#EDM Machining for Complex Designs

Explore tagged Tumblr posts

Text

EDM Machines in the Middle East: Precision Solutions for Modern Manufacturing

The manufacturing industry in the Middle East is experiencing a surge in demand for precision engineering, particularly in sectors like aerospace, automotive, medical devices, and electronics. As industries evolve, so does the need for cutting-edge technologies that can deliver high accuracy and intricate details. This is where EDM (Electrical Discharge Machining) machines come into play. These advanced machines are transforming manufacturing processes by offering unparalleled precision, versatility, and efficiency.

Phillips Corporation, a global leader in precision machining, provides state-of-the-art EDM machines in the Middle East. With the increasing need for complex parts that meet exacting standards, EDM technology has become a crucial part of modern manufacturing in the region. Whether you are in the aerospace industry, automotive sector, or working on intricate medical devices, Phillips Corporation offers EDM solutions that can help you achieve the highest quality components.

What are EDM Machines?

Electrical Discharge Machining (EDM) is a non-traditional machining process that uses electrical discharges (sparks) to remove material from a workpiece. This process is ideal for manufacturing components with tight tolerances and complex geometries that would be difficult or impossible to achieve with conventional machining techniques.

EDM machines can operate in two primary forms: Wire Cut EDM and Sinker EDM. In Wire Cut EDM, a thin wire is used as the electrode to cut through materials with extreme precision. This technology is particularly useful for cutting intricate shapes, sharp corners, and narrow features. Sinker EDM, on the other hand, uses an electrode to erode material from a workpiece by creating a series of sparks, allowing manufacturers to shape parts with complex features, cavities, and deep holes.

Both types of EDM machines are essential for industries that require high levels of accuracy and the ability to work with hard or sensitive materials.

Why Choose EDM Machines for Your Manufacturing Needs?

Unmatched Precision and Accuracy EDM machines are known for their precision and ability to achieve extremely tight tolerances, often within a few microns. This level of accuracy is crucial in industries like aerospace, automotive, and medical device manufacturing, where even the smallest deviation can lead to catastrophic failures. By choosing EDM machines, manufacturers can ensure that every component meets stringent quality standards.

Versatility Across Materials One of the standout features of EDM machines is their ability to work with a wide range of materials. Whether it’s hard metals like titanium, carbide, or tool steel, EDM machines can cut, shape, and refine materials that would otherwise be challenging to machine using conventional methods. This makes EDM machines an invaluable tool for industries that require intricate parts made from tough materials.

Complex Geometries Made Easy The ability of EDM machines to create intricate shapes and complex geometries sets them apart from traditional machining methods. Whether you need parts with sharp internal angles, small holes, or delicate features, EDM machines can produce these components with extreme accuracy, eliminating the need for time-consuming secondary operations.

Minimal Tool Wear and No Mechanical Stress Unlike traditional machining methods that rely on mechanical forces to cut material, EDM machines use electrical discharges to erode the material. This means there is no physical contact between the tool and the workpiece, resulting in no wear on the tool and no mechanical stress on the material. This leads to greater tool life and a higher level of precision throughout the machining process.

Efficiency and Cost-Effectiveness EDM machines can work with very little material waste due to their highly controlled process. Since the material is only eroded where it is needed, the overall efficiency of the machining process is greatly increased. Additionally, EDM reduces the need for secondary finishing operations, saving both time and money. For manufacturers in the Middle East looking to streamline their production processes, EDM machines offer a cost-effective solution without compromising on quality.

The Growing Demand for EDM Machines in the Middle East

The Middle East has seen rapid industrial growth in recent years, particularly in sectors like aerospace, automotive, and energy. This demand for high-precision parts and components has led to an increased reliance on EDM machines in the Middle East.

As industries evolve, there is a growing need for manufacturing technologies that can handle complex, high-precision parts with minimal waste. EDM machines are ideal for this, providing a solution that is both reliable and cost-effective. Moreover, with the Middle East becoming a hub for manufacturing innovation, businesses in the region are increasingly adopting EDM technology to stay competitive in a global market.

Phillips Corporation, with its expertise in precision engineering, has become a trusted partner for companies in the Middle East seeking top-quality EDM machines. Their range of machines caters to a variety of industries and manufacturing needs, ensuring that businesses can achieve the highest levels of accuracy and efficiency.

Why Choose Phillips Corporation for EDM Machines in the Middle East?

Phillips Corporation stands out as a leader in providing EDM machines in the Middle East. Their portfolio includes both Wire Cut EDM and Sink EDM machines, offering flexibility for different manufacturing needs. Phillips’ EDM machines are known for their precision, reliability, and efficiency, making them the ideal choice for industries that require high-quality components.

Beyond just supplying machinery, Phillips Corporation also offers comprehensive support, including expert consultation, installation, and ongoing technical assistance. Their team of experts ensures that businesses in the Middle East can maximize the potential of their EDM machines, boosting productivity and maintaining high standards of quality.

Conclusion

As the demand for precision manufacturing continues to rise, EDM machines in the Middle East have become a cornerstone of modern production techniques. Whether it’s cutting complex geometries, working with hard materials, or achieving tight tolerances, EDM machines provide unmatched accuracy and versatility. Phillips Corporation’s state-of-the-art EDM solutions ensure that businesses in the Middle East can meet these demands efficiently and effectively.

By choosing Phillips Corporation for your EDM needs, you are investing in the best technology available to stay ahead of the competition and deliver high-quality products to the market. With Phillips’ expertise and world-class EDM machines, the future of precision manufacturing in the Middle East looks brighter than ever.

1 note

·

View note

Text

CNC Machining Services in Bangalore: Driving Innovation and Precision

Summary

CNC machining services in Bangalore offer precision, efficiency, and scalability for industries like aerospace and automotive. Supported by skilled talent and advanced equipment, it's a top choice for modern manufacturing needs.

Introduction

Bangalore, widely recognized as India’s technological and industrial epicenter, is also home to a growing network of precision engineering and manufacturing units. In recent years, the rise of CNC (Computer Numerical Control) machining has revolutionized how businesses in this region produce high-accuracy components across diverse industries.

For manufacturers seeking efficiency, consistency, and precision, the availability of reliable CNC machining services in Bangalore offers a significant competitive edge. This article explores the city's CNC capabilities, the role of machine manufacturers, and how businesses can find the right partners without relying on brand names.

The Role of CNC Machining in Modern Industry

CNC machining enables automated control of machining tools using pre-programmed software. It is vital for industries such as aerospace, automotive, healthcare, and electronics due to its ability to deliver:

Exceptional accuracy with minimal error margins

Uniformity across large production volumes

Speed and efficiency in manufacturing processes

Flexibility in handling multiple materials, from metals to plastics

By reducing manual labor and improving consistency, CNC technology forms the backbone of advanced manufacturing. This is especially evident in Bangalore, where technology and manufacturing intersect to deliver world-class solutions.

Why Bangalore Stands Out for CNC Services

1. Established Manufacturing Clusters

Industrial zones such as those in Peenya, Bommasandra, and surrounding areas host a vast concentration of workshops and factories offering advanced machining services. The region’s infrastructure supports a variety of CNC operations, including:

Milling (3-axis and 5-axis)

Turning and boring

Wire EDM

Grinding and surface finishing

These capabilities allow CNC machining services in Bangalore to meet requirements from prototyping to large-scale production.

