#EMC Testing and Certification

Explore tagged Tumblr posts

Text

EMC Testing and Certification Nemko India

Nemko Provides EMC Testing, radio frequency (RF) testing, and certification services within regulatory requirements.

0 notes

Text

Comprehensive Drop Test Procedure for Product Durability

Ensure your products withstand impact and handling stress with our precise drop test procedure. We conduct controlled drop testing to evaluate structural integrity, packaging effectiveness, and overall durability. Our testing meets international quality standards, helping manufacturers improve product reliability and reduce damage risks. With our detailed drop test procedure, you can enhance consumer confidence and ensure your products perform well in real-world conditions. Contact us today to schedule your drop test assessment.

0 notes

Text

BIG NEWS! #GTG 10 meter anechoic chamber is officially putting into use!

The 10 meter semi-anechoic chamber is the gold standard for EMC testing. GTG 10 meter test range ensures fully compliant Emission and Immunity testing and is compliant to CISPR-16 with a measurement zone diameter of 5 meters. It's the most versatile and accurate EMC test chambers available.

Find more information about 10m semi anechoic chamber at https://gtggroup.com/newsroom/gtg-10-meter-anechoic-chamber-is-officially-putting-into-use/

0 notes

Text

Will aftermarket LED headlights damage your car's electrical system?

Short answer: Aftermarket LED headlights rarely damage modern cars, but they are a real risk in older vehicles if improperly installed or poorly designed. Here is a breakdown of potential electrical issues and protections:

⚡ Automotive Electrical Risks Circuit Overload (Older Cars):

Older wiring (pre-1980s) used thinner halogen wire (60-100W per bulb).

Most LEDs consume 15-50W per bulb → actual load is lower, only peak power consumption is higher.

Risk: Cheap LEDs without electric cooling fans or drivers can cause LEDs to fail or trip computer errors due to poor cooling. Example: A $15 LED bulb may only last a few months before failing.

Voltage Spikes and Ripple:

Substandard LED drivers can feed “dirty” current back into your vehicle’s systems. LED driver with intelligent IC, which can be compatible with 99.5% vehicle models, and help you avoid from led light flicker issue and radio interference .

Harmonic distortion may interfere with analog sensor, radio or ECU signals in pre-OBDII cars (before 1996).

Short circuit:

Poor insulation or loose soldering in cheap LED lights can cause poor contact or even short circuit.

Consequence: Blown fuse, burnt headlight switch or melted wiring harness (common in older cars with weak insulation).

CAN bus system error (modern cars):

Most cars after 2008 detect the health of the bulbs by pulse resistance check.

Insufficient LED resistance → can trigger false "bulb off" warnings or disable safety systems.

Solution: Add CAN bus decoder (load resistor) → but these decoders consume extra power and cause overheating. A built-in all-new CANBUS system is a must for high-quality LED lights to avoid dashboard error reports.

🔋 LED Installation Electrical Safety Checklist Problem | Risk Level | Solution

Fuse Compatibility | Low | LEDs consume less current → Generally safe Alternator Load | Low | LEDs save about 50W vs. halogen → Reduce load Wire Harness Melt | High | (Older Models) Use Relays + Good Wire Harness ECU/Radio Interference | Medium | Choose EMC-certified LEDs (Check FCC/CE Marks) Grounding Issues | High | Sand Erosion Near Ground Points → Secure with Dielectric Grease

📊 Power Consumption Comparison (Dual Headlight System) Bulb Type | Power Consumption | Current (12V System) Halogen (55W x2) | 110W Total Current | 9.2A Good LED (70W x2) | 140W Total Current | 10.8A Cheap LED (18W x2 + Fan) | 36W Total Current | 3A

Note: Low Wattage LED Headlights + The cooling fan may have poor heat dissipation design cost and effect, and cannot guarantee the service life. At the same time, the high-power LED integrated circuit system and heat dissipation cooling system that directly replaces the halogen lamp are designed, so low brightness, low power and short life LED solutions are forced to be selected!

🔧 Key protection measures for old cars Install relay harness

Bypass the aging headlight switch → Power directly from the battery.

Prevent the switch from melting (for example, Jeep CJ, Volkswagen Beetle).

Add series fuse

Install a 10-15A fuse close to the battery → Sacrificial protection. Avoid using "CANbus" bulbs on cars before 2000

Unnecessary resistance will increase heat → Burn out prematurely. Test voltage drop

Measure the voltage of the headlight socket:

11.5V at idle? → Safe.

