#Dry Syrup Powder Filling Machine

Explore tagged Tumblr posts

Text

High Speed Dry Syrup Powder Filling Machine

High Speed Dry Syrup Powder Filling Machine (powder syrup filling machine) including oral syrup filling machine is is suitable for Glass, Plastic, PET, HDPE, LDPE Bottles with maximum speed of 60 to 120 Bottles per minute depending on Powder Fill Volume, Type of Powder, Bottle Diameter and Bottle Neck Diameter.

The Machine works on proven time-tested Vacuum and Air Systems to Fill powder in Bottle achieving higher speed and higher accuracy. Machine with unique Bottle Lifting and Neck Holding system avoid spillage of powder on bottle shoulder, neck and body keeps bottle clean and also avoid wastage of powder. Machine with complete synchronization of Bottle Infeed Star Wheel, Powder Wheel movement and outfeed Star wheel for smoother operation. Machine with Rotary Bottle Moving system ensures very high-speed powder filing through independent moving funnel along with bottles for greater speed and performance without compromising speed and fill accuracy. Machines with unique vibratory system inside the funnel helps filling of semi free flow type powder at higher speed.

0 notes

Text

STARBUCKS DUPE BASICS from a long-former barista:

Starbucks defaults to 2% milk if you don't customize.

If you get a flavored drink, it's 3/4/5 pumps flavor per size (tall/grande/venti) for hot, 3/4/6 for iced. Milk for hot drinks is heated to 160*F for standard, 180 for extra hot. Espresso shot ratio is 1/2/2 for hot and 1/2/3 for iced. I believe all stores use the blonde espresso in their machines as standard.

Torani syrups are the best value and flavor selection but you can get them for half price in TJ Maxx/Home Goods/Marshalls etc vs buying online. If you plan on using them regularly buy a pack of the pumps and straws bc it's way easier to control the amount you put in.

A latte is flavor, espresso, milk. Macchiato is flavor, milk, espresso. Americano is espresso and water.

Cappuccino is half milk foam and half milk. Dry means more foam; wet is less foam.

Cold brew: coarse ground coffee in a mason jar, fill with water, leave in your fridge for 12-24 hours. Dilute with water or milk to taste/heart palpitations. Use a French press or pour over filter to strain the coffee from the grounds.

Iced coffee is double-strength regular coffee that's put in the fridge in a pitcher and poured over ice. Double strength keeps it from being watered down by the ice melting.

Iced matcha can be made with sweetened matcha powder mixed with milk and a simple syrup. I prefer vanilla for a richer taste. Any sweetened matcha powder works, it all tastes similar enough. Shake with ice, do not stir. This can be made in big batches in a glass pitcher and stored in the fridge for a few days to save time.

PSL can be made with torani pumpkin pie syrup mixed with a couple pumps of vanilla. Follow the guidelines above for espresso and milk.

Chai is chai syrup, milk and water (1/2 & 1/2). You can buy the branded chai concentrate at most grocery stores but you could likely find it cheaper online.

You can get a good espresso maker on Amazon for less than $50, this is what I've got and I use it daily with no issues. I use cafe bustelo espresso. A $4 vacuum pack lasts at least a few weeks with daily venti iced drinks for me.

woo so it looks like the boycotts are working

might post more about this later, but a longer-term sustained avoidance of companies that use our money to lobby politicians to act against our interests is, imo, one of the best ways to take our power back from them.

and this impact is from just a few weeks of boycott! so yeah if you didn't already know about this one, get you a coffee machine at home and look up the leaked recipes ;)

25K notes

·

View notes

Text

Precision meets hygiene with Bhagwati Pharma’s advanced Powder Filling Machines, crafted for industries where cleanliness and accuracy are non-negotiable. Whether you're filling dry syrups, sterile injectables, or powdered food and chemical products, these machines offer contamination-free operation and high filling accuracy. Designed to serve pharmaceutical, food, and chemical manufacturing lines, they combine performance with reliability.

visit https://www.bhagwatipharma.com/product-category/powder-filling-machines/

#shreebhagwatipharma#powderfillingmachine#pharmaindustry#foodindustry#ChemicalIndustry#pharmafillingline#foodmachinery#ChemicalProcessing#packagingsolutions

0 notes

Text

Experience unmatched precision with our Automatic Rotary Volumetric Dry Syrup Filling Machine – designed for spill-free, accurate dosing using vacuum technology and No Bottle–No Fill logic. With an 8-cavity powder wheel and Pick & Place Screw/ROPP Capping, it's built for seamless pharmaceutical automation.

