#Electric Power Distribution Automation Systems

Explore tagged Tumblr posts

Text

#Electric Power Distribution Automation Systems#Electric Power Distribution Automation Systems Market#Electric Power Distribution Automation Systems Market Trends

0 notes

Text

#career opportunities in EEE#Electrical and Electronics Engineering#EEE careers#MKCE#M.Kumarasamy College of Engineering#power generation and distribution#electronics design and manufacturing#telecommunications careers#AI in electrical engineering#machine learning in EEE#automation and control systems#research and development in EEE#higher education in EEE#teaching careers in EEE#electric vehicles careers#renewable energy careers

0 notes

Text

Industrial Miniature Circuit Breakers Market Geographical Expansion & Analysis Growth Development, Status, Recorded during 2017 to 2032

MCB and MCCB Market Projected to Reach USD 12.96 billion, at a 7.5% CAGR by 2030

Trends:

Several trends are shaping the industrial MCBs market:

• Growing IoT and automation adoption: Reliable circuit protection devices are needed since IoT and automation technologies are increasingly being used in industrial operations. Industrial MCBs are crucial parts of automated systems because they protect against electrical problems and improve the general security and effectiveness of industrial processes.

• There is a demand for intelligent and connected solutions, and industrial MCBs are evolving to include these features. This makes it possible to remotely monitor, diagnose, and operate electrical systems, which increases the effectiveness of maintenance and troubleshooting. The demand for intelligent industrial MCBs is being driven by the movement towards smart manufacturing and Industry 4.0.

Key Factors:

Several key factors are influencing the growth of the industrial MCBs market:

• Industrialization and infrastructure development: The need for industrial MCBs is being driven by continuing industrialization and infrastructure development initiatives around the world. To protect their electrical systems and equipment, industries like manufacturing, construction, oil & gas, and power generation need trustworthy circuit protection solutions.

• Safety and compliance rules: Reliable circuit protection devices are required in industrial contexts due to strict safety regulations and standards. Industrial MCBs offer an essential layer of defence against electrical problems, guaranteeing adherence to safety regulations and preventing accidents.

• Growth of electrical infrastructure: The need for industrial MCBs is driven by the growth of the electrical infrastructure, which includes substations, distribution networks, and data centres. Within these infrastructure projects, these circuit breakers are employed to protect and regulate electrical circuits.

In conclusion, developments like automation, IoT integration, energy efficiency, and the adoption of renewable energy sources have an impact on the market for industrial MCBs. The market's expansion is primarily being driven by industrialisation, safety requirements, the expansion of the electrical infrastructure, and the retrofit/replacement market. In order to satisfy the changing needs of industrial customers, manufacturers and suppliers should align their product lines with these trends and considerations.

Referrals to our Stringent datalytics company, trade journals, and websites that focus on market reports are encouraged. These sources frequently include thorough research, market trends, growth projections, competition analysis, and other insightful information about this market.

You can investigate the availability of particular reports linked to this market by going to our website or getting in touch with us directly. These reports frequently need to be purchased or subscribed to, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/industrial-miniature-circuit-breakers-market/10120/

Market Segmentations:

Global Industrial Miniature Circuit Breakers Market: By Company

• Kevilton Electrical Products

• Elmark

• Britec Electric

• R. STAHL EX-PROOF

• Siemens

• ABB

• Camsco Electric

• Iskra

• Dongguan Keiyip Electrical Equipment

• Schneider Electric

• China Suntree Electric

• Wenzhou korlen electric appliances

• Legrand

• Finolex

• Hager

• Eaton

Global Industrial Miniature Circuit Breakers Market: By Type

• B-MCB

• C-MCB

• D-MCB

Global Industrial Miniature Circuit Breakers Market: By Application

• Achitechive

• Power Industry

• Other

Global Industrial Miniature Circuit Breakers Market: Regional Analysis

The regional analysis of the global Industrial Miniature Circuit Breakers market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Industrial Miniature Circuit Breakers market report are as follows:

North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Industrial Miniature Circuit Breakers in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product.

Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Industrial Miniature Circuit Breakers in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors.

Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Industrial Miniature Circuit Breakers in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction.

Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors.

South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Industrial Miniature Circuit Breakers in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/explosion-proof-circuit-breaker-market/10057/

Reasons to Purchase Industrial Miniature Circuit Breakers Market Report:

• To gain insights into market trends and dynamics: this reports provide valuable insights into industry trends and dynamics, including market size, growth rates, and key drivers and challenges.

• To identify key players and competitors: this research reports can help businesses identify key players and competitors in their industry, including their market share, strategies, and strengths and weaknesses.

• To understand consumer behavior: this research reports can provide valuable insights into consumer behavior, including their preferences, purchasing habits, and demographics.

• To evaluate market opportunities: this research reports can help businesses evaluate market opportunities, including potential new products or services, new markets, and emerging trends.• To evaluate market opportunities: this research reports can help businesses evaluate market opportunities, including potential new products or services, new markets, and emerging trends.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Market Geographical Expansion & Analysis Growth Development#Status#Recorded during 2017 to 2032#Industrial Miniature Circuit Breakers#Circuit Protection#Electrical Safety#Industrial Automation#Energy Management#Electrical Distribution#Manufacturing Sector#Industrial Equipment#Industry Trends#Market Analysis#Electrical Engineering#Electrical Components#Market Dynamics#Industry Insights#Industrial Control#Electrical Systems#Power Distribution#Equipment Protection#Industrial Infrastructure#Market Forecast#Miniature Circuit Breaker Technologies#Electrical Industry#Safety Standards#Industrial Electronics#Circuit Breaker Market#Industrial Electrical Systems#Market Growth

0 notes

Text

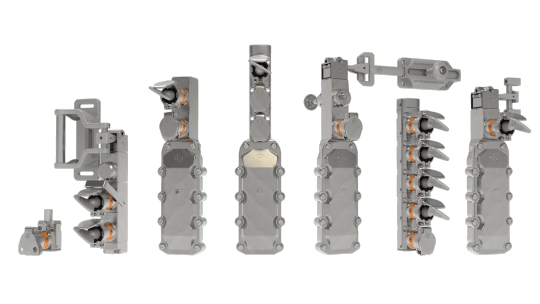

At LKH Electric (M) Sdn Bhd, our products are locally manufactured in i4.0 ready manufacturing facilities, ensuring the most rigorous quality control tests are conducted for reliable and safe power distribution.

