#Pressure Vessel

Text

The Role of Advanced Technology in Modern Pressure Vessel Tank Manufacturing

In today’s industrial landscape, the manufacturing of pressure vessels has evolved significantly, thanks to advancements in technology. Pressure vessels are critical components used across various industries, from oil and gas to chemical processing, power generation, and even food manufacturing. As industrial requirements grow more complex, modern pressure vessel tank manufacturers are leveraging cutting-edge technology to ensure safety, efficiency, and durability.

In this blog, we will explore how advanced technology is transforming the world of pressure vessel manufacturing and why working with experienced pressure vessel suppliers in India like Teknoflow Green Equipments Private Limited is crucial to ensuring top-quality products.

Precision in Pressure Vessel Design

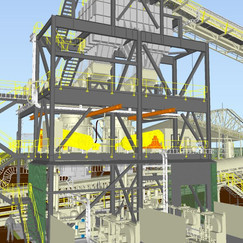

The foundation of any successful pressure vessel begins with its design. Modern pressure vessel manufacturers now use advanced software tools like Computer-Aided Design (CAD) and Finite Element Analysis (FEA) to create highly accurate and optimized designs. These technologies allow engineers to simulate different operating conditions, ensuring that the pressure vessel design can withstand extreme pressures, temperatures, and chemical exposure.

At Teknoflow Green Equipments Private Limited, the integration of advanced design tools ensures that every vessel meets the specific requirements of its application while adhering to strict safety standards. This high level of precision results in improved product performance and longevity.

Material Selection and Innovation

With the help of technology, pressure vessel tank manufacturers can now better evaluate and select materials based on the unique requirements of each application. High-performance materials like carbon steel, stainless steel, and specialized alloys are tested using advanced simulation tools to ensure they can withstand the pressure, corrosion, and temperature fluctuations in various industrial environments.

By leveraging advanced material science, pressure vessel suppliers in India such as Teknoflow Green Equipments Private Limited can manufacture vessels that are not only durable but also cost-effective and energy-efficient.

Automated Fabrication and Welding

In the past, fabricating a pressure vessel required highly manual processes, which could result in human error and inconsistencies. Today, automated fabrication techniques have revolutionized the manufacturing process. Automated welding systems, for instance, ensure that welds are of uniform quality, reducing the chances of defects or leaks in the vessel.

Pressure vessel manufacturers in India like Teknoflow Green Equipments Private Limited utilize state-of-the-art welding robots and fabrication technologies, improving production speed and accuracy. These advancements contribute to stronger, more reliable pressure vessels that require less maintenance over time.

Advanced Testing and Quality Assurance

Safety is a top priority in pressure vessel design and manufacturing. To ensure each vessel meets regulatory standards, modern manufacturers employ advanced testing methods such as radiographic testing, ultrasonic testing, and hydrostatic pressure testing. These non-destructive testing (NDT) techniques allow manufacturers to inspect every aspect of a pressure vessel without causing damage.

By utilizing these advanced quality control methods, Teknoflow Green Equipments Private Limited ensures that each pressure vessel meets both international and local safety standards. This commitment to quality makes them one of the most reliable pressure vessel suppliers in India.

Customization and Flexibility

One of the most significant benefits of advanced technology in the pressure vessel industry is the ability to offer customized solutions. Using 3D modeling software, pressure vessel manufacturers can create tailored designs that meet specific operational needs, such as unique size requirements, pressure ratings, or material specifications.

At Teknoflow Green Equipments Private Limited, customization is at the core of their service offerings. They work closely with clients to design and manufacture pressure vessels that meet the precise needs of each project, ensuring safety and operational efficiency.

Sustainability and Efficiency

As industries shift towards more sustainable practices, pressure vessel tank manufacturers are increasingly adopting green technologies to reduce their environmental impact. From energy-efficient fabrication processes to the use of eco-friendly materials, modern manufacturers are innovating to meet global sustainability goals.

Companies like Teknoflow Green Equipments Private Limited are at the forefront of this trend, implementing sustainable practices in their production processes. Their commitment to eco-friendly manufacturing positions them as leaders among pressure vessel manufacturers in India.

Conclusion

The role of advanced technology in pressure vessel manufacturing cannot be overstated. From precision design to automated fabrication and stringent testing, these innovations are helping manufacturers create safer, more reliable, and efficient pressure vessels. By working with leading pressure vessel suppliers in India like Teknoflow Green Equipments Private Limited, industries can benefit from high-quality, customized solutions that meet their specific operational needs.

As technology continues to evolve, the future of pressure vessel design and manufacturing will likely bring even more improvements in safety, efficiency, and sustainability.

