#ConveyorTechnology

Explore tagged Tumblr posts

Text

Composite Roller Market Poised for Strong Growth with Rising Sustainability and Efficiency Requirements

The composite roller market is experiencing significant growth, driven by technological advancements, increasing demand from industrial sectors, and a shift towards lightweight, durable, and corrosion-resistant materials. Composite rollers, made from materials such as carbon fiber, fiberglass, and other polymer composites, are rapidly replacing traditional metal rollers in industries like mining, paper & pulp, textile, and packaging. Their ability to withstand harsh environments while offering reduced maintenance costs has positioned them as a superior alternative.

Market Overview

Composite rollers are essential components in conveyor systems. Unlike traditional steel rollers, they offer high performance under tough conditions due to their lower weight, resistance to corrosion, and minimal noise levels. These characteristics make them ideal for applications in industries where environmental conditions—such as moisture, chemicals, or dust—can degrade traditional materials quickly.

According to recent market research, the global composite roller market is projected to grow at a compound annual growth rate (CAGR) of over 5% between 2024 and 2030. This growth is attributed to a combination of industrial expansion and the growing emphasis on efficiency and sustainability.

Key Market Drivers

1. Rising Demand in the Mining Industry

Mining operations require conveyor systems that can operate efficiently in harsh environments. Composite rollers are lightweight and durable, making them easier to transport and install, especially in remote locations. Their resistance to corrosion and abrasion significantly reduces the frequency of replacements and maintenance, lowering operational costs.

2. Focus on Energy Efficiency

As industries strive to reduce energy consumption, the adoption of lighter materials in conveyor systems has become a key strategy. Composite rollers, due to their low weight, reduce the load on conveyor belts and motors, leading to decreased energy usage and operational expenses.

3. Growth in the Pulp & Paper and Packaging Industries

The pulp & paper industry, known for its wet and chemically intense processes, benefits from the use of corrosion-resistant composite rollers. In the packaging sector, fast-paced operations require reliable and low-maintenance components, and composite rollers fulfill this need effectively.

4. Regulatory and Environmental Considerations

Government regulations aimed at reducing carbon emissions and promoting the use of recyclable and environmentally friendly materials are pushing companies to adopt composite solutions. These regulations are particularly impactful in developed regions such as North America and Europe.

Regional Insights

Asia-Pacific dominates the global composite roller market, primarily due to rapid industrialization and infrastructure development in countries like China, India, and Southeast Asia. The mining and manufacturing sectors in this region are particularly strong drivers of growth.

North America and Europe follow closely, supported by technological innovation and a strong emphasis on sustainability. These regions are also witnessing increased investments in research and development for advanced composite materials.

Latin America and Africa are emerging markets with untapped potential, especially with the expansion of mining and logistics operations.

Challenges in the Market

Despite the many advantages, the market faces certain challenges. The initial cost of composite rollers is higher than that of conventional steel rollers. For cost-sensitive industries, this can be a barrier to adoption, even though the long-term operational savings often outweigh the upfront investment.

Additionally, limited awareness and technical know-how in developing regions may slow down the adoption rate. However, this gap is gradually closing as suppliers increase their outreach and educational efforts.

Key Players and Competitive Landscape

Several global and regional companies are actively engaged in the composite roller market. Major players include:

Lorbrand Composites

Sandvik AB

Flexco

FMC Technologies

Nepean Conveyors

These companies are investing in R&D to develop more advanced and cost-effective composite roller solutions. Partnerships, mergers, and acquisitions are also common strategies being employed to strengthen market presence and expand product offerings.

Future Outlook

The future of the composite roller market looks promising. With industries increasingly prioritizing efficiency, safety, and sustainability, the demand for composite solutions is expected to rise steadily. Technological advancements, including smart rollers with embedded sensors for real-time monitoring, are likely to further enhance product value and appeal.

Moreover, as raw material costs fluctuate and environmental concerns become more pressing, the shift from traditional metal components to composites is expected to accelerate.

