#Customized SCADA Software

Explore tagged Tumblr posts

Text

customized scada applications

1 note

·

View note

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

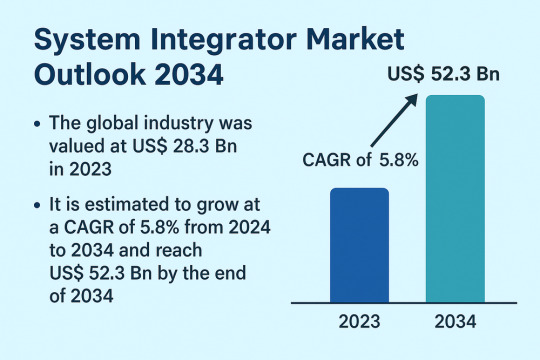

Automation and Integration Needs Power Robust Growth in System Integrator Market

The global System Integrator Market is poised for significant growth, projected to rise from US$ 28.3 Bn in 2023 to US$ 52.3 Bn by 2034, growing at a CAGR of 5.8% from 2024 to 2034. This growth is driven by the widespread adoption of industrial robots, technological advancements, and a pressing need among businesses to optimize operational efficiencies through connected systems.

System integrators play a pivotal role in designing, implementing, and maintaining integrated solutions that bring together hardware, software, and consulting services. These services support organizations in unifying internal and external systems, such as SCADA, HMI, MES, PLC, and IIoT, to enable seamless data flow and system interoperability.

Market Drivers & Trends: One of the primary market drivers is the rise in adoption of industrial robots. As industries accelerate automation, robotic system integrators have become vital in delivering customized, scalable, and high-performing solutions tailored to complex manufacturing needs.

Another major catalyst is the surge in technological advancements. Integrators are deploying cloud-based tools and platforms that provide real-time data insights, improve developer productivity, and support hybrid architectures. The increasing use of Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) in integration solutions is fostering innovation and growth.

Latest Market Trends

Several emerging trends are shaping the system integrator landscape:

Cloud modernization platforms such as IBM’s Z and Cloud Modernization Center are enabling businesses to accelerate the transition to hybrid cloud environments.

Modular automation platforms are gaining popularity, allowing companies to rapidly deploy and scale integration solutions across multiple industry verticals.

Edge computing and cybersecurity solutions are increasingly being integrated to support secure, real-time decision-making on the production floor.

Digital hubs and scalable workflow engines are being adopted by integrators to support multi-specialty applications with high adaptability.

Key Players and Industry Leaders

The system integrator market is characterized by a strong mix of global leaders and regional specialists. Key players include:

ATS Corporation

Avanceon

Avid Solutions

Brock Solutions

JR Automation

MAVERICK Technologies, LLC

Burrow Global, LLC

BW Design Group

John Wood Group PLC

TESCO CONTROLS

These companies are actively investing in next-generation technologies, enhancing their product portfolios, and pursuing strategic acquisitions to strengthen market presence. For instance, in July 2023, ATS Corporation acquired Yazzoom BV, a Belgian AI and ML solutions provider, expanding their capabilities in smart manufacturing.

Recent Developments

Olympus Corporation launched the EASYSUITE ES-IP system in July 2023 in the U.S., offering advanced visualization and integration solutions for procedure rooms.

IBM introduced key updates in 2021 and 2022 to streamline mission-critical application modernization using cloud services and hybrid IT strategies.

Asia-Pacific companies have led the charge in deploying advanced integrated systems, reflecting the rapid industrial digitization in countries such as China, Japan, and South Korea.

Market Opportunities

Opportunities abound in both mature and emerging markets:

Smart factories and Industry 4.0 transformation offer immense potential for integrators to offer comprehensive solutions tailored to real-time analytics, predictive maintenance, and remote monitoring.

Government-led infrastructure modernization projects, particularly in Asia and the Middle East, are increasing demand for integrated control systems and plant asset management solutions.

The energy transition movement, including renewables and electrification of industrial processes, requires new types of integration across decentralized assets.

Future Outlook

As industries pursue digital transformation, the role of system integrators will evolve from traditional project implementers to long-term strategic partners. The future will see increasing demand for intelligent automation, cross-domain expertise, and real-time adaptive solutions. Vendors who can provide holistic, secure, and scalable services will dominate the landscape.

With continued advancements in AI, IoT, and robotics, the system integrator market will continue to thrive, transforming operations across diverse sectors, from automotive and food & beverages to oil & gas and pharmaceuticals.

Review critical insights and findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82550

Market Segmentation

The market is segmented based on offering, technology, and end-use industry.

By Offering:

Hardware

Software

Service (Consulting, Design, Installation)

By Technology:

Human-Machine Interface (HMI)

Supervisory Control and Data Acquisition (SCADA)

Manufacturing Execution System (MES)

Functional Safety System

Machine Vision

Industrial Robotics

Industrial PC

Industrial Internet of Things (IIoT)

Machine Condition Monitoring

Plant Asset Management

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

By End-use Industry:

Oil & Gas

Chemical & Petrochemical

Food & Beverages

Automotive

Energy & Power

Pharmaceutical

Pulp & Paper

Aerospace

Electronics

Metals & Mining

Others

Regional Insights

Asia Pacific leads the global system integrator market, holding the largest market share in 2023. This leadership is attributed to:

Rapid industrialization and digital transformation in China, Japan, and India.

Strong investments in smart manufacturing and Industry 4.0 initiatives.

Government support for infrastructure modernization, especially through Smart City programs and cybersecure IT frameworks.

North America and Europe also show strong demand, driven by the presence of established manufacturing facilities and a robust focus on sustainable operations and green automation.

Why Buy This Report?

Comprehensive Market Analysis: Deep insights into market size, share, and growth across all major segments and geographies.

Detailed Competitive Landscape: Profiles of leading companies with analysis of their strategy, product offerings, and key financials.

Actionable Intelligence: Understand technological trends, regulatory developments, and investment opportunities.

Forecast-Based Strategy: Develop long-term strategic plans using data-driven forecasts up to 2034.

Frequently Asked Questions (FAQs)

1. What is the projected value of the system integrator market by 2034? The global system integrator market is projected to reach US$ 52.3 Bn by 2034.

2. What is the current CAGR for the forecast period 2024–2034? The market is anticipated to grow at a CAGR of 5.8% during the forecast period.

3. Which region holds the largest market share? Asia Pacific dominated the global market in 2023 and is expected to continue leading due to rapid industrialization and technology adoption.

4. What are the key growth drivers? Key drivers include the rise in adoption of industrial robots and continuous advancements in integration technologies like IIoT, AI, and cloud platforms.

