#ECU fault diagnosis

Text

Know OBD2 Before You Start That Development Project

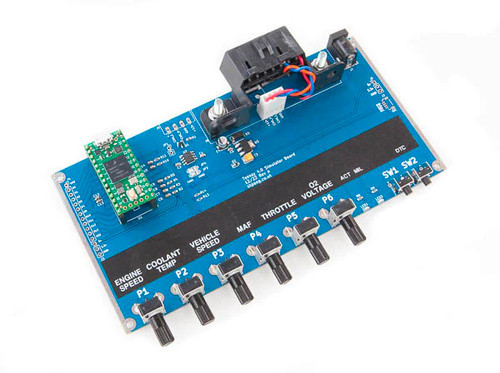

OBD2, or Onboard Diagnostics Second Generation, is a vehicle diagnosis system found in modern cars and trucks. The OBD2 system collects data from sensors and other monitoring devices, which are then examined by the vehicle's engine control unit (ECU) to determine whether any issues need to be addressed. Problems with the engine, gearbox, emissions system, and others, are among the most common faults that OBD2 can discover.

6 notes

·

View notes

Text

Unlocking the Power of Lexus OBD Services: Professional Insights for Accurate Vehicle Troubleshooting

Onboard Diagnostics (OBD) systems have revolutionized the way we diagnose and troubleshoot issues in modern vehicles. For Lexus owners, the OBD system serves as a critical tool for maintaining the car’s performance, identifying potential problems early, and ensuring that repairs are done efficiently and accurately. In this article, we will explore the importance of Lexus OBD services, provide insights into how they work, and explain why professional OBD services are essential for keeping your Lexus in top condition.

What is the Lexus Onboard Diagnostics (OBD) System?

Lexus, like most modern vehicles, comes equipped with an OBD system that monitors various components of the vehicle. The system collects data from sensors throughout the car and communicates this information to the vehicle’s onboard computer, known as the Engine Control Unit (ECU). If any component malfunctions or operates outside of its normal range, the OBD system triggers a warning, often in the form of the Check Engine Light.

There are two main types of OBD systems: OBD-I, used before 1996, and the more advanced OBD-II system, which is standard in all vehicles made after 1996. Lexus vehicles rely on the OBD-II system to monitor and manage everything from engine performance to emission controls, fuel efficiency, and safety systems.

How Lexus OBD Services Work

The OBD-II system in Lexus vehicles is designed to detect and log faults in real-time. When a problem is identified, the system generates a specific trouble code known as a Diagnostic Trouble Code (DTC). Each code corresponds to a particular issue, such as a malfunctioning sensor, misfire, or an issue with the catalytic converter.

Here’s how a typical OBD service works:

Connection to the OBD Port: A professional mechanic connects an OBD scanner to the vehicle’s OBD-II port, typically located under the dashboard.

Reading the DTC Codes: The scanner reads the stored DTCs, which indicate the nature of the problem. For example, the code P0301 refers to a misfire in cylinder one.

Interpreting the Codes: Technicians interpret the codes using manufacturer-specific information. While some codes are universal, others are specific to Lexus vehicles, requiring specialized knowledge to correctly diagnose the problem.

Diagnosing the Issue: After identifying the codes, the technician uses additional diagnostic procedures to confirm the exact cause. For instance, a misfire code might prompt the mechanic to check spark plugs, ignition coils, or fuel injectors.

Repairs and Resetting the System: Once the issue is repaired, the mechanic clears the error codes from the OBD system, and the Check Engine Light is reset. The vehicle is then tested to ensure the issue has been fully resolved.

Key Benefits of Lexus OBD Services

Lexus OBD services offer several advantages for vehicle owners, including:

Accurate Diagnosis: The OBD system provides precise information about what is wrong with the vehicle, eliminating much of the guesswork involved in diagnosing issues. This allows technicians to pinpoint the problem and address it efficiently.

Early Detection of Issues: Many problems can be detected by the OBD system before they become severe. For example, minor engine misfires, emissions issues, or sensor malfunctions may not be immediately noticeable by drivers but can cause significant damage if left unchecked. With early detection, you can avoid expensive repairs.

Improved Maintenance: Regular OBD diagnostics help keep your Lexus performing at its best. Technicians can monitor the health of critical systems such as the engine, transmission, and emissions, ensuring that any issues are addressed during routine maintenance before they escalate.

Enhanced Emission Control: The OBD-II system also monitors the vehicle's emissions performance, making sure that the car meets regulatory standards. If there’s an issue with the emission control system, such as a failing catalytic converter or oxygen sensor, the OBD system will notify the driver, allowing the problem to be addressed before it affects the environment or the vehicle’s drivability.

Common Lexus OBD Trouble Codes and What They Mean

Understanding the most common OBD-II codes in Lexus vehicles can help you gain insight into your car’s health. Here are a few key codes and their meanings:

P0171 – System Too Lean: This code usually indicates that the engine is receiving too much air and not enough fuel, often due to a vacuum leak or a faulty mass airflow sensor.

P0300 – Random/Multiple Cylinder Misfire: This code means that the engine’s cylinders are misfiring, which can result from issues with the ignition system, fuel system, or a mechanical problem in the engine.

P0420 – Catalyst System Efficiency Below Threshold: This code suggests that the catalytic converter is not working as efficiently as it should be, possibly due to age, contamination, or a faulty oxygen sensor.

P0442 – Evaporative Emission System Leak Detected: A small leak in the fuel system could trigger this code. The issue could stem from something as simple as a loose gas cap or a more serious problem with the evaporative emissions system.

The Importance of Professional OBD Services for Lexus

While many OBD-II scanners are available for personal use, professional OBD services are critical for ensuring accurate diagnostics and repairs. Here’s why:

Advanced Diagnostic Tools: Professional mechanics use sophisticated diagnostic equipment that provides more detailed information than basic consumer-grade scanners. These tools allow them to view real-time data, test individual components, and retrieve manufacturer-specific codes for Lexus vehicles.

Technical Expertise: Lexus technicians undergo specialized training to understand the nuances of Lexus OBD systems. This expertise is vital for accurately diagnosing issues and knowing how to properly address them.

Genuine Lexus Parts: Professional service centers have access to genuine Lexus parts, ensuring that any faulty components are replaced with high-quality parts that meet the manufacturer’s specifications. This ensures the vehicle’s performance and longevity.

Comprehensive Solutions: Rather than simply reading codes and making assumptions, professional mechanics use OBD services as part of a comprehensive diagnostic process. They inspect, test, and confirm the issue, providing a complete solution that resolves the root cause of the problem.

Conclusion

Lexus OBD services unlock a powerful tool for maintaining the health of your vehicle. By regularly utilizing these services, you can detect potential issues early, ensure accurate repairs, and optimize your Lexus’s performance and efficiency. While consumer OBD scanners may provide basic insight into your car’s health, professional OBD services offer the in-depth diagnostics and technical expertise required to keep your Lexus running smoothly.

For the best results, always rely on certified Lexus technicians who are familiar with your vehicle’s systems and have the tools needed to provide the most accurate and reliable solutions. With professional OBD services, you can enjoy peace of mind knowing that your Lexus is in peak condition, ready to deliver the performance and comfort it’s known for.

#lexus car#lexus service center#lexus car maintenance#lexus car mechanic#lexus obd services#lexus drive

0 notes

Text

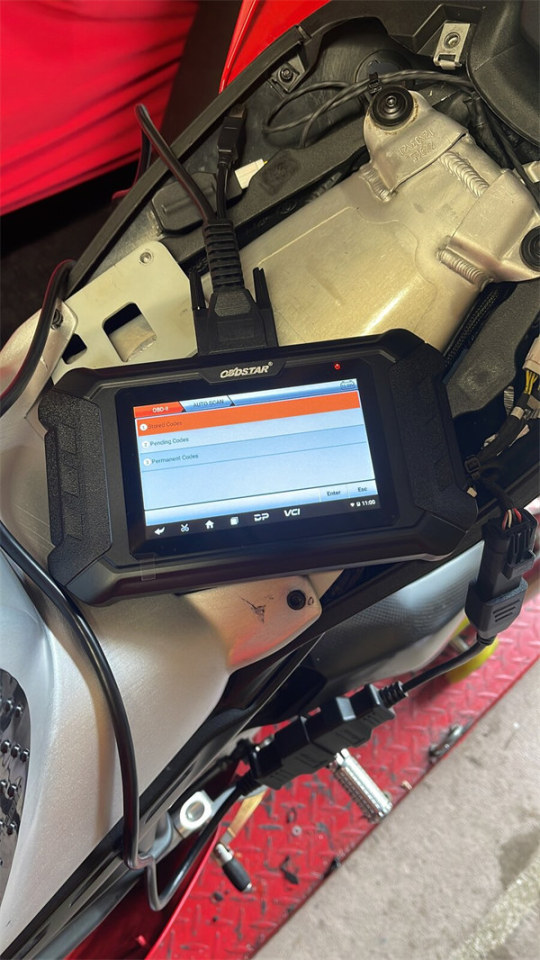

OBDSTAR iScan Ducati Motorcycle Diagnostic Scanner Feedback

OBDSTAR iScan DUCATI is a comprehensive tool that supports diagnosis, key programming, and some special functions for Motorcycles up to 2023 model.

