Don't wanna be here? Send us removal request.

Text

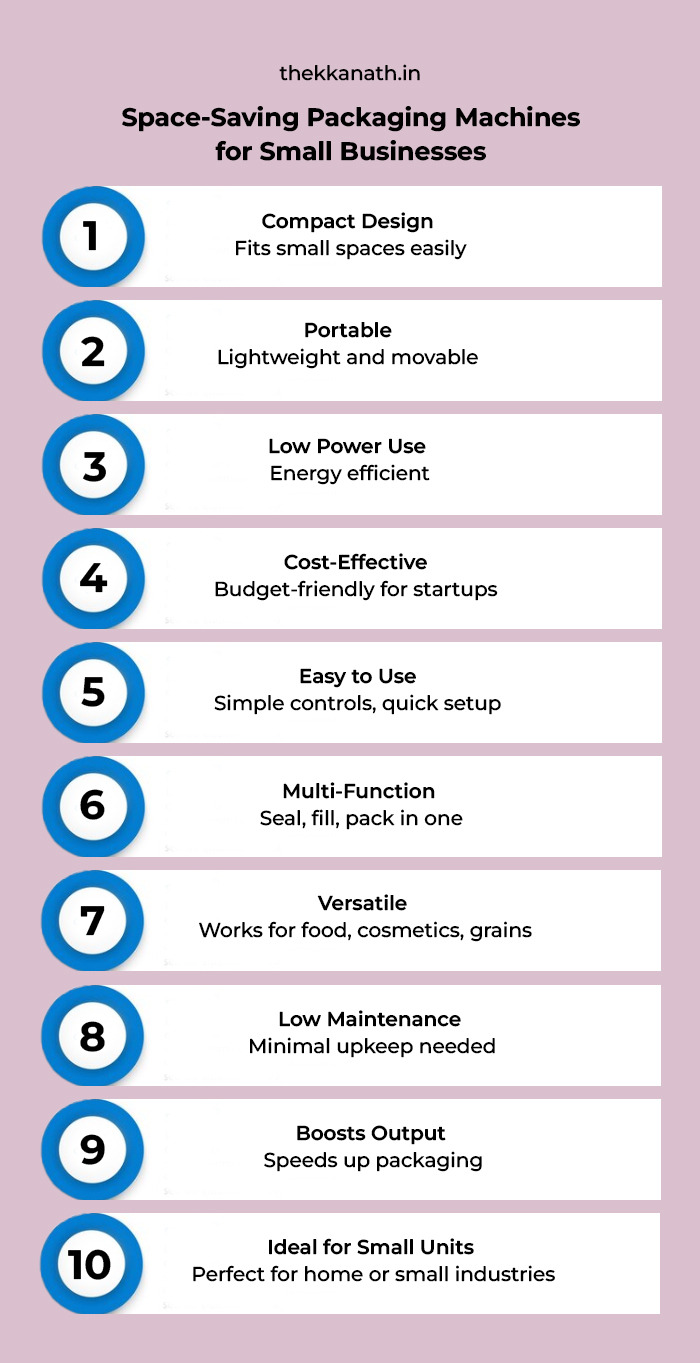

Space-Saving Packaging Machines for Small Businesses

Designed with small-scale operations in mind, our compact packaging machines offer powerful performance without taking up valuable space. Whether you're running a home-based business or a small industrial unit, these machines are the ideal solution to streamline your packaging process.

#technology#packing equipments#packing machine#packing supplies#packing manufacture#packing solution

0 notes

Text

Boost Your Packaging Efficiency with T-Tech’s Wrapping Machine

Are you wasting time and effort on manual wrapping that’s slow, messy, and tiring? It's time to switch to a smarter, faster solution. T-Tech’s advanced wrapping machine is engineered to deliver high-speed, damage-free packaging with professional consistency. Boost your productivity, reduce labor, and give your products the neat, secure finish they deserve. Tired of going round and round with tangled hands? Then switch to a smarter choice... T-Tech's advanced wrapping machine is designed for fast and damage-free operation. Learn more at https://thekkanath.in/

#packing machine#technology#packing equipments#packing supplies#packing manufacture#packing solution

0 notes

Text

Achieve efficient bulk packaging in minutes with T-Tech’s high-performance filling machine—engineered for precision, speed, and hassle-free operation." Explore more

#packing machine#technology#packing equipments#packing manufacture#packing supplies#packing solution

0 notes

Text

Ways to Reduce Packaging Costs Using Smart Machines

Possible Packaging is important for making money. You need to spend less on packaging if you want to make more money. Possible Businesses can save money and time by using smart packaging machines that can do the work by themselves. These machines are smart because they can think and act on their own. They can also make sure that the products are good and safe. These machines combine precision, speed, and adaptability, transforming packaging from a cost center into a competitive advantage. .

