#Draw Wire Potentiometer

Explore tagged Tumblr posts

Text

Draw Wire Potentiometer - Enhance Precision in Motion Sensing

Discover how draw wire potentiometers enhance precision in motion sensing with their high accuracy, versatility, and robust design for various industrial applications.

0 notes

Text

Lab 5: Arduino and P5.js :)

The objective of this lab was to establish serial communication between an Arduino and a P5.js sketch using the P5.SerialControl library. The goal was to read analog input from a potentiometer (or other sensor) and use this data to manipulate a sound parameter in P5.js. This experiment introduces the concept of serial communication and demonstrates how real-world input can create interactive experiences in a digital environment. The materials used were Arduino Uno Hardware , Breadboard, Jumper wires, Potentiometer (10kΩ) Arduino IDE software & P5.js web editor and installed P5.SerialControl library for P5.js (Darwin version).

Descriptive Circuit Overview:

As said above, the circuit consisted of an Arduino Uno, a 10kΩ potentiometer, and a serial connection to a P5.js sketch. The potentiometer is wired with:

The Potentiometer placed in the middle of the bread board.

Ground and power wires connected across the bottom edge of the breadboard.

The middle pin connected to A1 (analog input pin on the Arduino).

One outer pin connected to 5V power in the Arduino.

The other outer pin connected to ground (GND) in the Arduino.

This setup allows the potentiometer to function as a voltage divider. When the potentiometer is turned, the resistance changes, changing the voltage received by the Arduino’s analog input pin. The Arduino was able to read this voltage using the analogRead() command, converted it into a numerical value (range: 0 to 1023), and sent this data to the P5.js sketch over the serial communicator (P5.js Serial.Control).

Schematic:

Code Explanation Overview-Arduino:

The Arduino code initializes one analog pin, A1, to read input from the potentiometer. The values are then sent via the Serial.print() function in a comma-separated format, allowing P5.js to parse them correctly.

Pin Setup: The potentiometer’s pin is set as an input using pinMode(sensorPin, INPUT).

Analog Reading: The values A1 are continuously read using analogRead(sensorPin).

Serial Communication: The values are sent over the serial port using Serial.println(sensorValue);. The comma serves as a delimiter to separate multiple values.

This ensures that the final P5.js sketch can properly interpret and map the incoming data, which would be displayed in the serial console/monitor of the Arduino Uno, Serial Controller, and P5.js web editor console. In other words, the serial controller allows the code to be communicated from the Arduino software to the P5.js. The code is below:

int sensorValue = 0;

int sensorPin = A1;

void setup() {

// put your setup code here, to run once:

pinMode(sensorPin, INPUT);

Serial.begin(9600);

}

void loop() {

// put your main code here, to run repeatedly:

sensorValue = analogRead(sensorPin);

Serial.println(sensorValue);

}

Code Explanation Overview-P5.js:

The P5.js sketch establishes serial communication with the Arduino and reads the sensor data to control a visual representation through the resistance of the potentiometer.

Serial Communication Setup: The script initializes a serial connection using serial = new p5.SerialPort();, lists available ports, and attempts to open the correct one.

Data Reception: The function serial.on('data', gotData); listens for incoming serial data and stores it in a variable.

Data to Visuals: The sensor values are used to control the size of a circle on the canvas (circle(20,20,latestData);) in function draw().

Display of Values: The latest received data is displayed on the screen using text(latestData, 10, 10).

The code is below:

let serial; let latestData = "waiting for data";

function setup() { createCanvas(windowWidth, windowHeight);

serial = new p5.SerialPort();

serial.list(); serial.open('/dev/tty.usbmodem1301');

serial.on('connected', serverConnected);

serial.on('list', gotList);

serial.on('data', gotData);

serial.on('error', gotError);

serial.on('open', gotOpen);

serial.on('close', gotClose); }

function serverConnected() { print("Connected to Server"); }

function gotList(thelist) { print("List of Serial Ports:");

for (let i = 0; i < thelist.length; i++) { print(i + " " + thelist[i]); } }

function gotOpen() { print("Serial Port is Open"); }

function gotClose(){ print("Serial Port is Closed"); latestData = "Serial Port is Closed"; }

function gotError(theerror) { print(theerror); }

function gotData() { let currentString = serial.readLine(); trim(currentString); if (!currentString) return; console.log(currentString); latestData = currentString;

}

function draw() { background(255,255,latestData); fill(0,0,0); text(latestData, 10, 10);

fill(5,200,5); circle (20, 20 latestData);

// Polling method /* if (serial.available() > 0) { let data = serial.read(); ellipse(50,50,data,data); } */ }

Lastly, into the P5.js helm library file of the sketch, we put this P5.js Port Control Script link library in it as well:

<script language="javascript" type="text/javascript" src="https://cdn.jsdelivr.net/npm/[email protected]/lib/p5.serialport.js"></script>

Observations/Analysis:

When manipulating the potentiometer, the values ranged from 0 to 1023 (Arduino’s 10-bit ADC resolution). These values were mapped in P5.js to control the size of the circle in real-time, and went further to change the background color as well. The movement of the shape corresponded smoothly to changes in sensor input, proving the effectiveness of serial communication.

If we had applied the data to sound manipulation, the potentiometer’s values could have been mapped to control frequency, volume, or panning. The map() function would be used to scale the 0-1023 range into an appropriate audio parameter range in P5.js.

A demo video of the outcome is below:

Challenges and Troubleshooting:

Some challenges encountered included:

Serial Port Connection Issues: Initially, P5.js could not detect the correct serial port. This was resolved by having manually specifying the port (serial.open('/dev/tty.usbmodem1301');) in the script. This required a lot of troubleshooting code and hardware at first.

Conclusion:

This lab demonstrated how Arduino and P5.js can communicate through serial data, allowing physical input to control digital outputs. The way. that the potentiometer was able to change the size of the circle, isthe same way it can be used to turn vilume up and down on a device. Understanding serial communication opens up possibilities for interactive installations, such as motion-sensitive visuals or audio-controlled audio experiences. This aspect introduces new ways to map sensor input to audio-visual feedback, an essential skill in creative coding and physical computing.

In the future, this technique could be expanded by integrating multiple sensors and including the synthesis of sound assets to creat an immersive experience.

