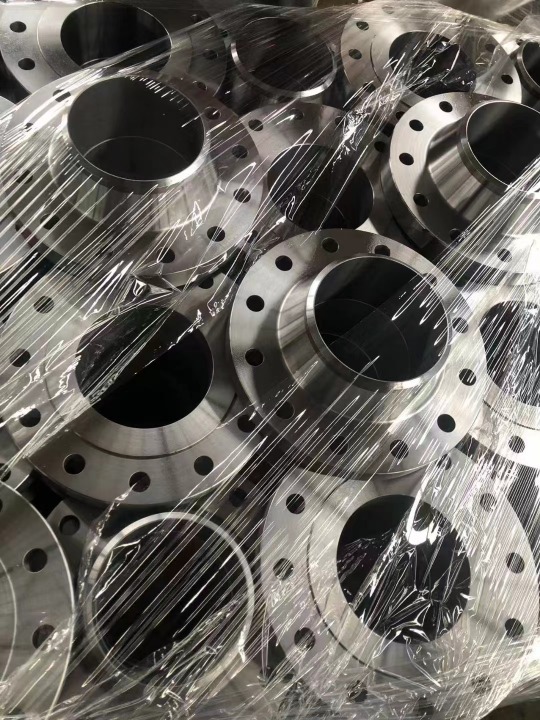

#Duplex steel flange

Text

Fully automatic flange CNC lathe

45 years of professional pipe fittings and flange manufacturers and suppliers

Duplex steel S3225 A815 WPS32205

1 note

·

View note

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

SS Flanges | EIL Approved Flanges | IBR Approved Flanges - Riddhi Siddhi Metal Impex

Riddhi Siddhi Metal Impex is one of the leading manufacturers of stainless steel flanges in India.

Stainless Steel Flanges: https://riddhisiddhimetal.com/stainless-steel-flanges-manufacturer-india/

EIL Approved Flanges: https://riddhisiddhimetal.com/eil-approved-flanges-manufacturers-india/

IBR Approved Flanges: https://riddhisiddhimetal.com/ibr-approved-flanges-manufacturers-india/

For more detailsVisit our website: https://riddhisiddhimetal.com/.

#Stainless Steel Flanges#EIL Approved Flanges#IBR Approved Flanges#Duplex Steel EIL Approved Flanges

0 notes

Text

The Benefits of Super Duplex Steel 2507 Flanges and How Jay Steel Corporation Supplies the Best

When your mission demands electricity, resilience, and unwavering performance in unforgiving environments, Super Duplex Steel 2507 Flanges become the undisputed champions. We are a leading Super Duplex Steel 2507 Flanges Supplier in India, we understand the vital position those flanges play in making sure the toughness and protection of your industrial operations.

But what exactly units Super Duplex 2507 Flanges apart? Let's delve into the superhero traits that lead them to the suitable desire for disturbing packages:

Unmatched Corrosion Resistance: Super Duplex 2507 boasts a completely unique metallurgical composition, proposing high chromium, molybdenum, and nitrogen content. This robust mixture presents them incredible resistance to a big selection of corrosive threats, together with:

Pitting and crevice corrosion

Chloride stress corrosion cracking (SCC)

Erosion-corrosion

General corrosion in acidic environments

This tremendous resistance makes Super Duplex 2507 Flanges best to be used in harsh environments like:

Offshore oil and gasoline exploration and manufacturing

Chemical processing flora

Petrochemical centers

Seawater programs

Pulp and paper mills

Superior Strength: Super Duplex 2507 Flanges are not simply corrosion warring parties; they're heavyweight champions in terms of strength. Their unique microstructure, combining austenitic and ferritic levels, offers almost double the power of normal ferritic or austenitic steels. This interprets to flanges which could resist high strain and extreme masses, making sure the integrity of your piping systems.

Cost-Effective Choice within the Long Run: While the in advance value of Super Duplex 2507 Flanges may appear better as compared to conventional metal flanges, their awesome sturdiness and durability cause them to a value-powerful funding in the long run. Their superior resistance to corrosion translates to fewer replacements and reduced protection downtime, leading to widespread fee savings over the lifespan of your task.

Why Choose us as Your Super Duplex Steel 2507 Flanges Supplier?

