#Digital Fly By Wire Control System

Explore tagged Tumblr posts

Text

LCA Tejas: Indigenous Digital Flight Control Computer tested successfully

Indigenous Digital Fly by Wire Flight Control System for Tejas: In a major step towards achieving self-reliance in defence sector, Indian scientists and engineers have successfully integrated indigenously developed Digital Fly by Wire Flight Control Computer (DFCC) in prototype LSP7 on Monday (February 19, 2024). The digital fly-by-wire flight control computer has been indigenously developed by…

View On WordPress

0 notes

Note

but android!art wireplay hhnnnnggg im shortcircuiting

cw (18+) : android!art, wireplay, implied corruption, first orgasm/simulated release

android!art asking you for help when his daily diagnostic tests sense that one of his wires has disconnected inside of his chest, opening up his chassis for you to dig your fingers inside and hopefully fix the issue.

and he’s fine with it all; no pain, no discomfort, no intense sensation linked to your touch there—at first.

but then your fingernail catches on the outside of a thick, blue wire close to his thirium pump, and suddenly his back is arching and his eyes are rolling under his lids and he’s gasping raggedly. he grabs onto your wrist, panting and writhing while his LED flickers from blue to red. he looks like a scared puppy, and you immediately notice that his pupils are unusually large beneath his fluttering lashes.

“i.. i’m sorry, i—.. that’s never happened before, i think my systems are just overworked and malfunctioning.. please, continue..”

so you do. you search through the colorful mess of his innards, your fingertips grazing each electrical tendril as you pass them by. it takes several long moments before you find the problem wire, and you’re just about to tell art the good news, but when you look up you find your breath catching in your throat.

he’s artificially flushed all over his face, his hands are gripping the edge of the sofa with white knuckles, and his head is lolling back lazily like he’s lost control of his expertly-engineered musculature.

“art?” you hum, “are you okay?”

he begins to quake, moaning lowly, and you can feel the scorching waves of heat radiating off of him.

he releases his grip on the couch only to readjust it and squeeze harder. you watch his adam’s apple bob as he swallows around a barely-contained whine.

“please, just— just plug it in, i can’t—“ he mewls.

you’ve never heard him sound so out-of-control before, but you want nothing more than to help him feel better. you line up the yellow wire with its designated socket, making note of the way his body jolts when you pinch it between the pads of your digits, and push it forward to click it back into place.

as soon as the connection is restored, art’s eyes are flying open—wide and wild—and then he’s wailing. his hips rush upward and knock your elbow in the process, his legs kicking out and convulsing as he curls in on himself. your own stomach swirls and flips as you take in the sight of his abdomen repeatedly tensing and relaxing in a vicious cycle of what appears to be.. hmm..

it takes a hand on his shoulder and your whispered reassurance for his cognitive capabilities to come back to him, but he can’t resist leaning forward to bury his face in your neck. his hands clutch your back, his breathing heavy and exhausted. his vision flares with pop-ups. “warning: systems overheating” and “warning: coolant levels low”.

“some.. something just happened.. i.. i’m embarrassed, i’m so sorry—please, will you exclude that from your memory? i’m.. i’m so hot inside.. i’m.. i don’t know wh—aah..”

he nuzzles the bridge of his nose into your skin, still holding you tight like he’s afraid you’ll go. you realize that he’s become an entirely different android in the last few minutes. some part of him has sprung loose.

you have to let him cool down for the entire rest of the evening before he’s back to normal, at which point you assume all is well again—only for him to pad sheepishly over to you the next afternoon to announce that another one of his wires has mysteriously slipped out of its port..

what a coincidence.

#android!art#wireplay wireplay wireplay mmmm#i love wireplay#something about it is just so perfect and yum#take this android!art snippet as further apology for the lack of the full fic#sage’s asks#art donaldson smut#art donaldson x reader#art donaldson x you#challengers smut#🌸 - ask prompts

353 notes

·

View notes

Text

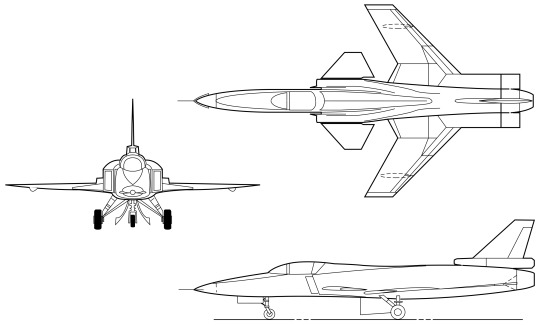

The Grumman X-29 Experimental Aircraft

The Grumman X-29 was an experimental aircraft developed by the United States in the 1980s, aimed at testing advanced aviation technologies. One of its most unique features was its forward-swept wings, which improved maneuverability and reduced drag. However, this design introduced significant aerodynamic challenges, such as the tendency of the wings to twist under stress. To address this, the X-29 utilized advanced composite materials, which provided the necessary strength without adding excess weight.

The X-29 was inherently unstable due to its forward-swept wings, necessitating a sophisticated digital fly-by-wire control system. This system allowed a computer to continuously make adjustments to keep the aircraft stable during flight. Additionally, the aircraft featured canard control surfaces, located in front of the main wings, which enhanced control and maneuverability, particularly at high angles of attack.

Another key feature of the X-29 was its variable-geometry engine inlets, designed to optimize airflow into the engine across different flight conditions. This design allowed the aircraft to maintain efficiency at various speeds and altitudes. Together, these innovative design elements made the X-29 a complex and advanced aircraft for its time.

The X-29 first flew on December 14, 1984, under the management of NASA and the United States Air Force. Two X-29 aircraft were constructed, and they accumulated over 400 test flights. These tests focused on exploring the aircraft's unique aerodynamic and flight control characteristics, providing valuable data on how forward-swept wings performed under various conditions.

The primary objective of the X-29 program was to investigate technologies that could be used in future fighter aircraft, with a particular focus on improving maneuverability and control at high angles of attack. Although the X-29 was never intended to enter production, the insights gained from its development contributed to future advancements in aircraft design.

While the X-29 did not see operational service, its legacy is significant. The technologies it explored, including forward-swept wings, composite materials, and digital flight controls, paved the way for innovations in fighter aircraft. Today, the X-29 is remembered as an important milestone in the study of unconventional aircraft designs and aerodynamics.

An interesting and lesser-known fact about the Grumman X-29 is that, despite its radical design, the aircraft reused components from existing fighter jets to save on development costs. Specifically, the fuselage of the X-29 was derived from the Northrop F-5A Freedom Fighter, and its landing gear was taken from the General Dynamics F-16 Fighting Falcon. This blending of cutting-edge technology with proven components from earlier aircraft helped keep the project within a more manageable budget, demonstrating a creative approach to experimental aircraft design during that era.

#responsive thoughts#aircraft#flight#experimental aircraft#x-series#military#jet fighter#x-29#forward swept wing

121 notes

·

View notes

Text

Did you know?

