#Digital Manometer

Explore tagged Tumblr posts

Text

0 notes

Text

Manometer Learning gradients~

You can support my artworks on Boosty - boosty.to/renka2802 There you can find art processes, high quality artworks and wips.

4 notes

·

View notes

Text

0 notes

Text

0 notes

Text

Gather the Necessary Tools and Materials for Installing a Cold Water Pressure Vessel

Before you begin installing a cold water pressure vessel, it’s important to have all the necessary tools and materials on hand. Having everything prepared will make the installation process smoother and more efficient, reducing the chance of delays or issues. Here’s a comprehensive list of tools and materials you’ll need:

1. Pressure Vessel

Description: The cold water pressure vessel itself is the most essential component.

Considerations: Choose a vessel that matches your system’s requirements in terms of size, pressure rating, and capacity. Ensure the vessel is certified for your application (e.g., ASME, CE, UL, NSF).

2. Pipe Fittings

You’ll need various pipe fittings to connect the pressure vessel to the water system. These should be compatible with the material of the vessel and the system’s piping.

Adapters: To connect different pipe sizes or materials.

Tees and Elbows: For routing water to and from the vessel.

Unions: To allow for easy disconnection of the vessel if needed.

Check Valves: To prevent water from flowing backward into the pressure vessel.

Pressure Relief Valve: For safety, in case the pressure inside the vessel exceeds the system's limits.

Pressure Switch: A device to monitor and control the system's pressure.

Considerations: Ensure all fittings are compatible with the size and material of the pressure vessel and water system pipes (e.g., PVC, copper, or steel).

3. Piping Material

You'll need the right type of piping to connect the pressure vessel to the system.

PVC Piping: Often used for residential systems due to its cost-effectiveness, ease of installation, and corrosion resistance.

Copper Piping: Common for systems where high temperatures and durability are required, though it’s more expensive.

Steel Piping: Used for industrial or commercial applications where strength and high-pressure ratings are needed.

Considerations: Choose the piping material that suits your system’s needs and pressure requirements.

4. Pipe Sealants and Threading Tools

To prevent leaks, use appropriate sealing materials and tools for securing threaded connections:

Teflon Tape: A common choice for sealing threaded pipe connections. It’s easy to apply and provides a watertight seal.

Pipe Joint Compound: An alternative to Teflon tape, this can be used in areas where extra sealing power is needed.

Pipe Wrench: To tighten pipe fittings securely.

Threading Tool: If you need to cut threads on pipes for fittings, a threading tool is necessary.

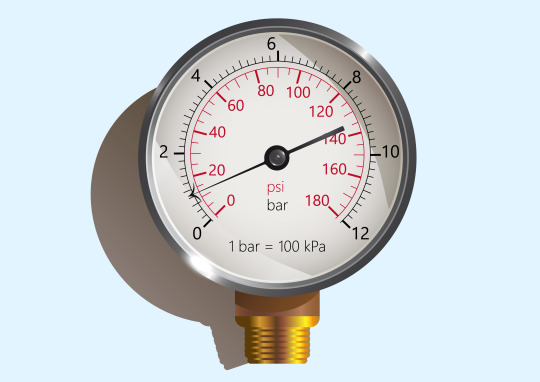

5. Pressure Gauge (Manometer)

Description: A pressure gauge is necessary to monitor the internal pressure of the pressure vessel and ensure that the system is operating within the desired range.

Considerations: The pressure gauge should be installed on the outlet of the pressure vessel and be rated for the system’s pressure. A digital gauge or analog dial gauge can be used.

6. Mounting Equipment (If Applicable)

For securing the pressure vessel in place, you may need mounting tools and hardware, especially if the vessel is large or heavy.

Bolts and Anchors: If you’re mounting the vessel to a concrete or solid surface (for vertical vessels), bolts and anchors will secure it in place.

Mounting Feet or Brackets: Some pressure vessels come with feet or brackets for mounting to the ground or wall. For horizontal vessels, ensure they are stable and level.

7. Safety Gear

Working with water systems involves potential risks, so be sure to have safety equipment.

Safety Gloves: To protect your hands from sharp objects or potential contaminants in the system.

Safety Goggles: To protect your eyes when working with tools, pipe sealants, or under pressure.

Work Boots: If the installation area is wet or you are using heavy equipment.

