Don't wanna be here? Send us removal request.

Text

Knowledge Sharing Series#2

What is the Process that undergoes in Oil Preheating Furnace?

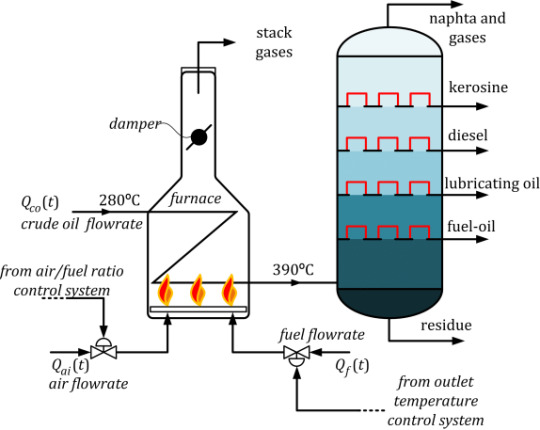

Crude Oil Entry: The desalted crude oil, which has already been heated and mixed with water to remove salt, enters the preheating furnace.

Heat Exchange: The furnace is typically designed with a series of tubes through which the crude oil flows. Hot flue gases, generated by burning fuel (such as natural gas or fuel oil), pass over these tubes, transferring heat to the crude oil.

Temperature Increase: As the crude oil flows through the tubes, it absorbs heat from the flue gases, gradually increasing in temperature.

Desired Temperature: The furnace is carefully controlled to ensure that the crude oil reaches the desired temperature, typically around 350°C to 360°C. This temperature is essential for effective vaporization of the lighter components in the crude oil.

Exit to Distillation Column: Once the crude oil has reached the target temperature, it exits the preheating furnace and enters the atmospheric distillation column, where the separation process begins.

#OilAndGas#Refinery#ChemicalEngineering#ProcessEngineering#Petrochemical#DownstreamProcessing#Distillation#UnitOperations#EnergyIndustry#Fuels#FossilFuels#PreheatingFurnace#CrudeOilPreheating#AtmosphericDistillation#DistillationColumn#HydrocarbonSeparation#RefiningProcess#OilAndGasEquipment#ProcessControl#HeatTransfer#Decontamination

1 note

·

View note

Text

Major Equipment in Atmospheric Distillation Unit (ADU)

The Atmospheric Distillation Unit (ADU) is the primary processing unit in most oil refineries.

It separates crude oil into various fractions based on their boiling points. The following are the key pieces of equipment found in an ADU:

1. Crude Oil Preheat Furnace:

Purpose: Heats the crude oil to a temperature close to its boiling point before it enters the distillation column.

Type: Typically, a fired heater that uses fuel gas or oil to generate heat.

2. Atmospheric Distillation Column:

Purpose: Separates the heated crude oil into different fractions based on their boiling points.

Components:

Tray or Packing: Used to provide contact between the vapor and liquid phases.

Reboilers: Heat the bottoms product to generate vapor.

Condenser: Cools the vapor to condense it into liquid.

3. Fractionators:

Purpose: Further refine certain fractions (e.g., naphtha, kerosene) to meet specific product specifications.

4. Strippers:

Purpose: Remove lighter components from heavier fractions to improve product quality.

5. Heat Exchangers:

Purpose: Recover heat from the process to reduce energy consumption.

Types: Shell-and-tube, plate-and-frame, etc.

6. Pumps:

Purpose: Transfer fluids between different equipment.

7. Piping:

Purpose: Connects the various equipment in the unit.

8. Instrumentation and Controls:

Purpose: Monitor and control the process variables (temperature, pressure, flow rate, etc.).

#oilrefining #petroleum #ADU #crudeoil #fractionation #petroleumengineering #energy #fuels #petrochemicals #chemicalengineering #processengineering #Quora #Question #Answer #Discussion #KnowledgeSharing #Learn #Explore #OilRefining #Petroleum #ADU #Distillation #Engineering #ProcessEngineering #ChemicalEngineering #Energy #Fuel #Petrochemicals #Share #Follow #Like #Comment

#atmosphericdistillationunit#ADU#distillationunit#chemicalengineering#petroleumindustry#refiningprocess#industrialengineering#engineering#science#technology#fractionatingcolumn#reboiler#condenser#overheadcondenser#refluxdrum#pumparound#feedtray#strippingsection#enrichingsection#chemicalplant#oilrefinery#petroleumproducts#processcontrol#automation#engineeringstudent#engineeringlife#education#ADUcomponents#ADUprocess#majorpartsofADU

1 note

·

View note

Video

youtube

Quote #quotes #viral #viralshorts #viralshort #viralvideo #viralvideos #...

0 notes

Photo

_Exude elegance and beautiful by sporting these Elegant Banarasi Cotton Jacquard Work Saree. Gorgeousness is within you!_ Catalog Name: *Mahika Elegant Banarasi Cotton Jacquard Sarees Vol 1* Fabric: Saree - Banarasi Cotton, Blouse - Banarasi Cotton, Size: Saree Length - 5.5 Mtr, Blouse Length - 0.8 Mtr Description - It Has 1 Piece Of Saree With Running Blouse and 1 Piece Of Blouse Work: Jacquard Designs: 8 Easy Returns Available in Case Of Any Issue Price : Rs 749 https://www.instagram.com/p/BvEct8OhHJC/?utm_source=ig_tumblr_share&igshid=kg1yunxr9hsq

0 notes

Text

ASM Handbook - Beryllium and Beryllium Alloys-ASM International (2010)

ASM Handbook - Beryllium and Beryllium Alloys-ASM International (2010)

0 notes