5. Who are the major players in the system integrator market? Prominent players include ATS Corporation, JR Automation, Brock Solutions, MAVERICK Technologies, and Control Associates, Inc.

6. Which industries are adopting system integrator services the most? High adoption is seen in industries such as automotive, oil & gas, food & beverages, pharmaceuticals, and electronics.

Explore Latest Research Reports by Transparency Market Research:

Multi-Mode Chipset Market: https://www.transparencymarketresearch.com/multi-mode-chipset-market.html

Accelerometer Market: https://www.transparencymarketresearch.com/accelerometer-market.html

Luminaire and Lighting Control Market: https://www.transparencymarketresearch.com/luminaire-lighting-control-market.html

Advanced Marine Power Supply Market: https://www.transparencymarketresearch.com/advanced-marine-power-supply-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Vidgastech is a leading innovator in Industrial Automation, delivering smart, scalable, and cutting-edge automation solutions to enhance manufacturing efficiency and precision. Our team of experts specializes in PLC programming, SCADA systems, IoT integration, robotics, and turnkey automation projects tailored to your industrial needs.

We help industries reduce downtime, boost productivity, and transition into Industry 4.0 with seamless automation technologies. With a strong commitment to quality, innovation, and customer satisfaction, Vidgastech is your trusted partner for transforming industrial operations.

Services:

PLC & SCADA Development

Industrial IoT (IIoT) Integration

Robotics & Machine Automation

Process Control & Monitoring Systems

Custom Industrial Software Development

Maintenance & Support Services

#Industry Automation#Industrial Automation Company#PLC SCADA Automation#Factory Automation#Smart Manufacturing#IIoT Solutions#Industrial Robotics#Vidgastech Automation#Industry 4.0 Solutions

0 notes

Text

Predictive Maintenance in Heavy Steel Industries: Boost Productivity

Predictive maintenance (PdM) is becoming a key option in the demanding heavy steel industries. There are equipment failure can lead to significant financial losses, safety hazards, and unscheduled downtime. Predictive maintenance in steel industries; provides a clever, data-driven method to preserve equipment health, and optimizes operations. As these industries deal with mounting pressure to cut expenses and boost productivity.

Why Predictive Maintenance is Crucial for Heavy Steel Industries

Extreme circumstances, such as high temperatures, enormous weights, and continuous vibration, are present in steel plants.

To reach productions targets, the sector depend on enormous gear such metal furnaces, rollers, conveyors, and casting equipment that must run constantly.

Any unplanned equipment failure has the potential to stop the entire production line, resulting in significant losses.

Here are some reasons; why this industry benefits greatly from predictive maintenance:

Minimizes unplanned downtime can avoid production interruptions by scheduling repairs during scheduled outages by anticipating failures in advance.

In a hazardous situation, preventing equipment failure lowers the chance of accidents.

Labor, equipment, and materials are saved by concentrating maintenance efforts just; where they are required.

Frequent condition monitoring prolongs the life of machinery by spotting small problems before they become serious ones.

Overall factory efficiency rises with fewer disruptions and more effective machinery.

Technologies Behind Predictive Maintenance

A variety of cutting-edge technologies are using in the heavy steel industry to monitor, analyze, and interpret machine data when PdM is used. Important elements consist of:

Real-time data on temperature, vibration, pressure, lubrication, and other variables is gathered via sensors and IOT devices.

AI models examine both live and historical data to find trends and anticipate potential malfunctions.

Large amounts of data are processed and stored via cloud-based platforms. So, they enable remote monitoring from different locations.

To aid in problem diagnosis and maintenance scenario testing, virtual copies of actual assets replicate current conditions.

PdM tools, including shaft alignment services, are integrated with Supervisory Control and Data Acquisition (SCADA) systems to provide centralized monitoring.

Common Use Cases in Steel Plants

Numerous crucial pieces of machinery and procedures in the production of steel can benefit from predictive maintenance:

Tracking temperature and vibration aids in the early detection of wear or misalignments.

Temperature and pressure sensors in blast furnaces can notify operators of anomalies before harm is done.

Electrical sensors in electric arc furnaces (EAFs) identify erratic current flow as a sign of electrode deterioration or malfunction.

Condition monitoring keeps mechanical breakdowns and motor burnout at bay.

Challenges in Implementation

Predictive maintenance has several advantages. However, there are drawbacks to its application in the heavy steel sector:

Sensors, software, and integration must be purchasing in advance when setting up PdM systems.

Custom solutions or modifications may be necessary; if legacy equipment is incompatible with contemporary IoT platforms.

Expertise in equipment monitoring and data processing is crucial yet frequently absent.

Strategic planning, leadership support, and training are necessary to transition from a traditional maintenance culture to a predictive model.

Real-World Impact and ROI

Remarkable gains in operational and financial performance get reporting by steel producers who have used predictive maintenance. For example, after putting PdM systems in place, multinational steel companies reported up to 30% lower maintenance expenditures, 40% less downtime, and 20% longer asset lifespans.

Final Remarks

Predictive maintenance is a calculated investment in the heavy steel industry’ future, not only a technical advancement. Steel producers need to implement more intelligent, flexible maintenance techniques as competition heats up.

Thus, predictive maintenance allows to less risk, cut expenses, and maintain the smooth operation of the steel production process by using real-time data.

So, our team also deals in many Laser Alignment Services, including Windmill Laser Alignment Services, EOT Crane Alignment, and other Geometrical Alignment Services.

0 notes

Text

Top Ranked Commercial RO Plant Manufacturer In Noida

A sudden increase in the demand & requirement fulfilments for clean water solutions in Noida, which is an industrial hub in a well-located geographic location that has given way for Commercial RO plants to be installed & operated to resolve all water-related issues. Now leading this water purification revolution, Netsol Water is the leading & most significant commercial RO plant manufacturer in Noida. Modern commercial RO plant systems from Netsol Water are implemented in a variety of industrial or residential settings, including small enterprises & major manufacturing plants.

The manufacturer of commercial RO plants in Noida along with other water treatment industries will be thoroughly discussed. We will discuss about these modern advanced technological innovations that Netsol Water offers with world-class facilities, along with all the benefits of our systems, as well as provide information on how we are changing the history of water treatment in this specific area.

The steady & strong development of commercial RO plants, particularly those made by Netsol Water

The industrial atmosphere within the surroundings of Noida has been changed significantly in the last several decades. More effective water treatment technologies, such as these commercial RO plants, are being installed as a result of increased legal requirements & public awareness of environmental protection along with water quality issues.

