#Effective Inventory Control Methods For Supply Chain Management

Explore tagged Tumblr posts

Text

Enhancing Manufacturing Excellence: 6 Key Benefits of SAP Business One

Staying ahead of the competition requires more than just producing high-quality products. It demands efficient operations, streamlined supply chains, and real-time decision-making capabilities. This is where SAP Business One, a robust Enterprise Resource Planning (ERP) solution, steps in to transform the manufacturing sector. In this blog, we will explore six significant benefits that SAP Business One brings to manufacturers of all sizes, from small businesses to mid-sized enterprises.

Better Visibility

One of the primary challenges in manufacturing is maintaining visibility into the complex web of supply chains, operations, and inventory resources. SAP manufacturing software addresses this challenge by providing enhanced visibility through seamless integration with shipping logistics and supply chains. This integration empowers manufacturers with real-time data, enabling them to make well-informed decisions promptly.

Furthermore, the platform offers customized and interactive dashboards that offer a 360-degree view of the entire manufacturing process. This flexibility in analysis and insights allows manufacturers to adapt swiftly to changing customer demands and meet stringent deadlines.

Improved Productivity

SAP manufacturing software incorporates Material Requirements Planning (MRP) functionality, which replaces outdated production scheduling methods with a structured, multilevel production process. MRP also facilitates resource planning for machine maintenance, leading to overall productivity improvements.

Additionally, the MRP wizard streamlines material procurement and production planning, significantly reducing pre-production lead times. This efficiency boost directly contributes to enhanced productivity and better resource utilization.

Cost Control

Cost control is a paramount concern for manufacturing companies. SAP manufacturing software offers a solution by optimizing daily operations, reducing waste, and simplifying processes. Informed decision-making, enabled by SAP manufacturing software, aids in identifying cost-saving opportunities and increasing overall business profitability.

Working Capital Management

Managing working capital is essential for the day-to-day operations of manufacturing companies. SAP manufacturing software offers a comprehensive suite of modules and capabilities that help in managing working capital effectively. This includes overseeing accounts receivables, accounts payables, cash flow, liquidity, and inventory planning.

Customized purchasing reports provide real-time insights into working capital challenges, replacing the traditional year-end or month-end reports. This level of control from SAP services allows manufacturers to make proactive decisions, ensuring the stability of their operations.

Inventory Management

Effective inventory management is critical for manufacturing success. SAP Business One equips manufacturers with advanced warehouse tracking features and real-time stock reports. These features help document stock levels and monitor stock transfers between warehouses, ensuring a lean inventory management approach.

The ERP solution strikes an ideal balance between inventory stock and production capacities, facilitating on-time product deliveries, efficient inventory cost management, and meeting customer demands effectively.

Regulatory Compliance

Manufacturers must adhere to industry regulations at every stage of the manufacturing process, from procurement to final product delivery. SAP Business One plays a crucial role in improving regulatory compliance by integrating these standards into its operations seamlessly.

Furthermore, the platform empowers manufacturers to embed quality control into their manufacturing processes, providing insights into vendor performance and enhancing customer satisfaction.

Conclusion

SAP system emerges as a powerful ally, offering a wide array of benefits to manufacturers. From improved visibility and productivity to cost control, working capital management, inventory optimization, and regulatory compliance, this ERP solution empowers manufacturing companies to thrive in a competitive environment. By embracing SAP Business One, manufacturers can embark on a journey toward excellence, ensuring they meet customer demands efficiently and maintain a strong position in the market.

2 notes

·

View notes

Text

Customized Solutions: Tailoring Supply Chain Strategies to Industry Needs

Supply chain management has become a crucial determinant of a company's performance in the ever-changing commercial environment of today. With the increasing specialisation and diversity of industries, it is evident that the conventional one-size-fits-all approach to supply chain strategy has been ineffective. In recent times, there has been a notable increase in the significance of tailored solutions, as enterprises acknowledge the importance of adapting their supply chain strategies to align with the distinct requirements of their respective sectors. This blog article aims to explore the significance of tailored supply chain solutions and their role in enhancing operational efficiency, minimising expenses, and facilitating industry-specific expansion. Smarter solutions for stronger supply chains. Partner with VNC Global - for top-class Supply chain management consulting in Australia to drive growth!

Understanding the Need for Customization:

Each sector functions inside its own specific environment, which is defined by particular obstacles, rules, and market forces. Therefore, it can be argued that a standardised supply chain approach is insufficient in addressing the intricacies specific to each sector. Customised solutions consider these variables, providing a personalised approach that is in line with the specific requirements of the industry.

Optimizing Operations for Efficiency:

The possibility for operational optimisation is a fundamental advantage of customising supply chain strategies to align with industry requirements. The utilisation of generic methodologies frequently leads to operational inefficiencies, manifesting in the form of surplus inventories, delays in processes, and bottlenecks. In contrast, customised solutions optimise operational efficiency by matching processes with the specific demands of the industry.

Industries characterised by significant fluctuations in demand may derive advantages from using agile supply chain methods that provide swift adaptations in production and distribution processes. Conversely, industries characterised by consistent and predictable demand patterns should prioritise the implementation of lean supply chain methods as a means to mitigate inefficiencies and achieve cost reductions. By optimising the supply chain in this manner, organisations can improve operational efficiency and responsiveness.

Reducing Costs and Enhancing ROI:

The issue of cost containment continues to be a persistent worry for firms operating in various sectors. Customised supply chain solutions are of paramount importance in effectively addressing this challenge. Tailoring tactics to the specific needs of an industry leads to the minimization of wastage, more efficient allocation of resources, and optimisation of costs. Experience real-time visibility, control, and savings. Invest in the best Supply chain management software in Australia offered by VNC Global!

Industries characterised by rigorous compliance requirements might derive advantages from supply chain strategies that prioritise the principles of traceability and transparency. By incorporating technology such as blockchain, enterprises can effectively verify regulatory adherence while concurrently mitigating the potential financial repercussions associated with product recalls. This technique not only results in cost savings but also serves to protect the reputation of the brand.

Fostering Industry-Specific Growth:

Customised supply chain solutions encompass more than just enhancing operational efficiency; they also play a significant role in fostering growth within certain industries. Industries undergo a natural progression, characterised by the impact of technology breakthroughs, market dynamics, and consumer preferences. The use of supply chain strategies customised to these elements facilitates the ability of firms to maintain agility and adaptability.

Consider the pharmaceutical business as an illustrative case. The emergence of personalised medication and the requirement for temperature-sensitive distribution may render conventional supply chain models inadequate. The implementation of a tailored approach that integrates cold chain logistics and real-time tracking systems guarantees the secure and effective transportation of delicate pharmaceuticals. The ability to adapt enables firms to effectively capitalise on emerging opportunities and navigate industry shifts.

Strengthening Industry Collaboration:

The implementation of tailored supply chain solutions frequently necessitates industry-wide collaboration and strategic collaborations. The act of exchanging best practices, insights, and resources is of utmost importance in order to collectively enhance operational efficiency. The cooperative efforts between entities not only yield advantages for individual enterprises but also contribute to the overall enhancement of the industry.

businesses characterised by intricate regulatory obligations have the potential to engage in collaborative efforts aimed at addressing compliance challenges. By pooling their resources, these businesses can collectively work towards the development of innovative technologies that facilitate the process of adhering to regulatory standards. Collaborative endeavours not only alleviate operational difficulties but also cultivate a sense of brotherhood among participants within the sector.

Final Thoughts:

In the contemporary landscape characterised by a wide range of industries and their corresponding complexities, the adoption of customization has emerged as a crucial strategy in the realm of supply chain management. Customising tactics to cater to the unique requirements of the sector allows organisations to enhance operational efficiency, minimise expenditures, and facilitate industry-specific expansion.

