#Conveyor Guide Roller

Explore tagged Tumblr posts

Text

Zinc-plated Conveyor Rollers for Logistics and Warehousing System.

#futian roller#conveyor roller#logistics#warehousing#material handling#pulley#cylinder#roller manufacturer#guide roller

0 notes

Text

My game recommendations

I had a reblog in my drafts folder for a couple of days to keep working on it and when I was done I saw that the original poster sadly deactivated reblogs on their post. They lovingly suggested that simmers should indulge in other games too, and I couldn't agree more. It is a special feeling to dive into a new game, learn new mechanics, and have a very different experience from the last game you played. I really put a lot of work into my answer, so I decided to make a new post for it.

I'm a simmer and a gamer (simming since 2000), gaming since 1994 or so. I used to play Everquest II way back when and dabble in Elder Scrolls Online but I quit for Baldur's Gate III which has me obsessed for months now, highly enjoyable. Sims 3 has fallen a few steps on my top 10 list in recent years, but I use it as a creative outlet anyway and do not tend to judge it against other games much. I do judge Sims 4 though, which is a sad state of affairs. I can have fun in it if I spend the time in CAS, or for the first 6 hours in a new expansion - but it's just too expensive for its little value, especially compared to other games on this list.

City Builder/Automation games:

Factory Town: super chill cozy vibe, automate logistics for your pixel-people town. Lovely game

Timberborn: build a town for cute beavers!

Farthest Frontier: a nice city simulation with some logistics and events such as raiders invading the town

Satisfactory: one of the most ambitious automation games, with amazing graphics, for people who like to puzzle, analyze/calculate, and really use their heads while gaming. I like to play it as a challenge and see how far I can take my spaghetti conveyor belts!

Frostpunk: a harrowing/grim atmosphere, dystopian, make hard choices for your town

Simulation games:

Roller Coaster Tycoon and Planet Coaster: I love building super scary rollercoasters and then riding them and trying to get people in the park to ride them too

Strategy games:

Anno 1800: I can spend my entire life in this game it feels, it is engaging and relaxing all at once - love this so much!

Action/adventure games:

Assassins Creed Origins: stunning world, super detailed visuals and fun combat mechanics

Scifi/Exploration

No Man's Sky: At first I thought this was more of a casual game, but prepare for a lot of grinding and long-ish quests. It is fun to discover new plants/creatures and name them!

Survival games:

Raft: great to play with friends too and it has a relaxed vibe but also survival mechanics that keep you engaged

The Long Dark: I love the art style and music so much, the story mode is great, the survival mode can be very challenging depending on settings and it is super immersive. Wrap yourself in a warm blanket to play 😂

Subnautica: my favorite game ever before Baldur's Gate 3 dethroned it! It is a game that will guide you to leave your comfort zone time and time again, but you choose when you feel ready for it. You can really follow your own pace and exploring the vast, beautiful, and terrifying depths of this ocean planet is absolutely immersive and filled with surprise and wonder. It has also very chill and calm base-building elements to counteract the scarier moments. The soundtrack is one of the best in terms of evoking feelings/ building atmosphere, do not turn off the sound while playing this game!!!

Storytelling games:

Life is Strange: a classic, it's fun to explore what we could change and what the consequences would be if we could go back in time.

Firewatch: very emotional and touching, leaving a lasting impression

Casual games:

Bridge Constructor Portal (the dark humor is a bonus, it's fun and trains your analytical thinking!)

Carcassonne (like the tabletop game, chill puzzle game)

Simulacra (you uncover a mystery on a phone, interesting idea!)

Retro Games:

My favorite old/retro game would be Black & White (from 2001), which I played when it originally came out, I loved it so much! The free camera was revolutionary at the time. You play a god who is powered by worshippers whom you can either provide and care for or reign terror over, and your actions decide your alignment, good, neutral, or evil. You get a creature that you can train (and will be more or less useful to your goals or disrupt them depending on how well you train it). IIRC, you can train the creature either in the story mode or sandbox/skirmish mode and then go back to story mode with a stronger creature. The mouse gestures which activate miracles in the air felt like a revolutionary new idea back then. The game is not available officially anymore, but it is downloadable from some abandonware websites and the community-made patches so it is still playable today! Writing this, I had to reinstall it right away... the nostalgia!

RPGs:

Cyberpunk 2077: it's just iconic, the city energy and car drives are nice, the story is interesting and it feels immersive

The Witcher 3: great quests and story, beautifully crafted open world

Baldur's Gate 3: I could also talk for hours about Baldur's Gate 3. If there is one game out there that everyone should have tried once in their life, it's that one. It really lets you try any strategy you want and did not actually expect to work in a video game, but in BG3, it does. Even cheaty ones like pushing enemies from a cliff or using explosives to blow stuff up. If you got surprise-attacked but have no weapon handy, you can throw a grease bottle at the enemy that can make them slip and fall, and then you can throw your burning torch at it to light everything on fire. You can stack boxes to climb up to reach something (or throw a goblin body onto someone's head, because it's perfectly normal to carry those around with you). You can be sneaky and steal stuff, even rewards from enemies. Don't like fighting? You can talk your way out of most fights if your character has the necessary skills and still complete quests that way. 95% of NPCs have something to say, and if you click them again, they will have another line. The narrator is awesome. The companions have so much character, the banter is great and every character has its own story arc and goal, the voice acting is phenomenal all around. Definitely get the talk-to-animals skill and use it on all animals, you'll have hilarious conversations! It's worth every penny, even if it's not on sale (and I hardly ever buy a game at full price, so that is saying a lot). Thanks for reading, I hope you feel inspired to try some new games! Have fun 😊

20 notes

·

View notes

Text

Types of Industrial Furnaces: A Comprehensive Guide to Heat Treatment Solutions

Industrial furnaces are essential to various manufacturing and processing industries that require high-temperature heat treatment. From metallurgy and automotive to aerospace and ceramics, furnaces play a pivotal role in transforming raw materials into finished products by altering their physical and chemical properties. Understanding the types of industrial furnaces can help you choose the right one for your application.

Here’s a detailed guide to the most commonly used industrial furnaces and their specific functions.

1. Batch Type Furnace

Batch furnaces process materials in discrete batches rather than a continuous flow. These are ideal for applications that demand flexibility in heating cycles and are suitable for small to medium production volumes. Batch furnaces are commonly used for annealing, hardening, tempering, and stress relieving processes.

Advantages:

High temperature control accuracy

Versatility for multiple applications

Cost-effective for small-scale operations

2. Continuous Furnace

As the name suggests, continuous furnaces allow for uninterrupted processing of parts along a conveyor or roller system. These are suitable for high-volume production where consistent throughput is essential. Industries like automotive and electronics often use continuous furnaces for brazing, sintering, or annealing.

Advantages:

High productivity

Reduced cycle times

Uniform heating across batches

3. Sealed Quench Furnace

Sealed quench furnaces are used for carburizing and hardening steel components in a controlled atmosphere. The sealed design prevents oxidation and allows for precise surface treatment. These furnaces often come with an integrated quenching chamber, making them ideal for hardening gears, shafts, and tools.

Advantages:

Clean, oxidation-free results

Accurate case depth control

Ideal for precision components

4. Pit Furnace

Pit furnaces are vertical furnaces where the workpieces are lowered into a cylindrical chamber. They are commonly used for heat treating long components like shafts, bars, and rods. Pit furnaces are excellent for annealing, normalizing, and carburizing applications.

Advantages:

Space-saving vertical design

Excellent for deep parts

Good temperature uniformity

5. Bell Furnace

Bell furnaces consist of a removable bell-shaped cover that lifts off the base. They are primarily used for bright annealing, normalizing, and recrystallization of steel coils, wires, and strips. Bell furnaces offer a protective atmosphere and excellent temperature control.