<10.9V? → Upgrade the circuit.

🛡️ Recommended safe LED brands For vintage cars: https://sngllighting.com/ (EMC shielding, new decoding system, excellent heat dissipation cooling system).

Modern/old hybrid cars: https://www.philips.com.au/c-m-au/car-lights/led-headlight-upgrade-kits (built-in surge protection) and https://sngllighting.com/ (intelligent IC led driver built-in a all-new CANBUS system).

Avoid: no-name LEDs on Amazon/eBay that don't have EMC/FCC/CE/ROSH certifications.

💥 Real failure example 1980 Mercedes 240D owner installed cheap LEDs:

Result: Fan shorted → headlight switch smoked → dashboard wiring burned out ($900 repair).

Cause: Ground wire dropped → voltage spiked to 18V.

✅ Safe Installation Steps Measure the base voltage of the headlight connector.

When installing the light, apply dielectric grease to all contacts.

For vehicles manufactured before 2000, use a relay harness.

After installation, test all electronics (wipers, radio, turn signals).

Bottom line: quality LED lights won't damage your electrical system if you: Buy certified bulbs (FCC, CE, DOT);

Use relays in vehicles manufactured before 2000;

Avoid underpriced brands. For peace of mind, high-output LED lights are still the safest retrofit option for classic cars. 🧰

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#headlight bulb#headlamps#headlamp#headlight#xenon headlights#headlight replacement#halogen headlights#yellow headlights#laser headlights#headlights#race cars#electric cars#classic cars#car#cars#porsche#carlos sainz#truck#automobile#lamborghini

2 notes

·

View notes

Text

BIS Certification for Smartwatches in India: A Complete Guide

In today’s fast-paced world, smartwatches have become an essential gadget for many. However, before you can sell or distribute smartwatches in India, it is mandatory to obtain a BIS (Bureau of Indian Standards) certification. This ensures that your products meet quality, safety, and performance standards as required by Indian regulations.

Here, we’ll break down everything you need to know about BIS certification for smartwatches and why Standphill India is the best consultancy to help you through the process.

What is BIS Certification?

The Bureau of Indian Standards (BIS) certification is a mark of safety, quality, and reliability for products sold in India. For smartwatches, BIS certification is mandatory under the Compulsory Registration Scheme (CRS). This ensures that your smartwatch complies with Indian safety norms and electromagnetic compatibility (EMC) standards, making it safe for consumers.

Why is BIS Certification Mandatory for Smartwatches?

Consumer Safety: Ensures the product is safe for use.

Legal Compliance: Selling uncertified products can lead to fines or bans.

Market Credibility: A BIS-certified product gains the trust of customers and retailers.

Global Standards: BIS certification aligns Indian products with international quality benchmarks.

Process for BIS Certification of Smartwatches

The BIS certification process for smartwatches involves several steps:

Application Submission: Submit your application with required documents, such as technical details and product samples.

Testing: The product is tested in BIS-approved laboratories for compliance with Indian standards.

Approval: Once the product passes testing, BIS issues the certification.

This process can seem complicated, but with the right guidance, it becomes much easier.

Why Choose Standphill India for BIS Certification?

When it comes to BIS certification, having a reliable consultancy by your side can save time, effort, and money. Standphill India is your one-stop solution for hassle-free BIS certification at the most affordable rates in the industry.

Key Reasons to Choose Standphill India:

Cost-Effective Solutions: Known as the cheapest BIS certification provider.

Expert Guidance: A team of experts to handle the entire process from start to finish.

Quick Turnaround: Fast and efficient services to get your product certified without delays.

Customer Support: Dedicated support to address all your queries.

Apply Today!

Don’t let certification hurdles slow down your business. Apply for BIS certification with Standphill India today and ensure your smartwatch meets the required standards!

Visit Our Website: www.standphillindia.in

Contact Us: 📞 96676 74225

Mail Us: ✉️ [email protected]

Take the first step towards compliance and market success with Standphill India!

2 notes

·

View notes

Text

Ensuring Regulatory Compliance for Wireless Devices

Regulatory Framework

Regulatory compliance for wireless devices is governed by various national and international authorities. In the United States, the Federal Communications Commission (FCC) plays a pivotal role in setting and enforcing regulations related to wireless devices. The FCC establishes guidelines for electromagnetic compatibility, radio frequency emissions, and more, to prevent interference and protect consumers.

