#Customized SCADA systems

Explore tagged Tumblr posts

Text

customized scada applications

1 note

·

View note

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

SCADA Integrators

The Essential Guide to SCADA Integrators: Enhancing Efficiency and Control

In today’s fast-paced industrial landscape, the role of SCADA (Supervisory Control and Data Acquisition) systems is more crucial than ever. These systems allow businesses to monitor, control, and optimize their operations in real time. However, the effectiveness of a SCADA system often hinges on the expertise of SCADA integrators. In this blog, we’ll delve into what SCADA integrators do, why they are important, and how they can help businesses unlock the full potential of their SCADA systems.

What Are SCADA Integrators?

SCADA integrators are specialists who design, implement, and manage SCADA systems tailored to a company’s specific needs. They play a critical role in ensuring that all components of a SCADA system work harmoniously together. This includes integrating hardware, software, and network elements to create a cohesive system that provides real-time monitoring and control.

Why SCADA Integrators Are Vital

Customization and Optimization: SCADA integrators bring a wealth of expertise in tailoring systems to fit unique operational requirements. They ensure that the SCADA system is not just a generic solution but a customized tool that enhances the specific processes of a business. This includes configuring dashboards, setting up alarms, and optimizing data collection methods.

Seamless Integration: Integrators are adept at bridging various components of a SCADA system. This means connecting sensors, PLCs (Programmable Logic Controllers), and other field devices with the central SCADA software. Their work ensures that data flows seamlessly from the field to the control room, facilitating accurate and timely decision-making.

Enhanced Security: Security is a major concern for SCADA systems, as they are often linked to critical infrastructure. SCADA integrators implement robust security measures to protect against cyber threats and ensure that sensitive data remains secure. This involves setting up firewalls, encryption protocols, and regular security audits.

Scalability: As businesses grow, their SCADA systems need to evolve. SCADA integrators help in scaling the system by adding new components, expanding data storage, and integrating with other enterprise systems. This scalability ensures that the SCADA system continues to meet the changing needs of the business.

Troubleshooting and Support: Even the most well-designed SCADA systems can encounter issues. SCADA integrators provide ongoing support and troubleshooting services to resolve any problems quickly. Their expertise minimizes downtime and ensures that operations continue smoothly.

Choosing the Right SCADA Integrator

When selecting a SCADA integrator, consider the following factors:

Experience and Expertise: Look for integrators with a proven track record and experience in your industry. Their familiarity with specific applications and standards can significantly impact the success of your SCADA system.

Customization Capabilities: Ensure that the integrator can tailor the system to your specific needs rather than offering a one-size-fits-all solution. Customization can lead to better efficiency and effectiveness.

Support Services: Assess the level of ongoing support and maintenance offered. A reliable SCADA integrator should provide comprehensive support to address any issues that arise post-implementation.

Security Measures: Verify that the integrator has a strong focus on security, implementing best practices to safeguard your system against potential threats.

Conclusion

SCADA integrators are indispensable partners in harnessing the full power of SCADA systems. Their expertise in customization, integration, security, scalability, and support ensures that businesses can achieve optimal performance and reliability from their SCADA solutions. By choosing the right SCADA integrator, companies can not only enhance their operational efficiency but also stay ahead in an increasingly competitive market.

If you’re considering upgrading or implementing a SCADA system, investing in a skilled SCADA integrator can make all the difference. With their help, you can unlock new levels of control, insight, and efficiency in your operations.

#SCADA Integrators#SCADA Systems#Industrial Automation#Control Systems#Data Acquisition#SCADA Integration#Industrial Control#System Optimization#SCADA Security#Automation Solutions#Industrial Efficiency#Custom SCADA Solutions#SCADA Support#PLC Integration#Real-Time Monitoring

0 notes

Text

The Benefits of Using Modular Switchgear Systems

Why Modern Industries Are Choosing Modular Solutions for Electrical Infrastructure

In today’s fast-paced industrial and commercial environments, electrical safety, efficiency, and scalability are more important than ever. That’s where modular switchgear systems come into play. Designed to meet the evolving needs of various sectors — such as manufacturing, commercial buildings, power utilities, and data centers — modular switchgear offers flexibility, safety, and long-term value.

In this article, we’ll explore the key benefits of using modular switchgear systems, and why they are becoming the preferred choice over traditional switchgear configurations.

What Is a Modular Switchgear System?

A modular switchgear system is a type of switchgear that is built from interchangeable modules or sections. Each module contains electrical components such as circuit breakers, busbars, relays, isolators, and fuses. These modules are pre-engineered and can be easily configured, added, or replaced based on the specific requirements of a facility.

Modular switchgear is used for the protection, control, and isolation of electrical equipment. It is typically found in low voltage (LV) and medium voltage (MV) power distribution systems.

Top Benefits of Modular Switchgear Systems

1. Flexibility and Scalability

One of the most significant advantages of modular switchgear is its flexible design. Whether you’re expanding an existing facility or starting from scratch, modular systems allow you to add or remove units without interrupting the entire system.

· Ideal for facilities expecting future expansion

· Easy to customize layout based on project demands

· Supports phased development in infrastructure projects

2. Enhanced Safety and Reliability

Modern modular switchgear systems are designed with advanced safety features. Segregated compartments, arc fault containment, and reliable insulation materials ensure operator safety and system reliability.

· Reduces risk of electrical faults and arc flashes

· Complies with IEC and ANSI safety standards

· Minimizes downtime during maintenance or upgrades

3. Ease of Installation and Maintenance

Thanks to its pre-fabricated modules, modular switchgear is faster and easier to install compared to conventional systems. It also simplifies troubleshooting and routine maintenance.

· Less on-site wiring and civil work required

· Individual modules can be isolated for servicing

· Reduces maintenance costs and system downtime

4. Compact and Space-Saving Design

With limited space in modern industrial setups, compactness is crucial. Modular switchgear systems are designed for space optimization, making them perfect for high-density environments.

· Vertical and horizontal expansion possible

· Reduced footprint compared to traditional gear

· Neat and organized layout improves cable management

5. Future-Proof and Upgrade-Friendly

Industries evolve, and so should your electrical infrastructure. Modular switchgear supports easy integration of new technologies, such as remote monitoring, IoT-enabled control systems, and energy management solutions.