8. Leveling Tools

Level: Whether installing a vertical or horizontal vessel, it's important to ensure the vessel is perfectly level during installation. Use a bubble level to check alignment both horizontally and vertically.

9. Pressure Switch

A pressure switch is used to control the pump’s operation. It monitors the system pressure and turns the pump on and off to maintain the correct pressure range.

Considerations: Choose a pressure switch that is compatible with the vessel’s rated pressure and the system’s operating pressure.

10. Tools for Basic Plumbing Installation

Basic plumbing tools will be required to install and adjust the piping, as well as to complete the connection to the system:

Pipe Cutter: For cutting pipes to the required length.

Hacksaw or Pipe Cutter: If you need to cut metal or PVC pipes to the right size.

Adjustable Wrench: For tightening nuts, bolts, and fittings.

Spanner: Useful for tightening connections that require a more precise fit than an adjustable wrench can provide.

11. Optional: Drainage Materials

If your installation requires venting or drainage, you may need additional materials to manage water flow or excess pressure.

Venting Pipe: Used if the pressure vessel requires venting to allow air escape when under pressure.

Drainage Pipe: For managing any excess water or pressure release from the system.

12. Instruction Manual or Manufacturer’s Guide

Always refer to the manufacturer's installation manual for specific instructions. The guide will provide critical information like:

Vessel pressure settings

Installation procedures for connecting the vessel to your system

Safety precautions

Maintenance and troubleshooting tips

Action: Before beginning installation, thoroughly read the manual to familiarize yourself with the specific requirements and recommendations for your pressure vessel model.

By gathering the right tools and materials, you’ll be well-prepared to install your cold water pressure vessel correctly and efficiently. Key items include:

Pressure vessel

Pipe fittings and sealants

Piping material suitable for your system

Pressure gauge and pressure switch

Mounting equipment for securing the vessel

Basic plumbing tools (wrenches, cutters, etc.)

Safety gear to protect yourself during installation

With these tools and materials, you’ll be able to install the pressure vessel effectively, ensuring your system operates smoothly, efficiently, and safely. For more info contact Pressure Vessel Suppliers in UAE or call us at +971 4 252 2966.

0 notes

Text

PRECISION IN AIRCRAFT MAINTENANCE: AVIONTEQ’S PITOT-STATIC TEST SET CALIBRATION SERVICES

In the world of aviation, safety is the paramount concern, and ensuring the reliability and accuracy of the instruments that monitor aircraft performance is crucial. One of the most critical aspects of this is the proper functioning of the aircraft’s Pitot-Static System, which directly impacts the airspeed indicator, altimeter, and vertical speed indicator. A malfunction in this system can lead to severe consequences, including inaccurate flight data, which could result in dangerous flight conditions. To mitigate such risks, regular calibration and testing of Pitot-Static test sets are required, and AvionTEq is a leading company in providing these essential calibration services.

UNDERSTANDING PITOT-STATIC SYSTEMS

The Pitot-Static System in an aircraft measures key parameters such as airspeed, altitude, and rate of climb or descent. The system consists of a Pitot tube, which measures the dynamic pressure of the air entering the tube during flight, and a static port, which measures the atmospheric pressure surrounding the aircraft. The combination of these measurements allows the aircraft’s flight instruments to provide pilots with accurate and reliable data, essential for flight navigation and safety.

Calibration and testing of these systems ensure that the instruments providing this vital data are operating correctly, especially when an aircraft undergoes maintenance or is brought back into service after a period of inactivity. In this context, AvionTEq offers specialized Pitot-Static Test Set Calibration services designed to meet the high standards of aviation safety.

AVIONTEQ’S EXPERTISE IN PITOT-STATIC TEST SET CALIBRATION

AvionTEq is a well-established leader in the aviation support industry, known for offering high-quality calibration and maintenance services for a wide range of flight instruments. Their Pitot-Static Test Set Calibration services are an essential offering that guarantees your aircraft’s flight instruments are performing at their best. Their team of skilled professionals works meticulously to ensure that your test sets meet the stringent requirements laid out by the Federal Aviation Administration (FAA) and international aviation standards.

