of a PLC, the handler thread responsible for the ADS UDP protocol requests for device discovery or routing table modification exits. After this thread exited, the PLC is not discoverable on the network. All connections using existing routing table information on the PLC can still be used for communication and hence, process data can still be exchanged between PLCs and the development environment.

It is possible to restart the handler thread by switching the runtime into CONFIG or RUN mode, no matter what state the runtime is currently in. A switch from RUN to RUN or CONFIG to CONFIG has the same effect, but the running code is restarted even when switching from RUN mode to RUN mode.

Note, zero-byte UDP packets are sent by nmap and possibly other network scanners to determine whether a UDP port on a host might be open. Therefore, these devices can be temporarily DoS’ed by normal defensive network scanning/vulnerability management activity.

Remediating the TwinCAT vulnerabilities

Both vulnerabilities have been addressed by Beckhoff after being reported by Rapid7. CVE-2019-5636 is addressed by Advisory 2019-004, and CVE-2019-5637 is addressed by Advisory 2019-007.

In the absence of applying updates or implementing mitigations provided by the vendor, users are advised to not allow untrusted UDP packets to reach their TwinCat PLC environment. It is good security hygiene to not expose these devices to the general internet, and instead, keep them on a logically segmented network where only trusted devices and users can communicate with them.

Disclosure timeline

Wednesday, July 24, 2019: Initial disclosure to the vendor

Friday, July 26, 2019: Acknowledgement from the vendor, CVE IDs reserved

Wednesday, Aug. 7, 2019: Advisory 2019-04 for CVE-2019-5636 published

Thursday, Aug. 15, 2019: Vendor update regarding CVE-2019-5637

Monday, Oct. 7, 2019: Advisory 2019-007 for CVE-2019-5637 published

Tuesday, Oct. 8, 2019: R7-2019-32 vulnerability disclosure published (planned)

#gallery-0-5 { margin: auto; } #gallery-0-5 .gallery-item { float: left; margin-top: 10px; text-align: center; width: 33%; } #gallery-0-5 img { border: 2px solid #cfcfcf; } #gallery-0-5 .gallery-caption { margin-left: 0; } /* see gallery_shortcode() in wp-includes/media.php */

Go to Source Author: Tod Beardsley R7-2019-32: Denial-of-Service Vulnerabilities in Beckhoff TwinCAT PLC Environment (FIXED) Original Post from Rapid7 Author: Tod Beardsley Rapid7 researcher Andreas Galauner has discovered two vulnerabilities affecting the…

0 notes

Text

Internet Technologies PG

Task

Provide short answers to the following six questions. Your answers should be clear, concise and to the point. Prepare a single document (MS Word or PDF, NOT both) along with title page and submit it online using EASTS.

Question 1: Discuss the advantages and disadvantages of star, bus, and mesh physical topologies. Provide real examples of each type. (5 marks)

Question 2: Explain encapsulation and decapsulation in a five layer TCP/IP protocol suite. How does multiplexing and de-multiplexing differ from encapsulation and decapsulation? (5 Marks)

Question 3: Calculate the approximate bit rate and signal level(s) for a 6.8 MHz bandwidth system with a signal to noise ratio of 132(5 Marks)

Question 4: Explain why the OSI model is better than the TCP/IP model. Why hasn't it taken over from the TCP/IP model? Discuss the advantages and disadvantages of both models. (5 Marks)

Question 5: What is the total delay (latency) for a frame of size 5 million bits that is being sent on a link with 10 routers each having a queuing time of 3.5 µs and a processing time of 1.8 µs. The length of the link is 1900 km, the speed of light inside the link is 2.2 x 108 m/s, the link has a bandwidth of 8 Mbps. Which component(s) of the total delay is/are dominant? Which one(s) is/are negligible? (5 Marks)

Question 6: According to RFC1939, a POP3 session is one of the following states: closed, authorization, transaction or update. Draw a diagram and explain to show these four states and how POP3 moves between them. (5 Marks)

Rationale

This assessment consists of six questions assessing a basic understanding of network & data communication models, next generation IP and application layer paradigm. This assessment covers the following learning objectives: define and explain various Internet technologies; describe and analyse the role and importance of Internet technologies in the modern world; and explain how different application layer services such as client-server and peer-to-peer paradigms work in the Internet.

