#Electrical Industry

Text

Elevate Your Electrical Systems with Radiant Enterprises – Premier Epoxy Insulator Manufacturers in India

Discover excellence in insulation solutions with Radiant Enterprises, the leading Epoxy Insulator manufacturer and exporter in India. Our commitment to quality extends to customized solutions, making us the preferred choice for tailored Epoxy Insulators that meet the unique needs of diverse industries. Trust Radiant Enterprises for superior craftsmanship, reliability, and innovation in every customised Epoxy Insulator manufacturer in India. Your electrical systems deserve the best, choose Radiant for unmatched quality and performance. With a legacy of precision engineering and a global footprint, we are dedicated to providing Epoxy Insulators that set the industry standard for durability and efficiency.

Partner with us for cutting-edge solutions that power a sustainable and connected future.

#Epoxy Insulator#Epoxy Insulators Manufacturers in India#Customised Epoxy Insulators Manufacturers in India#Epoxy Insulator Manufacturers in India#electrical company#electrical engineering#electrical industry#exportquality#innovativeinsulators#India

7 notes

·

View notes

Text

Medium voltage support insulator manufacturers in India | radiantenterprises

Elevate your electrical solutions with Radiant Enterprises, a top name among customised insulator manufacturers in India. Specializing in high-quality epoxy insulators, we cater to the specific needs of your projects with precision and expertise. As leading medium voltage support insulator manufacturers in India, we provide durable and reliable products that meet the highest industry standards.

Trust Radiant Enterprises for innovative and customized insulator solutions designed to enhance the performance and safety of your electrical systems.

#Epoxy insulator#Customised insulator manufacturers in India#Medium voltage support insulator manufacturers in India#epoxy bushing#epoxy insulator#epoxy resin#electrical company#electrical engineering#electrical industry#fuse cutouts#smart grid sensor#rail insulator#railway technology companies#train operating companies#locomotive#tramways#metro systems#traffic infrastructure#third rail#cable connector#innovative insulators#export quality

4 notes

·

View notes

Text

Market Dynamics in the Distribution Transformer Industry: Challenges and Opportunities

According to a new report published by Allied Market Research, the distribution transformer market size was valued at $25.2 billion in 2023, and is estimated to reach $47.5 billion by 2033, growing at a CAGR of 6.6% from 2024 to 2033.

A distribution transformer industry is a crucial component in electrical power systems, responsible for stepping down the voltage from the high levels used in transmission to the lower levels suitable for distribution to consumers. One of the primary functions of a distribution transformer is voltage transformation. It reduces the high voltage from the transmission system to a lower voltage suitable for distribution.

Asia-Pacific is the fastest growing segment in the distribution transformer market. Many countries in the Asia Pacific region are experiencing rapid urbanization, leading to increased demand for electricity in urban areas. Distribution transformers play a crucial role in delivering electricity from transmission grids to urban centers and industrial zones, meeting the growing energy needs of urban populations.

Several countries in the Asia Pacific region, such as Japan, South Korea, and Australia, are actively integrating renewable energy sources like solar and wind power into their electrical grids. Distribution transformers are essential for efficiently distributing electricity generated from these intermittent renewable sources to consumers, contributing to the region's energy transition.

The major players operating in the distribution transformer industry growth include ABB, Siemens, Schneider Electric, Eaton, General Electric Company, HD HYUNDAI ELECTRIC CO., LTD, Fuji Electric Co., Ltd., Toshiba Corporation, Padmavahini Transformers Private Limited, and Lemi Trafo Jsc.

Commercial establishments, such as offices, retail stores, and schools, also rely on distribution transformers to provide electricity for lighting, heating, cooling, and other electrical loads. These transformers are installed indoors or outdoors, depending on factors such as space availability and safety considerations.

In the industrial sector, distribution transformers play a critical role in powering manufacturing plants, refineries, data centres, and other industrial facilities. These transformers are typically larger and more robust than their residential and commercial counterparts, as they need to handle higher loads and operate under more demanding conditions. They are customized to meet the specific voltage and power requirements of industrial equipment and machinery.

The electrification of heating and cooling systems is expected to drive the growth of distribution transformer market. Electric heating and cooling systems, such as heat pumps and electric air conditioners, draw power from the electrical grid to provide heating and cooling services.

As more households and buildings adopt these electric alternatives to traditional fossil fuel-based systems, the overall demand for electricity rises. This increased demand places greater strain on the distribution infrastructure, including distribution transformers.

Heating and cooling systems often operate during peak demand periods, particularly during extreme weather conditions when heating or cooling needs are most significant.

Distribution transformers must be capable of handling these peak loads without overheating or experiencing voltage fluctuations. Higher efficiency transformers and those with greater thermal capacity are required to meet these demands effectively.

According to the Energy Information Administration, major electricity utilities in the U.S. spent $15.87 billion on transmission operations in 2022, up from $6.94 billion in 2010. The distribution network budget has grown from $3.64 billion in 2010 to $5.97 billion in 2022.

