#Crankshaft inspection procedure

Text

0 notes

Text

How to Verify the Quality of a Reconditioned Range Rover Engine

A reconditioned Range Rover engine can be an economical and sustainable alternative to purchasing a brand-new engine. These engines are often rebuilt to meet or exceed original factory specifications, making them a popular choice for engine replacements. However, not all reconditioned engines are created equal, and knowing how to assess their quality is vital for buyers. In this article, we will discuss eight key aspects to look for when verifying the quality of a reconditioned Range Rover engine, including reconditioning processes, testing standards, parts quality, warranty options, and more. By understanding these factors, you can make an informed decision that ensures your vehicle continues to perform optimally after the engine replacement.

Understanding the Reconditioning Process

The first step in verifying the quality of a reconditioned Range Rover engines is to understand the reconditioning process itself. Reconditioning typically involves dismantling the engine, cleaning all components, and replacing or repairing parts that are worn or damaged. This process should adhere to strict guidelines to ensure that the engine is returned to a condition that closely mirrors a new one.

Check that the reconditioning process involves replacing key components such as pistons, bearings, gaskets, and seals. In addition, the engine block and cylinder head should be thoroughly inspected for cracks or defects. Reliable suppliers will also perform precision machining to ensure components meet factory tolerances. By thoroughly understanding the steps taken to recondition the engine, you can gain confidence in its long-term reliability.

Evaluating the Source of the Reconditioned Engine

It’s essential to investigate the source of the reconditioned Range Rover engine. Reputable suppliers are transparent about the origins of their engines and provide full documentation regarding the reconditioning process. Suppliers that specialize in Range Rover engines often have access to genuine or high-quality aftermarket parts, which contributes to the overall reliability of the reconditioned unit.

Be wary of suppliers that offer low prices without providing adequate information about the engine’s history or the reconditioning process. Ask for detailed records of the engine's previous usage, whether it was sourced from a salvaged vehicle, and how extensively it has been reconditioned. A trustworthy supplier will provide full transparency to give you peace of mind.

Ensuring High-Quality Parts Are Used

One of the most critical aspects of verifying the quality of a reconditioned Range Rover engine is to ensure that high-quality parts are used. The components used in the reconditioning process, including pistons, crankshafts, timing belts, and oil pumps, should either meet or exceed the original manufacturer’s specifications. Using substandard parts will compromise the longevity and performance of the engine.

When purchasing a reconditioned engine, ask the supplier about the brands and grades of parts used in the rebuild. Original Equipment Manufacturer (OEM) parts are ideal, but high-quality aftermarket parts can also be acceptable if they meet stringent standards. Suppliers who prioritize quality parts are more likely to provide reliable reconditioned engines.

Testing and Inspection Standards

Testing and inspection are critical stages of the reconditioning process that help ensure the engine is safe and reliable for use. Once the reconditioning process is complete, reputable suppliers will subject the engine to a battery of tests. These may include compression testing, oil pressure testing, leak testing, and performance evaluation under load conditions.

Ask the supplier for information about their testing standards and procedures. Engines that undergo thorough testing are far more likely to offer reliable performance once installed in your Range Rover. Additionally, inquire about inspection certificates or documentation that guarantees the engine has been tested and passed all necessary checks.

Warranty Options for Reconditioned Engines

A solid warranty is one of the most effective ways to verify the quality of a reconditioned Range Rover engine. Most reputable suppliers will offer a warranty that covers both parts and labor for a certain period. The warranty period typically ranges from six months to three years, depending on the supplier and the condition of the engine.

When reviewing warranty options, ensure that it covers essential components and that there are no hidden exclusions. The availability of a comprehensive warranty demonstrates the supplier’s confidence in the quality of their reconditioned engines. Additionally, consider opting for extended warranties if available, as they provide extra protection and peace of mind.

Supply and Fit Services

One of the key advantages of working with a reputable engine supplier is the option to choose "supply and fit" services. These services offer a complete solution, where the supplier not only provides the reconditioned engine but also handles its installation. This ensures that the engine replacement process is carried out by trained professionals, reducing the risk of improper installation.

Read the full article

0 notes

Text

How Is The Reconditioning Process Carried Out For Range Rover Engines?

Reconditioning Range Rover engines is a meticulous process that ensures these high-performance vehicles maintain their reliability and longevity. This procedure is essential for car enthusiasts and everyday users who want to extend the life of their Range Rover without the expense of a brand-new engine. Reconditioning not only restores an engine's functionality but also enhances its performance, making it a cost-effective and environmentally friendly alternative to replacement. We will delve into the detailed steps of the reconditioning process, highlighting each critical stage to provide a thorough understanding of what it entails.

Initial Assessment and Diagnosis

The first step in reconditioning Range Rover engines is the initial assessment and diagnosis. This phase involves a thorough inspection of the engine to identify any issues or wear and tear. Experienced mechanics use advanced diagnostic tools to scan the engine for faults and assess its overall condition. Key areas of focus include the cylinder heads, crankshaft, camshaft, and pistons. A detailed report is generated, outlining the necessary repairs and replacements. This diagnostic step is crucial as it sets the foundation for the entire reconditioning process, ensuring that all issues are identified and addressed.

Disassembly of the Engine

Once the initial assessment is complete, the next step is the disassembly of the engine. This process involves carefully taking apart the engine, piece by piece. Every component, from the smallest bolt to the largest part, is meticulously removed and inspected. This step is labor-intensive and requires precision to avoid damaging any parts. The disassembly allows mechanics to clean each component thoroughly and check for any signs of wear, cracks, or other damage. By dismantling the engine completely, technicians can ensure that every part is evaluated for its condition and suitability for reuse.

Cleaning and Inspection of Components

After disassembly, the individual components undergo a rigorous cleaning process. Specialized cleaning solutions and equipment are used to remove oil, grime, and carbon deposits from each part. Ultrasonic cleaning machines may be employed for intricate components to ensure every nook and cranny is spotless. Following the cleaning, a detailed inspection is carried out. Components are measured for wear and compared against factory specifications to determine if they meet the required standards. Any parts that do not meet these standards are either repaired or replaced. This step ensures that only the best quality parts are used in the reconditioning process.

Repair and Replacement of Worn Parts

With the components cleaned and inspected, the next stage involves the repair and replacement of worn or damaged parts. Skilled technicians use precision tools and machinery to restore parts to their original specifications. This may include machining the cylinder heads, grinding the crankshaft, and replacing piston rings and bearings. In cases where parts are beyond repair, new OEM (Original Equipment Manufacturer) parts are sourced and installed. This ensures that the reconditioned range rover engine meets or exceeds the performance standards of a new engine. The repair and replacement process is critical for achieving optimal engine performance and reliability.

Reassembly of the Engine

The reassembly of the engine is a meticulous process that requires expert knowledge and precision. Each component is carefully reinstalled in the correct sequence, ensuring all parts fit together perfectly. Lubricants and sealants are applied where necessary to ensure smooth operation and prevent leaks. Torque specifications are followed rigorously to ensure that bolts and fasteners are tightened correctly. The reassembly process is like putting together a complex puzzle, where every piece must be placed accurately to ensure the engine functions correctly. This stage is vital for the overall reliability and performance of the reconditioned engine.