0 notes

Text

The Difference Between Low, Medium, and High Voltage Switchgear

Switchgear plays a critical role in the generation, transmission, and distribution of electrical power. It ensures safe and efficient operation by controlling, protecting, and isolating electrical circuits and equipment. But not all switchgear is created equal — low, medium, and high voltage switchgear are designed for different voltage levels and applications.

Understanding the differences between these types is crucial for electrical engineers, electricians, project managers, and anyone involved in power systems. In this article, we break down what sets them apart in terms of voltage range, components, applications, design, and safety considerations.

What is Switchgear?

Before diving into the differences, let’s clarify what switchgear is.

Switchgear refers to the combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential for de-energizing equipment for maintenance and for clearing faults in the power system.

Classification by Voltage Level

Low Voltage Switchgear (LV)

Voltage Range:

Up to 1,000V AC (typically 400V/690V in 3-phase systems)

Key Components:

Miniature Circuit Breakers (MCBs)

Molded Case Circuit Breakers (MCCBs)

Residual Current Devices (RCDs)

Contactors and relays

Busbars, metering, control panels

Applications:

Residential and commercial buildings

Data centers and office spaces

Light industrial automation

Control panels and motor control centers (MCCs)

Characteristics:

Compact and easy to install

High frequency of operation

Relatively simple maintenance

Often enclosed in modular panels

Standards:

IEC 61439

NEC (National Electrical Code)

Medium Voltage Switchgear (MV)

Voltage Range:

1kV to 36kV (sometimes up to 72.5kV)

Key Components:

Vacuum circuit breakers (VCBs)

SF₆ (sulfur hexafluoride) insulated switchgear

Current and voltage transformers (CTs, VTs)

Protective relays

Grounding switches

Applications:

Electrical substations

Large factories and industrial plants

Railways and airports

Renewable energy farms (wind/solar)

Characteristics:

Higher insulation and safety requirements

More robust protection systems

Often installed indoors or in compact outdoor enclosures

May use gas-insulated or air-insulated designs

Standards:

IEC 62271–200

IEEE C37 series

High Voltage Switchgear (HV)

Voltage Range:

Above 36kV (commonly 66kV, 132kV, 220kV, up to 765kV)

Key Components:

SF₆ circuit breakers

Air blast or oil circuit breakers (older systems)

Gas-insulated switchgear (GIS)

Disconnectors and earthing switches

High-end protection relays and SCADA integration

Applications:

National and regional power transmission networks

Power generation plants

Interconnecting large substations

Critical infrastructure (e.g., large data centers, airports)

Characteristics:

Complex installation and high-cost infrastructure

Requires rigorous safety procedures and specialized training

Often installed outdoors or in GIS (Gas Insulated Switchgear) format

Includes extensive monitoring and automation

Standards:

IEC 62271–100 (HV circuit breakers)

IEEE C37.06

ANSI C37 series

Safety Considerations

Always follow local electrical codes, use personal protective equipment (PPE), and conduct routine maintenance regardless of switchgear type.

Conclusion

Choosing the right switchgear type is critical for ensuring safe and efficient power distribution. Whether you’re designing a residential panel or a high-voltage substation, knowing the difference between low, medium, and high voltage switchgear helps you make informed decisions about equipment, safety, and performance.

Mastering this knowledge isn’t just good practice — it’s essential for anyone serious about a career in the electrical field.

10 notes

·

View notes

Text

Understanding the Role of Busbars, Circuit Breakers, and Relays in Switchgear

In the world of electrical distribution and control systems, switchgear plays a pivotal role in managing, protecting, and isolating electrical circuits and equipment. Within a switchgear assembly, components like busbars, circuit breakers, and relays are essential for ensuring efficient operation and maximum safety. Understanding the role of each of these components can help professionals and businesses make better decisions when designing or upgrading their electrical systems.

What Is Switchgear?

Switchgear is a general term that encompasses a wide range of electrical disconnect switches, fuses, circuit breakers, and associated equipment used to control, protect, and isolate electrical equipment. These systems are critical for both high-voltage and low-voltage applications and are commonly found in industrial plants, commercial buildings, power plants, and substations.

1. Busbars: The Power Distribution Backbone

Busbars are metallic strips or bars — typically made of copper or aluminum — that conduct electricity within a switchgear or distribution board. Their main function is to distribute electrical power to multiple circuits from a single input source.

Key Functions:

· Efficient Power Distribution: Busbars act as a central hub for distributing power to various outgoing circuits.

· Compact Design: Helps in reducing the overall footprint of the switchgear.

· Heat Dissipation: Designed to handle high currents while minimizing heat build-up.

Applications:

· Power distribution panels

· Switchboards and MCCs (Motor Control Centers)

· Panelboards and switchgear cubicles

2. Circuit Breakers: Protection from Overcurrent

Circuit breakers are automatic electrical switches designed to protect electrical circuits from damage due to overcurrent or short circuits. Unlike fuses, circuit breakers can be reset manually or automatically after tripping.

Key Functions:

· Fault Interruption: Instantly disconnects the circuit during faults to prevent damage or fire.

· Manual Switching: Can be used to manually turn circuits on or off during maintenance.

· Safety Compliance: Ensures that systems meet international safety standards (IEC, ANSI, etc.)

Types of Circuit Breakers:

· MCB (Miniature Circuit Breaker): Used for low-power applications

· MCCB (Molded Case Circuit Breaker): Handles higher loads than MCBs

· ACB (Air Circuit Breaker): Used for high-current circuits in industrial settings

3. Relays: The Sensing and Control Brains

Relays are electromechanical or solid-state devices that detect faults and send signals to circuit breakers or other control devices to disconnect the circuit. They are the “brains” behind the automatic protection mechanism of the switchgear.

Key Functions:

· Fault Detection: Monitors voltage, current, and other parameters to detect anomalies.

· Triggering Action: Sends signals to trip the circuit breaker when necessary.

· Automation and Coordination: Works in coordination with other protection devices to ensure selective tripping.

Types of Relays:

Overcurrent Relays

Differential Relays

Distance Relays

Earth Fault Relays

Why These Components Matter

Together, busbars, circuit breakers, and relays form the core of any switchgear system. When properly selected and configured:

· Downtime is minimized

· Equipment lifespan is extended

· Operational safety is enhanced

· Energy efficiency is improved

In an era where electrical reliability is non-negotiable, understanding these components isn’t just for engineers — it’s essential knowledge for decision-makers in any industry reliant on power.