OBDSTAR iScan DUCATI Highlights:

New android 5.1.1 operation system;

Simple and intuitive menu guidance allows you to quickly understand how to use the tablet;

Provide complete functions including automatic scanning, VIN recognition, control module programming and coding, ECU setting, instrument coding, tire pressure monitoring system, maintenance light reset, CO adjustment, idle speed adjustment, A/F value reset, ABS control unit setting, EOL mode, transmission memory reset, clear computer memory and key programming, etc;

Menu selection is more convenient and quick;

Record and play back real-time data streams,quickly and accurately locate sensor and component faults;

Wi-Fi connection to the internet, one-click software upgrade;

One-click remote help function, OBDSTAR technical staff offer remote assistance.

Lightweight and portable, your motorcycle repair helper.

One year update for free, after one year, it costs 80 USD for update per year.

Support multi-language: English (EN), Spanish (ES), Portuguese (PT), French (FR), German (DE), Italian (IT).

(The default language is English, please register the device before changing language.)

With Free M041 Cable(for 2019 and newer Ducatimotorcycle models)

Ducati Motorcycle Diagnostic Supported List 2024-02-29

Ducati Motorcycle IMMO Supported List 2024-02-29

Ducati Motorcycle ODO Supported List 2024-02-29 (Odometer adjustment function need to buy license.)

OBDStar IScan Series User Manual

Feedback 1:

Just bought an OBDSTAR iScan Ducati which arrived this morning.

I might have to read the instructions to get the best out of it, but a simple code read to find out why I have an engine light on worked well. So I’m happy so far. Now just need to fix it.

Feedback 2:

OBDStar unit arrived this morning. Have registered and updated it. Will connect it up to the Panigale V4S 2018 bike later with an update on how it worked out.

OK.I managed to enable the Bluetooth function on the bike with the OBDStar unit and read the DMS module.

However, the VIN number stored on it, is that of the bike the dealer connected it to, to originally activate the DMS module. The only way to erase that is at the dealer and reset it to my own VIN.

It does not seem to make much difference in terms of functionality though, as the Ducati Connect app lets me pair my phone with my bike and all the dash functions, such as Last Calls, Player On/Off etc, all work as described.

I will have them correct it when I eventually take the bike in for any software updates and to load the Akra exhaust map.

There is evidently a lot of functionality on the OBDStar unit and under the 'Special Functions' menu, you can enable/disable a number of items even reset the odometer, though I cannot condone it, if you do.

There are also a number of other features you can use, but these may potentially carry some risk to the ECU, so I am leaving them well alone.

It is most likely of interest if you want to reset or clear existing error codes, such as a DQS malfunction or a service light or removing an evap canister or Ex servo light error code (likely seen after fitting a different exhaust system).

Normally the updated software (such as the T800 or Akra map) will take care of these codes but if you are fitting something else such as a Spark or Arrow system, this may be of some benefit.

Managed to get hold of a flight case to replace the cardboard box the unit came in. £38 which is not bad really and a much better solution to protect the OBDStar unit and cables. Having measured the dimensions of the two layer foam packaging first, and checked the internal dimensions of the new case online, I didn't even have to trim the foam down as the whole thing fitted straight into the case. There is a small gap around the edges but it's still a pretty snug fit.

Feedback 3:

There is a way to select a different model to the one the unit thinks it is connected to.

Initially mine identified the bike automatically from the VIN encoded into the ECU. Correct me if I'm wrong but I surmise that this is how you're connecting to your bike? After an update to the OBDStar it seemed to stop recognizing the bike this way. So I now have to go to the diagnosis level of the menu and choose "Select from Vehicle" rather than "Auto Identify [VIN]".

Choose the 2nd option “Select from vehicle”

That then asks me to input serial.

Initially this was is a little confusing, until I realized that the spreadsheet has a column headed "Serial" containing a single alpha or numeric value matching the first character of the corresponding "Model" column. Entering "M" brings up a list of models including all the Multistradas.

Selecting the appropriate one brings up a list of the model year ranges to drill down further.

Selecting one of these and then clicking OK brings up the list of possible action headings such as; ENG ANS, Meter, Activations, BBS etc.

Clicking on one of these, from experience shows the year/year range again and that then results in the OBDStar trying to connect to the bike.

As this was done at my desk and without the bike plugged in I get the above message.

I haven't tried to connect to mine as anything other than what it is. Not sure if it will let you proceed if it's plugged into a model it's not expecting based on your previous selections?

Last year I did plug it into Monster to reset an error light.

Feedback 4:

I updated the OBDstar iScan yesterday and plugged it in to the bike just now. It’s a 2015 1200 DVT

I have way more activations available to me than I had before ... including the one i wanted - foglights:)

I have the lights and the genuine Ducati crash bars (I need to change over as I have SW Motech bars fitted at the mo) so that is a relatively straightforward job to finish off. Knowing the additional lights now function was the main thing. I can hang on now, until it warms up a bit

Someone asked if they stayed on, on full beam as well as dip beam somewhere on here? Yeah they do.

Feedback 5:

My OBDSTAR iScan Ducati motorcycle diagnostic tool has arrived today.

Impressed so far, all I've done on my initial session was to rest the PINs on my M821 and MTS1200GT, and have a scan through some of the other options. I'll be servicing my M821 fairly soon, and the Desmo for the MTS isn't too far away so that's when they'll be used in anger.

0 notes

Text

Understanding and Fixing BMW Car Computer Issues: Must-Know Updates and Maintenance Tips

Modern BMW vehicles are marvels of engineering, integrating advanced computer systems that manage everything from engine performance to navigation and safety features. These onboard computers, also known as Electronic Control Units (ECUs), are essential for the smooth operation of your car. However, like any complex system, they can encounter issues that may affect your vehicle's performance, safety, and overall driving experience. This article explores common BMW car computer problems, how to fix them, and essential maintenance tips to keep your vehicle's software up to date.

The Role of Computers in BMW Vehicles

BMW vehicles rely on a network of ECUs, each responsible for controlling specific systems within the car. These include:

Engine Control Module (ECM): Manages engine functions, including fuel injection, ignition timing, and emissions control.

Transmission Control Module (TCM): Controls gear shifts, ensuring smooth and efficient transmission performance.

Body Control Module (BCM): Manages electrical systems like lighting, windows, and locks.

Infotainment System: Handles multimedia functions, navigation, and connectivity features.

Safety Systems: Includes airbags, ABS, and stability control systems, ensuring driver and passenger safety.

Given their integral role, any malfunction in these computer systems can lead to significant issues, ranging from minor inconveniences to serious safety concerns.

Common BMW Car Computer Problems

BMW car computers can develop issues for various reasons, including software bugs, hardware failures, or external factors like voltage fluctuations. Here are some of the most common problems:

Software Glitches and Bugs

Software glitches are a frequent cause of computer problems in BMW vehicles. These can manifest as erratic behavior in the infotainment system, unexpected warning lights, or unresponsive control modules. Often, these issues arise from outdated software or bugs in the current version.

Faulty Sensors

BMW vehicles rely on numerous sensors to monitor everything from engine temperature to wheel speed. If a sensor fails or sends incorrect data, it can cause the associated ECU to malfunction. For example, a faulty oxygen sensor can lead to poor fuel efficiency and increased emissions, while a malfunctioning ABS sensor may compromise braking performance.

Communication Errors

The various ECUs in a BMW communicate with each other through a network called the CAN bus (Controller Area Network). If there’s a communication error, it can cause multiple systems to fail or behave unpredictably. This might manifest as warning lights on the dashboard, malfunctioning electronics, or even engine stalling.

Battery and Power Issues

The ECUs in your BMW require a stable power supply to function correctly. If the battery is weak or there are issues with the alternator, it can cause the computers to behave erratically. Symptoms may include flickering lights, intermittent system failures, or even a complete shutdown of electronic systems.