In a contemporary context where the ability to adapt and be agile is of utmost importance for achieving success, the adoption of tailored supply chain solutions is not only a choice but rather a strategic need. In the context of ongoing industrial development, enterprises that place emphasis on customised supply chain strategies establish themselves as frontrunners, equipped to effectively address the distinctive requirements of their specific environments. Supply chain excellence made attainable. Connect with VNC Global for tailored Supply chain management consulting in Australia!

#Supply chain management consulting in Australia#Supply chain management software in Australia#vncglobal

2 notes

·

View notes

Text

Road Freight Transportation: Your Complete Guide to Moving Goods Efficiently

Road freight transportation remains the backbone of global commerce, moving billions of tons of goods across countries every day. Whether you're a small business owner or managing a large corporation, understanding road freight services can help you make smarter logistics decisions and reduce shipping costs.

What is Road Freight and Why Does It Matter?

Road freight refers to the transportation of goods using trucks, lorries, and other commercial vehicles on highways and roads. This method handles approximately 70% of all cargo movement worldwide, making it the most popular choice for businesses of all sizes.

Unlike air or sea freight, road transportation offers unmatched flexibility and door-to-door delivery capabilities. You can ship everything from electronics to perishable goods, reaching even the most remote locations that other transport modes cannot access.

Key Uses of Road Freight Services

E-commerce Deliveries: With online shopping booming, road freight handles last-mile delivery for millions of packages daily. From Amazon orders to local grocery deliveries, trucks make it possible.

Manufacturing Supply Chains: Factories rely on road freight to receive raw materials and ship finished products. The automotive industry, for instance, uses specialized trucks to transport car parts between facilities.

Retail Distribution: Supermarkets, department stores, and retail chains depend on road freight to stock their shelves with fresh inventory from distribution centers.

Construction Materials: Heavy machinery, building supplies, and construction equipment are typically moved via road freight due to their size and weight requirements.

Types of Road Freight Services

Full Truck Load (FTL): When you have enough cargo to fill an entire truck, FTL offers cost-effective shipping with faster delivery times. Perfect for large businesses with bulk shipments.

Less Than Truck Load (LTL): Ideal for smaller shipments, LTL allows multiple customers to share truck space, reducing costs for everyone involved.

Express Delivery: Time-sensitive shipments benefit from express road freight services, ensuring same-day or next-day delivery within specific regions.

Temperature-Controlled Transport: Refrigerated trucks maintain specific temperatures for perishable goods like food, pharmaceuticals, and chemicals.

Specialized Freight: Oversized cargo, hazardous materials, and fragile items require specialized vehicles and handling procedures.

Common Challenges in Road Freight

Traffic Congestion: Urban areas and busy highways can cause significant delays, affecting delivery schedules and increasing fuel costs.

Fuel Price Fluctuations: Rising diesel prices directly impact shipping costs, forcing companies to adjust their pricing strategies regularly.

Driver Shortages: The trucking industry faces a growing shortage of qualified drivers, leading to capacity constraints and higher rates.

Environmental Regulations: Stricter emission standards require fleet upgrades, increasing operational costs for freight companies.

Infrastructure Limitations: Poor road conditions, weight restrictions, and bridge limitations can restrict routing options and increase maintenance costs.

Technology Integration: Many freight companies struggle to implement modern tracking systems and digital logistics platforms.

Benefits of Professional Road Freight Services

Working with experienced freight providers offers numerous advantages. Professional carriers provide real-time tracking, insurance coverage, and specialized handling for different cargo types. They also maintain regulatory compliance and have established networks for efficient routing.

Reliable freight partners help businesses reduce shipping costs through optimized routes and consolidated shipments. They also provide valuable expertise in packaging, documentation, and customs procedures for cross-border shipments.

The Future of Road Freight

The industry is rapidly evolving with electric trucks, autonomous vehicles, and smart logistics platforms. These innovations promise to address current challenges while improving efficiency and reducing environmental impact.

Digital freight platforms are making it easier for shippers to compare rates, track shipments, and manage their logistics operations from a single dashboard.

Choose the Right Freight Partner

Selecting the right road freight service provider is crucial for your business success. Look for companies with proven track records, comprehensive insurance coverage, and modern fleet management systems.

At www.arrkay.com, we understand the complexities of modern logistics and provide tailored road freight solutions for businesses across all industries. Our experienced team ensures your cargo reaches its destination safely, on time, and within budget. Contact us today to discuss your freight transportation needs and discover how we can optimize your supply chain operations.

0 notes

Text

Streamline Your ERP Plastic Manufacturing: The Otibro Techni Advantage

The plastic manufacturing industry is a dynamic landscape, constantly evolving with new materials, technologies, and customer demands. From injection molding to extrusion and blow molding, managing complex processes, intricate bills of material, and volatile raw material prices can be a Herculean task. Without a robust system, companies often grapple with inefficiencies, costly errors, and missed opportunities.

This is where a purpose-built ERP system becomes an absolute game-changer. And when it comes to tailoring ERP solutions specifically for the plastic industry, Otibro Techni stands out as a leading partner, understanding the nuanced challenges and delivering transformative results.

The Mold of Manual Management: Why Traditional Methods Fall Short

Many plastic manufacturers still rely on a patchwork of spreadsheets, isolated software, and manual processes. This often leads to:

Inaccurate Inventory: Difficulty tracking raw materials, work-in-progress, and finished goods leads to stockouts, overstocking, and wasted capital.

Production Bottlenecks: Inefficient scheduling, lack of real-time visibility into machine availability, and poor capacity planning cripple output.

Quality Control Challenges: Manual quality checks are prone to error, making it hard to maintain consistent product standards and ensure traceability.

Cost Overruns: Poor visibility into production costs, regrind management, and material consumption can erode profit margins.

Compliance Headaches: Meeting stringent industry regulations and maintaining audit trails becomes a daunting task.

Slow Decision-Making: Lack of centralized, real-time data means managers are often making decisions based on outdated information.

Forging a Future with ERP: The Otibro Techni Advantage

An ERP system designed for plastic manufacturing acts as a central nervous system, integrating every aspect of your operations into a single, cohesive platform. Here's how it transforms your business:

1. Precision Production Planning & Scheduling:

ERP systems enable precise scheduling of machines, molds, and labor. They account for multi-cavity tooling, family molds, and complex production sequences, ensuring optimal utilization of resources and minimizing downtime. This leads to significantly improved on-time delivery.

2. Intelligent Inventory Management:

Track raw materials (resins, additives, colorants), work-in-progress, and finished goods in real-time. Features like batch tracking, lot tracking, and FIFO/FEFO ensure optimal stock levels, reduce waste, and manage shelf-life-sensitive materials.

3. Robust Quality Control & Traceability:

From incoming raw material inspection to in-process checks and final product testing, ERP ensures consistent quality. It provides end-to-end traceability, allowing you to track every component from supplier to the finished product, crucial for compliance and swift issue resolution.

4. Optimized Cost Management:

Gain granular insights into your production costs, including raw materials, labor, machine usage, and overheads. Manage regrind effectively, identify cost-saving opportunities, and ensure accurate job costing and profitability analysis.

5. Streamlined Supply Chain & Procurement:

Automate purchase orders, manage supplier relationships, and gain real-time visibility into inbound shipments. This strengthens supplier collaboration and ensures timely availability of critical materials.

6. Real-time Reporting & Analytics:

Access comprehensive dashboards and generate real-time reports on key performance indicators (KPIs) like OEE (Overall Equipment Effectiveness), production output, waste percentages, and financial performance. This empowers informed decision-making.

Otibro Techni specializes in implementing ERP solutions that are not just generic software, but deeply tailored to the unique workflows of plastic manufacturing, whether you're dealing with intricate injection molded components, continuous extruded profiles, or large blow molded containers. Their expertise ensures that the system aligns perfectly with your specific operational needs, from managing multi-level BOMs to handling tooling controls.