1. Precision Engineering Minimizes Material Wastage

Packaging machines that are smart have control systems that make sure the packages are the right size, have the right seal, and are cut correctly. Possible - These machines help manufacturers save money by using less film, cutting film more accurately, and using smaller packaging. For instance, if your machine cuts 5 mm less film from each pack in 100,000 packs, the total amount of film saved is significant. In Kerala, many companies using pouch filling or form-fill-seal Packaging Machines in Kerala report material cost reductions of up to 10% just through precision optimization. .

2. Automated Systems Reduce Labor Dependence

Packaging departments have trouble finding enough workers, paying them well, and teaching them new skills. Smart machines replace manual steps like sealing, labeling, coding, and inspection with automated processes that run continuously. This makes it easier to use fewer operators and avoid mistakes. Automation helps businesses save money on workers and also makes sure their products or services are the same every time. As labor costs continue to rise, the ROI on intelligent automation grows year after year. .

3. Faster Output Leads to Lower Unit Costs.

Possible - Packing quickly helps you make more units in an hour and spend less money on each unit. Machines that work very quickly and smartly can make things 2 to 5 times faster than when people or other machines do them. Possible Manufacturers can make more products faster with this tool. They can fill bigger orders without hiring more workers or working longer hours. What is the overall impact. Packaging faster, using less electricity for each product, and making the production process more efficient. Speed is a major selling point for high-performance Packaging Machines in Kerala, especially in food and FMCG industries. .

4. Built-in Quality Control Reduces Product Rejection

Possible - When a pack is not sealed properly, has no label, or has the wrong code, it costs money to fix it, throw it away, or damage the brand. Smart machines have built-in features to ensure quality, such as sensors to find air leaks, vision systems to align labels correctly, and digital coders for precise printing. Possible These systems help make sure that every product is good enough to sell and that there are no mistakes. This reduces material loss, re-packing effort, and penalties related to compliance failures, especially in export-oriented sectors. .

5. Multi-Product Flexibility Reduces Machine Investment

Instead of buying multiple machines for different pack sizes or product types, modern smart packaging systems are designed to be flexible. With adjustable settings, changeable molds, and programmable controls, one machine can handle multiple SKUs. This saves money, time, and work for the equipment. Many advanced Packaging Machines in Kerala are built for multi-purpose use—making them ideal for small to mid-sized businesses managing multiple product lines with limited floor space. .

6. Predictive Maintenance Prevents Costly Downtime

When something unexpected happens in the production process, it can cost a lot of money. Some machines can tell when they need to be fixed before they break down. They use special devices to check how they are working right now. They alert operators about worn parts, unusual vibrations, or overheating before it leads to failure. This way of taking care of things before they break helps save money, time, and trouble later. Predictive analytics is fast becoming a standard feature in high-end Packaging Machines in Kerala, boosting uptime and equipment life. .

7. Energy-Efficient Operation Lowers Utility Bills

Possible - Packaging machines work for a long time, sometimes even more than a day. Energy-efficient machines designed with smart drives, motion control, and auto shutoff modes consume less electricity.Rephrase Factories with many packaging lines can save a lot of money on their monthly utility bills. Possible Smart machines help save energy by using less air, water, or steam for different kinds of packaging. This makes the machines cheaper to run. Possible - Kerala is a place where people care about the environment and want to save money. - Some companies in Kerala are using machines that use less electricity to package their products.

conclusion

By reducing waste, increasing speed, and optimizing resource usage, smart packaging machines do more than just automate—they unlock cost savings at every step. For manufacturers aiming to remain competitive in 2025 and beyond, investing in smart systems is not an option, but a necessity. If you're looking to reduce packaging costs while maintaining high production standards, it’s time to explore the new wave of Packaging Machines in Kerala that are making a real difference in modern industries.