When they are performing at their best, Netsol Water experts have witnessed this change on their own. Order lists are more comprehensive than ever before as commercial enterprises, especially those in the fabric textile, eateries, & pharmaceutical industries, have come to understand the value of having high-quality purified water. Because RO technology is configurable & customizable, it can be applied to eliminate impurities while decreasing total dissolved solids while maintaining a high standard of water quality.

Netsol Water Description

The team under Netsol Water of highly skilled engineers & technician at organizations like Netsol Water puts in continuous effort to craft designs along with constructing commercial RO systems that meet the unique requirements of our clients.

Owing much more to our flexibility, we can provide our best services to a variety of commercial businesses, ranging from big power plants to smaller processing firms. Being the top noble commercial RO plant manufacturer in Noida has gained itself a national reputation; Netsol Water has significantly earned recognition for its unwavering dedication to quality & innovation through numerous accolades.

Crucial Features Netsol Water designs & manufactures commercial RO plants.

1) Better Membrane Integration: The most advanced thin-film membranes available, known for their long lifespan & significant rejection rate, are commonly employed by Netsol Water or any other branches.

2) Automated Software Control Systems: Control panels built on SCADA Programmable Logic Controllers (PLC) ensure smooth functioning with real-time live data monitoring.

3) Systems for Pre-treatment: The purpose of the pre-treatment modules is to maintain & extend the life of the RO membranes.

4) Various Additional Treatments available with many options: In addition to various treatment methods for a variety of purposes, Netsol Water provides restoration or many mineral contents & pH balancing systems, depending on the particular characteristics of the water.

The principal sequence of events that must be followed by for fabricating commercial RO plants are as follows:

Procedures implemented in the manufacturing process to provide all of its customers with the highest quality of commercial RO plants:

1) Design Development Stage: Our engineers collaborate directly with clients to learn about their needs, then figure out distinctive designs for RO plants.

2) Purchasing Parts or Other Related Components for the RO Plants: Netsol Water buys instruments, pumps, including valves from reputable suppliers in addition to other premium parts.

Various Applications of Commercial RO Plants

Industries such as textiles, manufacturing of medicines, food & beverage production, power plants, along with other medical facilities including hospitals or hotels are just a few of the Noida industries that depend on our RO plant systems.

The advantages of utilizing Netsol Water as commercial RO plant manufacturer In Noida consist of:

We approach each assignment with an unmatched expertize due to our extensive knowledge in the water treatment sector.

1) Flexibility in the Event of Change Depending on what the client expects: We can offer distinctive solutions that meet client requirements thanks to our most recent creative designs along with revisions or modifications.

2) Helps with the ultimate buying decision: We provide thorough maintenance agreements along with rapid technical assistance.

3) Economical: Reduced operating costs are the direct result of energy-efficient structures along with enhanced processes.

4) Enforcement & Implementation by Regulatory Terms: By ensuring that our methods meet & exceed regulatory requirements, we provide our clients with stability by meeting their needs.

Conclusion

The commercial RO plant manufacturer in Noida is proliferating quickly as a result of growing industrial demand & worries about water quality. The top exporter or supplier in this rapidly changing industry, Netsol Water, has been consistently pushing the boundaries of quality & innovative thinking.

Netsol Water is totally dedicated to providing the most specialized, reliable, as well as successful commercial RO solutions, which might have propelled this business to the top of Noida's water treatment facilities.

#commercial ro plant#commercial ro plant manufacturer#water treatment plant#save water#water is life#netsol water#noida#greater noida

0 notes

Text

Bridging the Skill Gap with Process Control Simulation Training

"Why is it so hard to find skilled workers for industrial automation?"

"How do we train new employees without risking downtime or safety?"

"Is there a way to upskill our team without pulling them off active projects?" If you've ever asked these questions, you're not alone. The skills gap in industrial sectors—especially in process control and automation—is a growing concern for plant managers, HR teams, and training coordinators. The good news? Process control simulation training is becoming a game-changer. It's not just about learning theory; it's about giving your team hands-on experience in a risk-free, highly realistic environment. In this blog, let's explore how process control simulation training is helping companies bridge the skills gap, boost productivity, and future-proof their workforce.

🔧 What Is Process Control Simulation Training?

Process control simulation training uses software-based tools (and sometimes hardware-integrated systems) to simulate real-world industrial processes, such as chemical reactions, fluid flow, heating systems, or batch operations.

Employees interact with digital twins of systems rather than learning on a live plant or production line (which can be costly and risky). They can also practice controlling variables and troubleshoot simulated failures in a controlled and safe learning space.

📉 The Reality of the Skills Gap

Here's the harsh truth: as experienced engineers retire and tech continues to evolve, there's a growing mismatch between what employers need and what job seekers can do.

According to various industry reports:

Over 50% of manufacturers say they struggle to find qualified talent.

Many graduates enter the workforce without practical exposure to control systems, instrumentation, or advanced automation.

On-the-job training often means learning under pressure, which increases risk and slows down productivity.

That's where process control simulation comes in to level the playing field.

💡 Why Simulation Training Works So Well

Let's break it down—why is simulation training such a powerful tool for skill development?

1. Hands-On Without the Risk

Operators and engineers can learn to manage pumps, valves, sensors, and PID controllers without shutting down an actual plant or risking equipment failure.

✅ Outcome: Teams gain confidence and skills faster, without the anxiety of making real-world mistakes.

2. Real-Time Feedback and Learning

Simulation platforms offer instant feedback so learners can see every decision's cause and effect. Did a parameter spike? Was the valve response too slow? The trainee can adjust, repeat, and refine.

✅ Outcome: Faster learning curves and better problem-solving abilities.

3. Customized to Industry Needs

Whether you're in oil and gas, food processing, pharmaceuticals, or energy, process control simulation training can be tailored to match the systems your team uses every day.

✅ Outcome: No more generic training—only relevant, job-specific practice.

4. Supports All Experience Levels

From entry-level technicians to experienced engineers learning new platforms, simulation training fulfills people where they are.

✅ Outcome: Continuous professional development becomes scalable.

🧠 What Skills Are Developed?

Here are just a few areas where process control simulation builds competence:

Instrument calibration

Process variable tuning (temperature, flow, pressure)

PLC and SCADA integration

Alarming and fault detection

Start-up and shutdown procedures

Troubleshooting under abnormal conditions

It also enhances soft skills like decision-making, attention to detail, and collaboration using group-based simulations.

🏭 Real-World Benefits for Companies

Let's not forget the big picture—this isn't just a learning tool. It's a strategic investment.