Testing and Calibration

Once the engine is reassembled, it undergoes a series of tests and calibrations to ensure it performs optimally. Dyno testing is commonly used to simulate real-world driving conditions and measure the engine's performance. This includes checking for power output, torque, and fuel efficiency. Any deviations from expected performance are addressed by making necessary adjustments. Additionally, computerized diagnostic tools are used to fine-tune the engine's electronic systems, ensuring everything from fuel injection to ignition timing is perfectly calibrated. This thorough testing phase ensures that the reconditioned engine is ready for reliable use.

Quality Control and Certification

Quality control is a critical aspect of the reconditioning process. After testing and calibration, the engine undergoes a final inspection to ensure it meets all required standards. This includes checking for any leaks, abnormal noises, or other issues that could affect performance. Once the engine passes this rigorous quality control process, it is certified as reconditioned. Certification provides assurance to the customer that the engine has been restored to the highest standards of quality and reliability. This step is essential for building trust and confidence in the reconditioned engine.

Installation and Final Checks

The final step in the reconditioning process is the installation of the reconditioned engine into the vehicle. This involves carefully fitting the engine back into the Range Rover and connecting all necessary components, such as the transmission, exhaust system, and electrical systems. Once installed, the engine is subjected to a series of final checks to ensure everything is functioning correctly. This includes checking for any leaks, verifying the correct operation of all systems, and conducting a test drive. The final checks ensure that the reconditioned engine operates smoothly and reliably, ready to provide many more years of service.

Conclusion

Reconditioning a Range Rover Engines is a comprehensive and detailed process that restores the engine to its optimal performance. From the initial assessment and disassembly to the final installation and checks, each step is meticulously carried out to ensure the highest standards of quality and reliability. This process not only extends the life of the engine but also enhances its performance, making it a cost-effective and sustainable alternative to engine replacement. For Range Rover owners, understanding the reconditioning process provides peace of mind, knowing that their vehicle's heart is restored to its best possible condition.

Read the full article

0 notes

Text

Engine Reconditioning: Restore Power and Efficiency

Introduction:

Engine reconditioning is the main process for maintaining and enhancing the performance of internal combustion engines. Even if it’s a classic car, a daily commuter, or a high-performance vehicle, engine reconditioning guarantees that your engine runs smoothly, efficiently, and with robust power. Trust in the process of reconditioning to keep your car fit, so you can enjoy the ride with confidence and excitement every time you hit the road.

Understanding Reconditioning Process:

Engine reconditioning is often defined as engine rebuilding or remanufacturing, a meticulous process focused on restoring an engine to its original condition or even better. This detailed procedure goes far beyond simple repairs. It includes disassembling the engine, thoroughly cleaning and examining each component, replacing worn or damaged parts, and meticulously reassembling the engine. The main goal is to bring back the engine to meet or surpass its original performance standards.

Benefits of Engine Reconditioning:

Boost Performance: With improved horsepower and torque, a reconditioned engine works smoothly and more efficiently.

Increased Longevity: A perfectly reconditioned engine can last just as long, or even longer, than brand-new ones.

Cost Effective: Reconditioning an engine can be a more cost-effective choice as compared to purchasing a new one, mainly when dealing with rare or high-performance engines.

Environmental Impact: Regenerating the engine components reduces waste and demand for new parts, making reconditioning a greener choice.

The Engine Reconditioning Process:

- Initial Inspection and Disassembly:

The reconditioning process begins with a meticulous inspection. At first, the engine is removed from the vehicle and completely disassembled. Every part is meticulously examined to determine the extent of wear and damage. This part is important to recognize which part can be reused and which needs replacement.

- Cleaning and Surface Preparations:

After disassembling, all engine parts go through a meticulous cleaning, which includes a hot tank cleaning, ultrasonic cleaning, or further methods to remove oil, grease, carbon deposits, and other contaminants. Clean parts are easier to examine and prepare for the next steps.

- Machining and Rebuilding:

Machining is the crucial phase in the reconditioning process. It includes resurfacing the cylinder head, boring and honing cylinders, grinding crankshafts, and reconditioning connecting rods. Accuracy is dominant here, as even the smallest difference can affect the engine performance.

- Replacement of Worn Parts:

In the process of reassembling, any worn or damaged parts are replaced. It involves pistons, bearings, gaskets, seals, and valves. High-quality replacement parts guarantee the engine operates efficiently and reliably.

- Reassembly and Testing:

The last step involves meticulously reassembling the engine. This contains proper torque settings, alignment, and confirming all parts are accurately fitted. After reassembling, the engine is stringently tested to make sure it meets or exceeds original specifications. This can include bench testing, dynamometer testing, and real-world driving conditions.

- Engine Specifications:

While reconditioning an engine, certain specifications must be met to ensure excellent performance. Here are the main specifications and their performance:

- Cylinder Bore and Stroke:

The bore (diameter of the cylinder) and stroke (distance the piston travels) are the basic specifications. Accurate measurements are important for maintaining the engine’s displacement and performance characteristics.

- Compression Ratio:

Making sure that the engine’s optimal performance includes maintaining the perfect compression ratio, which is the comparison between the cylinder’s volume at the bottom of the piston stroke and its volume at the top. This main aspect of engine reconditioning guarantees that the power and efficiency levels match the manufacturer's specifications.

- Valve Timing:

The accurate timing of the valves, which are controlled by the camshaft is essential. It makes sure that the intake and exhaust valves open and close accurately when needed. This accuracy is important for optimizing both the intake of the air-fuel mixture and the flow of exhaust gases.

- Oil Clearance and Pressure:

The oil clearance process defines the space between moving parts, allowing for lubrication. Proper oil clearance and pressure are necessary to prevent engine wear and guarantee smooth operation.

Advanced Techniques in Engine Reconditioning:

- Cryogenic Treatment:

This treatment includes freezing engine elements to extremely low temperatures and then slowly returning them to room temperature. This process improves the strength and reliability of metal parts, reducing wear and extending the engine’s life.

- Plasma Coating:

In this process, the proactive layer is applied to the engine components like pistons and cylinder walls. This coating reduces friction and wear, boosting efficiency and longevity.

- Balancing and Blueprinting:

Balancing confirms that all rotating components (crankshaft, flywheel, etc) are balanced to minimize vibrations and wear. Blueprinting includes ensuring all engine parts meet accurate specifications, enhancing performance and reliability.

Conclusion:

Engine reconditioning is a comprehensive process designed to restore an engine’s performance and efficiency to original or even superior levels. This detailed procedure includes meticulously addressing each aspect of the engine, from cleaning and accurate machining to the strategic replacements of the parts and stringent testing. Even if you are an owner of a classic automobile or a modern vehicle enthusiast, engine reconditioning emerges as a cost-saving and environmentally responsible method to guarantee your engine works at peak performance and durability.