· Supports integration with SCADA and BMS systems

· Accommodates evolving energy needs

· Long lifecycle with upgrade options

6. Cost-Effective Over the Long Term

Though the initial investment may be higher than conventional switchgear, the long-term benefits of modular systems — including reduced downtime, lower maintenance costs, and scalability — make them a cost-effective solution.

· Lower total cost of ownership (TCO)

· Reduced operational expenses

· Optimized energy efficiency

Applications of Modular Switchgear Systems

Modular switchgear is suitable for a wide range of applications, including:

🏢 Commercial buildings

🏭 Industrial plants

⚡ Power generation and distribution

🖥 Data centers

🏥 Hospitals

🏗 Infrastructure projects and smart cities

Conclusion

If you’re looking for a smart, scalable, and reliable solution for your electrical distribution system, modular switchgear systems are a worthy investment. With benefits ranging from safety and efficiency to cost savings and future readiness, they offer a significant upgrade over traditional switchgear models.

3 notes

·

View notes

Text

Distillery Plant Manufacturer in India: RattanIndustrial’s Turnkey Solutions for Modern Distilleries

In India’s growing ethanol and alcoholic beverage sector, the demand for high-efficiency, environmentally compliant distillery plants is at an all-time high. Choosing the right distillery plant manufacturer is a critical step for businesses looking to achieve long-term success. Among the leading names in this domain, RattanIndustrial has earned a strong reputation for delivering turnkey distillery plant solutions that combine cutting-edge technology, robust design, and sustainable operations.

Why a Quality Distillery Plant Matters

A well-engineered distillery plant doesn’t just produce alcohol—it maximizes yield, minimizes operational cost, and ensures compliance with environmental norms. Whether for potable alcohol, industrial ethanol, or biofuel production, every component—from fermentation to distillation to waste treatment—needs to work in perfect harmony.

That’s where RattanIndustrial excels.

RattanIndustrial: A Trusted Distillery Plant Manufacturer in India

With years of proven experience in industrial plant design and equipment manufacturing, RattanIndustrial offers end-to-end distillery plant solutions for a wide range of feedstocks including:

Molasses

Grains (maize, sorghum, rice, etc.)

Cane juice and syrup

Multi-feedstock configurations

Our Distillery Plant Capabilities Include:

Custom Fermentation Systems Designed for faster cycles, higher yield, and ease of operation.

Multi-Pressure Distillation Columns Engineered for consistent output of RS (Rectified Spirit), ENA (Extra Neutral Alcohol), and Fuel-Grade Ethanol.

Integrated Evaporation & Effluent Treatment Ensures Zero Liquid Discharge (ZLD) and compliance with CPCB norms.

Automation and SCADA Integration For real-time monitoring, better control, and reduced human intervention.

Compact Layouts & Modular Construction Ideal for fast installation, future expansion, and efficient space usage.

Turnkey Distillery Plant Projects

RattanIndustrial handles everything from project planning and engineering to equipment manufacturing, installation, and commissioning. This single-point accountability ensures reduced downtime and faster go-to-market timelines.

Industries We Serve

Alcohol Beverage Manufacturers

Biofuel & Ethanol Plants

Pharmaceutical & Solvent Producers

Industrial Alcohol Units

Why Choose RattanIndustrial?

In-House Design & Fabrication

Energy-Efficient Technologies

Strict Quality Control

Timely Execution

Dedicated After-Sales Support

Whether you are setting up a new plant or upgrading an existing facility, RattanIndustrial ensures your distillery runs efficiently, sustainably, and profitably.

Final Thoughts

As a leading distillery plant manufacturer in India, RattanIndustrial delivers more than just machinery—they deliver performance, reliability, and long-term value. If you're looking for a complete, customized, and compliant solution for your distillery project, RattanIndustrial is the name you can count on.

Contact RattanIndustrial today to discuss your requirements and start building a smarter, more efficient distillery.

Visit:- https://www.liquorbottlingplants.com/distillery-plant.html

0 notes

Text

The Backbone of Industrial and Construction Integrity

In the realm of industrial infrastructure, precision-engineered wires are no less than silent workhorses. From holding reinforced steel bars together in massive construction projects to fastening corrugated boxes in logistics, high-performance wires ensure structural strength, operational efficiency, and safety. At the center of this reliability are quality-driven MS binding wire and stitching wire manufacturers, whose commitment to excellence defines the durability and consistency of the end application.

Among the leading contributors to this domain are MS Binding Wire Manufacturers in Punjab, known for producing wires that stand up to stress, corrosion, and fluctuating environmental conditions. Their emphasis on quality control, process automation, and customer-specific engineering has set a benchmark for the entire industry.

Category 1: Manufacturing Overview – From Rod to Wire

1. Raw Material Quality Assessment

The journey begins with sourcing high-grade low carbon or mild steel billets or rods. These undergo strict chemical composition testing to ensure ideal levels of carbon, sulfur, and phosphorus. This guarantees weldability and ductility in the final wire.

2. Wire Drawing Process

The steel rods are cold-drawn through calibrated dies that reduce the diameter while enhancing surface finish and tensile strength. The drawn wires are visually and digitally checked for:

Diameter precision

Surface finish

Absence of scaling or microcracks

3. Annealing and Stress Relieving

Annealing improves the ductility and softens the wire to make it suitable for bending and twisting. The wires are heated in controlled furnaces at specific temperatures and durations, then cooled under monitored conditions to ensure structural integrity.

Category 2: Precision Engineering – Binding Wire Standards

MS binding wires are essential in construction sites, used to bind rebars, scaffolding structures, and fencing frames. High-performance binding wire must comply with the following parameters:

Tensile Strength: Must allow twisting without snapping

Flexibility: Ensures easy handling on-site

Corrosion Resistance: Prolongs life in exposed conditions

Uniform Diameter: Enables consistent knotting and wrapping

Stitching Wire Manufacturers in India follow equally rigorous standards, especially when supplying wire for high-speed machinery in printing and packaging. For these wires, properties like coil tension, electroplated finish, and anti-rust coating become critical. Each batch is tested for:

Kink resistance

Smooth unwinding

Consistent breaking load

Surface uniformity for seamless operation

Category 3: Advanced Testing & Quality Control Methods

High-end manufacturers employ advanced QA/QC systems integrated throughout the production cycle. Key practices include:

Digital Micrometry: For real-time monitoring of diameter

Zinc Coating Meters: Ensures uniformity in galvanized wires

Torsion Testing Machines: Verifies durability under twisting stress

Salt Spray Chambers: Simulates long-term corrosion behavior

Technicians also use destructive testing on samples to assess tensile limits, elongation, and weldability. Every batch is traceable via unique identification tags and digital records, facilitating transparency and accountability.