✔️ Shorter onboarding time for new hires

✔️ Reduced operational downtime from human error

✔️ Higher retention and employee satisfaction

✔️ Stronger compliance with safety regulations

✔️ Better preparedness for automation upgrades

Companies using process control simulation in their training programs are more agile, efficient, and better positioned for growth.

🚀 Getting Started with Simulation Training

Are you ready to close the skills gap in your team? Here's how to begin:

Choose the right platform –

Look for simulation tools like Simulink, DCS emulators, or virtual PLC trainers.

Assess your team's needs –

Identify the processes or skills most needing improvement.

Design a structured training path –

Combine simulations with assessments and guided instruction.

Track progress –

Use KPIs to measure learning outcomes and improvements over time.

Encourage a culture of learning –

Make training constant, not just a one-time event.

Final Thoughts

Bridging the skill gap doesn't have to mean expensive hires or risky learning curves. With simulation training in process control, you can quickly, safely, and effectively give your team the necessary skills. As industries evolve, the companies that invest in their people through innovative training tools will be the ones that lead the way. So, if you're ready to turn your team into top-tier operators and problem-solvers, process control simulation might be your best bet. Count on skilled software developers of PiControl Solutions LLC to design and implement tools for process control simulation and train your team.

#model predictive control#advanced process control#process control companies#tuning software#pid autotune

0 notes

Text

Integrators Speak: What Makes Ignition Their SCADA Platform of Choice

SCADA Isn't Just a System—It’s a Strategic Decision

When your plant's efficiency, uptime, and scalability hinge on your SCADA system, choosing the right platform isn’t just a tech decision—it’s a business-critical one. And for more and more integrators and manufacturers, Ignition by Inductive Automation is the name that keeps rising to the top.

But why?

Let’s hear from those who work in the trenches—industrial integrators who implement, optimize, and rely on SCADA systems every day.

The SCADA Wish List: What Today’s Integrators Value Most

When evaluating the best SCADA software in 2025, experienced integrators say the same things matter:

Flexibility to fit diverse architectures.

Rapid development and deployment.

Ease of integration with MES, ERP, and IoT layers.

Licensing models that scale with the business, not against it.

Modern UI/UX for operators and stakeholders alike.

Ignition doesn’t just check these boxes—it redefines them.

Why Ignition SCADA Stands Out

Unlimited Licensing

One integrator put it best: “We’re not paying more just because a facility is growing.” Ignition’s licensing model allows for unlimited tags, screens, and clients—ideal for evolving operations.

Modular Architecture

With components like Perspective, Vision, MQTT Transmission, and Edge, integrators can build exactly what a plant needs—without bloat.

Web-Based Deployment

Forget clunky installs and patchwork updates. Launch from any browser, on any device.

Speed and Simplicity

From drag-and-drop design to streamlined SCADA system integration, Ignition helps integrators get systems up faster—with fewer headaches for their clients.

Beyond Features: A Platform That Powers Partnership

SCADA isn’t just about code—it’s about collaboration. And that’s where Ignition really shines.

Active Community & Support Inductive Automation’s forums, documentation, and user groups make it easy for integrators to solve problems fast—and innovate faster.

Inductive University Whether onboarding new talent or upskilling veterans, Ignition Inductive Automation offers robust training and certifications to keep teams sharp.

Scalable for Startups and Enterprises Alike From single-machine interfaces to enterprise-wide dashboards, integrators praise Ignition’s ability to grow with the customer—without forcing rework.

How It Stacks Up: Ignition vs. Other SCADA Platforms

Unlike traditional SCADA vendors that lock you into proprietary ecosystems, Ignition thrives on interoperability and openness. Whether integrating with SQL databases, MQTT brokers, or third-party APIs, it’s engineered to play well with others.

In fact, many integrators report migrating from legacy systems not just because of features—but because of frustration with outdated architectures and restrictive vendor policies.

Real Talk from the Field

“We’ve built systems for food processors, chemical plants, and packaging lines. Ignition let us design fast, customize deeply, and deliver value that made clients go ‘wow.’ It’s not just software—it’s a competitive advantage.” — SCADA Integrator, Midwest U.S.

INS3’s Take: The Platform You Can Build a Future On

At INS3, we work closely with integrators and manufacturers to solve real-world automation challenges. And time and again, Ignition emerges as the platform that meets today’s demands—and tomorrow’s dreams.

Whether you’re exploring your first SCADA deployment or replacing a legacy setup, we’re here to help you:

Evaluate your current tech stack.

Identify high-impact opportunities.

Build smarter, faster, and more connected systems.

SCADA That Supports Innovation, Not Limits It

If you're looking for a SCADA platform that empowers your integrators, delights your operators, and supports your business goals—Ignition SCADA by Ignition Inductive Automation is the answer.

Let’s build something scalable, intuitive, and future-ready—together.

0 notes

Text

Implementation of Digital Twin Technology: Bridging the Physical and Digital Worlds

Digital Twin technology is transforming industries by creating dynamic digital replicas of physical assets, systems, and processes. By integrating real-time data with simulation and analytics, digital twins enable better decision-making, predictive maintenance, and operational efficiency. The implementation process requires strategic planning, technological infrastructure, and a clear understanding of desired outcomes.

What Is a Digital Twin?

A digital twin is a virtual representation of a physical object or system across its lifecycle. It uses real-time data to simulate the performance and behavior of the asset. Unlike static 3D models, digital twins are dynamic and continuously updated through inputs from IoT sensors, enterprise systems, and environmental data.

Industries such as manufacturing, aerospace, healthcare, energy, and smart cities are leveraging digital twins to reduce costs, increase productivity, and drive innovation.

Key Steps in Implementing Digital Twin Technology

1. Define Objectives and Scope

Start by identifying the business problems or goals the digital twin is meant to address. These could include:

Predicting equipment failures

Optimizing operations

Enhancing product design

Improving customer experiences

Clearly defining the scope—whether it’s a single machine, an entire facility, or a supply chain—helps align resources and expectations.

2. Establish Data Infrastructure

Reliable data is the foundation of an effective digital twin. This includes:

Historical data for modeling

Real-time sensor data for monitoring

Operational data from ERP, MES, or SCADA systems

Cloud-based platforms are commonly used to integrate, store, and process this data at scale.

3. Select the Right Technologies

A successful implementation requires a combination of technologies:

IoT sensors: Collect physical asset data

Cloud computing: Offers scalability and remote access

Simulation tools: Enable virtual testing and modeling

AI/ML algorithms: Analyze trends and make predictions

AR/VR platforms: Provide immersive visualization and interaction

Selecting technologies that can be integrated smoothly into existing systems is crucial.