Your Future is Molded by Smart Choices

In the competitive world of plastic manufacturing, embracing digital transformation through a specialized ERP system is no longer an option, but a necessity. It’s about more than just efficiency; it’s about agility, resilience, and sustained growth. By partnering with experts like Otibro Techni, you can streamline your operations, minimize waste, elevate product quality, and ultimately, enhance your profitability.

Ready to unlock the full potential of your plastic manufacturing business? Connect with Otibro Techni today for a personalized demo of their industry-specific ERP solution and discover how you can achieve operational excellence.

0 notes

Text

The supply chain, a crucial component of any business dealing with physical goods, encompasses everything from raw material procurement to final product delivery. As global networks become more complex, the traditional methods of managing logistics and demand forecasting often struggle to keep pace. Artificial Intelligence (AI) emerges as a transformative solution, poised to revolutionize supply chain management by providing unprecedented levels of insight, efficiency, and adaptability. In this blog post, we'll delve into best practices and insights for optimizing supply chain efficiency with AI, drawing from real-world examples and industry expertise. The AI Advantage in Supply Chain Management AI’s role in supply chain management goes beyond mere automation. It brings a suite of capabilities that enable more informed decision-making and greater operational efficiency. These capabilities include: Predictive analytics. AI algorithms analyze historical data to forecast future demand, helping businesses avoid overstocking or stockouts. Real-time monitoring. AI-powered systems track shipments and inventory in real-time, providing instant alerts about potential disruptions. Optimization. AI can optimize routes, schedules, and resource allocation, minimizing costs and improving delivery times. Quality control. AI systems can detect defects or inconsistencies in products, ensuring higher quality and reducing returns. Risk management. AI assesses risks by analyzing data from various sources, helping businesses anticipate and mitigate potential supply chain disruptions. Best Practices for Implementing AI in the Supply Chain Implementing AI in the supply chain can lead to significant value, such as reduced costs, enhanced efficiency, and improved customer satisfaction. However, to maximize these benefits, businesses need to follow best practices that ensure seamless integration and optimal performance. Here are key strategies to help you effectively harness the power of AI in your supply chain operations. #1. Start with a Clear Strategy Before diving into the implementation of Al in logistics, it’s essential to have a clear strategy that aligns with your business goals. Identify the specific areas of the supply chain where AI can add the most value. Whether it's demand forecasting, inventory management, or logistics optimization, having a focused approach will ensure better outcomes. #2. Invest in Quality Data AI’s effectiveness depends on the quality of data it processes. Invest in robust data collection and management systems. Clean, accurate, and comprehensive data will lead to more reliable AI-driven insights and predictions. #3. Integrate AI with Existing Systems AI should complement, not replace, existing supply chain management systems. Ensure seamless integration by choosing AI solutions that are compatible with your current infrastructure. This will enable a smoother transition and maximize the benefits of AI without disrupting ongoing operations. #4. Focus on Employee Training The successful adoption of AI requires a workforce that is knowledgeable about its capabilities and limitations. Provide training programs to help employees understand how to work with AI tools effectively. This will foster a collaborative environment where human intelligence and AI work hand-in-hand. #5. Monitor and Adjust AI implementation is not a one-time task. Continuously monitor the performance of AI systems and make necessary adjustments. Regular evaluation will help identify areas for improvement and ensure that the AI continues to deliver optimal results. Insights from Industry Leaders To illustrate the transformative power of AI in supply chain management, let’s look at some real-world examples. Amazon Known for its cutting-edge logistics, Amazon uses AI to optimize its supply chain operations. AI algorithms predict product demand, manage inventory levels, and optimize delivery routes.

This not only improves efficiency but also enhances customer satisfaction by ensuring timely deliveries. Walmart Walmart leverages AI to streamline its supply chain processes. AI-driven predictive analytics help Walmart anticipate demand and manage inventory more effectively. Additionally, AI-powered robots in warehouses assist with sorting and packing, reducing manual labor and speeding up operations. Procter & Gamble P&G uses AI to monitor and manage its global supply chain. AI systems analyze data from various sources to identify potential disruptions and suggest corrective actions. This proactive approach helps P&G maintain a resilient and efficient supply chain. A Closer Look at AI Tools and Technologies Several AI tools and technologies have proven effective in optimizing supply chain efficiency: Machine learning. Machine learning algorithms analyze historical data to identify patterns and make accurate predictions about future demand and supply chain performance. Natural Language Processing (NLP). NLP helps in processing and analyzing large volumes of unstructured data, such as customer reviews and feedback, to gain insights into product quality and customer preferences. Robotic Process Automation (RPA). RPA automates repetitive tasks, such as data entry and order processing, freeing up human resources for more strategic activities. Computer vision. Computer vision technology inspects products for defects and ensures quality control in manufacturing and logistics processes. Blockchain. While not AI per se, blockchain technology complements AI by providing a secure and transparent ledger for tracking products throughout the supply chain, enhancing traceability and trust. Overcoming Challenges in AI Adoption Despite the numerous benefits, adopting AI in the supply chain comes with its challenges. Data privacy and security. Protecting sensitive data is crucial. Implement robust cybersecurity measures to safeguard data against breaches and ensure compliance with regulations. Change management. Introducing AI requires a cultural shift within the organization. Addressing resistance to change through clear communication and demonstrating AI’s value can facilitate smoother adoption. Cost and ROI. The initial investment in AI can be substantial. However, focusing on long-term benefits and ROI can justify the expenditure. Start with pilot projects to demonstrate value before scaling up. Skill gaps. The successful deployment of AI requires a blend of technical and domain-specific expertise. Bridging skill gaps through training and hiring experts can ensure successful implementation. The Future of AI in Supply Chain Management The future of AI in supply chain management looks promising, with ongoing advancements poised to bring even greater efficiencies and capabilities. Here are some trends to watch: AI and IoT integration. The Internet of Things (IoT) combined with AI will enable real-time monitoring and automation of supply chain processes, leading to even greater efficiencies. Autonomous vehicles. AI-powered autonomous vehicles, including drones and self-driving trucks, will revolutionize logistics and last-mile delivery, reducing costs and improving delivery times. AI-driven sustainability. AI can help businesses achieve sustainability goals by optimizing resource use, reducing waste, and improving energy efficiency throughout the supply chain. Advanced predictive analytics. Future AI systems will offer even more precise predictive analytics, enabling businesses to anticipate and respond to market changes with greater accuracy. Final Thoughts Optimizing supply chain efficiency with AI is not just a possibility; it is becoming a necessity in the competitive business landscape. By leveraging AI’s predictive analytics, real-time monitoring, optimization capabilities, and risk management, businesses can transform their supply chains into agile, efficient, and resilient operations.

However, successful AI implementation requires a clear strategy, quality data, seamless integration with existing systems, employee training, and continuous monitoring. Overcoming challenges such as data privacy, change management, cost, and skill gaps is crucial for reaping the full benefits of AI. As AI technology continues to evolve, its potential to enhance supply chain management will only grow. Embracing AI today will position businesses for success in the ever-changing global market.

0 notes

Text

Easy Ways to Manage Quick Business Growth

Introduction

Experiencing fast growth in your business is an exciting milestone. It’s a clear sign that your products or services are resonating with customers. However, if not managed properly, rapid expansion can lead to operational chaos, overwhelmed employees, poor customer service, and financial instability. For small and medium enterprises (SMEs), navigating this period effectively is critical to sustaining long-term success.

That’s where Grow With Consultants steps in. Our growth management experts help small businesses scale smartly, without compromising quality or control.