To know more, visit- https://www.parthec.com/product/automatic-rotary-volumetric-dry-syrup-filling-with-pick-place-type-screw-cappingropp-capping-machine-monobloc

#parthengineersandconsultant#DrySyrupFillingMachine#VolumetricFillingMachine#RotaryFillingMachine#AutomaticFillingMachine#PharmaceuticalMachinery#ScrewCappingMachine#ROPPcappingMachine#NoBottleNoFill

0 notes

Text

Unwrap - Premium Hazelnut Ganache Chocolate

Gift Hampers| Chocolate Gift Hampers| Cookies Gift Hampers| Personal and Corporate Gifts| Wedding Gift Hampers| Festival Gift Hampers| Dry Fruits| Wafer Rolls| Snacks Gift Hampers| Customized Gifts| Premium Herbal Teas

Joy comes in many flavors, and at Unwrap Happiness, we’ve mastered them all! From velvety chocolates and fragrant teas to the crunchiest nuts, we craft treats that celebrate India’s rich heritage with a fun, modern twist. Whether you’re marking a milestone, sharing a sweet moment, or simply indulging, our beautifully packaged hampers are designed to spread happiness—one bite at a time!

1. Manufacturing Process:

Step 1: Preparing the Hazelnut Ganache

Roast Hazelnuts (if not pre-processed):

Roast hazelnuts at 160°C (320°F) for 10-12 minutes to enhance flavor.

Blend into a fine hazelnut paste.

Melt Dark Chocolate:

Use a double boiler or tempering machine to melt couverture chocolate at 45-50°C (113-122°F).

Heat Cream and Sugar:

Warm heavy cream and glucose/invert sugar until just below boiling.

Emulsify:

Gradually mix the hot cream into the melted chocolate.

Add hazelnut paste and butter for a silky texture.

Stir gently until fully incorporated.

Cool and Set:

Let the ganache cool to room temperature (ideally 18-20°C) before piping.

Step 2: Preparing the French Biscuit (Feuilletine) Layer

Make Biscuit Dough:

Cream butter and sugar.

Add eggs, then fold in flour, baking powder, and salt.

Bake the Biscuit:

Spread thinly on a baking sheet.

Bake at 180°C (356°F) for 10-12 minutes until golden brown.

Let it cool completely.

Crush into Small Crisps:

Break into small feuilletine-style flakes for added crunch.

Step 3: Assembly & Chocolate Coating

Layer the Biscuit and Ganache:

Spread the hazelnut ganache over the crispy biscuit layer.

Allow to set for 4-6 hours at 16-18°C.

Cut into Bite-Sized Pieces:

Once firm, cut into small squares or bars.

Coat with Chocolate:

Temper dark/milk chocolate (31-32°C for dark, 29-30°C for milk).

Dip or enrobe the ganache-filled biscuit pieces in the tempered chocolate.

Decorate & Final Touches:

Sprinkle with chopped caramelized hazelnuts, gold dust, or cocoa nibs.

Let set at room temperature.

2. Ingredients:

Ganache Filling:

Hazelnut Paste (50%) – Made from finely ground roasted hazelnuts.

Dark Chocolate (40%) – Minimum 55-70% cocoa, for richness.

Heavy Cream (35-40%) – For a smooth, velvety texture.

Butter (5-10%) – Enhances mouthfeel and flavor.

Invert Sugar/Glucose Syrup (2-5%) – Prevents crystallization, improves shelf life.

Vanilla Bean Extract – Adds aromatic complexity.

Sea Salt (pinch) – Balances flavors.

Chocolate Coating:

Dark or Milk Chocolate (Couverture, 55%-70% cocoa content).

Cocoa Butter – For a glossy finish and smooth texture.

French Biscuit Layer (Feuilletine or Crispy Base):

Butter – For richness.

Flour – For structure.

Sugar – Adds sweetness and caramelization.

Eggs – Provides structure.

Baking Powder – Helps with lightness.

Salt – Enhances flavor.

Optional: Caramelized Biscuit Crumbs – Adds extra depth.