...Or it could be used in part to make a DIY iPod.

xx

0 notes

Text

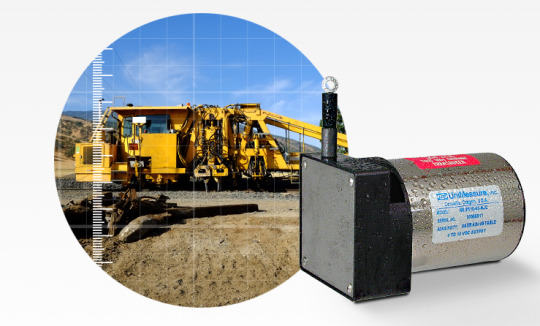

UniMeasure Inc

UniMeasure Inc

UniMeasure, Inc. has been manufacturing position and velocity sensors in Corvallis, Oregon since 1987. The company has steadily grown over the years to become a leader in the linear and rotary transducer industry with a focus on customer service, innovative design, and high-quality products. The Corvallis facility is ISO 9001:2015 certified with many raw materials and vendor services sourced in the local area. With a core group of long-standing employees, UniMeasure is dedicated to manufacturing position sensors in the USA and providing high-quality solutions while further enhancing customer experience.

UNIMEASURE LINEAR POSITION TRANSDUCERS

String Potentiometer

Often referred to as string pot, yo-yo pot, draw wire transducer, cable extension transducer, cable actuated transducer, UniMeasure extending wire rope linear position transducers have proven to be an attractive approach for a multitude of applications in many different industries. With relatively non-critical alignment requirements, compact size, and ease of installation wire rope actuated transducers are the linear position measurement system of choice in applications as diverse as bone densitometers in the medical industry, crash testing in the automobile industry, pump jacks in the crude oil extraction industry and irrigation and flood control in the water management industry. With a wide variety of electrical outputs, UniMeasure linear displacement measuring and position sensor products provide an extremely cost effective method for linear position feedback.

UNIMEASURE ROTARY POSITION TRANSDUCERS

Position Sensor

UniMeasure rotary position transducers provide an analog output signal that is directly proportional to the angle of rotation of the shaft of the device. With a voltage or 4 to 20 mA analog electrical output, UniMeasure rotary position transducers are also known as angle sensors, analog rotary shaft encoders and analog multiturn analog shaft encoders and absolute angle encoders. These position sensor devices are commonly used in applications where an absolute output signal is a must. Typical use occurs in closed loop process control and in testing applications where oscillatory rotary motion occurs. UniMeasure absolute analog rotary position transducers have proven to be an extremely cost effective alternative for measuring rotational positioning.

CONTACT US

UniMeasure Inc https://unimeasure.com/ ADDRESS: 4175 SW Research Way Corvallis, OR 97333 PHONE: (541) 757-3158

Facebook

1 note

·

View note

Text

Global Position Transducers Market growth, trend, opportunity and forecast 2023-2030

Position Transducers Market

The Position Transducers Market is expected to grow from USD 1.70 Billion in 2022 to USD 2.60 Billion by 2030, at a CAGR of 5.30% during the forecast period.

Get the sample report: https://www.reliablebusinessinsights.com/global-position-transducers-market-r1297260

Position Transducers Market Size

Position transducers are devices used to measure linear or rotary positions of objects accurately. The global position transducers market research report categorizes the market based on type, including draw wire linear position transducers, incremental encoder, absolute position encoders, inductive proximity sensors, LVDT transducer, linear potentiometer, magnetostrictive transducer, and non-contact or laser linear position sensors. The report also segments the market by application, including metal processing industries, geotechnics, rubber and plastic injection presses, earth-moving and agricultural machines, blowing machines, renewable energies, machines in the automotive sector, pneumatic and hydraulic sensors, and the food industry, and by region, including North America, Asia Pacific, Middle East, Africa, Australia, and Europe. Leading market players include TE Connectivity, Honeywell, Gerfan, Rota Engineering, Novotechnik, Allergo Microsystems, Panasonic, and Qualcomm Technologies. Regulatory and legal factors specific to market conditions are also analyzed in the report.

Position Transducers Market Key Players

TE Connectivity

Honeywell

Gerfan

Rota Engineering

Novotechnik

Position Transducers Market Segment Analysis

One of the latest trends in the Position Transducers market is the integration of sensors with advanced technologies such as IoT and AI. The sensors are designed to capture position, acceleration, and temperature data, which is then analyzed using advanced data analytics tools to provide valuable insights to manufacturers and service providers. Moreover, the miniaturization of Position Transducers is also a major trend in the market, enabling its installation in small and confined spaces.

In conclusion, the Position Transducers market presents various growth opportunities with its wide target market and increasing demand for automation and motion control systems. However, challenges such as high costs and regular maintenance and calibration requirements need to be addressed to ensure a sustainable revenue growth path. By integrating advanced technologies, manufacturers can enhance their product offerings, which could lead to increased market adoption and revenue growth.

This report covers impact on COVID-19 and Russia-Ukraine wars in detail.

KEY PRODUCT APPLICATION COVERED

Metal Processing Industries

Geotechnics

Rubber and Plastic Injection Presses

Earth-Moving and Agricultural Machines

Blowing Machines

KEY PRODUCT TYPES COVERED

Draw Wire Linear Position Transducers

Incremental Encoder

Absolute Position Encoders

Inductive Proximity Sensors

Contact Info:

Krishna Sharma

US:- +1 507 500 7209Email:- [email protected]

0 notes

Photo

Elmec Heaters offer wide range of Cost economic PID Temperature controller for processing Industries with SSR, Relay, 4 to 20ma, and 0 to 10 Volt out put , Our Micro processor based PID temperature controller can control the temperature ate higher accuracy up to +0.3% . We offer standard din size of 48 * 48 , 48 * 96 and 96 * 96. This temperature sensors are waidly used in Plastic, Rubber, Food processing Industries, Petro Chemical Industries etc,.

Linear magnetic encoder, Linear potentiometer, Draw wire encoder

#Linear potentiometer#linear transducer#Draw wire encoder#Elmec heaters India#Mica band heater#Ceramic infrared heater#Linear magnetic encoder

0 notes

Text

Further development on my Glitch Storm (check that tag for earlier posts). I've become rather fond of listening to the thing as I do other tasks, but it was a little unwieldy for that purpose — it had to be powered by USB, it was all sharp edges and exposed wires, and plugging in headphones required a Rube-Goldbergian series of adapters — first an inline potentiometer to lower the volume to tolerable levels, and then a mono-to-stereo converter so it didn't just drone in the left ear — so I've been upgrading.