Advantages:

Uniform heating and atmosphere control

Clean, bright finish

Suitable for sensitive materials

6. Salt Bath Furnace

Salt bath furnaces use molten salts to transfer heat to the material. These are used for applications requiring fast heating and uniform temperature, such as hardening, tempering, and case hardening. Salt baths also minimize oxidation and scale formation.

Advantages:

Fast heat transfer

Precise control over temperature

Clean surface finish

7. Gas-Fired Furnace

Gas-fired furnaces use natural gas or LPG as the fuel source. These furnaces are cost-effective and commonly used for forging, heat treatment, and melting applications. They offer high heating rates and are suitable for large-scale operations.

Advantages:

Energy efficient

Low operational costs

Suitable for high-temperature processes

8. Electric Furnace

Electric furnaces use resistance or induction heating for clean and controllable thermal processing. They are popular in laboratories, research facilities, and cleanroom applications. Electric furnaces can reach high temperatures with minimal emissions.

Advantages:

Precise temperature control

No combustion by-products

Environmentally friendly

9. Aluminium Annealing Furnace

These furnaces are specifically designed to soften aluminum alloys and relieve internal stress. They are used in industries manufacturing aluminum sheets, plates, or cast components.

Advantages:

Tailored for lightweight alloys

Prevents cracking and improves ductility

Enhances machinability and formability

Choosing the Right Industrial Furnace

Selecting the appropriate furnace depends on factors such as:

Type of material being processed

Required temperature and cycle time

Desired surface finish and metallurgical properties

Production volume

Energy source availability (electricity, gas, etc.)

Conclusion

The types of industrial furnaces vary widely, each designed to meet specific manufacturing needs. Whether you require batch flexibility, continuous production, surface treatment, or metal softening, there is a furnace designed to deliver optimal performance. By understanding each type's strengths and limitations, industries can enhance their heat treatment processes, reduce costs, and ensure product consistency.

#industrial furnace#types of industrial furnaces#furnace manufacturers#industrial furnace manufacturers

0 notes

Text

Unveiling the Backbone of Infrastructure: Top MS Steel Pipe Manufacturers in India

Mild Steel (MS) pipes are the silent workhorses of modern development. From towering skylines and intricate industrial frameworks to vital water supply systems and robust agricultural infrastructure, these versatile pipes form the very backbone of progress across India. Valued for their durability, malleability, and cost-effectiveness, MS pipes are in constant demand, fueling a dynamic manufacturing sector.

But in India's competitive market, how do you find the right MS Steel Pipe Manufacturers in India who guarantee quality, reliability, and competitive pricing? This comprehensive guide delves into the world of Indian MS pipe manufacturing, equipping you with the knowledge to make informed, strategic decisions.

Why MS Steel Pipes Are Indispensable

Mild steel, with its low carbon content (typically 0.05% to 0.25%), offers a unique blend of properties making it ideal for diverse applications:

High Tensile Strength: Capable of withstanding significant pressure and structural loads.

Excellent Weldability: Easy to weld and fabricate, reducing installation time and costs.

Ductility & Malleability: Can be easily bent and formed without fracturing, allowing flexible designs.

Cost-Effectiveness: More affordable than other steel alloys, making them popular for large-scale projects.

Versatility: Adaptable across sectors like plumbing, construction, oil & gas, and automotive.

Fire Resistance: Can withstand high temperatures, suitable for fire suppression systems.

Recyclability: An environmentally conscious choice, contributing to a circular economy.

The Manufacturing Process of MS Steel Pipes

The journey from raw material to finished pipe involves precise stages:

Raw Material Selection: High-grade mild steel coils are chosen for specific chemical composition.

Uncoiling & Cutting: Coils are uncoiled and precisely cut into strips.

Forming: Strips are gradually formed into a cylindrical shape using rollers (roll forming).

Welding: Edges are joined. Common methods include:

Electric Resistance Welding (ERW): Electrical current heats edges, pressed together to form a seamless joint. Known for uniform wall thickness.

Submerged Arc Welding (SAW): Electrical arc under flux, used for larger diameter pipes (LSAW).

Sizing & Shaping: Pipes achieve precise diameter and are straightened.

Cutting to Length: Pipes are cut to specified dimensions.

Heat Treatment (Optional): To enhance properties and relieve stress.

Surface Treatment/Coating (Optional): Galvanizing (zinc coating for corrosion resistance), painting, or other coatings.

Inspection & Testing: Rigorous quality checks (visual, hydrostatic, ultrasonic) ensure adherence to standards (e.g., IS 1239, IS 1161, IS 3589).

Key Applications of MS Steel Pipes in India

MS pipes are indispensable across numerous sectors:

Construction & Infrastructure: Structural supports, scaffolding, fencing, industrial sheds, bridges, railway electrification.

Water & Gas Transportation: Water distribution, irrigation, industrial lines, gas pipelines.

Oil & Gas Industry: Transportation of oil and gas, process piping.

HVAC Systems: Heating, ventilation, and air conditioning.

Automotive Industry: Chassis, exhaust systems.

Agriculture: Water wells, irrigation.

Firefighting Systems: Due to fire resistance.

General Engineering: Conveyor systems, machinery fabrication.

Navigating the Indian MS Steel Pipe Market: Trends and Considerations

The Indian steel pipes market is robust, driven by:

Massive Infrastructure Development: Government initiatives in smart cities, housing, and industrial corridors.

Expanding Oil & Gas Projects: Need for efficient energy transportation.

Focus on Sustainable Practices: Eco-friendly production and coated pipes for longer life.

Technological Advancements: Direct Forming Technology (DFT) for efficient production.

When choosing an MS steel pipe manufacturer, consider:

Quality Certifications: Adherence to Indian Standards (IS), ASTM, ISO.

Manufacturing Capabilities: Capacity to produce required types, sizes, and quantities.

Product Range: Diversity indicates market understanding.

Reputation & Experience: Proven track record of quality and service.

Customization Options: Ability to meet specific dimensions, coatings, or end connections.

Logistics & Delivery: Strong network for timely delivery.

Pricing: Compare quotes for value without compromising quality.

Leading MS Steel Pipe Manufacturers in India

India boasts a strong ecosystem of manufacturers. Prominent names often associated with quality and reliability include:

Jindal SAW Ltd.: Major player in ERW and seamless pipes.

Maharashtra Seamless Ltd.: Specializes in seamless pipes for high-pressure applications.

APL Apollo Tubes Limited: Leading in structural steel tubes and hollow sections.

Tata Steel: Produces high-quality MS pipes and galvanized iron pipes.

Surya Roshni Limited: Significant manufacturer of ERW mild steel pipes.

ISMT (Indian Seamless Metal Tubes) Limited: One of the largest seamless pipe manufacturers.

Welspun Corp Ltd.: Prominent global player with strong Indian presence.

Many regional manufacturers and distributors also contribute significantly to the supply chain.

Partnering for Success: Your Project's Foundation

Choosing the right MS steel pipe manufacturer is a critical decision impacting your project's success and longevity. By understanding pipe types, manufacturing processes, quality standards, and key players, you can confidently select a partner who will provide the robust and reliable backbone your infrastructure deserves.

0 notes

Text

Cross-Country Conveyors: Changing the Way Things Are Moved

Cross-country conveyors are long-distance systems designed to move materials across vast areas. These systems are essential in industries like mining, agriculture, and manufacturing because they efficiently transport bulk materials over considerable distances. This capability reduces the reliance on manual labour and trucks, which are both costly and harmful to the environment. Cross-country conveyors hold immense significance in the industry. They streamline operations by ensuring a continuous flow of materials and help lower transportation costs and reduce carbon footprints. In the mining industry, for example, these cross-country conveyors transport ore from remote sites to processing plants, maintaining a steady supply chain. In agriculture, they move harvested crops from fields to storage or processing facilities, preserving quality and minimising spoilage.