2. Skilled Technical Workforce

Bangalore’s strong educational ecosystem ensures a steady supply of CNC programmers, operators, and mechanical engineers. This talent pool plays a key role in upholding the quality and innovation standards expected from CNC-driven projects.

3. Integration of Smart Technologies

Manufacturers in the city are adopting cutting-edge tools like CAD/CAM software, IoT-enabled machines, and digital inspection systems. This tech-forward mindset results in smoother operations and better precision control throughout the production cycle.

Versatile CNC Services in Bangalore

A wide range of businesses turn to CNC company in Bangalore providers for various services, including:

a. Prototype Development

Startups and design teams frequently use CNC for quick-turn prototypes. It allows for fast iteration and testing without the need for expensive tooling.

b. Batch and Mass Production

When consistency and volume are critical, CNC is the preferred option. Bangalore’s machining providers can handle small runs to thousands of units with reliable accuracy.

c. Complex and Custom Parts

For components with intricate geometries, internal features, or specific surface finishes, multi-axis CNC machines provide the flexibility needed to create high-quality, complex parts.

d. Material Flexibility

Whether it’s aluminum, stainless steel, titanium, brass, or engineering-grade plastics, machining providers in Bangalore are equipped to handle a broad spectrum of materials, giving manufacturers full control over performance and cost.

CNC Machine Manufacturers in Bangalore: Supporting Production from the Ground Up

Behind the growth of the machining sector is a strong base of CNC machine manufacturers in Bangalore. These manufacturers design and produce the machinery that powers precision workshops across the region.

Available machines include:

Vertical and horizontal machining centers

CNC lathes and turning machines

CNC routers and engravers

Laser and plasma cutters

Wire EDM equipment

The proximity of machine builders to end users ensures faster maintenance support, easier access to spare parts, and the ability to customize machines according to project needs. Many of these manufacturers also offer automation features, like tool changers and robotic interfaces, allowing for improved throughput and efficiency.

Sectors That Rely on CNC in Bangalore

The application of CNC machining spans many industries in Bangalore, such as:

Aerospace & Defense: High-precision parts requiring tight tolerances

Automotive: Engine and transmission components, custom brackets, and bushings

Medical: Surgical tools, prosthetics, and orthopedic parts

Consumer Electronics: Precision housings, connectors, and circuit fixtures

Industrial Equipment: Gears, shafts, and custom machine parts

This wide usage reflects how critical the CNC company in Bangalore ecosystem is to the overall manufacturing economy.

How to Choose a CNC Machining Partner in Bangalore

Selecting the right service provider is essential to achieving quality results. Here’s what to consider:

1. Assess Capabilities

Make sure the provider can meet your technical requirements—tolerance levels, materials, and part complexity. Ask if they use 3-axis, 5-axis, or turning centers as needed for your components.

2. Verify Certifications

Look for recognized quality standards like ISO 9001, AS9100 (aerospace), or medical-grade certifications. These ensure process consistency and regulatory compliance.

3. Request Trial Jobs

Consider asking for sample components or test runs to evaluate the quality before committing to a larger batch.

4. Review Turnaround and Delivery

Timely delivery is critical. Evaluate the provider’s lead times and ability to handle urgent or bulk orders.

5. Check Post-Machining Services

Many companies offer additional services such as anodizing, powder coating, heat treatment, and assembly. Opting for full-service solutions reduces coordination efforts.

Advantages of CNC Machining Services in Bangalore

Choosing CNC service providers in Bangalore comes with several advantages:

Affordable and efficient solutions

Access to a well-trained engineering workforce

Latest software and machining technologies

Reliable support and fast turnaround

Proximity to major industrial and logistics hubs

These strengths make CNC machining services in Bangalore a smart choice for companies seeking quality and scalability.

Conclusion

CNC machining has become a vital part of manufacturing, and Bangalore is well-positioned to meet the growing demand. With a rich ecosystem of talent, machinery, and infrastructure, the city offers unmatched value for companies needing everything from rapid prototyping to large-scale production.Whether you're working on high-precision aerospace parts or consumer product enclosures, collaborating with a skilled CNC company in Bangalore ensures a smoother path to success. Combined with the support of innovative CNC machine manufacturers in Bangalore, the city continues to evolve as a national hub for precision engineering.

FAQ

1. What types of CNC machining services are available in Bangalore?

Bangalore offers a wide range of CNC services including turning, milling (3-axis and 5-axis), drilling, grinding, and wire EDM. Whether you need rapid prototyping or high-volume production, CNC machining services in Bangalore can accommodate diverse project requirements across various materials and industries.

2. Why choose CNC machining services in Bangalore over other cities?

Bangalore stands out due to its strong industrial ecosystem, skilled technical workforce, and access to advanced CNC technology. In addition, service providers here offer competitive pricing, fast turnaround, and compliance with global quality standards—all making Bangalore a preferred destination for precision manufacturing.

3. Are there certified CNC companies in Bangalore?

Yes. Many CNC companies in Bangalore follow international standards like ISO 9001 and AS9100, ensuring quality assurance and process reliability. Certifications demonstrate a company's commitment to meeting regulatory and industry-specific requirements.

4. Can CNC machining services in Bangalore handle custom and complex parts?

Absolutely. CNC providers in Bangalore are equipped with advanced multi-axis machines and trained personnel to handle intricate designs, tight tolerances, and complex geometries. They support both one-off custom jobs and large-scale production runs.

5. Who are the CNC machine manufacturers in Bangalore and what do they offer?

While we’re not naming specific brands, Bangalore is home to several CNC machine manufacturers that design and supply a variety of machines including turning centers, milling machines, routers, and laser cutters. These manufacturers also offer automation options and local support for businesses investing in new equipment.

6. How do I select the right CNC company in Bangalore for my project?

To choose the right CNC company in Bangalore, assess their technical capabilities, machinery, certifications, and track record. Also, consider lead time, quality control systems, and whether they offer additional services like coating, assembly, or inspection.

7. What industries benefit the most from CNC machining in Bangalore?

A wide range of industries rely on CNC machining in Bangalore, including aerospace, automotive, medical devices, electronics, and industrial equipment manufacturing. The versatility of CNC technology allows it to serve both high-precision and high-volume production needs efficiently.

0 notes

Text

Micro holes CNC drilling machine - DUOMI

A micro hole drilling machine is a specialized type of precision machining equipment designed to drill extremely small-diameter holes—typically ranging from a few microns up to 1 mm—into a variety of hard and delicate materials. These machines are essential for applications that demand ultra-fine detail, tight tolerances, and high repeatability, making them indispensable in industries such as aerospace, medical devices, electronics, watchmaking, and microfluidics.

Unlike conventional drilling machines, a micro hole drilling machine is built to handle the challenges of small-scale fabrication, such as maintaining thermal stability, vibration control, and fine spindle movement. Advanced models often use high-speed spindles, laser or EDM (electrical discharge machining) technology, and computer numerical control (CNC) systems to achieve precision and consistency that would be impossible with manual or traditional equipment.

One of the primary advantages of using a micro hole drilling machine is its ability to work with complex materials such as titanium, ceramics, glass, and hardened steel without causing cracks or deformation. These machines are also equipped with ultra-sensitive sensors and tool monitoring systems to ensure accurate positioning and depth control, which is especially important for components like surgical needles, fuel injector nozzles, or semiconductor parts.

Modern micro drilling machines may also support multi-axis movement, automatic tool changers, and cleanroom compatibility, which are critical in clean, high-tech manufacturing environments. Their ability to integrate with CAD/CAM software allows engineers to design and manufacture intricate parts with incredible precision.