Conclusion

Whether you’re designing a new electrical panel or upgrading an old one, choosing high-quality busbars, circuit breakers, and relays is critical to the safety and efficiency of your entire system. At AL Taqwa Oman, we specialize in premium-grade switchgear accessories that meet global standards and deliver unmatched performance.

Need help finding the right accessories for your panel? Contact our experts today and power your systems with confidence.

#electrical#electrical equipment#electrical supplies#switchgear#oman#electricity#busbar#relay#circuit breaker

8 notes

·

View notes

Text

How Do F1 Cars Work?: Power, Transmit, Suspend

Alright part 2 everyone. Let's go.

1.Power Units

You have probably heard lots of yammering about power unit components before. Things like 'they took on too many and now have a grid penalty' are common to hear. But what is the power unit, and what does that mean?

So the power unit refers to the engine system that helps power the car. The modern F1 car is a hybrid, a mix between a typical Internal Combustion Engine (ICE) and Energy Recover Systems (ERS). The modern F1 ICE is a 1.6 liter V6 turbocharged engine and can rev up to 15,000 RPM. It uses gasoline and generates a majority of the power. I've explained how it works in an older post, but briefly it compresses air and fuel and ignites it to create combustion which generates energy. The turbocharger is a part of the ICE that helps condense air more, in turn forcing the engine to create more energy.

The ERS has two components. The first is Motor Generator Unit-Kinetic (MGU-K), which recovers energy from braking, stores it in the battery (which stores energy from the two units), and can be used as a boost to power. The second is Motor Generator Unit- Heat (MGU-H). This unit recovers heat energy from the turbocharger and converts it to electrical energy. It can either charge the battery directly or assist the ICE.

When teams get in trouble taking too many power units it essentially means they have replaced something like the MGU-H too many times. There is a cap for how many times you can replace a power unit component, but with the addition of more races every year the FIA is under pressure to increase this limit. Almost every single car takes the penalty at some point.

2. Transmission

The transmission is the semi-automatic gear box inside of F1 cars, which for them is 8-speed. It is located at the rear of the car and connects to the power unit. This is a part of the car that is famous for having issues, and often when a drivers car retires it is due to a gear box failure. With paddle shifters located under the steering wheel, drivers can change the gear in which they are driving. Different gears effect the traction, grip, fuel economy, and speed of the car and are used strategically throughout the race. Part of the transmission is the differential. The differential distributes power between the rear wheels when cornering, allowing the inside tire to rotate slower than the outside tire. The final majorly important part of the transmission is the clutch. In F1 the clutch, which is a device that connects the engine and transmission to the car is automated and controlled by electronics. It is usually used when starting the race or leaving the pit lane.

Grip levels, cornering speeds, and straight-line speeds all play a crucial role in gear ratio calculations. The teams have to find the perfect balance between acceleration, top speed, and adaptability. The team’s engineers use advanced simulations and data analysis to calculate the optimal ratios for each gear. They also take into account factors like tire wear and fuel consumption to fine-tune their calculations. All of this information can be gathered from electronic data gatherers inside of the car, running simulations, and also the drivers reporting themselves. Its why radio communication is so important in F1. This decision can make or break a race, and we have seen drivers lose due to an incorrect gear decision.

3. Suspension

The suspension system works to keep the tires in contact with the road and helps absorb the shocks F1 cars experience. This is created through a variety of springs, shock absorbers, sway bars, etc. Without the suspension, the chassis would be experiencing the full extent of the shaking and pressure, which would do damage to the car and be very painful for the driver. Anytime you see a driver shaking like crazy in the car, it usually means there is something off with the suspension. Suspension also allows the force of the bumps and the kinetic energy to be stored by a spring, which is then compressed, absorbing the energy transferred by that bump in the road and allowing all four tires to grip the road. The biggest difference between street car suspension and F1 suspension is that in an F1 car each tire is independently sprung, which means that they move on their own, useful around corners.

In F1 cars they have a pushrod or pullrod suspension. These systems transfer pressure from the wheels to the suspension dampers and springs. In a push-rod system, the rocker arms are placed at the highest point in the car. As such, the rod is under pressure as it transfers compression forces upwards into the rocker arms. In a pull-rod system however, the rocker arms are located between the upper and lower control arms, at the center of the car This means every time it hits a bump or curb, the wheel pulls on the spring which causes the pull-rod to go up and outwards from the chassis. Both are regularly used suspension types.

Teams regularly change how their suspension is functioning, and it is by far one of the most tweaked systems on the car. Truly, a weak suspension can make any car one of the slowest cars on the grid. So next time you hear a. driver complain about how slow they are on the straights, or how much their back hurts, it usually means their suspension is not where it should be.

That's all for this post, next one should be about braking, the various electronics/sensors, cooling systems, and wrap up of how everything works together.

Cheers,

-B

19 notes

·

View notes

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

9 notes

·

View notes

Text

The Role of Relays and Timers in Industrial Automation Systems

In the world of industrial automation, efficiency, safety, and precision are crucial. Among the many components that contribute to a well-functioning automated system, relays and timers play a foundational role. These devices act as control elements that manage the flow of electricity, signal processes, and coordinate timing sequences — ensuring that operations run smoothly and safely.

In this article, we’ll explore how relays and timers work, their types, applications in automation systems, and how high-quality products — like those offered by Enza Electric — can enhance performance and reliability in industrial settings.

What Are Relays?

A relay is an electromechanical or electronic switch used to control a circuit by a separate low-power signal or multiple signals. In industrial automation, relays act as a bridge between the control system and the equipment being operated — allowing machines to be turned on or off automatically.

Types of Relays Commonly Used in Automation:

Electromechanical Relays (EMRs): Use physical moving parts; reliable and easy to maintain.

Solid-State Relays (SSRs): No moving parts; faster switching, longer lifespan, and better for high-speed applications.

Thermal Overload Relays: Protect motors and equipment from overheating.

Control Relays: Designed for controlling multiple contacts simultaneously in automation systems.

What Are Timers?

Timers are devices used to delay or repeat electrical signals at predetermined intervals. They help synchronize tasks, automate sequences, and provide controlled outputs over time — critical for complex industrial processes.

Common Timer Functions:

On-delay and off-delay timing

Interval timing

Cyclic or repeat cycle operation

Flashing and sequencing operations

Types of Timers:

Analog Timers: Manual dial settings, simple and cost-effective.

Digital Timers: Offer precise programming, displays, and flexible timing ranges.

