#Concrete Batching Plant

Text

Optimizing Construction Efficiency with India's Best Concrete Batching Plants

The construction industry in India is rapidly growing, and with this growth comes an increased demand for advanced technology and equipment. Concrete batching plants play a crucial role in this industry, allowing for the production of large quantities of concrete in a short amount of time. When it comes to choosing a concrete batching plant, it's essential to consider factors such as efficiency, cost-effectiveness, and reliability. In this blog, we'll explore why Nilkanth Engineering Works' concrete batching plants are among the best in India and how they can help optimize your construction process.

Nilkanth Engineering Works is a leading manufacturer of concrete batching plants in India. With over 20 years of experience in the industry, they have established a reputation for delivering high-quality products and exceptional customer service. Their concrete batching plants are designed to meet the demands of modern construction projects and offer a range of benefits and features.

Some of the key features of Nilkanth Engineering Works' concrete batching plants include:

Efficient Mixing: The plants are equipped with state-of-the-art mixing technology, ensuring that the concrete is thoroughly mixed and produced quickly.

High Capacity: The plants have a large capacity, making them ideal for large construction projects that require significant quantities of concrete.

Durable and Reliable: The plants are constructed using high-quality materials and components, ensuring that they are durable and reliable. This minimizes downtime and maintenance costs, helping to ensure that your construction project is completed on time.

Cost-Effective: Nilkanth Engineering Works' concrete batching plants are designed to be cost-effective, offering great value for money.

User-Friendly: The plants are easy to operate, making them ideal for companies of all sizes and skill levels.

In conclusion, Nilkanth Engineering Works' concrete batching plants are an excellent choice for construction companies looking to optimize their efficiency. With a range of features and benefits, these plants can help you achieve your goals with ease and cost-effectiveness. Choose Nilkanth Engineering Works today and experience the benefits of advanced technology and efficient construction.

#Concrete Batching Plant#Concrete Batching Plant Manufacturers#Best Concrete Batching Plant Manufacturers#concrete batching plants in India#concrete batching plants#Best concrete batching plants

2 notes

·

View notes

Text

youtube

#concrete batching plant#manufacturers of tractor transit mixers#concrete batching plants manufacturers in India#Cement silos manufacturers in India#Working Videos of Concrete Batching Plants#navya batching plants#navya transit mixer#construction equipment manufacturers in India#automatic concrete plants#exporters of Construction machines#compact concrete batching plants#Pan Mix Concrete Batching Plants#Mini transit mixer#Youtube

0 notes

Text

Transforming Construction Processes with Concrete Batching Plants

In the field of construction, efficiency, precision, and reliability are paramount. One pivotal innovation that has fundamentally transformed construction processes is Concrete Batching Plants. These plants, encompassing various types such as concrete mixing plants, batching equipment, cement batching plants, and ready-mix concrete plants, have revolutionized the landscape of construction operations worldwide.

Enhancing Efficiency with Concrete Mixing Plants

Concrete mixing plants serve as the cornerstone of modern construction projects, facilitating the seamless blending of constituent materials to produce high-quality concrete. By incorporating cutting-edge technology and advanced automation, these plants ensure precision in proportioning raw materials such as aggregates, cement, and water, resulting in a consistent and uniform mixture. The integration of state-of-the-art control systems enables real-time monitoring and adjustment, optimizing the production process and minimizing waste. As a result, construction timelines are significantly shortened, and operational costs are effectively reduced, driving unprecedented efficiency in project execution.

Streamlining Operations with Batching Equipment

Central to the success of concrete batching plantsis the utilization of sophisticated batching equipment. These precision instruments meticulously weigh and dispense each component of the concrete mix, ensuring accuracy and reproducibility. Equipped with advanced sensors and monitoring mechanisms, batching equipment maintains tight control over the mixing process, guaranteeing the adherence to stringent quality standards. By eliminating manual intervention and human error, these automated systems enhance operational reliability and consistency, empowering construction teams to deliver superior results with confidence.

Maximizing Productivity with Ready-Mix Concrete Plants

In the field of rapid construction, ready-mix concrete plants stand as a testament to innovation and efficiency. These facilities produce pre-mixed concrete formulations tailored to specific project requirements, offering unparalleled convenience and flexibility to construction contractors. By centralizing the production of concrete off-site, ready-mix plants minimize on-site labor and equipment requirements, thereby optimizing resource utilization and enhancing productivity. Furthermore, the stringent quality control measures implemented in these plants ensure that each batch of concrete meets or exceeds industry standards, guaranteeing exceptional performance and durability in construction applications.