4. Develop the Digital Model

Create a digital replica of the physical object using CAD tools and simulation software. Incorporate real-world physics and operational parameters to mirror actual performance.

At this stage, accuracy is vital. A precise model ensures reliability when forecasting behavior or optimizing performance.

5. Enable Real-Time Integration

The true power of a digital twin comes from real-time synchronization. This involves:

Integrating sensors and devices

Using APIs and middleware to connect systems

Enabling feedback loops between the digital and physical environments

This step transforms the model from a static replica into a living, breathing digital twin.

6. Test and Validate the Twin

Before full deployment, rigorously test the digital twin to ensure it matches real-world behavior. Use known scenarios and real-time inputs to confirm accuracy. Identify and resolve any discrepancies between the digital and physical systems.

7. Deploy and Continuously Improve

Once validated, the digital twin can be deployed to monitor and optimize operations. However, it must evolve alongside its physical counterpart. Continuous updates, machine learning enhancements, and sensor recalibrations are essential for long-term effectiveness.

Benefits of Digital Twin Implementation

Predictive Maintenance

By monitoring machinery in real time, digital twins detect early signs of wear or failure. Maintenance can be scheduled before issues escalate, minimizing downtime.

Operational Efficiency

Simulating different scenarios helps organizations identify bottlenecks, streamline workflows, and increase output without additional resources.

Cost Reduction

Digital prototyping reduces the need for physical models, lowering R&D expenses. Operational savings also arise from reduced breakdowns and energy optimization.

Faster Innovation

Virtual testing accelerates product development cycles. Engineers can iterate quickly, explore multiple configurations, and bring innovations to market faster.

Enhanced Customer Experiences

In retail, automotive, and real estate sectors, digital twins provide immersive virtual interactions, enabling personalized and engaging customer experiences.

Challenges and Considerations

Data Security Risks

Integrating real-time data streams and cloud systems increases exposure to cyber threats. Strong encryption, access controls, and compliance frameworks are necessary.

Data Quality and Availability

Accurate, timely data is essential. Incomplete or incorrect data can mislead simulations and produce poor decisions.

High Initial Investment

Upfront costs for hardware, software, and expertise can be significant. However, long-term gains in efficiency and cost savings often justify the investment.

Skilled Workforce Requirements

Digital twin implementation requires cross-functional expertise, including data scientists, engineers, and IT professionals. Upskilling and hiring may be necessary.

The Future of Digital Twin Technology

Digital twins are evolving rapidly. Integration with generative AI, 5G, and edge computing will unlock new levels of autonomy and intelligence. Soon, entire ecosystems such as smart cities, autonomous supply chains, and connected healthcare systems may function as networks of interconnected digital twins.

This shift represents a move toward real-time, data-driven decision-making at scale—a foundation for the next generation of digital transformation.

Conclusion

The implementation of digital twin technology is a strategic leap toward smarter, more resilient operations. While the process requires planning and investment, the long-term benefits—ranging from cost savings to innovation acceleration—make it a compelling choice for forward-thinking organizations. By merging the physical and digital worlds, digital twins unlock a powerful pathway to future-ready enterprise systems.

0 notes

Text

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

BL335: The Industrial-Grade ARM Computer Built for Node-Red - Perfect Balance of Performance and Cost!

In the fields of industrial automation and IoT, Node-Red has become the go-to tool for rapid development of data acquisition, protocol conversion, and edge computing, thanks to its visual programming and low-code features. However, not all hardware is perfectly suited for Node-Red—some are over-spec’d and wasteful, while others lack the necessary resources for smooth operation.

Beilai Technology' s ARMxy BL335 Industrial Computer, with its Node-Red-optimized hardware design, is the ideal choice for industrial users! It delivers smooth performance, rock-solid reliability, and competitive pricing to meet diverse industrial needs.

Why is the BL335 the Best Industrial Computer for Node-Red?

1. Dual-Core A7 Processor – Just the Right Performance

2× ARM Cortex-A7 @1.2GHz, optimized for lightweight applications—Node-Red runs smoothly without lag.

Unlike overpowered quad/octa-core processors, the dual-core A7 design avoids wasted resources, balancing performance and cost efficiency.

2. RAM & ROM Perfectly Matched for Node-Red

512MB/1GB DDR3 RAM, fully meeting Node-Red’s long-term stability requirements (recommended ≥512MB).

4GB/8GB eMMC storage, ensuring ample space for the OS, Node-Red, and data storage without bottlenecks.

3. Pre-Installed Node-Red, Ready Out of the Box

Comes with Ubuntu/Linux + Node-Red pre-installed—power it up and start developing immediately.

Pre-configured system images enable rapid deployment, significantly shortening project timelines.

4. Dedicated Node-Red Technical Support Team

Bairen Technology provides Node-Red application examples, development guides, and customized support to help users get started quickly.

Stuck with protocol conversion or data collection? Our expert team offers real-time remote assistance!

5. Rich Serial & Network Ports for Easy Data Acquisition

Optional 4-8x RS485/RS232 ports, supporting Modbus RTU, DL/T645, and other industrial protocols.

Dual Ethernet (Gigabit + Fast Ethernet), compatible with TCP/IP, MQTT, OPC UA, and more for flexible device integration.

6. Industrial-Grade Stability for 24/7 Reliability

Fully isolated serial ports & independent hardware watchdog prevent crashes, ensuring long-term stable operation.

Wide-temperature design (-40℃~85℃), built to withstand harsh industrial environments.

7. Flexible Expansion for Diverse Needs

Optional DI/DO, CAN, GPIO, AI/AO modules for seamless connectivity with PLCs, sensors, actuators, and more.

4,000+ I/O combinations—customize your setup without overspending.

8. Optimized Hardware, Unbeatable Value

A refined hardware design that perfectly balances performance, stability, and cost.

Priced at just 60%~70% of comparable solutions, making industrial IoT more accessible than ever!

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

✅ Data Acquisition: Easily connect PLCs, meters, and sensors with support for Modbus, CAN, MQTT, and more.

✅ Edge Computing: Local data processing reduces cloud dependency and network costs.

✅ Protocol Conversion: Use BLIoTLink software to quickly integrate with SCADA, Alibaba Cloud, Huawei Cloud, and other platforms.

✅ Remote Maintenance: BLRAT tool enables remote debugging, cutting on-site service costs.

Experience the Power of BL335 for Node-Red Today!

Website: www.BLIIoT.com

Free technical evaluations & industry solutions available!