0 notes

Text

Operating Conditions: A Critical Factor in Pressure Vessel Material Selection

The operating conditions under which a pressure vessel functions are crucial determinants of the material selection process. These conditions include the pressure, temperature, and the nature of the fluids or gases contained within the vessel. Choosing the right materials based on these factors ensures that the pressure vessel can perform efficiently, safely, and reliably over its intended lifespan. This blog will explore how different operating conditions influence material selection for steel Pressure Vessels and the considerations that must be made to optimize performance and longevity.

1. Pressure Considerations

1.1. High-Pressure Environments

In high-pressure environments, the material selected for the pressure vessel must be able to withstand significant internal forces without yielding or failing.

Material Strength: Materials with high tensile strength, such as carbon steel or alloy steel, are commonly chosen for high-pressure applications. These materials can endure the high stresses generated by the internal pressure, minimizing the risk of deformation or rupture.

Wall Thickness: For extremely high-pressure applications, increasing the wall thickness of the vessel can provide additional safety. However, this must be balanced with weight and cost considerations.

Fatigue Resistance: Vessels that undergo frequent pressure cycles require materials with high fatigue resistance to prevent the development of microcracks that could lead to failure over time.

1.2. Low-Pressure Environments

While low-pressure vessels are subjected to less stress, material selection is still critical to ensure safety and longevity.

Cost-Effective Materials: In low-pressure applications, materials such as standard carbon steel may be sufficient. These materials offer a good balance of strength and cost-effectiveness.

Corrosion Resistance: Even in low-pressure environments, corrosion can be a concern, especially if the vessel is exposed to corrosive fluids. Selecting materials with adequate corrosion resistance is essential to prevent leaks and extend the vessel’s service life.

2. Temperature Considerations

2.1. High-Temperature Environments

Operating at high temperatures places significant demands on the material’s thermal stability and strength.

Thermal Stability: Materials like stainless steel or alloy steels containing chromium, nickel, and molybdenum are commonly used in high-temperature applications. These materials maintain their strength and resist oxidation at elevated temperatures.

Creep Resistance: High temperatures can cause materials to deform slowly over time under constant stress, a phenomenon known as creep. Selecting materials with good creep resistance is essential to prevent long-term deformation in high-temperature environments.

Thermal Expansion: Materials must also have a low coefficient of thermal expansion to avoid excessive expansion or contraction, which could lead to stress and potential failure at joints or connections.

2.2. Low-Temperature Environments

Low temperatures can make materials more brittle, increasing the risk of fracture under stress.

Toughness at Low Temperatures: Materials like stainless steel or specially treated carbon steels are chosen for low-temperature applications due to their ability to retain toughness and ductility even in extreme cold.

Impact Resistance: In low-temperature environments, the material must also have good impact resistance to withstand sudden shocks or impacts without fracturing.

3. Corrosive Environments

3.1. Chemical Exposure

Pressure vessels that contain or are exposed to corrosive chemicals require materials that can resist chemical degradation.

Corrosion-Resistant Alloys: Materials such as stainless steel, duplex stainless steel, or nickel-based alloys are often used in chemically aggressive environments. These materials form a protective oxide layer on their surface, preventing corrosive substances from attacking the underlying metal.

Internal Linings: In some cases, additional protective linings or coatings may be applied to the interior of the vessel to enhance corrosion resistance and extend the material's service life.

3.2. Marine and Humid Environments

In marine or high-humidity environments, the risk of corrosion is significantly increased due to constant exposure to moisture and salt.

Marine-Grade Stainless Steel: Stainless steels, particularly marine-grade varieties, are commonly used in these environments due to their high resistance to pitting and crevice corrosion caused by saltwater.

Cathodic Protection: Implementing cathodic protection, such as sacrificial anodes, can also help protect the vessel from galvanic corrosion, especially in marine environments.

4. Fluid/Gas Characteristics

4.1. Reactive or Hazardous Substances

When a Pressure Vessel is used to store reactive or hazardous substances, the material must be compatible with the contents to prevent dangerous reactions or degradation.

Chemical Compatibility: Selecting a material that is chemically inert or resistant to the stored substance is critical. For instance, stainless steel is often used for vessels containing acids or other corrosive chemicals due to its resistance to chemical attack.

Leak Prevention: In vessels storing hazardous gases, materials must have low permeability and high resistance to cracking to prevent leaks, which could lead to catastrophic consequences.

4.2. Non-Reactive Substances

For non-reactive or benign substances, material selection can focus more on mechanical properties and cost-efficiency rather than chemical resistance.

Cost-Effective Choices: Materials like carbon steel may be suitable for vessels storing non-corrosive, non-reactive substances, offering a cost-effective solution without compromising safety.

5. Environmental and Regulatory Factors

5.1. Regulatory Compliance

Pressure vessels are subject to strict regulatory standards that dictate material selection based on operating conditions.