Optimizing Resource Utilization with Aggregate Batching

The efficient management of aggregates, a fundamental component of concrete production, is imperative for the success of any construction endeavor. Aggregate batching systems play a pivotal role in optimizing the utilization of these essential materials, ensuring precise dosing and blending to achieve the desired concrete mix properties. By utilizing advanced algorithms and algorithms, aggregate batching systems minimize material wastage and maximize resource efficiency, thereby reducing environmental impact and promoting sustainability in construction practices.

Conclusion

Concrete batching plants represent a paradigm shift in the construction industry, offering unparalleled levels of efficiency, precision, and reliability. From concrete mixing plants to ready-mix concrete plants, these innovative facilities have redefined the way construction projects are executed, enabling stakeholders to achieve unprecedented levels of productivity and cost-effectiveness. By harnessing the power of automation, advanced technology, and rigorous quality control measures, concrete batching plants have emerged as indispensable assets in the modern construction toolkit, driving progress and innovation across the globe.

Name: Coninfra Machinery Pvt.Ltd

Website: https://www.coninfra.in/

Address: 504, Sahitya Business Park, Nr. Keshav Hero Showroom , S.P Ring Road Nikol, Ahmedabad - 382350, INDIA

Phone No: +91 90999 41311

Faqs

What is a Concrete Batching Plant?

A Concrete Batching Plant is a facility that combines various ingredients to form concrete, such as water, aggregates, sand, cement, and additives. These ingredients are mixed in specific proportions to produce concrete of desired quality and consistency.

How does a Concrete Batching Plant work?

A Concrete Batching Plant works by first feeding the various ingredients into the batching equipment, where they are measured and mixed according to the predetermined recipe. Then, the mixed concrete is discharged into trucks or directly into concrete mixers for transportation to construction sites.

What are the benefits of using a Concrete Batching Plant?

Using a Concrete Batching Plant offers several benefits including:

> Improved efficiency and productivity in concrete production.

> Consistent quality control, ensuring uniformity in concrete properties.

> Reduced wastage of materials due to accurate batching.

> Flexibility to produce different types and grades of concrete according to project requirements.

> Enhanced safety measures in handling and mixing concrete ingredients.

What are the different types of Concrete Batching Plants?

Concrete Batching Plants come in various types based on their design, capacity, and mobility. Common types include:

> Stationary Concrete Batching Plants: Fixed in one location and suitable for large-scale projects.

> Mobile Concrete Batching Plants: Portable and easily movable, ideal for temporary construction sites.

> Compact Concrete Batching Plants: Space-saving designs suitable for small to medium-sized projects.

> Dry Mix Concrete Plants: Batch plants where all the ingredients are mixed except water, which is added at the construction site.

> Wet Mix Concrete Plants: Batch plants where all ingredients are combined with water before being discharged.

How to choose the right Concrete Batching Plant for my project?

Choosing the right Concrete Batching Plant involves considering factors such as:

> Project requirements including the volume and type of concrete needed.

> Available space for installation and operation.

> Accessibility to raw materials and transportation logistics.

> Budget constraints and long-term maintenance requirements.

> Environmental regulations and emission standards.

> Potential for future expansion or scalability of the plant.

0 notes

Text

A Simple Analysis of Concrete Batching Plant Price

In the world of construction, efficiency and cost-effectiveness are paramount. Concrete batching plants play a pivotal role in ensuring seamless operations and high-quality output. However, understanding the cost breakdown of different types of batching plants is crucial for informed decision-making. Let’s delve into the intricacies of this essential aspect.

Types of Concrete Batching Plants

1. Stationary Concrete Batching Plants: These plants are characterized by their fixed structure and are ideal for large-scale construction projects. The cost breakdown includes expenses related to land acquisition, initial setup, and maintenance.

2. Mobile Concrete Batching Plants: Offering unparalleled flexibility, mobile plants are suitable for projects requiring frequent relocation. Their cost breakdown typically comprises transportation expenses, installation costs, and ongoing maintenance.

3. Compact Concrete Batching Plants: Designed for small to medium-scale projects, compact plants combine efficiency with space-saving features. The cost breakdown involves factors such as equipment purchase, site preparation, and operational expenses.