The Typhoon’s cockpit features a digital fly-by-wire control system and a fully integrated avionics suite, including multi-function displays (MFDs), a voice-activated command system, and the advanced Helmet-Mounted Symbology System (HMSS).

@airtatoo via X

15 notes

·

View notes

Text

Aircraft Sensors Market Size, Share, Demand, Growth and Global Industry Analysis 2034

Aircraft Sensors Market is playing a pivotal role in the advancement of aviation technology, with the market projected to grow from $4.2 billion in 2024 to $8.5 billion by 2034, at a CAGR of approximately 7.3%. Aircraft sensors are integral to ensuring flight safety, monitoring performance, and improving overall operational efficiency. These sensors include pressure, temperature, proximity, and speed sensors, among others, which work seamlessly within an aircraft’s systems to provide real-time data for navigation, communication, fuel management, and engine monitoring. As aviation embraces digitalization and automation, the demand for advanced, reliable sensor technologies continues to rise across both commercial and military sectors.

Market Dynamics

The aircraft sensors market is experiencing substantial growth fueled by the aerospace industry’s shift toward smarter, safer, and more efficient aircraft. Leading this charge are sensors integrated into avionics systems, which have become increasingly sophisticated to support fly-by-wire systems, real-time diagnostics, and autonomous flight capabilities. Pressure and temperature sensors are the most widely used, holding significant market shares due to their critical role in engine health monitoring and environmental control.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS25456

Another strong growth driver is the increasing global air traffic, which necessitates not only new aircraft but also modernization of existing fleets. As airlines seek to enhance fuel efficiency and reduce emissions, sensors that enable precise engine monitoring and predictive maintenance are in high demand. On the flip side, the market faces challenges such as high development and certification costs, complex integration processes, and disruptions in the global semiconductor supply chain. These challenges, however, are met with innovations in smart sensor technologies, driven by the adoption of the Internet of Things (IoT) and artificial intelligence (AI) in aviation systems.

Key Players Analysis

The aircraft sensors market is highly competitive, with established players leading innovation and setting industry standards. Honeywell Aerospace, TE Connectivity, and Rockwell Collins are dominant forces, leveraging decades of aerospace experience to offer a diverse portfolio of sensors. These companies continually invest in R&D to improve sensor reliability, reduce weight, and enhance data processing capabilities.

Other key players like Safran Electronics & Defense, Thales Group, Curtiss-Wright, and Meggitt PLC contribute significantly to the market with advanced sensor solutions tailored to specific aircraft systems. Meanwhile, emerging players such as Aero Sense Innovations, Avionics Insight, and Sky Tech Dynamics are bringing disruptive technologies to the table, focusing on miniaturized, wireless, and multifunctional sensors. Strategic collaborations, mergers, and acquisitions are increasingly common as companies seek to enhance their product offerings and expand their global footprint.

Regional Analysis

North America remains the frontrunner in the aircraft sensors market, thanks to the presence of leading aerospace manufacturers, robust R&D infrastructure, and defense spending. The U.S. leads this regional growth, driven by innovation in avionics and strong support from regulatory agencies like the FAA.

Europe follows closely, with countries such as Germany, France, and the UK investing heavily in sustainable aviation technologies. The region’s focus on compliance with environmental and safety standards is a strong catalyst for sensor market expansion.

Asia-Pacific is emerging rapidly, propelled by booming air travel, increasing aircraft production, and the modernization of aviation infrastructure in countries like China and India. These nations are significantly expanding their aerospace capabilities, with government support further accelerating sensor adoption.

The Middle East and Africa present promising opportunities, especially in the Gulf states, where fleet modernization and airport development projects are underway. Latin America also shows steady growth, particularly in Brazil and Mexico, where aerospace industries are growing and placing greater emphasis on air safety and efficiency.

Recent News & Developments

The aircraft sensors market is seeing notable technological shifts. Companies are moving toward smart sensors that not only collect data but also analyze it in real time, enhancing operational responsiveness and decision-making. The integration of IoT and wireless communication into sensor design is revolutionizing aircraft systems by enabling remote diagnostics and continuous performance monitoring.

Recent regulatory changes by FAA and EASA have introduced stricter guidelines for sensor performance, prompting companies to refine testing and certification processes. Additionally, the global focus on fuel efficiency and carbon reduction has led to the development of sensors that contribute to optimizing flight routes and engine operation.

Noteworthy industry moves include Honeywell’s expansion into AI-powered sensor platforms and Thales’ investment in next-gen sensor integration for autonomous flight technologies. Meanwhile, supply chain vulnerabilities — especially due to semiconductor shortages — continue to affect production cycles and cost structures across the market.

Browse Full Report : https://www.globalinsightservices.com/reports/aircraft-sensors-market/

Scope of the Report

This report offers a comprehensive analysis of the Aircraft Sensors Market from 2025 to 2034. It covers critical aspects such as sensor types (pressure, temperature, proximity, etc.), products (wired, wireless, smart), technologies (MEMS, optical, infrared), and applications including engine monitoring, fuel management, and flight control. The analysis spans across commercial, military, and UAV segments, capturing trends in onboard, embedded, and remote sensor installations.

Additionally, the report dives into market drivers, trends, restraints, and opportunities. It explores regulatory impacts, innovation trends, and the role of sustainability in shaping future sensor technologies. By identifying competitive strategies and evaluating emerging players, the report provides a strategic roadmap for stakeholders aiming to navigate this high-tech, fast-evolving market landscape.

Discover Additional Market Insights from Global Insight Services:

Air Filters Market : https://www.globalinsightservices.com/reports/air-filters-market/

Deployable Military Shelter Market : https://www.globalinsightservices.com/reports/deployable-military-shelter-market/

Gaskets and Seals Market : https://www.globalinsightservices.com/reports/gaskets-and-seals-market/

Inflight Catering Market : https://www.globalinsightservices.com/reports/inflight-catering-market/

Combat Management System Market ; https://www.globalinsightservices.com/reports/combat-management-system-market/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

The Evolution of Automatic Winding Machines: From Manual Labor to Smart Manufacturing

Before automation transformed factory floors, coil winding was a painstaking manual task—demanding steady hands, sharp eyes, and a lot of time. Coils were wound by hand or using simple mechanical aids, with quality and consistency largely dependent on the operator’s skill. Fast forward to today, and automatic winding machines are not only handling the workload—they're doing it smarter than ever.

This journey from manual to smart manufacturing has reshaped how industries like electronics, aerospace, and automotive produce high-performance components. Let’s explore how it all began and where it’s headed next.

From Human Hands to Mechanized Precision

In the early 20th century, as electrical devices became more widespread, the demand for coils surged. Manual methods were no longer efficient or scalable, especially for precision-critical applications like transformers and motors.

