#EngineeringTips

Explore tagged Tumblr posts

Text

1 note

·

View note

Text

📏 How to decide which pressure angle to use for a gear system?

Guidelines to help you select the right gear angle for your project.

1 note

·

View note

Text

How to Choose the Right Cable Gland Size for Optimal Performance

Choosing the correct cable gland size prevents issues like inadequate sealing and electrical failures. Learn about different cable glands, key selection factors, and expert-recommended steps for a secure fit. Ensure safe and efficient electrical installations with the right gland size.

#CableGlands#ElectricalSafety#IndustrialSolutions#CableManagement#EngineeringTips#PowerDistribution#AtlasMetal

1 note

·

View note

Text

CNC Machining vs Metal Fabrication: Which Process Wins for Your Project?

⚙️ Struggling to choose between CNC machining and metal fabrication? Discover the pros, cons, and expert tips to pick the perfect manufacturing method for precision, speed, and cost-efficiency! 🔧 Dive into this ultimate comparison guide now:

1 note

·

View note

Text

Want to cut costs and stay ahead in the AEC industry? 🚀 Outsourcing is the answer! This video explains how it helps businesses save money, improve efficiency, and access top talent. Learn why outsourcing is a key strategy for 2025 and beyond.

🚀 Don’t Miss Out: https://www.youtube.com/shorts/oh2qfksEq1E

0 notes

Text

✨ Custom Polypropylene Plastic Machining: Challenges & Solutions for Engineers ✨

🔹 Struggling with polypropylene machining? Discover expert insights on overcoming challenges and ensuring precision & efficiency in your projects. ⚙️

🔹 Whether you need large-scale orders or OEM plastic products, this guide provides tailored solutions to streamline your production. 🏭💡

#PolypropyleneMachining#customplastics#OEMSolutions#EngineeringChallenges#PlasticManufacturing#IndustrialDesign#PrecisionEngineering#ManufacturingSolutions#EngineeringTips#materialscience

1 note

·

View note

Text

Different Types of Pipe Bends Explained | Uses & Applications

Pipe bends are essential in industrial piping systems, allowing directional changes while maintaining smooth fluid flow. Various types of pipe bends are used based on application, material, and bending angle. This guide explains different types of pipe bends, their applications, and key selection criteria.

Types of Pipe Bends

1. Short Radius (SR) Bend

Description: Compact bend with a radius equal to the pipe diameter.

Advantages: Saves space, used in tight piping layouts.

Applications: HVAC, plumbing, industrial piping.

2. Long Radius (LR) Bend

Description: Bend radius is 1.5 times the pipe diameter.

Advantages: Reduces pressure drop and turbulence.

Applications: Oil & gas pipelines, water distribution.

3. 3D Pipe Bend

Description: Radius is three times the pipe diameter.

Advantages: Ensures smooth flow with minimal resistance.

Applications: Petrochemical, marine, power plants.

4. 5D Pipe Bend

Description: Radius is five times the pipe diameter.

Advantages: Ideal for applications requiring gradual flow changes.

Applications: Refineries, chemical industries.

5. Miter Bend

Description: Made by cutting pipe segments and welding them at an angle.

Advantages: Cost-effective for large diameter pipes.

Applications: Industrial pipelines, water treatment plants.

6. J-Bend

Description: A 180-degree bend shaped like a 'J'.

Advantages: Used for drainage and condensate return.

Applications: HVAC, plumbing, condensers.

7. U-Bend

Description: A full 180-degree bend.

Advantages: Used in heat exchangers and condensers.

Applications: Power plants, industrial cooling systems.

8. Segmented Bend

Description: Created by welding multiple pipe segments.

Advantages: Customizable for large piping projects.

Applications: Large-scale industrial projects, HVAC.

9. Hot Induction Bend

Description: Made by heating and bending the pipe with induction coils.

Advantages: Precise bending with high strength.

Applications: Oil & gas, power plants.

10. Cold Bends

Description: Pipe bending done without heat.

Advantages: Retains material properties, used in small-diameter pipes.

Applications: HVAC, plumbing, automotive.

Comparison Table of Pipe Bends

Type of BendBend RadiusApplicationsShort Radius1DHVAC, plumbing, industrial pipingLong Radius1.5DOil & gas, water pipelines3D Bend3DPetrochemical, marine, power plants5D Bend5DRefineries, chemical industriesMiter BendCustomIndustrial pipelines, water treatmentJ-Bend180°HVAC, drainage systemsU-Bend180°Heat exchangers, cooling systemsSegmented BendCustomLarge-scale industrial applicationsHot Induction BendVariableOil & gas, power plantsCold BendVariablePlumbing, HVAC, automotive

FAQs

What is the difference between SR and LR bends?

Short radius (SR) bends have a compact design, ideal for tight spaces, while long radius (LR) bends ensure smoother fluid flow with minimal pressure loss.

Which pipe bend is best for oil and gas applications?