Hardware Failures

Over time, the hardware components of ECUs can wear out or fail. This could be due to age, exposure to extreme temperatures, or moisture ingress. Hardware failures can lead to permanent loss of functionality in affected systems, requiring repair or replacement of the ECU.

Diagnosing BMW Car Computer Issues

Diagnosing computer problems in a BMW requires specialized equipment and knowledge. Here’s how you can approach the diagnosis:

Use an OBD-II Scanner

An OBD-II (On-Board Diagnostics) scanner is a vital tool for diagnosing computer-related issues. When a problem occurs, the ECU stores a fault code that can be read using a scanner. These codes provide valuable insight into the nature of the issue, allowing for targeted troubleshooting.

Check for Software Updates

BMW regularly releases software updates to fix bugs, improve system stability, and enhance performance. If you’re experiencing issues, checking for and installing any available updates should be one of the first steps. This can often resolve software-related glitches.

Inspect Sensors and Wiring

Faulty sensors or damaged wiring can cause a range of issues. A visual inspection of the sensors and wiring harnesses can help identify any obvious damage or disconnections. In some cases, further testing with a multimeter may be necessary to confirm the sensor’s functionality.

Battery and Alternator Testing

Ensure that your BMW’s battery and alternator are functioning correctly. A weak battery or faulty alternator can cause voltage drops, leading to erratic behavior in the vehicle’s computer systems. A simple battery test or alternator check can help rule out these issues.

Consult a Professional

If you’re unable to diagnose the issue yourself, or if the problem seems complex, it’s advisable to consult a BMW specialist. They have the expertise, tools, and access to BMW-specific diagnostic software to accurately diagnose and repair any computer-related problems.

Fixing BMW Car Computer Issues

Once the issue has been diagnosed, the next step is to address it. Here’s how to fix common BMW car computer problems:

Software Updates

Installing the latest software updates is often the easiest way to resolve glitches and bugs. BMW offers updates through their dealerships, and in some cases, they can be installed via a USB drive or over-the-air (OTA) if your vehicle supports it. Regular updates help ensure that your car’s software remains stable and secure.

Sensor Replacement

If a faulty sensor is identified, replacing it with a new one is essential. Genuine BMW parts are recommended to ensure compatibility and reliability. After replacement, the system may need to be recalibrated to ensure the new sensor functions correctly.

Repairing or Replacing Wiring

Damaged wiring should be repaired or replaced to restore proper communication between ECUs. This might involve soldering broken connections, replacing corroded wires, or installing new wiring harnesses.

Battery and Alternator Replacement

If the battery or alternator is found to be faulty, replacing it with a new unit will restore stable power to the vehicle’s computer systems. It’s essential to choose a battery with the correct specifications for your BMW model to avoid further issues.

ECU Repair or Replacement

In cases where the ECU itself has failed, repair or replacement may be necessary. Some specialized shops can repair ECUs, while in other cases, replacing the unit with a new or refurbished one may be required. After installation, the ECU will need to be programmed to match your vehicle’s specific configuration.

Maintenance Tips to Prevent BMW Car Computer Issues

Preventing computer-related issues in your BMW involves regular maintenance and care. Here are some tips to keep your vehicle’s systems running smoothly:

Regular Software Updates

Keep your BMW’s software up to date by regularly checking for updates. This not only prevents issues but also ensures your vehicle benefits from the latest features and improvements.

Routine Inspections

Regularly inspect the sensors, wiring, and battery to catch potential problems early. Addressing minor issues before they escalate can prevent major system failures.

Proper Battery Maintenance

Maintain your battery’s health by keeping it clean and ensuring the terminals are free from corrosion. If your vehicle is not driven frequently, consider using a battery maintainer to keep it charged.

Use Genuine BMW Parts

When replacing sensors, wiring, or ECUs, always use genuine BMW parts. These parts are designed to work seamlessly with your vehicle’s systems, ensuring reliability and longevity.

Professional Service

Regularly service your BMW at a reputable workshop or dealership. Professional technicians can identify and address issues before they become serious, keeping your car’s computer systems in optimal condition.

Conclusion

BMW vehicles are equipped with sophisticated computer systems that require proper care and attention to function correctly. By understanding common computer-related issues, knowing how to diagnose and fix them, and following essential maintenance tips, you can ensure your BMW continues to deliver the performance and driving experience you expect. Regular updates, timely repairs, and the use of genuine parts are key to keeping your vehicle’s systems running smoothly, allowing you to enjoy the luxury and innovation that BMW is known for.

0 notes

Text

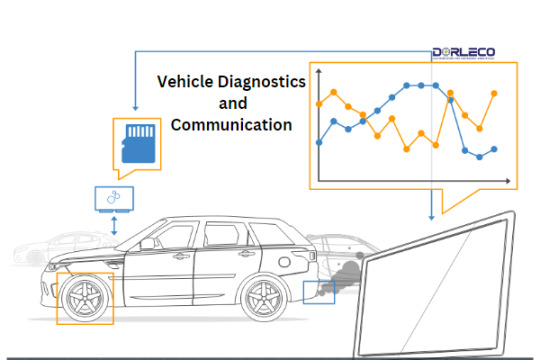

Vehicle Diagnostics and Communication

August 14, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

Vehicle communication and diagnostics are an integral part of modern car technology and are necessary for maintenance, performance tracking, and troubleshooting. These systems have significantly evolved with the creation of electronic control systems and the integration of cutting-edge technology into cars. Important aspects of automotive communication and diagnostics include the following:

1. On-board Diagnostics, or OBD:

OBD (On-Board Diagnostic): OBD is a standardized system that keeps track of an automobile’s engine and other vital systems. It comes in two versions: I and II. Introduced in the 1980s, OBD-I, or the first generation, was replaced as the industry standard by OBD-II, or the second generation, in the mid-1990s. OBD-II is more extensive since it uses standardized diagnostic connectors and codes.

2. Troubleshooting Diagnostic Codes (DTCs):

Codes for errors: When a fault is detected by an automobile’s onboard computer, a Diagnostic Trouble Code (DTC) is generated. These codes provide professionals with details about the specific scenario, allowing them to locate and resolve problems quickly.

3. Protocols for Communication:

In modern cars, the Controller Area Network, or CAN bus, is a commonly used communication protocol that allows various electronic control units (ECUs) to communicate with one another. It enables efficient communication and data sharing in real-time amongst different car systems.

4. Diagnostic Tools & Scan Tools:

OBD-II Scanners: Mechanics and auto owners use OBD-II scanners to extract DTCs, monitor live data, and execute various diagnostic procedures. To get data from the internal computer, these devices connect to the OBD-II port on the vehicle.

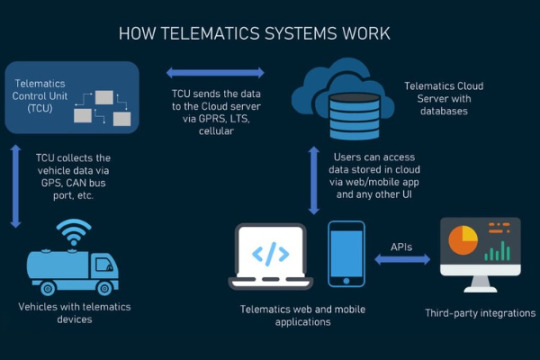

5. Remote diagnostics and telematics:

Telematics Systems: Many modern cars are equipped with telematics systems that allow for remote diagnosis and monitoring. The capacity of these systems to relay data to a central computer allows for real-time research of the health, performance, and maintenance needs of vehicles.

6. Manufacturer-Specific Diagnostics:

Manufacturer-only Systems: Certain manufacturers have proprietary diagnostic systems that might be able to meet or exceed OBD-II standards. It is often necessary to use specific hardware and software to perform extensive diagnostics on these systems.

7. Wireless Transmission:

Bluetooth and Wi-Fi: Wireless technologies like Bluetooth or Wi-Fi are used by certain diagnostic devices to link to an automobile’s onboard computer. As a result, doing diagnostics is now more versatile and convenient.

8. Advanced Driver Assistance (ADAS) Systems:

Sensor Diagnostics: Modern cars with advanced driver assistance systems (ADAS) use cameras and sensors to perform tasks like lane deviation warning and automated emergency braking. To guarantee optimal functioning, these sensors must be calibrated and monitored as part of the diagnostic processes for these systems.