The introduction of early automatic winding machines marked a turning point. These machines could repeatedly wind coils with consistent tension and speed, reducing labor costs and improving product uniformity. Still, these systems were largely mechanical, relying on cams, gears, and operator intervention for setup and control.

The Digital Leap: Early Automation

The next big leap came with the rise of electronic control systems. Programmable logic controllers (PLCs) and digital interfaces allowed users to set winding parameters such as turns, pitch, and speed with far more accuracy. This eliminated the need for manual adjustments between batches and drastically improved repeatability.

As industries demanded higher output with tighter tolerances, automatic winding machines evolved to meet the challenge. Features like multi-spindle operation, servo motors, and tension feedback systems became the norm, enabling machines to produce complex windings at high speeds with minimal error.

The Smart Manufacturing Era

Now, we’re in the age of smart manufacturing—where winding machines don’t just execute commands; they learn, adapt, and optimize in real time.

Thanks to AI, machine learning, and IoT integration, today’s automatic winding machines can:

Detect and adjust for variations in wire tension and core alignment on the fly

Predict maintenance needs before a breakdown occurs

Automatically log production data for quality assurance and traceability

Integrate with factory-wide systems to streamline inventory, scheduling, and analytics

For industries like aerospace, where reliability is non-negotiable, or automotive, where production speed meets high precision, these advancements offer a major edge.

The Real-World Impact

Modern manufacturers are seeing measurable benefits from these advancements: reduced downtime, higher throughput, better product consistency, and lower overall production costs. Companies like ACME Electronics, a global Coil Winding Machine Manufacturer Supplier, are leading the way by delivering cutting-edge winding solutions that meet the demands of Industry 4.0.

Final Thoughts

The evolution of automatic winding machines reflects the broader shift in manufacturing—from hands-on craftsmanship to digitally driven precision. As AI and smart technology continue to advance, the future of coil winding promises even more autonomy, efficiency, and innovation.

Is your production line ready to make the leap from automation to intelligent manufacturing?

#coil winding machine#winding machine#coil winder#programmable winding machine#automatic winding machines

0 notes

Text

How Smart Sensors are Elevating Efficiency and Growth in Aerospace

Within the aerospace sector, numerous sensing technologies play essential roles in upholding the safety, reliability, and performance of aircraft and space systems alike. Sensing elements are commonly integrated into specific assemblies to support specific operations, such as system monitoring, process control, navigation, fault detection, and environmental regulation. As aerospace technologies have continued to advance under ongoing research and development, there has been a notable shift toward the adoption of smart sensors that provide capabilities that far exceed those of traditional options. In this blog, we will provide a detailed overview of what smart sensors are, covering everything from how they differ from conventional alternatives to the many ways they are currently advancing aerospace applications.

Understanding Smart Sensors: Key Features and Benefits

Smart sensors are advanced devices that combine conventional sensing components with embedded microprocessors, memory, and communication interfaces. Unlike traditional options that simply detect and transmit raw data to external control units, smart sensors are capable of performing signal conditioning, data analysis, and communication completely autonomously. This allows them to deliver more actionable information, rather than just basic readings.

For example, while a conventional pressure sensor may be able to reliably provide an output voltage that is proportional to the pressure it is measuring, a smart pressure sensor will go beyond with internal processing of data, identification of abnormal patterns, and the notification of operators to handle situations with provided alerts. In some cases, the smart sensor may even communicate directly with control systems through digital interfaces like CAN, Ethernet, or wireless protocols to further simplify processes. Additional features like built-in calibration, fault detection, and temperature compensation may also be leveraged to make smart sensors more accurate and reliable in demanding conditions.

Flight Control and Avionics Systems

One of the most impactful applications of smart sensors is within modern flight control and avionics systems. These systems heavily depend on a network of sensing devices to manage inputs from pilots, assess flight conditions, and command actuator movements that control an aircraft, with real-time data and processing being critical. For instance, smart inertial measurement units (IMUs), gyroscopes, accelerometers, and pressure sensors are increasingly being utilized in these systems with their ability to optimally communicate with flight control computers.

Notable examples of smart sensor use within these settings include fly-by-wire systems, where sensors enhance responsiveness and stability while reducing pilot workload. Meanwhile, the self-diagnostic features of these devices make them popular for detecting faults early in control surfaces or avionics equipment, minimizing the risk of in-flight malfunctions and reducing maintenance delays.

Engine Health and Performance Monitoring

Aerospace propulsion systems regularly operate under extreme conditions, where having the most accurate and reliable measurements often proves essential. Smart sensors embedded in engines have proved monumental in offering real-time analytics and data sharing for parameters like temperature, pressure, vibration, and rotational speed. This serves to ensure that engines are running most efficiently while providing early warnings for potential issues like compressor stall, turbine fatigue, or bearing wear.

One example of use is the implementation of smart thermocouples and piezoelectric sensors within jet engines to monitor exhaust gas temperature (EGT) and pressure oscillations. These devices allow for the recording of readings while also detecting trends over time, feeding predictive maintenance algorithms that can schedule service intervals based on actual engine conditions, rather than fixed schedules. This leads to more optimized fuel usage, extended component life, and reduced downtime for airlines and defense operators.

Cabin and Environmental Control Systems

Smart sensors are also essential in managing an aircraft’s internal environment to ensure passenger comfort and safety. Temperature, humidity, air quality, and pressure sensors situated throughout the cabin and cockpit will feed data to environmental control systems (ECS), enabling automatic regulation based on real-time conditions. Smart air quality sensors are a notable example, such devices being able to detect the presence of volatile organic compounds (VOCs) or low oxygen levels, triggering ventilation adjustments or alerts as necessary.

These sensors improve not only comfort, but also energy efficiency, as they allow ECS units to operate only when needed. Their integration also supports lightweight system architectures by reducing the need for external processing units, a key factor in achieving fuel efficiency and emission reductions.

Landing Gear and Brake Systems

The inclusion of smart sensors in landing gear and braking systems serves to enhance an aircraft’s ability to detect load conditions, brake temperature, gear deployment status, and other important attributes. Strain gauges and temperature sensors featuring built-in processing elements are becoming more prevalent with their ability to analyze data locally, delivering warnings of overheating brakes or excessive structural loads during landing.

Spacecraft and Satellite Systems

Smart sensors are going beyond transforming aviation, with space systems also making great use of such technology. For example, satellites and spacecraft leverage these devices for attitude control, propulsion monitoring, solar array positioning, and thermal regulation, among other uses. As space missions demand minimal manual intervention, the autonomy and reliability of smart sensors is indispensable. Advanced MEMS-based smart sensors also offer lightweight, low-power solutions that can withstand the harsh conditions of space, enabling spacecraft to monitor their own health, communicate diagnostics to ground stations, and execute autonomous corrections.