Wireless Standards

Compliance with established wireless standards is fundamental to ensuring device interoperability and safety. Two widely recognized standards organizations are the Institute of Electrical and Electronics Engineers (IEEE) and the Wi-Fi Alliance. Devices must meet these standards to ensure that they can effectively connect to wireless networks and function correctly.

Radio Frequency (RF) Emissions

One of the primary concerns in wireless device compliance is the emission of radio frequency signals. Wireless devices must not emit harmful interference that can disrupt other wireless networks or devices. Manufacturers are required to conduct extensive testing to ensure their products conform to permissible RF emissions limits.

Electromagnetic Compatibility (EMC)

EMC compliance is crucial to prevent electromagnetic interference between wireless devices and other electronic equipment. Compliance ensures that wireless devices can coexist harmoniously with other electronic devices, enhancing user experience and preventing conflicts.

SAR (Specific Absorption Rate)

SAR measures the amount of radio frequency energy absorbed by the human body when using a wireless device. To protect users from excessive exposure to radio waves, regulatory bodies establish maximum SAR limits. Manufacturers must test and disclose the SAR levels of their products, enabling consumers to make informed choices.

Product Labeling and Certification

Regulatory compliance often requires manufacturers to obtain certification for their wireless devices. These certifications, such as FCC, CE (for European markets), or other regional certifications, demonstrate that a product meets all relevant safety and performance standards. Labeling on the device indicates its compliance status, ANATEL Certification for Brazil allowing consumers to identify certified products easily.

Security and Privacy Compliance

As wireless devices collect and transmit sensitive data, ensuring data security and privacy is a critical aspect of regulatory compliance. Regulations such as the General Data Protection Regulation (GDPR) in Europe and various data protection laws worldwide mandate that manufacturers take appropriate measures to safeguard user data.

Over-the-Air (OTA) Updates

OTA updates are crucial for maintaining the security and functionality of wireless devices. Manufacturers must design their devices to facilitate secure and regular updates, ensuring that vulnerabilities are promptly addressed.

User Education

Compliance isn't solely the responsibility of manufacturers and regulators; consumers play a vital role. Users should stay informed about the regulatory requirements for their wireless devices, including firmware updates and proper usage. Understanding the potential risks and best practices can enhance the overall safety and performance of these devices.

2 notes

·

View notes

Text

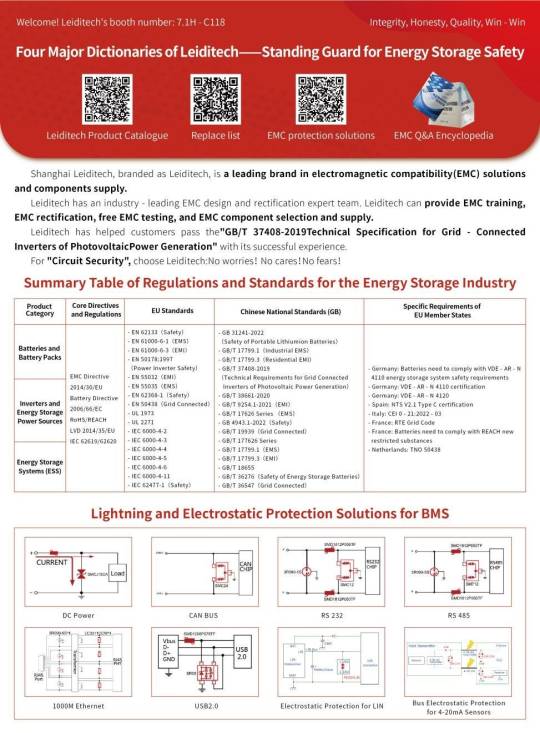

Leiditech Empowers Energy Storage Safety: Establishing a Full - Link Protection System

Leiditech Empowers Energy Storage Safety — Expert in Electrostatic and Surge Protection

In today’s booming new energy industry, the safety of energy storage systems has become the core proposition of the industry. As the “heart” of energy storage systems, the Battery Management System (BMS) faces multiple challenges such as surge impacts, electrostatic interference, and communication stability. As a professional supplier of protection solutions and components, Leiditech builds a triple — layer safety barrier for BMS with professional technologies:

l Power Supply Protection: High — power TVS diodes are adopted to achieve millisecond — level response to surge impacts, ensuring stable power supply for BMS. The system can maintain continuous operation even in scenarios of power grid fluctuations or lightning strikes.

l Signal Protection: ESD electrostatic protection devices provide anti — electrostatic capabilities for signal buses such as CAN and RS485, meeting the strict standards of contact discharge ±15kV and air discharge ±25kV, and ensuring zero — distortion transmission of communication signals.

l Full — Link EMC Solutions: Leiditech provides full — scenario protection covering power supply, signals, and interfaces, helping customers pass international certifications such as ISO 10605, and achieving a dual breakthrough in safety and energy efficiency.