At Jay Steel Corporation, we're extra than only a Super Duplex Steel 2507 Flanges Supplier. We are a committed companion to your achievement. Here's what units us apart:

Unwavering Quality: We supply our Super Duplex 2507 from relied on generators, making sure the highest excellence and adherence to worldwide standards.

Extensive Inventory: We hold a complete stock of Super Duplex 2507 Flanges in numerous sizes and specifications to satisfy your various venture wishes.

Customizable Solutions: We apprehend that each task has particular requirements. We offer custom flange production to meet your unique wishes and dimensions.

Technical Expertise: Our group of specialists possesses in-depth expertise of Super Duplex Steel 2507 and its programs. We can provide precious advice and aid to ensure you choose the proper flanges to your undertaking.

Looking for a reliable Super Duplex Steel 2507 Flanges Supplier in India?

Look no further than Jay Steel Corporation. Contact us today to discuss your challenge necessities and enjoy the extraordinary high-quality and provider that make us the leader in Super Duplex Steel Flange solutions.

In addition to Super Duplex 2507 Flanges, we are also an outstanding manufacturer of 2205 Duplex Steel Flanges. Explore our complete range of Duplex and Super Duplex metal merchandise to satisfy all your task needs.

0 notes

Text

#Duplex Steel S31803 Flanges Manufacturers#Duplex Steel S31803 Flanges Suppliers#Duplex Steel S31803 Flanges Stockists#Duplex Steel S31803 Flanges Exporters#Duplex Steel S32205 Flanges Manufacturers#Duplex Steel S32205 Flanges Suppliers#Duplex Steel S32205 Flanges Stockists#Duplex Steel S32205 Flanges Exporters

0 notes

Text

Super Duplex S32750 Flanges Suppliers in India

Super Duplex S32750 Flanges epitomize excellence in high-performance engineering. Crafted from the robust S32750 alloy, these flanges showcase unparalleled strength, corrosion resistance, and durability. Designed for demanding applications, they seamlessly marry innovation with reliability. The flanges, featuring a unique dual-phase microstructure, offer exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking. Their precision-engineered dimensions ensure a perfect fit, guaranteeing a leak-free and long-lasting performance. Whether in aggressive chemical environments or extreme temperatures, Super Duplex S32750 Flanges stand as a testament to cutting-edge metallurgy, providing a steadfast foundation for critical industrial systems. Elevate your project with the pinnacle of engineering prowess.

For more Information

Visit website: https://www.deepsteelalloys.com/super-duplex-steel-uns-s32750-2507-seamless-welded-flanges-manufacturer-exporter.html

Email: [email protected]

Contact: 9930466755

#Manufacturers#Suppliers#Exporters#Steel#Metal#Super Duplex S32750 Flanges Manufacturers#Super Duplex S32750 Flanges Suppliers#Super Duplex S32750 Flanges Stockists#Super Duplex S32750 Flanges Exporters

0 notes

Text

Precision and Quality: DOM Tubes Manufacturers

Discover excellence with our DOM Tubes Manufacturers. As industry leaders, we produce top-grade Drawn Over Mandrel (DOM) tubes that guarantee precision and reliability. With cutting-edge manufacturing techniques, we deliver tubes that meet the most stringent requirements. Partner with us for unmatched quality.

#dom tube#hydraulic tubes#j525 tubes#astm-a519#seamless mechanical tubing (a519 tubing)#stainless steel pipe#Alloy Steel Pipe and Tube manufacturer and supplier#Carbon Steel Flanges Manufacturer#Carbon Steel Pipes#Duplex And Super Duplex pipes#stainless steel pipe suppliers#stainless steel pipe tubing#Stainless Steel Flanges Supplier#Low Temperature Carbon Steel Pipes#Duplex Steel Flanges#galvanized pipes#steel pipes manufacturer#galvanized pipe manufacturer#a519 tubing#astm a312 pipe#galvanized pipe suppliers#ppgl coil manufacturers#ppgl coil manufacturers in india#ppgi coil manufacturers in india#ppgi coil manufacturers.

0 notes

Text

Duplex Steel S31803 Flanges Manufacturers

Duplex Steel Flanges are hardened alloys and also exceptionally corrosion-resistant. Microstructures of this steel are consist of Ferrite and Austenite phases’ mixture. As a result, they consist of the features of both ferritic and austenitic stainless Steel. It has a high-strength and excellent resistance to corrosion. Duplex Stainless Steel Flanges have excellent intergranular corrosion. It has an outstanding high resistance to corrosion cracking stress even in sulfide and chloride environments.