Let BL335 be your ultimate Node-Red partner—low cost, high efficiency, and the perfect engine for industrial IoT! 🚀

0 notes

Text

PLC SCADA Programming

Madox Malaysia is a leading automation solutions provider specializing in HMI development in Malaysia and PLC software development in Malaysia. We deliver user-centric Human-Machine Interface designs that enhance control, monitoring, and efficiency in industrial processes. Our PLC software development services are tailored to ensure seamless communication between machines and systems, enabling intelligent automation. With deep expertise in major platforms like Siemens, Allen-Bradley, and Omron, we build robust, scalable, and reliable automation systems. Our team focuses on precision programming, system integration, and real-time performance. Madox Malaysia supports industries such as manufacturing, energy, and process automation with customized, high-performance solutions. We are committed to delivering innovation, quality, and operational excellence. Choose Madox Malaysia for advanced HMI and PLC solutions that drive productivity and growth.

For more info please click the link:

0 notes

Text

Buraq Integrated Solutions

Buraq Integrated Solutions is a premier system integration, professional services, and software development company, offering cutting-edge technology solutions across multiple industries. Specializing in Industrial Automation, Automatic Weather Stations, Flood Early Warning Systems, PLC/SCADA, and IT Consultancy, Buraq Integrated Solutions provides tailored services to government bodies, financial institutions, telecom providers, energy sectors, healthcare, and educational institutions. With a commitment to delivering reliable, rapid, and robust solutions, Buraq Integrated Solutions has established itself as a trusted partner for businesses and government organizations seeking to enhance efficiency through automation and advanced technology. Comprehensive Solutions for Various Industries As a technology-intensive company, Buraq Integrated Solutions offers a diverse portfolio of services designed to meet the evolving needs of its clients. The company specializes in: 1. Industrial Automation & Control Systems - PLC Programming & SCADA Systems – Advanced industrial automation solutions for seamless control and monitoring. - HMI (Human-Machine Interface) – Intuitive systems for process control and operational efficiency. - Telemetry Systems – Real-time data acquisition and remote monitoring solutions. 2. Automatic Weather Stations & Flood Early Warning Systems - Environmental Monitoring Systems – Providing accurate weather data for improved forecasting. - Flood Early Warning Systems – Enhancing disaster preparedness through real-time flood detection technology. - GIS Survey & Mapping – Geographic Information Systems (GIS) for land and infrastructure analysis. 3. IT Consultancy & Software Development - Custom Software Solutions – Tailored applications for financial services, government institutions, and enterprise operations. - Cybersecurity & Data Protection – Ensuring the integrity and security of IT infrastructure. - Cloud-Based Solutions – Scalable and efficient cloud computing services for businesses. Industries We Serve Buraq Integrated Solutions delivers advanced technological solutions to a broad range of industries, ensuring efficiency, security, and automation in key sectors: Government (Local & Central): We provide digital transformation solutions that enhance the efficiency and effectiveness of local and central government operations. Financial Services: Our solutions help banks, insurance companies, and clearing houses streamline operations, reduce risks, and improve customer service. Telecommunications: We enable telecom companies to optimize their networks, improve service delivery, and stay competitive in a rapidly evolving industry. Energy & Utilities: Our solutions help energy providers and utilities improve operational efficiency, reduce costs, and enhance sustainability. Healthcare: We deliver technology solutions that improve patient care, streamline operations, and ensure compliance with regulatory requirements. Education: Our solutions help educational institutions enhance learning experiences, improve administrative efficiency, and prepare students for the future. Why Choose Buraq Integrated Solutions? ✔ Proven Expertise – A team of highly skilled professionals with vast industry experience. ✔ Innovative Technology – Implementation of the latest advancements in industrial automation and IT solutions. ✔ Custom-Tailored Solutions – Designed to meet the unique needs of each client. ✔ Reliable & Scalable Systems – Ensuring long-term efficiency and adaptability. ✔ Commitment to Excellence – Delivering quality-driven solutions that maximize performance. Get in Touch Buraq Integrated Solutions is your trusted partner for advanced technology solutions. Whether you need automation, IT consultancy, or environmental monitoring, we have the expertise to deliver state-of-the-art solutions that work. For inquiries, consultations, or collaborations, contact us today! Read the full article

0 notes

Text

Understanding the Automation Domain: Transforming Industries Through Intelligent Systems

Automation has emerged as a cornerstone of modern industry, revolutionizing how tasks are performed, systems are managed, and businesses operate. The automation domain encompasses a wide array of technologies and processes designed to minimize human intervention while maximizing efficiency, accuracy, and productivity. As digital transformation accelerates globally, the role of automation becomes increasingly pivotal in reshaping every aspect of the economy—from manufacturing to healthcare and finance to logistics.

What is the Automation Domain?

The automation domain refers to the interdisciplinary field focused on the creation and application of technologies that control systems or processes with minimal or no human input. It involves a blend of hardware (such as sensors, controllers, actuators) and software (like control algorithms, artificial intelligence, and machine learning) to perform tasks that were traditionally done manually.

Automation can be categorized into several types:

Industrial Automation – Involves automating manufacturing processes using robotics, PLCs (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) systems.

Business Process Automation (BPA) – Automates repetitive business tasks such as data entry, billing, or customer service using software tools.

Home Automation – Also known as smart home technology, it automates lighting, heating, security, and other household systems.

IT Process Automation (ITPA) – Streamlines IT operations like server management, backup, and security patching.

Robotic Process Automation (RPA) – Uses software robots to mimic human actions in digital systems to execute business processes.

Why Automation Matters

The importance of automation lies in its numerous benefits:

Increased Productivity: Automated systems can operate 24/7 without fatigue, leading to higher throughput and faster production cycles.

Enhanced Accuracy: Reduces human error, especially in data-sensitive or precision-required environments.

Cost Efficiency: While the initial investment may be high, automation reduces long-term labor and operational costs.

Improved Safety: Replaces humans in dangerous or hazardous environments, reducing workplace accidents.

Scalability: Automated systems can be scaled easily to meet growing demands without a proportional increase in manpower.

Key Applications Across Industries

Manufacturing: CNC machines, industrial robots, and automated assembly lines are integral to smart factories.

Healthcare: Automated diagnostic tools, surgical robots, and administrative software improve care quality and efficiency.

Retail: Automated inventory systems, self-checkout kiosks, and AI-driven customer service bots enhance the shopping experience.

Banking and Finance: RPA is widely used to process transactions, generate reports, and ensure compliance.

Transportation and Logistics: Autonomous vehicles, drone deliveries, and warehouse automation streamline supply chain operations.

Technologies Driving Automation

Artificial Intelligence (AI) & Machine Learning (ML) – Enables predictive maintenance, smart decision-making, and adaptive systems.

