#ETHERNET RELAY MODULE

Explore tagged Tumblr posts

Text

Ajitek Tech Solutions Pvt Ltd

0 notes

Text

Understanding Relay Module Circuits: A Comprehensive Guide

Introduction:

Relay module circuits are essential components in various electronic and electrical applications. These circuits act as switches, allowing control signals from one circuit to activate or deactivate another circuit. Relay modules provide an efficient way to isolate high-power devices from low-power control systems, ensuring safety and protection. In this comprehensive guide, we will delve into the fundamentals of relay module circuits, their working principles, applications, and address some frequently asked questions (FAQs) to provide a complete understanding of this crucial aspect of modern electronics.

I. What is a Relay Module Circuit?

A relay module circuit consists of an electromechanical relay mounted on a PCB (Printed Circuit Board). The relay is an electromagnetic switch that is actuated by a control signal, which can be either digital or analog. When the control signal triggers the relay, it closes or opens the electrical contacts, allowing current to flow through the output terminals and control external devices or circuits.

II. How Does a Relay Module Circuit Work?

Electromagnetic Coil: The relay module circuit has an electromagnetic coil that serves as the input or control element. When an appropriate voltage is applied to the coil, it creates a magnetic field, causing the relay's armature to move.

Normally Open (NO) and Normally Closed (NC) Contacts: A relay typically has two sets of contacts: Normally Open (NO) and Normally Closed (NC). In the resting state, the NO contacts remain open, and the NC contacts remain closed.

Switching Action: When the coil is energized, the armature moves, causing the NO contacts to close and the NC contacts to open. This switching action completes or interrupts the circuit, depending on the application.

III. Types of Relay Module Circuits:

Single-Pole, Single-Throw (SPST) Relay: SPST relays have one set of contacts and can either be Normally Open or Normally Closed.

Single-Pole, Double-Throw (SPDT) Relay: SPDT relays have one set of normally open contacts and one set of normally closed contacts. When the relay is energized, the NO contacts close, and the NC contacts open.

Double-Pole, Single-Throw (DPST) Relay: DPST relays have two sets of contacts that operate simultaneously, making or breaking the circuit.

Double-Pole, Double-Throw (DPDT) Relay: DPDT relays have two sets of NO contacts and two sets of NC contacts. They provide two separate circuits that can be independently controlled.

IV. Applications of Relay Module Circuits:

Home Automation: Relay modules are commonly used in home automation systems to control lighting, heating, ventilation, and air conditioning (HVAC) systems.

Industrial Automation: In industrial automation, relay modules are used to control motors, pumps, solenoids, and other high-power devices.

Automotive Electronics: In automobiles, relay modules are utilized to control various electrical systems, such as headlights, windshield wipers, and electric windows.

Robotics: Relay module circuits are used in robotics to control the movement of actuators and motors.

Security Systems: In security systems, relay modules are used to trigger alarms and control access points.

V. Advantages of Using Relay Module Circuits:

Isolation: Relay module circuits provide galvanic isolation between the control circuit and the load, ensuring safety and protecting sensitive components.

Low Power Control: Relay modules allow low-power control systems to switch high-power devices, eliminating the need for high-power control circuits.

Versatility: Relay module circuits are available in various configurations and voltage ratings, making them versatile and suitable for a wide range of applications.

Simple Operation: Relay modules are easy to install and operate, making them a popular choice in many electronic applications.

FAQs:

Q1. Can relay module circuits be used for both AC and DC applications? Yes, relay modules are available in both AC and DC versions, allowing them to be used in a wide range of applications.

Q2. What is the difference between a relay and a relay module? A relay is the basic electromagnetic switch, while a relay module includes the relay mounted on a PCB with additional circuitry for ease of use and integration into other systems.

Q3. Can relay modules handle high-current applications? Yes, relay modules are available in different current ratings, and they can handle high-current applications as per their specifications.

Q4. How do I choose the right relay module for my application? When selecting a relay module, consider the voltage and current requirements of your application, the type of load (AC or DC), and the number of contacts needed.

Q5. Can I use a relay module to control multiple devices simultaneously? Yes, some relay modules have multiple sets of contacts (DPDT or more), allowing you to control multiple devices independently.

Conclusion:

Relay module circuits are versatile and indispensable components in modern electronics and electrical systems. Their ability to provide isolation, low-power control, and versatility makes them ideal for a wide range of applications in various industries. By understanding the working principles and different types of relay modules, along with their numerous applications, designers and engineers can make informed decisions when integrating these circuits into their projects. Relay module circuits continue to play a critical role in enhancing the efficiency and control capabilities of electronic systems, contributing to advancements in automation and smart technologies.