Leiditech has an industry — leading expert team for EMC (Electromagnetic Compatibility) design and rectification. It can provide EMC training, EMC rectification, free EMC testing, and EMC component selection and supply.

Leiditech’s successful experience has helped customers rectify and pass Technical Specification for Grid — connected Photovoltaic Inverters (GB/T 37408–2019).

Scenario-Based Solutions: Precise Adaptation to Diverse Energy Storage Needs

Leiditech develops customized protection solutions for the differentiated requirements of different application scenarios, driving the implementation of energy storage technologies:

l New Energy Vehicles: Certified to ISO 10605 standards, our protection solutions withstand extreme electrostatic environments, adapting to the high-frequency communication and high-reliability requirements of in-vehicle BMS to safeguard power battery safety.

l Commercial & Industrial Energy Storage: Using low-leakage current designs (e.g., SM8S series), standby power consumption is reduced to the microamp level, meeting the low self-discharge needs of long-term energy storage. This is particularly suitable for scenarios such as photovoltaic energy storage and data center backup power supplies.

Regulatory Landscape of the Energy Storage Industry: China-EU Standard Comparison and Compliance Guide

Analysis of Compliance Key Points:

l EMC Testing: The EU’s EN 55032/55035 correspond to China’s GB/T 9254.1 (EMI) and the GB/T 17626 series (EMS). Special attention should be paid to electromagnetic radiation and anti-interference capabilities.

l Grid-connection Requirements: The EU’s EN 50438 directly aligns with China’s GB/T 19939 (photovoltaic) and GB/T 36547 (energy storage). It involves technical details such as power quality and protection

Panoramic Perspective of Battery Technology: A Comparison of Cost, Performance, and Application Scenarios

Insights into Technology Trends:

Lithium iron phosphate, leveraging its advantages of low cost and long lifespan, remains the dominant choice in the current energy storage market.

Although solid — state batteries are costly, their energy density of over 500Wh/kg and ultra — long lifespan indicate that they will be the disruptors of the next — generation energy storage technology.

The excellent performance of sodium batteries in the low — temperature environment of — 40℃ provides new possibilities for energy storage applications in northern regions.

Conclusion: From Protection to Empowerment, Leiditech Drives Energy Storage Safety.

Driven by the “Dual Carbon” Goals, the energy storage industry is evolving from “technology verification” to “large — scale application”. With the full — link EMC solution as the fulcrum, Leiditech not only provides protection capabilities for BMS from components to systems but also helps customers achieve technological innovation on the basis of safety and compliance by deeply interpreting regulatory standards and forward — looking layout of technology routes. In the future, as new technologies such as solid — state batteries and sodium — ion batteries mature, Leiditech will continuously iterate protection solutions and explore the ultimate answers to energy storage safety and energy efficiency together with the industry.

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

#EnergyStorage #BatterySafety #EMC #SurgeProtection #BMS #SmartEnergy #EVTech #RenewableEnergy #Leiditech #GridSecurity #SustainableTech #CleanEnergySolutions #PowerProtection

0 notes

Text

Semiconductor & Remote Testing Boost Auto Testing Services

The Mexico automotive testing market is projected to grow at a compound annual growth rate (CAGR) of 3.7% from 2023 to 2030. This upward trend is driven by increasingly stringent vehicle emissions and safety standards, expanding demand for electric vehicle (EV) testing, and growing adoption of advanced Testing, Inspection, and Certification (TIC) services in the country.

Mexico plays a strategic role in the global automotive supply chain, and as vehicle production accelerates, so does the demand for high-quality testing to ensure compliance, performance, and safety.

To Get Free Sample Report : https://www.datamintelligence.com/download-sample/mexico-automotive-testing-market

Key Market Drivers

1. Stricter Emission and Safety Regulations Mexico has tightened its regulatory framework in alignment with global standards, enforcing rigorous emissions controls and safety mandates. This includes the enforcement of soot-free vehicle emission norms and more stringent crash-testing protocols, prompting automakers and parts suppliers to expand testing operations.