#packing machine#technology#packing equipments#packing manufacture#packing supplies#packing solution

0 notes

Text

Packaging errors can lead to product damage, waste, and delays. Common issues like loose seals, label misalignment, incorrect filling, and material jams often arise from improper machine settings or lack of maintenance. Quick fixes include adjusting heat and pressure, calibrating labels, using the correct materials, and verifying coding setups. By identifying these problems early and applying simple adjustments, you can improve efficiency and ensure consistent packaging quality.

Learn more: https://thekkanath.in

#packing machine#packing equipments#packing manufacture#technology#packing supplies#packing solution

0 notes

Text

Common Mistakes to Avoid While Operating a Batch Coding Machine

Batch coding machines are essential for adding stacking numbers, manufacturing data, expiration data and other important details about product packaging. While these machines support quick and accurate labeling, small errors during operation can lead to major issues such as pressure errors, damaged products, and unexpected downtime. To make the most of the batch coding process, it is important to understand and avoid the mistakes that many operators make frequently without their knowledge.

1. Bad Machine - Setup

One of the easiest ways to create pressure problems is to set up the machine accidentally. If your machine is not properly aligned or you are in a hurry to set up, you can stack it with bent, weak or missing stacking code. Insufficient setup can slow production and lead to product waste. If you take the time to carefully place your machine and check your settings before you start, you can save the stack from drg and correcting avoidable errors.

2. It is attractive to save money by choosing cheaper inks and ligaments using inferior inks and ligaments, but this often leads to poor quality pressure. Low-quality inks can fade quickly, slightly fill, or even remove the packaging area. Additionally, the underlying ligaments can quickly wear out and leave residue on the machine, causing damage over time. Always use quality inks and ribbons approved for specific machine models for clean and durable prints.

3. Ignore Regular Maintenance

Regular maintenance is important to keeping the stacking coding machine in top condition, but many operators delay or skip this step, especially during busy production periods. Dust, ink remains, and worn parts accumulate, slowing down the machine or producing poor prints. Simple tasks like cleaning printheads, lubricating moving parts, and replacing worn components can exploit a significant contribution to the ability to prevent unexpected failures and costly repairs.

4. Incorrect temperature and pressure settings

Different packaging materials require different temperature and pressure settings to obtain clean and permanent pressure. If these settings are too high, it can damage the package. If you are too low, the ink may not be glued properly, which will lead to weak or incomplete batch cords. Always adjust the machine settings according to the materials used before starting full production. Calling the settings from the beginning will help you avoid product waste and ensure clear pressure.

5. Lack of proper user training

If untrained employees deal with the machine, the risk of error increases. Incorrect charging, incorrect setup, and bad handling can affect production and lead to mistakes that can damage the machine. It is important for all operators to see how to set up, run and maintain a batch coding machine. Regular training helps your team stay up to date and operate your equipment safely and correctly.

6. Do not check material compatibility

Not all packaging materials work well with all inks. Some surfaces may not hold the ink properly. This means that batch codes can quickly become confused or fade. Always test the ink in the packaging material to ensure it is adhered correctly and remains readable before running a large batch. By checking material compatibility in advance, you can avoid the results of poor quality and wasted materials before dealing with the results.

7. Weak quality control practices

Sometimes, stacking codes are only checked during production, which can allow false prints to slip through. Without regular, detailed quality tests, you may not notice typos, missing codes, or placement errors until it's too late. Creating a powerful quality control system that includes frequent and careful inspections will ensure that every product leaving the line has a clear and properly printed batch code.

Conclusion

Batch Coding Machines are reliable tools when used correctly, but they need proper setup, good materials, regular care, and skilled operators to perform at their best. Avoiding these common mistakes can help keep your machine running smoothly and your production line efficient. Paying attention to small details, like using the right ink, keeping the machine clean, and carefully monitoring print quality, can make a big difference in your output and product presentation.