0 notes

Text

ARMxy SBC Embedded Controller BL340 in sewage Treatment System Monitoring

Case Details

Introduction

Real-time monitoring of wastewater treatment systems is critical for ensuring water quality compliance, optimizing process flows, and reducing operational costs. The ARMxy BL340 series embedded controller, powered by the Allwinner T507-H quad-core ARM Cortex-A53 processor, offers high performance, low power consumption, and flexible I/O configurations, making it ideal for industrial Internet of Things (IoT) applications in wastewater treatment monitoring. This article explores the design and application of the BL340 in wastewater treatment systems, analyzing its technical advantages and practical outcomes.

System Design

Hardware Architecture

The BL340 series adopts a modular design, with core hardware components including:

Processor: Allwinner T507-H, quad-core Cortex-A53, up to 1.4 GHz, paired with 8/16 GB eMMC storage and 1/2 GB DDR4 memory, meeting data processing and storage requirements.

Sensor Interfaces: Supports various sensors via Y-series I/O boards, such as pH (Y33/Y34, 0-5/10V analog input), dissolved oxygen (Y31, 4-20mA input), turbidity (Y36, ±5V/±10V differential input), and temperature (Y51/Y52, PT100/PT1000 RTD).

Communication Modules: Includes 3×10/100M Ethernet ports, 2×USB 2.0, Mini PCIe (4G/WiFi/Bluetooth), and a NANO SIM slot for remote data transmission.

Power and Installation: Supports 9-36 VDC wide voltage input with reverse polarity and overcurrent protection, designed for DIN35 rail mounting, suitable for harsh wastewater treatment environments.

Environmental Adaptability: Certified with IP30 protection and -40~85°C wide temperature testing, ensuring reliability in humid, high-temperature, or vibrating conditions.

Software Architecture

The BL340 supports multiple operating systems and development tools, with a software architecture comprising:

Operating Systems: Linux-4.9.170, Ubuntu 20.04, or Android 10, with Docker container support for rapid deployment.

Protocol Conversion: Pre-installed BLloTLink software supports protocols like Modbus, MQTT, and OPC UA, compatible with cloud platforms such as AWS IoT Core and ThingsBoard.

Data Processing: Utilizes Node-Red and Qt-5.12.5 for data acquisition, processing, and visualization, supporting real-time water quality parameter analysis.

Remote Access: BLRAT tool enables remote maintenance and configuration, enhancing operational efficiency.

Functionality and Applications

Real-Time Water Quality Monitoring

The BL340 collects critical wastewater treatment parameters (e.g., pH, dissolved oxygen, turbidity, temperature, and conductivity) via Y-series I/O boards. For instance, the Y31 module connects to 4-20mA dissolved oxygen sensors, and the Y51 module supports PT100 temperature sensors. Data is sampled via ADC, processed by the BL340, and used to generate real-time water quality reports.

Remote Monitoring and Alarming

The BL340 uploads data to cloud platforms via 4G or WiFi modules, enabling remote monitoring through web interfaces or mobile applications. When water quality parameters exceed thresholds (e.g., pH <6 or >9), the system sends alerts via MQTT and can control valves or pumps using the Y24 relay module to automatically adjust processes.

Data Storage and Analysis

The BL340 supports local SD card storage and cloud backups, archiving historical water quality data. Node-Red facilitates trend analysis, such as correlating dissolved oxygen levels with aeration energy consumption, to optimize wastewater treatment processes.

Typical Application Case

In a municipal wastewater treatment plant, the BL340B (equipped with 3×Ethernet ports and 2×Y-board slots) was deployed to monitor a biological reaction tank. The system configuration included:

Hardware: BL340B-SOM341-X23-Y31-Y51, featuring 4×RS485, 4×DI/DO, 4×4-20mA inputs (dissolved oxygen, turbidity), and 2×PT100 (temperature).

Functionality: Real-time water quality data collection, uploaded to the ThingsBoard platform via 4G, with automated aeration pump control.

Results: The system operated stably, reduced manual inspections, improved effluent compliance, and lowered energy consumption by approximately 15%.

Technical Advantages

High Performance and Low Power: The quad-core Cortex-A53 processor with a 1.4 GHz clock speed ensures efficient data processing, while the wide-voltage power design minimizes energy use.

Flexible I/O Configuration: Supports various X/Y-series I/O boards, accommodating diverse sensor and control requirements.

Robust Communication: Multiple Ethernet ports and 4G/WiFi modules support complex network environments, with BLloTLink enabling seamless integration with mainstream cloud platforms.

Industrial-Grade Reliability: Certified through electromagnetic compatibility (EMC) and environmental adaptability tests (-40~85°C, IP30, vibration resistance), suitable for harsh wastewater treatment conditions.

