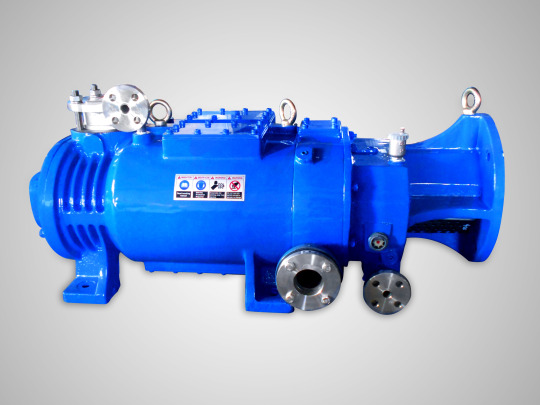

#Screw Vacuum Pump

Text

Comprehensive Guide to Screw Vacuum Pumps and Helium Leak Testing Systems

In the dynamic world of industrial applications, the efficiency and reliability of machinery are paramount. Among the crucial components in various industries are vacuum pumps, which play a significant role in processes ranging from manufacturing to scientific research. One of the standout types of vacuum pumps is the screw vacuum pump. In tandem with advanced helium leak detection systems, these technologies ensure the integrity and efficiency of critical operations. This blog delves into the intricacies of screw vacuum pumps, the importance of vacuum pump servicing and repair, and the role of helium leak detectors in maintaining optimal performance.

Understanding Screw Vacuum Pumps

Screw vacuum pumps are a type of dry vacuum pump known for their robust performance and efficiency. These pumps are designed to handle large volumes of gases and vapors without the need for lubricants or sealing fluids in the pumping chamber, making them ideal for clean applications.

Mechanism and Functionality

Screw vacuum pumps operate using two synchronized, helical screws that rotate in opposite directions within a cylinder. As these screws rotate, they trap and compress air or gas, moving it from the intake to the exhaust side. The compression of gases is achieved without contact between the screws and the cylinder, which minimizes wear and tear and eliminates the need for lubrication.

Key Features

Oil-Free Operation: Screw vacuum pumps do not require oil or other sealing fluids, making them suitable for applications where contamination must be avoided.

High Efficiency: These pumps provide high pumping speeds and consistent performance across a wide range of pressures.

Low Maintenance: The lack of lubricants reduces maintenance needs and operational costs.

Durability: The robust construction of screw vacuum pumps ensures long operational life even in demanding environments.

Applications of Screw Vacuum Pumps

1. Pharmaceutical Industry

Screw vacuum pumps are extensively used in the pharmaceutical industry for processes such as freeze-drying, solvent recovery, and vacuum distillation. Their oil-free operation ensures that pharmaceutical products remain uncontaminated.

2. Semiconductor Manufacturing

In semiconductor manufacturing, maintaining a clean and controlled environment is crucial. Screw vacuum pumps are used in processes such as wafer production and chemical vapor deposition, where their high efficiency and reliability are essential.

3. Food Processing

The food processing industry utilizes screw vacuum pumps for applications like vacuum packaging, dehydration, and freeze-drying. Their ability to handle large volumes without contamination ensures food safety and quality.

The Importance of Vacuum Pump Servicing and Repair

Maintaining the efficiency and reliability of vacuum pumps is critical for uninterrupted operations. Regular vacuum pump servicing and timely repair are essential to extend the life of the pump and ensure optimal performance.

Vacuum Pump Servicing

Vacuum pump servicing involves routine maintenance tasks aimed at preventing potential issues and ensuring that the pump operates at peak efficiency. Key aspects of servicing include:

Inspection and Cleaning: Regular inspection and cleaning of the pump components help prevent buildup of contaminants and wear.

Lubrication: For pumps that require lubrication, ensuring that the correct type and amount of lubricant is used is crucial.

Performance Testing: Testing the pump's performance regularly helps identify any deviations from the optimal operating parameters.

Vacuum Pump Repair

Despite regular servicing, vacuum pumps may encounter issues that require repair. Vacuum pump repair involves diagnosing and fixing problems to restore the pump's functionality. Common repair tasks include:

Seal Replacement: Worn or damaged seals can cause leaks and reduce efficiency. Replacing seals is a common repair task.

Component Replacement: Replacing damaged or worn components such as bearings, rotors, or screws is essential to maintain performance.