Read the full article

0 notes

Text

How to Find a Quality Used Engine for Sale

Engine

The engine, the machine's heart, converts heat from gasoline combustion into vehicle velocity through shortened gasoline and air vapor detonated in a sealed cylinder via spark.. The combination burns quickly, giving the truck the power to propel itself. The cylinder head, a retractable upper cover, combined the inner cylinder block, a housing for the engine's primary performing elements, make up the sturdy framework of the engine. The cylinder head contains valve-controlled passageways for fuel mixes and air introduction and elimination. The block houses pistons that convert translational piston action into rotating motion at the crankshaft, and the crankshaft, which turns the cylinder's valves, which eventually burn out.. It might be better to get a used engine as opposed to shelling out an immense amount of money for a brand-new engine. There are multiple auto salvage yards in the area that supply vehicles as well as trucks with outstanding Used Engines For Purchase that you can replace and install in the car you have. Here are a few suggestions for buying refurbished engines. To find a suitable cylinder for your car and potentially find similar vehicles, contact nearby auto salvage yards in your town and inspect the used engine's quality before visiting the garage to determine if they have similar vehicles. Certain vehicles have immaculate units even when the car body is entirely destroyed, something may surprise you.

Why Choose Tagore Auto Parts?

Choosing Tagore Auto Parts for your automotive needs comes with several benefits that set them apart from other suppliers. Here are some compelling reasons to consider Tagore Auto Parts:

Wide Selection:

ensuring that clients can locate portions for an extensive list of different makes and models, including domestic ones, foreign, vintage, and transportation vehicles, Tagore Auto Parts provides an extensive collection of parts for vehicles. Engines, gearboxes, engine components, electric power parts, suspension for an extended period brake systems, combustion systems, and other parts are all in stock. They provide performance and skilled parts in beyond OEM and aftermarket services choices. Tagore Auto Parts guarantees dependability and relationship with regular inventory changes and its expansive online catalog, therefore serving as an authoritative source for all vehicle needs.

Quality Assurance:

Tagore Auto Parts places a high priority on maintaining high standards, implementing each component throughout an extensive assessment and testing procedure. High performance as well as security requirements are consequently guaranteed. Either it's a rebuilt, refurbished, or used part, every single one is examined by their highly qualified technicians for guaranteed dependability. Tagore Auto Sections supplies low pricing on excellent quality, functional automotive parts to provide clients with contentment and confidence. Customers may save money without negatively impacting functionality or confidence thanks to their comprehensive inspection and testing procedures, which somewhat uphold their reputation in manufacturing durable, confident equipment. These affordable choices ensure you acquire the greatest value for your money while maintaining the finest possible condition for your car, making auto servicing and maintenance more accessible.

Expertise:

Tagore Auto Parts offers exceptional support and guidance to clients, with knowledgeable experts ready to assist in choosing and executing installation techniques, ensuring the best features for the specific requirements of your car.. The team of experts at Tagore Auto Parts is ready to provide you with intricate insights and practical solutions, irrespective of whether you are embarking on a challenging restoration or are just doing periodic inspections. Everyone's progress while comprehending on your motor automobile activities will benefit as a result.

Warranty and Support:

Tagore Auto Parts offers an effortlessly return policy and a thorough guarantee to support the quality of the items they sell. Their guarantee gives customers piece of mind by guaranteeing than any flaws or problems will be swiftly fixed right away. If necessary, it is uncomplicated to swap or return ingredients thanks to the clear replacement policy, what guarantees total satisfaction with your purchase. At Tagore Auto Parts, you may purchase with assurance recognizing that you are respected and safeguarded at every turn. Environmental Responsibility:

Tagore Auto Parts is a leading company in the automotive industry, committed to environmental responsibility. They encourage the reuse and recycling of car components, reducing waste and providing high-quality old and refurbished equipment. .

Reliable Delivery:

Tagore Auto Parts promises reliable delivery, so you can be sure your parts will reach on time and in good condition. Because to their efficient transportation strategies and careful packing, your orders will be delivered on time and safely. Some of you may depend on Tagore car parts for accurate and punctual transportation, which will reduce your stress levels even if how much routine maintenance or emergency auto repairs require.

Competitive Pricing:

Tagore Auto Parts offers affordable solutions for the vehicle needs while maintaining affordable prices. They help companies save expenses without sacrificing dependability through providing premium used and refurbished components at reasonable prices. Tagore Auto Parts have become a favored option for those on a tight budget on account of their dedication to offering low prices that guarantees buyers obtain value for their investment.

Contact Us

Tagore Auto Parts is committed to top-quality engine parts and great service. Got a question or need help? Contact us

Phone: +1 888-558-6437

Email: [email protected]

Website: www.tagoreautoparts.com

More visit:-

https://www.facebook.com/Tagoreautopartsofficial/https://www.instagram.com/tagoreautoparts/

1 note

·

View note

Text

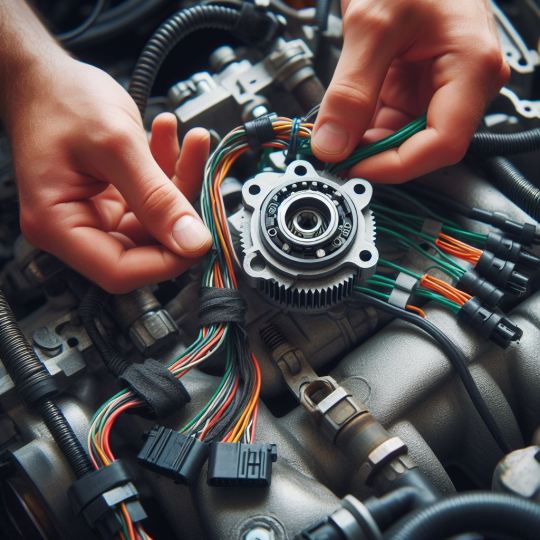

Common Car Repair: How To Fix Crankshaft Position Sensor Wiring Harness

Understanding the Crankshaft Position Sensor Wiring Harness

The crankshaft position sensor is a critical component that monitors the engine's crankshaft speed and position. While the sensor collects this vital data, the wiring harness ensures it gets accurately transmitted to the engine's computer (ECU). This harness comprises wires, connectors, and terminals designed to be durable, heat-resistant, and well-insulated to prevent electrical faults. However, like any part, it can wear down over time.

Symptoms of a Faulty Wiring Harness

A faulty crankshaft position sensor wiring harness can lead to various issues impacting the vehicle's performance, often mimicking a bad sensor itself:

- Check engine light illumination

- Hard starting or no-start conditions

- Erratic engine behavior like stalling, hesitation, or misfiring

- Reduced fuel efficiency

- Engine vibration or shuddering

- Irregular tachometer readings

- Poor acceleration

- Frequent stalling at low speeds/idling

- Engine shutoff while driving

These symptoms arise because the ECU cannot receive accurate data about the crankshaft's position and timing from the sensor due to wiring issues.

Diagnosing the Problem

Properly diagnosing the root cause is essential before attempting any repairs:

Visual Inspection - Look for damage like fraying, burns, cuts, loose connections, or corrosion on the wiring harness.

Scan for Error Codes - Use an OBD scanner to retrieve any diagnostic trouble codes related to the crankshaft position sensor.

Multimeter Testing - Check wire continuity by disconnecting the harness and using a multimeter to test each wire for uninterrupted connectivity.

Check Sensor Operation - If the harness appears okay, you may need to test the resistance of the crankshaft position sensor itself per specifications.

Monitor Engine Behavior - Observe for symptoms like hesitation, misfires, or stalling that could indicate a faulty sensor or harness.

Consult Service Manual - Refer to your vehicle's repair manual for model-specific diagnostic procedures and specifications.