Ease of Development: Node-Red and Qt tools simplify application development, with BLRAT supporting remote debugging, reducing deployment time.

Challenges and Solutions

Sensor Drift: Regular calibration or software compensation algorithms (e.g., Kalman filtering) enhance data accuracy.

Network Stability: 4G redundancy and local caching ensure reliable data transmission.

Data Security: MQTT over TLS and device authentication safeguard data transfers.

Conclusion

The ARMxy BL340 series embedded controller demonstrates significant advantages in wastewater treatment system monitoring due to its high performance, flexibility, and industrial-grade reliability. Its modular design and robust communication capabilities meet diverse monitoring needs, enabling wastewater treatment plants to achieve intelligent and efficient operations. As industrial IoT technologies advance, the BL340 will play an increasingly vital role in water treatment applications.

0 notes

Text

Authorized Weidmuller Distributor in Dubai, UAE, Middle East | Tanelect

Intro

Looking for an authorized Weidmuller distributor in Dubai, UAE, and the Middle East? Tanelect is your trusted destination for genuine Weidmuller electrical components and automation solutions. With years of experience in delivering high-quality products and unmatched customer service, we are proud to be the go-to partner for industries across the region.

Why Choose Tanelect as Your Weidmuller Distributor?

As an authorized Weidmuller distributor, we offer a comprehensive range of industrial connectivity and automation products, including:

Terminal blocks

Relays and interface modules

Power supplies

Marking systems

Surge protection devices

Industrial Ethernet and automation components

Weidmuller is known globally for its robust, reliable, and innovative solutions, and at Tanelect, we ensure that our customers get only the best, with timely support and efficient delivery.

More Than Just Weidmuller – A Complete Industrial Supply Hub

While we specialize in Weidmuller components, Tanelect is also a leading name among:

✅ Thermostat Suppliers in UAE & Dubai

We are one of the most reliable thermostat suppliers in UAE, offering high-quality thermostats for industrial and HVAC applications. Whether you need precision temperature control or robust thermostat models for demanding environments, Tanelect has you covered. If you are looking specifically for thermostat suppliers in Dubai, we are your local partner with expert knowledge and stock availability.

✅ Cutting Tools Suppliers in UAE

Tanelect is also recognized as one of the trusted cutting tools suppliers in UAE. We offer an extensive inventory of cutting tools that are engineered for efficiency, durability, and precision. From general-purpose to application-specific cutting tools, we are known as dependable cutting tools suppliers across the region.

Serving the Entire Middle East

Our reach goes beyond Dubai and the UAE — we serve industries across the Middle East with genuine Weidmuller products, and offer timely support to meet your project and maintenance needs. From energy and automation to manufacturing and infrastructure, we help businesses elevate their performance through advanced technology and reliable components.

Partner with Tanelect Today

If you are searching for an authorized Weidmuller distributor in Dubai, UAE, or the Middle East, look no further than Tanelect. Our commitment to quality, fast delivery, and expert support makes us the preferred supplier for industries that demand excellence.

Contact Us

Tareeq Al Najah Electrical Distribution Boards TR. LLC.

P.O. Box : 47259, Sharjah, United Arab Emirates.

+971 6 5533 768

+971 55 77 212 72

#current transformer distributors#top busbar support suppliers#conical insulator suppliers#best insulator suppliers#socket panel supplier#panel light suppliers#dmc busbar support suppliers#enclosure suppliers in uae

0 notes

Text

How CompactLogix from Allen-Bradley improves tray stacker automation

How CompactLogix from Allen-Bradley improves tray stacker automation Today, moving materials quickly and accurately is crucial. A tray stacker machine is a prime example of how automation can enhance productivity. This guide explores how an Allen-Bradley CompactLogix PLC system can be used to effectively control a tray stacker. This system works seamlessly with advanced automation tools like I/O modules, PowerFlex VFDs, Kinetix Servo Drives, and PanelView HMIs. How the Tray Stacker Functions A tray stacker machine automates the task of organizing trays. It features three conveyor belts that transport trays through the system.

The working can be summarized as tray positioning, lifting mechanism, stacking process and completion. Once any stack is completed, the conveyor system will move the stack out and proceed it to further processing and packaging. The control system should be strong enough to run the machine smoothly and accurately. The perfect setup will enhance the efficiency and productivity of tray stackers in any material handling operations.

How does the control system work? What are the crucial parts of it?

Allen-Bradley's CompactLogix is the main part of the tray stacker. The movement, lifting parts and safety are managed by the CompactLogix PLC. It is also responsible for the safety features by enabling the proper lifting. By the support of many input/output (I/O) modules, drives and network connections, it can be expanded with your needs.