Leak Repair: Identifying and repairing leaks in the system helps maintain vacuum integrity and efficiency.

Helium Leak Detection: Ensuring System Integrity

Helium leak detection is a critical process for ensuring the integrity of vacuum systems and components. Helium, being a small and inert molecule, is an ideal tracer gas for detecting leaks with high sensitivity.

Helium Leak Detector

A helium leak detector is a device used to identify and quantify leaks in vacuum systems. The detector typically consists of a mass spectrometer tuned to detect helium ions, which allows it to identify even the smallest leaks.

Helium Leak Testing Machine

A helium leak testing machine integrates the leak detector with automated testing capabilities. These machines are designed to perform comprehensive leak tests on components and systems, ensuring their integrity before deployment.

Helium Leak Testing System

A helium leak testing system includes all the components necessary for performing leak tests, including the helium source, leak detector, testing chamber, and control systems. These systems are used in various industries to ensure the reliability and safety of products and processes.

Applications of Helium Leak Testing

1. Aerospace Industry

In the aerospace industry, ensuring the integrity of components such as fuel tanks, valves, and pipelines is critical for safety and performance. Helium leak testing is used to detect and quantify leaks, ensuring that aerospace components meet stringent standards.

2. Automotive Industry

The automotive industry uses helium leak testing to ensure the integrity of components such as fuel systems, air conditioning units, and engine parts. Detecting and repairing leaks helps prevent failures and improve vehicle safety and performance.

3. Medical Devices

Medical devices such as pacemakers, catheters, and imaging equipment require high levels of reliability and safety. Helium leak testing is used to ensure that these devices are free from leaks, preventing potential malfunctions and ensuring patient safety.

Integrating Vacuum Pumps and Helium Leak Detection

The integration of vacuum pumps and helium leak detection systems is essential for maintaining the efficiency and reliability of critical processes. Here’s how these technologies complement each other:

Enhancing Pump Performance with Leak Detection

Helium leak detection helps identify leaks in vacuum pumps and associated systems, ensuring that the pumps operate at their optimal efficiency. By detecting and repairing leaks, businesses can prevent performance degradation and reduce operational costs.

Ensuring System Integrity

Vacuum systems in industries such as pharmaceuticals, semiconductors, and aerospace must maintain high levels of integrity to prevent contamination and ensure safety. Helium leak detection systems provide a reliable method for ensuring that these systems are leak-free and operating correctly.

Supporting Preventive Maintenance

Regular helium leak testing can be a part of preventive maintenance programs, helping identify potential issues before they lead to significant failures. By incorporating leak detection into maintenance schedules, businesses can enhance the longevity and reliability of their vacuum pumps and systems.

Choosing the Right Service Providers and Equipment

Selecting the right service providers for vacuum pump servicing, repair, and helium leak detection is crucial for maintaining the efficiency and reliability of your operations. Here are some factors to consider:

Expertise and Experience

Look for service providers with extensive experience and expertise in handling various types of vacuum pumps and leak detection systems. Their knowledge and skills are vital for accurate diagnostics, effective repairs, and reliable maintenance.

Quality of Equipment

Ensure that the equipment used for servicing and helium leak detection is of high quality and meets industry standards. High-quality equipment ensures accurate results and reliable performance.

Comprehensive Services

Choose service providers that offer comprehensive services, including installation, maintenance, repair, and leak detection. A one-stop solution provider can simplify management and ensure consistent quality across all aspects of vacuum pump servicing and leak detection.

Conclusion

Screw vacuum pumps and helium leak detection systems are pivotal technologies in modern industrial applications. The oil-free operation, high efficiency, and low maintenance requirements of screw vacuum pumps make them ideal for various industries, including pharmaceuticals, semiconductors, and food processing. Meanwhile, helium leak detection systems ensure the integrity and reliability of vacuum systems, preventing contamination and failures in critical processes.

Regular vacuum pump servicing and timely repairs are essential for maintaining optimal performance and extending the lifespan of the pumps. Integrating helium leak detection into maintenance programs further enhances system integrity and operational efficiency.

By choosing the right service providers and leveraging advanced technologies, businesses can ensure that their vacuum pumps and systems operate at peak performance, supporting high-quality production and maintaining safety standards. In a world where precision and reliability are paramount, screw vacuum pumps and helium leak detection systems stand out as indispensable tools in the industrial landscape.