3. Flavor Profile & Variations:

Main Flavor Notes:

✔ Nutty & Creamy – From roasted hazelnut paste. ✔ Rich & Velvety – From high-quality dark chocolate. ✔ Crunchy & Buttery – From the French biscuit layer. ✔ Balanced Sweetness – Dark chocolate and biscuit provide a contrast.

Flavor Variations:

Salted Caramel Version: Add caramel filling between ganache and biscuit.

Orange Zest Infusion: Enhance with candied orange zest for a citrusy note.

Espresso-Infused Ganache: Mix in espresso powder for a coffee kick.

Milk Chocolate & Hazelnut Praline: Use milk chocolate instead of dark, add more praline.

For More Details: https://www.unwraphappiness.in

#cookies gift hampers#chocolate gift hampers#festival gift hampers#dryfruits#wedding gift hampers#customized gifts#wafers sticks#herbal tea#snacks gift hampers#order gift hampers online

0 notes

Text

Brothers Pharmamach: Your Trusted Partner in Pharma Manufacturing Machinery, Supply & Export

In the pharmaceutical industry, accuracy, effectiveness, and reliability are important. The equipment that powers this sector needs to be cutting-edge, robust, and built to exacting international standards. Brothers Pharmamach takes pleasure in being a reputable brand in pharmaceutical manufacturing equipment, supply, and export since we understand the importance of these needs.

Following Good Manufacturing Practices (GMP), We offer dependable and effective equipment that boosts output in the biotech, pharmaceutical, and healthcare sectors. We are the go-to partner for pharmaceutical producers around the world because of our commitment to quality, innovation, and client satisfaction.

Why Choose Brothers Pharmamach?

With years of expertise and an unwavering commitment to innovation, Brothers Pharmamach has emerged as a leader in manufacturing top-quality pharmaceutical machinery. Here’s what sets us apart:

1. High-Quality and Precision Engineering: Every piece of equipment we produce is made with reliability and accuracy in focus. Our products, which range from packaging and label solutions to filling and closing equipment, guarantee flawless operation, minimizing downtime and increasing production.

2. Extensive Product Range

We offer a comprehensive range of pharmaceutical machinery, including:

Liquid Filling Machines

Washing-and-air-jet-cleaning-machines

Dry-syrup-powder-filling-machines

Capping-machine

Wet-glue-labelling-machines

Sticker-labelling-machine

Shrink-sleeve-machines

Print-apply-systems

Sticker-labelling-unique-features

Other Products

Each of our machines is built to adhere to Good Manufacturing Practices (GMP) and international quality standards.

3. Global Reach & Export Expertise: At Brothers Pharmamach, we don’t just serve the domestic market—we have an extensive global presence. We export to multiple countries, ensuring that pharmaceutical manufacturers worldwide have access to state-of-the-art machinery to enhance their production lines. Our well-established supply chain ensures timely deliveries and reliable after-sales support.

4. Innovation & Customization: We understand that every pharmaceutical company has unique needs. That’s why we offer customized machinery solutions tailored to specific production requirements. Our dedicated R&D team constantly works on developing new technologies to enhance efficiency and compliance.

5. Unparalleled Customer Support: Our company's primary focus is on customer satisfaction. From advice and installation to post-purchase servicing and maintenance, we offer full support. Our team of experts is always available to help customers optimize their manufacturing processes.

Partner with the Best in Pharma Manufacturing

In a competitive industry like pharmaceuticals, having the right machinery partner can make all the difference. Brothers Pharmamach is committed to delivering world-class solutions that empower pharmaceutical manufacturers to achieve excellence.

Looking for reliable pharma manufacturing machinery? Get in touch with Brothers Pharmamach today and take your production capabilities to the next level!

For more info: https://www.brothers.in/ Email ID: [email protected] Location: Plot No. 2, phase II, GIDC, Vatva, Ahmedabad 382445. Gujarat india Phone:9825300706 | 9825006052

#pharmaceutical machinery#pharmaceutical machine#pharmaceutical machine manufacturer#pharmaceutical machine supplier#pharmaceutical machine exporter in india#pharma machinery#pharma machinery manufacturer#pharma machinery supplier#pharmaceutical machinery manufacturers in ahmedabad

0 notes

Text

High-Speed Dry Syrup Powder Filling Machine – Shree Bhagwati Pharma

🔹 Efficiency: Fast processing, multiple filling heads, continuous operation. 🔹 Accuracy: Precise auger filling, minimal wastage, quality compliance. 🔹 Versatility: Handles various powders, ideal for pharma, food & cosmetics. 🔹 Functionality: Monoblock design, secure capping, reduced manual work. 🔹 Performance: Robust build, uninterrupted operation, multiple configurations.