Cross Country Conveyors: What Is the Process?

The process of setting up and operating a cross-country conveyor system involves several steps, starting with planning and design.

The first step is to conduct a thorough analysis of the terrain and the material to be transported. Engineers and designers use this information to create a blueprint for the conveyor system, taking into account factors such as the length of the conveyor, elevation changes, and the type of material being transported.

Once the design is finalised, the construction phase begins. This involves laying the conveyor belt and installing support structures such as pylons or trestles. Depending on the terrain, the installation may require significant earthmoving and construction work to create a stable path for the conveyor.

After construction, the system is equipped with various components that ensure its smooth operation. These include motors, pulleys, rollers, and sensors. The motors drive the conveyor belt, while the pulleys and rollers help guide and support it. Sensors are used to monitor the system’s performance, detecting any issues such as belt misalignment or blockages.

The final step is commissioning and testing the system to ensure it operates efficiently and safely. This involves running the conveyor at full capacity, checking for any operational issues, and making necessary adjustments.

Tools Used in Cross-Country Conveyors:

Several tools and components are essential for the construction and operation of cross-country conveyors:

Conveyor Belts: The backbone of the conveyor system, available in various materials and designs to suit different types of materials and operating conditions.

Motors and Drives: Provide the necessary power to move the conveyor belt. They are selected based on the conveyor’s length and the load it will carry.

Pulleys and Rollers: Pulleys drive the belt, while rollers support it and help maintain its alignment.

Sensors and Monitoring Equipment: Used for tracking the conveyor’s performance, detect issues, and ensure smooth operation.

Structural Supports: Includes pylons, trestles, and other supports that hold the conveyor in place, especially in uneven or challenging terrains.

Control Systems: Automated systems that manage the conveyor’s operation, adjusting speed and load as needed, and ensuring safety protocols are followed.

In what ways does Methods India work for Cross-Country Conveyors?

Methods India is a leader in bulk material handling solutions, constantly innovating new ways to transport materials. They specialise in planning, building, and operating cross-country conveyors. Committed to excellence and quality, Methods India provides custom solutions that enhance efficiency, productivity, and success for clients across various industries. Leveraging cutting-edge technology and a team of highly skilled professionals, they deliver top-notch services tailored to meet the unique needs of each client.

Conclusion

Cross-country conveyors play an important role in modern industry, offering an efficient, cost-effective, and environmentally friendly solution for transporting materials over long distances. Their implementation involves careful planning, design, and construction, followed by rigorous testing and monitoring. With the right tools and components, these systems can significantly enhance operational efficiency and sustainability in various sectors. As industries continue to seek ways to improve their supply chains and reduce their environmental impact, the importance of cross-country conveyors is likely to grow even further. Taking Methods India as a partner in this endeavour is a wise solution, ensuring expertise and reliability in achieving these goals.

0 notes

Text

The Role of Taping Head in Enhancing Packaging Efficiency

Defining the Taping Head in Packaging Machinery

The taping head is the core part of a carton sealing unit responsible for dispensing adhesive tape over the box flaps and cutting it with precision. It operates in coordination with the conveyor system or manually-fed carton sealer, ensuring that each carton receives a secure and professional seal.

It is designed to perform three primary functions:

Feed the tape from the roll

Apply pressure uniformly across the carton

Cut the tape at the correct length without wastage

Why Every Automated Line Needs a Taping Head

Incorporating a high-quality taping head into a packaging line offers numerous benefits beyond simple sealing:

1. Consistent Sealing Quality

Each carton is sealed identically, which enhances the professionalism and reliability of the packaging.

2. Reduced Manual Labor

The taping process is automated, significantly lowering the need for human intervention and labor costs.

3. Faster Throughput

With high-speed capability, a taping head can seal hundreds of cartons per hour, increasing operational efficiency.

Common Tape Types Compatible with Taping Heads

A wide variety of adhesive tapes are used with taping heads, each offering specific benefits for different packaging needs:

BOPP Tape (Biaxially Oriented Polypropylene) – Popular for general packaging due to its durability and clarity.

PVC Tape – Known for strong adhesive grip and temperature resistance.

Reinforced Tape – Suitable for heavy-duty applications and larger carton sizes.

Kraft Paper Tape – Eco-friendly option compatible with some taping heads designed for sustainability.

Versatility in Carton Sizes and Shapes

Modern taping heads are designed to accommodate a broad range of carton sizes. Adjustable mechanisms allow the taping head to reposition itself based on the carton height and width, making it ideal for dynamic and multi-size production lines.

Some models include:

Spring-loaded heads for handling variable box heights.

Heavy-duty taping heads for sealing large, bulky cartons.

Low-profile taping heads for shallow or narrow cartons.

Precision Engineering Behind the Taping Head

A taping head is more than just a moving part. It is a result of intricate engineering that combines:

Guide rollers for smooth tape flow

Tension control systems to prevent stretching or slack

Durable blades for clean and quick cuts

Pressure arms that adjust automatically for even tape application

This precision reduces tape misalignment, prevents downtime, and ensures an airtight seal for shipping durability.

Safety Features in Modern Taping Heads

Worker safety is a major consideration in industrial equipment. Taping heads often come with safety-focused designs such as:

Protective blade covers

No-jam mechanisms

Ergonomic access points for easy tape roll replacement

Anti-pinch guards to prevent accidents during operation

These safety features not only protect personnel but also extend the life of the equipment.

How to Maximize the Life of a Taping Head

To ensure long-term performance, it’s crucial to maintain the taping head regularly:

Clean the tape path weekly to remove adhesive residue

Inspect and replace worn-out blades

Lubricate moving parts as recommended

Check alignment to avoid tape skewing or tearing

Routine maintenance minimizes downtime and boosts productivity over time.

Integration with Packaging Automation

Today’s packaging lines demand full integration. Taping heads can be:

Manually fed in semi-automatic systems

Fully automated in conveyor-driven systems

Programmable to sync with robotic arms and IoT platforms

0 notes

Text

Ohio Loans for Small Business

Equipment in Columbus, Ohio: A Guide to Heavy Machinery Sales, Rentals, and Service Solutions

When it comes to powering Ohio’s construction, mining, forestry, and agricultural projects, few names are as trusted as Equipment Company. With a legacy spanning over 70 years, the company has become a go-to source for heavy machinery sales, rentals, and service throughout Columbus and beyond.

Whether you're a contractor launching a major infrastructure project, a landscaper in need of compact machinery, or a business owner seeking reliable equipment for long-term use, this guide will walk you through the essentials of buying, renting, and maintaining heavy equipment through Equipment in Columbus, Ohio.

Introduction to Equipment Company and Its Legacy in Ohio

Founded in 1952, Equipment Company in Columbus Ohio is a full-service dealer for some of the world’s leading heavy machinery brands. Headquartered in Columbus, Ohio, it operates multiple locations across the state and prides itself on delivering “the best equipment, backed by the best product support.”( Ohio loans for small business )

The company’s Columbus branch serves as a hub for:

• Heavy machinery sales

• Short- and long-term equipment rentals

• Field service and in-shop repairs

• OEM parts and maintenance support

• Specialized solutions for construction, forestry, aggregate, and more

With deep local roots and national brand partnerships, Columbus Equipment bridges the gap between world-class machinery and regional know-how.

Types of Heavy Equipment Offered: Excavators, Dozers, Cranes, and More

Columbus Equipment offers a vast inventory of heavy machinery suited for diverse applications. Whether you're managing site prep, road construction, or timber harvesting, they’ve got you covered.