Category 4: Regional Excellence and Technological Innovation

Renowned wire producers are investing in next-generation technologies to elevate both productivity and quality. Leading MS Binding Wire Manufacturers in Tamilnadu, for instance, have automated wire lines equipped with:

SCADA-controlled furnaces

Auto-lubricated dies for wire drawing

Inline defect detection systems

Robotic coil handling and packaging

Such automation not only improves efficiency but also reduces manual error, ensuring every meter of wire meets exacting standards.

Category 5: Packaging, Traceability & Customization

A hallmark of a quality manufacturer lies in how the product is delivered. Binding and stitching wires are:

Spool-packed, coiled, or bundled per client requirements

Rust-protected using VCI packaging where needed

Accompanied by mechanical and chemical test certificates

Barcoded and batch-coded for supply chain traceability

Custom options like color-coded binding wires, anti-corrosive coatings, or machine-specific stitching wire gauges offer added value to clients across industries.

Conclusion: The Path Forward for Precision Wire Manufacturing

As infrastructure, logistics, and manufacturing sectors grow, so does the demand for highly engineered wire solutions. This growth places a premium on consistency, durability, and performance — attributes only possible through disciplined manufacturing, quality control, and technical innovation.

In this evolving landscape, MS Binding Wire Manufacturers in Telangana are emerging as key contributors, offering products that comply with global benchmarks while catering to local project needs. Their expansion into sustainable practices, export-grade packaging, and digital quality tracking positions them as future-ready leaders in a mission-critical industry.

Final Thought: In wire manufacturing, excellence is never accidental — it is engineered, tested, and refined. As industries aim higher, the wires that bind them must rise even stronger.

#galvanized iron wires manufacturer (gi) in india#ms binding wires manufacturer in delhi#ms binding wires manufacturer in india#ms binding wires manufacturer in punjab#stitching wires manufacturer in maharashtra#stitching wires manufacturer in india#ms binding wires manufacturer in tamil nadu#galvanized iron wires manufacturer in delhi#galvanized iron wires manufacturer in maharashtra#ms binding wires manufacturer in telangana

0 notes

Text

Automation and Integration Needs Power Robust Growth in System Integrator Market

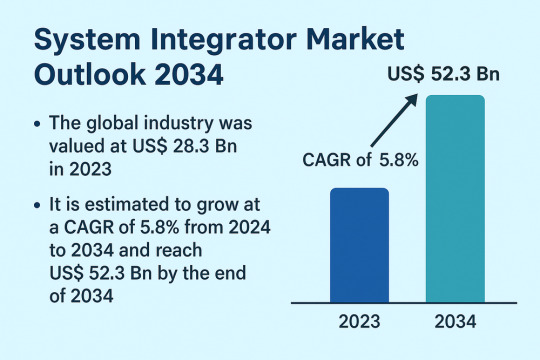

The global System Integrator Market is poised for significant growth, projected to rise from US$ 28.3 Bn in 2023 to US$ 52.3 Bn by 2034, growing at a CAGR of 5.8% from 2024 to 2034. This growth is driven by the widespread adoption of industrial robots, technological advancements, and a pressing need among businesses to optimize operational efficiencies through connected systems.

System integrators play a pivotal role in designing, implementing, and maintaining integrated solutions that bring together hardware, software, and consulting services. These services support organizations in unifying internal and external systems, such as SCADA, HMI, MES, PLC, and IIoT, to enable seamless data flow and system interoperability.

Market Drivers & Trends: One of the primary market drivers is the rise in adoption of industrial robots. As industries accelerate automation, robotic system integrators have become vital in delivering customized, scalable, and high-performing solutions tailored to complex manufacturing needs.

Another major catalyst is the surge in technological advancements. Integrators are deploying cloud-based tools and platforms that provide real-time data insights, improve developer productivity, and support hybrid architectures. The increasing use of Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) in integration solutions is fostering innovation and growth.

Latest Market Trends

Several emerging trends are shaping the system integrator landscape:

Cloud modernization platforms such as IBM’s Z and Cloud Modernization Center are enabling businesses to accelerate the transition to hybrid cloud environments.

Modular automation platforms are gaining popularity, allowing companies to rapidly deploy and scale integration solutions across multiple industry verticals.

Edge computing and cybersecurity solutions are increasingly being integrated to support secure, real-time decision-making on the production floor.

Digital hubs and scalable workflow engines are being adopted by integrators to support multi-specialty applications with high adaptability.

Key Players and Industry Leaders

The system integrator market is characterized by a strong mix of global leaders and regional specialists. Key players include:

ATS Corporation

Avanceon

Avid Solutions

Brock Solutions

JR Automation

MAVERICK Technologies, LLC

Burrow Global, LLC

BW Design Group

John Wood Group PLC

TESCO CONTROLS

These companies are actively investing in next-generation technologies, enhancing their product portfolios, and pursuing strategic acquisitions to strengthen market presence. For instance, in July 2023, ATS Corporation acquired Yazzoom BV, a Belgian AI and ML solutions provider, expanding their capabilities in smart manufacturing.

Recent Developments

Olympus Corporation launched the EASYSUITE ES-IP system in July 2023 in the U.S., offering advanced visualization and integration solutions for procedure rooms.

IBM introduced key updates in 2021 and 2022 to streamline mission-critical application modernization using cloud services and hybrid IT strategies.

Asia-Pacific companies have led the charge in deploying advanced integrated systems, reflecting the rapid industrial digitization in countries such as China, Japan, and South Korea.

Market Opportunities

Opportunities abound in both mature and emerging markets:

Smart factories and Industry 4.0 transformation offer immense potential for integrators to offer comprehensive solutions tailored to real-time analytics, predictive maintenance, and remote monitoring.

Government-led infrastructure modernization projects, particularly in Asia and the Middle East, are increasing demand for integrated control systems and plant asset management solutions.

The energy transition movement, including renewables and electrification of industrial processes, requires new types of integration across decentralized assets.

Future Outlook

As industries pursue digital transformation, the role of system integrators will evolve from traditional project implementers to long-term strategic partners. The future will see increasing demand for intelligent automation, cross-domain expertise, and real-time adaptive solutions. Vendors who can provide holistic, secure, and scalable services will dominate the landscape.