Programmable Timers: Ideal for complex automation routines requiring multiple sequences.

Key Roles in Industrial Automation Systems

1. Process Control and Sequencing

Relays and timers enable automated machines to follow a specific sequence — turning motors, lights, or pumps on and off in a logical order. For example, a conveyor system can use a relay-timer combination to control material flow with millisecond precision.

2. Safety and Protection

Relays protect systems by interrupting circuits in case of faults. Combined with timers, they can ensure delay before activating emergency stop functions, preventing false triggers and increasing worker safety.

3. Load Management

In high-demand industrial environments, relays help manage load distribution by selectively energizing or de-energizing machinery. Timers assist in staggered starts, reducing power surges.

4. Energy Efficiency

By automating start/stop functions and managing operation durations, timers help reduce unnecessary energy use. Relays ensure only the necessary loads are powered, minimizing wastage.

5. System Monitoring and Feedback

In smart automation, relays provide feedback signals to the control system. Timers assist with diagnostics by creating intervals for testing or data collection.

Benefits of Using High-Quality Relays and Timers

Choosing the right components significantly impacts system performance and longevity. Enza Electric’s relays and timers are engineered with:

High durability for tough industrial environments

Precision timing for reliable operation

Easy installation and compact designs

Compliance with international safety and quality standards

By integrating Enza’s low-voltage solutions, businesses in the GCC, MENA, and Africa regions benefit from cost-effective, scalable automation that supports both current needs and future expansion.

Common Applications in Industrial Sectors

Manufacturing Plants: Control of motors, robotic arms, and production lines.

HVAC Systems: Timed control of fans, compressors, and dampers.

Water Treatment Facilities: Sequenced operation of pumps and valves.

Packaging Machinery: Relay and timer-based coordination of packing, sealing, and labeling.

Food and Beverage Industry: Process automation with hygiene-compliant controls.

Final Thoughts

Relays and timers are the silent operators behind the success of industrial automation systems. From process optimization to enhanced safety and energy management, these components are indispensable.

When sourced from a trusted manufacturer like Enza Electric, businesses are not only investing in reliable hardware but also in the longevity, scalability, and safety of their entire operation.

Ready to Power Your Automation?

Explore Enza Electric’s wide range of relays, timers, and other low-voltage switchgear solutions designed to meet the evolving demands of modern industries. Visit www.enzaelectric.com to learn more or request a quote today.

9 notes

·

View notes

Text

What Is a Circuit Breaker and How Does It Work in a Switchgear Assembly?

In modern electrical power systems, reliability and safety are paramount. Whether it’s a residential building, industrial plant, or renewable energy facility, the control and protection of electrical circuits are essential. One of the most critical components used for this purpose is the circuit breaker. When integrated into a switchgear assembly, the circuit breaker plays a central role in ensuring operational continuity, preventing electrical faults, and safeguarding equipment and personnel.

This article explores what a circuit breaker is, it’s working principle, types, and its specific function within a switchgear assembly.

What Is a Circuit Breaker?

A circuit breaker is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by overcurrent, overload, or short circuit. Its primary function is to interrupt current flow after a fault is detected. Unlike a fuse, which operates once and must be replaced, a circuit breaker can be reset (manually or automatically) to resume normal operation.

Key Functions of a Circuit Breaker

· Interrupt Fault Currents: Quickly breaks the circuit in the event of an overcurrent or short circuit.

· Manual Switching: Can be used to manually open or close a circuit for maintenance.

· Automatic Protection: Operates automatically in response to abnormal current conditions.

· Isolation: Ensures safe isolation of electrical equipment during servicing.

How Does a Circuit Breaker Work?

Circuit breakers operate on a simple principle: detect a fault and interrupt the current flow.

Working Mechanism

1. Detection: Internal sensors such as thermal, magnetic, or electronic trip units detect abnormalities in current.

· Thermal Trip Unit: Uses a bimetallic strip that bends with heat from overcurrent.

· Magnetic Trip Unit: Uses an electromagnet that triggers a release when excessive current flows.

· Electronic Trip Unit: Uses current sensors and a microprocessor for precise tripping.

2. Tripping: Once a fault is detected, the trip mechanism activates, causing the breaker’s contacts to open.

3. Arc Extinction: When the contacts open, an electrical arc forms. The breaker extinguishes the arc using mechanisms like:

· Air-blast

· Vacuum

· SF₆ gas

· Oil

4. Resetting: After the fault is cleared, the breaker can be reset and put back into service.

Types of Circuit Breakers

What Is a Switchgear Assembly?

Switchgear is a centralized assembly of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential in power generation, transmission, and distribution networks.

Switchgear can be categorized by voltage level:

· Low Voltage (LV): Up to 1 kV

· Medium Voltage (MV): 1 kV to 36 kV

· High Voltage (HV): Above 36 kV

Role of Circuit Breakers in Switchgear Assemblies

Circuit breakers are core protection components within switchgear systems. Their role includes:

1. Fault Detection and Isolation

Circuit breakers detect and isolate faulty circuits to prevent system-wide failures and reduce downtime.

2. Load Control

Operators can use breakers in switchgear to safely connect or disconnect loads as required during routine operations or emergencies.

3. System Coordination

In coordinated protection schemes, different breakers in the switchgear are set with time-current characteristics to isolate faults precisely and efficiently.

4. Integration with Automation

Modern switchgear integrates circuit breakers with SCADA systems and smart relays, enabling remote monitoring and control.

Circuit Breakers in Renewable and Industrial Applications

In sectors like solar and wind energy, circuit breakers are specially designed to handle:

· Bidirectional current flow

· Rapid voltage fluctuations

· High fault levels due to DC sources

In industrial settings, breakers must handle high inrush currents, frequent switching, and harsh environments.

Maintenance and Safety Considerations

To ensure reliability:

· Regular Testing: Trip settings, insulation resistance, and contact resistance must be tested periodically.

· Visual Inspection: For signs of wear, overheating, or contamination.

· Replacement of Parts: Arcing contacts and insulation materials degrade over time and must be replaced as needed.

Safety measures include:

· Lockout/Tagout (LOTO)

· Grounding procedures

· Personal Protective Equipment (PPE)

Conclusion

Circuit breakers are indispensable for the protection and control of electrical systems. When embedded within a switchgear assembly, they offer enhanced reliability, automation capability, and system safety. Whether in a power substation, a manufacturing facility, or a renewable energy farm, the synergy of circuit breakers and switchgear ensures smooth, safe, and efficient operation.