Most Popular Categories:

• Excavators & Mini-Excavators

• Bulldozers

• Wheel Loaders

• Skid Steers

• Crushers & Screeners

• Cranes & Lifting Equipment

• Trenchers & Compactors

• Forestry Machines (Feller Bunchers, Mulchers, etc.)

• Material Handlers

• Hydraulic Attachments

Both new and used equipment is available, giving buyers flexible pricing options based on their project size and duration.

Industries Served: Construction, Forestry, Mining, Roadwork, and Agriculture

Equipment serves Ohio’s most equipment-intensive sectors with industry-specific solutions and machines engineered to meet exacting demands.(sba in ohio )

Construction & Infrastructure:

From site grading to demolition, contractors rely on excavators, bulldozers, and compact track loaders for every phase of a build.

Roadwork & Paving:

Pavers, milling machines, and compaction rollers are critical for Ohio’s growing transportation network.

Forestry:

With Ohio’s active timber industry, the company supports logging operations with Morbark and Komatsu forestry machinery.

Aggregates & Mining:

Crushers, conveyors, and screening equipment help mining companies maximize uptime and throughput.

Agriculture & Land Management:

Compact equipment, utility loaders, and specialty attachments serve the needs of farmers and landscapers alike.

Columbus Equipment’s knowledgeable team can tailor recommendations to fit your industry and operating environment.

Equipment Rental vs. Purchase: Which Option Is Right for Your Project?

One of the biggest decisions a business faces is whether to rent or buy heavy equipment. Columbus Equipment makes both options accessible, and understanding the benefits of each can save time and money.

Benefits of Buying:

• Long-Term Savings: Better return on investment over time

• Full Ownership: Ideal for frequently used core machinery

• Customization: Purchase-specific attachments or add-ons

Benefits of Renting:

• Lower Upfront Cost: No down payment or financing needed

• Flexibility: Use specialized equipment only when needed

• No Maintenance Costs: Columbus Equipment handles service and repairs

When to Rent:

• Short-term or one-off projects

• When trying out new machinery

• If cash flow is tight or seasonal work fluctuates

The Columbus location maintains a large rental fleet of newer-model machines, regularly inspected and maintained to factory standards.

Maintenance, Parts, and Support Services Available in Columbus

One of Columbus Equipment’s standout features is its dedicated service and support department, which helps keep machines running at peak performance.

Available Services:

• 24/7 Field Service with mobile technicians

• In-House Repair Shop for diagnostics and overhauls

• Preventive Maintenance Plans

• OEM Parts Inventory for Komatsu, Morbark, Takeuchi, and more

• Equipment Monitoring via Komtrax (telematics system)

For buyers, this means faster turnaround on repairs, less downtime, and extended equipment life cycles.

Top Equipment Brands Carried

Columbus Equipment partners with industry-leading manufacturers known for innovation, durability, and performance.

Key Brands:

• Komatsu – Excavators, dozers, wheel loaders, and intelligent machine control

• Takeuchi – Compact track loaders and mini-excavators

• Morbark – Forestry and wood recycling equipment

• Sennebogen – Material handlers and lifting solutions

• Wirtgen Group – Road construction machinery

• Manitowoc/Link-Belt – Cranes and lifting equipment

Access to these brands ensures that you get cutting-edge technology and dependable performance for any project.

Tips for Choosing the Right Equipment Dealer in Columbus, Ohio ( Small business loans ohio )

Investing in heavy equipment is a major decision. Here's how to choose the right dealer:

1. Reputation Matters – Columbus Equipment has over 70 years of service excellence in Ohio.

2. Parts and Service Availability – Choose a dealer with local support to minimize downtime.

3. Rental and Financing Options – Look for flexibility and tailored financial plans.

4. Training and Product Support – Columbus Equipment offers operator training and telematics to maximize machine usage.

5. Inventory Depth – The more options, the more likely you’ll find exactly what your project needs.

Conclusion: Power Your Next Project with Equipment in Columbus, Ohio

Whether you’re launching a new construction project, managing a forestry operation Simplistic Capital, or expanding your agricultural fleet, Equipment in Columbus, Ohio offers the machines, expertise, and support you need to get the job done right. Their commitment to quality equipment, expert service, and customer satisfaction makes them a top choice for professionals across the state.

Start your journey today—visit their Real estate investing ohio Columbus branch, request a quote, or browse available equipment online to find the solution that matches your business needs and budget.

0 notes

Text

Top 5 Common Packing Machine Issues and How to Solve Them

1: Unreliable sealing.

This issue arises when package seals are fragile, compromised, or inconsistent in their appearance. It frequently occurs due to improper sealing temperature, uneven pressure, or contamination on the sealing surfaces. To resolve this issue, clean the sealing jaws, verify the appropriate temperature and pressure settings, and replace any worn or damaged sealing components.

2: Incorrectly installed software.

Incorrect product feeding or improperly adjusted guide rails can lead to packages being crooked or misaligned. Displacement of the conveyor belt is a frequent reason. To resolve this issue, carefully inspect the alignment of the conveyors and guide rails, making any necessary adjustments to ensure a seamless and uninterrupted flow of products into the machine.

3: Cleaning up any messes or mistakes.

Overfilled or underfilled packages—or any visible spillage—are typically caused by calibration mistakes, clogged nozzles, or incorrect fill timing. Fix this by recalibrating the fill volume, cleaning or replacing the nozzles, and adjusting the machine's timing to better match the packaging speed and size.

4. Film Tearing or Jamming

When the packaging film tears or jams, it typically indicates poor film quality, incorrect tension, or improper loading. To prevent this, use high-quality, machine-compatible film, load the roll correctly, and adjust the film tension. Also, inspect rollers and belts to ensure they are functioning properly.

5. Machine Stops Unexpectedly or Fails to Start

Frequent shutdowns or startup failures can stem from electrical issues, sensor malfunctions, or activated emergency stop buttons. To fix this, inspect the power supply, check and reset emergency stops, clean and test sensors, and review the control panel for any error codes or alerts.

Conclusion: Routine Maintenance is the Best Prevention

These issues can mostly be avoided through regular maintenance. Clean machine parts daily, inspect mechanical and electrical components weekly, and follow the manufacturer’s maintenance schedule. This keeps your packing machine running smoothly and minimizes downtime.

#packing machine#technology#packing manufacture#packing equipments#packing supplies#packing services

0 notes

Text

Elevator Company

Marck Industries is a leading manufacturer based in Ahmedabad, Gujarat, specializing in elevators, elevator spare parts, EOT cranes, material handling equipment, and conveyor rollers. With over 22 years of experience, the company has established a strong presence both domestically and internationally, exporting to over 10 countries across Asia, the Middle East, and Africa.

Company Overview

Name: Marck Industries

Location: 15, Shriji Estate, Opp. Radhakrishna Soc., Nr. Dhandhar Panchal Wadi, Viratnagar Road, Odhav, Ahmedabad-382415, Gujarat, India

Website: marckindustries.com

Contact: +91-97271 56896 | +91-93286 23252

Email: [email protected] | [email protected]

Product Portfolio

Marck Industries offers a comprehensive range of products tailored to meet diverse vertical transportation and material handling needs:

Elevators: Passenger lifts, bungalow lifts, home lifts, hospital lifts, hydraulic lifts, and parking lifts

Elevator Spare Parts: Control panels, diverter pulleys, auto door parts, cabins, doors, drives, fans, guide shoes, and mechanical components

Elevator Full Lift Kits: Complete elevator systems for various applications

EOT Cranes: Including base-mounted hoists, chain hoists, double girder cranes, goliath gantry cranes, hydraulic goods lifts, jib cranes, M.E crab type hoists, and wire rope hoists

Material Handling Equipment: Drum handling equipment, electric stackers, floor cranes, goods lifts, hydraulic lifting tables, manual stackers, material handling trolleys, pallet trucks, scissor lifts, and wheelbarrows

Conveyor Rollers: Idler bearing housings, idler roller bearing housings for crushers, labyrinth seals, MS dust covers, and impact rubber rings

Why Choose Marck Industries?