In today's era of miniaturization, where devices are getting smaller but more powerful, micro hole drilling machine play a vital role in enabling technological innovation. Investing in this advanced machining technology can significantly improve your production capabilities, reduce waste, and open the door to a wide range of high-precision manufacturing opportunities.

0 notes

Text

Advancing Healthcare: Medical Industry Electronic Design & Manufacturing

In the rapidly evolving world of healthcare, technology is a driving force behind groundbreaking innovation. At the heart of this technological transformation lies Medical Industry Electronic Design and Manufacturing (EIDM) a highly specialized field responsible for developing the advanced electronic devices that power modern medicine.

From life-saving pacemakers to complex diagnostic imaging systems, electronic design and manufacturing are essential to creating reliable, accurate, and safe medical equipment. This blog explores the key elements, challenges, and trends in medical EDM and its vital role in advancing patient care.

What Is Medical Electronic Design & Manufacturing?

Medical EDM refers to the process of designing, developing, prototyping, testing, and manufacturing electronic components and systems used in medical applications. This includes devices for:

Diagnostics (e.g., MRI machines, blood analyzers)

Monitoring (e.g., heart rate monitors, pulse oximeters)

Therapeutics (e.g., insulin pumps, radiation therapy machines)

Implantables (e.g., pacemakers, neurostimulators)

The process encompasses both hardware development (circuit boards, sensors, enclosures) and embedded software engineering (firmware, user interfaces).

Key Components of the Design Process

Requirements Gathering & Conceptual Design Engineers work closely with medical professionals to understand clinical needs, regulatory constraints, and performance requirements.

Prototyping & Validation Using CAD software and rapid prototyping tools, initial designs are built and tested. Validation ensures the device meets medical standards and performs reliably under various conditions.

Regulatory Compliance All medical devices must comply with stringent regulations such as:

FDA (U.S. Food and Drug Administration)

ISO 13485 (Quality Management Systems for Medical Devices)

IEC 60601 (Safety of Medical Electrical Equipment)

Manufacturing & Assembly Precision manufacturing techniques are used to produce devices in sterile, controlled environments. Surface-mount technology (SMT), automated optical inspection (AOI), and cleanroom assembly are common.

Testing & Quality Assurance Extensive testing is required for safety, electromagnetic compatibility (EMC), and software validation to ensure product reliability and patient safety.

Challenges in Medical EDM

1. High Regulatory Burden

Navigating the global regulatory landscape is complex and time-consuming. Delays in approvals can impact time-to-market.

2. Miniaturization

As devices become smaller—especially for implantables—designers face constraints in power consumption, heat dissipation, and durability.

3. Data Security & Connectivity

Connected medical devices (part of the Internet of Medical Things, or IoMT) require robust cybersecurity to protect patient data and ensure system integrity.

4. Long Product Lifecycles

Medical equipment often remains in use for decades, requiring ongoing support, software updates, and component sourcing for legacy systems.

Trends Shaping the Future

✅ Wearable and Remote Monitoring Devices

The demand for at-home monitoring tools is driving innovation in compact, wireless, and user-friendly devices.

✅ AI and Machine Learning Integration

Smart algorithms are now embedded into medical devices to enhance diagnostics, predict health trends, and optimize treatment.

✅ 3D Printing in Prototyping and Production

3D printing accelerates development timelines and allows for customized parts, especially useful in prosthetics and dental applications.

✅ Sustainable Manufacturing

With a growing emphasis on green practices, manufacturers are exploring recyclable materials and energy-efficient production processes.

Why It Matters

The quality and precision of medical electronic design and manufacturing directly affect patient outcomes and clinical efficiency. Reliable devices enable earlier diagnosis, better treatment, and improved quality of life. As healthcare becomes more personalized and tech-driven, the importance of EDM continues to grow.

0 notes

Text

Mining Electronic Design & Manufacturing: Powering the Future of Resource Extraction

As the mining industry continues to evolve, so too does the technology that drives it. At the heart of this transformation is Mining Electronic Design & Manufacturing (EDM)—a highly specialized field that designs, develops, and produces electronic systems tailored to meet the demanding requirements of mining operations. From underground communication devices to automated control systems, EDM plays a vital role in improving safety, efficiency, and productivity.

What is Mining Electronic Design & Manufacturing?

Mining Electronic Design & Manufacturing refers to the creation of electronic components and systems specifically for use in mining environments. This includes:

Custom electronic circuit boards

Remote monitoring systems

Automated control units

Environmental sensors

Communication devices

Safety systems

These systems are engineered to withstand the extreme conditions typical of mining operations—such as high vibration, moisture, dust, and electromagnetic interference—while maintaining consistent and reliable performance.

Why Is EDM Important in the Mining Industry?

1. Enhanced Safety

Mining is inherently hazardous. Custom-designed safety systems—like gas detection sensors, real-time tracking, and emergency shutoff mechanisms—help prevent accidents and ensure worker safety.

2. Operational Efficiency

Real-time data collection and monitoring systems allow operators to make informed decisions, reduce downtime, and optimize resource extraction. Electronics can automate routine processes and provide predictive maintenance alerts, reducing the need for human intervention in risky environments.

3. Cost Reduction

Efficient and durable electronic systems reduce maintenance costs and improve the longevity of mining equipment. Automation also decreases the reliance on manual labor, lowering operational expenses.

4. Sustainability

Advanced monitoring and control systems ensure that mining operations comply with environmental regulations. These systems help manage energy usage, water consumption, and waste production more effectively.

Key Components of EDM in Mining

Rugged Hardware Design

Electronic systems used in mining must be housed in enclosures that are resistant to water, dust, and mechanical shock. Design engineers focus on using high-grade materials and robust construction to meet IP (Ingress Protection) and ATEX standards for explosive environments.

Embedded Systems

Custom embedded systems are programmed to control and monitor specific functions like drilling speed, conveyor belt performance, and motor operations. These systems are tailored to each piece of equipment, ensuring precise control and reliability.

Wireless Communication

Maintaining communication in underground or remote sites is challenging. EDM solutions include the integration of low-frequency radio, mesh networks, and satellite communication to ensure seamless data transfer between miners and surface teams.

Sensor Integration

Modern mining relies heavily on data. Sensors collect information on temperature, humidity, gas levels, equipment condition, and more. This data is transmitted to central systems for analysis and action.

Challenges in Mining EDM

Despite its benefits, EDM in mining is not without challenges:

Harsh Environments: Designing systems that can operate reliably under extreme conditions requires extensive testing and innovation.

Integration with Legacy Systems: Many mines use older equipment that may not be compatible with new electronics.

Regulatory Compliance: Ensuring electronics meet global and local mining safety regulations adds complexity to the design and certification process.

The Future of EDM in Mining

The future of Mining Electronic Design & Manufacturing is closely tied to technological advancements such as:

AI and Machine Learning: Predictive analytics will enable smarter decision-making and more efficient resource allocation.

Internet of Things (IoT): As more devices become interconnected, mines will become increasingly automated and data-driven.

Green Mining Technologies: Electronics that help reduce environmental impact will become even more important as global sustainability standards rise.

0 notes

Text

CNC Job Work Services Offered by Vihir Engineering

Vihir Engineering specializes in a wide range of CNC machining services, including:

CNC Turning: Precision turning operations to produce cylindrical parts with high accuracy.