At the temperatures, more than 300 degree Celsius Duplex Steel Flanges is still protected from the corrosion causes embrittlement. Duct ability is excellent in low temperatures also. The fabrication work is done only through the tools assigned for materials of stainless steel. Before they used must be cleaned properly. It is done to save the stainless steel from the cross-contamination from the corroded metals.

Many types of steel flanges are offered by Technolloy Inc. Engg.And Co.one of the most used flanges are Duplex Steel Flanges. They are the famous manufacturer, supplier and stockiest of all types of steel flanges in all over the world. Stainless steel is highly durable and low-cost alloy. The flanges of Stainless steel are used widely as they have the properties which make it the unbeaten quality material.

These flanges can be hardened by the treatment of heat. Duplex Steel Flanges are application industries are; They are used in off-shore oil drilling companies, used in Aircraft exhaust manifolds, uses in petrochemicals, in power generation, in gas processing, in pharmaceuticals, uses in specialty chemicals, spiral welded tube for burner pipes and fuels, pharmaceutical equipment, heat exchangers, and also in seawater equipment. Double Steel Flanges are available in the many designs like slip-on, weld-neck, blind, threaded, lap joint, and socket weld.

The test certificate is according to the EN 10204/31B. Material testing includes intergranular corrosion (IGC) test, flaring test, pitting resistance test, micro, and macro test, flattening test, positive material identification test, chemical analysis, hardness test, and mechanical testing such as tensile of area. The packaging is in wooden pallets and cases to avoid the damages of the material during its delivery and to maintain the trust of the customers.

#Duplex Steel S31803 Flanges Manufacturers#Duplex Steel S31803 Flanges Suppliers#Duplex Steel S31803 Flanges Stockists

0 notes

Text

Emcor Engineering: Your Trusted Partner for High-Quality Metal Products

Established in 2019-2020, Emcor Engineering has quickly become a highly acclaimed manufacturer, supplier, and stockist of ferrous and non-ferrous metal products, including high nickel alloys. We offer an extensive range of products such as pipes, tubes, flanges, buttwelded pipe fittings, forged fittings, tube fittings, sheets, plates, coils, bars, fasteners, shims, slitting coils, screws, washers, elbows, reducers, and tees.

Our relentless efforts to deliver premium quality products have earned us an unparalleled position in the industry. We import, export, supply, and trade a wide array of materials, including stainless steel, high nickel alloys, duplex and super duplex, titanium, and cupro nickel in all grades. Emcor Engineering is also a specialist in 400 series sheets and coils and is one of the leading foundry grade scrap suppliers in India. Trust us to meet your needs with exceptional quality and service.

#metal products manufacturers#SS Pipe manufacturers in India#SS Pipe Fittings manufacturers in India#SS Forged Fitting manufacturers in India#SS Flange manufacturers in India#Blind Flange manufacturers in India

3 notes

·

View notes

Text

Bellow Seal Safety Valve manufacturer in USA

SVR Global is the best Bellow seal safety valve manufacturer in USA supplying superior quality valves to petrochemical industries, oil industries and chemical industries in Baltimore, Seattle and Des Moines.It's main work is to discharge extra pressure from a system when it rises above a set limit. By doing so, potential safety risks and equipment damage are reduced. The bellows is a pliable, accordion-like component of the valve. It can expand or contract to maintain a tight seal up until the predetermined pressure is attained since it is sensitive to variations in pressure.Safety valves with a bellows seal are known for being able to maintain a tight seal even at low pressure levels. This qualifies them for uses where leak protection is crucial. When maintaining a sterile or clean environment is crucial, these valves are frequently employed in the petrochemical, pharmaceutical, food processing, and aerospace industries.A bellows seal safety valve's set pressure can be changed to suit the particular needs of the application. When the system's pressure rises over this threshold, the valve opens to let the extra pressure out.It is a particular kind of safety valve used in many sectors to safeguard machinery and processes from overpressure situations is the bellows seal safety valve. These valves have a bellows-like feature that helps maintain a seal, ensuring the valve stays leak-tight until it reaches a certain set pressure.