Expertise: Over two decades of experience in manufacturing and supplying elevator and material handling solutions.

Quality Assurance: Commitment to delivering high-quality products that meet international standards.

Innovation: Continuous research and development to incorporate the latest technologies and innovations in their products.

Customer Satisfaction: A strong focus on customer satisfaction with a dedicated team providing support and service.

For more information or to request a quote, visit their official website or contact them directly via the provided details.

0 notes

Text

Faridabad’s Leading Belt Conveyor Companies You Should Know

In today’s fast-paced industrial environment, efficient material handling is not just an operational requirement but a competitive advantage. Belt conveyors—a staple in manufacturing, logistics, and warehousing—are critical to ensuring smooth product flow and reducing manual handling time. When it comes to sourcing these essential systems in India, Faridabad stands out as a leading manufacturing hub.

This blog explores the top belt conveyor companies in Faridabad, highlighting their strengths, innovations, and what sets them apart. If you’re looking to invest in a high-performance conveyor solution, this guide will help you make an informed decision.

Why Faridabad Is a Belt Conveyor Manufacturing Hub

Part of the Delhi-NCR industrial belt and situated in Haryana, Faridabad has made a name for itself as a manufacturing hub for machinery and equipment. Its prominence in the belt conveyor manufacturing industry is a result of several factors:

Well-developed industrial infrastructure

Proximity to Delhi, Gurgaon, and major logistics corridors

Access to skilled labor and engineering talent

Presence of diverse industries driving demand

Supportive government policies for MSMEs and exporters

Thanks to this ecosystem, many belt conveyor manufacturers in Faridabad are now serving both domestic and global markets with world-class products.

What Makes a Good Belt Conveyor Manufacturer?

Before we delve into the top companies, here are the criteria that make a conveyor manufacturer stand out:

Engineering expertise and customization capability

High-quality raw materials and precision fabrication

Advanced automation integration (motors, PLCs, sensors)

Customer-centric approach with timely delivery

Strong after-sales support and spare parts availability

Compliance with safety and quality standards (ISO, CE)

Now, let’s look at the companies in Faridabad that embody these traits.

Top Belt Conveyor Companies in Faridabad

1. Neo Conveyors

Neo Conveyors is one of the most recognized names in the conveyor system manufacturing sector in Faridabad. Known for their custom-engineered belt conveyors, they cater to industries like cement, food processing, mining, packaging, and more.

Key Strengths:

Custom designs for bulk material handling

High-performance conveyors with minimal maintenance

Export-ready systems with CE certifications

2. Conveline Systems Pvt. Ltd.

Conveline Systems specializes in modular conveyor solutions, including belt conveyors, roller conveyors, and inclined systems. Their systems are widely used in e-commerce, warehousing, and packaging industries.

Key Features:

Modular, plug-and-play designs

Quick lead times and scalable systems

High-quality belts and automation-ready features

3. Jay Engineering

Established for over 20 years, Jay Engineering is known for its heavy-duty and precision conveyors. They manufacture industrial-grade belt conveyors for tough environments like foundries and assembly lines.

USP:

Rugged construction with high load capacities

Turnkey project execution with layout planning

Long-life motors and accessories

4. Saifi Con-Fab System Pvt. Ltd.

A pioneer in conveyor technology, Saifi Con-Fab offers advanced belt conveyor solutions for industries ranging from food to electronics. Their R&D-focused approach ensures innovative designs and automation integration.

Highlights:

In-house design and engineering team

Belt conveyors with integrated sensors and safety systems

Strong service support across India

5. Essar Engineers

Essar Engineers delivers a range of material handling equipment, with belt conveyors as one of their core offerings. Their strength lies in delivering high-quality products with fast turnaround times.

Specialties:

Standard and custom belt conveyors

Powder-coated and stainless steel options

Cost-effective and durable solutions

Key Features of Belt Conveyors from Faridabad

Belt conveyors manufactured in Faridabad offer a blend of quality, reliability, and cost-efficiency. Here are some common features:

✅ Sturdy Frame Construction

Made from mild steel, aluminum, or stainless steel for durability and resistance to corrosion.

✅ Custom Belt Materials

Options include PVC, rubber, modular plastic, and food-grade belts depending on the application.

✅ Adjustable Speeds and Height

Motorized speed control with VFDs and adjustable-height frames for operational flexibility.

✅ Portability and Compact Design

Many companies offer portable or foldable conveyors for smaller facilities.

✅ Automation-Ready

For smooth automation, sensors, smart controllers, and PLC systems are integrated.

Applications of Belt Conveyors

Many different businesses use belt conveyors manufactured in Faridabad:

Automotive: Assembly line movement and component transfer

FMCG: Carton and pouch transport in packaging lines

E-commerce & Warehousing: Sorting and order fulfillment

Pharmaceuticals: Clean, contamination-free product handling

Mining & Cement: Heavy-duty material transfer

Food Processing: Hygienic conveyors with wash-down features

Their adaptability and versatility make them essential across sectors.

Why Choose Faridabad Manufacturers?

Here’s why companies across India and abroad trust Faridabad belt conveyor manufacturers:

📈 Proven Experience

Many companies have decades of experience and serve top national brands.

💡 Engineering Expertise

Access to modern tools like AutoCAD, SolidWorks, and simulation testing ensures quality.

🌍 Export Capability

Several firms export to Middle East, Africa, and Southeast Asia, indicating trust and scalability.

💸 Competitive Pricing

Compared to imported systems, Faridabad manufacturers offer high performance at a lower cost.

🔧 Reliable After-Sales Support

Prompt service and availability of parts ensure minimal downtime.

Things to Consider Before Buying

The following should be taken into account while selecting a belt conveyor system:

The kind and volume of information that needs to be conveyed

The type and amount of information that must be communicated

Required speed and length of the conveyor

Inclination or level transfer

Environmental factors (temperature, moisture, hygiene)

Power source and space availability

Most manufacturers in Faridabad offer free consultations and site visits to recommend the right solution.

Final Thoughts

If you’re looking to optimize your material handling operations, belt conveyors are a smart investment—and there’s no better place to source them than Faridabad. With a blend of innovation, affordability, and manufacturing excellence, Faridabad’s conveyor companies are meeting the evolving needs of industries across India and beyond.

Whether you're a small business or a large enterprise, the right conveyor partner from Faridabad can help boost your productivity and operational efficiency.

📞 Ready to Upgrade?

Get in touch with Faridabad’s leading belt conveyor manufacturers today for customized solutions and expert guidance.

Address: Plot No. 7, Gali no 2 Sahupura Industrial Area, Near Bypass, Faridabd-121004 Haryana (India)

Phone No. : 9958352003

#BeltConveyor#BeltConveyorManufacturer#ConveyorManufacturerFaridabad#MaterialHandlingEquipment#IndustrialConveyors#FaridabadIndustry#ConveyorSystemsIndia#ManufacturingSolutions#FactoryAutomation#BeltConveyorIndia#CustomConveyor#IndustrialMachinery#MadeInIndia#EngineeringSolutions#VashnaviConveyor#FaridabadManufacturers#AutomationEquipment#HeavyDutyConveyors#SmartMaterialHandling#ConveyorBeltSystem

0 notes

Text

Gastro Line’s Complete Guide to Kombidampers and Kjevlemaskiner in Norway

Introduction: Why Modern Norwegian Kitchens Trust Gastro Line

Norway’s food-service sector is booming—from Oslo’s Michelin-starred dining rooms to Bodø’s neighbourhood bakeries. Yet rising labour costs and demanding guests mean chefs need smarter equipment that delivers consistent results. Gastro Line, a leading supplier of premium catering technology, meets that need with two powerhouse categories:

Kombidamper (combi steam ovens) for cooking flexibility

Kjevlemaskin (dough sheeter) for flawless pastry, pizza, and flatbread production

This 1 200-word guide explains how each machine works, why it matters for Norwegian kitchens, and how Gastro Line tailors solutions that lift both food quality and bottom-line performance.