Understanding how circuit breakers function and interact within switchgear assemblies is crucial for electrical engineers, facility managers, and anyone involved in the design, operation, or maintenance of electrical infrastructure.

5 notes

·

View notes

Text

One Stop for All Your Electrical Needs: Residential, Commercial, Industrial & Emergency Services in Red Deer

When it comes to finding a trusted electrical service provider in Red Deer, look no further than Bryant’s Electrical Ltd. With years of experience and a team of licensed, skilled professionals, Bryant’s Electrical Ltd. is your reliable partner for a full spectrum of electrical solutions — residential, commercial, industrial, and emergency. Whether you’re managing a home renovation or upgrading your office’s wiring, their services are tailored to meet every need with precision and care. If you’re searching for a dependable commercial electrician in Red Deer, Bryant’s Electrical Ltd. delivers expert workmanship, safety, and efficiency at every step.

Residential Electrical Services: Powering Homes with Safety and Innovation

Your home should be a place of comfort and safety — and that begins with a secure, up-to-date electrical system. Bryant’s Electrical Ltd. offers a wide array of residential services to ensure your house runs smoothly and safely.

Key Residential Services:

Electrical Repairs & Troubleshooting: From flickering lights to frequent breaker trips, their team quickly identifies and resolves electrical issues to keep your home safe.

New Installations: Whether it’s a new build or a remodel, Bryant’s Electrical handles all aspects of home wiring, lighting, switches, and panels.

Panel Upgrades: Modern households demand more power. If your electrical panel is outdated, an upgrade ensures safe energy distribution and avoids overloading.

Home Automation: Integrate smart lighting, thermostats, and security systems with ease.

EV Charger Installation: As electric vehicles become more common, Bryant’s Electrical is prepared to install residential charging stations tailored to your needs.

Each service is carried out with a commitment to quality and adherence to current safety codes, ensuring peace of mind for you and your family.

Commercial Electrical Services: Empowering Red Deer Businesses

Business owners need uninterrupted power to keep operations running smoothly. Bryant’s Electrical Ltd. specializes in commercial electrical solutions for offices, shops, restaurants, and other business environments.

Commercial Electrical Services Include:

Lighting Design & Installation: From energy-efficient LED upgrades to custom lighting plans, they improve visibility and ambiance while reducing operational costs.

Power Distribution Systems: Proper load management is crucial for safety and performance. Bryant’s ensures your systems can handle your business’s energy needs.

Surge Protection & Backup Power: Protect your data and equipment with whole-building surge protection and emergency backup generators.

Security & Fire Alarm Systems: Ensure safety with professional installation of integrated alarm systems and security lighting.

Scheduled Maintenance: Avoid expensive repairs or system failures with routine inspections and preventative maintenance.

Bryant’s Electrical understands the unique demands of commercial properties, and their responsive service ensures minimal disruption to your day-to-day operations. Their attention to detail and flexible scheduling make them a top choice for any business seeking a reliable commercial electrician in Red Deer.

Emergency Electrical Services: Ready When You Need Us Most

Electrical emergencies are unpredictable — and dangerous. Bryant’s Electrical Ltd. offers 24/7 emergency electrical services in Red Deer to respond quickly when issues arise.

Common Emergency Services:

Power outages affecting only your home or business

Burning smells or sparks from outlets

Exposed or damaged wiring

Sudden loss of lighting or electrical appliances

Breaker panel overheating

Their electricians arrive fully equipped to diagnose and fix the problem promptly, restoring safety and functionality to your property. Whether it’s midnight or a holiday, help is just a phone call away.

Industrial Electrical Services: Powering Large-Scale Operations

Industrial facilities operate on a much larger and more complex scale than residential or commercial properties. Bryant’s Electrical Ltd. is equipped to handle high-voltage systems, custom installations, and ongoing maintenance for manufacturing plants, warehouses, and other industrial sites.

Key Industrial Services:

Heavy Machinery Wiring: Ensure safe and proper connection of manufacturing and processing equipment.

Custom Electrical System Design: Every facility has unique needs. Bryant’s Electrical creates tailored systems for maximum efficiency and safety.

Preventative Maintenance Programs: Regular inspections prevent downtime and keep your equipment running smoothly.

Hazardous Location Installations: Their team is trained in installing electrical components in high-risk areas in compliance with all regulatory standards.

Load Calculations & Power Upgrades: Expand operations with accurate load assessments and scalable power solutions.

In industrial settings, even a small electrical issue can lead to significant downtime and loss. Bryant’s Electrical Ltd. offers long-term solutions and rapid response to ensure your systems run safely and efficiently. If you’re looking for an industrial electrician in Red Deer who understands the intricacies of heavy-duty electrical infrastructure, Bryant’s Electrical is the partner you can rely on.

Conclusion

From small residential fixes to complex industrial installations, Bryant’s Electrical Ltd. stands out as the one-stop destination for all electrical needs in Red Deer. Their commitment to quality service, fast response, and expert solutions makes them the preferred choice for homeowners, business operators, and industrial clients alike. Whether you need a quick repair, an emergency fix, or a full-scale installation, their team is just a call away.

Choose Bryant’s Electrical Ltd. — where your power is always in good hands, whether you’re in need of a commercial electrician in Red Deer or seeking a skilled industrial electrician in Red Deer for large-scale operations.

2 notes

·

View notes

Text

Does Sustainability Go Hand in Hand with Technology and the Global Shift to Electric Power?

Explore how Sustainability Next to Technology is Connected to Global Move Towards Electric Power.

The new generation of moving the world towards cleaner energy has electric power at the core of this transformation.

But do they, sustainability and technology, indeed go hand in hand?

Well, it’s no longer a hypothetical question, but a problem that determines the future path of power distribution and energy management.

Growing Demand for Sustainable Solutions:

Not long ago, the dream of electric power turned into a reality before you know it.

Cleaner has become a key aspiration of governments, industries, and consumers alike.

Sustainability imparts a different meaning to reducing carbon footprints.

This also means making power systems smarter and less dangerous, more efficient, cost-effective, and probably even creating a bit of redundancy.

This will mean purchasing components for the switchgear industry that reduce energy waste, extend life cycles, and facilitate the interfacing of renewable sources.

Energy-efficient circuit breakers, digital monitoring systems, modular switchgear components, and other accessories are becoming key players in the evolution.

Smart Technology: The Backbone of Sustainable Switchgear

The way the whole change in switchgear technology moves is, of course, toward modernization.