Conclusion: The Importance of Partnering with a Trusted Source for Smart Sensor Solutions

To fully benefit from the various benefits posed by smart sensing solutions, aerospace professionals must partner with a trusted source that is capable of delivering top-quality sensor solutions on demand while adhering to various regulations and expectations. This is where ASAP Purchasing comes in, a purchasing platform belonging to the aerospace and aviation parts distributor ASAP Semiconductor. Through ASAP Purchasing, the distributor connects its customers with a range of smart sensors that are suitable for demanding aerospace environments, everything being strictly sourced from trusted manufacturers and offered with the benefit of competitive pricing and timely delivery. With a range of ready-for-purchase offerings featured online and team members at the ready to support customers with any inquiries or requests, be sure to explore ASAP Purchasing today to see if it is the right option for you.

0 notes

Video

youtube

The 2024 St. Croix WaterCraft 2200 Electric Pontoon

Produced by a partnership between St. Croix WaterCraft and NorthStar Pontoons, this is an a purpose built All Electric Pontoon, there are no gas engine options. Join me as I do a full review with Bob from St. Croix WaterCraft. Listed below are the basic facts on the pontoon.

Boat Specifications:

Overall Length: 22 ft

Deck Length: 20 ft

Width: 8 ft

Pontoon Logs: 25 inches

Interior & Comfort:

Double Captains Chairs: Offers comfort and control for both drivers.

Front Bench & Front Lounger: Seating options for relaxation, plus a cup holder for added convenience.

Canopy: Provides shade for those sunny days on the water.

RGB Interior & Exterior Lights: Cool lighting for both aesthetics and functionality.

LED Anchor & Navigation Lights: Safety features that allow visibility even at night.

4-Step Boarding Ladder: Makes it easy to get on and off the boat.

Glove Box & Wine Tray: Storage options for small items and a unique addition for entertaining.

USB Ports: Power for devices when on the go.

Master Power Off: Safety feature to shut down everything.

Radio with Waterproof Speakers: For entertainment while cruising.

Bluetooth Capabilities: Wireless music streaming.

Electric Propulsion:

X40E Propulsion (60HP): The electric motor provides 60HP, offering quiet, clean, and efficient power.

Battery Setup:

4 x 96V Batteries

2 x 12V Batteries

Fly-by-Wire Steering: Modern, responsive control system.

Digital Motor Display: Keeps track of performance metrics and status.

Trailer:

JB Lund Bunk Trailer: Comes with the boat for easy transportation.

Key Highlights:

Eco-Friendly: Powered by electricity, making it a clean alternative to traditional gas-powered boats.

Comfort & Features: Includes modern amenities like Bluetooth audio, lighting, and comfortable seating options.

Convenience: The boat is equipped with all the essentials for a day on the water, from storage compartments to lighting and a powerful sound system.

#St Croix WaterCraft #Electric Pontoon #Pontoon Boat #2024 Boat Models #Eco Friendly Boating #Electric Boating #Watercraft Innovation #Pontoon Life #Sustainable Boating #Boat Review #Water Sports #Outdoor Adventure #Family Fun #Boating Lifestyle #Marine Technology #Electric Vehicles #Pontoon Party #Watercraft Enthusiast #Boat Show 2024 #Luxury Boating #Adventure On Water #Eco Conscious Living #Boat Lovers #St Croix 2024 #Watercraft Experience #Pontoon Fishing #Electric Boat

0 notes

Text

The Role of Avionics Companies in Advancing Modern Aviation

Introduction

Avionics, a critical component of modern aviation, encompasses electronic systems used in aircraft, spacecraft, and satellites. From navigation and communication to flight control and monitoring, avionics play a vital role in ensuring the safety, efficiency, and operational effectiveness of both commercial and military aircraft. Avionics companies are at the forefront of technological advancements, continuously innovating to enhance the performance and reliability of aviation systems.

The Evolution of Avionics Technology

The development of avionics has transformed aviation from a manual, mechanically controlled domain into a sophisticated, technology-driven industry. Early aircraft relied on basic instrumentation for navigation and communication, but the rapid progress in electronics has led to highly automated and integrated systems. Today, avionics companies focus on developing next-generation technologies, including digital flight control systems, glass cockpits, and artificial intelligence-driven automation.

One of the most significant advancements is the transition from analog to digital avionics. Digital flight decks, also known as glass cockpits, have replaced traditional analog gauges with multifunction displays (MFDs) that provide pilots with real-time data. This enhances situational awareness and reduces pilot workload, ultimately improving flight safety. List of some of the leading Avionics Companies- https://avionics.aerospacedefensereview.com/vendors/top-companies-in-avionics.html

Key Areas of Avionics Development

Avionics companies invest heavily in research and development to enhance several key areas of aviation technology:

Flight Control Systems

Modern flight control systems use fly-by-wire (FBW) technology, replacing manual hydraulic controls with electronic signals. This improves aircraft responsiveness, stability, and fuel efficiency.

Communication Systems

Advanced avionics have revolutionized aircraft communication, enabling real-time data exchange between pilots, air traffic controllers, and ground systems. The integration of satellite-based communication systems has also enhanced long-distance operations.

Navigation and Surveillance

Global Positioning System (GPS)-based navigation has significantly improved flight accuracy. Avionics companies develop sophisticated systems such as automatic dependent surveillance–broadcast (ADS-B) to enhance aircraft tracking and airspace management.

Weather Radar and Environmental Monitoring

Modern avionics incorporate advanced weather radar systems to detect and analyze atmospheric conditions, helping pilots avoid turbulence and severe weather. These systems contribute to passenger comfort and operational efficiency.

Cybersecurity and Artificial Intelligence (AI)

With increased digitization, avionics companies are also focusing on cybersecurity to protect aircraft systems from cyber threats. AI-powered avionics are being explored to assist in predictive maintenance, automated flight operations, and decision-making support.

The Future of Avionics

The aviation industry is evolving rapidly, with avionics companies playing a pivotal role in shaping its future. The integration of autonomous flight systems, electric and hybrid propulsion, and next-generation air traffic management solutions are expected to redefine air travel.

Emerging technologies such as augmented reality (AR) in cockpits, blockchain-based data security, and quantum computing for flight simulations are also gaining traction. Avionics companies are continually investing in innovation to make air travel safer, more efficient, and environmentally sustainable.

Conclusion

Avionics companies are instrumental in pushing the boundaries of aviation technology. Their contributions not only enhance flight safety and efficiency but also pave the way for the future of air travel. As the demand for advanced aviation solutions grows, these companies will remain at the forefront of innovation, ensuring that modern aircraft continue to evolve to meet the needs of an ever-changing aerospace landscape.

0 notes

Text

The Aircraft Flight Control System Market in North America is undergoing a significant transformation driven by advancements in technology, regulatory changes, and evolving industry demands. As aviation moves toward automation and digitalization, flight control systems are becoming increasingly sophisticated, offering enhanced safety, efficiency, and performance.