Key Automation Components

I/O Modules and Devices: The CompactLogix PLC connects to different sensors and devices through digital input/output (I/O) modules. These include models like the 1769-IQ16 for digital input and 1769-OB16 for digital output. - Input Sensors: These sensors are to detect the presence and determine the positions of the tray. - Output Actuators: The efficient stacking is ensured by these control elements. Alarms and pneumatic grippers help in this. PowerFlex Variable Frequency Drives (VFDs): The conveyors powered by the PowerFlex Variable Frequency Drives from Allen-Bradley. PowerFlex 525 (25B-D4P0N104), PowerFlex (20F11ND065AA0NNNNN) are a few examples. These drives have the communication aid of EtherNet/IP, which allows smooth working. Kinetix Servo Drives for Precision Control: The accurate tray stacking and lifting is made possible using Kinetix Servo Drives. Examples are Kinetix 5500 (2198-H008-ERS2)-High speed positioning, Kinetix 5700 (2198-D032-ERS3)- advanced motion control. The servo system will make sure the arms that lift the stack moves accurately and this will prevent the misalignment during stacking.

PanelView 5000-Human-Machine Interface (HMI): The PanelView 5510 (2715P-T12CD) HMI is the interfacing device between the operator and the machine. This is allowing the operator to control and monitor the proper operations in real time

The operators have the ability to: start or stop the machine, reset any faults occurring, viewing alarms and access system diagnostics. This is using the EtherNet/IP network.

Safety Integration: The most important thing for an industrial automation system is safety. Some systems prefers safety rated CompactLogix controllers, but mid sized machines like tray stacker often depend on safety solutions with wired technology which includes;

- Emergency stop buttons (800T-ESTOP) to quickly halt operations.

- Safety light curtains (440L-ADMS60) - Prevents accidents by detecting motion.

- Safety relays (440R-D22R2) Protects workers by preventing movements in required scenarios.

Why Choose CompactLogix for Tray Stacker Control?

- Scalability: Scalable by I/O modules for meeting the changing needs.

- High-Speed Processing: Precise control over stacking. Accurate processing.

- Seamless Integration: Helps to provide coordinated operations by easily connecting with Allen-bRADLEY VFD's, HMIs and servo drives.

- EtherNet/IP Connectivity: Prevents downtime by predicting maintenance. https://automationitems.com/blogs/how-compactlogix-from-allen-bradley-improves-tray-stacker-automation

0 notes

Text

A Guide to PLC Programming for Smart Manufacturing

Introduction

In today’s industrial landscape, automation is revolutionizing manufacturing processes, making them more efficient, reliable, and scalable. One of the key technologies driving this transformation is Programmable Logic Controller (PLC) programming. PLCs are essential components of smart manufacturing, enabling seamless automation, precise control, and real-time monitoring of industrial operations. This guide explores PLC programming, its importance, key components, and best practices for implementing it in smart manufacturing.

What is PLC Programming?

PLC programming is the process of creating, configuring, and optimizing software for Programmable Logic Controllers (PLCs). These are ruggedized digital computers designed to automate electromechanical processes in industries such as manufacturing, robotics, automotive, and energy. PLC programming allows these controllers to execute logical operations, manage data inputs and outputs, and communicate with other devices within a factory environment.

Importance of PLC Programming in Smart Manufacturing

With the advent of Industry 4.0, PLCs play a crucial role in enabling smart manufacturing. They provide:

Increased Efficiency: Automating processes reduces human intervention and enhances production speed.

Real-time Monitoring: PLCs allow continuous tracking of equipment performance and process status.

Improved Safety: Automation reduces the risk of human error and workplace accidents.

Seamless Integration: Modern PLCs connect with IoT, AI, and cloud-based systems for data-driven decision-making.

Cost Reduction: Minimizing downtime and optimizing resource utilization lead to significant savings.

Key Components of PLC Programming

PLC programming involves multiple components that work together to ensure efficient automation:

1. Hardware Components

Central Processing Unit (CPU): The brain of the PLC, responsible for executing program instructions.

Input Modules: Receive signals from sensors, switches, and other devices.

Output Modules: Control actuators, motors, and alarms.

Communication Modules: Enable connectivity with other devices via Ethernet, RS-232, or fieldbus protocols.

2. Software Components

Programming Languages: PLCs use specialized languages such as:

Ladder Logic (LD): Graphical representation resembling relay logic.

Structured Text (ST): Text-based high-level programming.

Function Block Diagram (FBD): Visual block-based programming.

Sequential Function Chart (SFC): Organizes complex processes into structured steps.

HMI (Human-Machine Interface): Interfaces that allow operators to interact with the PLC system.