With continued advancements in AI, IoT, and robotics, the system integrator market will continue to thrive, transforming operations across diverse sectors, from automotive and food & beverages to oil & gas and pharmaceuticals.

Review critical insights and findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82550

Market Segmentation

The market is segmented based on offering, technology, and end-use industry.

By Offering:

Hardware

Software

Service (Consulting, Design, Installation)

By Technology:

Human-Machine Interface (HMI)

Supervisory Control and Data Acquisition (SCADA)

Manufacturing Execution System (MES)

Functional Safety System

Machine Vision

Industrial Robotics

Industrial PC

Industrial Internet of Things (IIoT)

Machine Condition Monitoring

Plant Asset Management

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

By End-use Industry:

Oil & Gas

Chemical & Petrochemical

Food & Beverages

Automotive

Energy & Power

Pharmaceutical

Pulp & Paper

Aerospace

Electronics

Metals & Mining

Others

Regional Insights

Asia Pacific leads the global system integrator market, holding the largest market share in 2023. This leadership is attributed to:

Rapid industrialization and digital transformation in China, Japan, and India.

Strong investments in smart manufacturing and Industry 4.0 initiatives.

Government support for infrastructure modernization, especially through Smart City programs and cybersecure IT frameworks.

North America and Europe also show strong demand, driven by the presence of established manufacturing facilities and a robust focus on sustainable operations and green automation.

Why Buy This Report?

Comprehensive Market Analysis: Deep insights into market size, share, and growth across all major segments and geographies.

Detailed Competitive Landscape: Profiles of leading companies with analysis of their strategy, product offerings, and key financials.

Actionable Intelligence: Understand technological trends, regulatory developments, and investment opportunities.

Forecast-Based Strategy: Develop long-term strategic plans using data-driven forecasts up to 2034.

Frequently Asked Questions (FAQs)

1. What is the projected value of the system integrator market by 2034? The global system integrator market is projected to reach US$ 52.3 Bn by 2034.

2. What is the current CAGR for the forecast period 2024–2034? The market is anticipated to grow at a CAGR of 5.8% during the forecast period.

3. Which region holds the largest market share? Asia Pacific dominated the global market in 2023 and is expected to continue leading due to rapid industrialization and technology adoption.

4. What are the key growth drivers? Key drivers include the rise in adoption of industrial robots and continuous advancements in integration technologies like IIoT, AI, and cloud platforms.

5. Who are the major players in the system integrator market? Prominent players include ATS Corporation, JR Automation, Brock Solutions, MAVERICK Technologies, and Control Associates, Inc.

6. Which industries are adopting system integrator services the most? High adoption is seen in industries such as automotive, oil & gas, food & beverages, pharmaceuticals, and electronics.

Explore Latest Research Reports by Transparency Market Research:

Multi-Mode Chipset Market: https://www.transparencymarketresearch.com/multi-mode-chipset-market.html

Accelerometer Market: https://www.transparencymarketresearch.com/accelerometer-market.html

Luminaire and Lighting Control Market: https://www.transparencymarketresearch.com/luminaire-lighting-control-market.html

Advanced Marine Power Supply Market: https://www.transparencymarketresearch.com/advanced-marine-power-supply-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

PCC Panels | Power Control Center Panels – NextGen Power Control

At NextGen Power Controls, we specialize in designing and manufacturing high-performance PCC Panels (Power Control Center Panels) tailored for diverse industrial applications. As a trusted name in electrical control solutions, our Power Control Center Panels ensure the reliable distribution and control of power across large-scale industrial setups, enabling efficient operation and unmatched safety. Our PCC Panel is engineered with robust materials and state-of-the-art components to handle high electrical loads while maintaining operational stability. Built to comply with international safety and quality standards, these panels are suitable for industries like manufacturing, infrastructure, chemical plants, power stations, and commercial complexes. Each Power Control Center Panel is equipped with circuit breakers, busbars, relays, and overload protection devices to provide centralized control of multiple power feeders. Our panels support both manual and automatic modes, offering flexibility and precision in power management. The modular design ensures ease of installation, maintenance, and future upgrades. We offer custom-built PCC Panels based on client specifications, including compartmentalized designs for safe access, intelligent metering, fault diagnosis features, and compatibility with SCADA systems for real-time monitoring and remote control. Our expert engineering team ensures that each panel delivers optimal performance, long-term durability, and energy efficiency.

For More Details Clicks Here - https://www.nextgenpowercontrols.com/pcc-panel.html

0 notes

Text

Advantages and Disadvantages of Pressure Switch Compared to Traditional Mechanical Models

Technological Advancements in Pressure Switch Manufacturing

Pressure Switch Factory products often incorporate technologies in pressure sensing, allowing for enhanced functionality and integration with modern systems. Unlike traditional mechanical pressure switches that rely on physical deformation of diaphragms or bellows to trigger electrical contacts, modern factory-produced versions may use electronic sensors and microcontrollers. This results in greater accuracy, faster response times, and a wider range of customization.

Improved Precision and Control

One of the primary advantages of pressure switches from a specialized Pressure Switch Factory is their ability to offer high precision in pressure detection. Digital or electronic models can detect subtle pressure variations and offer tight switching differentials. Mechanical models, though reliable in many industrial applications, typically have broader switching bands and lower sensitivity, which can limit their usefulness in high-precision or automated environments.

Enhanced Integration with Smart Systems

Pressure switches developed by a modern Pressure Switch Factory are often designed to be compatible with PLCs, SCADA systems, and IoT platforms. This level of integration allows real-time monitoring, remote control, and data logging—features not typically available in older mechanical designs. As a result, smart pressure switches are better suited for predictive maintenance and system optimization.

Durability and Environmental Resistance

Many factory-engineered pressure switches are designed for demanding environments, offering high protection ratings such as IP67 or IP68. They often come with enhanced resistance to vibration, corrosion, and extreme temperatures. While traditional mechanical switches may still perform well in harsh conditions, they often require more frequent calibration and are susceptible to mechanical wear over time.

User-Friendly Features and Adjustability

Modern pressure switches from reputable factories usually feature user-friendly interfaces such as digital displays, LED indicators, or keypad settings for quick adjustments. These features make setup and troubleshooting much easier than with mechanical models, which often require manual tools and disassembly for any change in pressure settings.

Higher Initial Cost and Complexity

Despite the benefits, pressure switches from advanced factories generally come at a higher initial cost. Their electronic components, smart features, and digital interfaces contribute to increased pricing. Additionally, installation and setup may require technical expertise, which can be a barrier for small operations or users accustomed to the simplicity of mechanical models.