ASME Codes and Standards: The American Society of Mechanical Engineers (ASME) provides guidelines for material selection based on the pressure, temperature, and type of fluid or gas contained in the vessel. Compliance with these standards is mandatory to ensure safety and reliability.

Industry-Specific Regulations: Certain industries, such as nuclear, pharmaceutical, or food processing, may have additional material requirements based on the specific conditions and substances involved.

5.2. Environmental Impact

The environmental impact of material selection is becoming increasingly important, particularly in industries focused on sustainability.

Eco-Friendly Materials: Selecting materials with lower environmental impact, such as those that are recyclable or have a lower carbon footprint, is an emerging consideration in material selection for pressure vessels.

Longevity and Lifecycle Considerations: Materials that offer extended service life with minimal environmental degradation can contribute to more sustainable operations by reducing the need for frequent replacements and minimizing waste.

Operating conditions are a critical factor in selecting the right materials for steel pressure vessels. By carefully considering the pressure, temperature, corrosive environment, and the nature of the contained substances, engineers can choose materials that not only meet the operational demands but also ensure the safety, reliability, and longevity of the vessel. Understanding these factors and aligning material choices with regulatory standards and environmental considerations is essential for optimizing the performance and lifespan of pressure vessels in any industrial application. For more info contact Pressure Vessel Suppliers in UAE or call us at +971 4 252 2966.

0 notes

Text

youtube

.

1 note

·

View note

Text

Chicago, March 06, 2024 (GLOBE NEWSWIRE) -- The global Pressure Vessels Market size is expected to grow from USD 50.3 billion in 2023 to USD 62.7 billion by 2028, at a CAGR of 4.5% according to a new report by MarketsandMarkets™. A pressure vessel is a container designed to hold gases or liquids at a pressure significantly different from the ambient pressure. The pressure within the vessel may be higher or lower than the atmospheric pressure outside the vessel. Pressure vessels are used in a variety of industrial and commercial applications, including chemical processing, oil and gas production, power generation, and manufacturing.

#pressure vessels#pressure vessel#pressure vessels market#nuclear power plant#energy#energia#power#power generation#nuclear power#nuclear energy#power plant#power plants#chemical industry#chemical processing#oil and gas industry#oil and gas#oil and gas production#offshore oil and gas#manufacturing#refinery#oil refinery#chemical plant#processing vessels

0 notes

Text

Comprehensive Engineering Solutions with Little P.Eng.: Catalyzing Innovation Across Engineering

Engineering challenges in contemporary industry demand sophisticated, multidisciplinary approaches. Little P.Eng., a rising name in the engineering sector, has positioned itself as a nexus for solutions spanning various specialized fields, including structural engineering, piping design, piping stress analysis, seismic bracing design, storage tank design, material handling engineering services, pressure vessel design, electrical design, and CRN registration services. This article delves into each of these areas, highlighting the complexities, methodologies, and cutting-edge strategies employed by Little P.Eng. to cater to the evolving needs of diverse sectors.

Engineering services are the cornerstone of modern industrial and infrastructural developments. From the conceptualization of a project to its final commissioning, various engineering disciplines come into play to ensure functionality, safety, compliance, and efficiency. Little P.Eng., with its array of engineering services, has etched its mark by offering comprehensive solutions under one roof. The company's commitment to technical excellence, precision, and continual innovation positions it at the forefront of engineering consultancy.

Structural Engineering: Structural engineering, a critical subset of civil engineering, involves the analysis, design, and planning of structural components and systems to achieve design goals and ensure the safety and comfort of users or occupants. The experts at Little P.Eng. undertake detailed analyses, considering factors such as geology of the site, environmental conditions, and materials to be used, ensuring structural soundness against static and dynamic loading, including human traffic and environmental stressors.

The service spectrum includes:

Building Design: Erection of residential, commercial, and industrial structures with considerations for material efficiency, safety regulations, and aesthetic aspects.

Structural Analysis and Inspection: Employing advanced tools to analyze stress, strain, and load distribution and conducting inspections to assure structural integrity and longevity.

Foundation Design: Creating robust foundations, including piles, rafts, and footings, customized to site conditions and building requirements.

Retrofitting and Rehabilitation: Strengthening existing structures through modernization techniques, enhancing our capacity to withstand additional or unanticipated loads.

Piping Design and Piping Stress Analysis: Piping systems are lifelines of process industries, influencing operational efficiency, safety, and economic feasibility. Little P.Eng. offers comprehensive solutions in piping design, ensuring optimal layout and functionality, accommodating project constraints, and adhering to international standards.

Key aspects include:

Piping Layout and 3D Modeling: Developing detailed piping system layouts, incorporating equipment placement, structural design, and safety compliance, facilitated through advanced 3D modeling for accuracy and visualization.

Stress Analysis: Utilizing software tools like CAESAR II for precise stress analysis, determining strain and stress levels within piping systems under various scenarios, including temperature changes, fluid dynamics, pressure variations, and external forces, thereby verifying system reliability and identifying necessary supports and reinforcements.