How to fix crankshaft position sensor wiring harness? Repair Tools and Parts Needed:

- Replacement crankshaft position sensor

- Electrical tape

- Wire connectors

- Wire strippers

- Screwdrivers

- OBD scan tool

- Multimeter

- Protective gloves

Safety Precautions

- Disconnect the battery

- Work in a well-ventilated area

- Wear gloves and safety glasses

How to Fix the Wiring Harness

1. Locate the crankshaft position sensor and its wiring harness, often near the front bottom of the engine.

2. Access the sensor area by removing any obstructing components per instructions.

3. Inspect the harness closely for any visible damage.

4. Determine if a minor wire repair or full harness replacement is needed based on the damage.

5. For wire repair: Cut out damaged section, strip wire ends, join with solder and cover with heat-shrink tubing or electrical tape.

6. For full harness replacement: Disconnect old harness, install and route new one per diagram, and secure with clips/ties.

7. Reassemble any other components that were removed.

8. Reconnect battery and start engine to test repair.

Testing and Validating the Repair

- Visually inspect that wiring is well-secured and routed properly

- Use an OBD scanner to check for any lingering error codes

- Monitor engine for proper idling, acceleration, RPM stability

- Take it for a test drive checking for any abnormal performance

- Ensure the check engine light remains off

- Re-inspect wiring after a few days of driving

Prevention Tips

- Perform regular inspections of wiring for wear

- Avoid overheating and exposure to moisture

- Secure wiring away from moving/hot components

- Use dielectric grease on connectors

- Don't make modifications that could impact wiring

- Replace old/damaged protective components

- Use quality replacement parts

- Follow maintenance schedules

- Limit excessive idling

- Keep the engine bay clean and clear of debris

In summary, the crankshaft position sensor wiring harness plays a vital role in delivering accurate sensor data to the engine computer for proper operation. Addressing any wiring issues promptly by carefully diagnosing the root cause, using the right tools, precisely following repair steps, and validating the fix can prevent further drivability problems. Proper maintenance and protection of this wiring is also key for longevity. With the right knowledge and precautions, repairing this harness is an accessible job for the diligent DIYer.

0 notes

Text

How does BMW select the used engines that are suitable for reconditioning?

Introduction

When it comes to reconditioning used engines, BMW follows a meticulous selection process to ensure quality, reliability, and performance. In the automotive industry, reconditioned engines offer an environmentally friendly and cost-effective alternative to new ones. BMW's commitment to excellence extends beyond its production line to the refurbishment of BMW used engines. In this article, we delve into the sophisticated selection process BMW employs to identify engines suitable for reconditioning.

Understanding BMW's Engine Reconditioning

Overview of BMW's Engine Reconditioning Program

BMW's engine reconditioning program aims to breathe new life into pre-owned engines, aligning with the brand's commitment to sustainability and quality. The process involves a thorough assessment, repair, and restoration of used engines to meet BMW's stringent standards.

Initial Inspection and Assessment

Before any engine undergoes reconditioning, BMW conducts a comprehensive initial inspection and assessment. This step involves evaluating various parameters such as mileage, service history, wear and tear, and potential damage.

Criteria for Engine Selection

BMW applies strict criteria to select engines eligible for reconditioning. These criteria encompass factors like age, mileage, structural integrity, and the engine's overall condition. Only engines meeting BMW's high standards proceed to the reconditioning phase.

Diagnostic and Testing Procedures

Once selected, engines undergo extensive diagnostic tests to identify any underlying issues or malfunctions. BMW utilizes advanced diagnostic equipment and software to pinpoint areas requiring attention, ensuring thoroughness and accuracy in the assessment process.

Component Analysis and Replacement

During reconditioning, BMW meticulously analyzes each engine component, identifying parts that require replacement or refurbishment. From pistons and crankshafts to cylinder heads and valves, every component undergoes scrutiny to uphold BMW's performance and durability standards.

Precision Engineering and Refurbishment

BMW's reconditioning process integrates precision engineering techniques and state-of-the-art machinery to refurbish engine components to factory specifications. Skilled technicians meticulously restore components to ensure optimal performance and longevity.

Quality Assurance and Testing

Quality assurance is paramount in BMW's engine reconditioning process. Reconditioned engines undergo rigorous testing to validate performance, reliability, and durability. BMW subjects engines to simulated driving conditions and load tests to verify their functionality and resilience. Get the best information about the bmw engine visit at https://www.bmwenginesexpert.co.uk/ .

Environmental Sustainability and Compliance

BMW remains committed to environmental sustainability throughout its operations, including engine reconditioning. The company adheres to eco-friendly practices and regulations, minimizing waste generation and maximizing resource efficiency in the reconditioning process.

FAQs:

What types of engines does BMW recondition?

BMW reconditions a wide range of engines, including petrol, diesel, and hybrid variants used across its vehicle lineup.

How does BMW ensure the reliability of reconditioned engines?

BMW employs stringent selection criteria, diagnostic procedures, and quality assurance measures to ensure the reliability of reconditioned engines.

Are reconditioned BMW engines covered by warranty?

Yes, reconditioned BMW engines typically come with a warranty, offering customers peace of mind and assurance of quality.

How does BMW contribute to environmental sustainability through engine reconditioning?

BMW promotes environmental sustainability by refurbishing and reusing engines, reducing the need for new engine production and minimizing environmental impact.

Conclusion

In conclusion, BMW's engine reconditioning process exemplifies a harmonious blend of technological innovation, human expertise, and environmental stewardship. By adhering to stringent selection criteria, leveraging advanced diagnostic technologies, and prioritizing quality assurance, BMW ensures that reconditioned engines meet the highest standards of performance and reliability. As BMW continues to evolve its reconditioning practices, it remains committed to delivering sustainable solutions that enhance customer satisfaction while minimizing environmental impact.

Read the full article

#BMWenginemaintenance#BMWenginemaintenanceandrepair#BMWEngineOnline#BMWenginereplacement#BMWEngines#BMWusedengines#usedengines

0 notes

Text

How does BMW ensure the quality and reliability of its reconditioned engines?

Introduction

BMW, renowned for its precision engineering and commitment to excellence, extends its dedication to quality beyond manufacturing new vehicles. The company's reconditioned engines program exemplifies this commitment, offering customers a reliable and sustainable option for vehicle maintenance. We delve into BMW's meticulous process for ensuring the quality and reliability of its reconditioned engines, highlighting the steps taken to meet the brand's exacting standards.

Understanding Reconditioned Engines

Before delving into BMW's specific practices, it's crucial to understand the concept of reconditioned engines. Reconditioned engines, also known as remanufactured or rebuilt engines, undergo a comprehensive restoration process to meet original manufacturer specifications. This process involves disassembling, inspecting, and refurbishing various engine components to ensure optimal performance and longevity.

BMW's Commitment to Quality

BMW's reputation for precision engineering and performance excellence hinges on its unwavering commitment to quality. This dedication extends to every aspect of the company's operations, including its reconditioned engines program. By upholding stringent quality standards, BMW aims to deliver unparalleled reliability and customer satisfaction.

