#Compressor Valve

Explore tagged Tumblr posts

Text

Welcome to the heart of innovation and precision – the Globeox universe! In this blog, we embark on a fascinating journey through the intricate world of industrial engineering, focusing on a spectrum of exceptional products that define excellence and reliability. Join us as we explore the global perspective offered by Globeox in the realm of air compression and beyond.

#GlobeoxDiscoveries#Air Expansion Valve#Bull Nose#Bull Nut#Brasss Manifold Valve#Ball Valve#Ball NRV#Battery Air Heater Coil#Compressor#Compressor Valve#Cross Head & Bearing#Compressor Spares#Cylinder Head#Cardon Filter#Cylinder Valve#Cylinder Co2#Drain Valve#Push Pump2#Poppet Vallve#Isolation Valve#Piston Rod#Flexible Hose#cylinder Key#GLobe Valve#Inlet & Outlet Cam Set#Manifold Valve Spares#Piston Ring#Temperature Guage#Pressure Guage

1 note

·

View note

Text

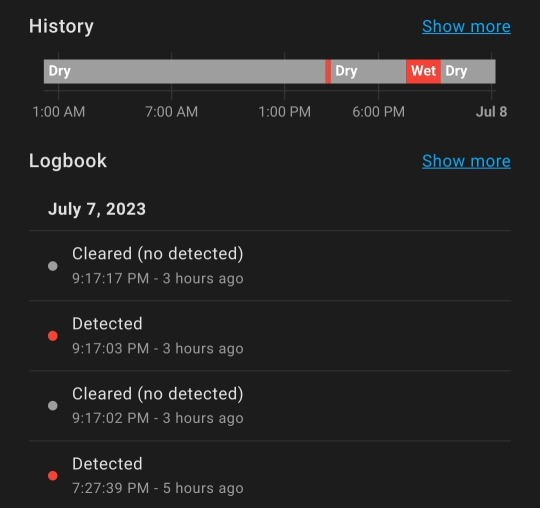

Installed a sensor on my girl so i know when

#Funy jokey#I've become addicted to cheap zigbee switches and sensors#I set this up so the air conditioner in our bedroom will stop running when the bucket is almost full theres something wrong with me#It works too and i love it :')#Next up is a small switched pump that will pump the water out for a set amount of time#Directly to the balcony plants#Our windowsill is too high up to run the condensed water out with gravity sadly so some kind of reservoir with sensor and pump has to do#Also planning a dedicated channel for outside air directly to the compressor with some kind of blowback valve#I hate mobile acs for how they are designed but there are no good high capacity mobile acs on the market yet#This should mitigate most of the issues though#The main issue is the lack of separation of compression and expansion stages which is why you should use outside air for the former#AND i have an hourly energy price contract which means i should switch the ac on/of on a set of preset conditions#I love tinkering and this is both pretty cheap and actually rewarding us with much better sleep during heat waves & less fuss#Also electricity savings#I put a bunch of stuff on this kind of sensing/logic already and its so nice to see your expenses go down with little to no impact#I feel like such a dad even though i dont have any kids#All of this is completely local and relatively cheap to set up but you have to like tinkering a little#Hmu if you want some advice i can point you away from large cloud based nonsense & help with initial startup#The two investments are a raspberry pi and a zigbee dongle#Possibly also a p1 reader or similar if you want data directly from your utilities#And after that most investments should be 10 dollars max per sensor or switch and most of the ali ones will work#And even have fancy features like somewhat accurately displaying power usage and current#Sorry for extremely rambly long tags i just get excited sometimes

2 notes

·

View notes

Text

Pressure washers are essential tools for both homeowners and professionals, but like any mechanical device, they require periodic maintenance. One key component that often gets overlooked is the Unloader valve Kit.

0 notes

Text

CNC Machined Ductile Iron Parts

#Casting exports#casting exporters#Gear box castings#gearbox casings#gear box castings manufacturer in india#gear box castings manufacturer#Compressor castings#compressor castings manufacturers#compressor castings manufacturers in india#Cast iron foundry in india#Ductile iron foundry#ductile iron foundry in india#Alloy cast iron#Casting sourcing#Cast iron pulleys#Valve bodies.

0 notes

Text

Fast & Fluid: Automatic Paint Dispensers & Mixers for Sale

Leading manufacturer of automatic paint dispensers and mixing machines. Find high-performance, reliable solutions for accurate paint mixing.

#idex india#pump and valves#diaphragm pump#pump manufacturer#valves manufacturer#industrial compressor

0 notes

Text

Refrigeration Expansion Valve Sizing and Selection Process

Proper expansion valve selection is critical for refrigeration system efficiency and reliability. This guide outlines the systematic approach to sizing and selecting expansion valves based on system requirements and operating conditions. Expansion valves regulate the flow of refrigerant into the evaporator, making their correct selection essential for system performance, energy efficiency, and…

#compressor protection#electronic expansion valve#energy efficiency optimization#evaporator capacity#evaporator pressure drop#expansion valve capacity correction#internal vs external equalization#liquid temperature effects#MOP protection#pressure drop calculation#refrigerant flow control#refrigerant subcooling#refrigeration expansion valve sizing#refrigeration system design#refrigeration system efficiency#superheat adjustment#thermostatic charge types#TXV selection#valve capacity tables#valve orifice sizing

0 notes

Text

What is the essential role of feed, hydraulic, and air compressor check valves in fluid systems?