👉 Don’t miss out on this opportunity! Act now and schedule your consultation today by calling +91 98211 17726, emailing [email protected],

Why Managing Rapid Growth Matters

Rapid growth might look like a dream come true — and often it is. But fast expansion can expose weak systems and limited resources, which may hurt your brand reputation or bottom line. Here’s why managing growth is vital:

Maintains customer satisfaction and service quality

Keeps employee morale and productivity high

Ensures financial stability and sustainability

Prevents internal burnout and system overload

Protects brand reputation during periods of change

Warning Signs of Uncontrolled Growth

Before diving into solutions, it’s important to recognize the red flags of uncontrolled growth:

Missing deadlines or deliveries

Frequent customer complaints

Employees working overtime or resigning

Difficulty in managing cash flow

Inadequate inventory or supply chain issues

Lack of visibility into daily operations

Easy Ways to Manage Quick Business Growth

1. Prioritize Scalable Systems Early

One of the first mistakes businesses make during rapid growth is sticking to outdated systems. Whether it's using spreadsheets to manage inventory or handling payroll manually, these methods can’t support a growing company.

Solution: Invest in scalable software solutions like ERP systems, cloud accounting platforms, CRM tools, and automated HR systems. These allow your business to manage increased demand without overloading your team.

2. Document and Optimize Processes

When business accelerates, inconsistency in operations becomes a big risk. Formalizing and optimizing your standard operating procedures (SOPs) ensures that every team member knows what’s expected, reducing errors and inefficiencies.

Steps to follow:

Map out all critical business processes

Identify bottlenecks and remove redundancies

Create clear SOP documentation and train staff accordingly

3. Hire Strategically and Early

If your team is stretched thin during peak growth, it’s time to bring in fresh talent — but strategically. Hiring out of desperation often leads to poor performance and bad culture fits.

Pro Tip: Build a recruitment pipeline before you desperately need people. Focus on hiring for key roles first — operations, finance, customer service, and sales — that can carry the weight of new demand.

4. Stay Customer-Centric

While you’re growing, your customers are watching. If product quality dips or delivery timelines stretch, they’ll look elsewhere. Retaining customers during expansion is just as important as acquiring new ones.

Ways to maintain customer satisfaction:

Proactively communicate delays or changes

Offer loyalty incentives to existing customers

Ensure customer support is well-staffed and trained

5. Focus on Financial Forecasting

During quick growth, it’s easy to misjudge how much cash you’ll need for expansion. Hiring, inventory, rent, and marketing all demand capital — sometimes more than you expect.

Recommendation: Create 6-month, 12-month, and 24-month financial forecasts. Update them regularly based on real-time data and adjust your expenses accordingly.

6. Strengthen Your Leadership Team

You can’t do it all alone. As a founder or CEO, you need a solid leadership team to delegate decisions, manage departments, and support your vision.

Key roles to consider:

Operations Manager

Finance Manager or Virtual CFO

Marketing Lead

HR Manager

If full-time roles aren’t affordable yet, outsource to growth management consultants like us who bring domain-specific knowledge without long-term contracts.

7. Maintain a Healthy Company Culture

As new people join and departments expand, your company culture can easily be diluted or lost. A toxic or chaotic culture can destroy productivity and drive away good employees.

Cultural best practices:

Share your vision and values often

Celebrate wins and recognize team efforts

Build strong internal communication channels

Maintain transparency during transitions

8. Revisit Your Business Model

Rapid growth might mean your original business model needs tweaking. Are you spending too much on low-margin services? Are you attracting the right customer segments?

Evaluate:

Which products or services are most profitable

What markets are responding well to your offerings

Whether pricing strategies need to evolve

If your distribution methods are scalable

9. Automate Where Possible

Repetitive tasks slow your team down. Automation helps reduce manual work, speed up processes, and free up time for strategic initiatives.

Automation examples:

Email marketing campaigns

Invoicing and payroll

Inventory alerts and reorders

CRM follow-ups and sales funnel actions

10. Engage a Growth Consultant

If you’re unsure about the next step, hiring a growth management consultant can offer massive benefits. From strategic planning and financial modeling to hiring strategies and systems implementation — they help small businesses grow without growing pains.

Why choose Grow With Consultants?

Proven track record with SMEs across India

End-to-end planning and execution support

Transparent, flexible engagement models

Industry-specific expertise across verticals

📞 Book a consultation now at +91 98211 17726

Real-World Example

Company: Digital Tech Services, Mumbai

Scenario: The company grew from 6 to 40 employees in 10 months and struggled with client deadlines, HR challenges, and budgeting errors.

What We Did:

Set up a project management system

Created a performance review framework

Streamlined payroll and billing

Improved forecasting with monthly financial models

Results:

Reduced delivery delays by 40%

Increased employee retention to 91%

Boosted profit margins by 23% in one year

Pitfalls to Avoid During Rapid Growth

Neglecting customer feedback

Micromanaging instead of delegating

Over-hiring without role clarity

Scaling before building the foundation

Ignoring cash flow and real-time financial data

The Role of Technology in Managing Growth

Technology isn’t just a support tool — it’s a growth enabler. From CRM platforms to AI-based analytics, the right tech stack can revolutionize how quickly and efficiently you scale.

Must-have tools:

Slack or Microsoft Teams for internal communication

QuickBooks or Zoho Books for financial management

HubSpot or Zoho CRM for customer relationships

Trello or Asana for project tracking

Google Analytics for digital performance

Tips for Long-Term Success

Always align growth initiatives with your vision and mission

Empower team members with training and tools

Constantly evaluate what's working and pivot when needed

Keep your end customers at the center of all decisions

Never compromise on quality for speed

Final Thoughts

Quick growth is an achievement — but sustaining that growth requires careful management. With the right mix of strategy, technology, and expert guidance, your business can turn a growth spike into a scalable success story.

Whether you're expanding your team, entering new markets, or upgrading your systems, Grow With Consultants is here to help.

Take the Next Step

Don’t let uncontrolled growth overwhelm you. Let’s design your expansion journey — strategically, sustainably, and successfully.

📞 Call Now: +91 98211 17726 📧 Email: [email protected] 🌐 Visit: www.growwithconsultants.com

Don’t miss out on this opportunity! Act now and schedule your consultation today.

#Grow With Consultants#Consultants#business consultants#business growth consultant#business growth strategies#business growth#business#Small Business Consultants

0 notes

Text

Revolutionizing Fuel Management with Petroleum Industry Software by EZTRAK

In today’s fast-paced energy sector, businesses in the petroleum industry are constantly seeking ways to enhance operational efficiency, reduce errors, and maximize profitability. As one of the most regulated and logistically complex industries, petroleum companies require reliable tools to streamline everything from fuel inventory management to distribution logistics. Enter EZTRAK Software — a game-changing solution tailored specifically to meet the unique challenges of the petroleum industry.

EZTRAK is a leading petroleum industry software provider in the USA, offering comprehensive tools that help fuel suppliers, distributors, and storage facility operators run smarter, safer, and more cost-effective operations.

Why Petroleum Companies Need Advanced Software Solutions

Fuel distribution and inventory management are highly sensitive operations. A single error can lead to massive financial losses, safety hazards, or non-compliance with environmental regulations. Traditional methods involving manual logs or outdated systems simply can’t keep up with the demands of the modern fuel economy.

That’s why industry leaders are turning to specialized petroleum industry software like EZTRAK to improve accuracy, ensure compliance, and gain real-time visibility into operations.

Key Features of EZTRAK Petroleum Industry Software

EZTRAK has designed its platform with the specific needs of petroleum businesses in mind. Its robust features bring unmatched control and insight to every stage of the fuel supply chain:

1. Real-Time Data Analytics

With EZTRAK’s real-time data monitoring, users gain instant access to insights on fuel usage, inventory levels, deliveries, and more. This enables proactive decision-making and reduces costly downtimes or stockouts.