The panels it's sandwiched between are 1.5mm thick styrene, purchased at the local hobby shop — they're often used for making buildings for architectural renderings or model railroad layouts. The cuts are a little haphazard — it fits the "glitch" aesthetic, but it's mostly due to not having worked with the stuff before. They're held on by 4-40 screws, under the black screw caps, which are held away from the board by homemade spacers made by cutting aluminum tubing. I do have better drawings of where all the mounting holes are, so a future version of these plates is in the offing.

I was using USB battery packs for a bit, but that gets cumbersome, so yesterday I mounted an on/off switch on the top panel which allows power from a 9v battery to flow in. I need a better mounting solution for the battery than "just holding it", but that'll come.

Finally, today I built a plug-in, all in one headphone adapter — it's a mono plug soldered onto a fader, which is then attached to a stereo jack. I don't have a photo of that — it's right now curing from being partially encased in room-temperature vulcanizing rubber to insulate the connections. That'll reduce the thing down to a single unit, rather than the object itself, two adapters strung on short extension cables, and an outboard battery pack.

(Why a headphone adapter and not just build in a volume knob and use a stereo jack? I still need to plug it into mono stuff — remember, I had to disable stereo output because plugging in a mono plug would short out the output — and without any attenuation, it's at the right level to drive my Eurorack-compatible stuff, so I can have my synth filters and such play with the output. So this way, I can have both worlds.)

1 note

·

View note

Text

SEMA is a hard show at which to properly appreciate cars. On one hand – it’s a show overflowing with some of the best builds you will see all year. On the other hand – it’s that same overflow that makes it almost impossible to keep your wits about you. It’s almost too much of a good thing. In a sea of thousands of cars, I feel like some inevitably get lost. The great thing is: The cars that are truly memorable, the cars you are talking about weeks and months after the show… are cars which rise above the temporary flash-in-the-pan Instagram fame. Some cars deserve to be immortalized. More than digital noise or passing fancy, they draw their inspiration from the timeless. The classic.

This 240Z certainly qualifies as one of these cars. While it has some innovations and forward thinking design elements, it also honors the tradition and legacy of Datsun’s Z car heritage. Car owner Dennis wanted a Z that could be as menacing on the street as it was on the track. In looking to manifest his dreams into reality, he was fortunate enough to meet aspiring builder Kyle Kuhnhausen. Kyle is a fresh out of business school automotive entrepreneur with a penchant for metal work. Ok, more than a penchant… he has a gift. From the paint scheme to the heavily gusseted cage, this car is well thought out & beautifully executed. How well executed? Well, when we talked he made sure I knew that the LS swap was a place holder engine until they built something truly epic for under the hood. WOW. Some place holder.

Let’s take a moment and revel in my three favorite aspects of this car.

First)

There is the paint scheme. Nimbus Grey (or battle ship grey in some parlance) has to be my personal favorite hue on show cars. It’s rich, it allows shadows to adopt a deep dark over tone, and light reflections to be silvery & pronounced. Every truly beautiful design looks amazing in this color. So… win number one? CHECK! The Peter Brock homage striping is as evocative and respectful of the Z’s motorsport heritage as it is a tasteful modern touch of racer bravado. I dig it. Those famous side stripes actually start on the hood at the vents and then cascade over the fender and down the side forming the Brock stripes we are all familiar with. A killer design cue that is at once forward thinking and period correct. Nicely done.

Second)

Let’s talk about that metal work. The Aero is mean, functional, and gives the car a seriously provocative stance. What’s more – it’s designed to just rip/break away cleanly in the case of a momentary lapse in driver skill (for example paying a visit to say, China Beach at the end of the straight at Mid Ohio). Well played Kyle, well played. However, as fantastic as that aero is, it is nothing compared to the beautifully executed roll cage. Meant to be a street car that can participate is serious track time… it had to be a car from which Dennis could easily get in and out. Kyle kept the safety high by fabricating one seriously artful, yet stout, fully gusseted integrated cage. Take a few moments and look at the cage in this car. I have severe race car envy. My race car has race car envy. Seriously. It is so good that it easily merits adjectives like superlative, excellent, exemplary. Bravo.

Third)

And this is one where so many cars sort of take a pass… the gauge cluster. When a car has track day toy duties, it’s easy to just pick up a digital display, mount it up, and just call it done. Not in this car. The cluster in this car is 13 individual pieces of aluminum lovingly hand shaped into what you see before you. It honestly called to mind some of the extreme and bespoke modern interpretations currently en vogue built around the Porsche 911. The Singer cars being the most notable, they take an air cooled 911 and massage every aspect of the car… and polish, preen, & refine it until it is absolutely jewel-like. The perfect 911. Well, that’s where this Z took me. It’s like a really nice 240Z… only polished to the highest possible degree. Everywhere you look there are tasteful touches. This instrument cluster exemplifies that. The angle at which it is canted toward the driver, the alignment of it inside the MOMO wheel. It’s absolutely glorious.

So yeah, this car is one of the highlights of last year’s SEMA show. It truly was. Bespoke modern takes on past classics are hot right now. Cars like the Singer 911s are fetching 500k and more per unit, so it makes builds like this kind of a serious proposition. Get it right and the value and classic status is legitimate. In the end, Dennis can drive this car on the road or the track, confident in the fact that he found the perfect enthusiast to execute his vision. And he can rest well in the fact that he’s now driving the Singer of Datsun 240Zs.