Check valves are essential components in fluid control systems, ensuring the proper direction of fluid flow and preventing backflow that could damage equipment or cause system failure. Whether you’re managing hydraulic systems, air compressors, or feed lines, the right type of check valve plays a critical role in the efficiency and longevity of your equipment. In this blog, we’ll take a closer look at three commonly used check valves: the feed check valve , hydraulic check valve , and air compressor check valve. Understanding the specific function of each valve can help you make better choices for system optimization and maintenance.

0 notes

Text

0 notes

Text

15 Diverse Applications of Air Compressor Valves

Air compressor valves play a crucial role in various industries, powering essential systems and ensuring smooth operations. From the automotive industry to healthcare, construction, and renewable energy, these valves have diverse applications that contribute to the efficiency and safety of different sectors.

0 notes

Text

What is Vapor Compression Cycle and How It Works?

On a scorching summer day, there’s nothing quite like the sweet relief of a cool blast of air conditioning. But have you ever wondered how that magic happens? Ever wondered how your fridge magically pulls coolness out of thin air? It’s not sorcery, folks, but a clever dance of physics called the vapor compression cycle. Today, we’re diving into the world of vapor compression cycles, the hidden…

View On WordPress

0 notes

Text

Asha Enterprises | Ammonia valves, Ammonia refrigeration compressors, Ammonia solenoid valves, Ammonia weldable valves Pune, India

Asha Enterprises is best Ammonia valves, Ammonia refrigeration compressors, Ammonia solenoid valves, Ammonia weldable valves, Ammonia level control with indicator, Ice plant equipment, Ice cans, Refrigeration compressor spare parts, Ammonia compressor spare parts, Ammonia IBT Coil, Ammonia condensers, Ammonia receiver storage tanks supplier, Manufacturer Company in Pune, Mumbai, Thane, Navi Mumbai, Kolhapur, Ratnagiri, Raigad, Nashik, Solapur, Latur, Aurangabad, Sindhudurg, Sangli, Solapur, Ahmednagar, Satara and Maharashtra.

#Asha Enterprises#Asha Enterprises in Pune#Asha Enterprises in India#Ammonia valves#Ammonia refrigeration compressors#Ammonia solenoid valves#Ammonia weldable valves#Ammonia level control with indicator#Ice plant equipment#Ice cans#Refrigeration compressor spare parts#Ammonia compressor spare parts#Ammonia IBT Coil#Ammonia condensers#Ammonia receiver storage tanks#Pune#Mumbai#Thane#Navi Mumbai#Kolhapur#Ratnagiri#Raigad#Nashik#Solapur#Latur#Aurangabad#Sindhudurg#Sangli#Ahmednagar#Satara and Maharashtra.

0 notes

Text

Understanding the Different Types of Auto Drain Systems for Air Compressors

In the realm of air compressors, the efficiency and longevity of your equipment greatly depend on proper maintenance and functionality. One crucial component often overlooked is the auto drain system. Ensuring your Air compressor auto drain operates seamlessly is vital for optimal performance and longevity. This comprehensive guide will delve into the various auto drain systems available, shedding light on their functionalities, benefits, and applications.

Before delving into the specifics, let's grasp why auto drain systems are integral to air compressor functionality. Air compressors accumulate moisture during operation, which, if not drained efficiently, can lead to corrosion, reduced air quality, and compromised equipment performance. Manual drainage methods are labour-intensive and prone to human error. Auto drain systems alleviate these concerns by automating the drainage process, ensuring timely removal of condensate without the need for manual intervention.

Types of Auto Drain Systems:

Timer-Controlled Drains:

Timer-controlled drains are among the simplest and most cost-effective auto drain systems available. These systems operate on preset intervals, activating regularly to expel accumulated condensate. While straightforward, they may only sometimes align with actual moisture accumulation rates, potentially leading to inefficient drainage or unnecessary energy consumption.

Electronic Sensor-Based Drains:

Electronic sensor-based drains offer a more sophisticated approach to condensate management. Equipped with sensors, these drains detect the presence of condensate and trigger drainage accordingly. By responding to actual moisture levels rather than predefined intervals, they optimize drainage efficiency and minimize energy wastage. However, compared to timer-controlled counterparts, electronic sensor-based drains may be more complex to install and maintain.

Zero-Loss Drains:

Zero-loss drains represent the pinnacle of auto drain technology, designed to eliminate condensate and compressed air loss. These drains employ advanced mechanisms to separate moisture from compressed air without releasing pressurized air during drainage. They contribute to energy savings and maintain system pressure stability by ensuring zero air loss. Although they typically command a higher upfront investment, long-term energy efficiency and equipment longevity benefits make them a compelling choice for many applications.