2. Growth in TIC Services The automotive TIC (Testing, Inspection, and Certification) market in Mexico was valued at approximately USD 635 million in 2022 and is expected to exceed USD 1.3 billion by 2030. Rising demand for emissions testing, component validation, and homologation processes is fueling this segment’s rapid growth.

3. Rise of Electric and Connected Vehicles The expansion of electric and connected vehicle production has introduced new testing requirements, such as high-voltage battery certification, electromagnetic compatibility (EMC) testing, and ADAS system verification. The EV testing market alone is projected to grow at over 13% CAGR, supporting battery durability and charging system validation.

4. Increase in Automotive Production Mexico remains one of the top vehicle-producing nations globally, with strong exports to North America and Europe. The growth in vehicle output especially in SUVs, EVs, and light trucks is increasing the need for robust local testing capabilities.

5. Industry 4.0 and Digitalization Automotive testing in Mexico is increasingly powered by automation, data analytics, and cloud-based platforms. These technologies streamline quality checks, accelerate certification, and improve data-driven insights for both OEMs and regulators.

Market Segmentation

The automotive testing market in Mexico is broadly segmented by:

Test Type: Engine and transmission testing, chassis testing, durability and vibration analysis, emissions testing, electrical and electronics testing.

Product Type: Emission analyzers, battery testers, chassis dynamometers, alignment systems, and digital diagnostic tools.

Vehicle Type: Passenger cars, commercial vehicles, and electric vehicles.

Engine and transmission testing accounts for the largest share, while EV-related testing is the fastest-growing segment due to increasing vehicle electrification and regulatory requirements.

Regional & Industry Trends

North American Integration Under trade agreements such as USMCA, Mexico aligns its automotive testing standards with the U.S. and Canada. This harmonization ensures products meet stringent export requirements and drives demand for localized testing labs.

EV Component Testing Expansion Mexico’s growing role in the EV supply chain especially in battery and power electronics has created a surge in testing facilities dedicated to thermal safety, high-voltage stress, and software validation.

Underinvestment in R&D Infrastructure Despite strong production capabilities, many Mexican OEMs and Tier 1 suppliers lack advanced R&D labs. This gap presents opportunities for third-party testing providers and international TIC firms to expand service offerings.

Market Challenges

1. Limited In-House Capabilities Many domestic automotive manufacturers depend on external partners for emissions and safety testing due to underdeveloped internal facilities.

2. Capital Intensive Equipment Needs Modern test benches, EMC chambers, and battery validation systems require substantial investment, creating barriers for small-to-medium testing service providers.

3. Regulatory Complexity Automotive testing in Mexico must meet both domestic standards and international certification protocols, which can increase the cost and complexity of compliance.

Get the Demo Full Report : https://www.datamintelligence.com/enquiry/mexico-automotive-testing-market

Future Outlook

EV Testing Growth The demand for electric vehicle testing services particularly battery certification, charger compliance, and motor control system validation is expected to accelerate sharply by 2030.

Digital TIC Platforms AI-driven diagnostics, cloud-based monitoring, and remote inspection capabilities are emerging as core features of next-generation testing services in Mexico.

Government Support and Investment As the Mexican government encourages local automotive innovation, public-private partnerships may fund R&D labs, skill development, and infrastructure upgrades to meet growing testing demand.

Cybersecurity and Software Validation As connected and autonomous vehicle systems expand, there will be a growing emphasis on secure software validation, over-the-air update testing, and data protection protocols.

Competitive Landscape

Key players in Mexico’s automotive testing and TIC ecosystem include:

SGS

TÜV Rheinland

Intertek

DEKRA

Robert Bosch

Siemens

Rohde & Schwarz

AVL

UL Solutions

Anritsu

These firms are expanding their local footprint by offering integrated mechanical, electrical, and digital testing solutions tailored to OEM needs and regulatory requirements.

Conclusion

Mexico’s automotive testing market is undergoing a transformation, driven by tighter regulations, increasing EV adoption, and the rise of smart vehicle technologies. As the country reinforces its position as a key player in global automotive manufacturing, demand for high-quality testing services is set to grow steadily through 2030. With targeted investment, digital innovation, and strategic partnerships, Mexico can not only meet domestic testing needs but also serve as a testing hub for the broader Latin American and North American regions.