🔗 Product Link: https://www.bhagwatipharma.com/product-category/dry-syrup-powder-filling-machine/

📩 Contact: [email protected]

📞 +91-9099940862

#DrySyrupFilling#PharmaMachinery#PowderFillingMachine#BhagwatiPharma#HighSpeedFilling#AutomatedPackaging

0 notes

Text

While conventional bore seals are cost-effective and easy to fit, they lack the reliability needed for secure sealing, often leading to leaks during transit. Temperature, natural relaxation, and mechanical stress can compromise their integrity. For a more dependable solution, our Automatic Induction Cap Sealing Machine offers rapid, high-tech sealing performance. With touch screen controls and superior system reliability, this machine is the ideal choice for industries like pharmaceuticals where precision is paramount.

For more details, visit - https://www.bhagwatipharma.com/automatic-auger-type-dry-syrup-powder-filling-machine/

0 notes

Text

Dry Syrup Powder Filler

Dry Syrup Powder Filler (Powder suspension filling machine) including dry syrup filling machine is powder filler suitable to fill large volume powder into PET/glass bottles. Filling Machine suitable to fill up to containers per minute depending on Powder Fill Volume, Type of Powder, Bottle Diameter and Bottle Neck Diameter.

The Machine works on proven time-tested Vacuum and Air Systems to Fill powder in Bottle achieving higher speed and higher accuracy. Machine with unique Bottle Lifting and Neck Holding system avoid spillage of powder on bottle shoulder, neck and body keeps bottle clean and also avoid wastage of powder. Machine with complete synchronization of Bottle Infeed Star Wheel, Powder Wheel movement and outfeed Star wheel for smoother operation. Machine with Rotary Bottle Moving system ensures very high-speed powder filing through independent moving funnel along with bottles for greater speed and performance without compromising speed and fill accuracy. Machines with unique vibratory system inside the funnel helps filling of semi free flow type powder at higher speed.

0 notes

Text

A Comprehensive Guide to Key Industrial Machines and Their Applications

In the industrial world, efficiency, precision, and quality are non-negotiable. Machines like packaging systems, shrink wrap machines, label printers, capsule filling machines, and visual inspection equipment are essential to meeting these standards. This article explores these critical machines, highlighting their features, benefits, and applications.

Machines for Packaging: Enhancing Productivity and Quality

Overview: Packaging machines are indispensable in manufacturing, ensuring products are packed securely and efficiently. Machines for Packaging cater to a variety of industries, from food to pharmaceuticals.

Key Features and Benefits:

Speed and Efficiency: Automates the packaging process, reducing manual labor.

Versatility: Supports multiple packaging formats like boxes, pouches, and bottles.

Cost-Effectiveness: Reduces material waste and operational costs.

Applications:

Food packaging (snacks, beverages).

Pharmaceutical packaging (tablets, syrups).

Cosmetic product packaging.

Example Product: Explore Packaging Machines for more details.

Shrink Wrapper Machines: Perfecting Product Bundling

Overview: Shrink wrapper machines use heat to apply a tight plastic film around products, offering a professional appearance and added protection.

Key Features and Benefits:

Protection: Shields products from dust, moisture, and damage.

Customizable Settings: Adjusts film thickness and heat for various product sizes.

Durability: Suitable for high-volume operations.

Applications:

Bundling beverages in multi-packs.

Packaging electronics and industrial tools.

Wrapping books and magazines.

Example Products:

Shrink Wrap Collating and Bundling Machine.

Shrink Wrap Machines: Simplifying Packaging Solutions

Overview: Shrink wrap machines are a variant of shrink wrapping machine designed for flexible, compact packaging, often used in retail and manufacturing.

Key Features and Benefits:

Ease of Use: Simple controls for quick operation.

Compact Design: Ideal for small to medium-sized operations.

Enhanced Appearance: Provides a clear, professional finish.

Applications:

Retail packaging of consumer goods.

Securing items for transportation.

Labels Printing and Sticker Label Printers: Precision in Branding

Overview: Label printing machines and sticker label printers enable manufacturers to customize labels for products, enhancing branding and compliance.