CNC Milling: Complex milling tasks to create intricate designs and features.

VMC (Vertical Machining Center) Operations: Advanced machining capabilities for detailed and precise components.

CNC Wire Cutting: Utilizing wire EDM (Electrical Discharge Machining) for fine and intricate cuts.

CNC Laser Cutting: High-precision laser cutting for various materials.

These services are available for a variety of materials, including metals and plastics, catering to industries such as automotive, aerospace, electronics, and more.

Why Choose Vihir Engineering for CNC Job Work in Asia?

Expertise Across Multiple Industries: Vihir Engineering has a proven track record of delivering high-quality CNC machining services across various sectors, ensuring that clients' specific requirements are met with precision.

Advanced Technology and Equipment: The company employs state-of-the-art CNC machines and software, enabling them to handle complex machining tasks efficiently and accurately.

Skilled Workforce: Vihir Engineering boasts a team of experienced engineers and technicians who are adept at interpreting detailed technical drawings and specifications, ensuring that each project is executed to the highest standards.

Commitment to Quality and Timeliness: The company adheres to stringent quality control measures and maintains strict timelines, ensuring that clients receive their products as per agreed schedules without compromising on quality.

Contact Vihir Engineering

For more information or to discuss your CNC machining requirements, you can reach out to Vihir Engineering through their official website: https://vihir.in/

Their team is ready to assist you with tailored solutions that align with your specific needs and industry standards.

0 notes

Text

Why Prototype Tools are often needed?

Prototype tools (molds), also known as rapid tools (molds), or soft tools (molds), are typically used before the production of formal production tools (molds). These molds help reduce the need for modifications to formal molds, quickly identify structural issues in the product design, and allow for component testing and validation. They also enhance the lifespan of formal molds. Prototype tools have low production costs, quick turnaround times, and short development cycles, significantly accelerating product upgrades and reducing the risks of new project investments.

Although other prototype manufacturing processes like 3D printing, CNC machining, or vacuum casting can often produce prototype parts faster and cheaper, the main advantage of rapid molds lies in their ability to produce commercial-grade parts with precise dimensions, using materials that match the design specifications. This allows clients to better understand whether the parts meet market demands and production standards, enabling them to test and confirm correct material choices.

Rapid molds can also be used to test production parameters. This enables engineers and designers to identify overlooked issues and implement redesigns or other measures to prevent defects in final parts.

Characteristics of Rapid Molds Rapid molds are essentially injection molds designed to quickly and cost-effectively produce large volumes of parts. They are typically chosen when there is a 90% confidence in the success of a product development project.

Materials Used for Prototype tools Simplified molds are usually made of materials such as aluminum alloy P20 or 45 steel. They are formed using processes like sand casting, forging, or machining from steel and aluminum plates or profiles via CNC machining. Auxiliary processes like wire cutting, electric discharge machining (EDM), and slow wire-feeding combine to quickly create a complete test mold. The final product is made using injection molding.

Prototype Tools Production Timeline The production cycle for a prototype mold can be as short as three days to complete a trial mold. In slower cases, it typically takes about seven days to finish a simplified quick mold. For large products, such as car front bumpers, the production of a rapid mold can generally be completed within 30–40 days. For smaller products, like 3C items such as battery charger enclosures, rapid molds can be completed within seven days.

Techniques for Making Prototype Tools To make prototype tools, processes are simplified based on the part design by minimizing the complexity of formal mold manufacturing methods, such as:

Using Standard Mold Bases: Employing standard mold bases and only manufacturing inserts, reusing mold frames, or machining directly without inserts. Reducing Automation: Replacing automatic ejectors, sliders, and inserts with manual removal processes or secondary machining methods. Easier Machiining Materials: Using faster machining materials such as aluminum or soft steel. Minimizing EDM: Reducing extra steps like EDM where possible. Low-Cost Components: Opting for lower-cost components. Since the production volume of prototype molds is typically not high, using simplified methods saves time and costs, ensuring the quick production of prototype molds.

You could visit www.eastmaster.com for more information. Contact Eastmaster and get a quote for your new project.

0 notes

Text

Why CNC EDM Wire Cut Machines Are Revolutionizing Precision Manufacturing

In today’s competitive industrial landscape, precision and efficiency are the keys to success. Among the various cutting technologies available, the CNC EDM wire cut machine stands out as a game-changer in tool and die manufacturing, aerospace, automotive, and electronics industries. If you're involved in any kind of metal cutting or precision machining, investing in a high-quality CNC EDM wire cut machine is no longer optional—it's essential.

What is a CNC EDM Wire Cut Machine?

CNC EDM (Electrical Discharge Machining) wire cut machines use electrical discharges (sparks) to erode material from a workpiece with incredible accuracy. The process involves a thin wire acting as the electrode, cutting through metal without direct contact. This non-contact process is ideal for machining hard metals and producing intricate shapes that conventional cutting tools can't handle.

Benefits of Using CNC EDM Wire Cut Machines

1. Exceptional Precision

One of the biggest advantages of CNC EDM wire cutting is its ability to produce parts with ultra-tight tolerances. Accuracy down to ±1 micron can be achieved, making it ideal for high-precision components in aerospace, defense, and medical equipment.

2. Smooth Surface Finish

Unlike traditional machining, wire EDM leaves a fine finish that often eliminates the need for secondary finishing processes. This can significantly reduce production time and costs.

3. Cuts Hardened Materials

EDM can machine hardened tool steel, tungsten carbide, titanium, and exotic alloys that traditional tools struggle with. This makes it invaluable for tool and die industries.

4. Complex Geometries

From sharp corners to narrow slots, a CNC EDM wire cut machine can create intricate shapes with ease, thanks to the flexibility of wire movement and precision control.

Applications Across Industries

Tool and Die Making: Producing dies, punches, and molds.

Automotive Industry: Manufacturing complex engine and transmission components.

Medical Devices: Crafting intricate surgical instruments and implants.

Aerospace Engineering: Machining lightweight, high-strength alloys for components.

Electronics: Creating fine-pitched connector dies and lead frames.

Features to Look for When Buying

When choosing a CNC EDM wire cut machine, consider the following:

Axis Control: Machines with multiple axis movement offer more flexibility.

Cutting Speed: A balance between speed and precision is key.

Wire Diameter Compatibility: Determines the detail and size of cuts.

Automation & CNC Programming: Reduces labor and increases productivity.

Cooling & Flushing Systems: Helps maintain accuracy and wire longevity.

Maintenance and Cost Efficiency

Modern EDM wire cut machines are designed for long service life with minimal maintenance. Consumables like wire and dielectric fluid must be replaced periodically, but the absence of direct contact reduces tool wear significantly.

Conclusion

The CNC EDM wire cut machine has become an indispensable tool for precision manufacturing. Its ability to cut hard materials, create complex shapes, and deliver superior finishes makes it a must-have for any high-tech workshop. Whether you’re a small tool room or a large-scale manufacturer, adopting EDM technology can take your production quality to the next level.

0 notes

Text

The Critical Role of High-Precision Wire Machines in Modern Manufacturing

In an era where manufacturing demands extreme accuracy, efficiency, and scalability, high-precision wire machines have become indispensable. These advanced systems—including wire EDM (Electrical Discharge Machining), CNC wire bending machines, and laser wire cutting systems—are revolutionizing production across industries.