Seismic Bracing Design: In regions prone to seismic activity, designing structures with adequate bracing is crucial to prevent collapse and minimize damage during earthquakes. Little P.Eng.'s seismic bracing designs are tailored to enhance the resilience of structures, factoring in regional seismic activity, local regulations, and material specifications.

Services involve:

Seismic Risk Evaluations: Assessing seismic risks associated with specific locations, analyzing historical data, and geological conditions.

Bracing System Design: Engineering customized bracing systems, including base isolators, cross-bracing, and shear walls, to dissipate seismic forces and minimize structural vulnerability.

Post-Earthquake Assessments: Inspecting and evaluating structures post-seismic activity for damage assessment and further reinforcement recommendations.

Storage Tank Design: Storage tanks, essential for industries requiring liquid or gas storage, entail specialized design parameters. Little P.Eng. focuses on custom solutions, factoring in the stored substance's characteristics, environmental considerations, and industry regulations.

The design process encompasses:

Material Selection and Design: Choosing appropriate materials resistant to the stored contents and environmental conditions, and designing tanks based on capacity requirements, pressure ratings, and structural regulations.

Foundation and Settlement Analysis: Ensuring ground stability and accommodating potential settlement or shifts without compromising tank integrity.

Safety and Emission Controls: Integrating features to prevent leaks, limit emissions, and safeguard against potential hazards, including explosions or toxic releases.

Material Handling Engineering Services: Efficient material handling is pivotal to operational success in manufacturing, warehousing, and distribution facilities. Little P.Eng. offers engineering solutions optimizing the movement, storage, control, and protection of materials throughout the process.

These services include:

System Design and Integration: Developing comprehensive systems combining conveyors, automated storage and retrieval systems, and transfer equipment, ensuring seamless, efficient operations.

Equipment Selection and Procurement: Advising on the appropriate equipment tailored to specific operational needs and assisting with acquisition from reputable manufacturers.

Safety and Ergonomics: Designing systems prioritizing operator safety and ergonomics, reducing workplace hazards and potential for injury.

Pressure Vessel Design: Pressure vessels, used for holding gases or liquids at high pressures, require meticulous design to prevent failure and catastrophic results. Little P.Eng.'s expertise lies in crafting pressure vessels compliant with industry standards like the ASME Boiler and Pressure Vessel Code.

Specific services involve:

Design and Analysis: Performing detailed calculations for wall thickness, stress distribution, and overall vessel geometry, ensuring safety under various pressure conditions.

Material Specification and Fabrication Oversight: Specifying suitable materials able to withstand extreme pressures and overseeing the fabrication process for quality assurance.

Inspection and Certification: Conducting thorough inspections and facilitating necessary certifications, confirming adherence to safety and operational standards.

Electrical Design: Electrical design services encompass the planning and execution of electrical systems, vital for the operational integrity of residential, commercial, and industrial projects. Little P.Eng.'s electrical engineers are adept at crafting systems that meet energy efficiency, safety, and performance standards.

Critical offerings include:

System Layout and Design: Creating comprehensive electrical systems, including power distribution, lighting, and emergency backup systems, tailored to specific project requirements.

Compliance and Safety: Ensuring designs meet electrical codes and safety standards, incorporating protective measures to prevent system failures, electrical shocks, or fire hazards.

Energy Efficiency Solutions: Proposing energy-efficient technologies and methodologies, contributing to sustainable and cost-effective operations.

CRN Registration Services: The Canadian Registration Number (CRN) is a number issued by each province or territory of Canada for the design of a boiler, pressure vessel, or fitting. The CRN identifies that the design has been accepted and registered for use in that province or territory. Little P.Eng. assists with the complex process of obtaining CRN certifications, essential for legal and safe operation within Canada.

This process includes:

Design Evaluations: Reviewing pressure equipment designs to ensure they comply with pertinent regulations and standards.

Documentation Preparation: Compiling and preparing extensive documentation required for CRN applications, including drawings, calculations, and material test reports.

Liaison with Authorities: Acting as an intermediary between clients and regulatory bodies, facilitating communication and expediting the registration process.

Conclusion: Little P.Eng. has emerged as a one-stop solution for diverse engineering needs, driven by a team of experts dedicated to upholding the highest standards of engineering excellence. Our approach is not just about meeting the minimum regulatory requirements; it is about designing safe, efficient, and sustainable systems that stand the test of time. By embracing advanced technologies, up-to-date methodologies, and a customer-centric approach, Little P.Eng. is setting new benchmarks in the engineering domain, contributing significantly to industrial innovation and infrastructural advancement.