9. Security online:

Security Issues: With automobiles becoming more networked, cybersecurity is becoming more important. Ensuring the security of automobile communication systems is crucial to prevent unauthorized access and potential cyber threats.

Advantages of Diagnostics and Vehicle Communication

Vehicle diagnostics and communication can benefit auto owners and mechanics in several ways. Here are a few key advantages:

1. Early Problem Identification

Vehicle communication and diagnostics enable the early detection of potential issues with the vehicle’s systems. By doing this, maintenance becomes proactive, and minor problems are prevented from becoming bigger, more costly ones.

2. Less Downtime

Quick and accurate diagnostics can reduce the time a vehicle takes without power. When problems are found and resolved quickly, vehicles spend less time off the road, which improves operational efficiency, especially in commercial fleets.

3. Cost-cutting Measures:

Finding and fixing issues early on may result in cost savings. If automobile owners address problems before they get worse, they can save spending a lot of money on repairs and replacements. Regular diagnostics can also lower operating costs by increasing fuel efficiency.

4. Increased Productivity:

Performance is increased by using diagnostics to ensure that every system in the vehicle is operating as effectively as possible. This includes engine efficiency, emission management, and general vehicle dynamics. More fuel efficiency and a more comfortable ride are two benefits of improved performance.

5. Emissions Management and Ecological Effects:

Enhanced diagnostics lead to better emission control. Verifying that the vehicle’s emission control systems are functioning properly helps to reduce harmful emissions, which is good for the environment, and to ensure that emission regulations are followed.

6. Telematics and remote monitoring:

The performance and health of a vehicle can be remotely monitored thanks to telematics technology. They are commonly connected to diagnostics and vehicle communication. This is especially helpful for fleet management because it lets managers keep an eye on the condition of multiple vehicles without physically inspecting them all.

7. Making Decisions Based on Data:

Vehicle diagnostics and communication give a wealth of data that can be analyzed to aid in decision-making. Fleet managers, mechanics, and automobile owners can utilize this information to create maintenance schedules, map out the best routes, and make strategic decisions about their fleet of vehicles.

8. Contentment with Customers:

The ability of service staff to accurately and quickly diagnose and resolve issues affects customer satisfaction. Vehicle owners place a high value on timely and efficient maintenance, and better diagnostics can enhance the whole experience for customers.

Diagnostics and Vehicle Communication’s Drawbacks

Vehicle communication and diagnostics have many benefits, but they also have some drawbacks and challenges.

1. Technical expertise and complexity:

Advanced diagnostics systems may require specific technical knowledge to diagnose and fix issues. This complexity could be difficult for individuals without the necessary knowledge or abilities, leaving them dependent on skilled mechanics or technicians.

2. Equipment and Training Costs:

Acquiring high-quality diagnostic equipment can be expensive, and training employees on how to use and interpret the equipment appropriately also adds to the costs. For individual vehicle owners or smaller auto repair shops, this might be a significant expense.

3. Compatibility Problems:

Compatibility problems might arise, especially in older cars or with aftermarket items. Some diagnostic methods and tools may not be completely compatible with every make and model, which may limit their applicability in specific situations.

4. Cybersecurity Risks:

Risks related to cybersecurity are probably going to rise as cars get more and more networked. Vulnerabilities in communication systems could be exploited by hackers, putting vehicle safety and data security at risk. To protect automotive communication systems, manufacturers need to implement robust cybersecurity measures.

5. Excessive Dependence on Technology:

An over-reliance on diagnostic tools could lead to a loss of interest in traditional troubleshooting methods. When technicians rely too heavily on automatic diagnostic results, they run the danger of overlooking less common or complex issues that require a deeper understanding of vehicle systems.

6. Privacy Issues:

Telematics systems raise privacy concerns since they are often integrated with vehicle diagnostics and communication. Regularly monitoring an automobile’s location and performance could be perceived as a privacy infringement; thus, laws and transparent channels of communication are required to alleviate these concerns.

7. Limited Capacity for Self-Help:

Even though many consumers may purchase OBD-II scanners, more advanced diagnostics typically require specific hardware and software. This increases the difficulty level for car owners to perform various diagnostic procedures themselves, hence increasing their reliance on professional services.

8. Rapid obsolescence of technology:

New technologies are being introduced regularly, and the automobile industry is changing quickly. The rapid pace of development can lead to the obsolescence of diagnostic equipment, posing a challenge for professionals and repair shops to remain current with the latest techniques and tools.

Conclusion:

To sum up, car diagnostics and communication are essential parts of contemporary automobile technology, offering a host of advantages as well as some drawbacks. The progression of OBD-II systems from basic to sophisticated, along with telematics and remote monitoring features, has completely changed the way cars are serviced and maintained. Early problem identification, less downtime, financial savings, optimal performance, and increased safety are among the benefits. These technologies guarantee regulatory compliance, improve consumer satisfaction, and enable data-driven decision-making.

Ongoing industry attention is necessary, nevertheless, because of obstacles including the complexity of diagnostic systems, the accompanying costs of training and equipment, compatibility problems, and cybersecurity dangers. The dynamic nature of this sector is further highlighted by privacy concerns, restricted do-it-yourself skills for sophisticated diagnostics, and the potential for quick technical obsolescence.

It will be essential to solve these issues through standardization, enhanced cybersecurity protocols, and easily available training as the automotive industry innovates more. A more effective, secure, and long-lasting automotive ecosystem will result from finding a balance between maximizing the benefits of car communication and diagnostics and minimizing any potential downsides. Future developments should bring about cars that are connected, maintained, and able to adapt to changing consumer demands as well as those of the automotive industry at large.

Check for our exciting list of (Vehicle Control Units) VCUs and the useful system Engineering services we provide. connect with us at [email protected]

#EVSoftwareserviceprovider#vehiclecommunication#vehiclecontrolunit#VCU#EVSoftware#evCODE#ADASCode#VCUSupplier#VCUManufacturer

0 notes

Text

Suzuki Outboard Troubleshooting Demystified: A Comprehensive Guide to Diagnostics and Service Resets

As a proud owner of a Suzuki outboard motor, you understand the importance of keeping your engine in top condition. However, even the most well-maintained outboards can experience issues from time to time. When faced with a problem, it's crucial to have the right tools and knowledge to diagnose and resolve the issue effectively. In this comprehensive guide, we'll demystify the process of Suzuki outboard troubleshooting, exploring diagnostic techniques, service codes, and reset procedures.

The Power of Diagnostic Tools

Suzuki outboard diagnostic tools are invaluable assets in the troubleshooting process. These specialized devices, often in the form of handheld scanners or software applications, can communicate directly with your outboard's electronic control unit (ECU), providing access to a wealth of diagnostic information.By connecting the diagnostic tool to your outboard's diagnostic plug or through a compatible diagnostic cable, you can retrieve and interpret error codes, monitor real-time engine data, and even perform system resets or updates.

Understanding Service Codes

One of the primary functions of Suzuki outboard diagnostic tools is the ability to read and interpret service codes. These codes, also known as diagnostic trouble codes (DTCs), are alphanumeric codes that provide insights into specific issues or faults within your outboard's systems.While some codes may seem cryptic at first glance, they can be deciphered using the diagnostic tool's built-in code library or by consulting your Suzuki outboard's service manual. By understanding the meaning behind these codes, you can pinpoint the root cause of the problem and take appropriate action.

Self-Diagnostics and Service Alarms

In addition to dedicated diagnostic tools, many modern Suzuki outboards are equipped with self-diagnostic capabilities. These built-in systems continuously monitor various components and systems, alerting you to potential issues through service alarms or warning lights.While these self-diagnostic features are convenient, they may not provide the same level of detail as a dedicated diagnostic tool. However, they can serve as an early warning system, prompting you to seek further diagnosis and potential service resets or service light resets.

Resetting Service Indicators

After performing maintenance or repairs on your Suzuki outboard, it's often necessary to reset service indicators or maintenance reminders. This process ensures that your outboard's electronic systems accurately reflect the work that has been done, preventing unnecessary service alarms or warnings from appearing prematurely.Depending on your outboard model, the service reset procedure may involve using a diagnostic tool, navigating through the outboard's display menu, or following a specific sequence of steps outlined in your service manual. It's essential to follow the correct reset procedure to avoid any potential issues or complications.