InZanity 240Z

CHASSIS

1972 Datsun 240z shell

10-point fully tig welded roll cage featuring flared hole body tie-in gussets

Lower jacking & towing points welded to bottom of main cage shelfs

Every unibody seam is fully stitch-welded inside & out, and seam sealed

All top strut mounts replaced with camber adjustable heavy duty plates

Pre-load adjustable tie-rod strut braces featured in engine bay

Tig welded fuel cell cradle with integrated rear center mount tow hook

Rear sub-mounted battery with remote charging points and kill switch

Custom tig welded engine & transmission mounts. Optimized center of gravity

50/50 weight distribution

Bolt-in aluminum transmission tunnel stiffeners / driveshaft hoops

Integrated scraping points for oil pan protection

BODY MODS

Trackspec Motorsports heat extracting louvers on hood & front fenders

Front fender-exit side exhaust with custom alloy diffusing louvers

Rear rockers clearanced for functional rear brake vents, and lowered 1.25”

Fender & rear emblems shaved

Antenna & side marker lamps shaved

CNC billet aluminum laser engraved KMC tail lamp insets

CNC billet aluminum quarter panel vent emblems featuring modernized “Z”

Rear bumper & mounts shaved

Symmetrical rear body pan recess, opposed to unsymmetrical stock recess

Front bumper shaved & swissed with dimple die punched holes

Reinforced rear hatch for functional spoiler mounts

Rear quarter panel turbulent air extraction holes with alloy bezels added

Wide “ZG” style flares, adding 6” of width to the rear fender wells

All body gaps cut, welded, and staked.

Shaved hood springs & streamlined hinges

Show grade bodywork

One-piece front & rear windscreen gaskets

POWER

GM 2004 LS1 engine with T56 6-speed manual transmission

Modified & ported 1.625” primary headers ceramic coated in gold

Bespoke 2.5” Fully pie-cut and tig welded exhaust with front X-pipe (167 weld joints)

Dual 8” sectioned Magnaflow Corvette style mufflers mounted in front wheel wells

Improved Racing 180 degree oil cooler thermostat with 400hp Setrab cooler

Holley Coil on Cover valve covers

Radium Engineering FCST fuel cell surge tank and full fuel system

Vibrant Performance –AN fuel lines

Modified stock throttle body with Lokar stainless throttle cable

Custom 4” aluminum air intake with K&N filter outside engine bay

Aluminum crossflow radiator with 16” Flex-A-Lite electric fan and custom shroud

Modified Hurst short shifter with KMC integrated transmission fluid top-fill

Centerforce single disc clutch

ACT Clutch Prolite lightweight flywheel

Custom one-piece driveshaft

Infinity Q45 R200 differential with VLSD limited slip unit and 3:54 final drive ratio

Nissan Armada CV axles

BRAKES

6-piston Wilwood front calipers & 4-piston Wilwood rear calipers

Fully functional ram-air 3” brake ducting to all 4 corners with custom caliper hats

ASD Motorsports hydraulic 16” e-brake system with braided -3an lines

Wilwood billet master cylinder with modified vacuum booster assembly

Optimized pedal box with reduced weight and improved pedal placement

3/16” Stainless hardlines and -3an braided flex lines

Wilwood proportioning valve with hidden custom mount

Remote Wilwood proportionating valve in-cabin adjustment knob custom retrofit

Custom aluminum master cylinder heat shield

SUSPENSION

Full Arizona Z-Car “Track Pack” billet aluminum adjustable suspension

Arizona Z-Car struts with coilover adjustable springs, modified for tire clearance

Apex Engineered bump steer adjustment kit and high steer knuckles.

Full polyurethane bushings

Modified front crossmember for improved roll center

ST Suspension front & rear sway bars with Energy Suspension polyurethane bushings

5 Lug converted hubs with front Wilwood spindles

ARP chromoly extended wheel studs

Stitch welded and reinforced front crossmember

AERO

Custom HDPE adjustable front air splitter with alloy radiator and brake dams

Custom HDPE adjustable rear diffuser with jacking point & air straighteners

Custom HDPE 6” side splitters with exhaust vent & rear brake vents integrated

Aluminum tunnel underbelly, mostly flat under entire car

Pitch adjustable 3-piece rear deck spoiler with Ringbrother’s micro hinges

ARP carbon fiber micro mirrors

Lexan headlamp aerodynamic fillers

4 Piece aluminum radiator ducting with cabin air ducts integrated

#gallery-0-33 { margin: auto; } #gallery-0-33 .gallery-item { float: left; margin-top: 10px; text-align: center; width: 33%; } #gallery-0-33 img { border: 2px solid #cfcfcf; } #gallery-0-33 .gallery-caption { margin-left: 0; } /* see gallery_shortcode() in wp-includes/media.php */

ELECTRONICS

Street and Performance engine wiring harness with reflashed stock ECU

Braille lightweight I25X lithium battery

Bowler Performance phantom key with Honda s2000 push button starter

Fully custom KMC chassis wiring harness

Fully integrated Passport 9500ci radar detector system

Alpine double-din 6” monitor with frenched backup camera, navigation, and satellite radio

Dakota Digital VHX-1100 competition dash with 16 digital readouts

Dakota Digital BIM 1 OBDII gauge interface

EPAS electronic power steering integrated into Woodward steering column with input potentiometer knob on dash

Custom carbon aircraft-style switch panel with u-shaped toggle protectors

Quick Latch removable main electronics panel featuring Marine resettable circuit breakers

WHEELS / TIRES

18” CCW 3-piece LM20 wheels with gloss black lips, satin black centers, and ARP bolts (18×10 front 18×11 rear)

BFGoodrich Rival S 200tw extreme performance tires (275/35zr18 front 315/30zr18 rear)

Gorilla extended race lug nuts

INTERIOR

MOMO Super Cup FIA homologated seats and alloy brackets

MOMO 350mm MOD. 07 suede steering wheel

MOMO 6pt. harnesses

MOMO quick release hub w/ bespoke manually machined adapter to race column

Highly modified pedal box

Longacre 17” wide rear view mirror

Bowler performance billet shift knob and lever

Aluminum bead-rolled hexagonal pattern fuel cell fire wall

Custom alloy center console, and 3-piece alloy bespoke quick removable dash

Smoothed transmission tunnel

Bespoke flared-hole heel plates

Flared-hole fabricated dead pedal and geometry optimized clutch and brake pedals

Custom heater with 4 vents hidden under removable dash

Hexagonally stitched suede door cards with carbon fiber aircraft riveted inserts

PAINT (All Axalta Refinishes Products)

Chromax Mosaic SBBC B9*01 – Color: Ford Stealth Grey

Imron 3.5 HG+ Polyurethane RH-3714 – Color: Gray 057

LF Epoxy DTM Primer Gray 2540S

Chroma Base “4 to 1” 2K Urethane Primer Filler Gray 7704S

Chroma Priemier Premium Appearance Clearcoat 72500S

Epoxy DTM Activator Medium Temp 2505S

Basemaker Medium Temperature 7175S

Activator-Reducer 60-70 Degree 7765S

Plas-Stick Flexible Additive 2350S

Chroma Premier Pro Normal Activator 14305S

#gallery-0-35 { margin: auto; } #gallery-0-35 .gallery-item { float: left; margin-top: 10px; text-align: center; width: 33%; } #gallery-0-35 img { border: 2px solid #cfcfcf; } #gallery-0-35 .gallery-caption { margin-left: 0; } /* see gallery_shortcode() in wp-includes/media.php */

OTHER

Rear sub-mounted SPA Technique fire suppression tank with 6 nozzles in cabin/engine

2-piece removable front chassis-mount tow hook

Proprietary differential snout oiling system with Tilton commercial pump and Setrab cooler

Functional side hood winglet to integrated tig welded alloy coolant expansion tank

Dual “II Much fabrication” differential and fuel system vents with custom bracketry and aluminum hard lines.