Internet of Things (IoT) – Connects devices and sensors for real-time monitoring and control.

Cloud Computing – Facilitates data storage, remote access, and scalable computing power.

Big Data Analytics – Provides insights into process optimization and performance monitoring.

5G & Edge Computing – Ensures fast and low-latency communication between devices and control systems.

Challenges in the Automation Domain

While automation brings transformative benefits, it also presents challenges:

Job Displacement: Automation may render certain jobs obsolete, raising concerns about employment and skills retraining.

Security Risks: Automated systems are vulnerable to cyber threats if not properly secured.

High Initial Investment: The cost of implementing automation can be a barrier, especially for small and medium enterprises.

Complex Integration: Combining new automation solutions with legacy systems can be technically challenging.

Future of Automation

The automation domain is continuously evolving. Trends such as hyperautomation—the use of advanced technologies like AI and RPA together to automate complex processes—are gaining traction. In the future, we can expect:

Increased use of autonomous systems (e.g., self-driving cars, drones).

Greater emphasis on human-machine collaboration through cobots (collaborative robots).

Ethical AI practices in automation design and deployment.

More accessible automation tools for non-technical users (citizen developers).

Conclusion

The automation domain is at the heart of the Fourth Industrial Revolution, driving significant change across industries. As technology advances, automation is not just about replacing human effort but augmenting it—making systems smarter, safer, and more sustainable. Embracing automation strategically will be crucial for businesses and societies aiming to stay competitive and resilient in the years ahead.

0 notes

Text

Remote Monitoring with PLC Panels: Managing Your Plant from Anywhere

Introduction

In today’s fast-moving industrial world, being physically present on the shop floor every hour of the day is neither practical nor necessary. Thanks to modern PLC Panels, plant managers and engineers can now monitor and control their operations from virtually anywhere.

This is where remote monitoring comes in—a game-changing feature that turns your PLC Panel into a smart control center for your entire plant.

What is Remote Monitoring in PLC Panels?

Remote monitoring allows real-time access to your PLC Panel’s data through cloud-based platforms or networked software systems. It enables you to:

View machine status live

Monitor performance metrics

Receive alerts and diagnostics

Control start/stop operations remotely

Whether you’re at another site, at home, or travelling, you can manage your plant operations with just a laptop or smartphone.

Benefits of Remote Monitoring with PLC Panels

Real-Time Oversight Instantly check the status of equipment and production without being on-site.

Faster Problem Resolution Receive immediate alerts for faults, so downtime can be minimized.

Cost Savings Reduce the need for constant physical supervision and travel between sites.

Improved Decision-Making Access to live data helps you make informed decisions quickly.

Enhanced Safety Monitor high-risk processes remotely, minimizing exposure for workers.

Ready to take control from anywhere? Partner with a reliable PLC Panel Manufacturer to implement secure, remote-ready automation systems.

Key Features to Look For in Remote-Ready PLC Panels

Ethernet and Wi-Fi Connectivity Enables seamless data transfer between your PLC and remote devices.

Cloud Integration Support Compatible with platforms like MQTT, OPC UA, or custom dashboards.

Secure Access Protocols SSL encryption, VPN access, and password protection keep your system safe.

User-Friendly Interfaces Easy-to-use mobile or web apps that show real-time visualizations.

SCADA or HMI Compatibility Gives a centralized view with alarms, trends, and historical data logs.

Industries That Benefit the Most

Water Treatment Plants – Monitor pumps, levels, and chemical dosing remotely

Renewable Energy Farms – Supervise solar or wind operations from central control

Cold Storage Units – Keep track of temperature and humidity offsite

Manufacturing Units – Detect faults or delays without halting production

Agricultural Automation – Manage irrigation or feeding schedules remotely

How to Get Started

Collaborate with an experienced Programmable Logic Controller Panel Manufacturer who can:

Customize the panel with remote access modules

Integrate your system with cloud services

Train your team to monitor and control remotely

Ensure top-level cybersecurity protocols are in place

Conclusion

Remote monitoring with PLC Panels is no longer a luxury—it’s a necessity in a digital-first industrial world. It saves time, boosts productivity, and enhances control like never before. To enable this, choose a PLC Panel Manufacturer that delivers smart, secure, and remote-ready solutions tailored to your industry.

Control your plant from anywhere—talk to a trusted PLC Panel Manufacturer and upgrade your operations today.

Also read:

PLC Panels vs. SCADA Systems: Understanding Their Roles and Differences

Why PLC Panels Are a Must-Have for Small and Medium Enterprises (SMEs)

Retrofitting Old Machinery with Modern PLC Panels

Using PLC Panels in HVAC Automation for Commercial Buildings

#plc electrical panel#plc#electrical panel#plc panel#Programmable Logic Controller Panel Manufacturer#PLC Panel Manufacturer

0 notes

Text

Building a Better Tomorrow: The Vision and Mission of Veera Group

In today’s fast-evolving industrial landscape, reliable, efficient, and future-ready solutions are the cornerstones of success. Veera Group has positioned itself at the forefront of this revolution, offering cutting-edge engineering, manufacturing, and automation services that power industries across the globe. With innovation as its backbone and excellence as its goal, Veera Group is not just building products—it’s building a smarter, more sustainable tomorrow.

Engineering Excellence with Purpose

At its core, Veera Group is an engineering powerhouse. The company is known for delivering custom-built solutions tailored to the unique needs of diverse industries including chemical processing, pharmaceuticals, oil & gas, food & beverage, and more. From concept to commissioning, Veera Group handles every aspect of project execution with precision.

Their engineering services include:

Process Design and Automation

Custom Fabrication

Mechanical & Electrical Engineering

On-Site Installation and Commissioning

These comprehensive services ensure clients get more than just a product—they receive a fully integrated solution that enhances productivity, safety, and long-term value.

World-Class Manufacturing Capabilities

Veera Group takes pride in its state-of-the-art manufacturing facilities. Equipped with advanced machinery and a highly skilled workforce, the company manufactures a wide range of process equipment including pressure vessels, heat exchangers, storage tanks, and modular process skids. Every product undergoes rigorous quality testing and adheres to international standards such as ASME, PED, and ISO.

The company's commitment to precision and quality ensures that each solution is not only technically sound but also cost-effective and durable. This reputation for excellence has earned Veera Group the trust of clients both in India and abroad.

Automation that Transforms Industries

As industries strive to improve efficiency and reduce operational costs, automation has become a necessity. Veera Group offers intelligent automation solutions that transform traditional systems into smart, responsive, and data-driven operations. Their team of control engineers and software experts design automation frameworks that streamline processes, enhance monitoring, and allow for seamless integration with existing systems.