Factors Influencing Costs

1. Capacity: The production capacity of a batching plant significantly impacts its cost. Higher capacity plants entail greater initial investment but offer economies of scale in the long run.

2. Technology and Features: Advanced technologies and additional features like automation, computerized control systems, and environmental protection measures contribute to the overall cost.

3. Maintenance and Operating Costs: Regular maintenance, spare parts availability, and energy consumption are ongoing expenses that need to be factored into the cost analysis.

Optimizing Cost Efficiency

1. Comparative Analysis: Conducting a comprehensive comparison of different types and models of batching plants helps in identifying the most cost-effective option tailored to specific project requirements.

2. Lifecycle Cost Assessment: Considering the lifecycle cost, including initial investment, operational expenses, and potential resale value, provides a holistic view of the financial implications.

3. Supplier Evaluation: Choosing a reputable supplier with a track record of delivering quality equipment and reliable after-sales support is crucial for minimizing unforeseen costs and ensuring long-term efficiency.

Understanding the cost breakdown of concrete batching plants empowers construction professionals to make informed decisions, maximize productivity, and optimize resource utilization. To explore further insights into enhancing construction efficiency and reducing costs, delve into our comprehensive guide. Read more for a deeper understanding.

0 notes

Text

Concrete Batching Plant Suppliers in India | Indian Trade Bird

Indian Trade Bird offers an extensive selection of high-quality concrete equipment to complement your construction projects. A concrete plant is a piece of machinery that mixes several ingredients to create concrete. It is also referred to as a batch plant, batching plant, or concrete batching plant. Our most well-known product is the Concrete Batching Plant, a versatile choice for precise and efficient concrete manufacturing. The concrete batching plant is the hub of your concrete production. It weighs, measures, mixes, and releases the concrete's ingredients precisely to meet your specifications. This reduces the possibility of errors happening on the job site and ensures a consistent mix quality. The core of your concrete manufacturing is the concrete batching plant. Modern technology is included in our concrete batching plants to help you run your business more efficiently.

For more details clicks here - https://www.indiantradebird.com/product/concrete-batching-plant

0 notes

Text

youtube

#ready mix concrete#concrete batching plant#concrete#construction#pouring#Crosby#Dayton tx#houston#Youtube

1 note

·

View note

Text

Mobile Concrete Batching Plant(INLINE BINS)

Fully Automatic Mobile Concrete Batching & Mixing Plant.

Available in 20/30/45/60 Cu.M. Per Hour Capacity.

Turbo Pan Mixer with spring based arms & blades. /SICOMA (Italy) Twin Shaft Mixer.

Inline Bins.

Large Mixer Platform for ease of Maintenance.

Easy & fast installation, commissioning & erection.

Flexible in adopting to different design mix.

Dual/Double conveyor Belts reduces cycle time and helps in achieving maximum output.

Tyres & tow bar provides mobility to the plant.

Added safety with limit switches in mixer.

Built on single Frame Structure/Chasis.

High accuracy weighing system.

Less Foundation required.

Consistent & uniform mixing.

Plant only require power supply.

Easily movable.

0 notes

Text

Portable concrete mixer manufacturer Chennai - Atlas

Contact portable concrete mixer manufacturer Chennai. Buy concrete batching plant from leading manufacturer of civil construction equipment.

0 notes

Text

What Are the Benefits of Using Automated Systems in a Batching Plant?

In the dynamic realm of concrete production, the integration of automated systems in batching plants has become a pivotal factor, revolutionizing the way we approach construction projects. Let's delve into the myriad advantages that propel these systems to the forefront of modern concrete manufacturing.

1. Precision and Consistency

Automated systems, whether in a mobile batch plant or a stationary concrete batching plant, guarantee precision in every mix. The meticulous algorithms ensure the exact proportions of raw materials, resulting in a consistent and high-quality end product.

2. Time is Money

Time efficiency is the cornerstone of any successful construction project. Automated batching plants streamline the production process, minimizing downtime and maximizing output. This time-saving advantage is especially crucial in the competitive world of construction.

3. Flexibility on the Go

For projects requiring mobility, a mobile batch plant equipped with automation technology offers unparalleled flexibility. The ability to produce concrete on-site reduces transportation costs and allows for a rapid response to changing project demands.