Marking criteria

The following guide will be used while assessing each component of this assessment item. NB All your work must be cited (CSU APA), otherwise up to 100% of marks can be deducted.

Presentation

Your assessment should be submitted in either MS Word or PDF format (PDF usually preserves the formatting, MS Word may not). Please do not submit your assignment in any other format and also do not submit multiple copies of the assessment. Please use A4 page size with Times New Roman / Ariel / Calibri font and use font size 11 or 12. The following should be included as minimum requirements for the assessment.

Order Now

#assignment help#assignment help online#assignment help sydney#assignment help australia#assignment help melbourne

0 notes

Text

The Anatomy of Electronics: A Guide to Component Decapsulation

In the intricate world of electronics, every piece plays a pivotal role in the overall performance and durability of the system. Understanding these components, their workings, and their structure is vital to maintaining and improving our electronic devices. One fundamental process that allows us to study the intricacies of electronic components is decapsulation.

Understanding Decapsulation of Electronic Components

Decapsulation, in the context of electronic components, is the process of exposing the inner structures of an encapsulated component. Encapsulation is often used in electronic components to protect delicate parts from environmental hazards. When we want to inspect these parts for quality control, reverse engineering, or failure analysis, we perform decapsulation.

The Need for Decapsulation

Why do we need to see what's inside our electronic components? The answer is simple yet multifaceted. Decapsulation allows us to understand how a component is structured, which can be crucial for troubleshooting and repairing. It's also integral to the quality assurance process, as it lets us examine whether the component has been correctly manufactured.

Decapsulation is also used during the failure analysis process, where faulty components are dissected to understand what went wrong. This knowledge can then be used to improve future manufacturing processes or to address issues in other similar components.

The Process of Decapsulation

Decapsulation is a careful process that requires precision and patience. It involves the use of different techniques, ranging from mechanical to chemical methods, depending on the type of encapsulant material used and the component itself.

Mechanical decapsulation involves physically removing the encapsulation using tools or machines. This method is often used for larger components or when the encapsulant material is hard.

On the other hand, chemical decapsulation uses acids or other solvents to dissolve the encapsulant material. This method is commonly used for smaller, more delicate components, or when the encapsulant material is resistant to mechanical methods.

Decapsulation: The Gateway to Understanding Electronics

Decapsulation of electronic components is like a gateway to the world of electronics. It lets us see the anatomy of the components that make up our devices, helping us understand how they work, how they can be improved, and how they can be fixed when things go wrong.

As we continue to push the boundaries of technology, our need for understanding our devices will only grow. By understanding decapsulation and its role in electronics, we can ensure that we are not just passive users of technology but informed participants in this exciting field.

In conclusion, the anatomy of electronics is a fascinating subject, and decapsulation is a key tool in exploring this realm. It is through this meticulous process that we can continue to ensure the quality, efficiency, and longevity of our electronic components, leading to more reliable and robust electronic devices.

#Decapsulation of electronic components#Best Decapsulation of electronic components#Top Decapsulation of electronic components

0 notes

Text

A Complete Guide to Understanding the IC Cracking Process

In the world of electronics and technology, the term crack IC refers to a specialized process that involves accessing and deciphering the encrypted data within integrated circuits (ICs). This is a critical skill for various applications, from repairing old equipment to advanced research and development. In this blog, we will explore what it means to crack IC, why it is necessary, and the methods used to achieve it.

What Does It Mean to Crack an IC?

To crack IC means to gain access to the data stored in an IC that is protected by encryption or other security measures. Integrated circuits are found in nearly every electronic device, from household appliances to complex industrial machinery. They often contain valuable programming and data that might be inaccessible due to encryption or obfuscation.

Cracking ICs can involve either retrieving lost data, understanding how a particular chip functions, or even reverse engineering to improve or replicate technology. The need to crack IC arises in several scenarios, including when dealing with discontinued products, recovering data from failed chips, or analyzing competitive technology.

Why Is Cracking IC Necessary?

Here are some common reasons why you might need to crack IC:

Repairing Discontinued Products: Older devices with ICs that are no longer produced can be repaired by accessing the data within the chips. Cracking ICs can provide the necessary information to fix or replace components.

Data Recovery: In cases where important data is lost or corrupted, cracking IC can help recover the information stored within the chip.