Conclusion

The composite roller market is on an upward trajectory, fueled by a combination of industry demand, regulatory support, and material innovation. As companies seek to modernize their operations and reduce environmental impact, composite rollers are set to become a key component in the future of industrial automation and material handling.

#CompositeRollerMarket#IndustrialInnovation#ManufacturingTrends#IndustrialAutomation#ConveyorTechnology

0 notes

Text

Upgrade your industrial operations with Lakhotia Conveyor Belts! Designed for maximum efficiency, durability, and safety, our belts are engineered to handle demanding environments with ease. Keep your processes running smoothly and safely with our reliable conveyor solutions.

📲 Contact Us Today

☎️ Phone: +919025194360

📧 Email: [email protected]

🌐 Website: www.lakhotiaindia.in

#ConveyorBeltBenefits#IndustrialEfficiency#LakhotiaBelts#HeavyDutyConveyor#WorkplaceSafety#IndustrialSolutions#DurableBelts#ProductivityBoost#ConveyorTechnology#ReliableTransport

0 notes

Text

Granule Loading Conveyor - VGA Automation

VGA Automation granule loading conveyor is a mechanical system used to transport granular materials from one location to another, typically within industrial or manufacturing settings. These materials can include grains, pellets, or other small particulate substances.

https://www.youtube.com/@vgaautomation7482 https://vgaautomation.blogspot.com/

#VGAAutomation#VGApackingmachine#VGA#vgaautomationGranuleLoadingConveyo#vgaGranuleLoadingConveyo#GranuleLoadingConveyo#ConveyorSystems#IndustrialEquipment#FactoryAutomation#vgaprocessingmachine#packingmachine#processingmachine#GranuleConveyor#IndustrialConveyor#ProductionLine#ConveyorTechnology#MaterialHandling#GranularMaterials#Warehousing#MaterialTransfer

1 note

·

View note

Text

Conveyor Systems Market Forecast 2024 to 2032

Conveyor systems are mechanical handling equipment that are used to move materials, products, and goods from one location to another within a controlled and efficient manner. They are widely used in various industries, including manufacturing, logistics, distribution centers, mining, agriculture, and more. Conveyor systems offer numerous benefits, such as increased productivity, reduced manual labor, improved safety, and optimized material handling processes.

The Conveyor Systems Market was valued at USD 13,324.84 Million in 2022 and is expected to register a CAGR of 4.92% by 2032.

The push towards automation and the implementation of Industry 4.0 principles have driven the demand for conveyor systems. These systems play a crucial role in creating interconnected, data-driven, and highly efficient production processes.

Get a Free Sample copy

#ConveyorSystems#MaterialHandling#IndustrialAutomation#LogisticsSolutions#ConveyorTechnology#EfficientTransport#WarehouseAutomation#ConveyorBelts

0 notes

Text

Conveyor Engineering Excellence: Masterful Techniques in Conveyor Jointing

Welcome to the world of seamless conveyor systems, where efficiency and reliability meet innovation and precision. At Conveyor Engineering Excellence, we take great pride in presenting groundbreaking techniques in conveyor jointing that elevate your operations to new heights. In this article, we delve into the heart of our expertise, exploring the art and science behind our cutting-edge conveyor jointing solutions.

Unveiling the Art of Conveyor Jointing

Conveyor jointing isn't just about connecting two ends; it's about creating a seamless transition that ensures the smooth flow of materials throughout your production process. Our techniques go beyond the conventional, embracing innovation and precision to deliver results that speak for themselves.

Precision Fusion Bonding: The Power of Molecular Integration

At Conveyor Engineering Excellence, we have mastered the art of precision fusion bonding. This technique involves molecularly integrating conveyor belt ends, creating an incredibly strong and reliable joint that can withstand even the most demanding operational conditions. Our advanced bonding technology ensures a joint that is not only robust but also minimizes downtime due to joint failures.