2. Fuel Tank Monitoring

Accurate and continuous fuel tank monitoring ensures that levels are always optimized. Whether you operate a fleet fueling station or bulk storage facility, EZTRAK alerts you to anomalies such as leaks, low levels, or overfills.

3. Automated Reporting and Compliance

Regulatory compliance is critical in the petroleum industry. EZTRAK automates the generation of environmental, tax, and operational reports—minimizing human error and ensuring timely submissions.

4. Inventory Tracking and Forecasting

Stay ahead with advanced inventory tracking and demand forecasting tools. Know when to order more fuel, where to allocate resources, and how to balance inventory across multiple locations.

5. Seamless Integration

EZTRAK Software integrates effortlessly with existing accounting, ERP, and dispatch systems. This ensures a smooth transition and reduces the need for multiple disconnected platforms.

Benefits of Using EZTRAK for Your Petroleum Business

Choosing the right petroleum industry software can revolutionize your operations. Here’s how EZTRAK delivers value:

Increased Accuracy: Reduce manual errors with automated monitoring and reporting.

Operational Efficiency: Optimize fuel distribution and asset management from a centralized dashboard.

Cost Savings: Avoid fuel losses, prevent overstocking, and cut administrative overheads.

Compliance Confidence: Ensure you meet all local and federal regulations with automated documentation and alerts.

Trusted Across the USA by Fuel Industry Professionals

EZTRAK Software is proudly made in the USA and trusted by petroleum companies nationwide. From independent distributors to large-scale fuel wholesalers, businesses are seeing tangible benefits from adopting EZTRAK’s innovative tools.

Whether you’re looking to modernize your operations, improve compliance, or gain better control over fuel management, EZTRAK’s petroleum industry software is the smart choice.

Ready to transform your petroleum business? Contact EZTRAK today to schedule a demo and see how our software can help you run a more efficient, compliant, and profitable operation.

0 notes

Text

Understanding Blood Collection and Storage: A Vital Step in Modern Healthcare By Clinfinite Solutions

In the world of modern medicine, blood is one of the most crucial components for saving lives. Whether it's for surgery, trauma care, or chronic illness treatment, having access to safe and properly stored blood is essential. At Clinfinite Solutions, we understand the significance of reliable blood collection storage practices, which play a critical role in ensuring patient safety and effective healthcare delivery.

What Is Blood Collection and Storage?

Blood collection is the process of drawing blood from a donor for transfusion or laboratory testing. This can be done through venipuncture, where a needle is inserted into a vein, or through specialized methods like apheresis, where specific blood components like plasma or platelets are separated and collected.

Once collected, blood must be properly labeled, processed, and stored in controlled environments. This process is known as blood collection storage, and it ensures the blood remains safe, sterile, and usable for medical procedures.

Importance of Proper Blood Collection Storage

The process of blood collection storage is not just about keeping blood cold; it involves a series of careful steps that maintain its quality and usability. Blood can spoil if not stored correctly, leading to waste and potentially dangerous situations in hospitals.

Proper storage:

Preserves the function of blood components (red cells, plasma, platelets).

Prevents bacterial growth and contamination.

Extends the shelf life of blood units.

Ensures timely availability during emergencies.

At Clinfinite Solutions, we follow international standards and use advanced technologies to ensure that the blood collected is stored under optimal conditions.

Storage Conditions for Different Blood Components

Blood is made up of several components, each of which requires specific storage conditions to maintain its effectiveness:

Red Blood Cells (RBCs) are stored at 1–6°C and can be kept for up to 42 days.

Plasma is frozen at -18°C or lower and can last up to one year.

Platelets need to be kept at 20–24°C with constant agitation and are viable for about 5–7 days.

Cryoprecipitate, derived from plasma, is also stored frozen at -18°C and lasts up to one year.

These strict storage requirements ensure that when blood is needed, it’s in the best possible condition to help a patient recover or survive.

The Role of Technology in Blood Collection Storage

Clinfinite Solutions utilizes cutting-edge refrigeration systems, temperature monitoring devices, and digital inventory systems to manage blood collection and storage efficiently. Our systems help track each unit of blood from the moment it is collected until it is transfused, maintaining full traceability and safety.

We also ensure:

Continuous temperature checks.

Automated alerts in case of storage failure.

Routine maintenance of storage units.

Adherence to global safety standards and regulations.

With technology, we reduce the risk of human error and improve the overall reliability of the blood supply chain.

Challenges in Blood Collection and Storage

Despite advances in technology, there are challenges in maintaining a stable blood supply:

Blood has a limited shelf life and must be used before expiry.

Storage units require constant electricity, which may not be reliable in some regions.

Proper training and quality control are necessary to prevent errors in labeling or storing.

At Clinfinite Solutions, we address these challenges through staff training, emergency backup systems, and regular audits to ensure best practices are followed every step of the way.

Conclusion

Blood collection storage is a backbone of emergency medicine and planned healthcare procedures. With rising medical needs, the demand for efficient and safe blood management systems is more important than ever. Clinfinite Solutions is proud to be at the forefront of this critical healthcare service, ensuring that every drop of blood collected is stored, preserved, and used with utmost care and precision.

#Blood sample storage guidelines#Types of blood collection#blood collection procedure step-by-step#Blood collection notes#Blood collection PDF#Principle of blood collection#How long can blood samples be stored at room temperature#Blood sample storage temperature

1 note

·

View note

Text

Digital Transformation & Industry 4.0: How AI is Reshaping Manufacturing

Manufacturing is undergoing a major change called Industry 4.0 — the fourth industrial revolution that combines AI, IoT, big data, and automation. Instead of isolated machines and manual tasks, factories are becoming connected systems that provide real-time insights and adapt to conditions quickly.

At the center of Industry 4.0 is AI-powered digital transformation, which is redefining how manufacturers operate and compete.

Why Are Manufacturers Adopting Industry 4.0 and AI?

Companies are turning to these technologies because

Increasing global competition requires faster, more efficient production

Customers demand better quality and quicker delivery

Supply chains are more complex and need constant monitoring

Workforce availability and costs create pressure to reduce manual work

Environmental regulations push for energy-efficient processes

Proactive maintenance reduces risk of unexpected equipment failure

Simply put: Keeping old methods means falling behind. Industry 4.0 tools allow manufacturers to run operations more effectively and with greater control.

How AI Supports Industry 4.0 on the Factory Floor

Here’s how AI is helping manufacturers improve key areas:

1. Predictive Maintenance — Preventing Unexpected Failures

AI uses sensor data and Condition-Based Monitoring (CBM) to forecast when machines might fail. Maintenance can then be planned in advance, avoiding costly breakdowns.

Results: Less downtime, lower repair expenses, longer machine life.

2. Quality Inspection Using Vision AI

AI-powered cameras inspect products rapidly to identify defects that humans might miss. This helps maintain consistent quality throughout production.

Results: Fewer defective products, improved customer satisfaction.

3. Improving OEE (Overall Equipment Effectiveness)

AI analyzes equipment and process data to find inefficiencies and causes of downtime, helping teams improve productivity.

Results: Better utilization of machines and clearer performance insights.

4. Inventory Management with AI Forecasting

AI predicts demand based on past sales and production trends to keep inventory levels balanced.

Results: Reduced inventory costs and prevention of production stoppages.

5. Monitoring Energy Usage

AI tracks energy consumption and highlights wasteful areas, supporting efforts to reduce expenses and meet sustainability targets.

Results: Lower energy costs and environmental impact.

6. Enhancing Worker Safety

AI systems monitor safety compliance and alert managers to unsafe conditions or behaviors immediately.

Results: Safer workplaces and fewer incidents.