0 notes

Text

#Helium Leak Detector#Helium Leak Testing Machine#Helium Leak Testing System#Dry Vacuum Pump Manufacturer#Screw Vacuum Pump

0 notes

Text

0 notes

Text

Why do we need to filter compressed air?

Filtering compressed air is essential for various reasons to ensure the proper functioning and longevity of compressed air systems and equipment. Here are some key reasons why filtering compressed air is necessary:

Equipment Protection: Compressed air filters act as the first line of defense for your pneumatic equipment. They prevent contaminants from entering the system and causing damage to sensitive components like valves, cylinders, and air motors. By keeping the air clean and free from harmful particles, filters help extend the lifespan of your equipment and reduce maintenance costs.

Product Quality: Where compressed air is used for product manufacturing or processing, the air quality becomes crucial. Contaminants in the air can contaminate products, affecting their quality and even causing health and safety concerns. Compressed air filters ensure that the air used in these processes is of a high standard, free from particles that can compromise the integrity of the final product.

Energy Efficiency: Clean air is essential for the efficient operation of pneumatic equipment. Contaminants in the air can cause blockages, increase friction, and reduce the system’s overall performance. This can lead to higher energy consumption and increased operating costs. By removing these contaminants, compressed air filters help maintain optimal system performance and improve energy efficiency.

Worker Safety: Depending on the industry, compressed air can be used for various applications, including cleaning, drying, and powering pneumatic tools. When the air contains contaminants, it can pose serious health risks to workers. Compressed air filters help ensure that the air used for these applications is safe and clean, protecting workers from inhaling harmful particles or substances.

Pattons offers filters you need for your compressed air system. Contact us today for more information.

Pattons offers ELGI Airmate Filters

ELGI's Airmate Filters(AF) are suitable for all applications that require filtered air for reliable performance. AF series filters provide the customer with best-in-class filtration and the lowest pressure drop. The filters are manufactured in compliance with applicable international standards (ASME, CE, CRN) and designed according to international quality standards.You can schedule an appointment with our Pattons Systems Specialist to understand the right choice of compressed air filters suited for your specific industrial needs based on your temperature and pressure loss tolerances.

Benefits of ELGi Airmate Filters

Types of Compressed Air Filters

Several types of compressed air filters available, each designed to target specific contaminants and provide different levels of filtration. The most common types include:

Coalescing Filters (Pre-Filter) P: Coalescing filters are used to remove oil and water droplets from the compressed air. They work by capturing these contaminants and allowing them to merge into larger droplets that can be easily drained away.

Particulate Filters (Fine Filter) F: These filters are designed to remove solid particles, such as dust, dirt, and rust, from the compressed air stream. They typically use porous media, such as paper or synthetic elements, to trap and hold these particles.

Carbon Filters (Absorber Filter) C: Activated carbon filters are used to remove odors, vapors, and other gaseous contaminants from the compressed air. They contain a bed of activated carbon that absorbs these substances, leaving the air clean and odor-free.

Maintenance and Replacement

Regular maintenance and periodic replacement are essential to ensure the effectiveness of compressed air filters. Filters should be inspected, cleaned, or replaced according to the manufacturer's recommendations or when the pressure drop across the filter exceeds a certain threshold. Pattons offers genuine OEM air compressor parts for major compressor brands, including filters, lubricants, valves, separators, belts, couplings, drains, and more. At Pattons, our systems specialist and service team can assist you in selecting the appropriate compressed air filters for your needs, as well as ensuring that they are correctly installed and maintained. Pattons is the ideal maintenance partner for your air compressor systems. Our comprehensive preventative maintenance program ensures your equipment runs smoothly and efficiently, extending its lifespan and saving you money. With certified technicians available 24/7 and OEM parts, Pattons provides the highest quality service to keep your machines in top condition. Pattons’ service agreements allow you to customize a plan that fits your specific needs, and our skilled service managers monitor and analyze each service to prevent potential failures. Choose Pattons as your compressed air partner and experience worry-free air compressor operation.