Power Dependency and Potential for Electronic Failure

Electronic pressure switches from a Pressure Switch Factory typically rely on a constant power source. This makes them unsuitable for applications where power reliability is a concern. In contrast, mechanical pressure switches are self-powered and continue functioning without external energy, which can be a critical advantage in certain safety systems or remote locations.

Maintenance and Service Considerations

Factory-produced smart pressure switches usually require less frequent maintenance due to fewer moving parts, but if they do fail, repairs may be more complex and expensive. Mechanical switches, on the other hand, are easier to service in-house and have a longer history of field-proven reliability. This simplicity can be particularly valuable in low-tech environments or for backup systems.

Conclusion

Pressure switches manufactured by a modern Pressure Switch Factory offer a wide array of benefits, including precision, smart system compatibility, and environmental durability. However, these advantages must be balanced against potential drawbacks such as higher costs, dependency on power, and increased complexity. When choosing between electronic and traditional mechanical pressure switches, the decision should be based on the specific needs of the application, the available infrastructure, and the level of automation desired.

Two modes can be switched. “Manual Mode” automatically starts and stops the electric water pump according to the set pressures, and also displays real-time pressure. Time mode used for filling up the water tower, the time setting will be changed as 0.1H,0.2H …0.9H, 1H, 2H …24H. Water shortage alarm.

0 notes

Text

Innovation in Flow Control: Insights from a Premier Butterfly Valve Manufacturer

In the complex world of material handling solutions, precise and reliable flow control is paramount to operational efficiency and safety. Butterfly valves, with their versatile design and robust performance, play a critical role across numerous industries. Understanding the nuances of their design, application, and the continuous advancements made by leading producers is essential for businesses seeking optimal performance. This deep dive into the world of industrial valves offers insights from Meto Systems, a premier butterfly valve manufacturer dedicated to pushing the boundaries of technology in flow control. We explore how continuous innovation by a top-tier butterfly valve manufacturer directly translates into enhanced system reliability and optimized material handling processes for our clients.

Advanced Materials Drive Butterfly Valve Manufacturer Excellence

The foundation of superior flow control begins with the materials used, and a top-tier butterfly valve manufacturer like Meto Systems consistently pioneers in this area. Innovations in alloy compositions, specialized coatings, and resilient elastomers significantly enhance valve durability, corrosion resistance, and operational lifespan. These advancements are crucial for applications involving abrasive slurries, high temperatures, or corrosive chemicals common in material handling. By meticulously researching and integrating cutting-edge materials, every butterfly valve manufacturer aims to deliver products that withstand the harshest environments, ensuring sustained performance and reducing the need for frequent maintenance. This commitment to material science is a hallmark of a premier butterfly valve manufacturer.

Precision Engineering from a Leading Butterfly Valve Manufacturer

Precision engineering is at the heart of every high-performing butterfly valve, a core competency for any reputable butterfly valve manufacturer. From the intricate machining of valve bodies and discs to the meticulous assembly of sealing components, accuracy directly impacts a valve's ability to provide leak-tight shut-off and precise flow regulation. Meto Systems employs advanced manufacturing techniques, including CNC machining and robotic assembly, to achieve unparalleled consistency and quality in every unit. This dedication to exact specifications ensures optimal performance across diverse industrial applications, making our reputation as a leading butterfly valve manufacturer well-deserved.

Smart Actuation by an Innovative Butterfly Valve Manufacturer

The efficiency and control of butterfly valves are significantly amplified by intelligent actuation systems, an area where an innovative butterfly valve manufacturer truly excels. Modern actuators offer not just on/off functionality but also proportional control, allowing for precise regulation of flow rates based on process demands. Integration with PLC and SCADA systems enables remote operation, diagnostic monitoring, and predictive maintenance capabilities. Meto Systems, as a forward-thinking butterfly valve manufacturer, develops and integrates sophisticated actuation solutions that enhance automation, reduce human intervention, and improve overall operational safety in material handling systems.

Custom Solutions from a Versatile Butterfly Valve Manufacturer

Many industrial applications demand more than off-the-shelf solutions, requiring a versatile butterfly valve manufacturer capable of delivering customized designs. From unique flange configurations and specialized seat materials to valves designed for extreme pressures or temperatures, the ability to tailor products to specific client needs is invaluable. Meto Systems prides itself on its engineering flexibility, collaborating closely with clients to understand their precise requirements and develop bespoke butterfly valve solutions. This dedication to customization solidifies our position as a responsive and adaptable butterfly valve manufacturer, ensuring that every valve precisely fits its intended application.

Quality Control: A Pillar for Every Butterfly Valve Manufacturer

Rigorous quality control processes are non-negotiable for any reputable butterfly valve manufacturer. From the initial inspection of raw materials to hydrostatic testing of finished products, every stage of manufacturing must adhere to stringent quality standards. Certifications such as ISO 9001 demonstrate a commitment to consistent quality management systems. Meto Systems implements a multi-stage inspection protocol, ensuring that every butterfly valve leaving our facility meets the highest performance and reliability benchmarks. This unwavering commitment to quality ensures that as a butterfly valve manufacturer, we deliver dependable components for critical material handling applications.

Global Reach and Support from a Premier Butterfly Valve Manufacturer

For industries operating on a global scale, partnering with a butterfly valve manufacturer that offers extensive reach and comprehensive support is crucial. This includes efficient logistics, readily available spare parts, and responsive technical assistance regardless of geographical location. Meto Systems has established a robust global network to ensure that our clients receive timely support and access to our full range of products and services wherever they are. Our commitment as a butterfly valve manufacturer extends beyond product delivery, encompassing a dedication to long-term client success and operational continuity.

Future Trends Shaped by a Visionary Butterfly Valve Manufacturer

The landscape of flow control is constantly evolving, driven by advancements in automation, data analytics, and sustainability. A visionary butterfly valve manufacturer continuously invests in research and development to anticipate future industry needs and integrate emerging technologies. This includes exploring smart sensors for real-time monitoring, materials for enhanced durability in harsh environments, and designs that minimize energy consumption. Meto Systems remains at the forefront of these innovations, ensuring that our products continue to set benchmarks for efficiency and reliability in material handling solutions. We are a butterfly valve manufacturer shaping the future of industrial flow control.