Understanding the Kombidamper: The All-in-One Oven Revolution

A Kombidamper combines convection heat and steam in a single cabinet, letting chefs roast, bake, steam, poach, or regenerate with pinpoint precision.

How a Kombidamper Works

Dry Heat Mode – Hot air circulates for even browning

Steam Mode – Saturated steam protects texture and nutrients

Combi Mode – Adjustable humidity delivers crispy outsides and juicy centres

Key Components

Boiler or Injection Steam Generator

Variable-speed Fan System

Humidity & Core-Temp Sensors

Touchscreen Programmable Controls

Benefits for Norwegian Kitchens

Benefit Impact on Menu & Margin 30–50 % Faster Cooking Turn tables quicker and lower energy costs Uniform Quality From cod loin to reindeer roast—same result, every service Reduced Shrinkage Up to 20 % less weight loss on proteins Multilevel Cooking Different dishes in one cycle—no flavour transfer Energy Efficiency Modern units exceed EU Ecodesign standards, ideal for Norway’s high electricity prices

Choosing the Right Gastro Line Kombidamper

Sizing by GN Capacity

6 × GN 1/1 – Perfect for café or bar kitchen

10 × GN 1/1 – Mid-size brasserie or school canteen

20 × GN 2/1 Roll-In – High-volume catering, cruise ships

Boiler vs Injection

Feature Boiler Injection Steam Volume High, constant Quick bursts Maintenance Needs descaling Simpler plumbing Ideal Use Sous-vide, bakery All-round cooking

Smart Features Worth Investing In

USB/Wi-Fi Recipe Upload for chain consistency

Automatic Washing System to save labour and water

Delta-T Slow Roast function for overnight cooking

Kjevlemaskin: The Secret to Perfect Dough in Seconds

A Kjevlemaskin automates rolling dough to a uniform thickness, crucial for pizzas, croissants, lefse, and lomper beloved across Norway.

How a Dough Sheeter Works

Two precision-ground rollers compress dough as an adjustable gap sets thickness. A conveyor feeds and returns the dough, eliminating manual rolling pins and inconsistent results.

Advantages for Bakeries & Pizzerias

Consistency – Every base or pastry sheet identical, improving bake quality

Speed – Up to 250 pcs/hour vs 40 pcs by hand

Labour Savings – One operator instead of two, freeing staff for toppings or fillings

Reduced Waste – Accurate portioning cuts flour and dough scraps

Types of Kjevlemaskiner Offered by Gastro Line

Bench-Top Sheeter – Fits small bakery counters

Floor-Standing Fold-Up – Large capacity, folds when not in use to save space

Automatic Pizza Press – Heated plates pre-bake bases for quick-service outlets

Integrating Kombidamper and Kjevlemaskin into Your Workflow

Example: Craft Pizza Concept in Bergen

Kjevlemaskin portions 180 g dough balls into perfect 32 cm bases in 7 seconds each.

Bases pass directly to Kombidamper in 300 °C combi-dry mode for 90-second par-bake.

During service, pizzas finish in 60 seconds on pizza stone accessory—total cook line footprint under 4 m².

Example: Hotel Breakfast in Tromsø

Overnight oats, eggs, and bacon batch-cooked in Kombidamper, ready at 06:00.

Kjevlemaskin rolls fresh cinnamon-bun dough the night before; pastries bake off at 05:30 automatically.

Result: 15 % labour saving and a breakfast spread that delights international guests.

Sustainability and Cost‐Control—Critical for Norway’s Hospitality

Norway’s strict environmental policies and high wages mean equipment choices have financial and CSR ramifications.

Energy and Water Consumption

A modern Gastro Line Kombidamper with heat-recovery uses up to 15 % less kWh and 30 % less water than legacy steam ovens.

Food Waste Reduction

Precise humidity control minimises over-cooking.

Dough sheeter allows exact portion control, cutting ingredient waste by up to 8 %.

The Circular Economy

Gastro Line offers buy-back and refurbishment programmes ensuring equipment lives a second life, aligning with Norway’s circular-economy targets for 2030.

ROI Calculator: When Does Upgrading Make Sense?

Parameter Manual Process With Kombidamper & Kjevlemaskin Staff Hours/Week 50 32 Electricity (kWh/Week) 420 330 Food Waste (kg/Week) 18 9 Annual Saving (Estimate) – NOK 240 000

Payback on a midsize package (NOK 210 000) is under 11 months—before factoring happier chefs and improved guest reviews.

Service, Training, and Support—The Gastro Line Promise

On-Site Survey – Assess ventilation, power, water, and workflow.

Installation & Commissioning – Certified technicians across all Norwegian counties.

Chef Training – Hands-on sessions covering sous-vide, bakery, allergen control.

24/7 Hotline & Remote Diagnostics – Downtime minimised via cloud-connected units.

Preventive Maintenance Plans – Fixed annual cost, includes gaskets, filters, and descaling.

Compliance with Norwegian Regulations

NS-EN 60335 Safety Standards

Mattilsynet Food-Safety Guidelines for cleaning cycles and HACCP

Ecodesign & Energy Labelling compliant, easing Enova funding applications

Gastro Line handles all certification paperwork so you stay focused on cooking.

Future-Proof Features: What’s Next?

AI-Driven Cooking Algorithms – Auto-adjust time and humidity based on load.

Recycled Stainless-Steel Cabinets – 70 % post-consumer content by 2027.

Hydroloop Steam – Captures and reuses up to 90 % of condensation.

Investing today secures compatibility with tomorrow’s tech updates, available via firmware.

Conclusion: Elevate Your Kitchen with Gastro Line

Whether you operate an artisan bakery in Stavanger, a seafood bistro in Ålesund, or a large catering facility in Oslo, upgrading to a Kombidamper and Kjevlemaskin from Gastro Line transforms efficiency, consistency, and sustainability. From flawless cinnamon buns to perfectly steamed salmon, these machines unlock creativity while safeguarding profit.

0 notes

Text

Boosting Warehouse Efficiency with Modern Material Handling Equipment

In the dynamic world of logistics, warehouses are under constant pressure to meet the demands of e-commerce, rapid order fulfillment, and cost efficiency. The key to staying competitive lies in optimizing operations, and modern material handling equipment is at the heart of this transformation. By automating tasks, enhancing safety, and maximizing space, these advanced tools drive productivity and streamline workflows. This blog explores how innovative equipment, such institu as that offered by Maini Materials Movement, revolutionizes warehouse efficiency.

The Role of Material Handling Equipment

Material handling equipment encompasses a range of tools designed to move, store, and manage goods within a warehouse. From forklifts to automated guided vehicles (AGVs), these systems reduce manual labor, minimize errors, and improve worker safety. By integrating advanced technologies like sensors, barcode scanners, and warehouse management system (WMS) compatibility, modern equipment ensures seamless operations, enabling warehouses to handle higher volumes with precision.

The benefits are clear: faster throughput, reduced operational costs, and safer work environments. Equipment like the maini golf cart exemplifies this, offering compact, maneuverable solutions for navigating tight spaces while transporting goods efficiently. Such tools are critical for meeting the demands of today’s fast-paced supply chains.