Common PLC Programming Languages

1. Ladder Logic (LD)

Ladder Logic is the most widely used PLC programming language due to its resemblance to electrical relay logic. It consists of rungs representing logical conditions that trigger specific actions.

2. Structured Text (ST)

Structured Text is a high-level language similar to Pascal or C, ideal for mathematical and algorithmic functions. It is used for complex calculations and data processing.

3. Function Block Diagram (FBD)

FBD uses interconnected blocks to represent logic functions, making it user-friendly for designing control processes without extensive coding.

4. Sequential Function Chart (SFC)

SFC organizes processes into steps and transitions, making it suitable for sequential operations like batch processing and robotic control.

Steps to Develop a PLC Program

1. Define the Requirements

Identify the system’s objectives, inputs, and outputs. Understand the process that needs to be automated.

2. Select the Right PLC Hardware

Choose a PLC based on processing power, memory, communication capabilities, and environmental conditions.

3. Develop the Logic Design

Create a flowchart or ladder diagram that defines the system’s operation.

4. Write the PLC Program

Using a suitable programming language, write and configure the control logic.

5. Test the Program in a Simulation Environment

Use PLC simulation software to test and debug the logic before deployment.

6. Deploy and Monitor the System

Upload the program to the PLC, conduct real-world testing, and continuously monitor system performance.

Best Practices for Efficient PLC Programming

Keep Code Organized: Use comments and labels for easy readability.

Modular Programming: Break down large programs into reusable modules.

Optimize Scan Time: Write efficient logic to minimize execution delays.

Implement Error Handling: Use fail-safe mechanisms and diagnostics.

Regularly Update Firmware: Ensure compatibility with the latest technologies.

Future of PLC Programming in Smart Manufacturing

With advancements in Industrial IoT (IIoT), Artificial Intelligence (AI), and cloud computing, PLC programming is evolving. Future trends include:

Edge Computing: Enhancing real-time data processing at the PLC level.

AI Integration: Implementing machine learning algorithms for predictive maintenance.

Wireless Connectivity: Using 5G for seamless device communication.

Cybersecurity Enhancements: Protecting industrial networks from cyber threats.

Conclusion

PLC programming is a fundamental aspect of smart manufacturing, enabling automation, efficiency, and connectivity. By leveraging advanced programming techniques and integrating with modern technologies, industries can optimize their manufacturing processes, reduce costs, and stay competitive in the evolving digital landscape. Understanding PLC programming is essential for engineers and automation specialists looking to build future-ready smart factories.

0 notes

Text

Revolutionizing Industrial Processes with Automation Components

Automation components are at the heart of modern industrial systems, enabling seamless, efficient, and reliable operations. Industries worldwide depend on these essential components to enhance productivity, optimize workflows, and achieve precision in their processes. At Ram Automations, we provide a comprehensive range of high-quality automation components from globally recognized brands, tailored to meet your industrial needs.

What Are Automation Components?

Automation components refer to the various parts and systems used to automate industrial processes. These components work together to improve operational efficiency, reduce downtime, and minimize human intervention in repetitive tasks. Key automation components include:

1. Sensors

Sensors detect environmental changes like temperature, pressure, or motion and send signals to other components for necessary adjustments.

Examples: Smart temperature sensors, pressure sensors, motion detectors.

2. Actuators

Actuators convert electrical signals into mechanical movements, enabling tasks like opening valves or moving robotic arms.

Examples: Pneumatic actuators, hydraulic actuators, and electric actuators.

3. Programmable Logic Controllers (PLCs)

PLCs act as the brain of automation systems, managing complex tasks and ensuring seamless operations.

Popular models: Allen-Bradley MicroLogix PLCs, Siemens SIMATIC PLCs.

4. Relays and Switches

These components regulate electrical currents, ensuring safe and controlled power distribution across devices.

Examples: Electromechanical relays, solid-state relays.

5. Communication Devices

Facilitate smooth interaction between various automation components. They ensure that systems work in harmony.

Examples: Industrial Ethernet, wireless communication modules.

Top Brands in Automation Components

At Ram Automations, we collaborate with globally renowned brands to bring you reliable automation solutions.

1. Allen-Bradley

Known for innovative automation systems.

Popular Products:

Programmable Logic Controllers (PLCs).

Human-Machine Interfaces (HMIs).

2. Siemens

Specializes in cutting-edge technology for industries like energy and manufacturing.

Popular Products:

SIMATIC PLCs, Drive Systems, Smart Sensors.

3. Schneider Electric

A leader in sustainable automation solutions.

Popular Products:

Modicon PLCs, Variable Frequency Drives (VFDs), Smart Sensors.