Tags:

CAESAR II

energy efficiency

structural engineering

material handling

3D modeling

safety standards

regulatory compliance

earthquake resilience

stress analysis

CRN registration

advanced technologies

engineering consultancy

fabrication oversight

rehabilitation

piping design

pressure vessel

project commissioning

retrofitting

electrical design

automated storage

operational excellence

system reliability

ASME compliance

seismic bracing

foundation design

storage tank

tank integrity

design evaluation

infrastructural advancement

industrial innovation

Engineering Services

Structural Engineering Consultancy

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#CAESAR II#energy efficiency#structural engineering#material handling#3D modeling#safety standards#regulatory compliance#earthquake resilience#stress analysis#CRN registration#advanced technologies#engineering consultancy#fabrication oversight#rehabilitation#piping design#pressure vessel#project commissioning#retrofitting#electrical design#automated storage#operational excellence#system reliability#ASME compliance#seismic bracing#foundation design#storage tank#tank integrity#design evaluation#infrastructural advancement#industrial innovation

0 notes

Text

0 notes

Text

The global Pressure Vessels Market is projected to reach USD 62.7 billion in 2028 from USD 50.3 billion in 2023 at a CAGR of 4.5% according to a new report by MarketsandMarkets™.

#pressure vessels market#pressure vessels#pressure#pressure vessel tank#pressure vessel#pressure vessel market#energy#power#electricity#power generation#utilities#nuclear energy#nuclear#nuclear power#nuclear power plant#power plants#power plant

0 notes

Text

Mild Steel Chlorine Gas Cylinder Manufacturers

Looking for the Best Mild Steel Chlorine Gas Cylinder Manufacturers. Chemtrade International is a leading distributor of Mild Steel Chlorine Gas Cylinder, providing high-quality products and exceptional service to customers across industries.

#Chlorine Cylinder#Mild Steel Cylinder#Chlorine Gas#Gas Cylinder Safety#Cylinder Handling#Industrial Safety#Chemical Industry#Gas Storage#Pressure Vessel#Gas Handling#Hazardous Material#Safety First#Gas Storage Safety#Cylinder Maintenance#Corrosion Resistance#Industrial Gas Cylinder#Gas Cylinder Storage#Gas Cylinder Transportation#Safe Cylinder Handling

1 note

·

View note

Text

Book available on Google Play book store, Amazon, Kindle, Scribd, Kobo, Apple book store, etc. Worldwide e-commerce store.

Pressure vessel and HVAC air cooled condenser ebook and paperback Book.

#pressure vessels#pressure vessel#industrial hvac#hvacmaintenance#hvac installation#hvac#air cooled condenser#air cooled chiller

0 notes

Text

quite funny

#drew these while listening to vessel#such an incredible album i cant believe ive been sleeping on it#pressure#pressure roblox#pressure fanart#sebastian solace#pressure sebastian#p.ai.nter#p.ai.nter pressure#my art#roblox art#roblox

432 notes

·

View notes

Text

Hey y'all! It's weird question time again! I think I might've asked this one before but I can't remember

1. Does high intensity exercise measurably drop your temperature? (as measured by one of those forehead thermometers)

2. Can the "high intensity exercise" be just singing while playing piano?

3. When I tried to tell a doctor I am bad at thermoregulation a while back and he kinda condescendingly said "no, human bodies are very good at that"...like...most people don't go into opossum body temperature range when they try to exercise, right???? You don't get so cold the bones in your hands and feet ache when it's only like low 60s in the house????

edit: my normal temperature is around 98.6 fahrenheit but if my body kicks into "getting too hot better adjust temperature mode" it will easily drop a full degree. The lowest I've gotten was in the 96 degree range, which is in the range for opossum body temperature, and I said "hey I'm opossum temperature!" when I saw the thermometer and it's one of those phrases you cannot unthink so it stuck

#the person behind the yarn#tj asks weird questions#for the record 'opossum temperature' is one of those phrases doctors are both amused and bemused by#also confused#up there with 'hey! I have normal human blood pressure today!'#in my experience my body is very very good at cooling down#because that involves getting rid of salt (sweating) and lowering blood pressure (vasodilation of blood vessels near the skin)#and there's nothing my body loves more than getting rid of salt and lowering my blood pressure#except maybe allergies#but it's very bad at warming back up#like sometimes in the winter I will be covered with blankets#and just unable to warm them up at all#cold to the touch. don't know why!#this winter was less bad than previous winters#but I also started my new meds in the fall and they are steroids#I suspect long term steroids might like. affect that#also I am living in a different house now and it didn't get as cold

38 notes

·

View notes

Text

hearing people whispering outside my door and i am going insane (the voices are real i just don't like hearing them bc i'm a traumatized chihuahua of a person)

#waiting for meds to kick in and thinking i maybe should have skipped a day for blood pressure reasons#i wanna take a shower and i cant bc we have a houseguest (nvm one i dislike immensely)#stirring up trouble#really just. it's fine to have people over and hang out and im sorry there's kind of a mess to get around bc of the construction project#i am trying to be a good and rational and reasonable person about this#but she is uh. kind of a transphobe with too much buy-in on white supremacy and cops. i am going to be uncomfortable at best.#she seems to be Trying?? but until she succeeds i am doing my best to maintain a safe distance...#idk maybe this is just a 'stay in my room and try to get some digital work done' day#need to not push it while im still adjusting to the meds. already prone to burst blood vessels...where are my headphones...