#packing machine#technology#packing manufacture#packing equipments#packing supplies#packing solution

0 notes

Text

Automating packaging improves speed, accuracy, safety, and cost-efficiency while reducing waste. It easily scales with production growth, making it ideal for modern industries. Learn more: https://thekkanath.in

#packing machine#technology#packing equipments#packing manufacture#packing supplies#packing solution

0 notes

Text

Top 5 Industries That Benefit from Manual Food Tray Sealers

In today's competitive market, proper packaging is extremely important to ensure product safety, freshness and quality. Manual hood connection sealers provide a simple, reliable and inexpensive packaging solution that meets these requirements in several industries. These machines are ideal for businesses that require rapid on-demand sealing without investing in complex or automated systems. It provides flexibility for various tray size seals, helping businesses maintain hygiene and efficiency. Packaged Meals and Tiffin Service Providers

Packaged Meals and Tiffin Service Providers rely on manual food connection seals for daily packaging modes. These businesses provide fresh food in their offices, homes and schools, and should ensure that all meals are safely packed to prevent leaks and maintain hygiene. Manual sealers with manual food sealers allow you to quickly close individual tablets of different sizes, making it easier to use small, bulk orders efficiently. Enclosed tablets also help to maintain the heat and freshness of the food during delivery and provide a better customer experience.

2. Small food processing unit to prepare snacks, sweets, baked goods, semi-bo foods

Manual food shell seals are very convenient. These companies often need flexible packaging solutions that allow you to manage a variety of tablet types and sizes all day long. Manual tablet seals allow for quick sealing of products such as samosas, schnitzellen, cakes, cookies and more, maintaining freshness and improving durability. These companies typically operate due to their low production capacity, so manual food connection sealers provide a budget (a friendly user-friendly packaging solution) that will continue to provide professional results.

3. Fresh product retailer and farmer market. The sealed packaging keeps the product clean, fresh and protected from external damage. It also reduces direct customer handling. This means that hygiene standards are maintained. Farmers and local sellers can quickly seal the sizes of different parts for retail ads and mass sales. Professional sealed tablets improve product presentations, make fruits and vegetables more attractive to customers and increase market value.

4. Shop supermarkets and packaging sections

Supermarkets and grocery stores use manual food shell seals on fresh foods to stuff meat, seafood, salads and fruits. In these busy environments where employees have to quickly pack their products for the shelf exhibition, daily stickers are needed every day. Manual tablet seals make this process quick, hygienic and flexible, allowing various product types and tray sizes to be sealed during the day. A sealed tablet helps to expand durability and ultimately reduces food waste and increases customer satisfaction.

5. Medical and Pharmaceutical Packaging Centers

The units for medical packaging and pharmaceutical facilities use manual sealing of food to pack sensitive objects such as medical kits, sterilization tools, diagnostic tools, and small laboratory samples. The sealing process provides a safe and operational package that protects the content from dust, moisture and contamination. For clinics, laboratories and small pharmaceutical companies, manual sealing sealers provide a convenient and affordable solution to meet packaging requirements. These machines ensure security and hygiene while handling smaller batch sizes, making them a practical option for medical applications.

Conclusion

Manual food tray sealers are versatile, simple, and essential for many industries. They offer reliable sealing that improves product safety, extends shelf life, and enhances packaging presentation without the complexity of automated machines.

Top Industries That Benefit:

Packaged Meal and Tiffin Service Providers

Small Food Processing Units

Fresh Produce Retailers and Farmers’ Markets

Supermarkets and In-Store Packaging Sections

Medical and Pharmaceutical Packaging Centers

If you are looking for a smart and cost-effective packaging solution, a manual food tray sealer can help streamline your packaging process and deliver secure, hygienic results. To explore reliable manual tray sealers, visit Thekkanath Technologies today.

#packing machine#packing equipments#technology#packing manufacture#packing supplies#packing solution

0 notes

Text

T-Tech's strapping machine ensures your goods stay safe, steady, and sealed. Secure every shipment with T-Tech for reliable protection and peace of mind.

Learn more: https://thekkanath.in/

#packing machine#technology#packing equipments#packing supplies#packing solution#packing manufacture

0 notes

Text

Top 5 Things to Consider Before Buying a Packing Machine

Purchasing a packing machine is a crucial choice that can substantially boost your production capabilities, decrease labor expenses, and optimize overall efficiency. Nevertheless, choosing the wrong machine can result in unforeseen issues like downtime, subpar packaging quality, or excessive expenses. To assist you in making an informed decision, here are the top five factors you should meticulously consider before purchasing a packing machine.

1: Type of product being packed.

The characteristics of your product play a significant role in determining the appropriate packing machine for your needs. Various products, including liquids, powders, granules, solids, or delicate items, necessitate machines equipped with specific functionalities. For instance, liquids necessitate accurate volume control, powders demand dust-proof enclosures, and food products typically require hygienic stainless-steel construction. Opting for a machine tailored to your product category guarantees superior performance and adherence to safety or industry regulations.