4. Honeywell

Recognized for its automation and control innovations.

Popular Products:

Flame Detectors, Pressure Transmitters, Control Systems.

5. Danfoss

Focused on energy-efficient and sustainable automation solutions.

Popular Products:

Pressure Transmitters, Pressure Controls.

Why Choose Automation Components?

Automation components are indispensable for industries looking to:

Enhance Productivity: Streamline operations and reduce downtime.

Improve Safety: Minimize manual interventions in hazardous processes.

Optimize Energy Usage: Achieve greater efficiency with smart technologies.

Ensure Accuracy: Eliminate human errors in repetitive tasks.

Your Partner in Automation – Ram Automations

Looking for reliable automation solutions? At Ram Automations, we pride ourselves on offering top-quality components and unmatched customer support. Whether you need PLCs, sensors, or any other industrial automation equipment, we have the expertise to guide you.

Why Choose Us?

Access to globally trusted brands.

Competitive pricing and swift delivery.

Expert support for installation and integration.

For more information, explore our wide range of automation components on Ram Automations today!

Final Thoughts

Investing in high-quality automation components can transform your industrial processes, enhancing efficiency and productivity. Choose Ram Automations for a seamless experience and solutions that fit your business needs. Contact us now to take your operations to the next level!

By incorporating automation components, your business can stay ahead of the curve and thrive in a competitive market. Make the smart choice with Ram Automations – your trusted partner in industrial automation!

0 notes

Text

6ED1052-1FB08-0BA2 – Logo Siemens 230RCE

6ED1052-1FB08-0BA2 – Logo Siemens 230RCE SKU:

6ED1052-1FB08-0BA2 Thông số kỹ thuật:

LOGO!

230RCE,logic module, display power supply / I/O:

115 V/230 V/relay, 8 DI/4 DO, memory 400 blocks, modularly expandable, Ethernet, integrated web server, data log, user-defined web pages, standard microSD card for LOGO!

Soft Comfort V8.4 or higher, older projects executable cloud connection, MQTT in all LOGO!

8.4 basic units Tình trạng:

Hàng có sẵn, mới 100% Chứng từ COCQ, tờ khai hải quan, có xuất hóa đơn VAT Hãng sản xuất:

Siemens Giảm thêm 5% khi mua sản phẩm cùng danh mục có giá cao hơn 👉 Xem thêm:

0 notes

Text

Choosing the Right PLC for Your Needs: A Beginner’s Guide

In the realm of PLC industrial automation, selecting the right Programmable Logic Controller (PLC) is crucial for ensuring the efficiency and reliability of your automation systems. PLCs are the backbone of modern industrial control systems, enabling automation of complex processes and machinery. If you’re new to PLCs, understanding the basics and choosing the right one for your needs can seem overwhelming. This beginner’s guide from Balaji Switchgears will help you navigate the selection process.

What is a PLC?

Key Factors to Consider When Choosing a PLC

When selecting a PLC for your industrial automation needs, consider the following factors:

Application RequirementsDetermine the specific requirements of your application. Consider the complexity of the process, the number of inputs and outputs needed, and the type of control required. Different PLCs are designed for varying levels of complexity and functionality.

Simple Applications: For basic control tasks with a limited number of I/O points, a compact PLC may suffice.

Complex Applications: For more complex processes requiring extensive I/O points, communication capabilities, and advanced control functions, a modular PLC with expansion options may be more suitable.

Processing Power and SpeedThe processing power and speed of a PLC are vital for handling the demands of your application. Evaluate the PLC’s CPU capabilities and processing speed to ensure it can manage your system’s real-time control requirements effectively.

Basic PLCs: Suitable for simpler tasks with lower processing demands.

Advanced PLCs: Designed for applications requiring high-speed processing and complex control logic.

Input/Output (I/O) CapabilitiesAssess the number and types of I/O points required for your system. PLCs come with various I/O configurations, including digital and analog inputs and outputs. Ensure the PLC you choose has sufficient I/O capacity to meet your application’s needs.

Digital I/O: Used for binary on/off signals, such as switches and relays.

Analog I/O: Used for continuous signals, such as temperature and pressure sensors.

Communication and NetworkingConsider the communication protocols and networking capabilities required for your system. Modern PLCs often support various communication protocols, such as Ethernet, Modbus, and Profibus, enabling integration with other devices and systems.

Basic Communication: For simple, standalone applications, basic communication capabilities may be sufficient.

Advanced Networking: For complex systems requiring integration with other devices or remote monitoring, ensure the PLC supports advanced networking options.

Expandability and FlexibilityEvaluate whether you need the ability to expand your system in the future. Modular PLCs offer expansion options, allowing you to add additional I/O modules, communication interfaces, or processing units as your needs evolve.