Power delivery spending has continuously climbed as utilities replace aging equipment and build transmission infrastructure to handle new renewable generation.

Distribution transformers are subject to various international standards and regulations to ensure their safety, reliability, and performance.

Organizations such as the International Electrotechnical Commission (IEC), the Institute of Electrical and Electronics Engineers (IEEE), and national regulatory bodies set standards and guidelines for the design, testing, and operation of transformers to ensure compliance with quality and safety requirements.

By product type, the underground vault segment is the fastest growing segment representing 7.0% of CAGR in the market during the forecast period.

By power rating more than 10,000 kVA is the fastest growing segment growing with the CAGR of 7.2% during the forecast period in the distribution transformer market share.

By phase type, three phase is the highest revenue contributor accounting for more than half of the distribution transformer market share.

By end-use, residential is the fastest growing segment representing 7.4% CAGR in the market from 2024-2033.

About Us

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

Pawan Kumar, the CEO of Allied Market Research, is leading the organization toward providing high-quality data and insights. We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

0 notes

Text

Plastic solid tubes, Plastic Cheese or Cylinders, Polypropylene Tubes

Manufacturer, Supplier and Exporter of Plastic solid tubes, Plastic Cheese or Cylinders, Polypropylene Tubes, cheese tubes are available in different weights and dimensions in Sangli, India.

Plastic Solid Cones, Perforated Dye Tubes, Perforated Dye Cones, Plastic Yarn Carriers, Textile industry, Spinning, Twisting, Texturizing, Yarn Dyeing & Carpet Industry, Injection Moulded products, Corrugated Pipe Industry, Electrical Industry, Manufacturer, Supplier and Exporter, Sangli, Maharashtra, India.

#Plastic Solid Cones#Perforated Dye Tubes#Perforated Dye Cones#Plastic Yarn Carriers#Textile industry#Spinning#Twisting#Texturizing#Yarn Dyeing & Carpet Industry#Injection Moulded products#Corrugated Pipe Industry#Electrical Industry#Manufacturer#Supplier and Exporter#Sangli#Maharashtra#India

0 notes

Text

Explore how Digital Twin Technology is transforming mobile apps and software systems to predict and prevent equipment failures in mechanical and electrical systems. Learn about its practical applications and advantages.

#Digital Twin Technology#Mobile Apps#Software#Software Development#Mobile App Development#Mechanical Industry#Electrical Industry#Electrical Systems#Mechanical Systems

0 notes

Video

youtube

Top 5 Good Design Steel Cabinet Frame Machine for Electrical Industry

#youtube#electronic#electrical industry#steel frame#metal parts#engineer#factory#technology#design for electrical industry