4. Error Elimination

Automation minimizes the margin for human error, enhancing the reliability of the batching process. This translates to fewer disruptions, reduced waste, and ultimately, cost savings for the customer.

5. Environmental Sustainability

Beyond efficiency, automated batching plants contribute to environmental sustainability. Precise material measurements result in reduced waste, and energy-efficient processes align with the growing emphasis on eco-friendly construction practices.

6. Integration with Industry 4.0

Embracing the era of Industry 4.0, automated batching plants seamlessly integrate with digital technologies. Real-time monitoring, data analysis, and remote control capabilities empower project managers with a comprehensive overview, enhancing decision-making.

7. Enhanced Safety Measures

Automated systems promote a safer working environment. With fewer manual interventions, the risk of accidents decreases significantly, ensuring the well-being of the workforce and reducing the likelihood of project delays due to safety issues.

8. Cost-Effectiveness

While the initial investment in automated systems may seem substantial, the long-term cost benefits are undeniable. Reduced material waste, lower labor costs, and increased productivity contribute to a compelling return on investment.

9. Future-Proofing Your Operations

Investing in automated batching plants is not just a contemporary trend; it's a strategic move to future-proof construction operations. Staying ahead in the industry requires embracing innovations that enhance efficiency, reliability, and sustainability.

Conclusion: Embrace the Future of Concrete Production

In the dynamic world of construction, automated batching plants, whether mobile or stationary, emerge as indispensable assets. The benefits extend beyond mere efficiency, encompassing precision, cost-effectiveness, and environmental consciousness. By investing in automated systems, you're not just upgrading your batching process of the batching plant— you're future-proofing your construction endeavors.

0 notes

Text

Learn how to choose the right concrete batching plant for your construction project. Discover key factors, types, and tips for selecting a plant that ensures efficiency, quality, and cost-effectiveness.

#concrete batching plant#concrete batching plants#Compact concrete batching plant#types of concrete batching plants

0 notes

Video

youtube

30cuM/hr Compact Bin Concrete Batching Plant | Navya Equipments

Compact Concrete Batching Plant | Manufacturers | Navya Equipments

#concrete batching plant#pan mixer#compact concrete batching plants#automatic concrete plants#navya concrete plants#navya batching plants#mobile concrete batching plant#inline concrete batching plants#concrete batching plant manufacturers#manufacturer of compact concrete batching plants in India#construction equipment manufacturers#30cuM/hr batching plant

0 notes

Text

Small Mobile Concrete Batching Plant

Small mobile concrete batching plant has the advantages of flexibility, cost-effectiveness, efficient production, adaptability and environmental protection. Small mobile concrete batch plants have several models, such as YHZS25, YHZS35, YHZS50, YHZS60, YHZS75 and YHZS90, which are suitable for a variety of large, medium and small ready mix concrete factories and industrial and civil construction projects such as highways, bridges and water conservancy. These mobile concrete batching plants are capable of mixing dry hard concrete, plastic concrete, fluid concrete, light aggregate concrete and various mortars, and thus have wide applications in various construction projects. They are especially suitable for construction projects that need to be moved frequently or set up temporarily, such as construction sites of bridges, highways, high-rise buildings and other construction projects.

With the acceleration of urbanization, there is an increasing demand for concrete in the construction engineering industry. In this case, the number and distribution of concrete batching plants have become the key factors restricting the progress of the project. The emergence of mobile concrete batching plant solves this problem to a large extent, providing a more convenient solution for the supply of concrete. The small mobile concrete mixing plant has been optimized and upgraded on the original mixing technology, which improves the working efficiency and improves the environmental protection, which can effectively reduce the waste of raw materials and environmental pollution, and meets the environmental requirements of modern construction. This makes them increasingly competitive in the market. Therefore, small mobile concrete batching plant is in greater demand in the market, especially in some occasions that require fast, flexible and environmentally friendly concrete supply.

The price of small mobile concrete batching plant varies depending on the model, configuration, brand and other factors. Generally speaking, the price of mobile concrete batching plant of small model is relatively low, but the specific price should be consulted and compared according to the actual demand and market situation. It should be noted that when buying mobile concrete batching plant, not only the price factor should be considered, but also the performance of the equipment, quality, after-sales service and other factors should be considered comprehensively to ensure that the purchase of cost-effective equipment.