Reasons Manufacturers Choose These Technologies

Increase operational flexibility to respond to market changes

Control costs by using resources more effectively

Maintain consistent product quality

Improve workplace safety and comply with regulations

Stay competitive in a changing market

Support environmental responsibility

Conclusion

Industry 4.0 and AI are essential for manufacturers aiming to improve performance and reduce risks. Companies relying on traditional methods face inefficiencies, quality issues, and lost opportunities.

Adopting AI-based solutions helps manufacturers run operations with better control, clearer insights, and more reliable outcomes.

0 notes

Text

Cloud-Based Warehouse Management System in India: Why It’s Industry’s Future

In today’s fast-paced world, where enterprises need to do things quicker and smarter than ever before, a warehouse management system is no longer a luxury—it is a necessity. Particularly in a rapidly growing nation like India, where retail, manufacturing, and e-commerce industries are booming, conventional methods of managing warehouse operations fall short. This is where an application of Cloud-Based Warehouse Management System (WMS) is used.

What is a cloud-based warehouse management system?

A cloud-based WMS is a computer program that allows businesses to track and manage warehouse activities such as tracking inventory, order picking, stock movement, and shipping—all in real time—over the internet. Instead of being on a single PC or local network, it’s installed on cloud servers, which means you can use it anywhere, anytime, from a laptop, tablet, or even a smartphone.

Why Indian Industries Need to Transition to Cloud-Based WMS?

1. India’s Growing Logistics and E-commerce Economy

India’s e-commerce industry is booming at a very fast rate, and with it the need for faster delivery and smart warehousing. With increasing numbers of businesses migrating to online sales and shipping pan-India, there is a demand for real-time visibility into inventory and warehouse operations.

2. Geographical Challenges

India is a huge nation with warehouses at times spread over some cities and states. It gets difficult to manage all of them with conventional systems. A cloud WMS gathers all your warehouses under one roof and simplifies multi-location management with affordability.

3. Affordability and Scalability

For most small and medium enterprises (SMBs), buying and hosting sophisticated hardware or local servers is not feasible economically. Cloud services are cheaper as you pay only for what you consume, and you do not have to bother about software updates and maintenance.

Benefits of Cloud-Based WMS

1. Real-Time Inventory Tracking

You always know what you have in inventory, don’t need anything more, and know the location of each item. This avoids stockouts and overstocks, which are costly and destroy customer confidence.

2. Remote Access and Control

You can access warehouse information and make on-the-go decisions no matter if you’re in Mumbai or having coffee in Goa. This convenience is highly beneficial for entrepreneurs and managers who frequently travel.

3. Enhanced Accuracy

Automation eliminates human mistakes. With barcode scanning, electronic pick sheets, and alerting systems, order fulfillment errors are reduced. That means happier customers and reduced backorders.

4. Faster Order Fulfillment Speed

Cloud WMS enables optimized configurations of the warehouse, efficient picking routes, and quick order processing. In an era where next-day delivery is the norm, speed is everything—and this system does not disappoint.

5. Cost Savings

Because everything is monitored and optimized, wastage declines. You don’t require as many employees to perform manual checks, and you can run operations with fewer mistakes. And because there’s no need for extensive IT infrastructure, the initial investment is low.

6. Easy Integration

The majority of cloud WMS software are capable of integration with other applications like ERP (Enterprise Resource Planning), accounting, and e-commerce platforms like Shopify, Flipkart, or Amazon. This establishes a seamless process from order entry to delivery.

7. Data Security and Backup

Your data is preserved on secure cloud servers with regular backups. Even if your local machine crashes or gets stolen, your warehouse data is secure and ready.

Conclusion

India is headed for a digital future, and warehouse and supply chain logistics need to catch up. A cloud-based Warehouse Management System is not only a trend—it’s becoming an imperative for businesses that want to stay competitive, get there quickly, and grow cost-effectively.

Whether you have a small trading business in Pune, a retail chain business in Delhi, or a manufacturing facility in Chennai, a cloud WMS can revolutionize how you operate your warehouse. It’s affordable, simple to operate, and made for the future. https://www.quickmovetech.com/cloud-based-warehouse-management-system-in-india-why-its-industrys-future/ https://x.com/QuickMove24 https://www.instagram.com/quickmovetechnologies/ https://www.youtube.com/@quickmovetechnologies

0 notes

Text

AI Applications in Coimbatore’s Manufacturing Sector

Coimbatore, often dubbed the "Manchester of South India," has long been a powerhouse of textile and engineering industries. With the rise of advanced technologies, the city is witnessing a new wave of innovation, one led by Artificial Intelligence (AI). In this blog post, we will explore how AI is revolutionizing the manufacturing sector in Coimbatore, improving productivity, reducing downtime, and driving smart decision-making across the board.

As companies increasingly integrate smart technologies, individuals aspiring to contribute to this industrial shift are enrolling in artificial intelligence programs to gain the skills needed to navigate and thrive in this evolving ecosystem.

The Rise of Smart Manufacturing in Coimbatore

The manufacturing sector in Coimbatore is undergoing a digital transformation. Traditional methods are being replaced by AI-powered systems that can analyze vast amounts of data in real time. These smart systems enable predictive maintenance, automate quality checks, and optimize production schedules all of which contribute to enhanced operational efficiency.

A growing number of professionals are recognizing the demand for AI expertise and opting for an best ai courses in coimbatore to stay competitive. In Coimbatore’s manufacturing units, AI algorithms are now used to forecast machinery failures and minimize unplanned downtimes, saving both time and money.

Predictive Maintenance for Industrial Equipment

Predictive maintenance is one of the most impactful applications of AI in manufacturing. By collecting data from IoT sensors embedded in machines, AI models can predict when a piece of equipment is likely to fail. This allows engineers to fix issues before they become critical, reducing both maintenance costs and production downtime.

In the dynamic industrial environment of Coimbatore, predictive maintenance is particularly valuable for sectors like textile manufacturing and precision engineering. These industries operate on tight schedules, and any disruption can be costly. Employees with hands-on training from an best ai & ml institute in coimbatore are better equipped to develop and implement these predictive models effectively.

Quality Control and Defect Detection

AI is playing a vital role in automating quality control processes. In traditional settings, visual inspection of products was labor-intensive and prone to human error. Today, machine vision systems powered by AI can identify defects with incredible precision and speed.

In Coimbatore’s foundries and textile mills, these systems are being used to detect irregularities in fabric patterns, surface imperfections, and dimensional deviations in metal parts. Implementing such advanced inspection techniques not only ensures high-quality output but also boosts customer satisfaction. Gaining expertise through an artificial intelligence can help professionals understand how to train and deploy these vision systems efficiently.

Artificial Intelligence Course Introduction

youtube

Supply Chain Optimization in Manufacturing

Efficient supply chain management is crucial for any manufacturing operation. AI helps optimize supply chain processes by forecasting demand, analyzing supplier performance, and managing inventory levels with accuracy. In Coimbatore, where industries often rely on complex supplier networks, AI tools are proving essential for maintaining lean and agile supply chains.

Manufacturers now use AI algorithms to predict the best times to reorder materials, avoid stockouts, and mitigate the impact of delays. With the knowledge from an artificial intelligence, professionals can design AI models that align supply and demand more effectively, reducing waste and enhancing profitability.

IOT(Internet of Things) Career Opportunities

youtube

Robotics and Automation in Assembly Lines

Coimbatore's manufacturing facilities are increasingly embracing robotics to streamline repetitive tasks and improve safety. AI-powered robots can perform intricate assembly operations with speed and consistency. These robots adapt to changes in product design and learn from their environment to become more efficient over time.

AI-driven automation is particularly beneficial for tasks that are dangerous, monotonous, or require high precision. For example, in the auto-component manufacturing sector, robotic arms handle delicate assembly operations that once required extensive manual labor. Employees trained through an artificial intelligence can contribute to designing and programming these intelligent robotic systems for optimal performance.