Key Features and Benefits:

High-Resolution Printing: Delivers sharp and clear labels.

Speed and Efficiency: Handles large volumes with ease.

Flexibility: Supports various materials and designs.

Applications:

Printing barcodes for retail.

Producing custom labels for branding.

Regulatory labeling in pharmaceuticals.

Example Product: Learn More About Labels Printing.

Capsule Filling Machines: Streamlining Pharmaceutical Production

Overview: Capsule filling machines automate the process of encapsulating powders, granules, or liquids into capsules.

Key Features and Benefits:

High Precision: Ensures accurate dosage in each capsule.

Automation-Friendly: Reduces manual intervention, increasing productivity.

Versatility: Handles a range of capsule sizes.

Applications:

Pharmaceutical companies for medicines.

Nutraceuticals for dietary supplements.

Cosmetics for encapsulated beauty products.

Example Product: Tablet and Capsule Counting and Filling Machine.

Stand-Up Pouches: Flexible and Efficient Packaging

Overview: Stand-up pouches are widely used for their convenience, durability, and ability to showcase products effectively.

Key Features and Benefits:

Space-Efficient: Stands upright for easy storage and display.

Eco-Friendly Options: Made from recyclable materials.

Customization: Available in various sizes and designs.

Applications:

Packaging snacks, coffee, and dry goods.

Storing chemicals or industrial powders.

Retail packaging for premium products.

Visual Inspection Systems: Ensuring Quality Assurance

Overview: Visual inspection systems utilize cameras and sensors to detect defects or inconsistencies in products.

Key Features and Benefits:

High Accuracy: Identifies defects undetectable to the naked eye.

Automation-Friendly: Integrates seamlessly into production lines.

Real-Time Reporting: Provides instant feedback for quality control.

Applications:

Inspecting pharmaceutical tablets for defects.

Detecting labeling errors in packaged goods.

Monitoring assembly lines for product consistency.

Conclusion

From packaging machines to visual inspection systems, these industrial tools are the backbone of modern manufacturing. They enhance productivity, maintain quality standards, and reduce operational costs, making them invaluable to businesses worldwide.

Whether you're bundling products with shrink wrappers or ensuring precision with label printing machines, investing in the right equipment is essential for scaling operations and staying competitive.

youtube

FAQs

What are shrink wrap machines primarily used for? Shrink wrap machines are used to encase products in a protective plastic film, providing durability and aesthetic appeal.

Can packaging machines handle multiple types of products? Yes, modern packaging machines are designed to handle various product types, including liquids, powders, and solids.

What is the role of capsule filling machines in the pharmaceutical industry? Capsule filling machines automate the encapsulation process, ensuring accurate dosages and efficient production.

Why are visual inspection systems important? Visual inspection systems ensure product quality by detecting defects and inconsistencies during production.

Are stand-up pouches eco-friendly? Yes, many stand-up pouches are made from recyclable materials, making them a sustainable packaging option.

0 notes

Text

Top Manufacturing Solutions for Pharma & Cosmetic Industries

In the dynamic world of pharmaceutical and cosmetic manufacturing, quality, efficiency, and precision are paramount. At Pharmachem Cosmetics, we understand the importance of using state-of-the-art equipment to ensure top-tier products. Whether you're producing ointments, oral liquids, or other cosmetic formulations, having the right machinery is crucial for success. In this blog, we'll highlight essential equipment and machinery that every manufacturer in the pharmaceutical and cosmetic industries should consider.

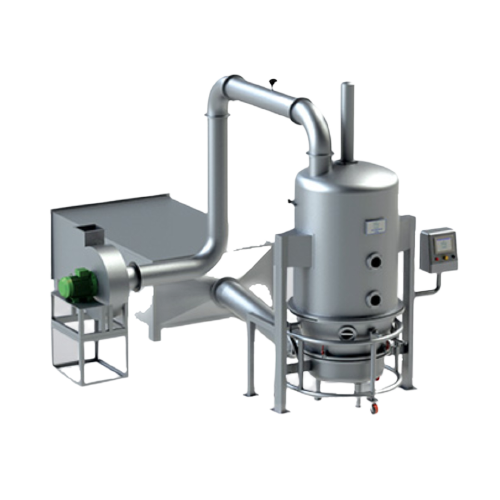

1. Fluid Bed Dryer Manufacturers: Enhancing Product Drying Efficiency

When it comes to drying powders, granules, or other materials in the pharmaceutical and cosmetic industries, Fluid Bed Dryers are indispensable. These dryers operate on the principle of fluidization, where hot air flows through the material, reducing moisture content quickly and efficiently. Fluid Bed Dryer Manufacturers like Pharmachem Cosmetics offer equipment designed for consistency, high-quality results, and energy efficiency, making them ideal for drying sensitive products such as powders, granules, and even some ointments.