Fixed PLCs: Ideal for applications with stable, unchanging requirements.

Modular PLCs: Suitable for applications where future expansion or flexibility is anticipated.

Programming and SoftwareThe ease of programming and the software available for the PLC are crucial factors. Ensure the PLC comes with user-friendly programming tools and software that match your expertise and programming needs.

Basic Programming Tools: Suitable for simple tasks with straightforward programming requirements.

Advanced Software: For complex applications, ensure the PLC supports advanced programming features and software.

Reliability and SupportChoose a PLC from a reputable manufacturer known for reliability and strong customer support. Reliable PLCs minimize downtime and maintenance issues, while excellent support ensures you have access to assistance when needed.

Reliable Manufacturers: Look for PLCs from established manufacturers with a track record of reliability.

Support Services: Ensure the manufacturer offers comprehensive support services, including technical assistance and documentation.

Balaji Switchgears: Your Partner in PLC Selection

At Balaji Switchgears, we specialize in providing top-quality PLCs and industrial automation solutions. Our team of experts can assist you in selecting the right PLC based on your specific needs and application requirements.

Expert Guidance: Our experienced professionals offer personalized advice to help you choose the most suitable PLC for your automation needs.

Comprehensive Range: We provide a wide range of PLCs with varying capabilities to match different applications.

Ongoing Support: We offer continuous support and maintenance services to ensure your PLC operates efficiently throughout its lifecycle.

Conclusion

Choosing the right PLC for your industrial automation needs is a critical decision that impacts the efficiency and reliability of your control systems. By considering factors such as application requirements, processing power, I/O capabilities, communication options, and expandability, you can make an informed choice. Balaji Switchgears is here to guide you through the selection process and provide the support you need for a successful automation project. Contact us today to learn more about our PLC solutions and how we can assist in optimizing your industrial processes.

Originally Published at:

0 notes

Link

Module PoE Ethernet Modbus TCP 6 kênh DI+6 kênh đầu ra Relay ICP DAS PET-7060 CR

0 notes

Text

Ajitek Tech Solutions Pvt Ltd

0 notes

Text

6ED1052-1MD08-0BA2 – Logo Siemens 12/24RCE

Mã sản phẩm: 6ED1052-1MD08-0BA2

Thông số kỹ thuật: LOGO! 12/24RCE, logic module, display power supply / I/O: 12/ 24 V DC/relay, 8 DI (4 AI)/4 DO, memory 400 blocks, modularly expandable, Ethernet, integrated web server, data log, user-defined web pages, standard microSD card for LOGO! Soft Comfort V8.4 or higher, older projects executable cloud connection, MQTT in all LOGO! 8.4 basic units

👉 Xem thêm tại: https://thanhthienphu.vn/6ed1052-1md08-0ba2/

#đạilýsiemens#thanhthienphu#thanh_thien_phu#dai_ly_siemens_viet_nam#thiếtbịđiênsiemens#thietbidiensiemens#đạilýsiemenstạiviệtnam#thanhthiênphú#dailysiemens

0 notes

Text

LoRa GSM RJ45 System Connect Multiple Wireless Node Greenhouse Planting

LoRa gateway S281 uses LoRa RF communication technology to transmit equipment data from multiple points in a discrete distribution to the gateway through wireless LoRa nodes, and the LoRa gateway processes the data and transmits it to the server through Ethernet or 4G network, thus realizing remote data acquisition and monitoring. LoRa gateway supports a variety of wireless LoRa nodes, including temperature&humidity, weather, soil, gas, RS485 to wireless module nodes. Support access to the cloud, can realize history record query, high and low temperature over limit abnormal alarm, support voice, WeChat, SMS, APP, WEB monitoring platform, email and other ways to alarm. Widely used in heating, greenhouse planting, breeding, workshop, warehouse, fresh, flow, liquid level, mine and other industries.

Support 50 wireless temperature&humidity, relay, digital input, soil, weather and other types nodes;

Support 50 RS485 serial wireless module nodes;

Monitoring radius up to 2KM;

Support 10 user numbers for receiving specific SMS alarm messages for device daily reports, dropouts, serial data overruns, and abnormal triggers;

Real-time monitoring of terminal battery power to ensure that device data is not dropped;

Using local configuration software, remote SMS and APP to set parameters, easy to operate and use.