0 notes

Text

RF Chambers| Anechoic Chambers | dmcrf

Perfect radio frequency (RF) performance is essential for wireless communication, radar systems, and Internet of Things (IoT) devices in today's hyper-connected world. Ensuring these systems operate without interference requires specialized testing environments—RF chambers. These shielded enclosures, also known as Anechoic Chambers or EMC (Electromagnetic Compatibility) chambers, are critical for industries ranging from defense to telecommunications.

What Are RF Chambers?

An RF Chamber is a controlled environment designed to block external electromagnetic interference (EMI) while allowing precise RF testing. These chambers come in two primary forms:

Shielded Chambers – Block outside RF signals to create an interference-free zone.

Anechoic Chambers – Absorb internal reflections using RF-absorbing materials (ferrite tiles, foam pyramids).

How Do RF Chambers Work?

Faraday Cage Principle: Metal walls (usually steel or aluminum) block external RF signals.

RF Absorbers: Interior linings minimize reflections for accurate antenna and radar testing.

Filtered Ports: Allow power and data cables to enter without leaking interference.

Without RF Chambers, wireless devices could suffer from signal degradation, failed compliance tests, or even security vulnerabilities.

Industries That Rely on RF Chambers

Defense & Aerospace

Radar cross-section testing for stealth aircraft.

Secure communications (TEMPEST certification).

Satellite and avionics testing.

Telecommunications

5G base station validation.

IoT device certification.

Mobile phone RF performance testing.

Automotive

Electric vehicle (EV) EMC compliance.

Autonomous vehicle radar testing.

Medical Devices

Ensuring wireless medical implants (pacemakers) don’t interfere with other devices.

Consumer Electronics

FCC/CE certification for Wi-Fi routers, Bluetooth devices.

Why Choose DMC RF for Your RF Chamber Needs?

DMCRF specializes in custom RF testing solutions, offering:

Tailored chambers for defense, telecom, and automotive sectors.

Global compliance expertise (FCC, CE, MIL-STD).

Cutting-edge absorber technology for accurate measurements.

RF Chambers play a pivotal role in wireless innovation, from 5G deployment to military communications. As technology advances, the demand for more sophisticated, AI-integrated, and sustainable Rf Testing Solutions will grow. Companies like DMCRF are at the fore front, providing the infrastructure needed to keep our connected world running smoothly.

Contact us

Phone Number : +1(613) 915 5533

Website: https://www.dmcrf.com/

0 notes

Text

6 Product Testing Tips You Shouldn’t Ignore Before Launching

Launching a new product? Whether it’s a fan, charger, motor, or electronic appliance — testing is more than just a formality. It’s your first line of defense against rejection, recalls, and certification delays.

At House of Testing, we’ve seen products fail at the last mile — simply because the right lab, standards, or steps weren’t followed. To help you avoid that, here are 6 must-know testing tips before your product hits the market:

✅ 1. Choose a NABL Accredited Lab

A NABL-accredited lab follows ISO/IEC standards. This is what makes your test reports valid and accepted by BIS, ISI, or TEC bodies. If your lab isn’t NABL certified — your approval may get rejected.

✅ 2. Understand Your Product Category

Different products = different testing rules. For example:

A ceiling fan needs high voltage, insulation, and endurance tests

A smart plug might need environmental and EMI/EMC testing Know what standards apply before submitting your sample.

✅ 3. Simulate Real-World Conditions

Don’t just test for lab approval — test for real-life usage. At House of Testing, we recreate:

Heat, humidity, voltage surges

Drop/impact conditions

Long-use durability tests

This ensures your product doesn’t just pass — it performs.

✅ 4. Request ISO-Compliant Reports

Ask your lab:

“Are your reports ISO/IEC compliant?” Only these are accepted by BIS and global regulators.

✅ 5. Avoid Unverified Labs

Quick tests from local labs might seem cheaper. But they often result in:

Rejected certification

No traceability

Lack of documentation

Loss of trust with vendors

Certified labs like House of Testing ensure your process is audit-ready.

✅ 6. Get End-to-End Certification Support

The best labs don’t just test — they help with:

BIS/ISI form submissions

Test plan consultation

Technical documentation Choose a lab that walks with you, not just one that hands over a report.

📌 Final Thought:

Testing isn’t the last step before launch — it’s the foundation of your product’s success.