FIND AIR COMPRESSOR FILTERS

#air compressor service#air compressor#compressed air dryers#Air Compressors#Screw Compressors#Reciprocating Compressors#Dryers#Vacuum Pumps#Piping

0 notes

Text

Screw Blowers at Best Price in Manufacturer and Supplier

Screw Blowers at Best Price in Manufacturer and Supplier the Most advanced energy efficient Blower with over 25% saving in power consumption to conventional blowers.

Available in wide sizes upto 9000 m3 / hr.

#air blower exporter#bio gas blowers#bio gas compressors#condencer exhausters#positive displacement blowers#turbo blower#roots blower#truck blowers#vacuum pump manufacturer#roots blower manufacturer#screw blowers

1 note

·

View note

Text

Dry screw pumps are increasingly used in the food industry, replacing wet pumps. An experienced technician has provided a helpful resource outlining the benefits of dry vacuum pumps in food packaging. This source explains the various advantages of dry pumps compared to other types of pumps used in the industry.

1 note

·

View note

Text

Atlas Copco's vacuum pump UAE range includes single stage rotary vane vacuum pumps, 2 stage rotary vane vacuum pumps and oil sealed rotary vane vacuum pumps with VSD technology

#oil sealed rotary vacuum pump#oil sealed rotary vane vacuum pump#vane type vacuum pump#oil lubricated rotary vane vacuum pump#Oil Sealed Rotary SCREW Type Vacuum Pump#Oil Screw Vacuum Pump#vacuum pump#vacuum pumps and systems#atlas copco UAE vacuum pump

0 notes

Text

Kaishan Compressor USA https://kaishanusa.com/ is a diversified industrial equipment manufacturer centering around rotary screw technologies. We are best known for producing compressed air equipment for a variety of industries. We engineer the highest quality rotary screw air compressors that enable us to build a better, more efficient future.

#Air compressors#industrial equipment manufacturer#rotary screw air compressors#rotary screw gas compressors#industrial vacuum pumps#centrifugal air compressors#ORC power generators#steam screw expanders

0 notes

Text

The Evolution and Impact of Modern Vacuum Technology: A Deep Dive into Single Stage Rotary Vane Pumps and Dry Vacuum Pumps

In the realm of industrial machinery, vacuum pumps hold a significant position due to their diverse applications and essential functions. From maintaining contaminant-free environments in semiconductor manufacturing to facilitating efficient operations in the pharmaceutical industry, vacuum pumps are indispensable. Among the various types, single stage rotary vane pumps and dry vacuum pumps stand out for their unique features and broad range of uses. This blog explores these two categories, delving into their mechanisms, applications, and the leading manufacturers that drive innovation in vacuum technology.

Understanding Single Stage Rotary Vane Pumps

Single stage rotary vane pumps are a type of positive displacement pump that utilizes rotating vanes to create a vacuum. These pumps are known for their simplicity, reliability, and efficiency, making them a popular choice in various industries.

Mechanism and Functionality

A single stage rotary vane pump consists of a rotor housed within a cavity. The rotor is offset within the cavity, creating a crescent-shaped gap. As the rotor turns, the vanes extend and retract, trapping air and compressing it against the pump casing to create a vacuum. The single stage design means that the compression process occurs in one step, which simplifies the construction and maintenance of the pump.

Key Features

Compact Design: Single stage rotary vane pumps are typically compact and lightweight, making them easy to integrate into existing systems.

High Efficiency: These pumps are designed to provide high efficiency, ensuring that they can achieve and maintain the desired vacuum levels with minimal energy consumption.

Durability: Built with robust materials, single stage rotary vane pumps are designed to withstand harsh operating conditions, ensuring longevity and reliability.

Applications of Single Stage Rotary Vane Pumps

1. Laboratory and Research

In laboratories, single stage rotary vane pumps are commonly used for applications such as vacuum filtration, degassing, and distillation. Their ability to provide consistent and reliable vacuum levels is crucial for maintaining the accuracy and precision required in scientific research.

2. Medical Industry

The medical industry utilizes these pumps in a variety of equipment, including vacuum-assisted wound closure systems and diagnostic devices. The compact and reliable nature of single stage rotary vane pumps makes them ideal for critical medical applications.

3. Industrial Processes

In industrial settings, single stage rotary vane pumps are used in processes such as packaging, drying, and material handling. Their efficiency and durability ensure that they can handle the demands of continuous operation in a manufacturing environment.