3D, 5D, and hot induction bends are commonly used in oil and gas pipelines for better fluid dynamics and durability.

How is a miter bend different from a standard bend?

A miter bend is made by welding multiple pipe segments, whereas standard bends are formed by heating or cold bending a single pipe.

Are U-bends and J-bends the same?

No, a U-bend is a full 180° bend used in heat exchangers, while a J-bend is a 180° bend but shaped like a 'J', commonly used in drainage systems.

#PipeBends#PipingSolutions#IndustrialPipes#PipelineEngineering#FluidFlow#OilAndGas#WaterPipelines#MechanicalEngineering#PipeFittings#Manufacturing#HVAC#SteelPipes#PlumbingSolutions#ProcessIndustry#EngineeringTips

0 notes

Text

The Ultimate Guide to Choosing the Right Shim for Your Industrial Applications

Shims play a vital role in ensuring precision in industrial machinery by aligning components and filling gaps. Selecting the right shim can be a challenge, but it’s essential for achieving the desired performance. In this guide, we’ll cover the key factors to consider when choosing shims, the available materials, and why working with trusted shim manufacturers in India is critical for high-quality products.

Types of Shims

There are various types of shims, each designed for specific applications. The most commonly used include:

Stainless Steel Shims: Ideal for heavy-duty applications, offering corrosion resistance and durability.

Brass Shim Sheets: Known for their flexibility and excellent conductivity, these are perfect for electrical applications.

Precut Shims: Ready-made shims that save time by offering precise and quick adjustments.

SS Shim Plates: Larger, stronger plates often used in industrial machinery for leveling and alignment.

Each type has its advantages, depending on your needs, whether it’s corrosion resistance, flexibility, or strength.

Material Selection

Choosing the right material for your shim is just as crucial as selecting the right type. Consider the following materials:

Stainless Steel: Best for rust-resistant, heavy-duty applications that require strength and longevity.

Brass: Offers excellent conductivity and flexibility, making it ideal for electrical or decorative uses.

Aluminum: Lightweight and corrosion-resistant, perfect for applications requiring less strength.

Your environment will largely dictate the material. For instance, if your shim will be exposed to high temperatures or moisture, stainless steel might be your best option.

How to Select the Right Shim

To ensure you choose the right shim, keep the following in mind:

Measure gaps accurately: Precision is key. You need to know the exact size of the gap or alignment issue.

Consider strength requirements: Choose a shim that can handle the load and conditions of your specific application.

Consult experts: For custom solutions, it’s wise to work with shim manufacturers in India, who can provide tailored options to suit your exact needs.

By carefully considering the type, material, and strength requirements, you can select the perfect shim for your industrial machinery. Working with trusted suppliers ensures you receive high-quality shim sheet metal, stainless steel shims, and brass shim sheets, whether you're opting for precut shims or SS shim plates.

#IndustrialSolutions#ShimSelection#EngineeringTips#IndustrialApplications#ManufacturingExcellence#PrecisionEngineering#IndustrialTools

0 notes

Text

Dive into the world of carbide rotary file grinding! 🌟 This video breaks down the essentials of using carbide files for effective decompression in your projects. From selecting the right file to practical grinding techniques, we've got you covered. Perfect for professionals and enthusiasts alike who are keen on precision and efficiency in their work. Don't miss out on these expert tips!

#CarbideGrinding#IndustrialTools#EngineeringTips#PrecisionMachining#ToolMastery#EfficiencyInAction#ProfessionalGrinding

0 notes

Text

Unlock the secrets to effortless disassembly! Discover how mastering screw puzzle matching leads to smooth dismantling.

1 note

·

View note

Text

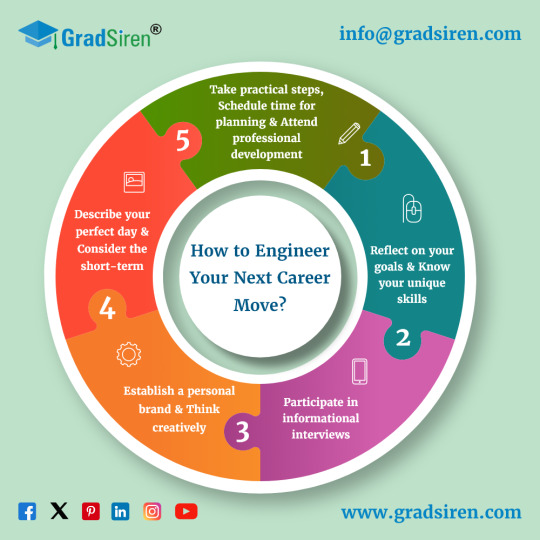

𝐍𝐚𝐯𝐢𝐠𝐚𝐭𝐞 𝐘𝐨𝐮𝐫 𝐂𝐚𝐫𝐞𝐞𝐫: 𝐄𝐧𝐠𝐢𝐧𝐞𝐞𝐫𝐢𝐧𝐠 𝐒𝐮𝐜𝐜𝐞𝐬𝐬 𝐎𝐧𝐞 𝐌𝐨𝐯𝐞 𝐚𝐭 𝐚 𝐓𝐢𝐦𝐞

#engineeringweek2024#engineeringlife#engineeringstudent#EngineeringExcellence#engineeringtech#engineeringtips#studentstips#careertips#engineeringchallenges#EngieeringCareer#StudentSuccess#studentslife#HappyEngineersDay#careerengineering#careerdevelopment#CareerGrowth

1 note

·

View note

Text

Unlock the secrets to conquering pulsation challenges in pumping with expert insights and practical solutions. Learn essential tips and techniques to optimize your pumping systems for smooth, efficient operation.