In summary, the small mobile concrete batching plant has a wide range of applications in construction projects, the market demand is large, and the price varies depending on the model, configuration, brand and other factors. When buying, you need to comprehensively consider factors such as equipment performance, quality, price and after-sales service.

This resource is from http://www.concrete-mix-plant.com/news/small-mobile-concrete-batching-plant.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes

Text

FULLY AUTOMATIC CONCRETE BATCHING PLANT

Automating a concrete batching plant involves integrating technology and control systems to streamline and optimize the process of producing concrete batches. Automation can enhance efficiency, accuracy, consistency, and overall production quality. Here are the key steps and aspects to consider when automating a concrete batching plant:r when automating a concrete batching

1 note

·

View note

Text

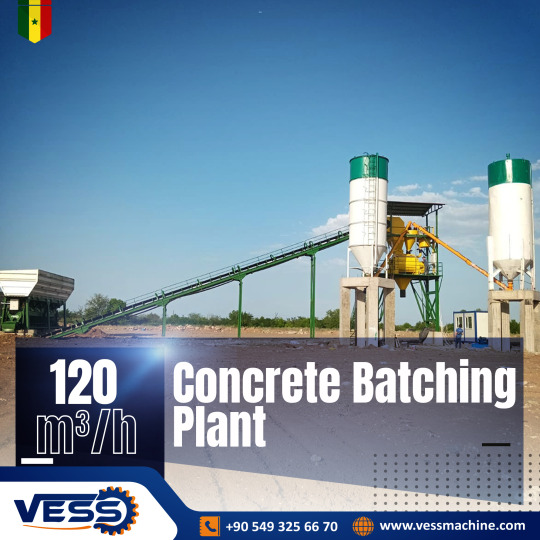

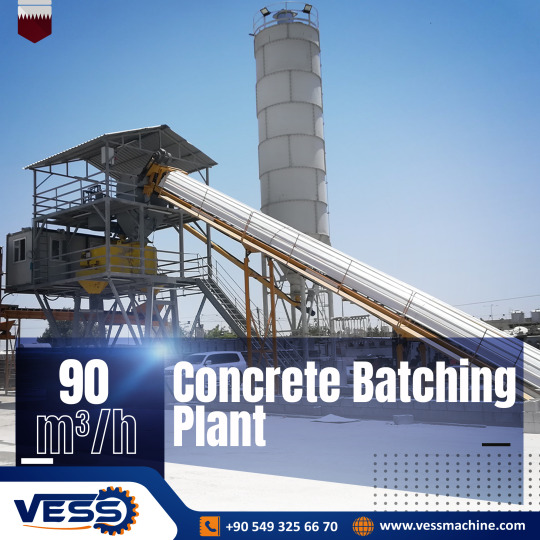

4 Different Concrete Batching Plants In Different Countries.

👉120 m3/h concrete batching plant in Senegal

👉90 m3/h concrete batching plant in Qatar

👉60 m3/h concrete batching plant in Georgia

👉30 m3/h concrete batching plant in Georgia

All of them are fully automatic models

further details: +90 549 325 6670

#concretebatchingplant #concrete #batchingplant #batching #concreteplant #construction

0 notes

Text

Concrete Batching Plant Manufacturer and Suppliers in India

The Concrete batching plant is an equipment that efficiently combines the various ingredients to make up concrete. The ingredients are sand, aggregate, water, air, cement, fly ash, and silica fume. These ingredients are mixed at different ratios depending on the final type of desired concrete. There are two main types of Concrete batching plants, which are the dry mix and the wet mix plants. A concrete batching plant is a machine in which ingredients of concrete are mixed and blended homogeneously to obtain concrete of desired strength and quality. The plants can be used wet or dry and has a wide array of configurations and production types including Ready Mix, Precast & Prestressed, Central Mix, and RCC. Because these plants offer total automation, superior performance, high production rates, and the highest quality manufacturing, they are very advantageous. As the volume drops through the maximum pressure field, the material is modelled into a solid compact sheet or flakes of ingredients.

For more details clicks here - https://www.indiantradebird.com/product/concrete-batching-plant

0 notes

Text

Portable concrete mixer manufacturer Chennai - Atlas Equipments

Contact portable concrete mixer manufacturer Chennai. Buy concrete batching plant from leading manufacturer of civil construction equipment.

0 notes