0 notes

Text

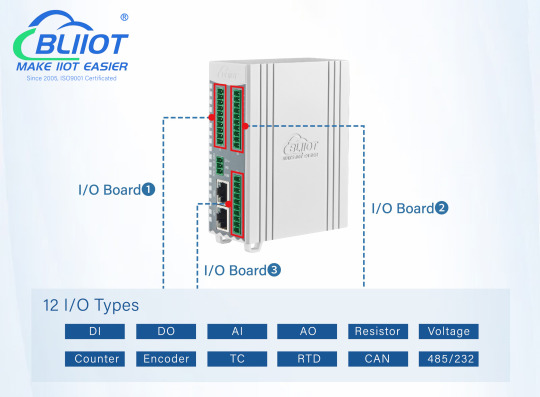

BLIIoT BACnet Ethernet IO Module BA190 for Building Automation

BACnet protocol I/O board 1~3 I/O boards are available, including DIN/DO/relay/AIN/AO/RTD/TC/RS485/RS232, etc. Over 1000 models can be combined to better meet the needs of on-site IO acquisition and save costs

#smartbuilidng hashtag#bms hashtag#bas hashtag#datacollection hashtag#remotemonitoring hashtag#remotecontrol

0 notes

Text

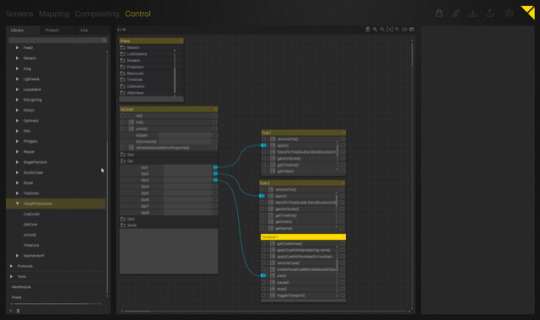

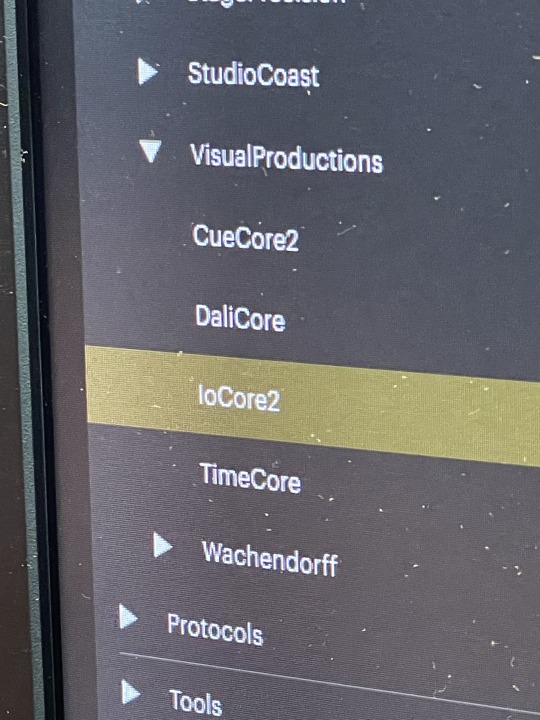

Pixera Media Server solutions & Visual Productions

The Pixera Media Server system is a compact yet extremely powerful media server range with many flexible options, including Visual Productions integration!

With Pixera, usability is key. The real-time media processing, compositing and management solution exists of high performance server hardware and innovative software applications. Pixera playout solutions are being used in museums, interactive installations, immersive experiences, theme parks, houses of worship and in many other markets across the globe.

A dedicated module within the PIXERA control interface allows for easy access to the compact IoCore2 unit‘s inputs and outputs. The IoCore2 is a network-based solid-state interface for GPIO signals. It features eight GPI ports that can be configured as digital contact-closures or analog 0-10V level inputs. The IoCore2 also has eight GPO ports that are fitted with potential free relay switches. Furthermore, it has a RS-232 port, a bi-directional DMX-512 port and supports many Ethernet based protocols.

When including an IoCore2 in your system, you instantly add interactivity to your immersive environment. Think of changing video content when crossing a photo electric beam, pushing a button changes screen or information, and much more.

When using CueCore2 with Pixera, you can even add automated lighting control, whether it be simple white lights or advanced RGBW lights which will enhance the atmosphere with subtle colour changes.

A DALI controlled lighting system? Include control of groups or intensity with DaliCore, integrated in Pixera Control IO.

Synchronising video content with audio? Converting timecode? Pixera can control and sync up audio- and video content across multiple screens when integrated with Visual Productions' TimeCore: compatible with all major timecode formats and all major frame rates.

0 notes

Text

Pilz 773730 PNOZ Mc8p

Pilz 773730 PNOZ Mc8p. Configurable safety system PNOZmulti expansion module Communication interface Ethernet/IP, Modbus TCP. Brand: PilzCategories: Relay moduleProduct ID: 773730Pilz 773730 PNOZ Mc8p

View On WordPress

0 notes