📍 Need BIS or NABL-certified testing? Contact House of Testing – Where Products Get Certified the Right Way contact us: +91-9899994387 Website: https://houseoftesting.com/ Instagram: https://www.instagram.com/houseoftesting?igsh=ZXoyZzMweXMxOHI3&utm_source=qr Facebook : https://www.facebook.com/share/1ajhbTkGp7/?mibextid=wwXIfr

0 notes

Text

E-Field Generator Market Report: Unlocking Growth Potential and Addressing Challenges

United States of America – June 19, 2025 — The Insight Partners is pleased to announce its new market study, “E-Field Generator Market: An In-depth Analysis of the E-Field Generator Market.” This report offers a clear overview of current market dynamics and sheds light on anticipated growth trends during the forecast period.

Overview of E-Field Generator Market

The E-Field Generator market is witnessing steady expansion, driven by rising demand across industries for precise electromagnetic testing and compliance verification. This report highlights the main factors behind market development, including technological improvements, stricter industry regulations, and growing investment in advanced testing infrastructure.

Key Findings and Insights

Market Size and Growth

Historical Overview: The E-Field Generator market is steadily expanding, supported by increasing use in sectors such as telecommunications, automotive, aerospace, and scientific research.

Key Factors: Growth drivers include the surge in electromagnetic compatibility (EMC) testing requirements, rapid industrial automation, and continuous innovation in high-performance field generation equipment.

Market Segmentation

By Type: High-Intensity E-Field Generators, Low-Intensity E-Field Generators

By Application: EMC Testing, Material Testing, Antenna Calibration, Scientific Research, Others

By End User: Automotive, Aerospace & Defense, Electronics & Electrical, Research Laboratories, Others

By Region: North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Spotting Emerging Trends

Technological Advancements: New designs focus on portability, energy efficiency, and higher field strength accuracy, improving testing capabilities and broadening applications.

Changing Consumer Preferences: End users now favor flexible, easy-to-integrate solutions that support stringent testing standards and reduce operational complexity.

Regulatory Changes: Updates in global EMC standards and compliance frameworks are encouraging industries to adopt advanced E-Field Generators to meet evolving certification needs.

Growth Opportunities

The E-Field Generator market presents promising opportunities through expansion into new industries, adoption in emerging economies, and continued technological upgrades. Companies focusing on cost-effective, compact solutions and customer-centric service models stand to benefit the most.

Conclusion

The E-Field Generator market: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast 2023-2031 report provides much-needed insight for a company willing to set up its operations in the E-Field Generator market. Since an in-depth analysis of competitive dynamics, the environment, and probable growth path are given in the report, a stakeholder can move ahead with fact-based decision-making in favor of market achievements and enhancement of business opportunities.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

To know more and get access to Sample reports. https://www.theinsightpartners.com/sample/TIPRE00014689

#E-Field Generator Market#EMC Testing Equipment#Electromagnetic Field Generators#Industrial Testing Solutions#Market Research Report

0 notes

Text

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions.

If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions. If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions.

If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

A Complete Guide to CE Certification: What It Is and Why It Matters

I. Introduction to CE Certification

The CE mark is one of the most recognizable compliance symbols in the world, found on a wide range of products sold within the European Economic Area (EEA). CE Certification indicates that a product meets EU safety, health, and environmental protection standards. But while it might look like a simple label, the certification process behind that mark is rigorous and essential for companies that want access to the European market.

Whether you're a manufacturer, importer, or distributor, understanding CE Certification is vital. This article will take a deep dive into what CE Certification is, the benefits it provides, the step-by-step process, applicable directives, and how to ensure compliance for your products.

II. What is CE Certification?

CE Certification stands for "Conformité Européenne," meaning "European Conformity." It is not a quality mark but a declaration that the product complies with EU legislation.

Key Facts About CE Certification:

Mandatory for products sold in the EEA.

Applies to both EU-based and non-EU manufacturers.

Covers more than 20 product categories, including electronics, machinery, toys, medical devices, and construction products.

By affixing the CE mark, the manufacturer declares that their product complies with all relevant EU directives and harmonized standards.

III. Why is CE Certification Important?

1. Legal Access to the European Market

Without CE marking, your product cannot legally be marketed or sold in the EEA. This applies even to e-commerce and imported goods. For businesses outside the EU, CE marking is essential to penetrate the European market legally.

2. Consumer Confidence and Safety

Products bearing the CE mark give consumers confidence that the item meets stringent European safety, health, and environmental standards. This helps protect users and reduces liability for manufacturers.

3. Competitive Advantage

Manufacturers with CE-certified products enjoy better acceptance in international markets. Some countries outside the EU view CE marking as a sign of high safety and quality standards.