Extensive use of ARP 12 Pt. stainless fasteners

Text by Tim Neely Photos by Dominick Barbero

InZane in the Membrane: Datsun 240Z SEMA is a hard show at which to properly appreciate cars. On one hand - it’s a show overflowing with some of the best builds you will see all year.

1 note

·

View note

Text

Advantages Of Using Potentiometers For Motor Speed Control

Motors and machinery in your tools must be able to be controlled at the correct speed if you want them to operate efficiently. If you allow yourself full-speed control, there will be little to no tool chatter and, every time, a flawless machined finish. You may choose the ideal cutting speed for every machining task and maintain your machine's operation at this speed to achieve the best results with full-speed controls. The generator output frequency can be precisely set by adjusting the engine speed with a motor speed potentiometer. Potentiometers come in a variety of varieties and are currently sold on the market. Potentiometers can be divided into two categories: linear and rotational. Motorized potentiometers are used in a range of industrial automation and process control applications, such as speed controls, flow meters, tensioning motors, etc., by providing automatic remote control and using a human control knob. A mechanical potentiometer has been converted into a potentiometer motor control. These devices are simple to install, operate, and maintain. They can be used with synchronizing or load-sharing units as well as supplying speed reference to any electronic regulator or AVR controller. An essential component of many different forms of machinery. These gadgets operate without a power source or additional circuits because they are passive gadgets. They enable precise voltage measurement and the transformation of fixed voltage into variable voltage. Potentiometer applications include managing audio equipment's loudness and measuring the position of a gaming joystick. These instruments do, however, have a significant impact on the marine industry. Advantages of potentiometer

1. Potentiometer works on the zero deflection method, so the possibility of error is very slight.

2. The standardization of potentiometers can be achieved directly by using a standard cell.

3. It is possible to increase the length of the potentiometer wire for a greater degree of accuracy.

4. This device does not draw current from the circuit that it is placed in. Along with the motor speed potentiometer, there is various marine equipment like protection relays, high-speed engine controllers, flexgen power systems, and more. These all make marine operations comfortable and easy. If you are searching for this kind of tool or equipment, Selco USA brings you a range of quality marine equipment.

Originally Published at: https://selcousa.wixsite.com/website/post/advantages-of-using-potentiometers-for-motor-speed-control

0 notes

Text

1. To determine resistivity of two / three wires by plotting a graph between potential difference versus current.

2. To find resistance of a given wire / standard resistor using metre bridge.

OR

To verify the laws of combination (series) of resistances using a metre bridge.

OR

To verify the Laws of combination (parallel) of resistances using a metre bridge.

3. To compare the EMF of two given primary cells using potentiometer.

OR

To determine the internal resistance of given primary cell using potentiometer.

4. To determine resistance of a galvanometer by half-deflection method and to find its figure of merit.

5. To convert the given galvanometer (of known resistance and figure of merit) into a voltmeter of desired range and to verify the same.

OR

To convert the given galvanometer (of known resistance and figure of merit) into an ammeter of desired range and to verify the same.

6. To find the frequency of AC mains with a sonometer.

Experiments Assigned for Term-II

1. To find the focal Length of a convex lens by plotting graphs between u and v or between 1/u and 1/v.

2. To find the focal Length of a concave lens, using a convex lens.

or,

To find the focal length of a convex mirror, using a convex Lens

3. To determine angle of minimum deviation for a given prism by plotting a graph between angle of incidence and angle of deviation.

4. To determine refractive index of a glass slab using a travelling microscope.

5. To find refractive index of a liquid by using convex Lens and plane mirror.

6. To draw the I-V characteristic curve for a p-n junction in forward bias and reverse bias.

_______________________________

#isc #icse #icsevscbse #icsememes #education #likeforlikes #like4likes #likesforlike #likeforfollow #liketime #likeforlikeback #likelike #likers #likeme #followforfollowback #follow #follow4followback #followers #followme #friends #study #instadaily #instagram #instagood #instalike #insta #instamood #instaphoto #instacool #india 📖📖📖📖

0 notes

Text

High torque servo motor arduino

#High torque servo motor arduino manual#

#High torque servo motor arduino full#

Similar to the Sweep sketch, the servo motor signal pin is attached to pin 9 of the Arduino UNO. On the Arduino IDE, go to File > Examples > Servo > Sweep. This library comes with the IDE so no additional downloads necessary. The Arduino Servo library has two easy-to-use examples. By the way, there are other ways to generate PWM besides the hardware PWM on the Arduino. Side note: But it doesn’t mean that the control pin is limited to only a PWM pin. This means this lead must be connected to any of the pins with the ~ in them. The yellow pin is where you would send PWM signals to the Arduino. Remember that the Arduino +5v pin is limited to 500 mA! Thus, the number (and sometimes, type) of servos you can use is limited. My MG996R draws 10 mA at idle, 170 mA when operating but without any load connected and stalls at 1400 mA (!). However, larger servos might draw more current which can reset the Arduino. Most servo motors run on 5V so you can attach the red lead to the Arduino’s +5V pin. Servo motors that don’t produce high torque typically contain plastic gears.Ī better look at the circuit board, dc motor and potentiometer: This servo motor is capable of producing high torque (rotational force), and thus has metal gears inside: Other servo motor brands have different colors for their wires but almost all uses red for +5V and black for ground. Servo Motor InternalsĪs you can see, there are three wires: red for +5V, black for ground and yellow for pulse. There is a way to make a continuous rotation servo and is shown in this tutorial. A continuous rotation servo is stronger than a an ordinary dc motor. The limited possible values for PWM signals needs to be mapped to a smaller range (of angles).