Seeking Professional Assistance

While many Suzuki outboard owners may feel confident in tackling basic diagnostics and troubleshooting, some issues may require the expertise of a certified Suzuki marine technician. These professionals have access to advanced diagnostic equipment, specialized knowledge, and the latest service bulletins and updates from Suzuki.If you encounter a particularly complex or persistent issue, or if you're unsure about the proper course of action, seeking professional assistance can save you time, money, and frustration in the long run. Authorized Suzuki service centers and mobile mechanics are equipped to handle even the most challenging outboard problems, ensuring your engine is restored to optimal condition. For mobile service options, you can explore Suzuki Mobile Service: Outboard Repair Without Boundaries.

Conclusion

By embracing the power of diagnostic tools, understanding service codes, and mastering service reset procedures, you'll be well-equipped to tackle a wide range of Suzuki outboard issues. However, remember that troubleshooting is an ongoing process, and staying up-to-date with the latest diagnostic techniques and service information is crucial for maintaining your outboard's peak performance and longevity. For insights into the costs associated with maintaining your Suzuki outboard, check out Suzuki Outboard Price: Unveiling the Financial Realities of Repair and Upkeep.

0 notes

Text

Best Top 5 Diagnostic Car Scanners for Professional Mechanics in 2024

In 2024, the automotive industry continues to evolve, making it essential for professional mechanics to have the best tools at their disposal. Best Diagnostic car scanners have become indispensable in modern auto repair, providing accurate and efficient diagnostics. Here, we explore the top 5 diagnostic car scanners for professional mechanics in 2024, helping you choose the right tool to enhance your service quality and efficiency.

1. EV Scanner DaTo DAS623 Ultimate EV

The EV Scanner DAS623 Ultimate EV by DaTo is a specialized diagnostic tool designed for electric vehicle battery inspection. It integrates comprehensive battery pack detection with whole vehicle system diagnostics, supporting code reading, code clearing, data stream analysis, action tests, and special functions.

Features:

Supports reading essential battery pack parameters like SOC, SOH, voltage, current, power, and temperature.

Comprehensive system detection for all NEV series, including code reading, code clearing, data flow analysis, action tests, and special functions.

Covers more than 95% of EV systems with continuous updates.

Supports testing of DC/DC converters, onboard chargers, high-voltage distribution boxes, and more.

Equipped with battery pack professional connectors and aviation plug connectors.

Dual Wi-Fi design for simultaneous VCI and internet access. Provides a whole vehicle topological graph for quick fault point identification.

2. DAS723 PRO ULTRA

The DAS723 PRO ULTRA, developed by DaTo, is a professional auto smart diagnostic tool that integrates ADAS calibration, anti-theft matching, tire tread detection, oscilloscope, multimeter, current clamp, and more. It supports full system and full function diagnosis with over 30 common special functions.

Features:Covers vehicle calibration with ADAS systems across Europe, America, Asia, and domestic vehicles.

Intelligent VIN identification, fast calibration, ADAS system scanning, and professional ADAS reports.

Anti-theft matching function for many models from various regions with continuous updates.

Whole system detection including code reading, code clearing, data stream reading, and action testing.

Can be used with a full series of ADAS calibration main racks. Supports 34 common maintenance functions.

3. DaTo Diagnostic Scanner DAS722

The DaTo Diagnostic Scanner DAS722 is a handheld, token-less vehicle testing tool featuring professional diagnostic and auto-repair functions built into an 8" Android-powered tablet. It includes three years of free software updates and supports 23 special functions.

Features:High-end tablet automotive diagnostic tool with comprehensive OE-level diagnostics.

Generic OBDII operations for retrieving vehicle diagnostic information.

Data management, bi-directional contact, and component active tests.

Feedback with data logging, auto scan, and manual selection options.

Auto VIN identification, adaptation, and initialization.

Workshop management and parameters digital and graphic display.

Remote control and ECU coding functions.

Three years of free online updates.

4. DaTo Diagnostic Scanner DAS528

The DaTo Diagnostic Scanner DAS528 is a handheld vehicle testing tool with a classic design that provides a new diagnostic experience. It can diagnose all systems, including engine, transmission, ABS, airbag, and more, and supports 21 special functions.

Features:

Extensive vehicle coverage for over 80 US, Asian, and European vehicle makes.

Exceptional OE-level system coverage for all electronic systems.

Complete capabilities for codes, live data, active tests, ECU information, adaptation, and matching.

Smart Auto Scan technology for easy vehicle identification.

Automatic system and software updates via Wi-Fi.

Advanced reset services with an independent menu for quick operation.

Bi-directional control or active test for efficient troubleshooting of actuators.

5. DaTo Bluetooth OBD2 Scanner DAS1026

The DaTo Bluetooth OBD2 Scanner DAS1026 is a wireless diagnostic scanner that goes beyond basic functions. It reads and clears fault codes, displays inspection and maintenance readiness status, and provides enhanced features such as live oxygen sensor data and EVAP system testing.

Features:Supports vehicles produced after 1996 with OBDII protocol in the US, Europe, and Asia.

Compatible with CAN J1850PWM, J1850VPM, ISO9141, and KWP2000 protocols.

Supports Android devices.

Displays live oxygen sensor data and EVAP system tests. Prints diagnostic reports via PC.

Conclusion

Choosing the right diagnostic car scanner can significantly enhance your efficiency and accuracy as a professional mechanic. The EV Scanner DaTo DAS623 Ultimate EV, DAS723 PRO ULTRA, DaTo Diagnostic Scanner DAS722, DaTo Diagnostic Scanner DAS528, and DaTo Bluetooth OBD2 Scanner DAS1026 represent the top choices for 2024, each offering unique features and benefits to meet various needs and budgets. Invest in a quality scanner to stay ahead in the competitive automotive repair industry.

For more information on the best diagnostic car scanners and other automotive tools, visit DaTo Scanners the leading supplier of diagnostic car scanners.

#diagnostic car scanners#diagnostic scanner#automotive#automotive diagnostic scan tools market#automotive tools#EVScanners#BluetoothODB3Scanners

0 notes

Text

Launch X431 Audi Peugeot Diagnostic Software Update

Launch X431 Released new diagnostic software for Audi and Peugeot!

Update Info:

AUDI V29.00

Added the fault guiding functions, guided functions and ADAS (Advanced Driver Assistance System) function for some 2022-2023 Audi models. Added basic functions and special functions for systems of most 2022 2023 models. Updated the data for performing the functions Read Data Streams, Basic Configuration, Matching, Actuation Test, Login, and Coding by Channel Number. Added the troubleshooting function for some DTCs. Optimized the data of online coding, online safety login, and online programming. Optimized the fault guiding system scanning and picture display. Optimized the system model identification for some special functions. Optimized the SFD (vehicle diagnosis protection) activation function. Optimized the special functions such as air suspension matching and personalization setting. Fixed the data stream reading bug in the nitric oxide catalyst emergency regeneration function

PEUGEOT V44.07

Added basic functions and actuation test for multiple types of ECU; optimized VIN automatic recognition function and speed scanning method.

*Please Update Launch X431 Subscription and check out the details

Stay tuned!

0 notes

Text

A Drivability Dilemma: What Happens If You Disconnect Throttle Position Sensor?

Understanding the Throttle Position Sensor

The throttle position sensor (TPS) is a vital component in modern vehicles that monitors the position of the throttle valve, which controls the amount of air entering the engine. Located on the throttle body, the TPS sends voltage signals to the engine's computer (ECU) indicating if the throttle plate is closed, partially open, or fully open. This data allows the ECU to precisely calculate the required air/fuel mixture and ignition timing for optimal engine operation and fuel efficiency.

What Happens If You Disconnect Throttle Position Sensor

Disconnecting the throttle position sensor can lead to a variety of issues impacting drivability:

Engine Performance Issues

- Poor engine running or stalling

- Rough or unstable idling

- Hesitation or lack of power during acceleration

- Increased fuel consumption

- Engine misfires

Warning Indicators

- Check engine light illumination

- Diagnostic trouble codes (DTCs) stored in the vehicle's computer

Transmission Problems

- In some vehicles, the TPS data also aids in transmission control, so disconnecting it can cause irregular or harsh gear shifting.

Failsafe Mode

- Many modern cars will activate a "limp mode" that restricts engine power and performance if critical sensors like the TPS malfunction as a protective measure.

Essentially, without the TPS data, the ECU cannot properly manage air/fuel delivery or ignition timing, resulting in combustion issues and compromised drivability.