IV. Products That Require CE Certification

The CE mark applies to a wide array of products. If your product falls under any of these categories, it must meet the CE requirements:

Electrical and electronic equipment (Low Voltage Directive, EMC Directive)

Machinery

Medical devices

Personal protective equipment (PPE)

Toys

Pressure equipment

Construction products

Gas appliances

Measuring instruments

Each category is regulated by a specific directive or regulation, such as the Machinery Directive 2006/42/EC or the Medical Device Regulation (EU) 2017/745.

V. Steps to Obtain CE Certification

1. Identify Applicable Directives and Standards

Determine which EU directives and harmonized standards apply to your product. Each directive outlines specific safety, health, and environmental requirements.

2. Assess Product Requirements

Conduct a conformity assessment based on the applicable directive. This may involve internal testing or third-party assessment, depending on the risk level of the product.

3. Choose a Conformity Assessment Procedure

EU directives provide various modules (e.g., A, B, C, D) based on the product’s complexity. For simple products, self-declaration may be sufficient. High-risk products often require a Notified Body.

4. Compile a Technical File

This includes all necessary documentation to prove compliance:

Design and manufacturing details

Test results

Risk assessment

User manuals

CE declaration of conformity

5. Affix the CE Mark

Once all requirements are met, affix the CE mark visibly, legibly, and indelibly on the product or its data plate. The CE marking must be at least 5 mm high.

6. Prepare the EU Declaration of Conformity

This formal document declares the product’s compliance and must be signed by the manufacturer or authorized representative.

VI. What is a Notified Body and When Do You Need One?

A Notified Body (NB) is an organization designated by an EU country to assess the conformity of certain products before being placed on the market. You need a Notified Body when:

Your product poses higher safety or health risks.

The directive requires independent testing or certification.

Notified Bodies are involved in reviewing the technical documentation, auditing production processes, or conducting laboratory tests. They issue an EU-type examination certificate, allowing you to proceed with CE marking.

Examples of directives requiring a Notified Body include:

Medical Device Regulation

Pressure Equipment Directive

Personal Protective Equipment Regulation

VII. Common Challenges in CE Certification

1. Misidentifying Applicable Directives

Many businesses fail to correctly determine which EU directives apply to their product. Misidentification can lead to non-compliance and legal penalties.

2. Incomplete Technical Documentation

A lack of detailed and organized technical files can delay CE marking. Always maintain updated and structured documentation ready for inspection.

3. Language Requirements

Instructions and safety information must be translated into the official language(s) of the destination EU country, which some companies overlook.

4. Improper Marking

Incorrect placement, sizing, or inclusion of additional logos can lead to product recalls. The CE mark must follow strict format guidelines.

VIII. CE Marking vs. Other Certifications

It’s important not to confuse CE Certification with other marks like:

UKCA (UK Conformity Assessed) – Required for the UK market post-Brexit.

FCC (Federal Communications Commission) – For electronic devices in the U.S.

UL (Underwriters Laboratories) – U.S.-based product safety certification.

CB Scheme – For international acceptance of electrical products.

CE marking is specific to the European Economic Area and does not indicate compliance with non-EU regulatory requirements.

IX. CE Certification for Non-EU Manufacturers

Manufacturers outside the EU must still comply with CE directives if they intend to sell in Europe. They must appoint an Authorized Representative (AR) based within the EU to act as a liaison with authorities and manage technical documentation.

Duties of the AR include:

Holding and providing the Declaration of Conformity

Cooperating with EU market surveillance authorities

Ensuring product compliance and traceability

X. Penalties for Non-Compliance

Failure to obtain CE certification or misuse of the CE mark can result in:

Fines and legal actions

Product recalls or bans

Reputational damage

Loss of access to the EU market

Market surveillance authorities across Europe regularly inspect products for CE compliance. Companies found in violation may be penalized or blacklisted from trading in the region.

XI. Conclusion: CE Certification as a Gateway to Europe

CE Certification is more than a regulatory hurdle—it's a powerful symbol of safety, quality, and conformity. For manufacturers, it opens the door to the European Economic Area and assures customers of your commitment to high standards.

Achieving CE compliance may seem complex, but with the right expertise and approach, it becomes a strategic advantage. Whether you are a startup or an established company, investing in proper CE certification processes can be the key to expanding your market reach, improving product safety, and ensuring regulatory peace of mind.

ce certification

0 notes