#DistillationColumn

Explore tagged Tumblr posts

Text

Distillation Setup: An Essential Tool in Chemical Separation

Distillation is a fundamental process used in various industries to separate and purify different components of liquid mixtures based on their boiling points. The distillation setup, comprising various components like distillation columns, skids, and extraction columns, plays a pivotal role in this process. Let's delve deeper into understanding what a distillation setup is, its key benefits, advantages, working principles, and the different types of components it encompasses.

What is a Distillation Setup?

A distillation setup is an apparatus designed to facilitate the distillation process, allowing the separation of liquid mixtures into their individual components by exploiting differences in boiling points. It typically comprises various components working together to achieve efficient separation, such as distillation columns, skids, condensers, boilers, and extraction columns.

Key Benefits of a Distillation Setup:

1. Separation and Purification:

- Enables the separation of components in liquid mixtures, purifying them for specific applications.

2. Versatility:

- Applicable across industries like pharmaceuticals, petrochemicals, food and beverage, and more.

3. Scalability:

- Distillation setups can be designed for various scales of production, from laboratory use to industrial-scale operations.

4. Resource Efficiency:

- Allows for the reuse and recycling of solvents and chemicals, contributing to sustainability efforts.

Advantages of a Distillation Setup:

- High Purity Output: Offers high-purity components by effectively separating substances with close boiling points.

- Cost-Effectiveness: Facilitates cost savings by reducing the need for additional purification processes.

- Process Control: Provides precise control over temperature, pressure, and flow rates, optimizing the separation process.

How does a Distillation Setup Work?

Distillation Column:

A crucial part of the setup, the distillation column, operates on the principle of continuous fractional distillation. It consists of trays or packing material where the liquid mixture enters from the top and is heated. Components with lower boiling points vaporize, rise through the column, condense, and are collected, while heavier components remain liquid and exit from the bottom.

Types of Distillation Components:

1. Distillation Skid:

- A compact, pre-engineered system comprising multiple components (such as pumps, heat exchangers, and control systems) mounted on a single frame. It's easily transportable and quick to install, ensuring efficiency and ease of operation.

2. Distillation Column:

- Various types include fractionating columns, packed columns, and tray columns. They differ in their internal structures, affecting efficiency and suitability for different applications.

3. Extraction Column:

- Often used in processes like liquid-liquid extraction, an extraction column facilitates the separation of components based on their solubility in different phases.

Conclusion:

Distillation setups are indispensable tools for industries requiring precise separation and purification of liquid mixtures. Their versatility, efficiency, and ability to cater to different scales of operation make them vital for various industrial processes, ensuring high-quality and pure end products. Understanding the components and working principles of distillation setups helps optimize their usage across diverse applications.

Rahul Engineering Global Pvt. Ltd. specializes in the design and production of advanced distillation setups catering to various industries. Our state-of-the-art distillation setups are meticulously engineered to ensure optimal efficiency and precision in separating and purifying liquids. Equipped with cutting-edge technology, our setups are customizable to meet specific client needs, offering a range of capacities and configurations. Whether for the pharmaceutical, chemical, or food and beverage sectors, our distillation setups are crafted with the highest quality materials, adhering to industry standards and designed to deliver superior performance, reliability, and ease of operation. Rahul Engineering Global provides Pune, India's best DISTILLATION SETUP Manufacturers. We offer different types of Products such as Distillation Setup, Batch Distillation Column, Distillation Skid, Distillation Columns. Trust Rahul Engineering Global Pvt. Ltd. for innovative distillation solutions that exceed expectations and enhance your production processes.

#distillationsetup#distillation#distillationsetupmanufacture#distillationsetupinpune#distillationsetupsupplier#bestdistillationsetup#topdistillationsetup#distillationskid#distillationcolumn#extractioncolumn

0 notes

Text

Knowledge Sharing Series#2

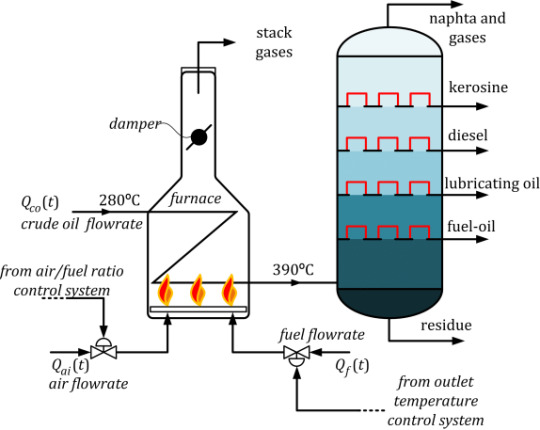

What is the Process that undergoes in Oil Preheating Furnace?