Key Types of Modern Material Handling Equipment

1. Forklifts

Forklifts remain a cornerstone of warehouse operations, capable of lifting and moving heavy loads with ease. Modern variants, such as counterbalance and reach trucks, are designed for specific tasks like stacking pallets on high racks. Their versatility maximizes vertical space, a critical factor in crowded warehouses.

2. Platform Trolleys

Platform trolleys are simple yet effective for short-distance transport. Their compact design allows navigation through narrow aisles, reducing manual lifting and boosting productivity. Durable and cost-effective, trolleys enhance workflow in space-constrained environments.

3. Conveyor Systems

Conveyor systems automate the movement of goods across the warehouse, minimizing manual handling. Roller, belt, and gravity conveyors handle everything from small packages to large pallets, accelerating order fulfillment in high-volume operations. Their continuous flow reduces bottlenecks and damage risks.

4. Pallet Jacks

Pallet jacks, available in manual or electric models, are ideal for moving palletized loads over short distances. Low-profile and narrow-aisle variants cater to tight spaces, ensuring efficient transport and easy access to inventory.

5. Automated Guided Vehicles (AGVs)

AGVs represent the cutting edge of automation. Guided by sensors or lasers, these robotic vehicles transport goods autonomously, interacting with other equipment to optimize workflows. They reduce human intervention, making them perfect for repetitive tasks in large warehouses.

6. Racking and Shelving Systems

Modern racking systems, such as selective or push-back racks, enhance storage efficiency. By organizing inventory and utilizing vertical space, they ensure quick access and replenishment, critical for high-turnover operations.

Benefits of Modern Equipment

1. Enhanced Productivity

Automation and streamlined processes allow warehouses to process more orders in less time. Equipment like the maini golf cart speeds up internal transport, enabling faster picking and packing.

2. Improved Safety

Advanced safety features, such as collision sensors and ergonomic designs, reduce workplace injuries. By eliminating heavy manual lifting, equipment protects workers from strain and accidents.

3. Space Optimization

Modern equipment maximizes both horizontal and vertical space. High-reach forklifts and compact trolleys ensure every square foot is used effectively, accommodating more inventory without expanding the warehouse footprint.

4. Greater Accuracy

Technologies like RFID and barcode scanning, integrated into conveyors and AGVs, improve inventory tracking. This reduces errors, ensuring accurate order fulfillment and real-time stock visibility.

5. Streamlined Workflows

Integration with WMS enables seamless coordination between receiving, storage, and shipping. This eliminates bottlenecks, ensuring smooth operations from start to finish.

Considerations for Implementation

Warehouse Layout: Assess aisle widths, ceiling heights, and storage configurations to select equipment that fits the space.

Load Requirements: Match equipment to the weight, size, and fragility of goods to ensure safe handling.

Training and Maintenance: Invest in staff training and regular maintenance to maximize equipment longevity and performance.

Scalability: Choose flexible solutions that can adapt to future growth, avoiding costly replacements.

Conclusion

Modern material handling equipment is a game-changer for warehouses aiming to boost efficiency and meet modern logistics demands. From forklifts to AGVs, these tools automate tasks, enhance safety, and optimize space, driving productivity and cost savings. Solutions from providers like Maini Materials Movement, including versatile options like golf carts, empower warehouses to navigate complex challenges with ease. By carefully selecting equipment tailored to your layout and needs, you can transform your warehouse into a high-performance hub of efficiency and reliability.

0 notes

Text

Automated Material Handling Solutions for Warehouses in UK

Warehousing is changing fast in the UK. Rising demands, tight deadlines, and labour shortages make automation more essential than ever. Automated material handling solutions for warehouses in UK are no longer a luxury. They are becoming the backbone of modern supply chains. These systems offer speed, accuracy, and reduced human error. From conveyors and robots to AGVs and AS/RS, automation is transforming how goods move in and out of UK warehouses.

Automated Material Handling Solutions for Warehouses in UK Let's explore how these solutions work, their benefits, and what makes them vital for warehouse operations across the UK.

Importance of Automated Material Handling Solutions for Warehouses in UK

Manual processes are slow and error-prone. In large warehouses, this leads to delays, bottlenecks, and damaged goods. Automated material handling solutions for warehouses in UK help solve these problems. They move materials quickly, with precision. They reduce the need for manual labour. This boosts efficiency, especially in sectors like e-commerce, retail, and third-party logistics. Automation also helps warehouses meet growing expectations. Customers want faster deliveries. Retailers want lower costs. Automation makes both possible.

Components of Automated Material Handling Solutions for Warehouses in UK

Conveyor Systems Conveyors transport goods across various zones of the warehouse. They come in different types—roller, belt, and chain conveyors. In UK warehouses, powered conveyors are often used in pick-and-pack areas. They are fast and ideal for repetitive movement of items. Automated Guided Vehicles (AGVs) AGVs are driverless transport systems. They follow pre-set paths or use sensors to navigate. They are useful in large UK distribution centres. They reduce walking time for staff. They are also safer, as they avoid collisions and follow strict routes. Automated Storage and Retrieval Systems (AS/RS) AS/RS systems are robotic arms or shuttles that place or pick goods from storage racks. They use vertical space better than manual systems. In urban UK warehouses with limited space, AS/RS help save floor area. They also allow 24/7 operation. Robotic Picking Systems These systems use robotic arms with grippers or suction cups. They pick items from bins and place them into totes or boxes. They often work with AI to recognize items. In the UK, where online shopping is massive, robotic pickers help with fast order fulfillment. Warehouse Management Systems (WMS) A WMS controls all automation in the warehouse. It manages inventory, coordinates machines, and tracks goods. It connects with ERP systems for better control. WMS also helps reduce human oversight by automating tasks like stock counts and reorder alerts.#AutomatedMaterialHandling, #WarehouseAutomationUK, #LogisticsSolutions, #MaterialHandlingEquipment, #SmartWarehousing, #AutomationInLogistics, #UKWarehouses, #IndustrialAutomation, #WarehouseEfficiency, #RoboticsInWarehousing, #SupplyChainInnovation, #AutomationTechnology, #WarehouseSolutions, #HandlingSystems, #FutureOfWarehousing Read the full article

#AutomationSystems#IndustrialTechnology#Logistics#MaterialHandling#OperationalEfficiency#Robotics#SmartLogistics#SupplyChain#UKWarehousing#WarehouseAutomation

0 notes

Text

Why Roller Conveyors Are Vital for Modern Material Handling: A Guide for Buyers

Introduction

In today’s fast-paced industrial landscape, efficiency is everything. From warehouses and logistics centers to manufacturing units and packaging lines, seamless material handling can significantly boost productivity. This is where roller conveyors come in—offering a durable, cost-effective, and low-maintenance solution for transporting goods. As leading roller conveyor manufacturers, we aim to educate customers on how these systems can revolutionize your operations.

What Are Roller Conveyors?

Roller conveyors are material handling systems that use cylindrical rollers mounted in frames to transport items. They come in various types, including:

Gravity Roller Conveyors – Rely on gravity to move items.

Powered Roller Conveyors – Use motors to drive rollers.

Flexible Roller Conveyors – Adjustable and mobile for dynamic needs.

Each type serves a specific purpose depending on your facility layout, product type, and workflow.

Key Benefits of Roller Conveyors

1. Increased Efficiency

Roller conveyors streamline operations by automating the transport of materials, reducing the need for manual labor and cutting down on transport time.

2. Low Maintenance

These systems are known for their reliability and minimal upkeep. With proper installation and occasional servicing, roller conveyors can run smoothly for years.