2: The production speed and output requirements.

Comprehending your manufacturing output is crucial. Packing machines are equipped with different speed capabilities to accommodate varying levels of production. Some are specifically designed for small-scale operations, while others have the capacity to handle large-scale packaging. When determining your packaging needs, it's crucial to calculate the required packaging rate, usually in packs per minute or hour, and select a machine that can handle both your current demand and future expansion. Purchasing a machine that is either too slow or too fast can result in inefficiencies and financial strain.

3: Compatibility of Packaging Material.

The machine's ability to work with various packaging materials is an important consideration. Depending on the specific requirements of your application, you may choose to utilize plastic films, paper, aluminum foil, or environmentally friendly alternatives. When selecting a machine, ensure that it is capable of processing your preferred materials without compromising the sealing quality or generating excessive waste. Furthermore, ensuring compatibility with materials that adhere to environmental or industry-specific standards can prevent the need for expensive modifications in the future.

4: Automation level, Usability.

Packing machines come in a range of automation levels, from manual and semi-automatic to fully automated systems. Fully automated machines can provide substantial labor savings and increased efficiency but may necessitate skilled operators and a higher upfront investment. Semi-automatic machines are more cost-effective and provide greater operational versatility, making them ideal for smaller enterprises or businesses with diverse product offerings. It's crucial to evaluate your workforce's skills and determine the most suitable level of automation to achieve your operational objectives.

5: Customer service and product availability.

While after-sales service and the availability of spare parts may not be the most exciting aspects, they are undeniably crucial for the smooth functioning of a vehicle. Even top-notch machines will require upkeep or periodic fixings. It is crucial to verify that the supplier provides reliable customer support, encompassing technical assistance, training opportunities, and readily accessible replacement parts. Having a reliable service partner can help reduce downtime and ensure that your production line operates efficiently.

ConclusionPurchasing a packing machine is a significant investment that demands thorough planning and thoughtful consideration. By carefully considering your product requirements, production goals, material preferences, automation needs, and service expectations, you can make an informed decision that enhances your business and sets you up for future success. Seeking guidance from packaging experts or reputable suppliers can provide additional assistance in choosing the most suitable solution that aligns with your unique requirements.

#packing machine#packing equipments#technology#packing manufacture#packing supplies#packing solution

0 notes

Text

Selecting the right packing machine is crucial for optimizing production and ensuring consistent packaging quality. This guide outlines the key factors to consider—from product type and packaging style to production volume, automation level, and long-term ROI. Whether you're packaging solids, liquids, or powders, evaluating efficiency, maintenance ease, compliance standards, and vendor support will help you make the best investment. Always test before buying to ensure the machine fits your specific needs. 👉 Learn more at: https://thekkanath.in/

#packing machine#technology#packing equipments#packing manufacture#packing supplies#packing solution

0 notes

Text

Fast, efficient, and reliable—our Strapping Machine guarantees secure and hassle-free packaging! With a 1-year warranty and spare parts availability, it's the perfect choice for seamless bundling. Get yours today!

Learn more:https://thekkanath.in/

#packing machine#packing equipments#technology#packing manufacture#packing supplies#packing solution

0 notes

Text

Packing machines are essential for efficient, consistent, and hygienic packaging across industries—but like any equipment, they can face issues. This infographic highlights five common problems in packing machines, along with quick, actionable fixes to minimize downtime and maintain productivity. Ideal for maintenance teams, machine operators, and production managers.

👉 For more insights, solutions, and advanced packaging technology, visit: https://thekkanath.in/

0 notes

Text

Top 5 Common Packing Machine Issues and How to Solve Them

1: Unreliable sealing.

This issue arises when package seals are fragile, compromised, or inconsistent in their appearance. It frequently occurs due to improper sealing temperature, uneven pressure, or contamination on the sealing surfaces. To resolve this issue, clean the sealing jaws, verify the appropriate temperature and pressure settings, and replace any worn or damaged sealing components.

2: Incorrectly installed software.

Incorrect product feeding or improperly adjusted guide rails can lead to packages being crooked or misaligned. Displacement of the conveyor belt is a frequent reason. To resolve this issue, carefully inspect the alignment of the conveyors and guide rails, making any necessary adjustments to ensure a seamless and uninterrupted flow of products into the machine.