Choosing the right Fluid Bed Dryer can significantly impact production timelines and product quality. At Pharmachem Cosmetics, we offer advanced Fluid Bed Dryers that meet industry standards and are customizable for different batch sizes and material types. Our equipment ensures uniform drying, preventing clumping and enhancing the overall product stability.

2. Ribbon Blender Mixer in Maharashtra: Optimal Mixing for Uniform Results

Uniformity in mixing is crucial for the success of any pharmaceutical or cosmetic product. The Ribbon Blender Mixer, a common choice in manufacturing plants, provides an efficient solution for blending powders and granules. This versatile equipment ensures thorough mixing of dry ingredients, resulting in uniform consistency throughout the batch.

Pharmachem Cosmetics, based in Maharashtra, is a leading provider of Ribbon Blender Mixers known for their precision and reliability. Whether you are blending active pharmaceutical ingredients (APIs) or cosmetic powders, our Ribbon Blender Mixers are designed to handle a wide range of formulations with ease. By providing a homogeneous blend, these mixers help in achieving the desired product quality, reducing waste, and optimizing production time.

3. Liquid Oral Manufacturing Plant Suppliers: The Backbone of Liquid Formulations

The demand for liquid oral medications and cosmetic products is on the rise. Whether it’s syrups, tonics, or oral gels, the liquid formulation process requires specialized manufacturing plants equipped with the latest technology. Liquid Oral Manufacturing Plant Suppliers like Pharmachem Cosmetics provide cutting-edge equipment for the smooth production of liquid formulations.

From raw material mixing to bottling and packaging, our liquid oral manufacturing plants are designed to ensure safety, hygiene, and efficiency. With automated systems and robust machinery, we help streamline your liquid production process, reducing contamination risks and ensuring consistent product quality. As a trusted supplier in the industry, Pharmachem Cosmetics ensures that your plant meets regulatory standards and operates at peak performance.

4. Ointment Manufacturing Plant Dealers: Producing High-Quality Ointments

Ointments are among the most widely used formulations in both the pharmaceutical and cosmetic industries. From topical treatments to skincare products, the right manufacturing process is essential to ensure the effectiveness and safety of the ointment. Pharmachem Cosmetics offers high-quality Ointment Manufacturing Plants, designed to produce consistent and reliable ointments for a variety of applications.

Our ointment manufacturing plants are equipped with advanced machinery such as mixers, homogenizers, and filling machines, designed to handle both small and large batches. As leading Ointment Manufacturing Plant Dealers, we provide you with everything you need to produce high-quality ointments while adhering to strict regulatory guidelines.

5. Multi Mill Manufacturers: Versatile and Efficient Milling Solutions

The Multi Mill is one of the most versatile machines used in the pharmaceutical and cosmetic industries. Capable of performing a range of functions such as grinding, milling, shredding, and crushing, the Multi Mill is an essential tool for reducing the size of materials for further processing. Whether you are working with APIs, herbal ingredients, or cosmetic raw materials, the Multi Mill ensures uniform particle size reduction, improving product consistency and performance.

At Pharmachem Cosmetics, we are proud to be recognized as leading Multi Mill Manufacturers, offering equipment that guarantees high throughput, durability, and ease of maintenance. Our Multi Mills are designed with user-friendly controls and are highly adaptable to different production needs.

Conclusion: Quality Equipment for Exceptional Products

At Pharmachem Cosmetics, we are committed to providing the highest quality manufacturing equipment for the pharmaceutical and cosmetic industries. Whether you are in need of Fluid Bed Dryers, Ribbon Blender Mixers, Liquid Oral Manufacturing Plants, Ointment Manufacturing Plants, or Multi Mills, we offer cutting-edge solutions to meet your production requirements.

Partner with Pharmachem Cosmetics today and elevate your manufacturing process to new heights. Our equipment ensures precision, efficiency, and safety in every batch, helping you deliver exceptional products to your customers.