Stringent Quality Control Measures

At the core of BMW's approach to reconditioned engines lies a series of stringent quality control measures. These measures are meticulously implemented at every stage of the remanufacturing process to guarantee the highest standards of performance and reliability. From initial inspection to final testing, each step is carefully executed to uphold BMW's reputation for excellence.

Thorough Inspection and Assessment

The journey of a reconditioned BMW engine begins with a thorough inspection and assessment of its components. Skilled technicians meticulously examine each part, identifying any signs of wear, damage, or irregularities. This meticulous assessment forms the foundation for the subsequent refurbishment process, ensuring that only components meeting BMW's exacting standards are utilized. More information about the mbw engine visit us at https://www.bmenginespecialists.co.uk/.

Precision Refurbishment Techniques

BMW employs precision refurbishment techniques to restore engine components to like-new condition. From cylinder heads to crankshafts, each part undergoes meticulous refurbishment using advanced machinery and techniques. Whether it's machining, honing, or polishing, BMW's technicians adhere to precise specifications to optimize performance and durability.

Utilization of Genuine BMW Parts

Central to BMW's commitment to quality and reliability is the utilization of genuine BMW parts in the reconditioning process. Genuine parts not only ensure compatibility and fitment but also uphold the integrity and performance characteristics of the original engine design. By using authentic components, BMW safeguards the reliability and longevity of its reconditioned engines.

Rigorous Testing Protocols

Before being deemed fit for installation, reconditioned BMW engines undergo rigorous testing protocols to validate their performance and reliability. These testing procedures encompass a comprehensive range of assessments, including dynamic testing, compression testing, and leak testing. By subjecting engines to simulated real-world conditions, BMW verifies their ability to deliver optimal performance and durability.

Environmental Sustainability

In addition to quality and reliability, BMW reconditioned engines program embraces environmental sustainability. By refurbishing existing engines, BMW reduces the environmental impact associated with manufacturing new components. This commitment to sustainability aligns with BMW's broader environmental initiatives, underscoring the company's holistic approach to responsible manufacturing and resource utilization.

Conclusion

BMW's reconditioned engine program exemplifies the brand's unwavering commitment to quality, reliability, and sustainability. Through meticulous inspection, precision refurbishment, and rigorous testing, BMW ensures that each reconditioned engine meets the exacting standards synonymous with the brand. By embracing genuine parts and sustainable practices, BMW not only delivers superior performance but also minimizes its environmental footprint. As customers seek reliable and sustainable solutions for vehicle maintenance, BMW's reconditioned engines stand as a testament to innovation, excellence, and enduring quality.

Read the full article

0 notes

Text

Reviving the Heart of Your Mercedes: Expert Engine Repair Services

Mercedes-Benz, renowned for its reliability and performance, is a brand synonymous with luxury and precision engineering. However, like any complex machine, even the most meticulously crafted Mercedes cars may encounter issues, particularly when subjected to poor maintenance or neglectful driving practices. Among the various challenges Mercedes owners may face, engine problems stand out as one of the most critical. In this article, we will explore the importance of engine repairs, shedding light on the vital components that demand attention and the expert services available to rectify these issues.

The Significance of Engine Repairs

The engine serves as the heart of any car, providing the necessary power to all dynamic components and systems. Without a properly functioning engine, a car is rendered lifeless. It kickstarts the vehicle and supplies energy to the electrical system, making the engine an indispensable component for the overall functionality of the car.

Engine repairs become imperative when certain components within the engine system begin to malfunction or show signs of damage. Ignoring these issues can lead to a cascade of problems, jeopardizing the health and performance of the entire vehicle. Expert engine repairs are crucial to identify and rectify these problems, ensuring the longevity and optimal performance of your Mercedes.

Common Engine Repairs for Mercedes

Engine Flush:

A simple yet crucial procedure, engine flushing involves removing dirt, debris, and contaminants from the engine. This preventive measure helps avoid more expensive repairs in the future, maintaining the health of the engine.

Spark Plugs and Ignition Coil Change:

Faulty spark plugs or ignition coils can disrupt the combustion process and compromise power generation. These components are inspected, cleaned, and replaced if necessary to ensure a smooth and efficient engine performance.

Engine Belt Replacement:

Aging and wear can lead to the deterioration of the timing belt in the engine. A worn belt can disrupt the timing processes, resulting in power loss. Regular inspection and timely replacement of the timing belt are essential for optimal engine function.

Piston Replacement:

Damaged piston seals and piston heads can significantly impact engine performance. Replacing these components is necessary to restore the engine's efficiency and power.

Crankshaft Repair:

As a major engine component, a damaged crankshaft can have severe repercussions. Replacement of the crankshaft is crucial to ensure the overall functionality of the engine.

Seal and Gasket Replacement:

Various seals and gaskets in the engine prevent leaks and ensure proper containment of fluids. Over time, these components can become damaged due to heat, pressure, and aging. Inspecting and replacing these seals prevent fluid leakages and contamination within the engine.

Engine Mount Replacement:

Engine mounts play a vital role in supporting and stabilizing the engine externally. Damaged mounts can compromise the engine's position and expose it to potential damage. Regular replacement of engine mounts safeguards the engine against vibrations and shocks, preserving its integrity.

Valve Maintenance:

Essential valves in the engine enable the intake and exhaust processes. Stuck valves can lead to critical issues, and thorough cleaning or replacement is necessary to maintain optimal engine performance.

Conclusion

Mercedes owners seeking top-notch performance and reliability must prioritize expert engine repairs. These services, typically available at authorized Mercedes service centers, offer a combination of expert technicians, genuine Mercedes parts, and meticulous care. The outlined engine repairs address crucial components, ensuring that your Mercedes operates at its peak efficiency.

The costs associated with engine repairs can vary depending on the type and extent of the fix required. However, investing in timely and expert engine repairs is a wise decision to avoid more significant issues and safeguard the long-term health of your Mercedes. Trusting your vehicle to skilled professionals who understand the intricacies of Mercedes engines ensures that your luxury car continues to deliver the performance and driving experience you expect.

0 notes

Text

Diaphragm Compressors

Diaphragm Compressors are basically sort of devices used for storage of atmospheric air that are too high in potential. This is usually used in pneumatic devices. By rotating the membrane this compresses air. The compressed air is then stored in a storage like tube section.To know more about the process of the air compressor, visit the VannDigit.

There is a hydraulic piston system in the diaphragm compressor which is designed in such a way that that bearings are removed and is well sealed, this is done so that the gas and the ionic liquids do not match. Many good manufactures like PDC Machines manufactures process gas compressors and other diaphragm gas compressors such as TFE and carbon monoxide compressors make quality diaphragm compressors. Membrane compressors is the other name given to these devices. CNC precision machining can provide ultra precise measurements on any sort of job and for any sort of product, part, etc. The more axes that the machine operates on the higher the results are for precision. Most of the time, the simplest precision capabilities comes from the CNC 5 axis machines. The cnc precision machining strategies explain by contour precision.

