#ConveyorSystem

Text

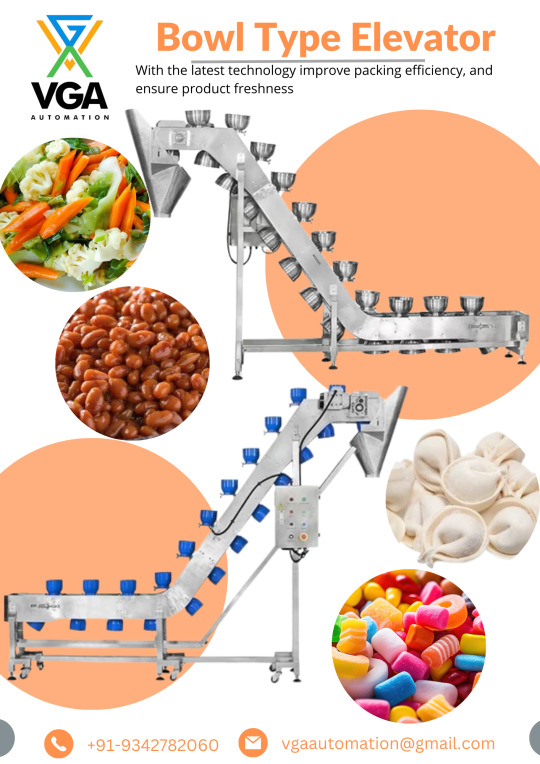

Bowl Type Elevator – VGA Automation

VGA Automation Bowl Type Elevator uses a chain drive system, with bowls attached to the chain, allowing discrete or pre-weighed materials to be transported in separate containers without mixing. This design also accommodates heating or cooling during transport, ideal for packing. It can be integrated with a packing machine or used with manual packing, making it suitable for frozen foods or high-temperature materials like frozen meat, frozen dumplings, seeds, hardware, crops, pharmaceuticals, and chemical products.

#VGAAutomation#VGApackingmachine#VGA#vgaautomationbowlelevator#BucketElevator#ZTypeElevator#MaterialHandlingconveyor#ConveyorSystem#IndustrialAutomation#BulkMaterialHandling#FoodProcessing#ProcessingEquipment#vgapackingmachine#Manufacturing#packingmachine#VerticalConveyors#cookedfoodHandling#PharmaceuticalMachiner#PackagingEquipment#ProductionLine#GrainHandling#IndustrialConveyor

1 note

·

View note

Text

Tsubaki Zip Chain Lifter | Material Handling

Tsubaki Zip Chain Lifter can be installed on an AGV with small footprint. It eliminates the need to mount a hydraulic tank. Zip Chain Lifter is used to laterally push a dolly and supply work pieces. With no projection at the end, this compact equipment does not need any pits. Transported items can "slip off" a sloped belt conveyor. Zip Chain Lifter can secure transported items.

SEIMITSU Factory Automation Pvt Ltd is an authorized distributor of Tsubaki products in India. To know more please visit https://www.seimitsu.in/tsubaki-material-handling-zip-chain-and-lifters.html

0 notes

Text

DKT Engineering

Our PVC & PU Conveyor Belt Product line covers genral and food grade bekts that are used in nearly every industry abd come in a variety of sizes and varieties

#conveyor#conveyorbelt#conveyors#conveyorsystems#rubberbelt#belt#engineering#conveyorsystem#konvey#automation#industry#materialhandling#belts#manufacturing#conveyorrollers#quarry#industrial#beltconveyor#quarrylife#bearing#conveyorbelts#pvcbelt#beltsplicer#vulcanising#r#enduroply#qpiltd#fabrication#quality#conveyoridlers

0 notes

Text

Customized Gearbox Solutions | SMD Gearbox

SMD Gearbox is dedicated to providing tailor-made solutions for your power transmission challenges, emphasizing our commitment to quality, innovation, and customer satisfaction. As your perfect partner for developing custom right-angle, parallel output gearboxes or any other type, we set ourselves apart.

When you need a dependable and efficient gearbox designed to your precise needs, look no further. Our team of skilled engineers and designers is resolute in delivering exceptional solutions crafted to suit your distinct requirements.

To learn more please visit https://www.smdgearbox.com/right-angle-gearbox

#gearboxmanufacturer#automatedguidedvehicle#spm#asrsshuttles#conveyorsystem#parallelgearbox#motioncontrolsolution#servogearbox#customizedsoulutions#smdgearbox

0 notes

Text

Front-Back Labeling Machine In Dubai

Shiv Shakti Machtech:Front-Back Labeling Machine In Dubai

Shiv Shakti Machtech is dedicated to offering high-end products and services in terms of technology.

Components of a Front-Back Labeling Machine

A Front-Back Labeling Machine typically comprises the following key components:

Label Dispenser: This component holds and dispenses label rolls, ensuring a steady supply of labels for the labeling process.

Conveyor System: A conveyor system transports the products or containers through the labeling station, maintaining product alignment and ensuring a continuous labeling process.

Labeling Head: Label applicators within the labeling head can be configured for both front and back labeling.These applicators dispense and apply labels onto the target surfaces accurately.

