#CountersunkWashers

Explore tagged Tumblr posts

Text

Step-by-Step Guide to Installing Countersunk Washers Properly | Expert Tips

When it comes to ensuring the stability and longevity of your mechanical or construction projects, the right washers can make a world of difference. Among the various types of washers available, countersunk washers are a popular choice for projects requiring a flush finish and strong load distribution. This step-by-step guide will walk you through the proper installation of countersunk washers, helping you achieve a perfect, secure fit every time.

1. What Are Countersunk Washers?

Countersunk washers are specially designed washers with a beveled edge that allows them to fit neatly into countersunk holes. They provide a flush surface, which is essential for applications where a smooth and seamless finish is needed, such as in furniture assembly, automotive work, and structural installations. Countersunk washers are typically used in combination with countersunk screws or bolts, ensuring a tight, even fit for a more durable assembly.

2. Why Should You Use Countersunk Washers?

You might wonder, why should I use countersunk washers instead of regular flat washers? The answer lies in the flush fit they offer. Using countersunk washers provides the following benefits:

Even Load Distribution: Countersunk washers evenly distribute the load, preventing stress concentrations around the fastener and increasing the longevity of the assembly.

Aesthetic Appeal: The beveled edges allow the washer to sit flush with the material, offering a cleaner, more polished look.

Prevents Damage: Countersunk washers protect the surface from damage caused by the screw or bolt head, reducing wear and tear on sensitive materials.

Enhanced Stability: They ensure a stable and secure fastening, especially in high-vibration environments.

3. Tools and Materials Needed

Before getting started, gather the following tools and materials to ensure the installation process goes smoothly:

Countersunk washers (Ensure you select the correct size for your screws or bolts)

Countersunk screws or bolts

Screwdriver or wrench (depending on the type of fastener used)

Measuring tape or caliper

Drill and countersink bit (for preparing the hole)

Rubber mallet or hammer (optional, for light tapping)

Clean cloth (for cleaning the area)

4. Step-by-Step Guide to Installing Countersunk Washers

Here’s how you can properly install countersunk washers in your project:

Step 1: Measure and Mark the Hole Location

Before installing your washers, it's essential to prepare the surface. Use a measuring tape to mark the exact location where you will drill. This ensures precision in your work and helps prevent misalignment. Make sure the hole is aligned with where the fastener will go.

Step 2: Drill a Countersunk Hole

Next, use a drill with a countersink bit to create a hole. The countersink bit helps create the beveled edge needed to fit the countersunk washer. The hole should be slightly larger than the diameter of your fastener but still small enough to hold it securely in place. The depth of the countersink hole should match the thickness of the washer to ensure a flush fit.

Step 3: Insert the Countersunk Washer

Now that the hole is prepared, take your countersunk washer and gently place it into the hole. The washer should sit flush with the surface, with the beveled edge facing inward to accommodate the head of the screw or bolt. If the washer doesn’t sit evenly, adjust the hole depth or diameter.

Step 4: Insert the Fastener

Place your countersunk screw or bolt into the washer, aligning it with the hole. Use a screwdriver or wrench to tighten the fastener. As you tighten, ensure the washer remains flush with the material. Be careful not to overtighten, as this could strip the threads or damage the washer.

Step 5: Check for a Flush Fit

After tightening, check to ensure that the countersunk washer is flush with the surface and that the screw or bolt head is seated properly. The washer should sit neatly, with no visible gaps between the washer and the surface. If the washer sticks out or doesn't fit evenly, back off the fastener and readjust the hole or washer placement.

5. Common Mistakes to Avoid

While installing countersunk washers is relatively straightforward, there are a few common mistakes to avoid:

Incorrect Hole Size: If the hole is too large or too small, the washer may not fit properly. Always check your washer and fastener size before drilling.

Insufficient Countersinking: Not using the correct countersink depth can prevent the washer from sitting flush. Ensure the hole depth matches the washer's thickness.

Overtightening: Tightening too much can lead to damage. It’s crucial to apply the correct torque to avoid stripping the threads or damaging the washer.

6. Final Tips for a Secure Installation

To ensure the best results when installing countersunk washers, follow these final tips:

Use High-Quality Washers: Invest in durable stainless steel washers or brass shim sheet washers for long-lasting performance.