Crude Oil Entry: The desalted crude oil, which has already been heated and mixed with water to remove salt, enters the preheating furnace.

Heat Exchange: The furnace is typically designed with a series of tubes through which the crude oil flows. Hot flue gases, generated by burning fuel (such as natural gas or fuel oil), pass over these tubes, transferring heat to the crude oil.

Temperature Increase: As the crude oil flows through the tubes, it absorbs heat from the flue gases, gradually increasing in temperature.

Desired Temperature: The furnace is carefully controlled to ensure that the crude oil reaches the desired temperature, typically around 350°C to 360°C. This temperature is essential for effective vaporization of the lighter components in the crude oil.

Exit to Distillation Column: Once the crude oil has reached the target temperature, it exits the preheating furnace and enters the atmospheric distillation column, where the separation process begins.

#OilAndGas#Refinery#ChemicalEngineering#ProcessEngineering#Petrochemical#DownstreamProcessing#Distillation#UnitOperations#EnergyIndustry#Fuels#FossilFuels#PreheatingFurnace#CrudeOilPreheating#AtmosphericDistillation#DistillationColumn#HydrocarbonSeparation#RefiningProcess#OilAndGasEquipment#ProcessControl#HeatTransfer#Decontamination

1 note

·

View note

Link

Finepac Structures one stop solutions for mass transfer technology.

2 notes

·

View notes

Photo

Chemical, Cosmetic & Pharma Machinery for Vast Industrial Applications

Nisha Engineering is the leader in manufacturing and supplying of pharmaceutical machinery and chemical machineries. We offer high-quality machineries including Pharma granulations, blenders, dryers, Pharma & cosmetic machineries as well as machineries used in chemical industries. We are manufacturer and supplier of pharmaceutical machineries like double cone blender, fluid bed dryer (F.B.D), rapid mixer granulator, storage tank, rotocone vacuum dryer, lifting & tilting device, distillation column, bucket filter. We deliver the right product to our client that provides the application-specific solution to our clients. Our pharmaceutical and chemical machineries has easy to use controls, low maintenance and is durable.

We offer the best products and services to our clients along with our third party inspection. We provide different documents like warranty certificate, heat chart, raw material test certificates, pressure test reports, running trial reports and other related reports and certificates required by our valuable clients. Our products are been tested and offered at the best price to our clients.

Buy Cosmetic Machinery visit: http://www.nishaengg.com/cosmetic-machinery/

0 notes

Photo

Continuous Glass Distillation Unit recently supplied to a University in Texas, USA. It comprises of a 10 sieve tray column, along with condensers, tanks, control valves, electric heaters, pumps and other control and monitoring Instruments. A touch-screen HMI (Siemens) was provided for monitoring and control of all key process parameters such as pulp flow rates, heater temperature and process temperature across 12 different points. This system was specially customized for students as a ‘Teaching Unit’ to enable them to understand the dynamics of continuous distillation. However, it can be easily used for industrial applications as well. Write to us for more details at [email protected] It comprises of a 10 sieve tray column, along with condensers, tanks, control valves, electric heaters, pumps, and other control and monitoring Instruments. A touch-screen HMI (Siemens) was provided for monitoring and control of all key process parameters such as pulp flow rates, heater temperature and process temperature across 12 different points. #usa #texas #ablazeglassworks #glassblowing #disillation #distillationprocess #distillationequipment #distillationcolumn #processplant #scientificglass #glassworks (at Ablaze Glass Works Pvt. Ltd.) https://www.instagram.com/p/B9qs2D4iDF7/?igshid=2gaf56ffyi9j

#usa#texas#ablazeglassworks#glassblowing#disillation#distillationprocess#distillationequipment#distillationcolumn#processplant#scientificglass#glassworks

1 note

·

View note

Link

Finepac Structures offering you distillation column design best practices guidelines to help you size and design distillation columns that perform optimally within your process parameters.