PRECISION CALIBRATION WITH STATE-OF-THE-ART EQUIPMENT

At AvionTEq, accuracy and precision are paramount. The company uses the latest technology and equipment to calibrate Pitot-Static test sets. These devices are highly specialized instruments designed to measure and simulate different pressure levels that aircraft may experience during flight. AvionTEq uses calibrated pressure pumps, digital manometers, and precision test sets to simulate flight conditions, ensuring that the system readings are both accurate and reliable.

Advertisement

The calibration process involves comparing the readings of the Pitot-Static test set with known values to detect any discrepancies or errors. Any deviation from the expected performance is then adjusted, and the test set is recalibrated to align with the correct specifications. This meticulous process ensures that test sets provide precise data that will guarantee accurate readings when used on actual aircraft.

COMPREHENSIVE TESTING PROCEDURES

AvionTEq’s Pitot-Static Test Set Calibration service includes several key procedures that ensure both the functionality and accuracy of the system. The primary tests performed during calibration include:

Pressure Simulation: The test set is subjected to various pressure levels to simulate different altitudes and airspeeds. This is crucial for ensuring that the test set mimics real-world conditions accurately.

Leakage and Integrity Checks: All components are thoroughly checked for leaks or wear that could lead to faulty readings during use.

Calibration of Altimeters and Airspeed Indicators: The readings from altimeters and airspeed indicators are compared to the simulated pressures and adjusted accordingly to ensure accuracy.

System Performance Verification: After calibrating the test set, AvionTEq performs a final verification to ensure that all components are functioning as expected and the system meets the required standards.

These checks and adjustments are critical to maintaining high levels of safety and reliability in aircraft performance monitoring.

WHY CHOOSE AVIONTEQ FOR PITOT-STATIC TEST SET CALIBRATION?

Industry Expertise: With years of experience and a team of skilled professionals, AvionTEq is one of the most trusted names in the industry for aircraft instrument calibration. They possess the knowledge to handle complex systems and ensure they function within the required parameters.

Comprehensive Services: AvionTEq doesn’t just offer calibration but a complete suite of services designed to keep aircraft instrumentation functioning optimally. They offer maintenance, repair, and troubleshooting services alongside their calibration offerings.

Precision and Accuracy: AvionTEq’s attention to detail and use of state-of-the-art calibration tools guarantees that every Pitot-Static test set is tested for accuracy and reliability, ensuring safety during flight operations.

FAA and International Compliance: AvionTEq adheres to all relevant standards and guidelines set forth by the FAA and other global aviation bodies. Their services ensure that all systems meet regulatory compliance, avoiding costly delays or issues related to non-compliance.

CONCLUSION

Pitot-Static test set calibration is an essential part of maintaining aviation safety, and AvionTEq has established itself as a leader in offering reliable, precise, and industry-compliant calibration services. With a commitment to quality and safety, their expertise in testing and calibrating Pitot-Static systems helps ensure that aircraft instruments deliver accurate, dependable performance. For aviation professionals seeking top-tier calibration services, AvionTEq provides a trusted, efficient solution that guarantees the integrity of flight instrumentation. For more details about pitot static test set calibration, please out site.

0 notes

Text

Digital vs. Analog Manometers: Which One Should You Use?

Digital vs. analog manometers – which one is right for you? Explore their differences, advantages, and best applications to make an informed choice. Read more!

0 notes

Text

How to Measure and Adjust Static Pressure in Your Blower System

Understanding Blower Static Pressure

Blower static pressure is a critical factor that determines airflow efficiency in ventilation, exhaust, and industrial applications. It represents the resistance to airflow within a system, affecting overall performance and energy consumption. Maintaining optimal static pressure ensures that your blower system operates efficiently without overloading the motor.

Tools and Techniques for Measuring Static Pressure

Accurately measuring static pressure in blowers requires the right tools and a step-by-step approach. Here are the essential tools and methods:

Tools You Need:

Manometer – Measures pressure differences within the ductwork.

Magnehelic Gauge – Provides precise static pressure readings.

Pitot Tube – Measures velocity pressure and static pressure.

Digital Pressure Gauge – Offers accurate digital readings for quick adjustments.

Step-by-Step Measurement Process:

Turn Off the System – Ensure safety before taking measurements.

Identify Measurement Points – Locate key points before and after the blower.

Insert the Probe – Place the measuring tool in the duct without blocking airflow.

Record Readings – Take static pressure readings at different points.