How Does a Generator Work? – The answer to that question starts with, “It depends!” It depends on the type of generator you’re speaking about. There are numerous types of generators. There are: Propane Generators, Diesel Generators, Wind Generators, Gas Generators, Natural Gas Generators and even Bio-Fuel Generators. Of course, there are probably some sources of generator power that I’ve missed. Generators that produce electricity operate on that same principle, just in reverse! Since I used a fan as an example, I’m going to spin things around and use a Wind Generator to explain this principle. This time we’re going to take the same fan and place it outside, not to provide a breeze, but to receive a breeze. As the wind blows, the blades on the fan turn. Attached to the blades is a shaft that goes into an electric generator motor. As this shaft attached to the motor turns, it produces electricity. Depending on the size of the generator, it may have just enough power to accommodate a small electric saw. Or, it can produce enough power to light up an entire hospital! Here you get the detail procedure about how do inverter generators work.

https://ml3i6vawpoq6.i.optimole.com/w:1920/h:1080/q:mauto/f:best/https://www.dswgascylinder.com/wp-content/uploads/2022/04/gas-cylinders-inspections-tests4.png

DIAPHRAGM COMPRESSOR AND ITS COMPONENTS:

The Check Valves:

The check valves are indicated to coordinate the working conditions and the procedure gas. The valves are effectively available for investigation, fix or substitution.

The Hydraulic Inlet Check Valve:

This is for hydraulic fluid inlet check valves.

The Hydraulic pistons:

Cylinder is to pressurize the stomach. For higher weights, a cylinder without a ring, without pressing, acclimates to the arrival to a solidified and honed sleeve.

Hydraulic valves over pump:

It controls the weight in the pressure driven framework. The joined development of the stem, ball, and spring decides the weight scope of the valve.

The glass for over pump site:

This is the glass cover through which we can see the hydraulic fluid.

The injection pump Hydraulic:

This is run by the crankshaft, the pump provides the fluid in the hydraulic system.

THE WORKING OF DIAPHRAGM COMPRESSORS:

The diaphragm compressor comprises 2 frameworks, a hydraulic framework and a pneumatic force framework. Metal diaphragm is a defensive segment between the two systems. The pneumatic force framework comprises 3 diaphragm metal plates which are sandwiched between two plate depressions, air info and yield forms.

Hydraulic crankshaft engine control framework that moves the cylinder in low weight. The exchange of this cylinder manages the hydraulic liquid inverse to bring down the side piece of the diaphragm, the depression swing causes an adjustment noticeable all around procedure.

A few segments of the hydraulic framework can consequently fill the siphon, hydraulic liquid valve and air hydraulic valve that siphons overabundance air. To guarantee that the hydraulic framework consistently meets the weight revolution, the programmed filling siphon sends quick fisherman in the hydraulic framework after the compressor is killed. When there is a compressive power on the principle cylinder, the check valve shields the hydraulic framework from the programmed filler siphon, in this way a weight sponsor can be created in a framework that restricts the hydraulic siphon valve.

HOW ARE DC (DIAPHRAGM COMPRESSORS) VALUABLE?

The diaphragm comes with many benefits and uses, it provides a void oil pressure because of the hermetic partition among gas and oil chamber, Scraped area free pressure because of static seals in the gas stream, Programmed shutdown if there should arise an occurrence of a diaphragm disappointment forestalls harm and this also has the capacity to release pressure till 3000 bar.

0 notes

Text

The Process of Forging: How Forged Components are Manufactured

Introduction:

Forging is a centuries-old manufacturing method that produces strong and long-lasting metal parts. In this post, we will look at the intriguing process of forging as well as how forged components are made. Let's explore the topic of forging, from raw ingredients to the finished product!

1. Understanding the Fundamentals of Forging: What exactly is forging, and why is it used?

- Forging processes include hammer forging, press forging, and roll forging.

- The advantages of forging over other methods of manufacturing.

2. Choosing the Right Material: -

- Metals commonly used in forging include steel, aluminium, titanium, and others.

- Considerations while selecting a forging material.

- The effect of material qualities on forged component performance.

3. Raw Material Preparation:

- Choosing and inspecting raw materials.

- Heating the material: the significance of temperature management.

- Different types of forging heating processes.

4. The Forging Method:

- Basic forging techniques include upsetting and drawing out.

Bending, punching, and trimming are examples of secondary forging operations.

- Material shaping and deformation techniques such as open-die forging and closed-die forging.

5. Heat Treatment and Finishing: -

-The role of heat treatment in improving mechanical properties.

- Common heat treatment methods include annealing, quenching, and tempering.

- Surface finishing techniques such as machining, grinding, and polishing.

6. Forging Quality Control: Ensuring the integrity of forged components through inspection and testing.

- Non-destructive testing procedures such as ultrasonic testing and magnetic particle inspection, among others.

- Compliance with industry norms and certifications.

7. Forged Component Applications: - Industries that rely significantly on forged components include automotive, aerospace, oil and gas, and so on.

Forged components include crankshafts, connecting rods, gears, and turbine blades.

- The benefits of using forged components in high-stress applications.

Conclusion:

Forging is a versatile and efficient production method that yields strong and dependable components. Each step in the forging process contributes to the strength and longevity of the end product, from selecting the correct material to the last finishing touches. Understanding the complexities of forging allows us to comprehend the critical role it plays in numerous industries as well as the extraordinary engineering that goes into forged components.

1 note

·

View note

Text

How Does The Reconditioning Process Improve The Performance Of A Land Rover Defender Engine?

In the realm of automotive engineering, the Land Rover Defender stands as a paragon of rugged durability and off-road prowess. Central to its performance is the Land Rover Defender Engine, a complex assembly of components that undergoes wear and tear over time. To maintain optimal performance, reconditioning emerges as a crucial process. We delves into how reconditioning enhances the performance of Land Rover Defender engines, exploring its key benefits and procedures.

Understanding Reconditioning

Reconditioning an engine involves a comprehensive overhaul to restore its functionality and efficiency. For Land Rover Defender engines, this process is particularly vital due to their robust use in challenging terrains and conditions. It typically includes disassembly, inspection, cleaning, and replacement of worn-out parts with new or refurbished components. This meticulous approach ensures that the engine operates at peak performance levels, delivering the power and reliability expected from a Land Rover Defender.

Key Benefits of Reconditioning

Reconditioning offers several significant advantages for Land Rover Defender engines. Firstly, it extends the engine's lifespan by addressing underlying issues and preventing potential failures. Secondly, it enhances reliability, reducing the likelihood of breakdowns during demanding off-road adventures. Thirdly, reconditioned engines often exhibit improved fuel efficiency and power delivery, optimizing the vehicle's overall performance. These benefits underscore the importance of regular maintenance and reconditioning in preserving the Defender's legendary capability.

Components of a Reconditioned Engine

A reconditioned Land Rover Defender engine undergoes meticulous attention to various components. Cylinder heads, pistons, crankshafts, and bearings are among the critical parts inspected and refurbished or replaced as necessary. Each component plays a vital role in the engine's operation, and their thorough reconditioning ensures that the engine functions smoothly and reliably under strenuous conditions. This comprehensive approach distinguishes reconditioning from routine maintenance, emphasizing its role in sustaining peak performance.

The Reconditioning Process

The process begins with the removal of the engine from the vehicle, followed by disassembly and thorough cleaning of components. Skilled technicians meticulously inspect each part for wear, damage, or signs of fatigue. Damaged components are either refurbished using specialized techniques or replaced with new ones to restore optimal functionality. Precision assembly and rigorous testing are integral to ensure that the reconditioned engine meets factory specifications and performs flawlessly in diverse driving scenarios.