Reverse Engineering: For engineers and researchers, cracking IC allows for detailed analysis of how a chip works. This can lead to improved designs or new innovations.

Understanding Competitor Technology: If you are working in a competitive field, crack IC can help you understand and potentially improve upon the technology used by others.

Methods to Crack ICs

Hardware-Based Cracking: This method involves physically accessing the IC to retrieve data. Techniques such as decapsulation, where the chip is carefully opened, and the use of focused ion beams (FIB) to analyze the internal circuits are common.

Software-Based Cracking: Known as non-intrusive attacks, this approach uses software tools to bypass encryption without physically damaging the chip. Techniques include voltage and current attacks, as well as using specialized software to extract data. This method is less invasive and preserves the integrity of the IC but can be more complex and less reliable depending on the chip’s encryption.

Choosing the Right Service for Cracking ICs

When searching for IC-cracking services, take into account the following aspects:

Experience: Choose a provider with a proven track record in cracking ICs. Experience in handling various chip models and encryption methods is crucial for success.

Technology: Ensure the service uses advanced tools and techniques for both hardware and software-based cracking. This ensures accuracy and effectiveness.

Reputation: To ascertain the reliability and quality of the service that the business provides, look for previous evaluations and comments from clients.

Legal Compliance: Confirm that the crack IC services comply with legal regulations to avoid any potential issues.

Understanding how to crack ICs is essential for many professionals working with technology. Whether you need to repair outdated equipment, recover lost data, or conduct research, knowing how to access and interpret the data within an IC can be highly beneficial. By choosing the right techniques and working with experienced professionals, you can successfully navigate the complexities of cracking ICs and achieve your technical goals.

0 notes

Text

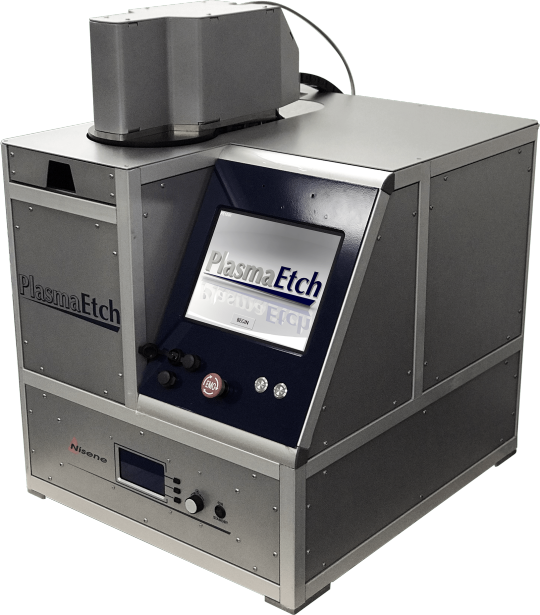

Revolutionizing Integrated Circuit Analysis: Copper Safe Acid Decapsulation and Decap System for IC

Traditional decapsulation methods often risk damaging these delicate components, but copper safe acid decapsulation employs a controlled chemical process that minimizes this risk.

0 notes

Text

Unveiling the Inner Workings: A Comprehensive Guide to IC Chemical Decapsulation

While this encapsulation is crucial for the IC's longevity and durability, it presents a challenge when access to the internal components is needed for analysis or reverse engineering. This is where IC chemical decapsulation comes into play.

0 notes

Text

Safeguarding Integrity: Copper-Safe Acid Decapsulation for Enhanced Semiconductor Analysis

Explore the innovative copper safe acid decapsulation method, ensuring the integrity of semiconductor components during analysis for unparalleled accuracy.

0 notes

Text

Revolutionizing Analysis: The Semiconductor Decapsulator Unveiled

Dive into the cutting-edge realm of semiconductor analysis with the revolutionary semiconductor decapsulator. Uncover the inner workings of chips, enabling precise examination and fostering innovation in electronic component research and development. Explore the transformative impact of this advanced decapsulation technology.

0 notes

Text

Dive into the world of electronic component testing on the acid decapsulation system. Uncover the hidden potential of acids in the decapsulation process and how it's revolutionizing electronic component analysis. Explore the cutting-edge techniques and insights at Nisene for a deeper understanding of this powerful method.

0 notes

Text

Get The Best Decapsulation of Electronic Components at Low Cost

For more info visit - https://www.nisene.com/about/

0 notes