Conclusion

The relentless pursuit of innovation is what sets a premier butterfly valve manufacturer apart in the competitive landscape of material handling solutions. Meto Systems is dedicated to engineering excellence, utilizing advanced materials, embracing smart actuation, and offering customized solutions, all underpinned by unwavering quality control. Our global reach and commitment to supporting future trends ensure that our clients benefit from the most reliable and efficient flow control components available. Partnering with an industry leader like Meto Systems means investing in the long-term performance and sustainability of your operations. Our mission as a leading butterfly valve manufacturer is to provide not just products, but solutions that empower your business to achieve unprecedented levels of productivity and safety.

0 notes

Text

Vidgastech is a leading innovator in Industrial Automation, delivering smart, scalable, and cutting-edge automation solutions to enhance manufacturing efficiency and precision. Our team of experts specializes in PLC programming, SCADA systems, IoT integration, robotics, and turnkey automation projects tailored to your industrial needs.

We help industries reduce downtime, boost productivity, and transition into Industry 4.0 with seamless automation technologies. With a strong commitment to quality, innovation, and customer satisfaction, Vidgastech is your trusted partner for transforming industrial operations.

Services:

PLC & SCADA Development

Industrial IoT (IIoT) Integration

Robotics & Machine Automation

Process Control & Monitoring Systems

Custom Industrial Software Development

Maintenance & Support Services

#Industry Automation#Industrial Automation Company#PLC SCADA Automation#Factory Automation#Smart Manufacturing#IIoT Solutions#Industrial Robotics#Vidgastech Automation#Industry 4.0 Solutions

0 notes

Text

How Manufacturing Execution Systems (MES) Enhance Supply Chain Management

In today’s competitive manufacturing landscape, supply chain management efficiency is essential. A Manufacturing Execution System (MES) is a key asset for achieving this, as it provides a digital solution for real-time monitoring and control of production activities. MES bridges the gap between shop-floor operations and enterprise-level systems, offering comprehensive visibility into production, inventory, and quality. By supporting supply chain management, MES enhances responsiveness, reduces costs, and optimizes resource allocation.

Real-Time Production Tracking and Decision-Making

A Manufacturing Execution System enables real-time tracking of production stages, providing complete visibility into order and material status. Integrated with Level 1 and Level 2 systems (such as CNC, HMI, and SCADA), MES supports quick production and quality decisions based on actual data. This capability minimizes lead times and reduces downtime, allowing manufacturers to meet demand accurately. By synchronizing production data with supply chain needs, MES ensures that production schedules align with demand efficiently.

Optimized Inventory and Resource Management

MES plays a crucial role in inventory management by monitoring Work-in-Progress (WIP) and Finished Goods (FG) inventory at each stage of manufacturing. Using the bill of materials (BOM), MES tracks input material consumption and updates raw material (RM) and WIP inventory in real time. The Manufacturing Execution System manages RM inventory levels, triggering reorders based on minimum and maximum thresholds, which aligns resources with production schedules. This inventory control capability supports efficient supply chain management by reducing carrying costs and preventing stockouts.

Enhanced Quality Control and Genealogy Tracking

Quality management is strengthened with MES, as it captures and validates product quality throughout production. MES monitors for defects and deviations, allowing for immediate corrective actions to minimize rework and scrap. End-to-end traceability and genealogy tracking are key features of a Manufacturing Execution System, as they allow manufacturers to trace defects back to their origin, identify areas for improvement, and address customer complaints effectively. Automated test certificates and quality documentation ensure compliance and maintain product standards, further supporting supply chain quality.

Shop-Floor to Top-Floor Visibility

MES offers a unified view of production metrics across the organization, delivering insights from the shop-floor to the top-floor. It tracks inventory, order status, production delays, and yield, enabling management to make informed decisions at all levels. This comprehensive visibility helps identify production bottlenecks and resolve issues proactively, enhancing overall supply chain management efficiency.

Intelligent Decision-Making and Automation

By leveraging intelligent algorithms, MES supports real-time decision-making and auto-allocation on the shop floor. MES analyzes operational data to predict potential failures and optimize production parameters, thereby reducing downtime and improving output. Automated data capture across production stages enables efficient decision-making, facilitating continuous improvement in manufacturing processes.

Improved Coordination with Suppliers and Distributors

A Manufacturing Execution System can be integrated with supplier and distributor systems, sharing real-time production schedules and inventory data across the supply chain. This integration enhances transparency and fosters stronger relationships with partners, ensuring timely material deliveries and improved synchronization within the supply chain network.

Key Benefits of MES in Supply Chain Management

- Reduced WIP and Lead Times: By optimizing inventory management and production scheduling, MES helps minimize WIP levels and lead times, supporting efficient supply chain management.

- Enhanced Quality and Traceability: Real-time quality monitoring and genealogy tracking improve product quality, ensuring that only defect-free products enter the supply chain.

- Complete Production Visibility: Shop-floor to top-floor insights enable data-driven decision-making, improving operational efficiency.

- Optimized Resource Utilization: MES ensures raw materials and resources are used efficiently, reducing waste and maximizing productivity.

With its comprehensive tracking capabilities, intelligent automation, and seamless integration, a Manufacturing Execution System is indispensable for any organization looking to enhance supply chain resilience and performance. By enabling real-time visibility, optimized inventory management, and proactive quality control, MES empowers manufacturers to meet customer demands, reduce costs, and boost agility in an increasingly competitive market.

1 note

·

View note

Text

Leading Distillery Plant Manufacturer in India: RattanIndustrial’s Expertise in Complete Distillation Solutions

In the fast-evolving world of alcohol and ethanol production, having a technologically advanced and efficiently designed distillery plant is critical for operational success. As a trusted distillery plant manufacturer in India, RattanIndustrial has emerged as a leading name, delivering turnkey solutions with precision, innovation, and industry expertise.

Why Choose an Expert Distillery Plant Manufacturer?

A well-designed distillery plant ensures:

Higher alcohol recovery

Lower energy consumption

Environmentally compliant waste management

Smooth integration of fermentation, distillation, and evaporation systems

That’s where RattanIndustrial comes in—with the capability to provide end-to-end distillery plant solutions that are both efficient and cost-effective.

RattanIndustrial: Your Trusted Partner in Distillery Plant Manufacturing

With decades of experience in manufacturing distillation systems and related equipment, RattanIndustrial offers complete design, engineering, and commissioning support for molasses-based, grain-based, and multi-feedstock distillery plants.