Single Stage Oil Sealed Vane Pumps: Enhancing Performance

Single stage oil sealed vane pumps operate on the same principle as the standard rotary vane pump but with an added layer of oil sealing. This design enhances the performance and longevity of the pump by providing better sealing and lubrication.

Advantages of Oil Sealing

Improved Vacuum Levels: The oil seal reduces leaks, allowing the pump to achieve higher vacuum levels.

Enhanced Lubrication: Oil serves as a lubricant for the moving parts, reducing wear and extending the life of the pump.

Reduced Maintenance: The oil sealing system minimizes the need for frequent maintenance, making these pumps more cost-effective in the long run.

The Role of Dry Vacuum Pumps in Modern Industry

Dry vacuum pumps represent a significant advancement in vacuum technology, offering a cleaner and more efficient alternative to traditional oil-sealed pumps. As their name suggests, dry vacuum pumps operate without the use of oil or other sealing fluids, which presents several advantages.

Types of Dry Vacuum Pumps

1. Dry Screw Vacuum Pump

Dry screw vacuum pumps use two intermeshing screws to trap and compress air, creating a vacuum. The absence of oil in the compression chamber means that the pumped gases remain uncontaminated, making these pumps ideal for sensitive applications.

2. Dry Rotary Vane Pump

Similar to the oil-sealed rotary vane pump, the dry rotary vane pump uses rotating vanes to create a vacuum. However, these pumps are designed to operate without oil, which reduces contamination and maintenance requirements.

Advantages of Dry Vacuum Pumps

Contamination-Free Operation: The absence of oil eliminates the risk of contamination, which is critical in industries such as pharmaceuticals and food processing.

Lower Maintenance: Without the need for oil changes and other fluid maintenance, dry vacuum pumps require less upkeep, reducing downtime and operating costs.

Environmental Benefits: Dry vacuum pumps are more environmentally friendly, as they eliminate the need for oil disposal and reduce the risk of oil leaks.

Applications of Dry Vacuum Pumps

1. Semiconductor Manufacturing

In the semiconductor industry, maintaining a contaminant-free environment is crucial for producing high-quality products. Dry vacuum pumps are used in processes such as wafer fabrication and coating, where even the slightest contamination can affect product performance.

2. Pharmaceutical Production

The pharmaceutical industry relies on dry vacuum pumps for processes such as freeze-drying and vacuum distillation. The contamination-free operation ensures that the purity and quality of pharmaceutical products are maintained.

3. Food Processing

In food processing, dry vacuum pumps are used for applications such as packaging and dehydration. Their ability to operate without oil ensures that food products remain uncontaminated and safe for consumption.

Leading Manufacturers of Vacuum Pumps

Several manufacturers are at the forefront of developing innovative vacuum pump technologies, providing high-quality solutions for various industries.

1. Edwards Vacuum

Edwards Vacuum is renowned for its range of vacuum solutions, including both single stage rotary vane pumps and dry vacuum pumps. Their commitment to innovation and quality has made them a trusted partner for businesses worldwide.

2. Leybold GmbH

Leybold GmbH offers a comprehensive portfolio of vacuum pumps, including single stage oil sealed vane pumps and dry screw vacuum pumps. Their focus on advanced technology and customer satisfaction ensures that they provide reliable and efficient solutions.

3. Pfeiffer Vacuum

Pfeiffer Vacuum is known for its high-performance vacuum pumps, catering to a diverse range of industries. Their dry vacuum pumps are designed to deliver exceptional performance while minimizing environmental impact.

Conclusion

The evolution of vacuum technology, from single stage rotary vane pumps to advanced dry vacuum pumps, has significantly impacted various industries. These pumps are essential for maintaining efficiency, reliability, and cleanliness in critical processes, ensuring that industries can meet their production and quality standards.

Single stage rotary vane pumps, with their compact design and high efficiency, remain a staple in laboratories, medical devices, and industrial processes. The addition of oil sealing further enhances their performance, making them suitable for more demanding applications.

On the other hand, dry vacuum pumps represent a leap forward in vacuum technology. Their contamination-free operation, lower maintenance requirements, and environmental benefits make them an attractive choice for industries such as semiconductor manufacturing, pharmaceuticals, and food processing.