0 notes

Text

Diving into the world of slurry pumps - because choosing the right one matters! 💡💪 Here are some tips on how to select the perfect fit.

0 notes

Text

PI Test of Transformer: All You Need to Know

The PI test of transformer is a crucial diagnostic tool used to assess the insulation health of power transformers. Electrical equipment relies heavily on insulation to function safely and effectively. Over time, insulation can degrade due to moisture, temperature, contaminants, and age. The polarization index (PI) test provides insights into the condition of this insulation and helps maintenance engineers make decisions about the operational readiness of a transformer.

PI Test of Transformer: All You Need to Know Transformers are vital assets in any power system. Their failure could cause unplanned outages, equipment damage, or even safety hazards. Conducting the PI test is part of a broader suite of maintenance and diagnostic tests designed to extend the life of the transformer and improve system reliability.

Importance of PI Test of Transformer

The PI test of transformer plays a key role in predictive maintenance. It allows plant operators to schedule downtime in a controlled manner and avoid unexpected failures. By assessing the dielectric properties of the insulation, the PI test estimates how well the insulation will perform under stress. It is widely recognized by standards organizations and used globally. The results of the test not only highlight the health of insulation but also provide a basis for further detailed analysis when necessary. The test is especially useful when a transformer has been exposed to moisture or has been idle for a long time.

Understanding the Concept Behind PI Test of Transformer

To grasp the PI test of transformer, it is important to understand what the Polarization Index (PI) is. The PI is the ratio of insulation resistance measured after 10 minutes to that measured after 1 minute. This gives a simple but reliable indication of the moisture content and contamination in the transformer insulation. A higher PI value suggests good insulation, while a lower value indicates possible degradation. Here is the polarization index formula used: Polarization Index (PI) = IR₁₀ / IR₁ Time (minutes)Insulation Resistance (IR) in MΩ1IR₁10IR₁₀ The result is typically a number ranging from 1.0 to above 4.0. A low PI value often means the transformer insulation has absorbed moisture or contaminants, which can lead to insulation failure. Read More....#PITest, #TransformerTesting, #InsulationResistance, #ElectricalMaintenance, #PowerTransformer, #PIValue, #MeggerTest, #ElectricalEngineering, #TransformerPI, #HighVoltageTesting, #PreventiveMaintenance, #SubstationTesting, #TransformerHealth, #ElectricalSafety, #EngineeringTips Read the full article

#ElectricalEngineering#ElectricalTesting#HighVoltageTest#InsulationResistance#MeggerTesting#PITest#PowerSystems#PreventiveMaintenance#SubstationEquipment#TransformerTest

0 notes

Text

Are you aware that optimal performance in #multistagepumps goes beyond component design? 🌟 Discover how #advancedhydrauliccontrol techniques can significantly enhance efficiency and reduce energy waste in large-scale pumping applications. From industrial cooling to major water supply projects, learn how these innovative solutions can extend pump lifespan and minimize maintenance needs.

👇🏻Dive into #MrNOP's tip for this week and unlock smarter water solutions. 💧

#WaterSolutions #PumpsTechnology #HydraulicEfficiency #EnergyEfficiency #EngineeringTips #SaudiProjects #KSAEngineering #MechanicalEngineers #PumpsExperts #WaterInnovation #SaudiLinkedIn

🌟هل تعتقد أن تصميم المضخة وحده هو سر الأداء الأمثل؟🌟

اكتشف كيف يمكن لتقنيات #التحكم_الهيدروليكي المتقدم أن تقلل من هدر الطا��ة وتزيد من كفاءة المضخات متعددة المراحل في المشاريع الكبرى

تعرف على الحلول الذكية التي تطيل عمر المضخة وتقلل الصيانة. 👇🏻اقرأ نصيحة Mr. NOP لهذا الأسبوع

#السعودية #مشاريع_الرياض

0 notes

Video

youtube

What Happens If You Connect a Capacitor to a Generator? | Electrical Tips

#ElectricalEngineering #GeneratorSafety #CapacitorConnection #PowerFactor #AlternatorTips #ElectricalConcepts #PowerFactorCorrection #EngineeringTips #GeneratorProtection #ElectricalBasics #Capacitor

0 notes