Here’s an in-depth look at why these machines are essential for modern manufacturing:

Wire Machinery Manufacturers

1. Unparalleled Precision for Complex Components

High-precision wire machines achieve micron-level accuracy, making them ideal for industries where even the slightest deviation can lead to product failure.

Wire EDM can cut intricate shapes in hardened metals with tolerances as tight as ±0.0001 inches (±0.0025 mm).

CNC wire forming machines produce consistent, repeatable bends for medical devices, springs, and electrical contacts.

Laser wire cutting ensures clean, burr-free cuts for delicate applications like aerospace and electronics.

This level of precision is critical for industries such as: ✔ Medical devices (surgical tools, implants) ✔ Aerospace (turbine blades, fuel system components) ✔ Automotive (fuel injectors, transmission parts) ✔ Electronics (micro connectors, sensor components)

2. Material Versatility & Reduced Waste

Unlike traditional machining, high-precision wire machines work with a wide range of materials, including:

Exotic alloys (Inconel, titanium)

Hardened steels (tool steels, stainless steel)

Delicate materials (copper, brass, tungsten)

Since these machines use non-contact cutting methods (like EDM and laser), they minimize material distortion and waste, leading to cost savings and sustainable manufacturing practices.

3. Faster Production & Lower Labor Costs

Automation in high-precision wire machines reduces dependency on manual labor while increasing throughput.

Wire EDM can run unattended for hours, cutting multiple parts simultaneously.

CNC wire benders produce thousands of identical components with zero variation.

Automated feeding systems ensure continuous production with minimal downtime.

This efficiency is crucial for high-volume manufacturing while maintaining strict quality control.

Wire Machinery Manufacturers

4. Enabling Miniaturization & Advanced Designs

As products become smaller and more complex (e.g., microelectronics, medical implants), traditional machining struggles to keep up.

High-precision wire machines excel in: ✔ Micro-machining (creating tiny, intricate parts) ✔ Prototyping (fast, accurate iterations for R&D) ✔ Complex geometries (undercuts, sharp internal corners)

Without these machines, manufacturing cutting-edge technology would be slower, costlier, and less reliable.

5. Cost-Effective Long-Term Investment

While high-precision wire machines require an upfront investment, they pay off quickly by: ✅ Reducing scrap rates (less material waste) ✅ Lowering rework costs (fewer defective parts) ✅ Extending tool life (non-contact processes wear out tools slower) ✅ Improving ROI (faster production = higher profits)

6. Future-Proofing Manufacturing with Smart Technology

The latest high-precision wire machines integrate IoT, AI, and real-time monitoring, enabling:

Predictive maintenance (reducing unexpected downtime)

Adaptive machining (auto-adjusting for material variations)

Data-driven optimization (improving cycle times and accuracy)

This positions manufacturers to stay competitive in Industry 4.0 and beyond.

Conclusion: A Must-Have for Competitive Manufacturing

High-precision wire machines are no longer a luxury—they are a strategic necessity for any manufacturer aiming to: ✔ Produce flawless, high-tolerance parts ✔ Reduce costs and waste ✔ Speed up production cycles ✔ Stay ahead in tech-driven industries

Wire Machinery Manufacturers

Companies that invest in these advanced systems gain a significant competitive edge, ensuring long-term success in an increasingly demanding market.

0 notes

Text

CNC Machining Services in Bangalore: Precision Manufacturing in the Silicon Valley of India

Bangalore, often referred to as the Silicon Valley of India, is known globally for its thriving IT and technology sectors. However, beyond software and startups, Bangalore has also emerged as a stronghold in advanced manufacturing. Among the many services that contribute to the city’s industrial success, CNC machining services in Bangalore play a pivotal role.

CNC (Computer Numerical Control) machining is a cornerstone of modern manufacturing, enabling precision, efficiency, and repeatability in the production of critical components. With rising demand across automotive, aerospace, electronics, medical devices, and other sectors, CNC machining in Bangalore has grown both in scale and capability.

In this blog, we explore why Bangalore has become a hub for CNC services, what makes the city’s CNC ecosystem unique, and what you should look for when selecting a CNC company in Bangalore for your project.

The Growing Importance of CNC Machining in Bangalore

CNC machining is the process of using pre-programmed computer software to control the movement of tools and machinery in manufacturing. This allows for precise, complex cuts and the fabrication of components with tight tolerances.

Bangalore’s manufacturing industry has embraced CNC technology due to its numerous advantages:

High Precision: CNC machines can produce intricate parts with minimal error.

Repeatability: Once a design is programmed, it can be replicated thousands of times without variation.

Speed: CNC machines work faster than manual methods, reducing turnaround times.

Automation: Reduces labor costs and increases safety and efficiency.

This technology has become essential for industries that demand both high volume and high precision—traits that define many of Bangalore's leading manufacturing sectors.

Why Bangalore Is the Ideal Place for CNC Machining

The strategic rise of CNC machining services in Bangalore is not accidental. Several key factors have converged to make the city a preferred destination for precision manufacturing:

1. Skilled Workforce

Bangalore is home to some of the best engineering colleges and technical institutions in the country. As a result, the city produces a large pool of technically proficient professionals who are well-versed in CNC programming, CAD/CAM software, mechanical design, and quality control.

2. Established Industrial Ecosystem

Bangalore has long been a manufacturing base for sectors like aerospace, defense, automotive, and electronics. These industries require high-precision components and systems, creating a constant demand for CNC machining services. The symbiosis between industry demand and CNC capability has driven innovation and investment in the sector.

3. Access to Modern Technology

The use of advanced CNC machinery, including 3-axis, 4-axis, and 5-axis machines, is now commonplace in Bangalore. These machines enable the production of highly complex geometries with excellent accuracy, suitable for even the most demanding industries.

4. Infrastructure and Connectivity

Bangalore’s connectivity through air, road, and rail enables efficient transport of raw materials and finished goods. Combined with modern industrial parks and manufacturing hubs, this makes it easier for companies to operate and scale their CNC operations.

What to Expect from CNC Machining Services in Bangalore

When you work with a CNC company in Bangalore, you’re gaining access to a robust set of services that go beyond simple part fabrication. These may include:

CNC Milling & Turning: These core services allow for the creation of precise mechanical parts from metals and plastics.

Surface Grinding: To achieve perfect flatness or smoothness for specific components.

EDM (Electrical Discharge Machining): For creating intricate shapes that are difficult to achieve with conventional machining.

Rapid Prototyping: CNC machining is often used for prototyping to validate part designs before mass production.

Batch Production: Small, medium, or large batch manufacturing with guaranteed repeatability and consistency.

Whether you're producing prototypes or scaling for mass production, CNC machining in Bangalore offers solutions to suit every stage of the manufacturing lifecycle.

Trends in CNC Machining in Bangalore

As the manufacturing landscape evolves, CNC machining services in Bangalore are adapting to meet global standards. Some of the notable trends include:

1. Integration with Industry 4.0

With the rise of smart manufacturing, CNC machines are now being integrated with IoT sensors and cloud-based platforms. This allows for real-time monitoring, predictive maintenance, and improved operational efficiency.

2. Use of Advanced Materials

Bangalore’s CNC sector is increasingly machining exotic and high-performance materials such as titanium, Inconel, and carbon composites—materials often used in aerospace and defense.

3. Demand for Micro-Machining

As devices become smaller and more complex, especially in the medical and electronics industries, the demand for micro-machining services has increased. CNC technology in Bangalore has risen to this challenge with equipment capable of high-precision micromachining.