TYPES

Spring-loaded bellow seal safety valves

Pilot-operated bellow seal safety valves

Balanced bellow seal safety valves

Bellow seal relief valves

Vacuum relief bellow seal valves

INDUSTRIES

•oil and gas industries

•Petrochemical industries

•Aerospace industries

•Aircraft hydraulic systems

•Water industries

•Petroleum industries

•Heating boilers

Available materials: Cast Iron and Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91], WCB, WC6, SS304, SS316, DUPLEX STEEL.

Ends: Flanged, Buttweld, Socket weld, Threaded

Class: 150 to 2500

Nominal Pressure: PN25 to PN450

Size: 1/2” to 64”

https://svrglobal.net/products/balanced-bellow-seal-safety-valve/

2 notes

·

View notes

Text

Gate Valve supplier in Oman

Middleeast valve is one of the best Gate valve supplier in Oman . We supply to cities like Ibri, Sur, Muscat, and Mutrah.

A gate valve is a type of valve used to control the flow of fluids (liquids or gases) by using a gate or wedge-like disc that moves perpendicular to the flow path to either block or allow the passage of the fluid.

The main function of a gate valve is to provide a tight shutoff, effectively stopping the flow of fluid through the pipeline when the valve is fully closed, and allowing unrestricted flow when the valve is fully open. Gate valves are commonly used in applications where the fluid flow needs to be completely shut off, such as in water supply systems, oil and gas pipelines, industrial processes, and more.

Gate valves consist of several main components, including the body, gate (wedge), stem, actuator, and seats. Here's how they work:

Open Position:

In the open position, the gate (wedge) is fully retracted into the valve body, allowing the fluid to flow through the valve with minimal obstruction. The gate moves perpendicular to the direction of the fluid flow. The valve is opened by turning the valve stem (either manually using a handwheel or with an actuator) which is connected to the gate.

Closing Position:

To close the valve, the stem is turned in the opposite direction, causing the gate to move down into the flow path of the fluid. As the gate descends, it gradually restricts the flow until the valve is completely closed. The gate makes contact with the valve seats located at the bottom of the valve body, forming a tight seal that prevents any further flow.

Middleeast valve is the greatest Gate valve supplier in Oman and are known for their ability to provide a tight seal and low pressure drop when fully open. However, they might require more turns to fully open or close compared to other valve types like ball valves. It's important to use gate valves in appropriate applications and avoid using them for flow regulation where frequent adjustments are necessary.

Description:

Available materials: SS304, SS904, SS904L, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, super duplex

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operations: Hand Wheel Gate valve, Gear operated Gate valve, Electric actuated Gate valve and Pneumatic Actuated Gate valve

Ends: Flanged(FF,RF,RTJ), Buttweld, Socket weld, Threaded

Standards: API607, DIN, BS, ANSI, AWWA, ASME, API6D

Gate valve types:

Rising Stem Gate Valve

Non Rising Stem Gate Valve

Bellow Seal Gate Valve

Pressure Seal Gate Valve

Cryogenic Gate Valve

Forged Gate Valve

Gate valve advantages :

They have low fluid resistance.

They have superior sealing capability.

They come with a wide application range.

They have dual flow directions.

Gate valve Industries:

Textiles.

Power generation.

Refineries.

Petrochemical plants.

Shipbuilding

Chemical industry.

Paper factories.

Gate valve parts:

Hand wheel.

Stuffing Box.

Bonnet

Gasket

Stem

Flange

Disk

Body seats

Packing

Body

Visit our website: https://www.middleeastvalve.com/product-category/gate-valve/

2 notes

·

View notes

Text

Monel K500 Blind Flanges Exporters

Monel Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types. A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

Monel Blind Flanges are used for testing the flow of gas or liquid through a pipeline or vessel. It helps to close the end of piping systems or vessel openings. It allows easy access to the pipeline when there is a requirement to work done inside the line. They are used in high pressure applications available in all grades, materials, size and specifications. Blind pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind pipe flanges, the standard height is 1/16" for blind pipe flanges under 400 ( 2.4360)#. For blind pipe flanges of 400 ( 2.4360)# and up, the standard blind pipe flange raised face height is 1/4".