Real-Time Production Monitoring and Analytics

AI allows manufacturers to monitor production lines in real-time. By aggregating data from sensors and devices, AI systems provide dashboards that highlight performance indicators such as output rate, energy consumption, and machine efficiency. In Coimbatore, factories that integrate such AI systems are able to make data-driven decisions quickly.

This kind of real-time insight allows plant managers to adjust operations dynamically to meet production goals. Whether it's reallocating resources or identifying bottlenecks, AI offers the intelligence needed to act promptly. Understanding how to harness these technologies begins with an artificial intelligence that covers data science, machine learning, and industrial IoT concepts.

Sustainability and Energy Efficiency

With growing concerns about climate change and resource management, sustainability has become a key focus for manufacturers. AI helps monitor energy usage, optimize resource allocation, and minimize waste. In a city like Coimbatore, where industries must balance profitability with environmental responsibility, AI plays a crucial role in driving green manufacturing initiatives.

AI algorithms can identify patterns in energy consumption and suggest adjustments that reduce the carbon footprint. For instance, AI can automatically adjust HVAC systems or lighting based on factory occupancy. Those who complete an artificial intelligence can develop the skills needed to build these sustainability-focused models.

Customization and Smart Product Design

Manufacturers in Coimbatore are increasingly leveraging AI to create customized products. AI tools analyze customer data and preferences to design products that align with individual requirements. Whether it’s a customized textile print or a tailored industrial component, AI makes mass customization possible at scale.

This shift requires a deep understanding of AI algorithms, user behavior analytics, and data integration all of which are covered in a comprehensive artificial intelligence. As customers demand more personalized solutions, businesses with AI-capable teams will lead the way.

AI-Driven Decision Support Systems

Decision-making in manufacturing often involves complex trade-offs between cost, quality, and speed. AI-based decision support systems help manufacturers simulate scenarios, evaluate outcomes, and choose optimal strategies. These tools are becoming essential in Coimbatore’s competitive industrial landscape.

For example, AI can recommend whether to run a second shift, switch suppliers, or adjust pricing based on market demand. Engineers and managers with an artificial intelligence background can leverage these insights to align business operations with strategic goals.

The Road Ahead: Challenges and Opportunities

While AI offers numerous advantages, implementing it in Coimbatore's manufacturing sector isn't without challenges. Issues like data silos, lack of skilled professionals, and resistance to change can slow down AI adoption. However, these challenges also present opportunities for growth.

Companies that invest in workforce development especially by encouraging participation in an artificial intelligence can build internal AI capabilities and become industry leaders. By fostering a culture of innovation and continuous learning, Coimbatore’s manufacturing ecosystem can maintain its competitive edge.

Artificial Intelligence is no longer a futuristic concept; it’s a present-day necessity for modern manufacturing. In Coimbatore, AI is enhancing efficiency, quality, and competitiveness across various sectors. From predictive maintenance to smart customization, the applications are vast and growing.

As businesses continue to integrate AI into their operations, the demand for skilled professionals will rise. Enrolling in Datamites for artificial intelligence course is the first step toward contributing meaningfully to this transformation. With the right skills and mindset, professionals in Coimbatore can lead the AI revolution in manufacturing and shape the future of the city’s industrial success.

0 notes

Text

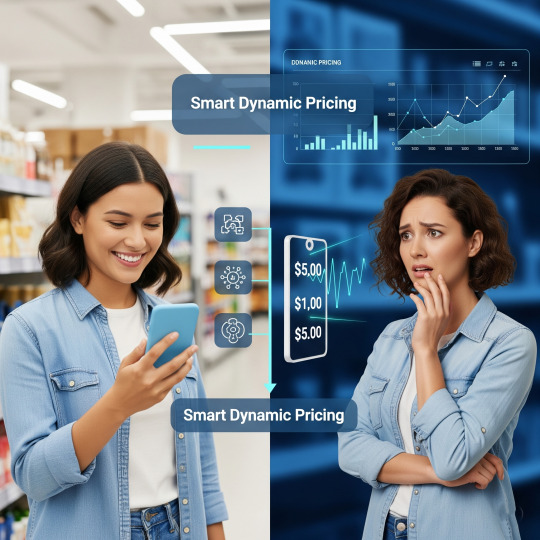

How Dynamic Pricing Impacts Customer Loyalty in Retail

In today’s highly competitive retail environment, pricing isn’t static — it’s dynamic. Retailers are increasingly adopting dynamic pricing strategies to respond to shifting market conditions, customer behavior, and competitor activity.

While this pricing model can drive revenue and operational efficiency, there’s a crucial question retailers must answer:

How does dynamic pricing affect customer loyalty?

Let’s explore the pros and cons of dynamic pricing, its potential impact on long-term customer relationships, and how retail data analytics solutions can ensure the right balance between profitability and trust.

🛒 What is Dynamic Pricing in Retail and How Does It Work?

Dynamic pricing refers to the practice of changing product prices in real time based on a variety of factors such as:

Customer browsing and purchasing behavior.

Market demand and product popularity.

Inventory levels and supply chain disruptions.

Competitor pricing trends.

Seasonal or time-based events (like flash sales).

Retailers use algorithms powered by AI and data analytics to determine the optimal price for each product at a given time. This strategy is commonly seen in e-commerce, travel, and hospitality, but it’s becoming increasingly prevalent in physical retail as well.

📈 Why Retailers Rely on Dynamic Pricing

Retailers adopt dynamic pricing for several compelling reasons:

Maximize profits during high-demand periods.

Clear inventory quickly by reducing prices on slower-moving products.

React to competitors’ pricing in real time.

Offer personalized pricing based on customer segments.

For example, during a festive sale or a product launch, prices might start low to generate buzz and increase once demand spikes. Alternatively, loyal customers may receive exclusive deals that don’t appear to new visitors.

⚠️ The Risk: Is Dynamic Pricing Bad for Customer Loyalty?

This is where things get tricky. While dynamic pricing benefits retailers operationally, it can erode customer trust if not managed carefully. Here are some potential pitfalls:

Perceived Unfairness Customers may feel exploited if they see the same item priced differently within hours or across users. This inconsistency can raise concerns about fairness.

Reduced Brand Trust When pricing seems unpredictable or intentionally inflated, especially during urgent buying moments, customers may question your brand’s integrity.

Cart Abandonment and Frustration If a price changes during checkout or after a product is saved for later, it could lead to abandoned carts and negative reviews.

Weakened Loyalty Over Time If customers consistently feel they’re not getting the best deal, they may stop trusting your pricing strategy and explore alternatives, even if your product quality remains high.

🤝 Can Dynamic Pricing Improve Customer Loyalty?

Yes, when done right, dynamic pricing can enhance loyalty. It’s not the pricing method that damages relationships, but how it’s applied.

Here’s how it can strengthen loyalty:

Offer personalized discounts to frequent buyers.

Give loyal customers early access to price drops.

Reward behavior like referrals or reviews with dynamic offers.

Use AI to ensure fairness, so customers feel pricing is still value-based.

This is where retail data analytics solutions play a pivotal role. They help retailers apply dynamic pricing with intelligence, fairness, and customer-centric strategies.

�� Role of Retail Data Analytics Solutions in Dynamic Pricing

To execute dynamic pricing effectively and ethically, businesses rely on retail data analytics solutions that:

Segment customers based on purchase patterns, loyalty scores, and price sensitivity.

Monitor customer reactions to price changes in real time.

Balance pricing rules between profitability and customer satisfaction.

Predict the impact of pricing strategies on long-term customer retention.

These solutions bring clarity and control, helping businesses shift from reactive pricing to predictive, loyalty-focused pricing.

🛠️ Best Practices to Balance Dynamic Pricing and Customer Loyalty

To ensure your pricing strategies support, rather than harm, long-term relationships:

✅ Be Transparent

Let customers know why prices change — based on demand, stock levels, or time-limited offers.