#Multi Mill Manufacturers#Ribbon Blender Mixer in Maharashtra#Fluid Bed Dryer Manufacturers#Liquid Oral Manufacturing Plant Suppliers#Ointment Manufacturing Plant Dealers

1 note

·

View note

Text

Brothers Pharmamach Sticker Labelling Machines and Powder Filling Machine

Brothers Pharmamach has been strengthening its positions as the Pioneer in the Packaging Machine Manufacturing industry in India. Brothers Pharmamach, the largest Manufacturers & Exporter of Pharmaceutical and Labelling Machinery in India is a result of a merger between some of the leading brands such as BHAVANI & AMBICA Labelling.

Sticker Labelling Machine Manufacturer

The largest Manufacturers & Exporter of Sticker labelling machines are essential in various industries for applying labels to products, ensuring accurate and efficient packaging.

Automatic sticker labelling machine

sticker labelling machine for bottle

round bottle sticker labelling machine

hologram sticker labelling machine

Ampoule Sticker Labelling Machine

Rotary Bottle Sticker labelling machine

label applicator label dispenser security

label applicator tax label applicator

Tube labelling machine

Powder Filling Machine Manufacturer

The largest Manufacturers & Exporter of Powder filling machines are crucial in industries that handle powdered products, such as pharmaceuticals, food, and chemicals.

automatic dry syrup filling machine

dry syrup filling machine

dry syrup powder filling line

dry syrup filling and sealing machine

Linear auger powder filling machine

For More Details Click here : https://www.brothers.in

0 notes

Text

The Auger Type Powder Filling Machine ensures accurate powder dosing with an advanced pneumatic bottle holding system. Equipped with a PLC-controlled auger mechanism, this system guarantees precise filling, seamless operation, and contamination-free processing. The integration of bottle sensors and magnetic clutch technology enhances accuracy, ensuring that each bottle is filled with the exact amount before release.

For more details, visit- https://www.bhagwatipharma.com/automatic-auger-type-dry-syrup-powder-filling-machine/

0 notes

Text

Dozing unit for accurate filling, Suitable for Powders like talcum powder, tooth powder, hygroscopic powders like Horlicks, boost, bournvita, complan etc; Powder Spices like chilly powder, turmeric powder, hing etc; coffee in powder form, ayurvedic Churan, dry syrup, pesticides, other various types of NON FREE flowing powders.

0 notes

Text

Ever wondered how our Automatic Rotary Volumetric Dry Syrup Filling Machine operates? It begins by precisely dispensing and measuring dry syrup powder into containers using an auger type filling mechanism. The rotary mechanism ensures continuous operation, optimizing efficiency throughout the filling process. Integrated sensors maintain precision control, ensuring accurate dosage and preventing wastage. After filling, seamless integration with packaging equipment completes the process, readying products for distribution.

For more information, visit - https://www.parthec.com/product/category/dry-syrup-powder-filling-machine-line

0 notes

Text

Pharmaceutical Filling Machines and their Applications

The pharmaceutical industry relies on accurate and efficient technology to deliver life-saving treatments. One crucial component in this process is the pharmaceutical filling machine. These machines play a vital role in ensuring accurate and consistent dosing of medications into various containers, from tablets and capsules to vials and syringes.

Pharmaceutical Filling Machines

From Powders to Liquids, Filling Every Need

Pharmaceutical filling machines are the workhorses of pharmaceutical production. They automate the process of filling pre-determined quantities of medication into specific containers. This not only ensures accuracy and consistency but also significantly increases production speed compared to manual filling. These machines are designed to handle a wide range of products, from delicate powders and tablets to viscous liquids and creams.

The Uses of Pharmaceutical Filling Machines

Ensuring Sterility and Streamlining Production

The applications of pharmaceutical filling machines extend far beyond simply filling containers. Many machines are equipped with features that ensure the sterility of the filling process, a critical factor in maintaining the safety and efficacy of medications. Additionally, some filling machines can be integrated with other equipment such as capping and labeling machines, creating a streamlined production line for maximum efficiency.