Double-Check Your Work: Before finalizing the installation, double-check that everything is properly aligned and securely tightened.

Consider Shim Washers: In some applications, you may need to add shim washers to help distribute the load more evenly.

By following these steps, you can ensure that your countersunk washers are installed correctly, providing optimal support and performance for your projects.

Conclusion

Installing countersunk washers properly is crucial for ensuring the durability and effectiveness of your fastenings. Whether you’re working on machinery, structural installations, or DIY projects, taking the time to install washers correctly will pay off in terms of performance and aesthetics. I hope this step-by-step guide has given you the confidence to tackle your next project with ease.

#CountersunkWashers#InstallationGuide#ExpertTips#DIYProjects#WasherInstallation#StepByStepGuide#FastenerTips#HardwareHowTo#HomeImprovement#ToolTips

0 notes

Text

Washer Manufacturer | F436 Fasteners: Complete Guide for Manufacturers, Suppliers, and Buyers

In the world of fastening solutions, washers play a crucial role in ensuring the stability, longevity, and integrity of assemblies. These small but essential components distribute load, prevent loosening, and protect surfaces from damage. From industrial machinery to household appliances, washers are indispensable.

Introduction to Washers

Washers are thin plates (typically disk-shaped) with a hole in the middle that is used to distribute the load of a threaded fastener, such as a bolt or nut. They serve multiple functions:

Load Distribution: Preventing localized stress on surfaces.

Vibration Absorption: Minimizing loosening due to vibrations.

Sealing: Preventing leakage in fluid systems.

Spacing: Adjusting the gap between components.

Depending on the application, washers can be made from various materials, including mild steel (MS), stainless steel (SS), brass, copper, and high-nickel alloys.

Introduction to F436 Washer

F436 fasteners primarily consist of hardened steel washers manufactured in accordance with the ASTM F436 specification. These fasteners are designed to be used with structural bolts, nuts, and assemblies, particularly in high-strength structural connections. The ASTM F436 standard ensures the washers are capable of handling the heavy loads and environmental conditions encountered in structural steel construction, bridges, towers, buildings, and other critical infrastructure.

The unique properties of F436 fasteners, especially washers, include excellent hardness, strength, and resistance to deformation under load, making them an essential component in high-strength bolted connections.

What are ASTM F436 Washers?

ASTM F436 is a standard that defines the chemical, mechanical, and dimensional specifications for hardened steel washers designed for use with:

ASTM A325 (now ASTM F3125) structural bolts

ASTM A490 (now ASTM F3125) structural bolts

Other high-strength bolted assemblies

They are typically flat washers that help distribute the load evenly and protect the mating surfaces from damage due to tightening torque and dynamic loads.

Types of F436 Fasteners

While ASTM F436 specifically covers washers, many people often refer to "F436 fasteners" to describe the broader assembly they're part of. Below are common F436 fastener components:

1. F436 Hardened Washers

F436 Type 1: Hardened washers manufactured from standard carbon steel, providing high strength and durability.

F436 Type 3: Hardened washers produced from weathering steel, offering superior corrosion resistance, ideal for outdoor and exposed applications.

Coated F436 Washers: Including zinc-plated, hot-dip galvanized, mechanical galvanized, and others for corrosion protection.

2. F436 Assembly Components

Though technically not part of ASTM F436, these are typically used with F436 washers:

Structural Bolts (ASTM F3125 A325 or A490)

Heavy Hex Nuts (ASTM A563)

Tension Control Bolts

Anchor Bolts

Applications of F436 Fasteners

F436 washers and associated fasteners are widely used in industries that demand strong, durable, and reliable connections, such as:

Structural Steel Construction

Bridges

Transmission Towers

Wind Turbines

Cranes

Offshore Platforms

Skyscrapers

Infrastructure Projects

Their high hardness prevents embedding and deformation when high-strength bolts are tightened to the required pretension levels.

ASTM F436 Material Specifications

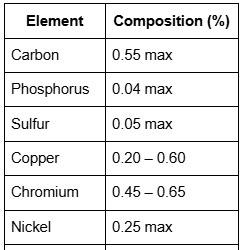

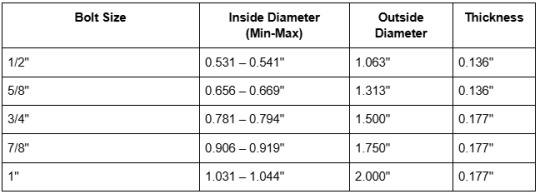

Chemical Composition (Type 1 - Carbon Steel)

Chemical Composition (Type 3 - Weathering Steel)

Mechanical Properties

This high hardness ensures the washers will not deform under high clamping forces.