Float Operated Drains:

Float operated drains utilize a float mechanism to detect the presence of condensate within the drain trap. When the condensate level reaches a certain threshold, the float opens the valve, allowing drainage. This mechanism offers a reliable and cost-effective solution for small to medium-sized air compressor systems. However, they may not be as precise or efficient as electronic sensor-based or zero-loss drains.

Choosing the Right Auto Drain System:

Selecting the optimal auto drain system for your air compressor depends on various factors, including system size, operating conditions, moisture levels, and budget constraints. A thorough assessment of these factors will help determine the most suitable option for your requirements. Additionally, consulting reputable drain valve manufacturers can provide valuable insights and assistance in selecting the right solution for your application.

Conclusion:

In air compressor maintenance, overlooking the importance of auto drain systems can lead to detrimental consequences for equipment performance and longevity. Understanding the different types of auto drain systems allows users to make informed decisions tailored to their unique needs. Whether opting for timer-controlled drains, electronic sensor-based drains, zero-loss drains, or float operated drains, prioritizing efficient condensate management is essential for maximizing air compressor efficiency and reliability. For expert guidance and top-quality auto drain solutions, trust Trident and its network of trusted drain valve manufacturers to meet your condensate management needs with precision and reliability.

By providing this comprehensive overview, Trident aims to equip readers with the knowledge needed to make informed decisions regarding their Air compressor auto drain maintenance practices, ultimately ensuring optimal performance and longevity of their equipment.

0 notes

Text

The Best Corken Compressors for Your Needs

In industrial settings, compressors are vital components that drive various processes forward. They are essential for tasks like air compression, gas handling, and refrigeration, playing a role in improving efficiency and productivity. This article will discuss the kinds of compressors, their uses, and important factors to consider when choosing the right compressor for your specific requirements. We'll cover topics such as unloading compressors, ammonia compressors, LPG compressors, and CORKEN compressors to give you an understanding of how they work and where they can be applied.

#Ammonia Compressor#CORKEN Compressor#LPG Compressor#LPG Transfer#unloading compressor#Vane Pump#Pump and Valves#IDEX India

0 notes

Text

Best Compressor Valve Plates In India

Enhance compressor performance with Indian Trade Bird's compressor valve plates. Our platform connects you with trusted suppliers offering high-quality valve plates designed to optimize airflow and increase efficiency in compressor systems.

Valve plates play a crucial role in regulating air intake and exhaust in compressors, ensuring smooth operation and maximum performance. Whether you're in the automotive, manufacturing, or construction industry, our diverse range of valve plates caters to various compressor models and applications. Indian Trade Bird simplifies the procurement process, offering competitive pricing and timely delivery to keep your compressor systems running smoothly. With our platform, you gain access to a wide network of reputable suppliers known for their reliability and commitment to quality.

0 notes

Text

Role of Heat Pump Components in Modern Hot Water Systems

Curious about components of hot water systems? Let's explore how each component works in harmony to provide reliable, eco-friendly hot water for your home.

Call on Toll-free number 1300 011 015. Mail us on- [email protected] Visit us- https://www.hitechhotwater.com.au/role-of-heat-pump-components-in-modern-hot-water-systems/

#heat pump components#hot water system parts#hot water system tempering valve#heat pump evaporator#heat pump compressor#heat pump condenser#heat pump water heater storage tank#heat pump controller#heat pump expansion valve

0 notes

Text

What are the main parts of chiller?

WHAT IS A CHILLER & HOW DOES IT WORK? | INDUSTRIAL CHILLER.

Chillers consist of four essential components; an evaporator, a compressor, a condenser, and an expansion unit. In addition, every chiller system contains a refrigerant.

A chiller is a vital component in air conditioning and industrial cooling systems, consisting of several key parts that work together to remove heat from a space or process. The main parts of a chiller include the compressor, evaporator, condenser, and expansion valve.

Compressor: This is the heart of the chiller, responsible for compressing the refrigerant gas. It raises the pressure and temperature of the refrigerant, preparing it for the cooling process.

Evaporator: The evaporator absorbs heat from the surrounding environment or a process fluid, causing the refrigerant to evaporate and turn into a low-pressure, low-temperature gas. This chilled gas is then sent to the compressor to restart the cycle.

Condenser: The condenser releases the heat absorbed by the refrigerant in the evaporator. It transforms the high-pressure, high-temperature gas into a high-pressure liquid by dissipating the heat into the air or another cooling medium.

Expansion Valve: This valve regulates the flow of the refrigerant, reducing its pressure and temperature before it enters the evaporator. This process allows the refrigerant to absorb heat efficiently in the evaporator.

These components work in a continuous cycle, facilitating the transfer of heat and maintaining the desired temperature in various applications, from commercial buildings to industrial processes.

#What are the main parts of chiller#chiller#Chillers#compressor chillers systems#compressor to restart#condenser cooling process#evaporator#expansion valv ehigh-temperature#industrial cooling systems#industrial processes#low-temperature#garefrigerant gas#Reynold india#Water Chillers

0 notes