Vulcanization Redefined: Strength That Endures

Vulcanization has been a staple in conveyor jointing, but we've taken it to the next level. Our experts have redefined the vulcanization process, optimizing temperature, pressure, and duration to create joints that exhibit exceptional strength and longevity. This reimagined vulcanization process guarantees reduced maintenance costs and increased operational efficiency.

Innovative Fastening Solutions: Merging Strength and Flexibility

In a world that demands adaptability, our innovative fastening solutions provide the perfect balance between strength and flexibility. From modular belt systems to hinged joint mechanisms, our fastening techniques allow for easy maintenance and quick replacements without compromising on operational integrity.

The Science of Material Compatibility

The success of a conveyor jointing technique lies in understanding the materials being used. Our engineers are well-versed in the science of material compatibility, ensuring that the jointing methods employed are tailored to the specific properties of your conveyor belt materials. This meticulous approach guarantees not only a secure joint but also minimizes wear and tear on your equipment.

Conclusion: Elevating Your Conveyor Systems

In the world of conveyor systems, precision jointing isn't just a necessity—it's a game-changer. At Conveyor Engineering Excellence, we're not content with the status quo. Our commitment to pushing the boundaries of innovation has led us to develop techniques that redefine conveyor jointing. With precision fusion bonding, reimagined vulcanization, innovative fastening solutions, and material compatibility expertise, we're here to elevate your conveyor systems to new realms of efficiency and reliability.

Visit Conveyors Joint blog to learn more about the art and science behind our masterful conveyor jointing techniques. Experience the future of conveyor engineering with Conveyor Engineering Excellence.

0 notes

Text

KZ Bearings used in outdoor power equipment come with specialized features that enhance their durability, performance, and resistance to challenging outdoor conditions. Email us Your inquiry - [email protected] Visit our Website : https://www.kgbearing.com/ Linktr.ee - https://linktr.ee/kgbearingindia?fbclid=PAZXh0bgNhZW0CMTEAAaZNHUcRoU6Hayd1nGYqpzFzVIkfS95DYwrU3mBllaUiDNzyy8bn8b9X3QQ_aem_GGNR_NWqogSi1BFK4z24Iw #KZBearings #DeepGrooveBearings #viralpost #trendy #OutdoorPowerEquipments #SmoothOperation #HeavyLoadBearings #IndustrialBearings #EfficientConveyors #LowFrictionBearings #DurableBearings #PrecisionBearings #ConveyorTechnology #IndustrialSolutions #ManufacturingExcellence #MaterialHandling #HeavyDutyBearings #BearingSolutions #DurableBearings #industrialbearings

0 notes

Text

Enhance productivity with Lakhotia’s elevator belts designed for swift and reliable material handling in industries.

📲 Contact Us Today

☎️ Phone: +919025194360

📧 Email: [email protected]

🌐 Website: www.lakhotiaindia.in

#EfficiencyMatters#BucketElevator#ProductivityBoost#LakhotiaSolutions#ConveyorTechnology#IndustrialUse#MaterialHandling#LakhotiaBelts#ConveyorEfficiency#DurableBelt

0 notes

Text

🚛 Looking for Reliable Conveyor Belt Solutions?

At Lakhotia India, we specialize in high-quality conveyor belts designed for efficiency and durability across industries. From manufacturing to logistics, we provide the perfect solution for seamless material handling.

⚙️ Our Expertise Includes: 🔸 Custom conveyor belts 🔸 Heavy-duty & industrial-grade solutions 🔸 Fast delivery and reliable support

Streamline your operations with Lakhotia India—the trusted name in conveyor technology.

📞 Contact us today for a free consultation!