Coating Options for F436 Washers

To improve corrosion resistance, particularly in outdoor or marine conditions, ASTM F436 washers can be supplied with a variety of protective coatings:

Hot-Dip Galvanizing (HDG)

Mechanical Galvanizing

Zinc Electroplating

Geomet® or Delta Protekt® coatings

Phosphate and Oil Coating

Note: Coating thickness and method must meet the requirements to ensure proper fit and function in bolted assemblies.

Advantages of F436 Fasteners

High Hardness: Resists embedment and helps maintain preload during tightening and operation.

Excellent Load Distribution: Protects mating surfaces during tightening.

Durability: Withstands severe loading and vibration conditions.

Corrosion Resistance: Especially for Type 3 and coated variants.

Compliance with International Standards: Ensures global application across industries.

ASTM F436 vs. Other Washer Standards

Why Choose Ananka Fasteners for F436 Fasteners?

As a leading manufacturer, stockist, and exporter of high-strength structural fasteners, Ananka Fasteners offers:

In-House Production: Equipped with state-of-the-art CNC machines and advanced forging capabilities.

Quality Control: ISO-certified manufacturing processes with rigorous quality checks at every stage.

Customized Solutions: Fully customized washer manufacturing as per client drawings and specifications.

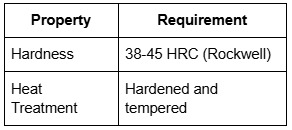

Sizes and Dimensions Chart (Sample)

Inspection and Testing for F436 Fasteners

To ensure quality and compliance, F436 washers undergo rigorous testing:

Hardness Testing (Rockwell HRC)

Dimensional Inspection

Coating Thickness Testing

Chemical Analysis (Spectrometer)

Heat Treatment Verification

Visual Inspection

Frequently Asked Questions (FAQ)

Q1. Can F436 washers be reused?Generally not recommended in structural applications as hardness may be affected after the first installation.

Q2. Are F436 washers compatible with galvanized bolts?Yes. F436 washers are often hot-dip galvanized to match the coating of structural bolts.

Q3. Where are ASTM F436 fasteners commonly used?Bridges, buildings, steel structures, towers, heavy industrial equipment.

Q4. Do you offer third-party inspection (TPI)?Yes. Ananka Fasteners offers TPI services from agencies like BV, SGS, TUV, Lloyd’s, etc.

Conclusion

ASTM F436 fasteners, especially washers, play a crucial role in ensuring the integrity, safety, and long-term durability of structural connections. Their high hardness, precise dimensions, and corrosion-resistant options make them indispensable for structural steel projects worldwide.

Whether you're a contractor, procurement manager, or project engineer, choosing the right F436 fastener supplier ensures your project meets all safety and performance standards. Ananka Fasteners is fully equipped to fulfill all your F436 fastener needs, offering exceptional quality and worldwide export services.

#WasherManufacturer#Fasteners#SpringWasher#PlainWasher#FlatWasher#CountersunkWasher#StainlessSteelWashers#MildSteelWashers#IndustrialFasteners#GlobalSupplier#FastenerIndustry#MadeInIndia#ExportQuality#OilAndGas#MarineIndustry#CustomFasteners#Ananka#AnankaFasteners#manufacturer#tumblr#tumblr blog#blogs

0 notes

Photo

#countersunkwasher made from #titanium #ti6al4v #racingcars #motorcycle #bicycle #tuning https://www.instagram.com/p/CAPrQIQnAV4/?igshid=2t9k4ocqwp1y

0 notes

Photo

Standoff+screw+countersunk washer+hex screw driver Anyone interested? Pm us😀 #cncdroneparts#hardware#standoff #spacer #screwdriver#screw #carbonsteel#washer #countersunkwasher#gaskets #screwgaskets #fpvaccessories#hexscrewdriver#fpvtools#miniquad#fpvracing #fpvfreestyle #miniquadclub#drone#rcparts

#carbonsteel#miniquadclub#drone#screw#fpvaccessories#gaskets#standoff#countersunkwasher#screwdriver#fpvtools#fpvracing#hexscrewdriver#cncdroneparts#rcparts#fpvfreestyle#hardware#screwgaskets#spacer#miniquad#washer

0 notes

Text

The Advantages of Using Countersunk Washers in Mechanical Projects | Key Benefits

When it comes to mechanical projects, every detail matters, especially the small components that hold everything together. One such vital yet often overlooked component is the countersunk washer. Whether you're assembling machinery, working on vehicles, or handling DIY tasks, using the right washers can make all the difference in durability and efficiency.