3. Cost-Effective

From installation to operation, roller conveyors provide great ROI, especially for businesses handling large volumes of goods.

4. Customizable Design

Manufacturers offer tailor-made solutions to meet unique requirements—whether you need a straight conveyor, curved section, or integrated solution with sensors and controls.

Choosing the Right Roller Conveyor Manufacturer

When investing in a roller conveyor system, selecting the right manufacturer is crucial. Here’s what to look for:

Experience & Expertise: A proven track record in delivering high-quality, durable systems.

Customization: Ability to design according to specific operational needs.

After-Sales Support: Reliable customer service and technical support.

Quality Materials: Use of robust materials for long-lasting performance.

Compliance: Systems that meet international safety and quality standards.

Industries That Benefit Most

Roller conveyors are widely used across industries such as:

E-commerce and Warehousing

Automotive and Manufacturing

Food & Beverage

Pharmaceuticals

Packaging & Distribution

Each industry benefits from tailored conveyor solutions that ensure smooth material flow and reduced downtime.

Future Trends in Roller Conveyors

As automation and Industry 4.0 continue to evolve, roller conveyors are also adapting. Expect features like:

IoT-enabled Monitoring

Automated Sorting Systems

Energy-efficient Motors

Modular & Scalable Designs

Manufacturers who stay ahead of these trends can offer cutting-edge solutions that future-proof your operations.

Conclusion If you're planning to upgrade or install a material handling system, roller conveyors are a smart, scalable, and economical choice. Partnering with the right roller conveyor manufacturer ensures you get a system tailored to your workflow—backed by expert advice, customization, and after-sales support.

Looking to enhance your operational efficiency? Contact us today to learn how our roller conveyor solutions can transform your facility.

0 notes

Text

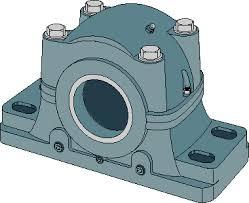

Difference between Plummer Block vs. Pillow Block for industrial use

Introduction

In industrial machinery, supporting rotating shafts is critical for smooth operation and long service life. Two commonly used bearing housings for this purpose are plummer blocks and pillow blocks. While they might look similar, each has unique features suited for different industrial applications.

At Nisuka Industries, a trusted conveyor gearbox manufacturer in India, we understand the importance of using the right components to maintain reliable, efficient operations. In this blog, we explain the key differences between plummer blocks and pillow blocks for industrial use.

What is a Plummer Block?

A plummer block is a type of bearing housing designed to support a rotating shaft using a bearing inside it. It is usually made from heavy-duty materials like cast iron or cast steel, providing strong support for shafts operating under high loads and severe conditions. Plummer blocks are commonly used in heavy industries where durability, strength, and the ability to handle misalignment are essential.

These housings can accommodate spherical roller bearings or ball bearings and are often fitted with seals to protect against dust, dirt, and moisture.

Key features of Plummer Blocks:

High load-bearing capacity

Suitable for harsh environments

Can handle shaft misalignment

Designed for easy maintenance

What is a Pillow Block?

A pillow block is also a bearing housing that holds a rotating shaft but is usually designed for lighter-duty applications compared to plummer blocks. Pillow blocks are often made from lighter materials like pressed steel or cast iron and typically house ball bearings.

They are ideal for systems that operate at moderate speeds and loads, such as conveyors, agricultural equipment, and light industrial machinery.

Key features of Pillow Blocks:

Easy installation

Lower load-bearing capacity

Generally used in cleaner environments

Cost-effective for lighter applications

When to Choose a Plummer Block?

If your application involves high loads, high speeds, or tough environmental conditions (such as mining, heavy conveyor systems, cement plants, or crushers), a Plummer block is the better choice. At Nisuka Industries, as a trusted SMSR gearbox manufacturer in India, we often recommend Plummer blocks for industries that need robust and heavy-duty solutions to keep their production lines running smoothly.

Plummer blocks also allow for easy bearing replacement without disturbing the shaft alignment, saving downtime during maintenance.

When to Choose a Pillow Block?

If you are working with lighter loads and relatively clean environments, such as food processing units, small conveyors, packaging lines, or agricultural machinery, a pillow block is a cost-effective and practical solution. Pillow blocks are quick to install, easy to replace, and ideal for machines that don't experience extreme working conditions.

Many of our customers who use our conveyor belt tensioner manufacturer in India products in smaller setups also prefer pillow blocks due to their easy integration with conveyor systems.

Importance of Choosing the Right Bearing Housing

Choosing the wrong type of bearing housing can result in increased wear and tear, frequent breakdowns, and costly downtime. By selecting the correct housing — whether a plummer block or a pillow block — industries can ensure:

Better load distribution

Reduced maintenance costs

Longer equipment life

Smoother machine operation

As a leading conveyor gearbox manufacturer in India, we always guide our customers to select components that match their specific operational needs.

Main Differences Between Plummer Block and Pillow Block

Plummer blocks and pillow blocks differ in several key features that make them suitable for different industrial applications. When it comes to load capacity, plummer blocks are designed for high-load conditions, whereas pillow blocks are built to handle moderate to low loads. In terms of material, plummer blocks are constructed from heavy-duty cast iron or cast steel, giving them the strength needed for tough environments, while pillow blocks are typically made from cast iron or pressed steel, making them lighter and more suitable for less demanding applications.

The application areas for each also vary significantly. Plummer blocks are commonly used in heavy industries such as mining, cement production, and crushers, where equipment is exposed to extreme stress and harsh working conditions. In contrast, pillow blocks are used in light to medium industries, including conveyor systems and agricultural machinery, where the operational environment is more controlled. Speaking of environments, plummer blocks are built to withstand harsh, dusty, and wet conditions, whereas pillow blocks perform best in cleaner, indoor, or semi-protected environments.

When it comes to the type of bearings used, plummer blocks are versatile and can house spherical roller bearings or ball bearings, making them ideal for handling misalignment and heavy stresses. Pillow blocks, on the other hand, mostly use ball bearings, which are sufficient for moderate operational loads. Maintenance needs also differ; plummer blocks require regular maintenance to ensure longevity and optimal performance, especially given the tough conditions they face. Pillow blocks, by comparison, require minimal maintenance and are easier to manage in routine operations.

Finally, the cost is an important distinguishing factor. Plummer blocks are generally more expensive because of their robustness, high load capacity, and durable construction. Pillow blocks are a more economical choice, offering an affordable solution for applications that do not demand heavy-duty performance.

Nisuka Industries – Your Trusted Partner

At Nisuka Industries, we don’t just manufacture high-quality gearboxes and conveyor accessories; we also guide our customers in choosing the right mechanical components for their applications. As a reputed Shaft mounted gearbox manufacturer in India and a supplier of conveyor belt tensioner in India, we know that even small choices like the correct bearing housing can make a big difference in system performance.

We offer:

Expert consultation for selecting plummer blocks or pillow blocks

High-quality gearboxes for conveyor systems

Durable tensioning solutions to extend belt and bearing life

Reliable after-sales service and support

Our mission is to deliver complete, reliable, and efficient solutions to industries across India and beyond.

Conclusion

Both plummer blocks and pillow blocks are essential components in industrial machinery, but their applications differ based on load, environment, and operational needs. Plummer blocks are the preferred choice for heavy-duty, harsh environments, while pillow blocks are ideal for lighter, cleaner operations.

If you are setting up or upgrading your industrial machinery, trust Nisuka Industries — the leading conveyor gearbox manufacturer in India, SMSR gearbox manufacturer in India, and supplier of conveyor belt tensioner in India — to provide the right advice, products, and support for your success.

#what is Plummer block#plummer block manufacturer in India#shaft mounted gearbox manufacturer in india

0 notes