B16.5 ASTM A182 Blind Flange, Fusion Bonded Epoxy Coating, EN 1092-2 PN16 Blind Flange, ASME B16.5 Dual Monel Alloy Blind Flange, ANSI B16.5 Class 150 Flat Face Blind Flange, Monel Alloy Reducing Blind Flange Stockiest.

Standards Specification:

Size : 1/2" to 48"

Specifications : ASTM A182

Rating: 150#, 300#, 600 (2.4640)#, 900#, 1500#, 2500#,

Material & Grade :

Stainless Steel :Grade: 304 (1.4301), 304L (1.4307), 304H (1.4948), 309 (1.4828), 309S, 310, 310S (1.4845) , 316 ( 1.4401), 316H, 316L( 1.4404 /1.4432) , 317, 317L (1.4438), 321 (1.4541), 321 H(1.4878), 347 (1.4550), 347H (1.4961), 904L (1.4539)

Duplex Steel:Grade: 2205 (1.4507)

Super Duplex Steel:Grade: 2507 (UNS S32750) (1.4410) (UNS S32750)

Inconel :Grade: Inconel 600 (2.4640), Inconel 601 (2.4851), Inconel 625 (2.4856), Inconel 718(2.4668)

Incoloy :Grade: Incoloy 800 (2.4958), Incoloy 800H, Incoloy 800HT

Nickel :Grade: Nickel 200, Nickel 201

Titanium :Grade: Gr.1 (3.7025) , Gr.2 (3.7035) , Gr.3:(3.7055) , Gr.5(3.7164/65), Gr. 7(3.7235) , Gr. 11 (3.7225)

Hastalloy :Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X.

For More Information

Visit Our Website - http://www.kobsindia.in/monel-blind-flange.html

Contact Us -9819523999

Email Id - [email protected]

4 notes

·

View notes

Text

SS Flanges | EIL Approved Flanges | IBR Approved Flanges | Duplex Steel EIL Approved Flanges

Riddhi Siddhi Metal Impex is one of the leading manufacturers of stainless steel flanges in India.

Stainless Steel Flanges: https://riddhisiddhimetal.com/stainless-steel-flanges-manufacturer-india/

EIL Approved Flanges: https://riddhisiddhimetal.com/eil-approved-flanges-manufacturers-india/

IBR Approved Flanges: https://riddhisiddhimetal.com/ibr-approved-flanges-manufacturers-india/

For more detailsVisit our website: https://riddhisiddhimetal.com/.

#Stainless Steel Flanges#EIL Approved Flanges#IBR Approved Flanges#Duplex Steel EIL Approved Flanges

0 notes

Text

Difference between duplex and super duplex stainless steel

The terms "duplex" and "super duplex" are frequently heard when it comes to stainless steel, but what exactly do they mean? Jay Steel Corporation, as a leading duplex and super duplex stainless steel materials manufacturer, supplier, stockist, and exporter in India, is here to shed light on the differences between these two exceptional alloys. We offer an extensive range of products, including super duplex 2507 strips, sheets & plates, duplex 2205 strips, sheets & plates, super duplex 2207 flanges, duplex 2205 round bars, as well as wire mesh, fittings, and fasteners to cater to your diverse project requirements. Furthermore, our commitment to quality and affordability extends to various countries worldwide, making us a trusted name in the global market. If you're in search of a reliable Super Duplex 2507 strips, sheet & plate supplier, Duplex 2205 strips, sheet & plate manufacturer, or any other product among them, you've come to the right place!

In this blog post, we will delve into the difference between duplex and super duplex stainless steel, shedding light on their unique characteristics and applications.

Duplex Stainless Steel

Duplex stainless steel, represented by grades like 2205, is a remarkable material known for its balanced combination of properties from both austenitic and ferritic stainless steel. This alloy contains a significant amount of chromium, which enhances its corrosion resistance, and it also features molybdenum and nitrogen for added strength and durability. Here's a closer look at the key characteristics of duplex stainless steel:

Corrosion Resistance: Duplex stainless steel provides excellent resistance to corrosion, making it suitable for various industrial applications, including chemical processing, water treatment, and offshore oil platforms.

Strength and Toughness: Duplex steel is characterized by high tensile strength and exceptional toughness, allowing it to withstand extreme temperatures and mechanical stress.

Cost-Effective: Its balanced composition and competitive pricing make duplex stainless steel a cost-effective choice for many projects.