From SCADA and PLC programming to full-scale automation of production lines, Veera Group is enabling industries to embrace Industry 4.0 with confidence.

A Commitment to Sustainability and Innovation

What truly sets Veera Group apart is its unwavering commitment to sustainability and innovation. In a world grappling with environmental challenges, Veera Group takes a proactive approach by offering eco-friendly solutions, reducing energy consumption, and promoting green manufacturing practices.

The company’s R&D initiatives focus on developing technologies that are not only efficient but also environmentally responsible. This future-forward mindset ensures that Veera Group remains a leader in both performance and purpose.

Trusted by Clients Worldwide

With a strong track record of successful projects and long-term partnerships, Veera Group has established itself as a trusted name in industrial engineering. Their client-first approach, transparency, and dedication to delivering excellence have made them the preferred partner for organizations looking to scale their operations and embrace modern engineering solutions.

Conclusion: Partnering for Progress

Veera Group’s holistic approach to engineering, manufacturing, and automation makes it a one-stop destination for industries seeking innovation, quality, and reliability. Whether you are looking to optimize your operations, implement smart manufacturing, or simply need a trusted partner to bring your industrial vision to life—Veera Group has the expertise, infrastructure, and passion to make it happen.

Visit veeragroup.net to explore their full range of services and discover how they can help take your business to the next level.

0 notes

Text

Leading Automation Solutions and Robotic Welding Fixture Manufacturers in Pune and India

In this blog, we’ll explore how these technologies work and which companies are leading the way in Pune and across India.

Automation Solutions Companies in Pune

Pune is home to some of India’s best automation solutions companies. These companies help factories reduce human error, increase speed, and improve safety.

From assembly lines to material handling, automation plays a crucial role in modern manufacturing. PLC programming, SCADA systems, robotics integration, and sensor-based automation are now widely adopted.

Why choose automation solutions in Pune?

Skilled engineering talent

Strong IT and mechanical ecosystem

Cost-effective and scalable solutions

Some automation companies in Pune also offer complete turnkey projects. These include electrical control panels, robot cells, and HMI-based systems.

Whether you are in automotive, packaging, or FMCG, automation helps save time and reduce costs. Many companies in Pune now focus on Industry 4.0 technologies and smart factory integration too.

BIW Projects Design & Manufacturing Solutions Provider

BIW (Body-in-White) is a key phase in vehicle manufacturing. It involves the design and welding of the car body structure before painting. Companies that offer BIW project design and manufacturing solutions focus on both accuracy and speed.

What is BIW design?

BIW design involves:

Weld spot planning

Fixture design

Simulation for strength and rigidity

Robotic path planning

Leading providers ensure the entire BIW assembly line is optimized. From conveyors to clamps, every part is designed with precision.

Services provided by BIW solutions providers:

3D modeling and simulations

Robotic cell integration

Process validation

Fixture and gripper manufacturing

Turnkey BIW lines

The demand for BIW solutions is high in Pune due to the presence of top automotive OEMs and Tier-1 suppliers. Companies in this domain work with global quality standards and provide support from concept to commissioning.

Welding SPMs Design & Manufacturing in Pune

SPM (Special Purpose Machines) are custom machines designed for specific tasks. In welding, Welding SPMs are widely used for high-volume, repetitive jobs. Pune has many experienced players in designing and manufacturing welding SPMs.

These machines are tailored for:

Spot welding

MIG welding

TIG welding

Seam welding

Welding SPMs increase production efficiency and ensure consistent weld quality. Most machines are semi-automatic or fully automatic and can be integrated with robotic arms.

Benefits of Welding SPMs:

Reduced cycle time

Improved safety

High repeatability

Custom tooling options

Pune-based SPM manufacturers use CAD/CAM software and simulate the entire process before production. From fixture design to final assembly, everything is handled in-house.

They also offer after-sales service, control panel integration, and remote troubleshooting. That’s why industries in Pune trust local SPM makers for high-performance and durable welding machines.

Robotic Welding Fixtures Manufacturers in India

For robotic welding to work effectively, the fixtures holding the parts must be perfectly designed. This is where robotic welding fixtures manufacturers in India come into play.

What is a robotic welding fixture?

It is a tool used to:

Secure the components to be welded

Maintain alignment and accuracy

Allow easy loading and unloading

Minimize operator involvement

These fixtures are made with high-strength steel and use pneumatic or hydraulic clamping systems. Some also have sensors to detect part placement and alignment.

Leading Indian manufacturers offer:

Design and simulation of fixtures

Integration with robotic arms

Support for different weld processes

Customization based on component geometry

Robotic welding fixtures made in India are exported globally. These are used in industries like automotive, aerospace, defense, and construction machinery.

Why Pune and India Are Ideal for Automation and Welding Solutions

Pune and other Indian cities are now global players in the field of industrial automation and welding technologies. Here's why:

Skilled workforce: Engineers with mechanical, electrical, and automation expertise.

Cost-effective manufacturing: High quality at lower cost.

Technology integration: Use of advanced CAD tools, simulation software, and robotics.

Global supply chain: Export-ready capabilities with strong logistics support.

Whether you're setting up a new plant or upgrading an old one, Pune-based companies offer end-to-end solutions. From automation and SPMs to BIW systems and robotic fixtures, everything is locally available and globally reliable.

FAQs

Q. What are automation solutions in manufacturing? Automation solutions involve using machines, sensors, and software to run industrial processes with minimal human input.

Q. What is BIW in the automotive sector? BIW stands for Body-in-White, the stage in car manufacturing where the vehicle frame is assembled before painting.

Q. How do SPMs improve productivity? Welding SPMs are designed for speed, accuracy, and repetitive tasks. They cut down manual work and increase efficiency.

Q. Are robotic welding fixtures expensive? Not necessarily. Indian manufacturers offer cost-effective fixtures that meet international standards.

Q. Can I get custom automation solutions in Pune? Yes, many Pune-based companies offer customized automation systems based on your industry needs.

Final Thoughts

If you are searching for:

Automation solutions companies in Pune

BIW projects design & manufacturing solutions provider

Welding SPM’s design & manufacturers in Pune

Robotic welding fixtures manufacturers in India

— then Pune is the place to explore top-tier engineering and manufacturing partners.

These companies not only offer cutting-edge products but also partner with you through the entire journey—from design to delivery.

#automation solutions pune#BIW projects india#welding SPMs pune#robotic welding fixtures india#industrial automation#smart manufacturing#automotive manufacturing india#special purpose machines#robotics integration#pune engineering companies#robotics welding

0 notes