Causes of Throttle Position Sensor Failure

- Wear and tear over time

- Electrical issues like wiring faults or loose connections

- Contamination from debris, oil or moisture

- Improper calibration or sensor misalignment

- Physical damage from impact

- Oxidation and corrosion

- Defects from manufacturing

Calibrating the Throttle Position Sensor

While procedures can vary by vehicle, a basic calibration typically involves:

1. Engine off

2. Locate the TPS

3. Fully depress and release accelerator pedal 5-10 times

4. Turn ignition off and allow ECU to relearn pedal values

5. Start engine and idle to allow ECU adaptation

Bypassing or Cleaning the Sensor

- Bypassing the TPS is generally not recommended unless performed by a professional, as it can severely impact engine operation.

- Cleaning the TPS with an electronics cleaner may provide a temporary fix for light contamination, but a faulty sensor will likely need full replacement.

Replacing the Throttle Position Sensor

1. Disconnect battery negative cable

2. Locate TPS on throttle body and disconnect wiring

3. Remove any fasteners securing old sensor

4. Install new TPS, securing it in the correct position

5. Reconnect battery and start engine

6. Perform test drive to verify repair

Post-Replacement Steps

- Reset TPS by disconnecting battery briefly

- Use a scan tool to clear any diagnostic trouble codes

- Test drive to monitor throttle response and drivability

- Keep monitoring for any recurring issues

- Follow recommended maintenance schedules

In summary, the throttle position sensor is crucial for managing engine air/fuel delivery and performance. Disconnecting or having a faulty TPS can significantly impact drivability through issues like rough running, poor acceleration, and transmission problems. Proper diagnosis is key, as the TPS may need calibration, cleaning or full replacement to restore optimal engine operation. Following the recommended procedures and testing thoroughly after replacement is important to avoid further issues.

0 notes

Text

VW Check Engine Light Comes On & Off 5 Key Components to Check

The sudden illumination of the check engine light in your VW car can be a cause for concern, leaving many drivers wondering about the potential issues affecting their vehicle. While it's easy to assume that the problem lies solely within the engine, it's crucial to understand that various interconnected systems contribute to the overall performance of your car. In this article, we will explore the reasons behind the check engine light, emphasizing the importance of diagnosis and highlighting key components to inspect when faced with this warning.

Understanding the Check Engine Light

The check engine light serves as a vigilant indicator, signaling potential issues within the car's systems that extend beyond the engine itself. When problems arise in critical systems affecting energy generation, monitoring devices send signals to the Engine Control Unit (ECU) and On-Board Diagnostics (OBD) systems. The ECU then triggers the check engine light and stores trouble codes that provide insights into the root cause of the problem.

Diagnosing Check Engine Light Problems

Effectively diagnosing the issues triggering the check engine light can be a daunting task, considering the myriad of interconnected components in a modern vehicle. Utilizing an OBD2 scanner proves to be a valuable tool, allowing users to retrieve trouble codes and gain a better understanding of the potential culprits. However, it's essential to focus on specific areas prone to causing check engine light problems in VW cars.

Transmission Check

A malfunctioning transmission can disrupt the energy generation process, leading to a noticeable decrease in power output. Monitoring systems recognize this imbalance, triggering the check engine light. It's advisable to have the transmission thoroughly checked for faults, ensuring optimal performance and preventing further complications.

Ignition System Inspection

The ignition system plays a pivotal role in igniting the fuel and air mixture, directly impacting power generation. Components such as spark plugs and ignition coils need regular inspection and replacement to avoid power loss issues. Identifying faults in the ignition system early on can prevent more significant problems and keep the check engine light at bay.

Fuel System Examination

Faulty fuel system components, such as low fuel pressure or leaks, can compromise the combustion process. The insufficient fuel in the combustion chamber triggers the check engine light. Regular checks and timely replacements of fuel system components are crucial to maintaining the proper fuel-air ratio and preventing power loss.

Oxygen Sensor Verification

The oxygen sensor monitors the oxygen levels in the exhaust gas, providing vital information to the ECU for fuel-air ratio adjustments. A faulty sensor can send inaccurate data, leading to power loss and the illumination of the check engine light. Regular checks and prompt replacement of the oxygen sensor are essential for optimal engine performance.

Exhaust System Evaluation

Components like the catalytic converter, exhaust manifold, and EGR valve contribute to proper air flow in and out of the engine. When these parts become faulty, they hinder the engine's ability to generate power efficiently, prompting the check engine light. Thorough inspection and timely replacement of exhaust system components are crucial for sustained performance.

Conclusion

In conclusion, a glowing check engine light in your VW car should not be ignored, as it can signify underlying issues that extend beyond the engine itself. Timely diagnosis and attention to key components such as the transmission, ignition system, fuel system, oxygen sensor, and exhaust system are essential for maintaining optimal performance. Utilizing tools like OBD2 scanners can streamline the troubleshooting process, providing valuable insights into trouble codes. To ensure a comprehensive diagnosis and resolution of check engine light problems, it is advisable to seek professional assistance at a VW service center. By addressing these issues promptly, you can safeguard your vehicle's performance and enjoy a smoother driving experience.

#volkswagen car#volkswagen check engine light#volkswagen service center#volkswagen mechanic#volkswagen car services

0 notes

Text

OTOFIX D1 Plus OE Level Automotive Test Diagnostic Scan Tool ECU Coding Upgraded With 36+ Service Functions

OTOFIX D1 Plus OE Level Automotive Test Diagnostic Scan Tool ECU Coding Upgraded With 36+ Service Functions

OTOFIX D1 Plus

OTOFIX D1Plus is the upgrade of D1 Pro, come with better hardware, Bi-directional diagnostic tool that provides one-stop solutions. Full system diagnosis, comprehensive service functions, active test and OE-level diagnosis, ECU onling Coding and DTC analysis — you can do them all.

Full Maintenance Service Function

-Oil Service Reset:

Performs reset for the Engine Oil Life system, which calculates an optimal oil life change interval depending on the vehicle driving conditions and climate, and turns off the warning light;

-TPMS Service:

Quickly looks up the tire sensor IDs from the vehicle's ECU, as well as perform TPMS programming and reset procedures after tire sensors are replaced;

-EPB Service:

Initialize the throttle actuators to the default state for regulating throttle (or idle engine) operations accurately;

-ABS/SRS Services:

Performs various bi-directional tests to check the operating conditions of both the Anti-lock Braking System and the Supplemental Restraint System;

-SAS Service:

erforms steering angle adjustment, clears steering sensor fault memory, and turns off steering wheel warning light;

-DPF Regeneration Service:

Clears particulate matter from the DPF filter to stabilize the filter performance.

-BMS Service:

Perform a reset on the vehicle battery for clearing the fault information and re-match the battery;

-Brake Bleed:

When your brake pedal becomes soft and inconvenient to control, this diagnostic tool can perform bi-directional tests to check the Anti-lock Braking System;

-IMMO Service:

Clear the lost car key's information and program the new key into the ECU database to protect the user's car from being stolen;

-Injector Coding:

Make the cylinder better identify injector after ECU or injector is replaced;

-SAS Service:

to perform calibration for the Steering Angle Sensor and clear steering sensor fault memory;

-Throttle Adaptation:

initialize the throttle actuators to the default state for regulating throttle (or idle engine) operations accurately

-Headlamp, Suspension, Lang change, Odometer, Seats, CHG tire size, TEC learn and WIN DR ROOF, etc

All Systems in-depth Diagnosis Function

-Read/Erase Codes and show ECU information:

OTOFIX D1 Plus can read and show the specific information for the tested control unit, including unit type, version numbers. Displays detailed information of DTC records retrieved from the ECU and erases DTC records and other data from the ECU.

-Live Data:

Retrieves and displays live data and parameters from the test vehicle's ECU.

-Active Test:

This function can test specific subsystems and components. It's also called Actuator Test or Function Test.

OTOFIX D1 Plus performs complete systems diagnoses including functional tests, retrieve vehicle diagnostic information (trouble codes), freeze frame data and live data for various vehicle control systems (engine, transmission, ABS, etc.), providing its users with all the information pertinent to a vehicle's health quickly and in an accessible, reader-friendly format.

Outstanding Performance

- Industry-Leading Software Update and Impeccable Wide Vehicle Coverage

- Advanced hardware 10.4-inch screen with 128G storage and 4G memory

- Powerful and fast diagnosis for all vehicle systems, covering 10,000+ car models >>check the vehicle coverage

- Full System Bi-directional Active Test. Capable of codes, live data, active test, ECU information, adaptation, matching, etc.

- FCA Secure Gateway Access with AutoAuth subscription,

- Forthcoming Cloud Data management and Repair & Diagnostic Database.