Compare Readings – Evaluate whether the system pressure is within the optimal range recommended by Central Blower.

How to Adjust Static Pressure for Optimal Performance

Once you've measured static pressure, adjustments may be necessary to ensure efficient blower operation. Follow these steps:

Adjusting Static Pressure:

Check for Blockages – Remove dust, debris, or obstructions from ducts and filters.

Optimize Duct Design – Ensure ductwork is properly sized and sealed to prevent air leaks.

Adjust Fan Speed – Increase or decrease blower speed to achieve the desired static pressure.

Use Dampers and Bypass Systems – Control airflow resistance using dampers for precise adjustments.

Upgrade to a High-Performance Blower – If static pressure issues persist, consider upgrading to a Central Blower model designed for higher efficiency.

FAQs About Blower Static Pressure

1. What is a good static pressure range for my blower?

The ideal static pressure depends on your system’s requirements. Most HVAC and industrial blower systems operate within 0.5" to 2.0" WC (water column), but this varies based on application.

2. What happens if static pressure is too high?

High static pressure restricts airflow, leading to overheating, motor strain, and reduced efficiency. Adjustments to duct design or blower speed may be needed.

3. How often should I check static pressure?

It’s recommended to measure blower static pressure during routine maintenance, at least every six months, or if you notice airflow issues.

4. Can I adjust static pressure without professional help?

Yes, minor adjustments such as cleaning filters, sealing ducts, and adjusting dampers can be done yourself. However, complex issues may require Central Blower experts.

Call to Action

Optimizing blower static pressure is key to maximizing airflow efficiency and system longevity. If you need expert guidance, Central Blower offers high-performance blower solutions tailored to your needs.

Get in touch today to find the right blower for your application or learn more about optimizing static pressure for maximum efficiency!

#Blower static pressure#How to measure static pressure in blowers#Adjusting static pressure#Optimal static pressure

0 notes

Text

Digital Manometer MM45 - MEXTECH

Looking for Digital Manometer MM45 manufacturers in India? MEXTECH is one of the top manometer suppliers in Mumbai.

0 notes

Text

Digital Manometer DM9600

The DM 9600 is a precision manometer used for accurate pressure, differential pressure, and temperature measurements. The DM 9600 has 0.5% accuracy and resolution to 0.001. DM 9600 75 mBar Accuracy: +/-2 Pa or 0.5% from measuring range Resolution: 0.1 Pa

Product Link

0 notes

Text

The Evolution of Lab Equipment: From Analog to Digital

Laboratories have undergone significant transformations over the years, evolving from rudimentary setups to sophisticated, technology-driven environments. This evolution is particularly evident in lab equipment, which has transitioned from analog to digital forms, dramatically enhancing research capabilities, accuracy, and efficiency. This article explores the key developments in lab equipment, examining the transition from analog to digital and the implications of this evolution for modern scientific research.

1. The Analog Era: Foundations of Laboratory Equipment

a. Characteristics of Analog Equipment

In the early days of laboratory work, most instruments were analog, relying on mechanical and electro-mechanical components to function. Instruments such as analog thermometers, manometers, and spectrophotometers used physical scales, needles, and dials to display measurements. While effective, these devices had limitations, including susceptibility to human error and difficulty in obtaining precise readings.

b. Importance of Calibration

During the analog era, calibration was crucial to ensure the accuracy of measurements. Manual calibration involved adjusting instruments based on known standards, requiring skilled technicians to perform the process. Despite its challenges, this hands-on approach laid the groundwork for the importance of precision in laboratory work.

2. The Transition to Digital: A Technological Revolution

a. Introduction of Digital Instruments

The late 20th century marked the beginning of the digital revolution in laboratory equipment. The introduction of digital technology brought forth a new era of instruments capable of providing more accurate and reliable measurements. Digital thermometers, multimeters, and balances quickly gained popularity, offering enhanced readability, automated calculations, and improved data storage.

b. Enhanced Precision and Accuracy

Digital instruments eliminated many of the inaccuracies associated with analog devices. They use sensors and electronic components to capture data, resulting in higher precision and reduced human error. For instance, digital balances can measure weights to an accuracy of 0.0001 grams, a feat that was challenging to achieve with analog scales.

c. Data Management and Connectivity

Digital lab equipment often includes built-in data management features, allowing researchers to store and analyze large volumes of data easily. Instruments can connect to computers and laboratory information management systems (LIMS) to streamline data collection and reporting. This capability has revolutionized the way scientists conduct research, enabling real-time data analysis and collaboration.