0 notes

Text

The Aircraft Flight Control System Market is projected to grow from USD 17550 million in 2024 to an estimated USD 33706.6 million by 2032, with a compound annual growth rate (CAGR) of 8.5% from 2024 to 2032.The aircraft flight control system (FCS) market has seen remarkable growth in recent years, driven by advancements in technology, the increasing demand for air travel, and the expanding role of unmanned aerial vehicles (UAVs). This article delves into the dynamics of the market, exploring key trends, drivers, challenges, and the future outlook.Flight control systems are essential for the safe and efficient operation of aircraft. They ensure stability, manage aerodynamic forces, and provide pilots with the ability to maneuver the aircraft. Modern FCS incorporates advanced technologies such as fly-by-wire systems, autopilots, and automated flight control, enhancing safety and performance. These systems are deployed across various types of aircraft, including commercial, military, and UAVs.

Browse the full report at https://www.credenceresearch.com/report/aircraft-flight-control-system-market

Key Market Trends

Technological Advancements

The adoption of fly-by-wire systems, which replace traditional mechanical controls with electronic systems, has revolutionized the market. These systems are lighter, more reliable, and provide enhanced control precision.

Integration of Artificial Intelligence (AI) and machine learning (ML) in autopilot and automated flight systems is another significant trend. AI-driven systems enable predictive maintenance and adaptive flight operations.

Growing Demand for UAVs

The proliferation of drones for military, commercial, and recreational purposes has significantly boosted the demand for advanced flight control systems. UAVs rely heavily on sophisticated FCS to ensure precision and stability in operations.

Focus on Sustainability

Airlines and manufacturers are increasingly prioritizing eco-friendly designs. Lightweight FCS components reduce overall aircraft weight, leading to improved fuel efficiency and reduced emissions.

Market Drivers

Increase in Air Travel

The rise in disposable incomes and globalization has led to an upsurge in air travel. Consequently, the demand for new aircraft with state-of-the-art flight control systems has grown.

Defense Modernization Programs

Governments worldwide are investing in advanced military aircraft and UAVs, further driving the market for sophisticated flight control technologies.

Focus on Safety

Enhanced safety regulations and the need to minimize human error in flight operations are pushing manufacturers to develop more reliable and automated flight control solutions.

Challenges in the Market

High Development Costs

Developing advanced FCS requires significant investment in research, development, and testing. These costs can pose a barrier, particularly for smaller manufacturers.

Regulatory Compliance

Adhering to stringent aviation safety standards and certification requirements can be a complex and time-consuming process for FCS manufacturers.

Cybersecurity Concerns

The increasing reliance on digital and automated systems makes FCS vulnerable to cyber threats. Ensuring robust cybersecurity measures is a critical challenge for the industry.

Future Outlook

The global aircraft flight control system market is poised for robust growth in the coming years. The increasing adoption of electric and hybrid-electric aircraft, coupled with advancements in automation and AI, will redefine the landscape of flight control systems. Additionally, the rising demand for UAVs across various industries, including logistics, agriculture, and surveillance, will continue to propel market expansion.

As manufacturers address challenges such as cost and cybersecurity, the focus will remain on innovation, safety, and sustainability. The integration of cutting-edge technologies and adherence to evolving regulatory standards will be pivotal in shaping the future of this dynamic market.

Key Player Analysis:

Airbus SAS (France)

BAE Systems (U.K.)

Collins Aerospace (U.S.)

Honeywell International Inc. (U.S.)

Leonardo SpA (Italy)

Lockheed Martin Corporation (U.S.)

Moog (U.S.)

Parker Hannifin (U.S.)

Safran (France)

Thales Group (France)

The Boeing Company (U.S.)

Segmentation:

By Component

Flight Control Computers

Cockpit Control

Sensors

Others

By Fit

Linefit

Retrofit

By Technology

Fly-By-Wire

Digital Fly-By-Wire

Hydro-Mechanical

Power Fly-By-Wire

By Platform

Commercial Aviation

Military Aviation

Business & General Aviation

By Aircraft Type

Fixed-wing

Rotary-wing

By Region

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/aircraft-flight-control-system-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

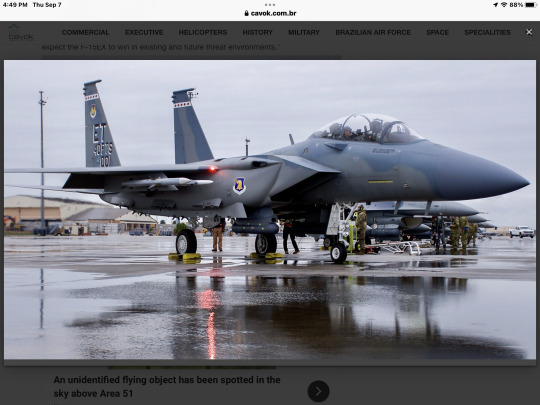

BOEING: F-15EX fighters for Poland

Fernando Valduga By Fernando Valduga 09/07/2023 - 12:10 in Military

Boeing is presenting the F-15EX fighter to Poland as a potential U.S. Department of Defense's potential foreign military sales (FMS) program.

The announcement was made at the MSPO International Defense Industry Annual Exhibition, where Boeing highlights advanced defense systems, capabilities and services.

“Poland's interest in the F-15EX confirms its dedication to the preparation and effectiveness of its military forces,” said Tim Flood, senior director of Global Business Development for Europe and the Americas. “The F-15EX offers superior interoperability, support and accessibility, along with a robust industrial plan that would support Poland's goal of developing independent defense capabilities.”

Boeing has made significant investments in the F-15EX, making it the most capable multifunctional fighter in production today. The aircraft offers greater survival capacity and capacity with:

fly-by-wire flight controls,

a new electronic warfare system,

a FULL GLASS digital cockpit,

the latest mission systems and software capabilities,

as well as the ability to carry advanced hypersonic weapons.

“The F-15EX is the most advanced fighter in the world, with unparalleled capacity, lethality and survivability and is the right choice to strengthen Poland's safety needs,” said Rob Novotny, director of Business Development of Boeing's F-15 program. “Through improved interoperability with U.S. and NATO forces, technological growth capacity and an economic operational life of more than 20,000 hours, Poland can expect the F-15EX to win in existing and future threat environments.”

The F-15EX is in production with two aircraft delivered to the U.S. Air Force. Indonesia recently became the 8º country to select the F-15 and will become the first export customer of the last EX variant when the sale is finalized.

Boeing has been present in Poland for more than 30 years. Based in Warsaw, Boeing Digital Solutions & Analytics operations in Gda? sk and parts and distribution services in Rzeszow, Boeing employs more than 1,000 people in Poland and is currently establishing a strong engineering capacity in all three locations. In addition to its growing presence in the country, Boeing is an important partner of the Polish aviation industry and has strong relations with local communities, industry, airlines, the Polish government and the Polish Armed Forces.

Tags: Military AviationboeingF-15EXPAF - Polish Air Force / Polish Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Daytona Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work throughout the world of aviation.