As technology continues to advance, the future of vacuum pumps looks promising. Innovations in energy efficiency, automation, and sustainability will further enhance the performance and versatility of these essential devices. Leading manufacturers like Edwards Vacuum, Leybold GmbH, and Pfeiffer Vacuum will continue to play a pivotal role in driving this progress, ensuring that businesses worldwide can rely on cutting-edge vacuum solutions to meet their evolving needs.

In conclusion, understanding the different types of vacuum pumps and their applications is crucial for selecting the right solution for specific industrial needs. Whether opting for a single stage rotary vane pump for its simplicity and reliability or a dry vacuum pump for its contamination-free operation and environmental benefits, businesses can leverage these technologies to enhance their operations and achieve their goals.

0 notes

Text

Unlocking Precision and Efficiency: Exploring Tekman's Innovative Products

Tekman is a well-known innovator and dependable name in the field of industrial technology. Tekman has a long history of engineering excellence and a solid reputation for providing innovative solutions that raise the bar for the industry. Tekman's wide range of products meets the changing demands of companies in many industries, from sophisticated testing systems to precise machinery. We'll examine Tekman's key goods in-depth in this review, emphasizing their features, advantages, and uses.

The Helium Leak Detector: Precision at Its Finest

The Helium Leak Detector, a complex device that can detect even the smallest leaks with unmatched accuracy, is the centerpiece of Tekman's testing arsenal. The Helium Leak Detector guarantees uncompromised quality assurance, making it ideal for sectors like aerospace engineering and automobile production where product integrity is crucial. Because of its sophisticated sensor technology and user-friendly interface, operators can use it smoothly and identify leaks with ease. Businesses may feel secure in the knowledge that their products exceed the highest standards of safety and dependability when they use the Helium Leak Detector from Tekman.

Streamlining Testing Processes with the Helium Leak Testing Machine

Tekman provides a flexible solution designed to meet the needs of contemporary production environments, the Helium Leak Testing Machine, for companies wishing to optimize their testing methods. With its sturdy build and intuitive interface, this device makes leak detection precise and efficient for a variety of uses. The Helium Leak Testing Machine makes sure that every product, including electronic components and pharmaceutical packaging, is put through a rigorous inspection process before being sold. Tekman's machine enables organizations to improve overall efficiency and optimize their testing operations with its automated capabilities and customized settings.

The Helium Leak Testing System: A Comprehensive Approach to Quality Assurance

The Helium Leak Testing System: A Thorough Method In the current fast-paced industrial environment, thorough quality assurance is a must. In this situation, Tekman's Helium Leak Testing System is useful since it provides a comprehensive method for quality assurance and leak identification. For companies looking to maintain the highest standards of product integrity, this system offers a comprehensive solution through the integration of sophisticated sensors, data analytics, and real-time monitoring capabilities. Tekman's Helium Leak Testing System is engineered for smooth integration into current production lines, guaranteeing little disturbance and optimal efficiency, from initial setup to continuous maintenance.

Leading the Way as a Dry Vacuum Pump Manufacturer

Tekman is at the forefront of innovation when it comes to developing vacuum solutions that satisfy the requirements of contemporary industry. Tekman, a top manufacturer of dry vacuum pumps, provides an extensive selection of pumps with unparalleled dependability and performance. Tekman's dry vacuum pumps are the go-to option for companies in a variety of industries, such as semiconductor manufacturing and pharmaceutical production, because they are precisely engineered and long-lasting. These pumps save maintenance expenses and downtime by maintaining constant suction levels with their energy-efficient design and sturdy construction.

Unleashing Power and Efficiency with the Screw Vacuum Pump

A powerful combination of efficiency and performance, the Screw Vacuum Pump completes Tekman's range of vacuum solutions. This pump, which is designed to withstand the most rigorous applications, uses cutting-edge screw rotor technology to produce excellent vacuum performance while consuming the least amount of energy. Tekman’s Screw Vacuum Pump is an excellent choice for dependable and uniform output in a variety of industries, including chemical processing, food production, and environmental applications. This pump is made to resist the demands of industrial use thanks to its durable construction and user-friendly features, guaranteeing long-term dependability and affordability for companies of all sizes.

A Legacy of Excellence

With a decades-long tradition, Tekman has constantly fulfilled its commitment to quality. With unwavering innovation and a dedication to client satisfaction, Tekman has gained the respect and allegiance of companies all around the world. Its constant commitment to quality and dependability distinguishes it as a market leader with a successful track record.