Types of Pharmaceutical Filling Machines: A Machine for Every Need

Pharmaceutical Filling Machines Manufacturer in India

At Lodha Machines, we understand the diverse needs of the pharmaceutical industry. That's why we offer a wide range of pharmaceutical filling machines. We manufacture Pharmaceutical Filling Machines in India and offer a variety of pharma machines, including:

Liquid Filling Machines: Liquid Filling Machines ensure accurate and efficient filling for medications with various viscosities, from thin liquids like mouthwashes to thicker syrups and suspensions. These machines utilize different filling methods depending on the product's properties, ensuring consistent dosing for every container.

Powder Filling Machines: Designed for precise dosing of powdered medications, Powder Filling Machines can handle a wide range of powder flow characteristics. They often employ auger filling systems or volumetric dosing techniques to accurately measure and fill powders into capsules, tablets, and other dry dosage forms.

Injectable Liquid Filling Machines: Injectable Liquid Filling Machines are crucial for maintaining the sterility and safety of injectable medications. They incorporate features like laminar airflow systems and sterilized filling nozzles to ensure aseptic filling of syringes and vials with liquid pharmaceuticals.

Dry Syrup Filling Machines: Efficiently handle the unique flow properties of dry syrups, which can be both light and fluffy yet prone to clumping. Dry Syrup Filling Machines utilize specialized filling techniques to ensure accurate and consistent dosing, preventing issues like underfilling or product bridging within the container.

Syrup Filling Machines: Ideal for filling various types of syrups and suspensions, Syrup Filling Machines offer versatility for handling liquids with a range of viscosities. They often utilize volumetric filling principles or pump systems to ensure consistent and accurate dosing for each container, maintaining the intended concentration of the medication.

Ointment Filling Machines: Precisely dispense ointments, creams, and gels, ensuring consistent product delivery for topical medications. Ointment Filling Machines handle viscous materials with ease, employing filling techniques like piston pumps or volumetric dosing systems to accurately fill tubes, jars, or other containers.

Tablet and Capsule Filling Machines: High-speed machines for accurate counting and filling of tablets and capsules. Lodha Machines, a leading capsule filling machine manufacturer, offers a variety of options to suit your needs, from basic capsule fillers to high-capacity machines with automated counting and sorting systems (capsule filling machine price may vary depending on features).

Capping and Sealing Machines: Securely seal containers after filling, ensuring product integrity and preventing contamination. Capping and Sealing Machines are comes in various configurations, from simple capping machines for applying lids to more complex sealing systems that utilize heat, pressure, or a combination of both to create a tamper-evident seal.

Sticker Labeling Machines: Apply labels for product identification and information. Sticker Labeling Machines integrate seamlessly with filling lines, automatically placing labels on containers with precise positioning and ensuring consistent application. They can handle various label types and sizes, providing essential product information for patients and healthcare professionals.

Ampoule Filling Machines: Designed for the specific requirements of filling ampoules, which are fragile glass vials used for sterile injectable medications. Ampoule Filling Machines handle ampoules with care, employing gentle filling processes and sterilized environments to maintain product sterility and prevent breakage.

Vial Filling Machines: Efficiently fill vials of various sizes, used for a wide range of liquid and powdered medications. Vial Filling Machines offer versatility, accommodating different vial sizes and ensuring consistent filling levels. They may utilize volumetric filling methods or pump systems depending on the product's characteristics.

Sterile Filling Machines: Maintain a sterile environment throughout the filling process, critical for injectable medications and other pharmaceuticals requiring aseptic conditions. Sterile Filling Machines incorporate advanced features like laminar airflow systems, HEPA filters, and sterilized filling components to prevent contamination throughout the filling process.

Conclusion

One stop solution for Pharmaceutical Machinery

Pharmaceutical filling machines are a critical investment for any pharmaceutical company. They ensure the accuracy, efficiency, and sterility of medication production. Lodha Machines, a trusted pharmaceutical machinery manufacturer company that are offering variety of pharma machine in india, including tablet making machine manufacturers and Powder Filling Machine, offers a comprehensive range of filling machines to meet your specific needs. Contact Lodha Machine today to discuss how our machines can help you streamline your production process and deliver life-saving medications with confidence.

If you have any questions regarding the filling machines for pharmaceutical industry, please visit our site or contact our team at Lodha Machine at [email protected] or +91-9687731331, +91-9687631331.

#Pharmaceutical Filling Machines#Top Pharmaceutical Filling Machines#Pharmaceutical Filling Machines Manufacturer#Pharmaceutical Filling Machines in India

0 notes