- Online coding, refresh hidden functions and guided functions on supported vehicles

0 notes

Text

Fault Diagnosis and Maintenance of Carter 320A Excavator's Slow Movement and Weak Excavation

Fault Diagnosis and Maintenance of Carter 320A Excavator's Slow Movement and Weak Excavation

Fault Diagnosis and Maintenance of Carter 320A Excavator's Slow Movement and Weak Excavation

CAT Caterpillar ET 4 Diagnostic Adapter Truck Diagnostic Tool

The CAT320A excavator produced by Caterpillar in the United States is an early product of

Caterpillar. It is equipped with electronic monitoring, engine control and pump valve control systems.

It has a high degree of automation, good comprehensive performance and low price. In recent years,

there has been a large amount of domestic ownership, and most of them are second-hand mobile

phones. Most of the monitoring systems of these excavators are damaged. Once a fault occurs, the fault

code cannot be read out, and it can only be diagnosed and eliminated manually. Slow movement and

weak excavation are common faults in the second-hand CAT320A excavator. The following will

introduce the diagnosis and maintenance methods from the circuit system and hydraulic system with examples

.2023 CAT ET 2023A 2022A & 2019C Full Service Download and Installation Service

(1) Troubleshooting of the circuit system Fault phenomenon: A CAT320A excavator moves slowly

and digs weakly; when the boom or stick is extended to the bottom, the engine is severely blocked. The control of the digging speed and digging force of the excavator with a computer is realized by the

computer controlling the pilot oil circuit through the proportional solenoid valve according to the

change of the external load, thereby changing the angle of the swash plate of the variable pump.

Therefore, the pilot oil pressure should be checked first, and the measured pressure is 3.9 MPa, which

is normal; then check the pilot oil circuit, and the proportional solenoid valve can be checked

according

to the method shown in Figure 1. Use a DC clamp meter (set in mA gear) to clamp a single wire of the

large-scale solenoid valve, set the mode switch to a heavy load, start the engine, and perform actions.

The clamp meter has no current indication. Unplug the plug, turn on the key switch, measure the input

terminal voltage is about 24V, normal, measure the proportional solenoid valve terminal resistance. ,

indicating that the proportional solenoid valve coil is open circuited. Remove the proportional solenoid

valve 1 for inspection, and find that the lead wire at the rubber seal of the incoming line has been

fatigued and broken. Re-weld the rubber seal and put it back into the test run. When doing the action,

the reading of the DC clamp meter changes between 250-300mA, the whole car functions normally, and

the fault is eliminated.

12.2021 Caterpillar ECM ECU Flash Files Full Set Download

(2) Troubleshooting of the hydraulic system Fault phenomenon: A CAT320A excavator moves slowly

and digs weakly, but it does not hold the car, and it feels that the engine load is very light. The speed of

the excavator is determined by the flow rate, and the digging force is determined by the pressure output

by the main pump. Therefore, this fault needs to be checked from two aspects of flow and pressure

control. First, check according to the method in Figure 1. The reading of the DC clamp meter changes

between 280~600 mA, and the measured output pressure of the proportional solenoid valve changes

between 1.5-3.7 MPa, indicating that the proportional control system and the pilot oil circuit work

smoothly. normal. Then measure the output pressure of the upper and lower main pumps, which are all

around 26 MPa, which is low. Upon inquiry, the machine had been adjusted before, saying that the main

relief valve was broken and the pressure could not be adjusted. Raise the engine to the rated speed, and

adjust the main relief valve 1 in the middle of the multi-way valve group, as shown in Figure 2. Screw

the adjustment rod to the bottom, and the pressure rises to 27 MPa, indicating that there is indeed a

problem with the main relief valve. Remove the main relief valve for cleaning, and screw the piston

cavity on the relief valve 4 turns inward, and then reinstall the main relief valve. The flow valve is

adjusted, the pressure rises, and the pressure of the main pump is adjusted to 32MPa. At this time, the

digging force increases, but the whole vehicle still moves very slowly.

10.2021 Caterpillar SIS EPC+Service Manual download & Full Installation Service

Figure 2 Multi-way control

valve group Then adjust the power regulator of the upper and lower main pumps, turn the adjusting

screw inward, the power increases, and retreat outward, the power decreases. Because, hydraulic power

= Flow × pressure. When the pressure is constant, increase the power, the system flow will increase,

and the speed of the whole vehicle will become faster. The first time the adjustment screw is screwed in

1/4 turn, the speed does not change, and then screwed in 1/2 turn, the speed still does not change,

indicating that the fault lies in the flow regulating valve in the multi-way control valve. The flow

regulating valves 2 and 3 of the upper and lower main pumps are installed on the bottom surfaces of the

left and right ends of the multi-way control valve group, as shown in Figure 2. Remove the flow

regulating valves 2 and 3, and find that the inside of the valve core is blocked by paper scraps from the

oil filter, then open the hydraulic oil tank cover, and find that the oil return filter has been sucked

through two large holes, and then drain the oil immediately , Clean the hydraulic system, change the

filter, and refuel. Cleaned the flow regulating valve and put it back on. After a test run, the speed was

unexpectedly fast, but the engine felt a little suffocated. The owner said that the car had never been so

fast since I bought it. Then slowly back out the adjustment screw of the power regulator until the speed

is moderate, but the car does not hold back. At this point, the fault is completely eliminated. The driver

said that the machine works the same as a new car now.

(3) Summary CAT320A excavator, if the movement is slow, the engine is stuck, and the pilot oil circuit

is normal, it is mostly the proportional solenoid valve and the solenoid valve control circuit. There are

no faults such as grounding, short circuit and open circuit. Because the speed of the excavator's

movement and the size of the digging force vary with the size of the external load. As the external load

increases, the engine speed decreases. When the computer detects that the pump speed drops, the

control current input to the proportional solenoid valve will decrease, and the angle of the swash plate

of the variable pump controlled by the pilot oil circuit will become smaller, the output flow of the

pump

Caterpillar CAT Factory Password Calculator Generator 10 Digits VM Version

will decrease, the engine load will decrease, and the speed will rise. until it matches the engine set rpm

until the speed is equal. At this time, the engine is working at the best state of the throttle setting

position, and the engine will not only exert the maximum efficiency but will not hold the car or stall.

When the proportional control circuit fails, the output of the pump cannot adapt to the change of the

external load. When the external load continues to increase, because the output of the pump cannot be

automatically adjusted, the speed of the engine will continue to decrease until the engine is turned off,

so serious problems occur. Car suffocation phenomenon. The diagnosis and elimination of this fault

are

suitable for all excavators with computers. If the movement is slow, the excavation is weak, but the

engine does not hold the car. When the pilot oil circuit is normal, it is mostly because the pressure and

flow adjustment system is faulty. Firstly, adjust the main relief valve, adjust the pressure of the main

pump to 30~32MPa, and then adjust the flow. If adjusting the power regulator can not adjust the flow

to the required range, you can adjust the flow regulating valve. The adjustment of the flow regulating

valve is adjusted by increasing or decreasing the gasket, the gasket increases, the flow increases, and

the gasket decreases, the flow decreases. If there is a flow tester, connect the flow sensor to each single-

pump circuit in series, and raise the engine to the rated speed, and adjust the flow to 240 L/min under

no-load conditions. If there is no flow tester, the flow can only be adjusted by the speed of the

movement, experience and feeling. The author used the above method to repair several CAT320A

excavators with computer control, and all achieved good results.

https://www.heavydutydiag.com/product/caterpillar-sis-2021-data-01-2021-full/

0 notes

Text

CGDI CG70 Clear Crash Data on Great Wall 3658120XP1MBA Airbag ECU

How to use CGDI CG70 Airbag Reset Tool to clear crash data on a Great Wall 3658120XP1MBA airbag ECU?

Here is the operation guide.

Connect CGDI CG70 and a computer which has installed CG70 Airbag Reset software

Open CG70 software

Input 365812 in the search box to quickly find Great Wall 3658120XP1MBA

Check wiring diagram

Need to connect GND, +12V, CANH and CANL four cables

Connect CG70 Airbag Reset Tool and Great Wall airbag ECU via the professional harness properly

Start to read DTC and then clear the crash data one key by clicking “Auto Repair”

Done!