42 notes

·

View notes

Text

The Foundation of Durable and Reliable Steel Pressure Vessels

The quality of materials used in the construction of steel pressure vessels is paramount to their performance, safety, and longevity. High-quality materials ensure that the vessel can withstand the rigorous demands of industrial applications, including exposure to high pressures, extreme temperatures, and corrosive environments. This blog will explore the critical aspects of material quality in steel pressure vessels, focusing on the types of materials used, the factors that influence material selection, and the impact of material quality on the vessel’s overall durability.

1. Importance of Material Quality in Pressure Vessels

1.1. Structural Integrity

The structural integrity of a pressure vessel is directly linked to the quality of the materials used in its construction.

Strength and Ductility: High-quality materials possess the necessary strength to endure internal pressures without deforming or failing. Ductility is also crucial as it allows the material to absorb stresses without fracturing, which is vital for handling pressure fluctuations and preventing catastrophic failures.

Fatigue Resistance: Pressure vessels are often subjected to cyclic loading, where they undergo repeated pressurization and depressurization. Materials with high fatigue resistance are essential for preventing the development of cracks and ensuring long-term reliability.

1.2. Corrosion Resistance

Corrosion is one of the most significant threats to the longevity and safety of steel pressure vessels. The material’s ability to resist corrosion determines how well it can withstand harsh environments.

Material Composition: The presence of elements such as chromium, nickel, and molybdenum in steel alloys enhances corrosion resistance by forming a protective oxide layer on the surface. This layer shields the underlying steel from corrosive agents, significantly extending the vessel’s service life.

Environmental Suitability: High-quality materials are selected based on their compatibility with the specific environment in which the vessel will operate. This ensures that the material can resist the types of corrosion it will encounter, such as pitting, crevice corrosion, or stress corrosion cracking.

1.3. Safety and Reliability

Using high-quality materials is crucial for ensuring the safety and reliability of pressure vessels, particularly in high-stakes industrial applications.

Consistency in Material Properties: High-quality materials are manufactured to stringent standards, ensuring uniformity in their mechanical properties. This consistency is essential for predicting how the vessel will behave under different operating conditions, which is key to maintaining safety.

Resistance to Environmental Factors: Quality materials are better equipped to resist environmental factors such as extreme temperatures, chemical exposure, and mechanical wear, all of which contribute to the overall safety and longevity of the vessel.

2. Types of Materials Used in Steel Pressure Vessels

2.1. Carbon Steel

Carbon steel is widely used in Pressure Vessels due to its excellent mechanical properties and cost-effectiveness.

Properties: Carbon steel offers a good balance of strength, ductility, and toughness, making it suitable for a broad range of pressure and temperature conditions.

Limitations: While carbon steel is cost-effective, it is susceptible to corrosion, especially in aggressive environments. Additional protective measures, such as coatings or linings, are often required to enhance its durability.

2.2. Stainless Steel

Stainless steel is the material of choice in applications where corrosion resistance is critical.

Properties: Stainless steel contains chromium, which forms a passive oxide layer that protects the steel from corrosion. It also has high strength and can withstand high temperatures, making it ideal for demanding environments.

Applications: Stainless steel is commonly used in industries such as food and beverage, pharmaceuticals, and chemicals, where hygiene and corrosion resistance are essential.

2.3. Alloy Steel

Alloy steels are used when enhanced mechanical properties or corrosion resistance are required. These steels contain additional alloying elements such as chromium, nickel, molybdenum, and vanadium.

Properties: Alloy steels offer superior strength, toughness, and resistance to wear and corrosion, making them suitable for high-pressure or high-temperature applications.

Applications: Alloy steels are often chosen for pressure vessels used in the oil and gas industry, power generation, and other sectors where the operating conditions are particularly harsh.

2.4. Duplex Stainless Steel

Duplex stainless steels combine the properties of austenitic and ferritic stainless steels, offering a unique balance of strength and corrosion resistance.

Properties: Duplex stainless steel is known for its high strength and excellent resistance to stress corrosion cracking, making it ideal for use in harsh environments.

Applications: This material is commonly used in the chemical and petrochemical industries, where vessels are exposed to highly corrosive substances and extreme temperatures.

3. Factors Influencing Material Selection

3.1. Operating Conditions

The operating conditions under which the pressure vessel will function play a crucial role in material selection.