3. Key Developments in Digital Lab Equipment

a. Automation and Robotics

The integration of automation and robotics into laboratory equipment has further advanced research capabilities. Automated pipetting systems, liquid handling robots, and robotic arms can perform repetitive tasks with speed and precision, freeing researchers to focus on complex analyses and experimental design.

b. Advanced Analytical Techniques

Digital technology has enabled the development of advanced analytical techniques, such as high-performance liquid chromatography (HPLC), mass spectrometry (MS), and nuclear magnetic resonance (NMR) spectroscopy. These instruments provide in-depth insights into chemical compositions, molecular structures, and biological processes, facilitating groundbreaking research across various disciplines.

c. User-Friendly Interfaces

Modern digital lab instruments feature intuitive interfaces that simplify operation. Touchscreen displays, user-friendly software, and guided protocols make it easier for researchers to operate complex equipment, reducing training time and improving overall efficiency.For more detail click https://magenetic.com/product-category/mixing/

4. The Impact of Digital Evolution on Scientific Research

a. Improved Efficiency and Productivity

The shift from analog to digital lab equipment has significantly improved efficiency and productivity in scientific research. Automated processes reduce the time required for sample preparation and analysis, enabling researchers to conduct more experiments in less time. This increase in throughput is particularly beneficial in high-throughput screening environments, where speed is essential.

b. Enhanced Collaboration and Sharing

Digital technologies have also fostered greater collaboration among researchers. Cloud-based platforms and shared databases allow scientists to store, analyze, and share data seamlessly. This collaborative approach enhances transparency and accelerates the pace of scientific discovery.

c. Accessibility to Advanced Techniques

The evolution of lab equipment has made advanced analytical techniques more accessible to a wider range of researchers. Smaller laboratories and academic institutions can now utilize sophisticated digital instruments, leveling the playing field and promoting innovation in various fields.

5. Challenges and Considerations

a. Equipment Cost and Maintenance

While digital lab equipment offers numerous advantages, the initial investment can be significant. Laboratories must consider budget constraints when acquiring new technology. Additionally, regular maintenance and calibration of digital instruments are essential to ensure continued accuracy and reliability.

b. Data Security and Integrity

As laboratories increasingly rely on digital data management systems, concerns about data security and integrity arise. Protecting sensitive research data from cyber threats and ensuring compliance with data protection regulations is crucial for maintaining trust in scientific research.

6. Conclusion

The evolution of lab equipment from analog to digital has transformed the landscape of scientific research, providing researchers with advanced tools to enhance accuracy, efficiency, and collaboration. As technology continues to advance, laboratories must stay informed about emerging trends and developments in digital equipment to remain competitive and innovative. By embracing these changes, researchers can leverage the power of modern lab equipment to unlock new discoveries and contribute to the advancement of science. The journey from analog to digital represents a significant milestone in the quest for precision and excellence in laboratory work, shaping the future of research across diverse fields.

0 notes

Text

Global Absolute Manometer Market Analysis and Growth Forecast for 2024 - 2031

The global absolute manometer market is witnessing significant growth as industries increasingly prioritize precision measurement in various applications. Absolute manometers are essential instruments used for measuring pressure relative to a perfect vacuum, making them crucial in sectors such as manufacturing, aerospace, and pharmaceuticals.

Overview of Absolute Manometers

The global absolute manometer market is poised for substantial growth, driven by increasing demand for precision measurement in various industries. As technological advancements continue to evolve

An absolute manometer is a pressure measurement device that provides readings relative to a vacuum (zero pressure). Unlike gauge manometers, which measure pressure relative to atmospheric pressure, absolute manometers offer highly accurate measurements essential for scientific and industrial processes.

Types of Absolute Manometers

Bourdon Tube Manometers

These devices use a curved tube that straightens under pressure, providing a mechanical movement that translates into a pressure reading.

Widely used in various industrial applications due to their reliability and durability.

Digital Absolute Manometers

Utilize electronic sensors and digital displays for precise readings.

Offer advanced features such as data logging and remote monitoring.

Capacitive Manometers

Measure pressure by detecting changes in capacitance caused by pressure variations.