IoT-type embedded devices for monitoring, AI-driven prediction of maintenance needs, and design for energy-efficient low-voltage contactors all transform the way the whole power is managed.

It ensures reduced energy losses and very much optimized peak condition behavior, as well as improved safety-all these fulfilling both sustainability and day-to-day operating efficiency objectives.

1. Digital Monitoring and Automation

It is all about real-time data.

Smart monitoring solutions provide instant access to information regarding the efficiency of the use of electricity, fault detection, and energy efficiency.

With this, downtime and failures incurred can be minimized, and energy consumption can be optimized-thus, saving unnecessary wastages of electricity.

2. Modular and Recyclable Components

Energy efficiency doesn’t only mean sustainability as far as power is concerned-it also has to do with waste.

Adaptive switchgear designs allow easy upgrades and replacements, which can prolong the life cycle of an electrical system while simultaneously reducing the amount of waste made for materials.

Adoption of recyclable and non-toxic materials in accessories for switchgear also minimizes environmental impact.

3. Energy-Efficient Contactors and Circuit Breakers

New advanced low-loss contactor and circuit breaker technologies, which increase energy efficiency, cut down heat dissipation and losses in the circuits.

Fewer losses in energy mean low operating costs and a reduced carbon footprint; these are the two main factors that are becoming crucial for today’s modern companies striving to meet sustainability goals.

Switchgear Accessories to Play a Critical Role in the Green Revolution

It is only through highly competent switchgear accessories that a truly sustainable power infrastructure may be realized: from low-voltage surge protectors that ensure a longer life for the system to biodegradable insulation materials, the right kind of components would all play their part in making a difference.

Eco friendly insulation: Using sustainable materials in insulation applications reduces the negative impacts on the environment while maintaining the safety and efficiency associated with conventional insulation types.

Adaptive Protection Relays: These help to ensure the stability of power and eliminate the breakdowns, thus eliminating the costs of frequent replacement and repairs.

Using Busbar Systems to Reduce Energy Losses: The more efficient a conductor is, the less its resistance and heat loss, and the better it transmits energy.

Balancing Innovation and Cost with Performance

In fact, the passage from several manufacturers and traders is the perception that sustainability involves more costs.

But in reality, such first costs are outweighed by very many long-term benefits.

The merger of lower maintenance costs, lower periodicity recall for new replacement pieces, and greater shelf life compliance does make sustainable switchgear a smart business choice.

Conclusion: The Future of Sustainable Energy

Technology and sustainability aren’t separate paths any longer; they’re bearing down more on a linear convergence as the world flows into a different shape concerning energy.

Change is a space that we all own.

The future is here-now!

6 notes

·

View notes

Text

Explosion-proof Circuit Breaker Market Share, Size, Type, Demand, Overview Analysis, Trends, Opportunities, Key Growth, key points, Development and Forecasts by 2032

Market Overview:

The explosion-proof circuit breaker market refers to the segment of the circuit breaker market that caters to hazardous or potentially explosive environments. Explosion-proof circuit breakers are designed to prevent the ignition of flammable gases, dust, or other hazardous substances in order to ensure the safety of personnel and equipment in such environments.

The global Circuit Breaker market size was valued at USD 5427.73 million in 2021-2022 and is expected to expand at a CAGR of 6.91% during the forecast period, reaching USD 8105.33 million by 2030.

Key Factors: Several key factors are driving the growth of the explosion-proof circuit breaker market:

severe safety laws: Businesses operating in risky areas, such as those in the oil and gas, chemical, mining, and manufacturing sectors, must adhere to severe safety laws. To reduce the risk of explosions and guarantee worker safety, these standards require the use of explosion-proof circuit breakers.

Industrialization and infrastructure development are progressing at an accelerated rate, which is driving up demand for explosion-proof circuit breakers. Businesses in hazardous environments including oil refineries, power plants, chemical plants, and mining activities need effective circuit protection solutions.

Technological developments: The market for explosion-proof circuit breakers has grown as a result of the development of sophisticated technologies in circuit protection, such as improved arc quenching mechanisms and improved insulating materials.These technical developments provide improved performance and dependability in risky circumstances.

Demand: The increased focus on safety in dangerous areas is predicted to drive up demand for explosion-proof circuit breakers. Explosion-proof circuit breakers are being adopted by industries across all sectors, including oil and gas, chemical, mining, and manufacturing, in order to adhere to safety laws and safeguard their operations.

Explosion-proof circuit breakers that meet the strict safety standards and regulations of diverse industries should be the primary focus of manufacturers and suppliers in this industry. To meet the changing needs of the market, they should also emphasise the strength, dependability, and simplicity of maintenance of their products.

Referrals to our Stringent datalytics, trade journals, and websites that focus on market reports are encouraged. These sources frequently include thorough research, market trends, growth projections, competition analysis, and other insightful information about this market.

You can investigate the availability of particular reports linked to this market by going to our website or getting in touch with us directly. We offer thorough and in-depth information that might be helpful for firms, investors, and individuals interested in this industry, but these reports frequently need to be purchased or subscribed to.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/explosion-proof-circuit-breaker-market/10057/

Market Segmentations:

Global Explosion-proof Circuit Breaker Market: By Company

• Phoenix Contract

• Connecticut Electric

• Murrelektronik

• Eaton

• Siemens

• ABB

• Culter-Hanmmer

• Westinghouse

• Schneider

• Blue Sea Systems

• IDEC

• Carling Technologies

• Bussman

• AudioPipe

• Buyers Products

• ITE

• Panduit

• Powerwerx

• Stinger

• Federal Pacific

• Murray Feiss

Global Explosion-proof Circuit Breaker Market: By Type

• High Voltage

• Medium Voltage

• Low Voltage

Global Explosion-proof Circuit Breaker Market: By Application

• Petrochemical

• Military Industry

• Others

Global Explosion-proof Circuit Breaker Market: Regional Analysis

The regional analysis of the global Explosion-proof Circuit Breaker market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Explosion-proof Circuit Breaker market report are as follows:

North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Explosion-proof Circuit Breaker in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product.

Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Explosion-proof Circuit Breaker in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors.

Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Explosion-proof Circuit Breaker in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction.

Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors.

South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Explosion-proof Circuit Breaker in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/explosion-proof-circuit-breaker-market/10057/

Reasons to Purchase Explosion-proof Circuit Breaker Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can assist companies in assessing market opportunities, such as those presented by possible new goods or services, emerging markets, and trends..