#High torque servo motor arduino full#

Originally designed for converting rotational motion to linear motion, servo motors do not need full 360 degree rotation (see crank mechanism).

There are two reasons why servo motors don’t rotate for a full circle: There is mechanical stop at the gear assembly to limit the rotation of servo motors to 180 degrees. If you want to get the exact pulse width for a specific angle, you must test your servo motor. The exact pulse width could vary per servo motor. The position of the servo motor arm corresponds with the width of the pulse: From SM2608 Hardware Hacking Workshop Also, the gears boost the torque output of the servo motor. The gear assembly slows down the rotation of the motor to a speed that the potentiometer can catch up.

The potentiometer (via voltage divider) generates a voltage equivalent to that of the input pulse that stops the DC motor, indicating equilibrium.

As the motor turns, the gear assembly turns and thus also turns the potentiometer.

When a pulse is applied, the two inputs on the error amplifier is no longer equal and thus the amplifier drives the motor.

The inputs to the error amplifier are equal and the motor is undriven.

When the DC motor is at stop, it means the motor shaft and potentiometer knob are in its equilibrium position.

A servo motor accepts pulses and outputs rotation.

The operation of the servo motor can be described by the diagram below: It follows the concept of servomechanism.

5 Use Potentiometer to Control a Servo MotorĪ servo motor is a special device containing a dc motor, feedback electronics and a set of gears.

4.2 Using Microseconds instead of Angles.

4 Programming an Arduino for Servomotors.

3 Arduino to Servo Motor Wiring Diagram.

#High torque servo motor arduino manual#

We recommend using manual pulse lengths if possible: check if you can set your servo controller to custom pulse lengths and try 0.75ms to 2.25ms. Note that the default servo pulse widths (usually 1ms to 2ms) will not give a full range of motion on this servo. Position "0" (1.5ms pulse) is middle, "90" (~2ms pulse) is all the way to the right, "-90" (~1ms pulse) is all the way to the left. To control with an Arduino, we suggest connecting the orange control wire to pin 9 or 10 and using the Servo library included with the Arduino IDE ( see here for an example sketch). Please note, this servo will 'hold' the position even when no signal is sent! Works great with the Motor Shield for Arduino, our 16-channel Servo Driver, or by just wiring up with the Servo library. Of course, it's not nearly as strong as a standard servo. Good for beginners who want to make stuff move without building a motor controller with feedback & gearbox, especially since it will fit in small places. You can use any servo code, hardware, or library to control these servos. The tiny little servo can rotate approximately 90 degrees (45 in each direction) and works just like the standard kinds you're used to but smaller. Add more power to your robot with this metal-geared MG90D servo.

0 notes

Text

Draw Wire Potentiometer - Enhance Precision in Motion Sensing

Discover how draw wire potentiometers enhance precision in motion sensing with their high accuracy, versatility, and robust design for various industrial applications.

0 notes

Text

Didn’t plug output cables from pins 3 and 4 and was losing my mind trying to get my lights to light up. Haha. Got it working now, understanding how the Arduino’s physical pins correspond within the code a little better.

Having trouble finding my analog input range, statement not printing. Because of that I think my lights just aren’t functioning as they’re supposed to BUT I do have an expected response from touching my sensors and seeing the lights react. It is not an on off situation but they do flicker and such. Will need to figure that out... Figured it out!!! I changed the range arbitrarily as my sensors are different kinds of touch sensors, and got it to where the lights turn on and off.

Next moment that gave me trouble was misinterpreting how I should power my LED from the potentiometer, I was drawing a wire from the left side of the bread board to the right side, as you can see in the next image. I wasn’t conceptualizing the Arduino as a command center as much as it is and didn’t realize that the wire from the A9 pin was all that was needed to control the LED. Also the brown wire is coming from the Ground part of my potentiometer which is just a silly mistake on my part.

Once I removed this useless brown wire, my circuit stopped being confused and the dimmer effect worked perfectly!!

At last I figured out where the Serial Console is, was able to figure out readings for the button lab and sensor lab! The “tap”, “short Press”, “long press” lab got me excited for potential for tinkering with some sound reactive things, messing with pitch based on the time... we’ll see.

0 notes

Text

Use an Arduino touchscreen to draw the waveforms that you’d like your synth to produce

Ordinarily, producing complex waveforms on microcontrollers requires precise adjustments within code in order to work, and this can become quite tedious. Additionally, having to wire up physical inputs such as potentiometers for quick tuning adds a lot of sprawl to a project. This is partially what inspired Kevin, who runs the DIY Electromusic website, to construct a small, Arduino-based device that allows users to sketch the waveform they want outputted via PWM.

The main components of this project are the ILI9488 touchscreen display shield that fits onto an Arduino Uno, along with an amplifier/speaker and an optional output filtering circuit to clean up the audio. Kevin’s unit takes in a MIDI note on the Uno’s RX pin and passes it through a wavetable function that applies the currently shown waveform on the screen to the note being requested.

Kevin also made a slight modification to the previously mentioned project by replacing the wavetable with a series of five sliders that correspond to various parameters for a MIDI granular synthesizer. His analog version had five large potentiometers that plugged into the analog input pins on an Uno, but this newer version greatly cleaned things up and gives more room for experimentation.

To read more about these innovative audio control projects, you can view them on Kevin’s website here and see a quick demo below.

youtube

The post Use an Arduino touchscreen to draw the waveforms that you’d like your synth to produce appeared first on Arduino Blog.

Use an Arduino touchscreen to draw the waveforms that you’d like your synth to produce was originally published on PlanetArduino

0 notes

Text

What is a pendant push button switch and how does it works?

Pendant push button:

The pendant push button is used to control the EOT crane or hoist. The crane pendant station controls the overhead crane with a wired mechanism. Many wire cables are connected from the pendant to the control panel. As soon as the switch button is pressed on the control panel then it immediately provides power to the motors. The crane pendant can control the many moments of the crane including the start and stop buttons. The term crane pendant is designed and commonly used to describe the control unit connected to the crane's electronic mechanism. The device is connected to a long cable and hung from an overhead crane like a pendant. Also known as overhang control or overhang control unit. It draws energy from the same power source that powers the crane itself.