Pressure and Temperature: The material must be able to withstand the maximum pressure and temperature it will encounter. High-pressure or high-temperature environments may require materials with higher strength and thermal stability.

Corrosive Environment: If the vessel will be exposed to corrosive chemicals or extreme environmental conditions, materials with high corrosion resistance, such as stainless steel or corrosion-resistant alloys, should be chosen.

3.2. Regulatory Standards

Pressure vessels are subject to strict regulatory standards that govern material selection based on the application and operating environment.

ASME Standards: The American Society of Mechanical Engineers (ASME) sets guidelines for materials used in pressure vessels, ensuring they meet specific requirements for safety and performance.

Industry-Specific Regulations: Certain industries, such as nuclear or pharmaceutical, may have additional regulations that influence material selection, often requiring higher-grade materials or specific alloys.

3.3. Cost Considerations

While material quality is critical, cost is also a factor in material selection.

Material Cost vs. Longevity: Although high-quality materials may have a higher initial cost, they often provide a longer service life and require less maintenance, making them more cost-effective over time.

Performance vs. Budget: Engineers must balance the need for high performance with budget constraints, selecting materials that offer the best value for the application at hand.

4. Impact of Material Quality on Vessel Durability

4.1. Enhanced Durability

High-quality materials contribute to the overall durability of the pressure vessel, reducing the likelihood of failures and extending the vessel’s service life.

Resistance to Wear and Tear: Quality materials are more resistant to mechanical wear, corrosion, and other forms of degradation, ensuring that the vessel remains functional over an extended period.

Reduced Maintenance Costs: Vessels constructed with high-quality materials require less frequent maintenance and are less prone to unexpected failures, leading to lower long-term costs.

4.2. Improved Safety

Using high-quality materials enhances the safety of pressure vessels by reducing the risk of catastrophic failures.

Preventing Material Failures: High-quality materials are less likely to crack, corrode, or fail under pressure, reducing the risk of accidents and ensuring the vessel operates safely.

Compliance with Safety Standards: Ensuring that materials meet or exceed regulatory standards contributes to overall safety and compliance, minimizing the risk of accidents and liability.

Material quality is the foundation of a durable and reliable steel pressure vessel. By selecting high-quality materials that are appropriate for the operating conditions and environmental factors, industries can ensure the long-term performance, safety, and cost-effectiveness of their pressure vessels. Investing in superior materials not only extends the vessel’s service life but also enhances its reliability and reduces maintenance costs, making it a wise choice for any application. For more info contact Pressure Vessel Suppliers in UAE or call us at +971 4 252 2966.

0 notes

Text

me: keeps drawing random one-off fanarts from things that aren't currently big at all

also me: why no notes on my arte

#grateful for all of u lol#but why no notes !! lol !! i want attention i want engagement#i need to be LOVED and sharing my art is the vessel through which i ascribe my self worth...#it's like how if you have a long list of movies to watch ur still more likely to just.#watch some random movie you heard about 2 minutes ago that seems interesting. if u have spare movie time#bc it's lower pressure or smth#idk brother ! idk#im just chillin here in my cave drawing things apparently only i want to see and like maybe 5 other people#welcome to my cave#alligates says things#yo being an artist on the internet is genuinely awful. social media is not built for my delicate ass#even popular artists (i might technically be a popular artist) like i Know it sucks babe. i know#anyway 'no notes' generally in the past i could hit like. 500 ? with relative ease ? sometimes#yall i'm struggling to hit 100. why 7 reblogs and 35 likes. this is not the way#i'm a creator on the internet complaining about numbers ! not really gonna stop me tho#let's be honest whether or not i'm getting attention my ability to draw or not is contingent on. my own psychological ass. and little else#thank u for listening. it is my bedtime. goonite#if you read all these tags... idk. tell me the name of your favourite flower !

90 notes

·

View notes

Text

Staunch Supporters

Bacterial toxins can compromise blood vessels' leakiness affecting blood pressure. This study reveals that blood vessel lining cells' membranes, under the control of proteins called caveolin-1 and cavin1, stiffen to regulate the leakiness via tunnels called transendothelial cell macroapertures

Read the published the research article here

Video from work by Camille Morel and colleagues

Institut Pasteur, Université Paris Cité, CNRS UMR6047, Inserm U1306, Unité des Toxines Bactériennes, Département de Microbiologie, Paris, France

Video originally published with a Creative Commons Attribution 4.0 International (CC BY 4.0)

Published in eLife, March 2024

You can also follow BPoD on Instagram, Twitter and Facebook

25 notes

·

View notes

Text

"Reliable Pressure Vessels: Safeguarding Your Processes with Confidence"

Process Skid

Process equipment, controls, monitoring devices, and ancillaries are all contained in a self-contained module known as a process skid that is supported by a frame. It can concentrate on a single particular process or objective or merge several processes into a single unit. It is portable and simple to install. The process systems are fabricated off-site in a fabrication facility, while civil site modifications are concurrently finished at the plant site. This can be an alternative to conventional stick-built construction. It can be applied to processes such as batch mixing, solvent recovery, delayed differentiation, and distillation.