4. Sustainability Initiatives

There is a growing emphasis on sustainable manufacturing. Many CNC service providers in Bangalore are adopting environmentally friendly practices such as efficient waste management, energy conservation, and the use of recyclable materials.

Choosing the Right CNC Company in Bangalore

With so many options available, selecting the right CNC partner is essential for the success of your project. Here are some key criteria to consider:

Experience and Expertise: Look for providers with experience in your industry and the technical capability to meet your specifications.

Machine Capabilities: Make sure they have a range of CNC equipment suitable for the scale and complexity of your project.

Quality Assurance: A good CNC provider will have a quality control process in place, including precision measurement tools and inspection systems.

Lead Time and Flexibility: Ensure they can meet your deadlines and adapt to changing requirements.

Communication and Support: Transparent communication and ongoing support are essential for smooth project execution.

Future Outlook

The future of CNC machining services in Bangalore looks promising. As the world continues to move toward more complex manufacturing needs, Bangalore is poised to become not just a national but an international hub for CNC excellence.

The growth of EV (electric vehicle) manufacturing, increased investment in aerospace and defense, and India's emphasis on becoming a global manufacturing powerhouse (via "Make in India") all indicate a bright future for the CNC industry in the region.

Conclusion

If you're looking to produce high-quality components with precision and reliability, CNC machining services in Bangalore offer the ideal solution. The city’s rich ecosystem of technology, talent, and infrastructure makes it a compelling destination for businesses across the globe.

Whether you're a startup needing prototypes or an established firm scaling your production, partnering with a CNC company in Bangalore ensures that you benefit from innovation, efficiency, and cost-effective manufacturing. Combined with the growing capabilities of CNC machine manufacturers in Bangalore, the city provides an end-to-end solution for all your precision engineering needs.

#cnc manufacturing near me#cnc machining bangalore#cnc machining services in bangalore#cnc machine manufacturers in bangalore

0 notes

Text

High-Precision EDM Solutions: Transforming Manufacturing with Accuracy and Efficiency

In the world of modern manufacturing, precision is essential, especially when it comes to producing intricate parts and components with tight tolerances. High-precision EDM solutions have become a critical tool in industries that require exceptional accuracy, complex geometries, and the ability to machine hard materials. Electrical Discharge Machining (EDM) offers manufacturers a versatile and efficient solution for machining materials that are difficult to handle with traditional methods.

This article explores the features, benefits, and applications of high-precision EDM solutions and how they are enhancing manufacturing capabilities across various industries.

What Are High-Precision EDM Solutions?

High-precision EDM solutions refer to advanced EDM technology that enables manufacturers to create highly accurate parts through the use of controlled electrical discharges. During the EDM process, an electrode is used to create sparks that erode material from the workpiece, allowing it to be shaped with remarkable precision. This process can be used for a wide variety of materials, including hard metals, ceramics, and composites, making EDM solutions ideal for industries where material hardness is a challenge for traditional machining methods.

EDM is capable of machining parts with complex geometries, including intricate shapes, undercuts, and tiny holes, which may be impossible or extremely difficult to produce using conventional methods. With high-precision EDM, manufacturers can achieve extremely tight tolerances, often within the micrometer range, ensuring high-quality results every time.

Key Features of High-Precision EDM Solutions

Superior Accuracy and Precision: High-precision EDM solutions offer the ability to achieve tolerances as fine as 0.002mm or better. This precision is essential in industries like aerospace, automotive, and medical device manufacturing, where even the smallest deviation can lead to performance issues. The technology ensures that every part produced meets the exact specifications, offering consistency and repeatability in every batch.

Capability to Machine Hard Materials: One of the primary benefits of EDM is its ability to machine hard materials that traditional machining methods struggle to handle. Materials such as hardened steel, titanium, tungsten carbide, and other tough alloys can be machined with ease using high-precision EDM solutions. This makes EDM an indispensable tool for industries requiring durable, high-strength materials.

Complex Geometries and Fine Details: EDM is especially effective for creating parts with complex geometries and intricate details that are difficult to achieve through conventional processes. Whether it’s fine holes, sharp edges, or complex internal shapes, high-precision EDM solutions can produce these intricate designs with ease, ensuring that manufacturers can meet the design requirements of their clients.

Minimal Mechanical Stress: Unlike traditional machining processes that involve mechanical force, EDM uses electrical discharges to remove material. As a result, there is minimal mechanical stress on the workpiece, making EDM ideal for machining delicate, thin-walled, or intricate components. This reduces the risk of material deformation or damage during the machining process.

Efficiency and Speed: High-precision EDM solutions are designed for high efficiency, allowing manufacturers to complete complex tasks faster than with traditional methods. The ability to perform intricate tasks with fewer passes and less manual intervention reduces cycle times and boosts overall production speed. Additionally, the automation and precision of EDM systems ensure that manufacturers can produce consistent results with minimal setup time.

Benefits of High-Precision EDM Solutions

Improved Part Quality: With the ability to achieve extremely tight tolerances and fine surface finishes, high-precision EDM solutions ensure that parts are made with the highest quality standards. The process produces smooth surfaces that are ideal for parts requiring minimal post-machining finishing. This makes EDM an excellent choice for industries where part performance, safety, and reliability are critical.

Reduced Material Waste: Since EDM is a non-contact process, there is minimal waste generated during machining. The sparks used to erode material only remove the required amount, meaning that the workpiece is utilized efficiently. This reduction in material waste translates into lower costs and improved sustainability for manufacturers.

Cost Savings: Although high-precision EDM solutions can have a higher initial investment compared to traditional machining methods, the long-term cost benefits are significant. The ability to machine complex shapes without the need for additional tooling or multiple setups saves manufacturers both time and money. Furthermore, the longevity and efficiency of EDM machines result in reduced operational costs and greater return on investment.

Increased Design Flexibility: High-precision EDM solutions provide manufacturers with greater design flexibility. Complex parts that may be impossible to produce using traditional methods can be easily created with EDM. This freedom allows manufacturers to explore new designs and innovations without being limited by the constraints of conventional machining technologies.

Faster Prototyping: High-precision EDM allows for quick prototyping of parts, enabling manufacturers to test designs and make adjustments faster. The speed and precision of EDM systems help accelerate the product development process, allowing companies to bring products to market faster and gain a competitive advantage.

Applications of High-Precision EDM Solutions

Aerospace Manufacturing; The aerospace industry demands the highest levels of precision, particularly for components like turbine blades, engine parts, and fasteners. High-precision EDM solutions are used to machine these complex components from high-strength materials like titanium and superalloys, ensuring they meet the strict standards required for performance and safety.

Medical Device Manufacturing: The medical device industry relies on high-precision EDM solutions for producing parts such as surgical tools, implants, and diagnostic equipment. These parts often require tight tolerances and smooth finishes to ensure their functionality and safety. EDM’s ability to machine delicate materials like titanium and stainless steel makes it a critical tool in medical device production.

Automotive Manufacturing: The automotive industry uses high-precision EDM solutions for the production of components such as gears, fuel injectors, and electronic connectors. EDM’s ability to machine complex parts with high precision ensures the efficiency and durability of automotive components, contributing to the overall performance and safety of vehicles.

Tool and Die Making: In tool and die making, high-precision EDM solutions are essential for producing molds, dies, and punches used in manufacturing. EDM allows for the creation of highly detailed, accurate tooling, which is crucial for mass production and ensuring consistent quality in molded parts.