How does the pendant push button switch work?

The pendant push button station works can work with the help of two men. The one who is on the ground floor guiding another man sitting in the cab of an overhead crane or it can be controlled from the ground using buttons or toggle controllers. This control unit can be connected to the crane itself or, like many modern cranes, it can be a remote radio unit. The operator uses a pendant button with a cable attached to the crane and suspended from the overhead crane to control the crane. When the crane crosses the runway, the operator walks alongside the crane. You can use the pendant to control the lifting of the load. Until about ten years ago, all bridge cranes were operated by wired suspension control devices. Industrial machinery, especially EOT Crane & Hoist can be easily controlled from the factory floor. Several combinations of switches can be made using a single speed, double speed, or potentiometer. Any number of buttons requires only four cables of 0.25sq mm main. The button has a top layer of silicones to protect the label from the button.

Types of push-button pendants:

Pendant push button control has many types and they are as follows:

1) Two Buttons:

The EOT crane can be operated in only 2 directions i.e. one up and another in the down direction.

2) Four Buttons:

The four-button push-button pendant switch can control the crane in an up, down, start and stop manner.

3) Six Buttons:

The six-button can comprise the overhead crane in on, off, east, west, up, and down directions respectively.

4) Eight Buttons:

The eight buttons of the pendant switch comprise the hoist crane in up, down, on, off, east, west, north, and south direction.

5) Ten Buttons:

The ten button push-button switch can operate the EOT crane in on, off, up, down, east, west, north, south, one-speed version, and two-speed version in a respective manner.

Reason for choosing pendant control switch:

A pendant control device, or simply a crane pendant device, is a crane control device connected to a crane mechanism. This type of devices are used to control EOT crane operations from the ground without the guidance of ground crews. Nowadays, many cranes use radio-operated control equipment, which can be controlled from a distance. Either the radio remote control or pendant crane control both the devices and their own some advantages and some cons so choosing the controlling the device for EOT cranes is absolutely up to you.

Many industries built the pendant for EOT cranes but the best crane pendant control manufacturers in India you will only get from the Anand systems engineering privately limited. Anand pendant cranes are designed in such a way that they can use for harsh conditions industrial purposes. This pendant switch reduces the manpower because sometimes another man is required to operate the cranes.

#crane pendant#pendant push button switch#crane pendant control manufacturers in India#pendant push button#pendant switch#pendant crane control#pendant push button control#crane pendant cable#pendant push button station

0 notes

Text

Position Transducers Market Research Report And Predictive Business Strategy By 2026: TE Connectivity, Qualcomm Technologies, Rota Engineering

According to Acquire Market Research Position Transducers Market Report 2021 discusses various factors driving or restraining the industry, which will help the future market to grow with promising CAGR. The Position Transducers Research Reports offers an extensive collection of reports on different markets covering crucial details. The report analysis the competitive environment of the Position Transducers Market is based on company profiles and their efforts on increasing product value and production.

The report profiles the key players in the market, along with a detailed analysis of their individual positions against the regional landscape. The study conducts SWOT analysis to evaluate strengths and weaknesses of the key players in the Position Transducers Market. The researcher provides an extensive analysis of the Position Transducers Market size, COVID-19 impact qualitative analysis, share, regional scope, recent trends and advancements, gross revenue, and profit margin to accurately draw a forecast and provide expert insights to investors to keep them updated with the trends in the market.

Get Free Sample PDF (Including Tables and Figures, Charts & Graphs) of Position Transducers Market: https://www.acquiremarketresearch.com/sample-request/375816/

Extensive evaluation of major competitors performing in the global Position Transducers market:

TE Connectivity

Qualcomm Technologies

Rota Engineering

Honeywell

Panasonic

Gerfan

Allergo Microsystems

Novotechnik

The Position Transducers Market competitive landscape provides details by competitor. Details included are organization overview, company financials, revenue generated, Industry potential, investment in research and development, new Position Transducers Market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the company’s focus related to Position Transducers Market.

Position Transducers Market Segmented By Type:

Draw Wire Linear Position Transducers

Incremental Encoder

Absolute Position Encoders

Inductive Proximity Sensors

LVDT Transducer

Linear Potentiometer

Magnetostrictive Transducer

Non-Contact or Laser Linear Position Sensor

Position Transducers Market Segmented By Application:

Metal Processing Industries

Geotechnics

Rubber and Plastic Injection Presses

Earth-Moving and Agricultural Machines

Blowing Machines

Renewable Energies

Machines in Automotive Sector

Pneumatic and Hydraulic Sensors

Food Industry

Grab Your Report at an Impressive Discount: https://www.acquiremarketresearch.com/discount-request/375816/

Furthermore, this Position Transducers Market study will help our clients solve the following issues:

Identifying key cannibalizes: Strong substitute for a product or service is the most prominent threat. Our clients can identify key cannibalizes of a market, by procuring our research. This helps them in aligning their new product development/launch strategies in advance

Cyclical dynamics: We foresee dynamics of industries by using core analytical and unconventional market research approaches. Our clients use insights provided by us to manoeuvre themselves through market uncertainties and disruptions

Interrelated opportunities: This Position Transducers Market report will allow clients to make decisions based on data, thereby increasing the chances that the strategies will perform better if not best in the real world.

Spotting emerging trends: Our Ecosystem offering helps the client to spot upcoming hot market trends. We also track possible impact and disruptions which a market would witness by a particular emerging trend. Our proactive analysis helps clients to have an early mover advantage

Position Transducers Market breakdown data by region: North America (United States, Canada and Mexico), Europe (Germany, France, UK, Russia and Italy), Asia-Pacific (China, Japan, Korea, India and Southeast Asia), South America (Brazil, Argentina, Colombia etc.), Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

Key Questions Answered in Position Transducers Market Report:

What is the size and CAGR of the Position Transducers Industry?

What are the key driving factors of the most profitable regional Position Transducers market?

Which are the leading segments of the Position Transducers market?

How will the Position Transducers Industry advance in the coming years?

What are the main strategies adopted in the Position Transducers market?

What is the nature of competition in the Position Transducers Market?

What growth impetus or acceleration market carries during the forecast period?

Which region may hit the highest market share in the coming era?

What trends, challenges, and barriers will impact the development and sizing of the Position Transducers Market?

How Does This Position Transducers Market Insights Help?