Known for their high accuracy and sensitivity, often used in research and development.

Market Drivers

Increasing Demand for Precision Measurement

As industries evolve and technological advancements occur, the demand for precise pressure measurement is growing. Absolute manometers are preferred for applications requiring high accuracy, such as laboratory experiments and calibration processes.

Growth in Manufacturing and Process Industries

The expansion of manufacturing and process industries, particularly in emerging economies, is driving the demand for absolute manometers. These instruments are essential for maintaining product quality and ensuring safety in production processes.

Technological Advancements

Innovations in sensor technology and data processing are enhancing the capabilities of absolute manometers. The introduction of smart manometers with IoT connectivity is making it easier for industries to monitor pressure remotely and integrate measurements into their digital infrastructure.

Regional Analysis

North America

North America is a key market for absolute manometers, driven by a strong presence of manufacturing and pharmaceutical industries. The region's focus on technological advancements and regulatory compliance further supports market growth.

Europe

Europe is home to several leading manufacturers of pressure measurement instruments. The region's stringent quality and safety regulations in various industries, including automotive and aerospace, are fueling the demand for high-precision absolute manometers.

Asia-Pacific

The Asia-Pacific region is expected to see the fastest growth in the absolute manometer market. Rapid industrialization, increasing investments in infrastructure, and the growing need for precise measurement in various sectors are driving demand in countries like China and India.

Key Players in the Market

WIKA Instrument, LP

A global leader in pressure measurement technology, known for its high-quality absolute manometers and innovative solutions.

Honeywell International Inc.

Offers a wide range of pressure measurement products, including advanced digital absolute manometers for various applications.

Emerson Electric Co.

Known for its precision measurement instruments, Emerson provides reliable absolute manometers designed for industrial applications.

Future Trends

Integration of IoT and Smart Technologies

The future of the absolute manometer market is likely to be shaped by the integration of IoT technologies. Smart absolute manometers will enable real-time monitoring and data analysis, improving operational efficiency and decision-making processes.

Focus on Sustainability

As industries strive to reduce their environmental impact, there will be a growing emphasis on sustainable manufacturing practices. Absolute manometers that support energy-efficient processes and reduce waste will gain popularity.

Expansion in Emerging Markets

Emerging markets will continue to present significant opportunities for the absolute manometer market. As industries in these regions expand, the demand for high-precision measurement instruments will grow, driven by the need for quality control and safety compliance.

Conclusion

The global absolute manometer market is poised for substantial growth, driven by increasing demand for precision measurement in various industries. As technological advancements continue to evolve, the market will likely see innovations that enhance functionality and integration with digital systems. Stakeholders must adapt to these trends to meet the evolving needs of industries and capitalize on the growing opportunities in the absolute manometer market.

#Global Absolute Manometer Market Size#Global Absolute Manometer Market Trend#Global Absolute Manometer Market Growth

0 notes

Text

Digital Manometer Testo 510 Brand : Testog Model Name/Number : 510 Measuring range : 0 to 100 hPa Resolution : 0.01 hPa Operating temperature : 0 to +50 °C Measuring rate : 0.5 s Storage temperature : -40 to +70 °C Buy : https://vegabazaar.com/product/best-digital-manometer-testo-510/

0 notes

Text

Precision at Your Fingertips! 🔍🌟

Step into the future of measurements with cutting-edge digital electronics! 🌡️💻 From accurate manometers to smart thermometers and data loggers, these tools redefine precision in monitoring and recording. 📈🔬 Whether you're a scientist, engineer, or simply curious about data, digital electronics empower you with real-time insights and easy-to-read displays. It's not just about technology; it's about making informed decisions with confidence. 📊🔍

0 notes

Text

Precision in Aircraft Maintenance: AvionTEq’s Pitot-Static Test Set Calibration Services

In the world of aviation, safety is the paramount concern, and ensuring the reliability and accuracy of the instruments that monitor aircraft performance is crucial. One of the most critical aspects of this is the proper functioning of the aircraft’s Pitot-Static System, which directly impacts the airspeed indicator, altimeter, and vertical speed indicator. A malfunction in this system can lead to severe consequences, including inaccurate flight data, which could result in dangerous flight conditions. To mitigate such risks, regular calibration and testing of Pitot-Static test sets are required, and AvionTEq is a leading company in providing these essential calibration services.