0 notes

Text

ASPCHEM

Ribbon Blender Manufacturer in Mumbai

http://aspchem.com/aboutus.aspx

0 notes

Text

Working and Applications of a Distillation Column

The separation process, which has been a pillar of the chemical and industrial sectors for hundreds of years, is essential in various applications. Be it the purification of water, the refinement of crude oil, or even the production of alcoholic beverages, a distillation column plays a very significant role in separating mixtures based on differences in boiling points. This blog will further explain how a distillation column works, its mechanisms and values, and the exact science behind this remarkable procedure.

What does the term 'distillation column' mean?

A normal simple distillation column is simply a vertical vessel designed to separate a liquid mixture into its pure components by manipulating the differences in boiling points of the substances that comprise the mixture.

Applications of Distillation Columns

From the separation and purification of substances based on boiling points, distillation columns nowadays find their application in almost every industry. The applications of a distillation column vary from simple everyday product applications to complicated industrial processes. The major uses of the distillation column are as follows:

Petroleum Refining: Perhaps one of the most familiar uses of distillation columns is petroleum refining. Crude oil contains a mixture of hydrocarbons at a wide range of boiling points. The distillation column will fractionate crude oil into fractions like gasoline, diesel, and kerosene, among others, with heavier products like lubricating oils and bitumen. After that, fractions can be subjected to further processing and purification.

Chemical Manufacturing: Application in the chemical industry is huge, particularly in separating and purifying many chemicals and chemical intermediates. They are also helpful in the production of high-purity chemicals, solvents, and intermediates that later will become raw materials for other chemical processes.

Alcohol Production: Perhaps the central process of alcoholic beverage production is that of distillation. This involves heating the fermented liquids in a column of distillation, separating the alcohol from water and other components, and raising the alcohol content for whiskey, vodka, and rum types.

Pharmaceuticals: Pharmaceutical industries employ distillation columns to purify drugs, separate their intermediates, and prepare high-purity solvents and reagents. Separation of the different components in the mixture assures safe and useful pharmaceutical products.

Food and Beverage Industry: The columns purify and concentrate food and beverage products. They regard the processes of concentrated fruit juices, essential oils, and flavor extracts.

Natural Gas Processing: The crude natural gas being dispensed contains NGLs, which are refined via distillation columns into propane, butane, and ethane. These liquefied natural gases have uses in industries such as fuel, feedstock for petrochemical production, and heating.

Aromatics Production: distillation columns for separating and purifying aromatic compounds in plastics, polymers, and synthetic fiber production.

Water Desalination: The processes may be used to remove salts and other impurities from seawater to give fresh water. Though other methods of desalination, such as reverse osmosis, are more prevalent, distillation is still a very viable alternative in some instances.

Biofuel Production: During the production of biofuels, distillation columns play their part in the process of producing ethanol from renewable sources like corn and sugarcane. This results in contaminated biomass fermentation with alcohol, generally an aqueous solution, which needs to be distilled to separate ethanol and concentrate it.

Environmental Applications: The distillation columns could further be used in ecological remediation for polluted liquids by separating contaminants from clean water or any other clean solvents.

Distillation is used in the perfume and fragrance industries to recover essential oils from plant materials, which are used in perfumes and fragrances, cosmetics, and aromatherapy products.

Waste Management: A few uses of distillation columns exist in some waste management processes to separate either valuable materials or components from the waste streams; this aids in resource recovery and minimizes the impact on the environment. These applications only prove the wide-ranging importance of the distillation column across industries. With improving technology and design comes the improvement of competence in distillation procedures, making this parting technique essential to various industrial processes and a wide array of everyday products. Components of the Distillation Column

There are just a few components that make up a distillation column. Each contribution makes for efficiency and accuracy in the separation process.

Reboiler: It is located at the bottom of the distillation column and provides heat. The heat from the reboiler vaporizes the liquid mixture and initiates the separation process.

Column Body: The distillation column is composed of a series of trays or packing materials. Such trays or packings, do provide surface area for vaporization, condensation, and mass transfer. The column is divided into several sections, sometimes referred to as "stages," all having particular functions.