Labeling Controls: The machine's control panel allows operators to set parameters, adjust label placement, and monitor the labeling process.

Sensor Systems: Optical sensors or detectors are used to detect the position and orientation of products, ensuring labels are applied in the correct locations.

Adjustment Mechanisms: Front-Back Labeling Machines often feature adjustment mechanisms to accommodate various product sizes, shapes, and labeling requirements.

Applications of Front-Back Labeling Machines

Front-Back Labeling Machines are used in a wide range of industries for labeling products such as:

Bottles and containers in the beverage industry

Food packaging

Cosmetics and personal care products

Pharmaceutical and medical product packaging

Household and cleaning product containers

Industrial manufacturing

We Provide Front-Back Labeling Machine in Dubai Including Jebel Ali, Al Aweer, Al Lisaili, Marqa, Al Faqa, Ud al-Bayda, Urqub Juwayza, Lahbab.

Read the full article

#AdjustmentMechanisms#Ahmedabad#AlAweer#AlFaqa#AlLisaili#ConveyorSystem#Dubai#Exporter#FrontBackLabelingMachines#Front-BackLabelingMachine#Front-BackLabelingMachineInDubai#Gujarat#India#JebelAli#LabelDispenser#LabelingControls#LabelingHead#Lahbab#Manufacturer#Marqa#SensorSystems#ShivShaktiMachtech#Supplier#Udal-Bayda#UrqubJuwayza

1 note

·

View note

Text

Reach New Heights: Elevate Your Factory's Potential with Our Conveyor Belts

Are you looking to revolutionize your factory's productivity and efficiency? Look no further! At ConveyorsJoint, we bring you state-of-the-art Conveyor Belts that will take your factory operations to new heights!

Unleash Unmatched Performance:

Factory Conveyor Belt meticulously engineered with cutting-edge technology to handle heavy loads, streamline material handling, and maintain seamless operations. No matter the industry or application, our belts ensure smooth transportation of goods with minimal downtime.

Tailored Solutions for Your Factory:

We understand that every factory is unique. That's why we offer customizable conveyor solutions to perfectly fit your requirements. Our team of experts will work closely with you to design and implement a conveyor system that maximizes your factory's potential.

Superior Quality, Unbeatable Durability:

Quality is our top priority. Our Conveyor Belts are crafted using premium-grade materials, making them incredibly robust and long-lasting. You can trust our belts to withstand the toughest of conditions, reducing maintenance costs and boosting your factory's overall performance.

Global Reach, Local Support:

With a wide network of satisfied clients across the globe, Conveyors Joint is your reliable partner in elevating factory efficiency. Wherever your factory is located, our dedicated support team is always ready to assist you with prompt service and expert advice.

Sustainable Solutions:

At Conveyors Joint, we believe in sustainable manufacturing practices. Our Conveyor Belts are designed with energy efficiency in mind, reducing your factory's carbon footprint while enhancing productivity.

#FactoryConveyorBelts#ConveyorBeltSolutions#ManufacturingAutomation#IndustrialProductivity#EfficientFactoryOperations#ConveyorSystem#MaterialHandling

0 notes

Video

youtube

Conveyor Belt Test Run | Stainless Steel Incline Belt Conveyor

0 notes

Text

Top Quality Conveyor System - Swisser Instruments

We supply a optimum quality Conveyor System that is one of the best mechanical handling apparatuses that is used in many industries. We are one of the ideal Conveyor System Manufacturers and Suppliers in India.

0 notes

Text

If you are searching for the high-quality Telescopic Belt Conveyor Machine in India affordably, we Modern Sheller are the best manufacturer in providing you with fully automatic Telescopic conveyor Belt . Telescopic conveyor equipment increase the Efficiency and productivity in material handling industries and reducing Manual handling process providing high safety for Labour.

1 note

·

View note

Text

Four-Wheel Overhead Conveyors system

Four-wheel overhead conveyors have revolutionized the manufacturing and logistics industries by providing a highly efficient and versatile material handling solution.

VISIT- https://alineconveyors.com/

Efficient and Space-Saving Design

The four-wheel overhead conveyor system is engineered with efficiency in mind. By utilizing overhead space, it minimizes floor clutter, allowing for smooth movement of materials without obstructing personnel or vehicles. The compact design optimizes space utilization and enables seamless integration with existing production layouts, maximizing overall productivity.

Flexible and Customizable Configurations

One of the major advantages of four-wheel overhead conveyors is their adaptability to diverse applications. These systems can be customized with different track layouts, curvatures, and inclines to meet specific material handling requirements. From simple point-to-point transfers to complex multi-level installations, the flexibility of four-wheel conveyors ensures efficient and tailored solutions.

Enhanced Material Flow and Accessibility

With their elevated position, four-wheel overhead conveyors facilitate smooth material flow throughout the production floor. By transporting items overhead, they eliminate potential ground-level obstacles and bottlenecks, providing unobstructed access to workstations, assembly lines, and storage areas. This streamlined workflow reduces handling time and enhances operational efficiency.