Technological Advancements in Reconditioning

Advancements in technology have revolutionized the reconditioning process for Land Rover engines. Computerized diagnostic tools, precision machining equipment, and 3D modeling software enable technicians to achieve unprecedented accuracy and efficiency. These technologies facilitate detailed analysis of engine performance metrics, guiding targeted interventions to enhance reliability and performance. As technology continues to evolve, so too does the efficacy of reconditioning in maintaining the Defender's status as a pinnacle of automotive engineering.

Cost Considerations and Long-Term Savings

While reconditioning entails upfront costs, it offers substantial long-term savings for Land Rover Defender owners. By extending the engine's lifespan and improving efficiency, reconditioning reduces maintenance expenses and minimizes the risk of costly repairs associated with engine failures. Moreover, reconditioned engines often exhibit enhanced fuel economy, translating into lower operational costs over time. Thus, investing in reconditioning proves economical and prudent for enthusiasts and professionals alike who rely on the Defender's enduring performance.

Environmental Impact and Sustainability

Reconditioning Land Rover Defender engines aligns with sustainability goals by promoting resource conservation and reducing environmental footprint. By refurbishing existing components rather than replacing entire engines, reconditioning minimizes waste generation and conserves valuable raw materials. Furthermore, enhancing engine efficiency through reconditioning reduces carbon emissions associated with fuel consumption, contributing to environmental stewardship. These eco-friendly benefits underscore reconditioning as a sustainable practice essential for preserving both performance and the planet.

Conclusion

In conclusion, reconditioning significantly enhances the performance of Land Rover Defender engines by restoring reliability, optimizing efficiency, and extending lifespan. This meticulous process addresses wear and tear accumulated during rigorous off-road use, ensuring that the Defender maintains its iconic status as a vehicle of choice for adventurers and enthusiasts worldwide. Embracing reconditioning not only enhances driving experience but also embodies a commitment to sustainability and long-term value. As automotive technology continues to evolve, reconditioning remains a cornerstone in preserving the legacy of Land Rover's legendary capability.

Read the full article

#LandRoverDefenderEngine#LandRoverDefenderEngineTechnology#LandRoverDefenderengines#LandRoverDefenderenginesforsale

0 notes

Text

Repair of the Crankshaft or Polishing and Grinding

RA Power observed during crankshaft polishing on vessel the formation of bearing line marks and pitting marks as a result of bearing failure or bearing top layer loss. It is apparent that the crankshaft experiences the following issues as a result of extended use of diesel engines and reciprocating machinery: Expansion of ovality and taper past the boundaries due to the fact that, depending on the limitations stated in the engine care handbook, the hardness may increase or decrease. Cracks in the main journals and crank pin are removed by grinding and polishing.For more information about crankshaft machining and polishing, contact us at [email protected], 0124-425-1615, or +91-9810012383.

#crankshaft grinding machine manufacturer#crankshaft grinding and repair#in situ grinding crankpins#grinding of crankshaft#crankshaft grinding machine#onsite crankshaft grinding machine#crankshaft grinding#babbitt bearing#crankshaft repair services#caterpillar crankshaft repair

0 notes

Text

How to test ignition control module honda civic

1.How to test ignition control module honda civic

The ignition control module is an essential component in a vehicle's ignition system. In the case of the GM 3.8, the ignition control module is responsible for controlling the ignition spark in each cylinder of the engine. Knowing how to test this component is important to diagnose ignition problems and avoid costly and unnecessary replacement. In this article, we'll explain how to test the GM 3.8 ignition control module, including the necessary steps, required tools, and common problems that can be encountered during the process.

2. What is GM 3.8 Ignition Control Module?

The GM 3.8 Ignition Control Module is an electronic device that controls the ignition spark in each cylinder of the engine. The module receives signals from the crankshaft position sensor and the camshaft position sensor to determine the proper time to produce the ignition spark. It then sends a signal to the ignition coil to spark at the correct time.

2.1 Ignition Control Module Functions

The GM 3.8 Ignition Control Module is responsible for several important functions, including:

Check engine ignition timing

Monitor engine speed and engine load

Produce the ignition spark at the right time

Check the intensity of the ignition spark

2.2 Ignition Control Module Location

The GM 3.8 Ignition Control Module is typically located on top of the engine, near the ignition coil. It may be attached to the engine with screws or clips, depending on the model of the vehicle.

3. Why is it important to test the GM 3.8 Ignition Control Module?

The ignition control module is a critical component of a vehicle's ignition system. If the module is faulty, it can cause ignition problems such as difficulty starting the engine, loss of power, and increased fuel consumption. It is important to test the GM 3.8 Ignition Control Module to diagnose any ignition problems and avoid unnecessary costly replacement of other parts in the system.

4. Tools Needed to Test GM 3.8 Ignition Control Module

To test the GM 3.8 Ignition Control Module, you will need the following tools:

Digital multimeter

ignition test probe

vehicle service manual

5. Steps to Take Before Testing the GM 3.8 Ignition Control Module

Before testing the GM 3.8 Ignition Control Module, it is important to follow the steps below:

5.1 Verification of electrical connections

Check the electrical connections going to the ignition control module to make sure they are good and fit properly. If there are any problems with the connections, resolve them before continuing with the test.

5.2 Visual inspection of the ignition control module

Perform a visual inspection of the ignition control module. Look for signs of physical damage, such as cracks, burns, or corrosion. If the module appears to be damaged, replace it before continuing with the test.

6. GM Ignition Control Module Test Procedure 3.8

The procedure for testing the GM 3.8 Ignition Control Module is as follows:

6.1 Ignition Control Module Internal Resistance Test

Using the digital multimeter, measure the internal resistance of the ignition control module. Consult the vehicle's service manual for reference values. If the measured resistance is outside the specified range, the module may be faulty and need to be replaced.

6.2 Ignition Control Module Output Signal Test

Using the ignition test probe, verify that the ignition control module is producing proper output signals. Connect the ignition test probe to the ignition coil and adjust the reference values according to the vehicle's service manual. If the output signal is out of range, the module may be faulty and need to be replaced.

6.3 Ignition Control Module Input Voltage Test

Using the digital multimeter, measure the input voltage of the ignition control module. The value must be within the range specified in the vehicle's service manual. If the input voltage is out of range, the module may be faulty and need to be replaced.

7. Interpretation of GM Ignition Control Module Test Results 3.8

If the test results indicate that the GM 3.8 Ignition Control Module is working properly, it means that the ignition problem is not related to the module. In that case, you can continue to search for other ignition system problems. If the test results indicate that the ignition control module is defective, it is necessary to replace it to correct the ignition problem.

8. Troubleshooting Common Problems Testing the GM Ignition Control Module 3.8

During testing of the GM 3.8 Ignition Control Module, common problems may arise, such as:

8.1 Electrical connection problems

If there are problems with the electrical connections, such as loose or corroded connections, they can affect the signal from the ignition control module. Check the connections and resolve them as necessary before continuing with the test.

8.2 Ignition Control Module Output Signal Problems

If the ignition control module output signal is not within the range specified in the vehicle's service manual, it may be necessary to replace the ignition control module.