Key Offerings:

Turnkey Distillery Projects RattanIndustrial manages the complete project cycle—from concept design to commissioning—offering single-window solutions for new setups and plant expansions.

Custom Plant Design Each plant is engineered to match the client’s production needs, site conditions, and operational goals.

Advanced Fermentation Systems Designed for maximum alcohol yield, reduced cycle times, and optimal temperature control.

Multi-Pressure Distillation Columns Built for superior performance and minimal energy consumption, tailored for ENA, RS, and fuel-grade ethanol.

Effluent Treatment and Zero Liquid Discharge (ZLD) RattanIndustrial incorporates effluent treatment units and evaporation systems that meet the latest environmental norms.

Modular Design & Automation Plants are future-ready, with provisions for automation, SCADA systems, and easy scalability.

Industries We Serve

RattanIndustrial’s distillery plants are widely used in:

Alcohol Beverage Industry

Ethanol Fuel Production

Pharma-grade Alcohol Manufacturing

Industrial Solvents

Why RattanIndustrial?

Experienced Engineering Team with in-depth process knowledge

Robust Quality Control across every stage of manufacturing

On-time Project Delivery with structured execution planning

24/7 Technical Support post-commissioning

Sustainable & Energy-Efficient Designs

Conclusion

If you are planning to set up or expand a distillery, RattanIndustrial is the partner you can trust. As a top-tier distillery plant manufacturer in India, they bring together innovation, reliability, and deep industry knowledge to deliver plants that perform exceptionally—right from day one.

Contact RattanIndustrial today to explore tailor-made distillery solutions that elevate your production efficiency and product quality.

Visit:- https://www.liquorbottlingplants.com/distillery-plant.html

0 notes

Text

Enhancing Food & Beverage Operations with Atlantech Flow Meters

In the dynamic world of the Food & Beverage Industry, precision, hygiene, and process efficiency are non-negotiable. From liquid ingredients to cleaning processes, accurate fluid measurement plays a vital role in ensuring consistent product quality and operational efficiency. That’s where Atlantech Flow Meters come into the picture.

As one of the leading flow meter manufacturers in India, Atlantech delivers innovative flow measurement solutions tailored to meet the specific demands of food and beverage processing.

Why Flow Meters Are Critical in the Food & Beverage Industry

In applications involving beverages, dairy, oils, syrups, or cleaning-in-place (CIP) solutions, it’s essential to:

Maintain hygienic standards

Prevent product loss

Ensure accurate mixing and dosing

Monitor real-time flow during production

Electromagnetic flow meters from Atlantech are ideal for such applications because they offer non-intrusive, highly accurate, and contamination-free flow measurement.

Key Applications of Atlantech Flow Meters in F&B

1. Juice and Beverage Processing

Atlantech flow meters ensure precise volume control during mixing, bottling, and filling. They also integrate with SCADA systems for real-time monitoring and data analysis.

2. Dairy Industry

From raw milk intake to cream separation and pasteurization, accurate flow data helps maintain consistent quality and comply with food safety regulations.

3. Breweries and Soft Drinks

In breweries, flow meters help monitor fermentation and bottling processes. For soft drinks, they ensure consistency in flavor and carbonation by controlling syrup-to-water ratios.

4. Oils and Syrups

Measuring viscous liquids like edible oils and syrups requires durable, low-maintenance solutions. Atlantech flow meters are designed to handle these tough conditions with ease.

5. Cleaning-In-Place (CIP) Systems

CIP processes require controlled flow of cleaning agents. Atlantech flow meters optimize chemical usage, saving cost and improving sanitation cycles.

Why Choose Atlantech?

As one of the trusted electromagnetic flow meter manufacturers in India, Atlantech stands out due to:

✅ Food-grade, hygienic construction materials

✅ High accuracy and repeatability

✅ SCADA compatibility for smart monitoring

✅ Multiple end connection options (flanged, threaded, tri-clamp, etc.)

✅ Custom configurations for specialized F&B requirements

Smart Flow Management = Better Production Outcomes

By integrating Atlantech Flow Meters into your production line, you gain:

Reduced product wastage

Enhanced product consistency

Greater traceability and quality control

Optimized water and resource usage

Final Thoughts

If you’re looking for reliable, efficient, and sanitary flow measurement in food and beverage manufacturing, Atlantech offers the perfect solution. Trusted by leading brands, we are proud to be among the top flow meter manufacturers in India driving innovation in fluid handling systems.

👉 Get in touch with Atlantech today to explore tailored flow solutions for your food and beverage processes.

#flow meters#electromagnetic water meter#digital water flow meter manufacturer in india#electromagnetic flow meter suppliers in india#digital water flow meter#digital water flow meter india#digital water meter#digital flow meters#electromagnetic flow meter manufacturers in india#electromagnetic flow meters

0 notes

Text

Adlite Electricals proudly presents its advanced range of 11kV & 33kV CG VCB Panels, engineered for high-performance, safety, and reliability across medium-voltage electrical systems. As one of the leading switchgear manufacturers in India, we specialize in providing vacuum circuit breaker (VCB) technology that ensures arc-free interruption and minimal maintenance over the product's lifecycle. Our 11kV HT VCB Panel and 33kV VCB Panel are ideal for a variety of applications, including industrial plants, power utilities, infrastructure projects, and commercial installations. Available in Indoor VCB Panel and Outdoor VCB Panel configurations, these panels cater to the diverse needs of our global clients. We offer specialized solutions like 11kV ICOG Panel, 33kV ICOG Panel, and ICOG VCB Panel, all of which meet international standards for quality, durability, and operational safety.

As a trusted CG VCB Panel Dealer in India, Adlite Electricals is also a recognized CG Authorised Dealer in India, with a strong presence in the domestic and global markets. Our panels are widely supplied and installed in various regions including Delhi, Sri Lanka, Bangladesh, Nepal, Bhutan, Vietnam, Laos, Nigeria, South Africa, Sudan, South Sudan, Iraq, Iran, Afghanistan, Dubai, Abu Dhabi, and Kenya. As a global exporter, we are known as a reliable CG VCB Panel Supplier from India, CG VCB Panel Dealer in Dubai, Switchgear Manufacturer in Abu Dhabi, and CG VCB Panel Dealer in Africa. We also serve as a trusted VCB Manufacturer in Delhi, offering customized panels that are manufactured under stringent quality control processes to ensure long-lasting performance in challenging environments. Our range includes CG VCB Panel in India, CG VCB Panel in Africa, and CG VCB Panel in Bangladesh, supporting power distribution across borders.