Partnering for Success

At Tekman, the sale of a product is only the start of an enduring collaboration; the journey never ends. With a staff of committed experts and an extensive global network of service centers, Tekman offers its clients unmatched assistance at every stage of the process. To guarantee seamless operations and optimal uptime, Tekman's specialists are available for installation, training, and continuous maintenance.

Conclusion: Elevating Industry Standards with Tekman

In conclusion, Tekman's wide selection of goods reflects its dedication to quality, innovation, and dependability. Tekman's solutions, which range from high-performance vacuum pumps to precise testing equipment, enable enterprises to reach new heights of production and efficiency. Tekman continues to be a dependable partner for companies looking to stay ahead of the curve as issues emerge and industries continue to change. Tekman is well-positioned to take the lead in influencing the direction of industrial technology because of its consistent commitment to quality.

#Helium Leak Detector#Helium Leak Testing Machine#Helium Leak Testing System#Dry Vacuum Pump Manufacturer#Screw Vacuum Pump

0 notes

Link

Understanding how these devices work can help you make an informed decision when purchasing one for your business needs—so don’t be afraid to ask questions! With proper care and maintenance, your screw vacuum pump can last many years while providing reliable service whenever you need it most!

0 notes

Text

#air compressor service#air compressor#compressed air dryers#Air Compressors#Screw Compressors#Reciprocating Compressors#Dryers#Vacuum Pumps#Piping

0 notes

Text

Vacuum System And Package at Best Price in Noida

Swam dry screw vacuum pumps are designed under SWAM’s unique screw profile engineering to fulfill wide range of chemical and industrial processes. It is operating by rotating a paired screws that efficiently admit gases from inlet into the pump inside and compress through the screw’s swept volume toward the discharge.

For more information Visit Now :https://swamatics.com/ProductDetails.aspx?prod=Vacuum%20Systems%20and%20Packages

#air blower exporter#best process gas blowers#bio gas compressors#Twin lobe blowers#bio gas blowers#Turbo Blower#Mechanical vacuum re compressor#Aeration blowers#Combustion air blowers#Oxidation blowers#Dry screw vacuum pumps#Vane pumps#tri lobe rotary piston#Vacuum system and packages#Tri lobe blowers#Mechanical vacuum boosters

0 notes

Text

Intro Post

This is an 18+ fetish blog. I am 37, cis queer woman. I was on old birth kink Tumblr before the purge and am back now after a few years.

I mostly write short birth stories on reblogs and sometimes some original longer fiction. I don't RP. You can send story prompts, if you like, but no guarantee I'd ever get to them.

Likes:

Long, very painful labors

Long pushing and crowning

Hospital births (stirrups, IV's, catheters, being monitored)

Medical intervention when the patient is struggling (forceps, vacuum, episiotomy)

Painful birth injuries (broken pelvis, broken tailbone, serious tears, ruptured uterus)

Surgical intervention (either a c-section after a very difficult vaginal attempt or repair of birth injuries, up to and including hysterectomy)

Post birth pain (crying while delivering the placenta, whining while tears are stitched up, in a lot of pain going in to or being wheeled out of surgery, being really sore after birth)

Nursing struggles (engorged breasts, pain while nursing, being milked with a breast pump while tears are sewn up or the patient is waking up from surgery)

Not birth related, necessarily, but I also love gynecological and abdominal surgery fantasies, especially around the patient being intubated and then waking up in a lot of pain.

Dislikes:

Children in the room while the person is birthing

Water births

Sensual births (I'd rather their face be screwed up in pure agony, not ecstasy)

#preggo kink#maesiophilia#birth kink#giving birth#labor and delivery#painful birth#med fet#surgical fet#hospital birth

70 notes

·

View notes

Text

Atlas Copco UAE Vacuum Pump Solutions & services.

#vacuumpumpsuae#vacuum pump#industrial vacuum pump#vacuum pumps and systems#dry vacuum pump#oil sealed vacuum pump#vane type vacuum pump#oil sealed rotary vacuum pump#Oil Screw Vacuum Pump#screw type vacuum pump#rotary screw vacuum pump#liquid ring vacuum pump#water ring vacuum pump

1 note

·

View note