Electronics Manufacturing: In the electronics industry, high-precision EDM is used for producing small, intricate components like connectors, capacitors, and micro-electronics. The ability to machine small, delicate parts with high accuracy is critical for ensuring the functionality and performance of electronic devices.

Conclusion

High-precision EDM solutions have revolutionized the manufacturing industry by providing manufacturers with the ability to produce highly accurate, complex parts from tough materials. Whether in aerospace, automotive, medical device manufacturing, or tool making, EDM is an essential technology for achieving high-quality results with exceptional precision.

The benefits of high-precision EDM—including improved part quality, reduced material waste, faster prototyping, and greater design flexibility—make it an invaluable tool for businesses looking to stay competitive in today’s fast-paced market. By adopting high-precision EDM solutions, manufacturers can ensure they meet the exacting demands of their industries while optimizing their production processes for efficiency and cost savings.

0 notes

Text

Mastercam Pro 2025 Crack serial key 2025 Download

DOWNLOAD LINK

Mastercam is a popular Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software developed by CNC Software Inc. It is widely used in manufacturing and machining industries for part design, milling, turning, wire EDM (Electrical Discharge Machining), and other types of CNC (Computer Numerical Control) programming. Mastercam is known for its powerful, intuitive tools that help users design and create parts for machining, optimize toolpaths, and prepare machine instructions.

Key Features of Mastercam:

CNC Programming:

2D & 3D Milling: Mastercam provides robust tools for 2D and 3D milling, making it possible to create complex part designs and machining toolpaths.

Lathe and Turning: It includes powerful lathe and turning modules to program CNC lathes for turning operations, including multi-axis turning and live tooling.

1 note

·

View note

Text

New Product Development in Pharma: Strategies for Faster Market Entry

Bringing a new pharmaceutical product to market is a time-intensive and highly regulated process. Traditional New Product Development (NPD) in the pharmaceutical industry takes an average of 10-15 years, from discovery to commercialization. However, in a competitive landscape, companies must adopt innovative strategies to accelerate drug development, streamline approvals, and reduce time-to-market while maintaining compliance and quality.

Key Challenges in Pharma NPD

1. Lengthy Regulatory Approvals

Pharmaceutical companies must comply with FDA (USA), EMA (Europe), MHRA (UK), and other global agencies, each having distinct approval processes. Regulatory bottlenecks often lead to delays in clinical trials, submissions, and market entry.

2. Complex Clinical Trials

Clinical trials, the most time-consuming phase of drug development, face challenges such as patient recruitment, ethical approvals, and protocol compliance. Delays in trial execution directly impact market timelines.

3. High R&D Costs and Uncertain ROI

Developing a new drug requires billions in investment, with no guarantee of success. Pharma companies must manage budget constraints, risk assessment, and resource allocation efficiently to ensure commercial viability.

4. Supply Chain and Manufacturing Bottlenecks

Scaling up drug production while ensuring quality, compliance, and global distribution readiness remains a significant challenge. Manufacturing delays can stall product launches, affecting revenue generation.

Strategies for Faster Market Entry in Pharma NPD

1. Implement AI and Digital Technologies in Drug Discovery

AI and machine learning can significantly accelerate drug discovery by analyzing vast datasets to identify potential drug candidates faster. AI-driven platforms help predict molecule behavior, optimize formulations, and reduce preclinical testing time.

2. Optimize Regulatory Submissions with Automation

Using Regulatory Information Management Systems (RIMS) and Electronic Document Management Systems (EDMS) can help automate regulatory submissions, reducing errors and approval delays. Proactive communication with regulatory agencies through early-stage consultations can also streamline the approval process.

3. Leverage Adaptive and Decentralized Clinical Trials

Traditional clinical trials are time-consuming and expensive. Implementing adaptive trial designs allows real-time modifications based on interim results, leading to faster decision-making. Decentralized clinical trials (DCTs) using remote patient monitoring and digital platforms improve recruitment speed and engagement, reducing trial durations.

4. Strengthen Cross-Functional Collaboration

Breaking down silos between R&D, regulatory, manufacturing, and commercial teams ensures a seamless transition from drug discovery to market launch. A centralized project management approach enhances communication and decision-making efficiency.

5. Utilize Fast-Track Regulatory Pathways

Many regulatory agencies offer accelerated approval pathways for breakthrough drugs. Pharma companies should explore:

Fast Track (FDA) – Speeds up drug reviews for serious conditions.

Breakthrough Therapy Designation (FDA) – Provides early-stage guidance for promising treatments.

Priority Review (FDA, EMA) – Shortens review times for high-impact drugs.

Adaptive Licensing (EMA) – Allows phased market access while additional data is gathered.

6. Optimize Supply Chain and Manufacturing Scalability

Ensuring an agile supply chain with on-demand manufacturing, predictive analytics, and AI-driven inventory management can reduce delays in production and distribution, supporting faster market entry.

Conclusion

Pharma companies must adopt a tech-driven, regulatory-smart, and collaborative approach to reduce time-to-market. By integrating AI in drug discovery, automating regulatory processes, optimizing clinical trials, and leveraging fast-track approvals, organizations can achieve faster commercialization without compromising safety or compliance. In today’s fast-paced industry, speed is a competitive advantage—companies that embrace digital transformation and strategic execution will lead the future of pharmaceutical innovation.

0 notes

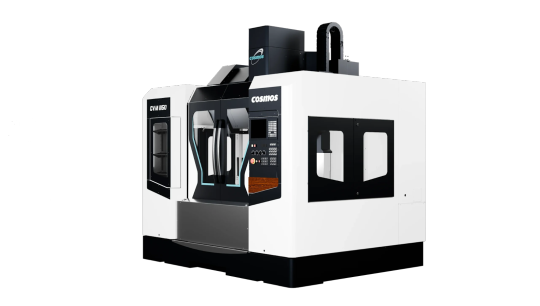

Text

5 Common CNC Machines & What They Do

What Is CNC?

What Is CNC (Computer Numerical Control)?CNC (Computer Numerical Control) is a process used in the manufacturing sector that involves the use of computers as a control system for machining tools. Automation ensures production is highly precise, efficient, and easily replicable. CNC machines are popularly used in automotive, aerospace, electronics, and medical manufacturing industries. Learning about the various types of CNC machines is important in determining what CNC machines are best for your application.

5 Types of CNC Machines

There are several types of CNC machine tools, each designed for specific manufacturing tasks. Here are five common types:

CNC Milling Machines

Used for cutting and shaping solid materials. It can processing operations like drilling, tapping and contouring.

Plant users with diversified processing technologies are often used in modern CNC machine tools.

CNC Lathe Machines

Dedicated to longitudinal working, lathe operations, machining cylindrical elements.

It is highly efficient for precision machining and producing symmetrical objects.

There are several types of CNC lathe machines available for different applications.

CNC Plasma Cutters

Shares a very high powered plasma torch to nozzle to fly metal.

Ideal for heavy-duty fabrication industries.

CNC Laser Cutters

Employs a laser beam to accurately cut materials such as metal, plastic, and wood.

Delivers smooth edges and fine detailing Go to top

(CNC) Electrical Discharge Machines (EDM)

Shapes materials using electrical sparks

Ideal for complex and precise components.

Cosmos Impex is the best CNC machine manufacturer in India with various industrial applications in specific solutions at CNC machining. So, whether you are looking for advanced types of CNC lathe machines or specialized types of CNC machine tools; we will provide you with all.