📞 Call us at +91 9025194360 🌐 https://lakhotiaindia.in/

[ conveyor belt suppliers, rubber conveyor belt suppliers, bucket conveyor belt ]

#conveyor belt suppliers#rubber conveyor belt suppliers#bucket conveyor belt ]#lakhotiaindia#conveyorbelt#materialhandling#industrialsupply#manufacturing#logistics#automation#customsolutions#heavyindustry#beltsolutions#conveyortechnology#industrialbelts#efficiency#reliableproducts#qualitymanufacturing#transportation#supplychain#equipment#businesssolutions#madeinindia

0 notes

Text

Maintain the smooth operation of your system! 🔄✨ Proper pulley alignment is the secret to preserving your belt's longevity and ensuring uninterrupted performance. Trust in precision alignment for reliability you can count on. 🔧🔍

Read more: https://lakhotiaindia.in/

Contact us: +919025194360

#ConveyorBelts#RubberBelts#RubberConveyorBelts#ConveyorSystems#MaterialHandling#IndustrialSolutions#Manufacturing#Logistics#SupplyChain#ConveyorComponents#MotorizedPulleys#DriveSystems#PowerTransmission#Engineering#Automation#Efficiency#Productivity#Innovation#IndustrialEngineering#ConveyorTechnology

0 notes

Text

Don't allow resistance to hold you back! 🚫⚙️ Discover why smooth operations hinge on proper lubrication. Unlock the potential of your machinery with the right lubricants for enhanced performance and longevity. 🔧🛢️

Read more: https://lakhotiaindia.in/

Contact us: +919025194360

#ConveyorBelts#RubberBelts#RubberConveyorBelts#ConveyorSystems#MaterialHandling#IndustrialSolutions#Manufacturing#Logistics#SupplyChain#ConveyorComponents#MotorizedPulleys#DriveSystems#PowerTransmission#Engineering#Automation#Efficiency#Productivity#Innovation#IndustrialEngineering#ConveyorTechnology

0 notes

Text

Enhance the longevity of your power transmission systems with professional Chevron belt maintenance! 🛠️⚙️ Ensure peak performance and reliability with expert care tailored to your needs. Trust in our team to keep your systems running smoothly. 🔧🔍

Read more: https://lakhotiaindia.in/

Contact us: +919025194360

#ConveyorBelts#RubberBelts#RubberConveyorBelts#ConveyorSystems#MaterialHandling#IndustrialSolutions#Manufacturing#Logistics#SupplyChain#ConveyorComponents#MotorizedPulleys#DriveSystems#PowerTransmission#Engineering#Automation#Efficiency#Productivity#Innovation#IndustrialEngineering#ConveyorTechnology

0 notes

Text

Z Type Bucket Elevator - VGA Automation

VGA Automation Z-type bucket elevator is a type of conveyor system used to transport bulk materials vertically, horizontally, or in a Z-shaped pattern. It's particularly useful for materials that need to be moved with minimal spillage or breakage, such as grains, snacks, seeds or delicate items.

#VGAAutomation#VGApackingmachine#VGA#vgaautomationBucketElevator#BucketElevator#ZTypeElevator#MaterialHandlingconveyor#ConveyorSystem#IndustrialAutomation#BulkMaterialHandling#FoodProcessing#ProcessingEquipment#vgapackingmachine#Manufacturing#packingmachine#VerticalConveyors#AgriculturalEquipment#PharmaceuticalMachiner#ConveyorTechnology#ProductionLine#GrainHandling#IndustrialConveyor

1 note

·

View note

Text

VGA Automation straight roller conveyor is a type of material handling equipment commonly used in industrial settings for the transportation of goods or materials from one place to another. It consists of a series of rollers mounted on a frame, allowing items to be moved smoothly along the conveyor line. Straight roller conveyors are versatile and can be customized to suit different applications, such as light-duty or heavy-duty operations, depending on the weight and size of the materials being transported. They are often used in warehouses, distribution centers, manufacturing plants, and logistics facilities for efficient and automated handling of products