Super Duplex Stainless Steel

Super duplex stainless steel, such as grade 2507, takes the attributes of duplex steel to the next level. It offers even higher levels of corrosion resistance and strength, making it ideal for the most demanding applications. Let's explore the unique features of super duplex stainless steel:

Enhanced Corrosion Resistance: Super duplex steel contains higher levels of chromium, molybdenum, and nitrogen, which grant it outstanding resistance to aggressive environments, including those with high chloride content.

Strength and Durability: With a higher alloy content, super duplex steel excels in both mechanical strength and resistance to pitting and crevice corrosion.

Applications: Super duplex stainless steel is used in industries where standard duplex or austenitic stainless steels may fall short. It is found in offshore structures, desalination plants, and chemical processing units.

Comparing Duplex and Super Duplex Stainless Steel

Composition: The primary difference lies in the alloying elements. Super duplex stainless steel contains a higher proportion of chromium, molybdenum, and nitrogen, which contributes to its exceptional corrosion resistance.

Corrosion Resistance: While duplex stainless steel provides good corrosion resistance, super duplex stainless steel excels in hostile environments, making it suitable for more demanding applications.

Strength: Super duplex stainless steel generally has a higher tensile strength and is better equipped to withstand extreme conditions.

Cost: Super duplex stainless steel is typically more expensive than its duplex counterpart due to its superior properties and alloy composition.

Final Words!

The main difference between duplex and super duplex stainless steel lies in their composition and performance characteristics. Duplex stainless steel offers an excellent balance of properties, while super duplex stainless steel elevates those properties to meet the most demanding requirements. Regardless of your project's specific needs, Jay Steel Corporation stands as a reliable source for top-notch materials, ensuring that you can find the perfect stainless steel solution for your applications. Moreover, our commitment to competitive pricing and premium quality ensures that we are the top choice for businesses in Singapore, Malaysia, Nigeria, Thailand, USA, France, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, Jordan, Bahrain, Russia, Germany, the United Kingdom, and Italy at the most reasonable in the market!

#super duplex stainless steel#duplex stainless steel#Duplex 2205 Round Bar#Super Duplex 2507 Strips#Sheet & Plate#Duplex 2205 Strips#Duplex 2205 Flanges#Super Duplex 2507 Fasteners

0 notes

Text

Duplex Steel S32205 Flanges Exporters

For More Information :

Email : [email protected]

Call Us : 8828369483

#manufacturers#business#duplex steel S32205 flanges#Duplex Steel S32205 flanges manufacturers#duplex Steel S32205 flanges exporters

0 notes

Text

Duplex Steel S32205 Flanges Manufacturers

Duplex steel flanges are set blends and, moreover, particularly safe. The microstructures of this steel incorporate ferrite and austenite stages' blend. Along these lines, they contain parts of both ferritic and austenitic-treated steel. It has high strength and wonderful protection from isolating. Duplex-set steel flanges have breathtaking intergranular isolating. It has a strikingly high security against deteriorating breaking pressure, even in sulfide and chloride conditions.

Specification of Duplex Stainless Steel S31803/S32205 Flanges

Duplex Stainless Steel Flanges Specification : ASTM A182 / ASME SA182

Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard : ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size : 1/2" (15 NB) to 48" (1200NB)

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges : BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

For more Information

Visit website: https://www.deepsteelalloys.com/duplex-steel-uns-s31803-2205-seamless-welded-flanges-manufacturer-exporter.html

Email: [email protected]

Contact: 9930466755

#Duplex Steel S31803/S32205 Flanges Manufacturers#Duplex Steel S31803/S32205 Flanges Suppliers#Duplex Steel S31803/S32205 Flanges Stockists#Duplex Steel S31803/S32205 Flanges Exporters#Duplex Steel S31803/S32205 Flanges Manufacturers in India#Duplex Steel S31803/S32205 Flanges Suppliers in India#Duplex Steel S31803/S32205 Flanges Stockists in India#Duplex Steel S31803/S32205 Flanges Exporters in India#Duplex Steel S31803/S32205 Flanges Manufacturers in Mumbai#Duplex Steel S31803/S32205 Flanges Suppliers in Mumbai#Duplex Steel S31803/S32205 Flanges Stockists in Mumbai#Duplex Steel S31803/S32205 Flanges Exporters in Mumbai

0 notes