In this article, I’ll guide you through the key advantages of using countersunk washers, explore their applications, and show you why they’re essential for precise and professional assembly in mechanical projects.

What Are Countersunk Washers Key Benefits?

Countersunk washers are specialized washers designed to complement countersunk screws or bolts. Their conical shape matches the head of a countersunk fastener, allowing the fastener to sit flush or slightly below the material’s surface. This creates a smooth finish, reducing the risk of snags or protrusions that could cause damage or injury.

These washers are commonly made from durable materials like stainless steel, brass, or even plastic, depending on the application.

Why Use Countersunk Washers?

You might be wondering, "Why should I bother with countersunk washers?" The answer lies in their ability to enhance the stability and aesthetics of your mechanical projects. They not only provide a clean, flush finish but also help distribute loads evenly, preventing damage to the surface or the fastener.

Key Benefits of Countersunk Washers

Using countersunk washers offers a host of advantages that make them indispensable in many mechanical applications:

1. Enhanced Stability

Countersunk washers ensure that screws or bolts stay securely in place by preventing movement or loosening under pressure. This stability is crucial for projects involving high vibration or heavy loads.

2. Flush and Professional Finish

Because these washers are designed to match the countersunk fastener’s shape, they allow the screw or bolt to sit flush with the surface. This improves the project’s overall appearance and prevents snagging on protruding fasteners.

3. Even Load Distribution

By spreading the load across a larger surface area, countersunk washers protect the material from cracking, warping, or deformation. This is especially important when working with softer materials like wood or plastic.

4. Surface Protection

Countersunk washers act as a barrier between the fastener and the material, reducing the risk of scratches, dents, or other damage.

5. Corrosion Resistance

Washers made from materials like stainless steel or brass are resistant to corrosion, making them ideal for outdoor or high-moisture environments.

6. Versatility

Countersunk washers are compatible with a variety of fasteners and materials, making them suitable for numerous applications.

Common Applications of Countersunk Washers

You’ll find countersunk washers used in a wide range of industries and projects, including:

Automotive Industry: Ensuring secure fastening of vehicle components while maintaining a sleek finish.

Aerospace Applications: Providing stability and reliability in high-pressure environments.

Furniture Assembly: Achieving a polished look while preventing material damage.

Electronics: Protecting delicate components from damage while ensuring precise assembly.

Marine Applications: With corrosion-resistant materials, countersunk washers are perfect for boats and other water-exposed equipment.

Choosing the Right Countersunk Washer

Selecting the appropriate countersunk washer for your project involves a few key considerations:

1. Material

Stainless Steel Countersunk Washers: Ideal for strength and corrosion resistance.

Brass Washers: Great for electrical conductivity and decorative finishes.

Plastic Washers: Suitable for lightweight or non-conductive applications.

2. Size and Fit

Ensure the washer matches the dimensions of the countersunk screw or bolt for a seamless fit.

3. Load Requirements

Consider the load your project will bear and select a washer that can handle the stress without deforming.

4. Environment

Choose materials that can withstand the conditions of your project, such as moisture, temperature, or chemicals.

Conclusion

Countersunk washers are a small but significant component that can elevate the quality and durability of your mechanical projects. From enhancing stability and protecting surfaces to providing a sleek, professional finish, they offer a wide range of benefits.

By choosing the right material and size, you can ensure your assembly is not only secure but also visually appealing and long-lasting. So, the next time you’re working on a project, don’t underestimate the power of a well-placed countersunk washer—it might just be the key to success!

#CountersunkWashers#MechanicalProjects#EngineeringTips#WasherBenefits#DIYMechanical#ProjectEfficiency#TechInEngineering

0 notes