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Explosion-proof Circuit Breaker Market#Breakers#Market Dynamics#Safety Regulations#Equipment Protection#Industrial Automation#Oil and Gas Industry#Chemical Industry#Mining Sector#Process Industries#Electrical Infrastructure#Electrical Components#Risk Mitigation#Market Forecast#Industry Insights#Electrical Industry#Safety Standards#Electrical Systems#Power Distribution#Electrical Control#Circuit Breaker Technologies#global research market report

0 notes

Text

How Custom Epoxy Insulators Reduce Downtime in Electrical Systems

In today's fast-paced industrial world, even a few minutes of electrical system downtime can translate into substantial financial losses. Whether it is in power transmission, distribution, or industrial automation, the reliability and stability of electrical components play a crucial role. One of the unsung heroes in this landscape is the epoxy insulator — particularly those that are custom-made for specific system requirements.

At Radiant Enterprises, we specialize in high-quality insulators that are engineered to minimize failure risks and ensure continuous operation. This article explores how custom epoxy insulators significantly reduce downtime in electrical systems, improve overall performance, and offer long-term cost savings.

What Are Epoxy Insulators?

An epoxy insulator is a type of electrical insulation component made from high-grade epoxy resin, often reinforced with glass fibre. These insulators are known for their excellent electrical, mechanical, and thermal properties. Because of their robustness and reliability, epoxy insulators are extensively used in switchgear, transformers, circuit breakers, and other high-voltage and medium-voltage applications.

Unlike porcelain or ceramic insulators, epoxy insulators offer better performance in compact spaces and harsh environments. Their ability to withstand high mechanical stress, temperature variations, and environmental factors makes them an ideal choice for modern electrical infrastructure.

The Value of Custom-Made Support Insulators

Not all electrical systems are created equal. They often differ in configuration, voltage ratings, and environmental exposure. That is where custom made support insulators come into play.

Custom epoxy insulators are tailored to meet the specific mechanical and electrical requirements of your system. These insulators are designed to align perfectly with the physical constraints and performance needs of a given setup. This level of customization ensures a better fit, easier installation, and optimized function — all of which directly contribute to reducing downtime.

For example, in outdoor substations where high moisture and pollution levels are common, using a custom outdoor support insulator with enhanced tracking and erosion resistance can prevent flashovers and failures, which in turn keeps your system running smoothly.

Benefits of Custom Epoxy Insulators in Reducing Downtime

1. Enhanced Mechanical Strength

Custom epoxy insulators can be designed to meet specific load-bearing requirements. This is particularly important in environments where insulators must support heavy conductors or be mounted in positions that experience vibration or mechanical stress. A poorly designed insulator may crack under pressure, leading to system failures. A custom made support insulator, on the other hand, can be engineered with reinforced resin systems to handle extreme loads, reducing the risk of breakdowns.

2. Optimized Thermal Performance

Epoxy resin insulators offer excellent thermal resistance. However, in applications involving high current or elevated ambient temperatures, a standard insulator might degrade over time. A customized epoxy insulator manufacturer in India like Radiant Enterprises can create insulators with specific thermal ratings and formulations that maintain integrity even under prolonged high-temperature exposure. This leads to a longer lifespan and fewer unexpected shutdowns.

3. Improved Dielectric Properties

By customizing the composition and design, cast resin post insulators can be made to exhibit superior dielectric strength. This minimizes the risk of partial discharge or electrical arcing, both of which are common causes of equipment failure and subsequent downtime. Customization also allows for the inclusion of features like embedded electrodes or shielding to manage field stress, thereby boosting operational reliability.

4. Resistance to Environmental Stressors

Outdoor environments expose insulators to UV radiation, moisture, dust, and pollutants. A custom outdoor support insulator can be treated with special coatings or additives that resist these stressors, preventing surface degradation and flashover incidents. This customization ensures consistent performance regardless of weather conditions, reducing the need for frequent maintenance or unexpected repairs.

5. Faster Installation and Maintenance

A custom made support insulator is typically designed for easy integration into your existing setup. This means faster installation with fewer adjustments, and in many cases, plug-and-play compatibility. When maintenance is required, modular or standardized custom designs can facilitate quick replacement, further minimizing system downtime.

youtube

Applications Where Custom Epoxy Insulators Make a Difference

Power Generation and Distribution

Power plants and substations rely on cast resin post insulators to ensure safe and efficient energy flow. Custom insulators reduce arcing and withstand high fault currents, making them indispensable for preventing system disruptions.

Railways and Transportation

Electrified rail networks, especially high-speed systems, require outdoor support insulators that can handle dynamic loads and vibrations. Customization allows the design to meet the specific needs of traction and auxiliary power systems.

Renewable Energy Systems

Solar and wind installations often face harsh environmental conditions. Customized epoxy insulator manufacturers in India like Radiant Enterprises offer insulators that can operate reliably in saline, humid, or dusty environments without performance loss.

Industrial Automation and Switchgear

In automation panels and switchgear, space constraints are a major challenge. Custom epoxy insulators are compact and can be molded to fit snugly into tight spaces while still meeting the necessary voltage and mechanical specifications.

Why Choose Radiant Enterprises?

Radiant Enterprises is one of the leading customized epoxy insulator manufacturers in India, known for our focus on quality, performance, and client-specific solutions. Here is what sets us apart:

Tailored Solutions: Every insulator is custom-engineered based on your technical drawings or system requirements.

High-Grade Materials: We use premium epoxy resins and fillers to ensure durability and high performance.

In-House Testing: All insulators undergo rigorous mechanical, thermal, and electrical testing before dispatch.

Wide Application Range: From cast resin post insulators to outdoor support insulators, we cater to diverse industries.

With decades of experience and a dedicated R&D team, we ensure that each product contributes to your system’s uptime, efficiency, and safety.

Conclusion

The impact of custom epoxy insulators on reducing downtime in electrical systems cannot be overstated. From enhanced mechanical strength and thermal performance to superior environmental resistance, the benefits are clear. When sourced from reputed customized epoxy insulator manufacturers in India like Radiant Enterprises, these components offer unmatched reliability and longevity.

Investing in custom made support insulators, whether it is for cast resin post insulator needs or robust outdoor support insulator applications, is a proactive step toward building a more resilient and efficient electrical infrastructure.

Let Radiant Enterprises be your trusted partner in creating customized insulator solutions that not only meet but exceed your expectations. Contact us today to learn more about our product offerings and how we can help optimize your systems for uninterrupted performance.