Understanding Pitot-Static Systems

The Pitot-Static System in an aircraft measures key parameters such as airspeed, altitude, and rate of climb or descent. The system consists of a Pitot tube, which measures the dynamic pressure of the air entering the tube during flight, and a static port, which measures the atmospheric pressure surrounding the aircraft. The combination of these measurements allows the aircraft’s flight instruments to provide pilots with accurate and reliable data, essential for flight navigation and safety.

Calibration and testing of these systems ensure that the instruments providing this vital data are operating correctly, especially when an aircraft undergoes maintenance or is brought back into service after a period of inactivity. In this context, AvionTEq offers specialized Pitot-Static Test Set Calibration services designed to meet the high standards of aviation safety.

AvionTEq’s Expertise in Pitot-Static Test Set Calibration

AvionTEq is a well-established leader in the aviation support industry, known for offering high-quality calibration and maintenance services for a wide range of flight instruments. Their Pitot-Static Test Set Calibration services are an essential offering that guarantees your aircraft’s flight instruments are performing at their best. Their team of skilled professionals works meticulously to ensure that your test sets meet the stringent requirements laid out by the Federal Aviation Administration (FAA) and international aviation standards.

Precision Calibration with State-of-the-Art Equipment

At AvionTEq, accuracy and precision are paramount. The company uses the latest technology and equipment to calibrate Pitot-Static test sets. These devices are highly specialized instruments designed to measure and simulate different pressure levels that aircraft may experience during flight. AvionTEq uses calibrated pressure pumps, digital manometers, and precision test sets to simulate flight conditions, ensuring that the system readings are both accurate and reliable.

The calibration process involves comparing the readings of the Pitot-Static test set with known values to detect any discrepancies or errors. Any deviation from the expected performance is then adjusted, and the test set is recalibrated to align with the correct specifications. This meticulous process ensures that test sets provide precise data that will guarantee accurate readings when used on actual aircraft.

Comprehensive Testing Procedures

AvionTEq’s Pitot-Static Test Set Calibration service includes several key procedures that ensure both the functionality and accuracy of the system. The primary tests performed during calibration include:

Pressure Simulation: The test set is subjected to various pressure levels to simulate different altitudes and airspeeds. This is crucial for ensuring that the test set mimics real-world conditions accurately.

Leakage and Integrity Checks: All components are thoroughly checked for leaks or wear that could lead to faulty readings during use.

Calibration of Altimeters and Airspeed Indicators: The readings from altimeters and airspeed indicators are compared to the simulated pressures and adjusted accordingly to ensure accuracy.

System Performance Verification: After calibrating the test set, AvionTEq performs a final verification to ensure that all components are functioning as expected and the system meets the required standards.

These checks and adjustments are critical to maintaining high levels of safety and reliability in aircraft performance monitoring.

Why Choose AvionTEq for Pitot-Static Test Set Calibration?

Industry Expertise: With years of experience and a team of skilled professionals, AvionTEq is one of the most trusted names in the industry for aircraft instrument calibration. They possess the knowledge to handle complex systems and ensure they function within the required parameters.

Comprehensive Services: AvionTEq doesn’t just offer calibration but a complete suite of services designed to keep aircraft instrumentation functioning optimally. They offer maintenance, repair, and troubleshooting services alongside their calibration offerings.

Precision and Accuracy: AvionTEq’s attention to detail and use of state-of-the-art calibration tools guarantees that every Pitot-Static test set is tested for accuracy and reliability, ensuring safety during flight operations.

FAA and International Compliance: AvionTEq adheres to all relevant standards and guidelines set forth by the FAA and other global aviation bodies. Their services ensure that all systems meet regulatory compliance, avoiding costly delays or issues related to non-compliance.

Conclusion

Pitot-Static test set calibration is an essential part of maintaining aviation safety, and AvionTEq has established itself as a leader in offering reliable, precise, and industry-compliant calibration services. With a commitment to quality and safety, their expertise in testing and calibrating Pitot-Static systems helps ensure that aircraft instruments deliver accurate, dependable performance. For aviation professionals seeking top-tier calibration services, AvionTEq provides a trusted, efficient solution that guarantees the integrity of flight instrumentation. For more details about pitot static test set calibration, please out site.

0 notes