Distillation Trays or Packing: These trays or packing inside a column act as surfaces for vaporization and concentration. The trays have holes that allow the passage of vapor to the top, and the packing is typical of resources that allow large surface areas to come into contact with rising vapor and descendant liquid.

Distillate Outlet: This is a point at which the detached and cleaned mechanisms (distillate) exit the column. It is usually located at the top of the column.

Bottoms Outlet: The bottom part of the column is fitted with an outlet for discharge of the remaining mixture, which may further contain higher-boiling mechanisms or scums.

The Distillation Process: Fractional Distillation

Fractional distillation is the most frequently used type of industrial and laboratory method. It conducts a series of cycles of vaporization and condensation inside the column, with each cycle contributing to separation. How it works:

Boiling: The liquid mixture at the base of the column is heated in the reboiler. The component with the lowest boiling point starts to boil and ascends the column.

Mass Transfer: During the rise of vapor from the column, it comes into contact with the liquid either on trays or stuffing. As the vapor condenses, releasing heat and transferring energy to the liquid, so does the mass transfer, which causes higher boiling mechanisms to condense and flow back down.

Equilibrium and Enrichment: At each stage of the column, equilibrium between the vapor and liquid phases is established. The vapor enriches in a lower-boiling component; the liquid enriches in a higher-boiling component.

Multistage Process: This process is repeated in each stage of the column, where the vapor becomes progressively more concentrated in the lower-boiling component as it rises and the liquid becomes progressively more concentrated in the higher-boiling component as it falls.

Separation: Finally, the rich vapor exits the column top with the distillate outlet. Condensed, it comprises purified distillate. While this is happening, the residual mixture in the liquid phase, called "bottoms," comes out of the column via the bottoms outlet.

Conclusion

Rahul Engineering Global Private Limited is a top manufacturing company, specializing in the design, fabrication, and installation of excellent distillation columns in Pune, India. With a strong promise of excellence and client gratification

0 notes

Text

The Importance of Pressure Vessels in the Chemical Industry

Pressure Vessel Design and Fabrication: Best Practices Understanding the Different Types of Pressure Vessels and Their Uses Safety Considerations for Working with Pressure Vessels Maintenance and Inspection of Pressure Vessels:

Pressure vessels are critical components in many industrial processes, particularly in the chemical industry. They are used for storing, processing, and transporting various substances, including gases and liquids, at high pressures and temperatures. As such, pressure vessel design, fabrication, maintenance, and inspection are critical to ensuring the safety, reliability, and efficiency of industrial operations.

At Rahul Engineering PVT LTD, we specialize in pressure vessel design, fabrication, and maintenance, providing our clients with high-quality solutions that meet their specific requirements. In this blog, we'll be discussing the importance of pressure vessels in the chemical industry and sharing best practices for pressure vessel design, fabrication, safety considerations, and maintenance.

The Importance of Pressure Vessels in the Chemical Industry

Pressure vessels are essential in the chemical industry, where they are used for a wide range of applications, including storing and transporting various chemicals, fuels, and gases. They are also used in chemical reactions, where they play a critical role in controlling temperature, pressure, and other process variables.

Properly designed and fabricated pressure vessels are essential for ensuring the safety and reliability of chemical processes. They must be able to withstand high pressures, temperatures, and other environmental factors, including corrosion and chemical attack. Moreover, they must be designed and constructed to meet stringent safety regulations and standards, including ASME, API, and other industry-specific standards.

Pressure Vessel Design and Fabrication: Best Practices

Designing and fabricating pressure vessels require specialized skills, expertise, and equipment. At Rahul Engineering PVT LTD, we follow industry best practices to ensure that our pressure vessels meet the highest standards of safety, reliability, and performance. These include:

Material Selection - The choice of materials is critical to the performance and durability of pressure vessels. We use high-quality materials that can withstand the specific process conditions and environmental factors, including temperature, pressure, and chemical exposure.

Design -We use state-of-the-art software and engineering tools to design pressure vessels that meet our clients' requirements and industry standards. Our design process considers all relevant factors, including structural integrity, stress analysis, fatigue, and corrosion resistance.

Fabrication - Our fabrication process uses advanced welding, machining, and assembly techniques to ensure the highest level of quality and precision. We follow strict quality control procedures to ensure that our pressure vessels meet all specifications and standards.