8.3 Ignition Control Module Input Voltage Problems

If the ignition control module input voltage is not within the range specified in the vehicle's service manual, it may be necessary to replace the ignition control module.

9. Care and Precautions When Testing the GM 3.8 Ignition Control Module

When testing the GM 3.8 Ignition Control Module, it is important to take certain precautions to avoid damaging the component or putting your personal safety at risk. The following are some important tips and precautions:

Follow vehicle service manual instructions at all times

Use proper, quality tools to avoid damaging the ignition control module

Disconnect the battery before starting the test to avoid electric shock

Do not touch metal parts of the vehicle while testing to avoid electric shock

Wear appropriate clothing and personal protection, such as gloves and safety glasses

10. GM 3.8 Ignition Control Module Maintenance Tips

To keep your GM 3.8 ignition control module in good condition, it is important to follow these tips:

Perform periodic visual inspections of the module for signs of damage or corrosion

Clean the module's electrical connections regularly to prevent dirt or corrosion buildup

Replace the GM 3.8 Ignition Control Module per vehicle service manual recommendations

11. Conclusion

Testing the GM 3.8 ignition control module is an important task in diagnosing ignition problems on a vehicle. By following the proper steps and using the correct tools, it can be determined if the module is working properly or if it needs to be replaced. It is important to follow proper precautions when testing to avoid damaging the module or putting your personal safety at risk. If you are not comfortable performing the test yourself, it is best to seek the help of a professional mechanic.

12. Frequently asked questions

1. What is GM 3.8 Ignition Control Module?

The GM 3.8 Ignition Control Module is an electronic component that controls the ignition spark in each cylinder of the engine. It is responsible for controlling the ignition timing of the engine, monitoring the speed and load of the engine, producing the ignition spark at the proper time, and controlling the intensity of the spark.

2. Why is it important to test the GM 3.8 Ignition Control Module?

It is important to test the GM 3.8 Ignition Control Module to diagnose ignition problems in the vehicle. If the module is defective, it can cause ignition problems such as difficulty starting the engine, loss of power, and increased fuel consumption. Testing the module also helps avoid unnecessary costly replacement of other parts of the system.

3. What are the tools needed to test the GM 3.8 Ignition Control Module?

The tools needed to test the GM 3.8 ignition control module are a digital multimeter, an ignition test probe, and the vehicle's service manual. These tools are needed to measure the internal resistance of the module, check the output signal, and measure the input voltage. It is important to use proper, quality tools to avoid damaging the ignition control module.

0 notes

Text

Consider These Few Points To Determine Your Engine Overhauling

A car’s engine does not stay intact forever. There will be a time when it says no. But, question is here that is it possible to revive an engine? Can an engine live up to the expectation again? Of course! One such procedure to revive a car's engine is an engine overhaul.

Essentially, an engine overhaul gives a car’s engine a new lease on life. The heat and regular wear and tear are the main causes of engine degradation over time. When a car is driven too hard or have to survive in harsh conditions, some engines deteriorate more quickly than others.

Besides, there could be poor car maintenance such as insufficient engine oil or delay in repair. Let put the causes aside, and focus on revival. For this, it is necessary to learn the engine overhauling first.

What does engine overhaul signify?

No doubt! A car’s engine is one of the most complicated pieces of machine. It consists of a huge number of small and large components. Once a car’s engine has lived a particular or travelled certain distance, it might need some sort of cleaning as well as worn parts replacement.

A car engine overhaul comes into picture when a vehicle's engine starts to experience serious issues. In this process, the mechanic disassembles the engine as part of an overhaul in order to inspect the internal parts and determine whether they are in need of repair. During an overhaul, internal components like piston rings, bearings, gaskets, and camshaft may need to be replaced, depending on their condition and the nature of the issue.

Apart from replacement, mechanic conducts the cleaning of surfaces to remove the dirt or carbon build ups. It also requires considering the internal surface of cylinder so that pistons can fit into their places properly.

Given that the engine will have new components inside of it, the process is enormous and requires a number of steps. Instead of leaving the engine in your car's chassis, the engine is removed for this task. Since all of the components must be taken apart and then put back together, the procedure usually takes a week to finish.

Consider Service My car for such your car’s engine overhaul keeping the service satisfaction and cost efficiency in mind. Our experts never let you disappointed.

However, engine overhaul is fine, but how do you determine that your car’s engine is expecting an overhaul. Here, we are sharing some essential points to comprehend the right timing of visit a workshop.

A degraded Engine starts to misfire

Overtime engine components degrade so does their efficiency. However, a poor engine starts to misfire due to improper air to fuel ratio inside the cylinder. You sometimes experience jerks at low revolutions or having poor acceleration while pressing the accelerator.

Sometimes, spark plugs have their part to do as they can fail in providing proper spark at times. However, a spark plugs replacement at Service My car is not very expensive as compare to complete engine overhauling.

Strange Noises under the hood

Strange noises start to appear all of a sudden under the hood. These are initial signs of a worn-out or loose part. However, the knocking sound that suggests issues with the crankshaft and piston rods is the most terrifying noise.

It's best to have your engine checked out by a professional if it's making unusual noises. Waiting until your car breaks down could end up costing you much more.

Unusual Engine Oil Consumption

Your car will eventually start using more engine oil than usual. Up until a leak, it is a telltale sign of an unhealthy engine. A car that has been driven extensively is more likely to experience an early engine problem and may require engine overhauling sooner than usual.

You may have an engine leak or damaged piston rings if you frequently need to top off your engine oil or if your low oil pressure warning light illuminates. It's possible for engine oil to leak into the combustion chamber as a result of damaged piston rings.

If it is complemented by the white exhaust smoke at the tailpipe, your vehicle need immediate attention. Blue smoke comes out from tail pipe when engine oil burns in engine.

Engine overheats frequently

Overheating is a symptom of inadequate cooling inside the engine. It might be the result of a radiator leak. If the cooling system is working properly, the problem is most likely a faulty cylinder head gasket that lets coolant into the combustion chamber.

A serious issue that can cause additional mechanical failures is an overheating engine. If the engine temperature warning light illuminates, make sure to take your car to the closest service centre of Service My Car to have it checked.

Besides, a constant stream of black smoke is really a concern. It is sign of excessive carbon build-up at pistons and intake valves. If you do not take immediate, you car’s engine might get choked sooner or later.

However, Service My Car would be worthy choice for a car engine repair or even overhaul. You won’t receive years of expertise and modern methodology under one roof. Book a car service or order a car repair quote at our website and app anytime.

If you need any type of maserati service or repair including maserati oil change, maserati ac repair or detailing, service my car provides you free pickup and delivery plus full car servicing at the nearest maserati servicing center.

1 note

·

View note

Text

RA Power Solutions is having an experience of over four decades and recommends following inspection procedures for crankshaft prior to the fitment of bearings which should be followed for enhancement of the bearing life and to avoid any major breakdown of the crankshaft.

#grinding journals and crankpins#grinding of crankshaft main journal#repair of crankshaft main journal#Crankshaft inspection procedure#polishing crank journals#crankshaft journals polishing#crankshaft journal crankpin grinding#crankshaft grinding machine#crankshaft repair#crankshaft grinding#crankshaft grinding services#metal stitching#white metal bearing#metal locking#cast iron crack repair

0 notes