A process skid, often referred to as a packaged process unit or modular process unit, is a pre-engineered, self-contained system that includes all of the necessary tools and parts for a particular industrial process. It is created in a controlled environment while being developed and constructed off-site, then moved to the facility to be installed and integrated into the overall procedure.

Process skids are frequently used in a variety of industries, including water treatment, petrochemicals, food and beverage manufacturing, oil and gas, and petrochemicals. Compared to conventional on-site construction, they have many benefits, including:

Efficiency: The controlled environment in which process skids are constructed makes for effective manufacture and assembly. Compared to on-site building, this shortens the construction process and lowers expenses.

Pressure Vessel

A container called a pressure vessel is made to carry gases or liquids at a pressure that is significantly higher than the atmospheric pressure. The size of the vessel, the contents, the working pressure, mass restrictions, and the number of items required will all affect the construction methods and materials that are most suited for the pressure application. There have been deadly mishaps involving pressure vessels throughout their development and use. Consequently, engineering authorities supported by Law 23 regulate pressure vessel design, manufacture, and operation.

A pressure vessel is a container made to keep liquids or gases at a pressure that is much higher than the surrounding atmosphere. These containers are designed to withstand the internal pressure put on them by the chemical they are holding, protecting the workers and the machinery.

Many different industries, including oil and gas, chemical processing, power production, pharmaceuticals, and many more, use pressure vessels. They have a variety of uses, including heat exchangers, liquid or gas storage, and the facilitation of chemical reactions.

Here are some significant characteristics and factors, e.g., pressure vessels:

Engineering standards and concepts are used in the design of pressure vessels to guarantee their structural integrity under high pressure.

They are typically spherical or cylindrical and manufactured from pressure-resistant materials like carbon steel, stainless steel, or other alloys.

The thickness and material choice are influenced by variables such as the substance being contained, the operating temperature, and the pressure level.

Inlet and outlet ports, inspection ports, safety relief valves, and instrumentation openings on pressure vessels are frequently strengthened.

Safety:

The safety of pressure vessels is of the utmost significance. To avoid malfunctions that could have disastrous results, they must be created, manufactured, and operated according to industry norms and regulations.

During construction, pressure vessels are subjected to stringent testing and inspection, including non-destructive examination methods like ultrasonic testing, radiography, or pressure testing.

Pressure vessels must be inspected, maintained, and periodically tested to ensure their continued safe operation.

Pressure Reduction To guard against overpressure situations, pressure release valves, and rupture discs are included in pressure vessels. To keep the vessel from exceeding its design parameters, these mechanisms let go of extra pressure.

The maximum permitted working pressure, operating temperature, and characteristics of the contained substance are only a few of the variables that influence the choice and sizing of pressure relief devices.

Standards and Codes:

Depending on the industry and jurisdiction, several norms and standards apply to pressure vessels. Examples include the PED (Pressure Equipment Directive), API (American Petroleum Institute) standards, and the ASME Boiler and Pressure Vessel Code.

Vaporizer Singapore

An instrument used to vaporize material for inhalation is a vaporizer. Cannabis and other substances undergo heating in a vaporizer until the active ingredients boil and release vapor. The active substances in this vapor are then breathed in, entering the body through the lungs’ alveoli. Water vaporizers heat Your plant materials are heated by vaporizers using electricity or butane gas to achieve temperatures below burning.

What is the difference between a heat exchanger and a pressure vessel?

A pressure vessel is a closed container made to store gases or liquids at a pressure that is significantly higher than the surrounding atmosphere. Heat is transferred between multiple fluids using heat exchangers. A network of metal tubes is found inside the most popular pressure vessel heat exchangers. These tubes enable one product to move through them while another item moves around them.

A vaporizer is a tool used to change a substance from a liquid or solid form into a vapor or gas. This is accomplished by heating the substance and forcing it to evaporate or sublimate.

Vaporizers are frequently used for several moral things, including:

Inhalation: Vaporizers are frequently used to inhale cannabinoids, essential oils, or other therapeutic or recreational substances. The substance is heated to a point at which its active constituents become vapor that can be inhaled.

Vaporizers are used for humidification to raise the humidity in a room or other enclosed space. When water or a liquid solution is heated, a vapor is created that adds moisture to the air, reducing dryness or improving the environment.

Vaporizers are used in industrial settings for activities including heating, drying, or producing particular atmospheric conditions. They are employed to aid different manufacturing or chemical operations by vaporizing liquid materials.

0 notes