Understanding the Different Types of Pressure Vessels and Their Uses

Pressure vessels come in various shapes and sizes, depending on their specific application and process requirements. Some of the most common types of pressure vessels include:

Storage Tanks - Used for storing liquids, gases, and other substances under pressure.

Heat Exchangers - Used for transferring heat between fluids or gases.

Reactors - Used for chemical reactions, including mixing, heating, and cooling.

Separators - Used for separating and purifying substances, including gas and liquid mixtures.

Distillation Columns - Used for separating and purifying liquids based on their boiling points.

Safety Considerations for Working with Pressure Vessels

Working with pressure vessels requires strict adherence to safety regulations and standards. Some of the key safety considerations for working with pressure vessels include:

Proper Training - All personnel who work with pressure vessels must receive proper training on the safe use, handling, and maintenance of the equipment.

Safety Devices - Pressure vessels must be equipped with safety devices, including relief valves, rupture discs, and pressure gauges, to ensure safe operation.

Regular Inspection - Pressure vessels must be regularly inspected and maintained to ensure that they are in good working condition and meet all safety regulations and standards.

#pressurevessels #chemicalindustry #safety #design #fabrication #maintenance #inspection #reactors #agitators #materials #qualitycontrol #ASME #API #safetydevices #training #reliability #performance #distillationcolumns #heatexchangers #separators #storage tanks

#pressurevessels#chemicalindustry#safety#design#fabrication#maintenance#inspection#reactors#agitators#materials#qualitycontrol#ASME#safetydevices#training#reliability#performance#distillationcolumns#heatexchangers#separators#storage tanks

0 notes

Text

Gas Dehydration Equipment – Finepac India

Finepac manufacture and supply quality range of process equipment for gas dehydration, TEG and amine contactor. It is very important process in gas processing.

http://finepacindia.in/teg-and-amine-contractors.html

#distillationcolumn#distillation equipment#demister pad#used oil refining#oilwaterseparetion#structured packing#column packing#packed column#static mixers

0 notes

Text

Gas Processing Systems

issuu

Gas dehydration is an important process in gas processing. The produced gas is saturated with water, which must be removed. If not removed it can create problems like corrosion, water condensation and plugs created by ice or gas hydrates. In addition other contaminants like H2S, CO2 and mercaptans must also be removed. Gas treatment systems like dehydration and gas sweetening removes these impurities and makes the gas suitable for transportation and further use.

#biodiesel plant#structured packing#demister pad#distillationcolumn#distillation equipment#distillationunit#used oil refining#oilwaterseparetion#gas dehydration#mist eliminator#packed column

0 notes

Text

Mass Transfer Technology | Finepac

#gas dehydration#column packing#column internals#structured packing#biodiesel plant#demister pad#distillationcolumn#distillation equipment#distillationunit#used oil refining#static mixers

0 notes

Text

Process Design for Separators

In association with Kirk Process solutions, Finepac offers process design and engineering services to develop optimised solutions for your separator vessels by optimising the design concept, vessel sizing and separator internal selection to meet the targeted performance.

#packed column used oil refining gas dehydration oil water separation#structured packing#static mixers#distillationcolumn#distillation equipment#demister pads#gas dehydration#used oil refining

0 notes

Text

Perforated Baffle Plates | Finepac

issuu

After the inlet device, the liquid passes through distribution baffles which may be single or a matched pair of transverse perforated baffle plates in the liquid zone. Their primary function is to provided a barrier and distribute the liquid evenly from the turbulent inlet zone to the calm separation zone.

#static mixers#structured packing#demister pad#biodiesel plant#packed column#column packing#column internals#distillationsystems#distillationcolumn#distillation equipment#demister pads#used oil refining#gas dehydration

0 notes

Text

Conceptual Design Studies in Separation Technologies - Finepac

With our extensive knowhow and unique range of separation technologies, We can provide you with conceptual designs to support you in the development of new or improved processes to help you find the best solution

http://finepacindia.in/conceptual-design.html

#distillationcolumn#distillation equipment#demister pad#static mixers#packed column used oil refining gas dehydration oil water separation

0 notes

Text

Process Design for Separators | Finepac

In association with Kirk Process solutions, Finepac offers process design and engineering services to develop optimised solutions for your separator vessels by optimising the design concept, vessel sizing and separator internal selection to meet the targeted performance.

0 notes