#Custom made support insulator#Epoxy insulator#Customized epoxy insulator manufacturers in India#Cast resin post insulator#Outdoor support insulator#United States of America#USA#Youtube

5 notes

·

View notes

Text

How High-Quality Low-Voltage Switchgear Accessories Save You Money!

One of the main goals of industrial power systems is to cut costs without sacrificing performance.

Upgrading your low-voltage switchgear accessories is one frequently disregarded method to accomplish this.

Let’s discuss how purchasing high-quality switchgear accessories can extend the life of your electrical infrastructure, reduce operating costs, and boost system performance in this guide.

What Are Low-Voltage Switchgear Accessories?

Low-voltage switchgear accessories are parts that improve how well your electrical switchgear systems work, keep them safe, and make them reliable. These include:

- Circuit breakers

- Contactors

- Busbar systems

- Surge protection devices (SPDs)

- Control relays

- Communication and monitoring modules

They offer power distribution, fault protection, and real-time system monitoring and are therefore crucial in industrial automation and energy management.

1. Minimize Downtime and Improve Productivity

Cheap, low-quality parts are likely to break down, grinding work to a standstill. Every hour of unscheduled downtime at a plant equals lost work and income.

✅ Advantage:

The superior switchgear elements can withstand more load, function through more switch cycles, and withstand more demanding conditions. It guarantees power flows smoothly at all times and decreases the possibility of shutdowns.

2. Extend the Lifespan of Equipment

Switchgear accessories form the first line of defense for your equipment. Low-quality accessories will let surges or faults pass through and can destroy costly equipment like motors, drives, and PLCs.

✅ Advantage

Stable components such as motor protection relays and surge protection devices maintain voltage levels constant and prevent overloads, thus safeguarding equipment downstream of them.

3. Reduce Maintenance and Replacement Costs

Sustained maintenance, breakdown calls, and replacement components are costly over time. Cheap parts fail early, thereby adding to your maintenance load.

✅ Advantage:

Purchasing robust, low-maintenance accessories translates to fewer services and repairs, which results in overall savings.

4. Improve Energy Efficiency

Loss of power and energy inefficiency typically start with old or badly designed switchgear devices. Even small problems within a big system can lead to higher energy bills.

✅ Advantage:

Good-quality accessories provide the highest conductivity and proper switching, allowing for optimal voltage output maintenance and avoiding energy wastage.

5. Enhance Electrical Safety and Regulatory Compliance

Faulty accessories are a main cause of electrical fire and safety hazards. Substandard systems can also fail to meet industry standards.

✅ Advantage:

Good quality switchgear parts typically conform to IEC, UL, or other important standards for safe functioning and regulatory compliance.

Conclusion: Small Components, Big Savings

Cheap accessories can appear to be a good deal initially but can turn out to be costly over time. Employing quality low-voltage switchgear accessories guarantees that:

- Less system crashes

- Equipment lasts longer

- Reduced maintenance

- Reduced energy costs

- Safer operations

Looking for Reliable Low-Voltage Switchgear Accessories?

At Almond Enterprise, we specialize in supplying industrial-grade switchgear components that deliver long-term performance and value.

Contact Our Experts: [email protected] for tailored recommendations

7 notes

·

View notes

Text

Top 5 Industrial Automation Low-Voltage Switchgear Accessories You Need to Utilize

Stable and proper electrical systems are most important in industrial automation, and low-voltage switchgear is one of the most important elements that connects these systems. However, to reach the best performance, safety, and lifespan, the correct accessories for low-voltage switchgear need to be selected.

In this article, we will discuss the 5 must-have low-voltage switchgear accessories that industrial automation requires to run at its optimum and be less down.

1. Circuit Breakers – Protection and Safety from Overloading

Circuit breakers are the most important devices of low-voltage switchgear equipment. Circuit breakers safeguard electric circuits from problems like short circuits, overloads, and faults by breaking power supply to the circuit when they detect abnormal conditions.

Why They Are Important?

- Protect equipment from electrical fire and damage.

- Comply with industry safety standards.

- Recover quickly from a fault.

Recommendation: Use high-level circuit breakers with remote monitoring and diagnostic capabilities to improve automation efficiency.

2. Surge Protection Devices (SPDs) – Voltage Spike Protection

Voltage spikes and transients destroy electrical equipment in automation systems. SPDs function by absorbing excess voltage, thereby safeguarding sensitive hardware.

Why They Are Important?

- Reduce electrical surge downtime.

- Protect the automatic equipment and control panel from damage.

- Extend the life of electrical equipment.

Pro Tip: Install SPDs with real-time sensing sensors. That way, you can detect and fix voltage problems as they occur.

3. Busbar Systems – More Efficient Power Distribution

A busbar system is important since it allows the transmission of electrical energy more efficiently in switchgear setups. Busbars conduct better, lose less energy, and work better with systems than regular wiring.

Why They Matter?

- Simplified and less costly wiring installation.

- Minimization of energy losses by reducing the power loss.

- Simple extension to and integration with automated systems.

It is suggested that insulated busbar systems shall be employed for safety and to prevent accidental short circuits.

4. Motor Protection Relays – Intelligent Monitoring for Motors

Electric motors are a fundamental component of industrial automation. Motor protection relays safeguard motors against overloading, phase imbalance, and overheating to enable motors to run faultlessly and continuously.

Why Are They Important?

- Prevent costly motor failure and operational downtime.

- Allow remote monitoring for easy predictive maintenance. - Improve operational efficiency with auto-reset.

Tip: Incorporate programmable motor protection relays with automation systems for real-time monitoring and control.

5. Remote Monitoring and Control Devices – Increasing Automation Scope

New businesses must monitor switchgear remotely to be efficient and have low maintenance costs.

Remote monitoring devices allow operators to monitor voltage levels, power consumption, and system status from a distance.

Why Are They Important?

- Perform routine maintenance to avoid unexpected breakdowns.

- Require fewer resources and time to reduce manual inspections.

- Increase system reliability with real-time fault notifications.

Pro Tip: Implement IoT-enabled remote monitoring systems for easy integration with industrial automation systems.

Final Thoughts:

Buy good quality low-voltage switchgear accessories when you purchase them for safety, performance, and efficiency in industrial automation.

Circuit breakers, surge protective devices, busbar systems, motor protection relays, and remote monitoring systems will help you to ensure a healthy and strong electrical system.

10 notes

·

View notes