Increased Safety and Ergonomics

Four-wheel overhead conveyors prioritize safety by keeping materials off the ground, minimizing the risk of accidents or damage. Additionally, these conveyors can be equipped with ergonomic features such as adjustable heights and ergonomic handling tools, reducing strain on workers and promoting a safer and healthier work environment.

Conclusion

In conclusion, four-wheel overhead conveyors offer numerous advantages in terms of efficiency, flexibility, safety, and ergonomics. Their ability to optimize material flow, conserve space, and adapt to different configurations make them indispensable tools for a wide range of industries. By implementing these conveyors, businesses can enhance productivity and streamline their operations effectively.

#conveyor belts#conveyorsystem#manufacturing#roller conveyor#folexin#folexinbuy#folexinprice#folexinscam#hypocbdskinspray

0 notes

Text

youtube

How to Do Belt Installing of Batch Asphalt Mixing Plant?

The asphalt plants or asphalt mixing plant is one plant that is used for mixing the dry warm aggregate, padding and asphalt for homogeneous mixture at the required temperature. And it is widely used to the construction of highway, city road and parking lot.

The major components of a batch asphalt mixing plant are the cold- feed system, asphalt cement supply system, aggregate dryer, mixing tower, and emission-control system.

The main activity of an asphaltbatch type mixing plant is that it heats up aggregates and then mixes them with bitumen and other adhesive substances to generate hot mix asphalt. The quantity and nature of the aggregate are dependent on the specific requirements.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#concrete#asphalt plant#asphaltplant#heavy equipment#construction#mobile asphalt drum mix plant#conveyor belts#conveyorsystem#roller conveyor#screw conveyor#conveyorize#belt conveyor#Youtube

1 note

·

View note

Text

Z Type Bucket Elevator - VGA Automation

VGA Automation Z-type bucket elevator is a type of conveyor system used to transport bulk materials vertically, horizontally, or in a Z-shaped pattern. It's particularly useful for materials that need to be moved with minimal spillage or breakage, such as grains, snacks, seeds or delicate items.

#VGAAutomation#VGApackingmachine#VGA#vgaautomationBucketElevator#BucketElevator#ZTypeElevator#MaterialHandlingconveyor#ConveyorSystem#IndustrialAutomation#BulkMaterialHandling#FoodProcessing#ProcessingEquipment#vgapackingmachine#Manufacturing#packingmachine#VerticalConveyors#AgriculturalEquipment#PharmaceuticalMachiner#ConveyorTechnology#ProductionLine#GrainHandling#IndustrialConveyor

1 note

·

View note

Text

ITOH DENKI Distributor in India | DC Power Moller

Itoh Denki Power Mollers are one of the biggest innovations in conveyor industry. Its unique features like its easy integration in conveyor line, customized sizes, integrated control logics, Network communication (IoT) increases its value in market. DC power Moller consists of its built-in motor with drive which automates conveyor line by transmitting power to idler roller.

SEIMTISU Factory Automation is an authorized distributor of ITOH DENKI in India. Please visit our website to know more at https://www.seimitsu.in/itoh-denki-mdr-brushless-dc-motor-driver-card.html or you can contact us on following details

EMAIL ID- [email protected]

Contact No- +91 9028121211

#seimtisu#itohdenki#conveyorsystem#materialhandling#dcpowermoller#dcroller#mdr#authorizeddistributor#supplier#logistics

0 notes

Text

PU Conveyor Belt

DKT Engineering Enterprises has been in the business of manufacturing top-quality PU conveyor belts since 2010. Our offered range of products finds its wide applications in various areas such as Food processing, Medicine, Electrics, Printing, Packaging, Textile industries, and many more. The unique features of the PU Conveyor Belt are low maintenance, durability, and affordability. For more, you can visit our Website

#puconveyorbelt#manufacturer#conveyor#quality#production#manufacturing#supplier#conveyorsystem#dktee#navimumbai#worldwidesupplier#exporters#suppliers#industrialbelts#manufacturers#industrial#dktengineeringenterprises#india#mumbai

0 notes

Text

Itoh Denki Slide Open Gate Conveyor Module| SEIMITSU

Itoh Denki offers a wide range of automated sliding open gate conveyors to make easy work of opening and closing your conveyor with the Itoh Denki Slide Open Gate! Our motorized sliding gate conveyor systems are designed to open and close automatically with the push of a button, allowing for easy access and control over who is allowed to enter or exit. This convenient, easy-to-install system is perfect for business. Conveyor Modules are used in many industrial applications like automotive, agriculture, food and beverages, packaging, manufacturing, warehouse, and logistics.

SEIMITSU is an authorized distributor of Itoh Denki.

Contact Details:

Email Id: [email protected]

Contact: +91 9028121211

For more information visit us: https://www.seimitsu.in/itoh-denki-conveyor-module-FRAT-GPR.html

0 notes

Photo

A screw feeder is ideal for discharging smaller quantities of product delivered in 50 lb bags. It allows accuracy in powder dosing. Sodimate offers customized, flexible, and rigid screw feeders for every operation. Upgrade your feeding system today. Contact Us!

1 note

·

View note