Related news

MILITARY

Russian Shahed drones exploded in Romania, but Romanian president denies

06/09/2023 - 21:22

MILITARY

US plans to send more F-35 fighters to the UK amid tensions with Russia

09/06/2023 - 16:00

MILITARY

Myanmar Committee sends severe message to Pakistan about unusable JF-17 Thunder fighters

06/09/2023 - 12:00

HELICOPTERS

Nigeria will receive 18 attack helicopters from Turkey and the US

09/06/2023 - 08:53

BRAZILIAN AIR FORCE

IMAGES: Open Gates 2023 at Brasilia Air Base gathers 80,000 people

06/09/2023 - 08:18

MILITARY

Is the influence of the West diminishing in South America?

05/09/2023 - 23:18

6 notes

·

View notes

Text

Exploring the First Pilot Cockpit: History and Evolution

The First Pilot Cockpit refers to the early design and development of aircraft cockpits, the command centers for pilots in aviation. The cockpit has evolved significantly over time, from its rudimentary beginnings to the highly sophisticated systems we have today. Below is a look at the history and evolution of the pilot cockpit.

Early Beginnings (Pre-World War I) The earliest aircraft, such as the Wright brothers’ 1903 Flyer, had no defined cockpit. Pilots were essentially seated in the open air or in rudimentary structures, often with very limited control. The cockpit as we understand it today didn’t exist, and pilots had to manage with basic instruments like altimeters, compasses, and rudimentary flight controls.

World War I (1914-1918) As aviation technology advanced, so did the cockpit. World War I saw the introduction of open cockpits, often with the pilot sitting in front of the engine, exposed to the elements. Pilots had few instruments—just a few gauges to measure altitude, speed, and engine performance. These cockpits were quite cramped and uncomfortable, with little regard for ergonomics.

Interwar Period (1918-1939) Between the World Wars, aviation technology progressed rapidly. The cockpit began to take shape with better seating arrangements, improved instruments, and better pilot visibility. The introduction of more complex aircraft required pilots to handle more equipment and make more decisions mid-flight, leading to the development of more advanced cockpits.

During this time, designers created the first flight decks for multi-crew aircraft, particularly with the rise of commercial and military airliners. They began to give more serious consideration to the cockpit’s ergonomic design and the accessibility of controls.

World War II (1939-1945) The demand for faster and more powerful aircraft during World War II brought significant changes to the design of cockpits. This period saw the introduction of fully enclosed cockpits, with more advanced instruments and controls for the pilot to manage the increasing complexity of aircraft systems.

Instruments like artificial horizons, magnetic compasses, and more advanced navigation aids were introduced. The development of fighter jets also led to the design of smaller, more specialized cockpits. Additionally, multi-crew cockpits became more common in larger bombers and transport planes.

Post-War Era (1945-1970s) After WWII, commercial aviation boomed. This led to the development of larger aircraft with more advanced systems. The cockpit further refined instruments, automating them to provide more functionality while reducing pilot workload.. The flight deck began to feature more advanced navigation systems, autopilot controls, and cockpit layouts designed for comfort.

One of the most significant developments during this time was the introduction of glass cockpits, where electronic displays replaced traditional analog instruments. This allowed for clearer, more integrated views of the aircraft’s critical systems, navigation, and flight data.

The Glass Cockpit (1980s – Present) The introduction of “glass cockpits” revolutionized aviation. Glass cockpits replaced traditional mechanical gauges with digital displays that could show a wide range of information on a single screen. This allowed pilots to more efficiently manage flight data, navigation, and other critical information, all while simplifying the cockpit layout.

In commercial aviation, this period also saw the introduction of fly-by-wire systems, which replaced mechanical flight controls with electronic ones, offering smoother control and more precise handling.

Modern Cockpits (2000s – Present) Today’s cockpits are the epitome of technological integration. Modern commercial and military aircraft feature advanced flight management systems (FMS), automated navigation, and highly advanced communication systems. Many cockpits have reduced the number of physical controls, shifting more tasks to the cockpit’s software.

There is now an emphasis on pilot ergonomics, with seats and controls designed for long flights and ease of access. Cockpits are also becoming more automated, reducing the workload on pilots during flight, especially on autopilot. Furthermore, advanced safety features, such as terrain avoidance systems and collision prevention, have made cockpits much safer.

The Future of Cockpit Design Looking forward, the evolution of the cockpit continues with the advent of new technologies like artificial intelligence, advanced flight control systems, and even augmented reality (AR). AR could be used to project essential flight information directly onto a visor or display, providing pilots with more immediate access to critical data.

The growing trend of unmanned aerial vehicles (UAVs) and drones will also influence cockpit design, with the control systems evolving to accommodate more remote piloting and autonomous operations.

The Evolution of Aircraft Cockpits From Analog to Digital: A Technological Shift The transition from analog to digital technology marked a pivotal moment in the evolution of aircraft cockpits. In the early days of aviation, cockpits were dominated by mechanical instruments like dials, gauges, and manual controls. These analog systems were functional but had limitations in terms of data integration, accuracy, and ease of use.

With the advent of digital technology in the late 20th century, aviation saw a radical shift in cockpit design. The introduction of glass cockpits was one of the most significant milestones. Analog instruments were replaced by digital displays, allowing for a more efficient and integrated presentation of flight data. Pilots could now see multiple systems—such as navigation, flight data, and weather information—on a single screen, reducing the need for multiple dials and gauges. This change improved cockpit organization and accessibility.

Digital systems also brought enhanced accuracy and reliability. With digital sensors and computing systems, information like altitude, airspeed, and navigation data became more precise, contributing to smoother flights and better decision-making for pilots. The integration of Fly-By-Wire technology, which replaced mechanical flight controls with electronic systems, further streamlined the cockpit, offering smoother and more responsive controls.

Additionally, the digital shift allowed for automation in flight management. Systems like Flight Management Systems (FMS) and Autopilot could perform complex tasks that previously required manual input, reducing pilot workload and increasing efficiency, especially on long-haul flights. The move to digital technology fundamentally transformed cockpit design, making modern aircraft more reliable, intuitive, and safer.

Modern Cockpit Features and Enhancements Modern cockpits are a blend of advanced technology, design optimization, and pilot-focused features, reflecting decades of evolution in aviation. One of the most significant upgrades in recent years is the integration of glass cockpits. These digital displays have replaced traditional analog gauges, providing pilots with real-time data on flight performance, weather, navigation, and engine status on clear, easy-to-read screens.

Alongside these displays, touchscreen interfaces have become a key feature in many modern aircraft. These systems allow pilots to interact more intuitively with flight management systems, controlling everything from navigation to communication and autopilot functions with just a few taps. The shift to touchscreen technology not only simplifies control but also reduces the physical space needed for controls, making the cockpit more spacious and organized.