#VGAAutomation#VGApackingmachine#VGAautomationcandypackingmachine#VGA#vgaautomationStraightRollerConveyor#RollerConveyor#MaterialHandling#ConveyorSystem#WarehouseAutomation#LogisticsSolution#ManufacturingEquipment#IndustrialAutomation#SupplyChainManagement#ConveyorTechnology#EfficientTransportatio#Industrialconveyor#Inductrialconveyorsystem#vgaautomationconveyor#conveyor#vgaconveyor

1 note

·

View note

Text

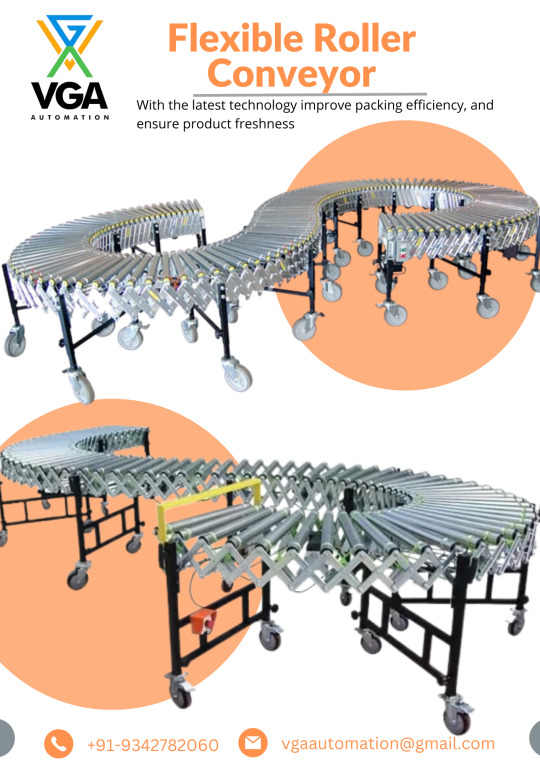

VGA Automation Flexible Roller Conveyor is a type of conveyor system that uses multiple rollers mounted on axles to transport goods or materials. Unlike rigid conveyors, which have a fixed structure, flexible roller conveyors can be extended, curved, and adjusted in various configurations to suit different layouts and applications. They are commonly used in warehouses, distribution centers, manufacturing facilities, and logistics operations to move items efficiently and smoothly along the conveyor line. Flexible roller conveyors offer flexibility, ease of installation, and versatility in handling a wide range of products.

#VGAAutomation#VGApackingmachine#VGAautomationcandypackingmachine#VGA#vgaautomationFlexibleRollerConveyor#FlexibleRollerConveyor#ConveyorSystem#MaterialHandling#WarehouseAutomation#Logistics#DistributionCenter#RollerConveyor#FlexibleConveyor#ConveyorTechnology#SupplyChain#IndustrialAutomation#rollerconveyor#gravityrollerconveyor#Vgaconveyorsystem#vgarollerconveyor

1 note

·

View note

Text

VGA Automation curve belt conveyor is a type of conveyor system used for transporting materials or products around a curved path. Unlike straight belt conveyors that move items in a linear fashion, curve belt conveyors are designed to handle curves, bends, and changes in direction. They are commonly used in industries such as manufacturing, logistics, and warehousing to move items smoothly along a curved route within a facility.

#VGAAutomation#VGApackingmachine#VGAautomationcandypackingmachine#VGA#vgaautomationCurveBeltConveyor#CurveBeltConveyvgaautomation#ConveyorSystems#MaterialHandling#Logistics#Manufacturing#WarehouseAutomation#IndustrialConveyors#CurveConveyors#BeltConveyorTechnology#ConveyorDesign#beltconveyor#MaterialHandlingconveyor#ConveyorTechnology#conveyor#pvcbeltconveyor

1 note

·

View note

Text

Are you ready to take your conveyor systems to the next level? Look no further! We're thrilled to present to you the cutting-edge innovation that will transform the way you approach conveyor jointing: Joining Forces.

0 notes