3: Cleaning up any messes or mistakes.

Overfilled or underfilled packages—or any visible spillage—are typically caused by calibration mistakes, clogged nozzles, or incorrect fill timing. Fix this by recalibrating the fill volume, cleaning or replacing the nozzles, and adjusting the machine's timing to better match the packaging speed and size.

4. Film Tearing or Jamming

When the packaging film tears or jams, it typically indicates poor film quality, incorrect tension, or improper loading. To prevent this, use high-quality, machine-compatible film, load the roll correctly, and adjust the film tension. Also, inspect rollers and belts to ensure they are functioning properly.

5. Machine Stops Unexpectedly or Fails to Start

Frequent shutdowns or startup failures can stem from electrical issues, sensor malfunctions, or activated emergency stop buttons. To fix this, inspect the power supply, check and reset emergency stops, clean and test sensors, and review the control panel for any error codes or alerts.

Conclusion: Routine Maintenance is the Best Prevention

These issues can mostly be avoided through regular maintenance. Clean machine parts daily, inspect mechanical and electrical components weekly, and follow the manufacturer’s maintenance schedule. This keeps your packing machine running smoothly and minimizes downtime.

#packing machine#technology#packing manufacture#packing equipments#packing supplies#packing services

0 notes

Text

Types of Packing Machines & Their Applications

At TheKkanath, we offer a variety of packing machines, including VFFS, HFFS, filling, sealing, blister, cartoning, stretch wrapping, and batch coding machines. These are ideal for packaging powders, snacks, liquids, pharmaceuticals, and more. Visit thekkanath.in to explore our full range.

#technology#packing machine#machinery#sealingsolutions#sealingmachine#sealing the deal#packing manufacture#packing equipments

0 notes

Text

Choosing the Right Packaging Machine for Your Business Needs

In the new world of product delivery and changing manufacturing, packaging is no longer an end process—it's a strategic process that impacts efficiency, brand recognition, and consumer confidence. Whatever your business is—food and beverage, pharma, cosmetics, or consumer products—your packaging process must be smart, scalable, and sustainable. The starting point for that process is your packaging machine. Selecting the right one can save time, reduce expense, and enhance your bottom line. And if you're operating in South India, an investment in the right Packaging Machine in Kerala can provide local reliability and long-term payback.

The choice of a packaging machine begins with one question: What are you packaging? Every product category poses unique challenges. Delicate contents require careful treatment, powders need dust-free filling, and liquids need precise no-spill dispensing. A one-fits-all situation seldom applies. That's why consulting experts familiar with your product's nature and packaging behavior is crucial. Sourcing a specialty Packaging Machine in Kerala increases your chances of equipment matching your product's needs, cutting trial-and-error downtime.

Another important point to keep in mind is volume of production. If you’re a startup or small business, a semi-automatic or manual machine might be a cost-effective way to begin. But as your business scales, your equipment should keep pace. High-speed, fully automated machines can process thousands of units per day with minimal human input. They improve consistency and cut down on labor costs. Choosing a scalable Packaging Machine in Kerala means you won't outgrow your technology too soon—and leaves you with space to grow with confidence.

Let's not leave out packaging materials. From flexible pouches and films to rigid containers and biodegradable ones, packaging trends are moving towards innovation and sustainability. Your machine needs to be compatible with these materials and provide adjustable features such as packaging size, seal type, and temperature control. The appropriate Packaging Machine in Kerala will provide the flexibility to keep up with new materials, keeping your brand up-to-date and eco-friendly.

Perhaps the single most significant though frequently overlooked facet is post-sale support and servicing. Even with the best machine, periodic service and intermittent fixes are needed from time to time. Dealing with a proven local dealer means not just faster response to services and repair times but also an assurance of ready availability of spares, technical support, and future enhancements. By making the investment in a Packaging Machine in Kerala, you have an uncompromising ally who's at your call a stone's throw away—not across a continent.

In short, the selection of a suitable packaging machine is not simply a purchasing choice—it's a decision to make an investment in your company's future. It influences how you produce, your product's appearance on store shelves, and whether your customers enjoy the finished item. With well-planned intentions, expert counsel, and hardware built to satisfy your goals, your packaging procedure can be the key to a competitive advantage.

1 note

·

View note