Another crucial enhancement is the rise of Fly-By-Wire technology, where electronic systems replace traditional mechanical linkages between the pilot and the aircraft’s control surfaces. This system offers greater precision and smoother control, enhancing both performance and safety, especially in high-speed and high-altitude flight.

Automated flight systems such as Autopilot and Flight Management Systems (FMS) have become increasingly sophisticated, enabling the automation of routine tasks like altitude control, speed adjustments, and course plotting. This reduces pilot workload, allowing them to focus on higher-level decision-making and ensuring smoother and more efficient flight operations.

Importance of Ergonomics in Cockpit Design Ergonomics in cockpit design plays a crucial role in ensuring pilots’ comfort, efficiency, and safety during flight. Given that pilots often spend long hours in the cockpit, the design of the seating, controls, and overall environment can significantly impact their physical and mental well-being. The key goal of cockpit ergonomics is to reduce pilot fatigue, enhance situational awareness, and improve overall performance by creating an environment that supports the human body’s natural movements and needs.

One critical ergonomic consideration is the arrangement of flight controls and displays. Controls should be within easy reach, allowing pilots to operate them with minimal effort and without straining. For instance, seats are designed to be adjustable, providing optimal posture to prevent discomfort and muscle strain during extended flights. The placement of displays is also essential to minimize head and eye movement, enabling pilots to quickly and easily access information without distraction or discomfort.

Ergonomics also focuses on user-friendly interfaces. Designers carefully craft digital systems, such as glass cockpits, to present complex information in a clear, intuitive format, reducing cognitive load and preventing information overload. Intuitive controls and displays lower the likelihood of errors and enhance overall flight safety.

In sum, good ergonomic design helps pilots maintain alertness, make better decisions, and reduce the risk of accidents related to physical discomfort or poor interaction with the cockpit systems.

Human Factors and Pilot Performance Human factors play a critical role in pilot performance, as the physical, cognitive, and emotional states of pilots can directly influence their decision-making abilities, reaction times, and overall effectiveness in managing flight operations. Pilot performance is impacted by the ergonomic design of the cockpit, which must be optimized to align with human capabilities and limitations.

The cockpit should allow for efficient interaction with flight systems, minimizing the need for unnecessary actions or excessive mental effort. If controls and displays are intuitively placed and easy to operate, pilots are more likely to respond swiftly in critical situations, reducing the risk of errors. Additionally, incorporating features like adjustable seating and climate control can help mitigate fatigue, which can be particularly important on long-haul flights.

Cognitive factors are equally significant. Overloading pilots with too much information or poorly organized data can lead to mistakes, especially under stress. Therefore, modern cockpit design places emphasis on simplifying tasks, automating routine operations, and presenting data in an organized manner. This allows pilots to maintain focus on the most critical tasks, improving performance and safety.

Mental states, such as stress or fatigue, also influence pilot performance. Cockpit environments that prioritize comfort and reduce distractions enable pilots to better handle stressful situations. Moreover, clear visual displays, such as Heads-Up Displays (HUDs) and advanced alert systems, enhance situational awareness, allowing pilots to make informed decisions with minimal cognitive strain.

Pilot Training and Cockpit Familiarization Pilot training ensures that pilots are well-prepared to operate an aircraft efficiently and safely. A key aspect of this training is cockpit familiarization, where instructors teach pilots to navigate the cockpit layout and systems before they fly a real aircraft. This familiarization helps pilots build confidence in understanding the various flight instruments, controls, and emergency systems, preparing them for both normal and abnormal flight conditions.

Familiarizing pilots with the cockpit design, layout, and functions is crucial for developing muscle memory and reducing cognitive load during flight. During initial training, pilots learn how to use the various instruments and controls intuitively, creating a streamlined process for flight operations. This helps them respond quickly to changing conditions and unexpected situations. For example, when an alert system activates or a malfunction occurs, the pilot must know exactly where to find the relevant controls and displays to manage the issue effectively.

As part of cockpit training, pilots also undergo simulation training, where they can practice operating the aircraft in a realistic, risk-free environment. This enables them to gain hands-on experience in a variety of scenarios, ranging from routine to emergency situations, without the consequences of actual flight. Simulations help pilots develop decision-making skills, teamwork (for multi-pilot operations), and the ability to manage stress and fatigue. Cockpit familiarization through simulation allows pilots to learn not only the technical aspects of the cockpit but also how to operate under pressure, making them well-prepared for real-world flights.

#PilotCockpit#FlightDeck#AviationTechnology#DroneSurvey#AtomAviation#CockpitDesign#FlightTraining#PilotTraining#HumanFactorsInAviation#SimulationTraining#ModernAviation#ErgonomicsInCockpit#AviationInnovation#FutureOfAviation#GlassCockpit

1 note

·

View note

Text

The Complete Mumbai Homeowner's Guide to Year-Round Pest Protection (With Focus on Rodent Control)

Seasonal Pest Patterns

Mumbai's unique climate creates distinct pest challenges throughout the year. Understanding these patterns is crucial for effective year-round pest protection. According to the Environmental Protection Agency, pest activity can increase by up to 40% during seasonal transitions.

Summer Pest Control (March-May)

Common Issues

Cockroach infestations increase by 60%

Ant colonies expand rapidly

Flying insects become more active

Early rodent breeding cycles begin

Prevention Tips

Seal food storage containers

Fix water leaks promptly

Install mesh screens

Regular cleaning schedule

Proper waste management

Expert Tip: Focus on early morning inspections when pests are most active in summer.

Monsoon Challenges (June-September)

Rodent Influx

Professional rodent control services in Mumbai report a 75% increase in rodent activity during monsoons. Key factors include:

Flooding of underground burrows

Search for dry shelter

Increased food scarcity

Higher reproduction rates

Waterproofing Measures

According to the World Health Organization, proper waterproofing can reduce pest infestations by up to 70%.

Essential Steps:

Seal ground-level entry points

Install door sweeps

Repair roof leaks

Clear drainage systems

Apply weather stripping

Winter Preparation (October-February)

Priority Areas:

Food storage spaces

Warm corners

Utility rooms

Attic spaces

Basements

Preventive Measures:

Inspect and seal gaps

Remove outdoor debris

Clean gutters

Check roof tiles

Trim vegetation

Essential Tools and Products

Must-Have Items:

Inspection Tools:

Flashlight

Inspection mirror

Moisture meter

Digital camera

Prevention Equipment:

Caulking gun

Weather stripping

Wire mesh

Exclusion materials

Monitoring Devices:

Pest monitors

Rodent stations

Insect traps

Motion sensors

Monthly Maintenance Checklist

Indoor Tasks:

Check all entry points

Inspect food storage areas

Monitor dark corners

Clean behind appliances

Check utility areas

Outdoor Tasks:

Inspect perimeter

Clear vegetation

Check drainage

Monitor waste areas

Maintain gardens

Professional Treatments

When Needed

Seek professional help when:

Multiple pests are spotted

DIY methods fail

Structural damage occurs

Health risks emerge

Seasonal transitions approach

What to Expect

Initial Visit:

Thorough inspection

Problem identification

Treatment plan

Cost estimate

Timeline discussion

Follow-up Services:

Regular monitoring

Preventive treatments

Documentation

Adjustment of strategies

Cost-Saving Tips

Short-term Savings:

Regular maintenance

Early intervention

Proper storage

Clean environments

Quick repairs

Long-term Investment:

Quality materials

Professional services

Prevention systems

Staff training

Documentation

Long-term Protection Strategies

Physical Barriers:

Proper sealing

Quality materials

Regular maintenance

Professional installation

Environmental Management:

Humidity control

Temperature regulation

Ventilation

Landscape management

Documentation System:

Pest sightings

Treatment dates

Success rates

Cost tracking

Future planning

Implementation Schedule

Daily Tasks:

Basic inspection

Clean-up routines

Monitor trouble spots

Report issues

Weekly Tasks:

Detailed inspection

Preventive measures

Equipment check

Area rotation

Monthly Tasks:

Professional inspection

Deep cleaning

System updates

Strategy review

Success Metrics

Track these indicators:

Pest sightings frequency

Treatment effectiveness

Cost per prevention

Response time

Resolution rate

Conclusion

Effective year-round pest protection in Mumbai requires:

Understanding seasonal patterns

Regular maintenance

Professional partnerships

Quick response

Proper documentation

Take action today:

Schedule professional inspection

Implement prevention measures

Create maintenance schedule

Prepare emergency protocols

Document everything

Remember: Prevention is always more cost-effective than reaction. Invest in quality materials and professional services for long-term success.

0 notes

Text

Why are digital billboards so expensive?

In the world of advertising, digital billboards have become an increasingly popular choice for businesses looking to make a significant impact. These high-tech displays offer vibrant visuals, dynamic content, and the ability to reach a broad audience. However, with these advantages comes a higher price tag. The cost of digital billboards is often a point of discussion, and many wonder why these modern advertising tools come with such a premium. In this article, we will delve into the reasons behind the expense of digital billboards, particularly focusing on LED digital mobile billboards for rental in Canada, provided by Grow More, a leading agency in this space.

Cutting-Edge Technology

One of the primary reasons digital billboards are expensive is the advanced technology involved in their creation and operation. Unlike traditional billboards, which are static and rely on printed materials, digital billboards use LED (light-emitting diode) technology to display high-resolution images and videos. These LEDs are capable of producing bright, vivid colors that capture the attention of passersby, even in broad daylight. The quality and longevity of these LEDs come at a cost, as they are designed to operate continuously for years, withstanding various weather conditions without losing brightness or clarity.

The technology behind digital billboards also includes sophisticated control systems that allow for real-time content updates. Advertisers can change their messages on the fly, display multiple ads in rotation, and even integrate dynamic elements like live data feeds. This flexibility and interactivity make digital billboards far more versatile than their traditional counterparts, but they also contribute to the overall expense. The software and hardware required to manage and display this dynamic content are complex and costly to develop, maintain, and upgrade.

Installation and Maintenance Costs

The installation of a digital billboard is a significant undertaking, requiring specialized equipment and expertise. Unlike traditional billboards, which can be erected with relatively simple scaffolding, digital billboards need a stable and secure structure to support the heavy and sensitive electronic components. The installation process often involves custom-built frames, cranes, and other heavy machinery, all of which add to the cost.

Once installed, digital billboards require ongoing maintenance to ensure they continue to operate at peak performance. This maintenance includes regular inspections, cleaning, and repairs to the LED panels, wiring, and control systems. Given the complexity of the technology, these tasks often require specialized technicians who are trained to handle the intricacies of digital displays. The need for continuous upkeep and the associated labor costs contribute to the overall expense of digital billboards.

Energy Consumption

Another factor that makes digital billboards expensive is their energy consumption. LED digital billboards, while more energy-efficient than older lighting technologies, still require a significant amount of power to operate. These billboards are typically illuminated 24/7, which means they need a constant and reliable source of electricity. The energy costs associated with keeping a digital billboard running around the clock can be substantial, particularly in areas with high electricity rates.

In Canada, where Grow More operates, the cost of energy can vary depending on location and season. This variability can influence the overall operating costs of LED digital mobile billboards, making them more expensive to run compared to traditional billboards that do not require continuous illumination.

Regulatory Compliance and Permitting

Digital billboards are subject to a range of regulations and permitting requirements, which can also drive up costs. Many municipalities have strict rules governing the placement, size, and brightness of digital billboards to minimize distractions for drivers and reduce light pollution. Navigating these regulations often requires working with legal experts and urban planners, adding to the overall expense.

Additionally, obtaining the necessary permits to install and operate a digital billboard can be a time-consuming and costly process. The fees associated with these permits, along with the potential need for community outreach or negotiations with local authorities, further contribute to the high cost of digital billboards.

Customization and Content Creation

The content displayed on digital billboards is another area where costs can add up. Unlike traditional billboards, which use printed graphics, digital billboards require digital content that is specifically designed for high-resolution LED screens. This content often includes animations, videos, and other dynamic elements that are more engaging than static images. Creating this type of content requires skilled designers and animators, who charge for their expertise.

For companies like Grow More, which provides LED digital mobile billboards for rental in Canada, offering customized content creation services is a key part of the business. Ensuring that each advertisement is visually appealing, on-brand, and effective in capturing attention requires investment in top-tier creative talent. The cost of these creative services is typically passed on to the client, contributing to the overall expense of using digital billboards.

Environmental Considerations

While digital billboards are often seen as a more environmentally friendly option compared to traditional billboards, due to the elimination of paper and ink, there are still environmental considerations that can influence costs. The production and disposal of electronic components, such as LED panels and control systems, have an environmental impact that companies need to manage responsibly. Additionally, the energy consumption associated with digital billboards, as mentioned earlier, can contribute to their carbon footprint.

Grow More is committed to sustainability and strives to minimize the environmental impact of its LED digital mobile billboards. This commitment includes investing in energy-efficient technologies, recycling electronic components, and participating in carbon offset programs. While these initiatives are crucial for protecting the environment, they also add to the overall cost of providing digital billboard services.

Conclusion

In summary, the high cost of digital billboards can be attributed to several factors, including cutting-edge technology, installation and maintenance expenses, energy consumption, regulatory compliance, content creation, and environmental considerations. These costs are reflective of the advanced capabilities and advantages that digital billboards offer over traditional advertising methods.

For businesses in Canada looking to leverage the power of digital advertising, Grow More provides a compelling solution with its LED digital mobile billboard trucks for rental. While the upfront costs may be higher, the potential return on investment, in terms of visibility, engagement, and brand impact, can be well worth the expense. By choosing Grow More, businesses can access state-of-the-art advertising technology, customized content, and expert support to ensure their campaigns achieve maximum impact.

0 notes