CGDI CG70 Airbag Reset Tool:

0 notes

Text

Carcode For Programming And Repairing Electronic Components Of Your Vehicle

Carcode is the process of using specialized tool/software to change or modify the computer settings and functionalities of a car’s electronic control units (ECUs) or modules. Automotive coding can be used for a variety of purposes, including enabling or disabling certain features, altering performance parameters, and modifying the behaviour of various automotive systems. It enables customers to access and modify certain settings in these ECUs in order to tailor the functioning of their automobiles. Although it may seem intriguing, it’s vital to keep in mind that automobile coding may invalidate warranties or break legal rules in some areas, so it’s critical to investigate and understand the repercussions before trying any alterations.

WHY IS CARCODE IMPORTANT?

Car coding is important for several reasons:

Customization and Personalization: Owners may customize their cars to suit their tastes thanks to carcodes. They may use it to activate and provide software functions that might not be turned on by default. The whole driving experience may be improved, and the owner’s wants can be better met by such personalization.

Activating Hidden functions: A few vehicles include functions that are not turned on by default. Users can get access to these hidden features through coding, which offers extra functionalities and features that might not be present in the initial configuration.

Performance Enhancement: performance-minded drivers and Auto enthusiasts may employ carcode programming to tweak vehicle settings to boost performance, such as increasing horsepower, altering throttle response, or modifying transmission behaviour.

Diagnostic and troubleshooting: coding tools may be used to read and interpret diagnostic trouble codes (DTCs) from a vehicle’s onboard diagnostic (OBD2) system. This aids in the identification and diagnosis of faults, making it easier for personnel to troubleshoot and repair difficulties.

ADDITIONAL ADVANTAGES OF CARCODES:

Keeping Up with Technology – As automotive technology progresses at a rapid pace, coding enables older vehicle models to make use of some of the newest features and enhancements seen in newer cars. This can increase the lifespan of older ones while also improving their general functionality.

Improved User Experience – By allowing customised settings and functions, it makes driving more user-friendly and convenient. Drivers can modify the behaviour of their autos to fit their driving style and preferences.

Recalls and Software Updates – Car coding may be used to install software updates and handle recalls without visiting a dealership, saving annoyance and possible expenses for the car owner.

Emission Compliance and rules – In some circumstances, automobile coding may be utilized to adjust the vehicle to meet emission standards and rules in different countries.

Retrofitting contemporary amenities – Older automobile models may lack key contemporary amenities that have become standard in newer vehicles. Carcode can assist with repairs of some of these amenities in older cars. For example: adding a Bluetooth scanner or upgrading infotainment systems.

THINGS THAT YOU HAVE TO TAKE INTO CONSIDERATION

Coding must be approached with caution and responsibility. Improper practices or illegal alterations can result in safety hazards, voiding warranties, and legal complications. Coding should only be done by those who have the requisite skills, and any changes should adhere to local rules and regulations.

In addition, it should also not be used to circumvent safety measures or influence emission controls. Such behaviours can jeopardize road safety and add to pollution. Responsible automobile coding should concentrate on legal adaptations and changes that improve the overall driving experience while remaining within legal and ethical constraints.

IS CAR MILEAGE STILL IMPORTANT NOWADAYS?

We are all aware that one of the most crucial considerations when buying a car is a tool for carcodes and odometer reading. But why is it so crucial, and what does mileage truly mean?

People mistakenly assume that more mileage always results in greater wear and tear and maintenance expenditures. These kinds of automobiles are regarded as being well-kept and also having a greater resale value. This is the key motivator for other people to reset their odometers. They employ various automobile equipment to alter the speedometer’s digital readings.

However, the meanings of “low” and “high” are continually evolving. What used to be regarded as “high” is no more the same due to technological advancement. For example, a hundred thousand miles used to signify a vehicle was too old for driving, but today they may go as much as 200 000 miles with no breaking down.

Although the miles might provide useful data and become a useful analyzer, people use the carcode to manipulate a car computer. other factors are as vital. You must carefully evaluate past owners’ driving behaviours as well as the settings on which it was operated. These considerations tend to be even more vital than the numbers displayed on a monitor.

WHY IS ADJUSTING THE MILEAGE ON A DIGITAL ODOMETER SO POPULAR NOWADAYS?

People often modify the mileage reading on a digital odometer to increase the resale value of their vehicles. In autos, carcodes are used to influence the computer center and shorten the distance. There are still a few primary reasons why people attempt to adjust mileage.

Misfunction is among the most frequent causes of odometer adjustments. It’s possible that the dashboard is no longer showing the appropriate data. Therefore, you should be able to check a car’s mileage.

Computers often show incomplete data after repairs. You should update it right away because this is a fairly typical occurrence for practically all models.

Each automobile is put through a number of tests and inspections before being put up for sale. An electronic odometer restoration device is typically used by testers. It assures the deletion of the last recorded mileage.

One of the common uses of the carcode for changing the mileage on the odometer is physical damage to the control panel. The odometer malfunctions as a result, and the computer system may display false information.

UTILIZATION OF VARIOUS GADGETS

Modern digital odometers appear to be safer since they save data in system storage units, but their data is still susceptible to manipulation. A rollback tool is a tool that will change the final statistics on the dashboard. After utilizing this device, the mileage will be less than the actual distance traveled. However, diagnostic tools can immediately locate the interference that can cause more problems.

The mileage data is completely restored via the resetting method. As a result of using these methods, your total mileage will display as “0”. As you can see, knowing how many miles your automobile has involves more than just looking at the odometer. Despite the fact that this gadget looks to be a success, reset tools suffer from the same problem: Carfax, a dealer or a scanner tool will certainly identify carcodes. As a result, it is neither completely feasible nor ideal for the clients or service centers.

The correction tool alters any number and shows the desired result. This gadget, often known as an adjustment tool, allows you to select the number of miles shown in your car. The biggest disadvantage of this strategy is that the information is easily traceable.

CAR CODING MILEAGE BLOCKER

A mileage blocker is a piece of equipment that prohibits all control units from registering miles. It does not delete, reverse, or change any existing data. The main goal is to prevent the computer from adding extra miles while driving. The premier distinction between this carcode tool and previous approaches is that it is completely untraceable and undetectable. The German experts at Super Kilometer Filter designed this distinctive gadget with temperature-resistant and superior components that will operate flawlessly in any situation. It also includes DIY setup instructions, so anyone can use it without any further assistance.

As a result, the mileage blocker is a unique solution for people who want to change their distance while leaving no trace. It’s a simple, modest, yet entirely effective solution to a modern problem. This device is completely on another review level compared to other versions of carcodes. Fortunately, this digital vehicle odometer tool can be purchased on the SKF website. So, after installing the mileage blocker, you may use it without having to think about how to check a car’s mileage. Keep in mind that this gadget is only for testing and tweaking. If you use it unethically, you may face legal consequences. Please check the help page or contact customer service if you have any more questions.

TAKEAWAY

Carcode has developed as an engaging realm for automobile owners and enthusiasts, with unmatched chances for customization, detailing, performance enhancement, and discovering hidden features. With enormous power, however, comes great responsibility. Before commencing the journey of vehicle coding, interested parties should educate themselves and appreciate the necessity of safety, dependability, and legal compliance. Car coding may genuinely uncover the hidden potential of your favorite vehicle when treated with caution and a zest for invention, making every drive a unique and thrilling journey.

0 notes

Text

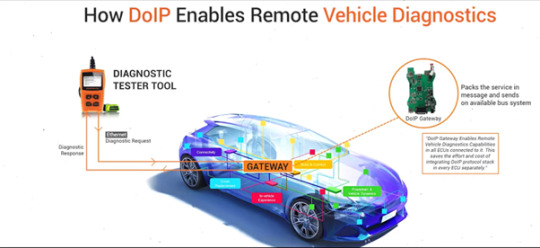

Unified Diagnostic Services Protocol: Enabling Remote Diagnostics for Vehicle ECUs

In the new era of connected cars, the ability to diagnose and troubleshoot vehicle issues remotely has become an invaluable feature. Traditional vehicle diagnosis requires a physical connection to the vehicle's electronic control unit (ECU), which can only be done in a garage or service centre. But with the advent of the Unified Diagnostic Services (UDS) protocol, the game has changed entirely. This blog post will examine how UDS protocol is playing a key role in enabling remote diagnostics in connected cars.

The Essence of Unified Diagnostic Services

Unified Diagnostic Services (UDS) is an automotive diagnostic communication protocol established by the International Organization for Standardization (ISO) under ISO 14229-1. The protocol provides a comprehensive framework for vehicle diagnostics and maintenance, offering services for tasks like reading or erasing fault memory, adjusting vehicle parameters, and programming new firmware.

DoIP and UDS Enabling Remote Vehicle Diagnostics

UDS Protocol and the Power of Remote Diagnostics