Our panels are designed with the latest vacuum technology, ensuring rapid arc extinction, thermal stability, and enhanced system protection. Every component of the HT Panel is tested for reliability and performance, ensuring your electrical systems run smoothly and securely. Adlite's panels also offer compatibility with SCADA and remote-monitoring systems, making them ideal for modern infrastructure. Whether you are looking for a Switchgear Dealer in Dubai, a CG VCB Panel Dealer in Kenya, or a Switchgear Manufacturer in South Sudan, Adlite provides a solution built for your operational and environmental needs. Our products have earned a strong reputation for delivering quality and innovation, making us a preferred CG Supplier from India and CG Manufacturer in India.

As one of the fastest-growing exporters of 11kV VCB Panel Supplier from Delhi and 33kV VCB Panel Supplier from India, we are proud to offer tailor-made solutions for clients in both emerging and developed markets. We also support specialized demand from projects looking for a CG Authorised Dealer in Bangladesh, Switchgear Manufacturers in Africa, or a CG VCB Panel Dealer in South Africa. We understand the unique requirements of each country and ensure that our panels are built to handle different climatic and voltage conditions effectively. Our commitment to excellence has helped us become a reputed CG VCB Panel Dealer in Sudan, Switchgear Manufacturer in Sudan, and a trusted source for CG VCB Panel in South Sudan.

In markets such as Iraq, Iran, and Afghanistan, where robust and maintenance-free electrical solutions are critical, our VCB Panels are widely used for their simplicity, safety features, and durable build. Our strong logistics network ensures timely delivery of panels, whether it’s a CG VCB Panel in Vietnam, a Switchgear Manufacturer in Laos, or a CG VCB Panel Dealer in Nigeria. We also proudly serve the growing demand in Nepal and Bhutan, where we are recognized as a premier CG VCB Panel Dealer with on-ground support and services. Adlite Electricals is also one of the few Indian manufacturers to cater to multiple international governments, utility providers, and infrastructure developers with certified, tested, and approved CG VCB Panels.

Our mission is to deliver reliable, cost-effective, and sustainable switchgear solutions that power tomorrow’s infrastructure. If you are seeking a professional partner for 11kV VCB Panels, 33kV VCB Panels, or a dependable CG VCB Panel Dealer in India, Adlite Electricals offers a complete portfolio backed by world-class service. Whether your requirement is for a VCB Manufacturer in Delhi or a CG Authorised Dealer in Africa, we have the knowledge, capacity, and network to meet your goals. Join hands with us for safe, efficient, and smart power distribution — trusted by thousands of clients across Asia, Africa, and the Middle East.

#11 KV HT VCB panel#Outdoor VCB Panel#11kV VCB Panel#33 kV VCB Panel#supplier of VCB panel#Indoor VCB Panel#Vacuum Circuit Breaker#11kV ICOG panel#ICOG VCB panel#ICOG panel#33kV ICOG panel#CG VCB Panel#HT Panels#CG VCB supplier from India#CG Supplier from Delhi#CG Manufacturer In India#VCB Manufacturer in Delhi#CG VCB Panel Dealer In India#CG Authorised Dealer In India#CG VCB Panel In India#Switchgear Manufacturers In India#CG VCB Panel Dealer In Sri Lanka#CG VCB Panel Manufacturer In Bangladesh#CG Authorised Dealer In Bangladesh#CG Authorised Dealer In Africa#Authorised Dealer Of CG In Africa#CG VCB Panel In Africa#Switchgear Manufacturers In Africa#CG VCB Panel In Dubai#CG VCB Panel Dealer In Dubai

0 notes

Text

What Makes a Top Trading and Contracting Company in Muscat for Large Automation Projects?

Selecting the right partner for large-scale industrial automation projects in Muscat is a critical decision that can significantly impact a business's operational efficiency, safety, and ultimately, its profitability. It's not enough to simply find a supplier; you need a strategic partner who understands the complexities of industrial automation and can deliver end-to-end solutions. When identifying the top trading and contracting company Muscat for such ventures, businesses should consider a multi-faceted approach, looking beyond just competitive pricing.

1. Specialised Expertise and Proven Track Record

The foremost criterion is demonstrable expertise in industrial automation. A truly top company will have a deep understanding of various automation technologies, including PLCs, SCADA systems, robotics, and industrial IoT. Look for a track record of successfully completed projects that are similar in scale and complexity to yours. They should be able to provide case studies or client testimonials showcasing their ability to handle the entire project lifecycle, from initial design and engineering to installation, commissioning, and ongoing support. This proven history is crucial for ensuring your project is in capable hands.

2. Comprehensive Product Portfolio and Key Partnerships

A leading trading and contracting company in this domain should offer a comprehensive range of high-quality industrial automation products. This means they should be able to source and supply all necessary components, from sensors and controllers to intricate wiring and safety systems. Crucially, they should also have strong partnerships with reputable global manufacturers. For instance, being among the leading Phoenix Contact distributors in Oman is a significant advantage. This partnership ensures access to cutting-edge technology, genuine parts, and direct technical support from the manufacturer, which is invaluable for complex automation systems. A broad portfolio and strategic partnerships ensure they can provide bespoke solutions, not just off-the-shelf products.

3. Engineering Capabilities and Technical Support

Beyond trading, the "contracting" aspect signifies their ability to execute projects. This requires robust in-house engineering capabilities. A top firm will have experienced engineers who can design custom automation solutions, integrate diverse systems, and troubleshoot complex technical issues. Their technical support should extend beyond mere product delivery to include pre-sales consultation, system design assistance, installation guidance, and post-sales maintenance. The quality and availability of phoenix contact distributors in Oman and their technical support can be the difference between a smooth project and prolonged downtime. They should be able to provide immediate assistance and long-term service contracts.

4. Adherence to Quality, Safety, and Industry Standards

In industrial environments, quality and safety are non-negotiable. The chosen company must demonstrate strict adherence to international quality management standards (like ISO certifications) and rigorous safety protocols. This commitment should be evident in their product selection, installation practices, and workforce training. For automation projects, compliance with industry-specific standards (e.g., those for oil & gas, manufacturing, or utilities) is paramount. A reputable top trading and contracting company Muscat will have all necessary local and international certifications and a clear focus on delivering solutions that are not only efficient but also safe and compliant.

0 notes