Our Research Specialist Analyses Research Methodology overview consists of Primary Research, Top Company Share Analysis, Secondary Research, Model ( including Macroeconomic indicators, Demographic data, and Industry indicators i.e. Expenditure, sector growth, infrastructure, and facilities, etc), Research Limitations, and Revenue Based Modeling. Comprehensive analysis of Position Transducers Market Based on current analysis & future analysis, which is based on historic data also featured in this Research Reports.

Strategic Points Covered in TOC:

Section 1: Introduction, market driving force product scope, market risk, market overview, and market opportunities of the global Position Transducers market

Section 2: Evaluating the leading manufacturers of the global Position Transducers market which consists of its revenue, sales, and price of the products

Section 3: Displaying the competitive nature among key manufacturers, with market share, revenue, and sales

Section 4: Presenting global Position Transducers market by regions, market share and with revenue and sales for the projected period

Section 5, 6, 7, 8 and 9: To evaluate the market by segments, by countries and by manufacturers with revenue share and sales by key countries in these various regions.

About Us:

We understand the role of data that plays in the growth of business empires.

Acquire Market Research is a market research-based company empowering companies with data-driven insights. We provide Market Research Reports with accurate and well-informed data, Real-Time with Real Application. A good research methodology proves to be powerful and simplified information that applied right from day-to-day lives to complex decisions helps us navigate through with vision, purpose and well-armed strategies. At Acquire Market Research, we constantly strive for innovation in the techniques and the quality of analysis that goes into our reports.

Get in Touch with Us:

Phone No: +1 (800) 663-5579

Email: [email protected]

Website: https://acquiremarketresearch.com/

Address: 555 Madison Avenue, 5th Floor, Manhattan, New York, 10022 USA

0 notes

Text

Post #10: Project Proposal

Project proposal

This project proposal is for the SynthTar, a dedicated music synthesizer built from the components of a single expired home laptop. My aim is to make use of the entirety of the original devices hardware to create a viable musical instrument, wasting nothing. This audio-visual project will demonstrate and uncover the potential and hidden value of obsolete or unused devices for new products, artwork and entertainment. The project will eventually be made open-source to encourage people to replicate it, upcycling the waste in their homes and expanding or developing the ideas.

An old laptop PC will be disassembled into its base components and reassembled into an electronic musical instrument capable of creating sound and visuals. I envision it to be played like a guitar, featuring a main body made from the screen and an extended fretboard design, with PC keyboard keys on the neck to produce notes. The notes could then be manipulated or looped with input devices connected to the internal hardware USB-ports, e.g. a mouse, or an Arduino Midi controller with potentiometers. For example, changing the decay on notes, repeating percussion sequences, and different wave formats.

The sound data would then be translated into visual displays which appear on the laptops original screen. The project is coded with Max, running on the laptop’s processor and internal hardware.

Rationale

The primary purpose of the project lies in the inherently damaging consumerist culture surrounding technology and electronic devices. Phones, laptops and appliances are designed to become obsolete or break down within a matter of years, so that users have to constantly buy the latest model. This uses non-renewable resources, overseas labour and international shipping, which is harmful for consumers and the environment. Meanwhile, the devices which are no longer useful pile up in landfills or in homes.

This project will demonstrate the power and value of upcycling, where waste is reengineered for new purposes. By making new uses for old technology, it will not go to waste and encourage people to engage with this issue in ways they find enjoyable.

The project aims to be both artistic and functional in its rationale, drawing from the likes of Electronicos Fantasticos, who have achieved cultural success and recognition with similar ideas.

The secondary rationale is the visual spectacle and interest factor of the proposed product. People are naturally drawn to unique or novel ideas, particularly over the internet, meaning that others will be able to find entertainment in the project from afar and lend attention to the primary rationale. I believe the project has a good chance to succeed in this aspect.

Build plan

Obtain an unused laptop and disassemble it into its various components. Observe and make note of how different components connect and should be reassembled. (2 days)

Make detailed sketches of the design for the device to follow later (2 days)

Produce main synthesizer program on MAX. Develop the groundwork for a complex MIDI output device with a patch that creates simple notes based on key presses. Create triggering method and output for sounds. (5-10 days)

Add to the initial patch with necessary features such as looping, different sound styles (i.e. the sound of the synth and wave shape, percussion sounds and instrument imitation) and modifiers. (10-15 days)

Source scrap material for the main structure, including metal beams and wood. Design the structure based on materials at hand- This should be a simple frame, and will expose the internal wiring of the device for aesthetic effect. Construct it using basic methods, i.e. with Duct tape. (5-8 days)

Reassemble the laptop components in the desired fashion. Apply them securely to the structure. Add USB devices, external speaker, and MIDI controller. (3 days)

Copy Max patch copy to the internal laptop hard drive and run it on the new device.

Test the finished synthesizer and make final adjustments. (3 days)

Risks

• The laptop components become damaged, break down or are otherwise unusable.

• Computer hardware is quite fragile and will break easily if mistreated. This could cause the entire setup to be ruined and a new laptop would have to be sourced. Great care will need to be taken in disassembling and reassembling.

• Too much time is spent on the MAX synthesizer patch, and not enough left to turn it into the proposed instrument.

• Creating the minimum viable product is important but leaving it at such a stage somewhat defeats the rationale.

• That the laptop cannot be reassembled at the end. Make the hardware exposed to repair and replace where needed.

• Soldering work or other more difficult processes are required. I will ensure I have access to such tools early on.

• Unable to source frame materials from waste. The plan is structured to leave this element until near the end to allow more time to find suitable components.

Legacy

If the project succeeds, it will provide a new method for engaging with old or unused electronic items which can be followed by others and create a new form of musical instrument.

I expect the project to develop my personal skills in presenting coding work to audiences, as well as my technical expertise in working in MAX and generally with Synthesized sound and midi signals- versatile skills which can be applied further to future projects. I hope that the project principles will help encourage people to rethink their approach to the technological waste mounting in their homes and open new ideas about the treatment of waste.

To this end, I hope that the project will find success on the internet and particularly on social media for its entertaining design and premise, if nothing else.

Expected outcome: A working SynthTar running the Max patch. A viable musical instrument which has a pleasant sound, captures the imagination and sticks as much as possible to waste material.

Minimum Viable Product: A working Max patch which functions as a synthesizer, running on an old laptop.

0 notes