For more details on our CNC machines and services, visit Cosmos Impex and discover how we can enhance your production capabilities.

0 notes

Text

Precision CNC Job Work Services by Vihir Engineering in Ahmedabad

In the heart of Gujarat's industrial hub, Vihir Engineering stands out as a trusted provider of high-precision CNC machining services. Located in Ahmedabad, the company caters to a diverse clientele across sectors such as automotive, aerospace, medical devices, and consumer electronics.

What Is CNC Job Work?

CNC (Computer Numerical Control) job work involves the use of automated machines to precisely cut, mill, drill, or shape materials like metals, plastics, and composites. This process ensures high accuracy, repeatability, and efficiency, making it ideal for producing complex components in large volumes.

Vihir Engineering's CNC Capabilities

Vihir Engineering offers a comprehensive range of CNC machining services, including:

CNC Turning: Ideal for cylindrical parts, this process offers high-speed operations and tight tolerances.

CNC Milling: Suitable for complex shapes and contours, providing versatility in design.

CNC Grinding: Ensures smooth finishes and precise dimensions, especially for hard materials.

CNC Wire EDM: Allows for intricate cuts and fine details, particularly in hard metals.

The company employs advanced machinery and skilled technicians to deliver components that meet stringent quality standards.

Serving Diverse Industries

Vihir Engineering's CNC job work services are utilized across various industries, including:

Automotive: Production of engine components, transmission parts, and chassis elements.

Aerospace: Manufacturing of flight-critical parts and assemblies.

Medical Devices: Creation of surgical instruments and diagnostic equipment components.

Consumer Electronics: Fabrication of enclosures, connectors, and internal components.

The company's commitment to quality and precision has earned it a reputation as a reliable partner for OEMs (Original Equipment Manufacturers) and Tier 1 suppliers.

Get in Touch

For more information or to request a quote, visit Vihir Engineering or contact them at:

Email: [email protected]

Phone: +91-63531 35337

Whether you're looking for a single prototype or a large production run, Vihir Engineering is equipped to meet your CNC machining needs with precision and reliability.

0 notes

Text

The Ultimate Guide to Metal Fabrication in Electronics Manufacturing and Mold Processing

Description: Discover the role of metal fabrication in electronics manufacturing and mold processing. Learn about the latest trends, techniques, and benefits of metal fabrication in these industries.

Introduction Metal fabrication is a cornerstone of modern manufacturing, playing a critical role in industries like electronics manufacturing and mold processing. From creating intricate components for electronic devices to producing durable molds for mass production, metal fabrication is essential for precision, durability, and innovation. In this article, we’ll explore the importance of metal fabrication in these industries, the latest trends, and how it drives efficiency and quality.

What is Metal Fabrication? Metal fabrication is the process of cutting, bending, shaping, and assembling metal materials to create structures, components, or products. It involves various techniques such as welding, machining, stamping, and casting. In industries like electronics manufacturing and mold processing, metal fabrication ensures the production of high-quality, precise, and durable parts.

The Role of Metal Fabrication in Electronics Manufacturing Electronics manufacturing relies heavily on metal fabrication to produce components that are both functional and reliable. Here’s how metal fabrication contributes to this industry:

1. Precision Components

Electronic devices require tiny, intricate parts that must meet strict tolerances. Metal fabrication techniques like CNC machining and laser cutting ensure the production of precise components such as connectors, heat sinks, and enclosures.

2. Durability and Reliability

Metals like aluminum, copper, and stainless steel are commonly used in electronics for their durability and conductivity. Metal fabrication ensures these materials are processed to withstand harsh conditions and provide long-lasting performance.

3. Customization

Electronics manufacturers often need custom parts for unique designs. Metal fabrication allows for the creation of bespoke components tailored to specific requirements.

Metal Fabrication in Mold Processing Mold processing is another industry where metal fabrication plays a vital role. Molds are used to produce a wide range of products, from plastic parts to metal components. Here’s how metal fabrication enhances mold processing:

1. High-Quality Molds

Metal fabrication techniques like CNC milling and EDM (Electrical Discharge Machining) are used to create molds with exceptional precision and surface finish. This ensures the final products are free from defects and meet quality standards.

2. Durability for Mass Production

Molds must withstand repeated use without losing their shape or precision. Metal fabrication ensures molds are made from durable materials like tool steel, which can endure high-pressure and high-temperature conditions.

3. Complex Geometries

Modern products often require molds with intricate designs. Metal fabrication enables the creation of complex geometries that traditional methods cannot achieve.

Key Metal Fabrication Techniques in Electronics and Mold Processing

1. CNC Machining

CNC (Computer Numerical Control) machining is a widely used technique in both electronics manufacturing and mold processing. It offers high precision and repeatability, making it ideal for creating complex parts and molds.

2. Laser Cutting

Laser cutting is used to cut metal sheets with extreme precision. It’s particularly useful for creating thin, intricate components for electronic devices.

3. Stamping

Stamping is a cost-effective method for producing large quantities of metal parts. It’s commonly used in electronics manufacturing for components like brackets and connectors.

4. Welding

Welding is essential for joining metal parts in both electronics and mold processing. Techniques like TIG (Tungsten Inert Gas) welding ensure strong, durable bonds.

5. EDM (Electrical Discharge Machining)

EDM is used in mold processing to create intricate shapes and fine details. It’s particularly effective for hard metals that are difficult to machine using traditional methods.

Benefits of Metal Fabrication in Electronics and Mold Processing

1. Enhanced Precision

Metal fabrication techniques ensure components and molds are produced with high accuracy, reducing the risk of errors and improving product quality.

2. Increased Efficiency

Advanced fabrication methods like CNC machining and laser cutting streamline production processes, reducing lead times and costs.

3. Versatility

Metal fabrication can be applied to a wide range of materials and designs, making it suitable for diverse applications in electronics and mold processing.

4. Durability

Fabricated metal parts and molds are highly durable, ensuring long-lasting performance even in demanding environments.

Latest Trends in Metal Fabrication

1. Automation and Robotics

The integration of automation and robotics in metal fabrication is revolutionizing the industry. Automated systems improve efficiency, reduce labor costs, and enhance precision.

2. Additive Manufacturing (3D Printing)

3D printing is gaining traction in metal fabrication, allowing for the creation of complex geometries and reducing material waste.

3. Sustainable Practices

Manufacturers are increasingly adopting eco-friendly practices, such as recycling metal waste and using energy-efficient fabrication techniques.

4. Advanced Materials

The use of advanced materials like titanium and composites is expanding the possibilities of metal fabrication in electronics and mold processing.

Choosing the Right Metal Fabrication Partner When selecting a metal fabrication partner for electronics manufacturing or mold processing, consider the following factors:

Experience and Expertise: Look for a partner with a proven track record in your industry.

Advanced Equipment: Ensure they use state-of-the-art fabrication tools and techniques.

Quality Assurance: Choose a partner with robust quality control processes.

Customization Capabilities: Opt for a partner who can meet your specific design and material requirements.

Conclusion Metal fabrication is an indispensable part of electronics manufacturing and mold processing, driving innovation, precision, and efficiency. By leveraging advanced techniques like CNC machining, laser cutting, and EDM, manufacturers can produce high-quality components and molds that meet the demands of modern industries. As trends like automation, additive manufacturing, and sustainable practices continue to shape the future of metal fabrication, businesses that embrace these advancements will stay ahead of the competition.

0 notes