✅ Communicate Clearly

Use messaging like “Today’s Deal” or “Limited-Time Price” to prepare customers for price shifts.

✅ Reward Loyalty

Offer locked-in pricing or guaranteed discounts for loyal customers or subscribers.

✅ Avoid Over-Automation

Always review algorithm decisions for fairness and accuracy.

✅ Test Before You Roll Out

Run A/B tests on pricing changes and monitor key metrics like churn rate, average order value, and customer lifetime value.

🧠 Final Thoughts

Dynamic pricing, when executed with customer experience in mind, can be a powerful lever for both sales growth and customer engagement. But it’s a delicate balance. Go too far, and you risk eroding the very loyalty you’re trying to build.

With the support of retail data analytics solutions, retailers can implement dynamic pricing that’s personalized, predictive, and loyalty-friendly — creating pricing strategies that not only drive conversions but also win trust for the long term.

In the age of smart shopping, smart pricing isn't just about profit — it’s about people.

🔊 Voice Search Optimized FAQs

Can dynamic pricing affect loyal customers negatively❓

Yes, if not applied fairly. Frequent changes or a lack of transparency can reduce trust, especially among repeat buyers.

How can retailers make dynamic pricing fair❓

Use customer data and retail data analytics solutions to set rules and offer personalized, value-driven pricing.

Is dynamic pricing good for small retailers❓

Yes, but it must be carefully managed to avoid alienating customers. Data-driven pricing strategies can work for retailers of all sizes.

Can dynamic pricing be personalized❓

Absolutely. Dynamic pricing becomes more effective when customized based on user behavior, location, and purchase history.

0 notes

Text

Customized Solutions: Tailoring Supply Chain Strategies to Industry Needs

Supply chain management has become a crucial determinant of a company's performance in the ever-changing commercial environment of today. With the increasing specialisation and diversity of industries, it is evident that the conventional one-size-fits-all approach to supply chain strategy has been ineffective. In recent times, there has been a notable increase in the significance of tailored solutions, as enterprises acknowledge the importance of adapting their supply chain strategies to align with the distinct requirements of their respective sectors. This blog article aims to explore the significance of tailored supply chain solutions and their role in enhancing operational efficiency, minimising expenses, and facilitating industry-specific expansion. Smarter solutions for stronger supply chains. Partner with VNC Global - for top-class Supply chain management consulting in Australia to drive growth!

Understanding the Need for Customization:

Each sector functions inside its own specific environment, which is defined by particular obstacles, rules, and market forces. Therefore, it can be argued that a standardised supply chain approach is insufficient in addressing the intricacies specific to each sector. Customised solutions consider these variables, providing a personalised approach that is in line with the specific requirements of the industry.

Optimizing Operations for Efficiency:

The possibility for operational optimisation is a fundamental advantage of customising supply chain strategies to align with industry requirements. The utilisation of generic methodologies frequently leads to operational inefficiencies, manifesting in the form of surplus inventories, delays in processes, and bottlenecks. In contrast, customised solutions optimise operational efficiency by matching processes with the specific demands of the industry.

Industries characterised by significant fluctuations in demand may derive advantages from using agile supply chain methods that provide swift adaptations in production and distribution processes. Conversely, industries characterised by consistent and predictable demand patterns should prioritise the implementation of lean supply chain methods as a means to mitigate inefficiencies and achieve cost reductions. By optimising the supply chain in this manner, organisations can improve operational efficiency and responsiveness.

Reducing Costs and Enhancing ROI:

The issue of cost containment continues to be a persistent worry for firms operating in various sectors. Customised supply chain solutions are of paramount importance in effectively addressing this challenge. Tailoring tactics to the specific needs of an industry leads to the minimization of wastage, more efficient allocation of resources, and optimisation of costs. Experience real-time visibility, control, and savings. Invest in the best Supply chain management software in Australia offered by VNC Global!

Industries characterised by rigorous compliance requirements might derive advantages from supply chain strategies that prioritise the principles of traceability and transparency. By incorporating technology such as blockchain, enterprises can effectively verify regulatory adherence while concurrently mitigating the potential financial repercussions associated with product recalls. This technique not only results in cost savings but also serves to protect the reputation of the brand.

Fostering Industry-Specific Growth:

Customised supply chain solutions encompass more than just enhancing operational efficiency; they also play a significant role in fostering growth within certain industries. Industries undergo a natural progression, characterised by the impact of technology breakthroughs, market dynamics, and consumer preferences. The use of supply chain strategies customised to these elements facilitates the ability of firms to maintain agility and adaptability.

Consider the pharmaceutical business as an illustrative case. The emergence of personalised medication and the requirement for temperature-sensitive distribution may render conventional supply chain models inadequate. The implementation of a tailored approach that integrates cold chain logistics and real-time tracking systems guarantees the secure and effective transportation of delicate pharmaceuticals. The ability to adapt enables firms to effectively capitalise on emerging opportunities and navigate industry shifts.

Strengthening Industry Collaboration:

The implementation of tailored supply chain solutions frequently necessitates industry-wide collaboration and strategic collaborations. The act of exchanging best practices, insights, and resources is of utmost importance in order to collectively enhance operational efficiency. The cooperative efforts between entities not only yield advantages for individual enterprises but also contribute to the overall enhancement of the industry.

businesses characterised by intricate regulatory obligations have the potential to engage in collaborative efforts aimed at addressing compliance challenges. By pooling their resources, these businesses can collectively work towards the development of innovative technologies that facilitate the process of adhering to regulatory standards. Collaborative endeavours not only alleviate operational difficulties but also cultivate a sense of brotherhood among participants within the sector.

Final Thoughts:

In the contemporary landscape characterised by a wide range of industries and their corresponding complexities, the adoption of customization has emerged as a crucial strategy in the realm of supply chain management. Customising tactics to cater to the unique requirements of the sector allows organisations to enhance operational efficiency, minimise expenditures, and facilitate industry-specific expansion.

In a contemporary context where the ability to adapt and be agile is of utmost importance for achieving success, the adoption of tailored supply chain solutions is not only a choice but rather a strategic need. In the context of ongoing industrial development, enterprises that place emphasis on customised supply chain strategies establish themselves as frontrunners, equipped to effectively address the distinctive requirements of their specific environments. Supply chain excellence made attainable. Connect with VNC Global for tailored Supply chain management consulting in Australia.

#Supply chain management consulting in Australia#Supply chain management software in Australia#VNC Global

2 notes

·

View notes

Text

Autonomy across industries: agentic artificial intelligence

Introduction

Transformative artificial intelligence, agentic AI is changing corporate operations by allowing systems to act independently, make decisions and adjust to challenging surroundings. Agentic AI systems use sophisticated reasoning, real-time data processing and goal-directed behavior to carry out chores independently—unlike conventional artificial intelligence, which depends on preprogrammed rules or human supervision. From healthcare to manufacturing, finance to logistics, agentic artificial intelligence is driving efficiency, creativity and scalability across industries. The applications, advantages, and future possibilities of agentic artificial intelligence are investigated in this article together with its effects on current businesses.

What is Agentic AI?

Agentic AI is intelligent systems aspiring with little human interference, learning from their surroundings, and autonomous decision-making. These systems dynamically execute jobs by combining contextual awareness, natural language processing and sophisticated machine learning. Key characteristics include:

Autonomy: Agentic AI can run independently, deciding with predetermined goals and real-time data programmability.

Adaptability: It adapts by learning from fresh information, changing approaches to best results.

Goal-Oriented Behavior: Whether maximizing supply networks or tailoring consumer experiences, agentic AI coordinates activities with defined objectives.

Interoperability:It perfectly links with current systems, therefore improving workflows without the need for major remodels.