0 notes

Text

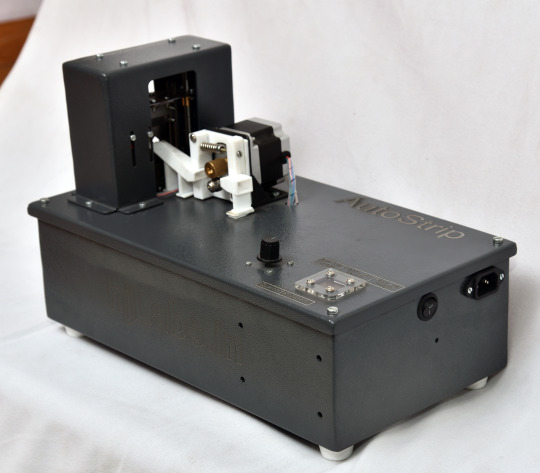

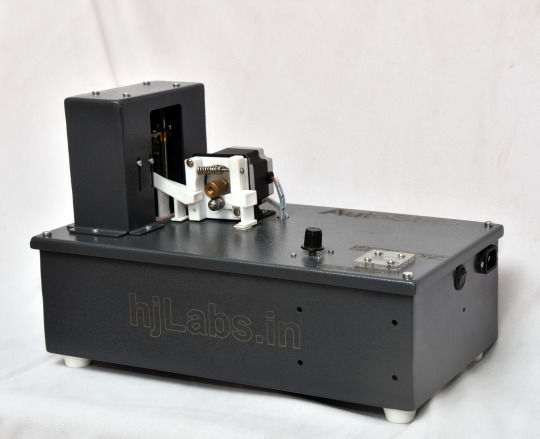

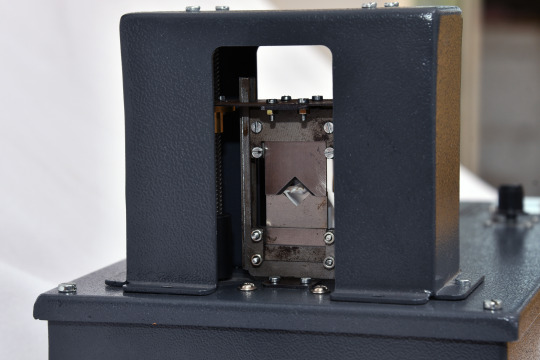

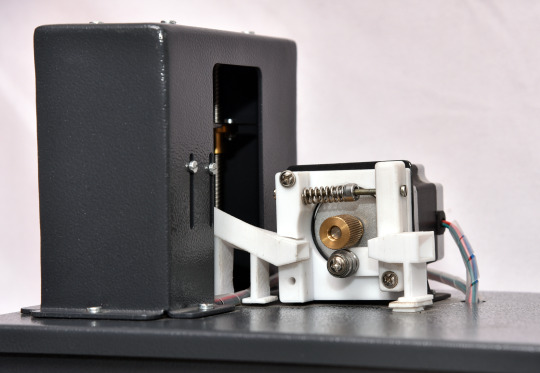

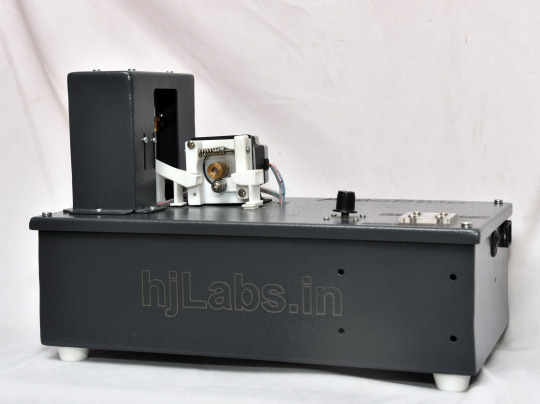

🔌 Ultimate Cable Processing Machine | Boost Efficiency & Precision! Discover the Future Today!

Experience unmatched efficiency with our 🚀 Auto Wire Cutting & Stripping Machine. Say goodbye to manual labor with our 🔧 #InnovativeTool. Ideal for electrical, automotive, and telecommunications industries.👩🔧👨🏭. For purchases, message us on WhatsApp or Telegram at 📱 +917016525813. Buy now : https://hjlabs.in/product/%f0%9f%94%8c-industrial-wire-cable-cutting-stripping-machine-precision-automatic-cutter-for-efficient-production/ #WireStripper #AutomationTech #ElectricalTools #TimeSaver 🎯 https://youtu.be/hi66O8-YRXs https://www.youtube.com/watch?v=MlTAD-kieaw 3d Design and Code files on grabcad : https://grabcad.com/library/automatic-wire-cutter-and-stripper-machine-1 only cutting machine : https://www.youtube.com/watch?v=TzW5WMWv-x8 Acrylic version : https://www.youtube.com/watch?v=bnWMskTA5V4 https://linktr.ee/hemangjoshi37a WhatsApp & Telegram : +917016525813 Email : [email protected] Place a custom order on hjLabs.in : https://hjLabs.in ----------------------------------------------------------------------------- Checkout Awesome Videos : SWiBoard - A Killer Gadget to Boost Your Boring Switchboard : https://youtu.be/BrakSGmQZB8 રુધિર વહીનીઓ અને એના કર્યો. : https://youtu.be/T7mMcEYNKyQ મનુષ્યમાં પરિવહન તંત્ર | परिसंचरण तंत्र : https://youtu.be/vxa6o_wrWnY હદય અને હદયના ધબકારા : https://www.youtube.com/watch?v=9v3MK6oTOeA AutoCut V2 - Automatic Wire Cutting Machine : https://www.youtube.com/watch?v=bnWMskTA5V4 મનુષ્યમાં ઉત્સર્જન-તંત્ર : https://www.youtube.com/watch?v=UUGI-CFKsWI

#industrial wire cutter#cable stripping machine#automatic cable cutter#precision wire processing#efficiency#manufacturing equipment#automation#wire and cable industry#quality control#productivity#industrial technology#wire cutting technology#cable stripping equipment#industrial automation#electrical industry#manufacturing solutions#wire processing machinery#cutting-edge tools#automation benefits#production efficiency#cable management#wire manufacturing

1 note

·

View note

Text

electrical wires again, edited by me

2K notes

·

View notes

Text

Explosion-proof Circuit Breaker Market Share, Size, Type, Demand, Overview Analysis, Trends, Opportunities, Key Growth, key points, Development and Forecasts by 2032

Market Overview:

The explosion-proof circuit breaker market refers to the segment of the circuit breaker market that caters to hazardous or potentially explosive environments. Explosion-proof circuit breakers are designed to prevent the ignition of flammable gases, dust, or other hazardous substances in order to ensure the safety of personnel and equipment in such environments.

The global Circuit Breaker market size was valued at USD 5427.73 million in 2021-2022 and is expected to expand at a CAGR of 6.91% during the forecast period, reaching USD 8105.33 million by 2030.

Key Factors: Several key factors are driving the growth of the explosion-proof circuit breaker market:

severe safety laws: Businesses operating in risky areas, such as those in the oil and gas, chemical, mining, and manufacturing sectors, must adhere to severe safety laws. To reduce the risk of explosions and guarantee worker safety, these standards require the use of explosion-proof circuit breakers.

Industrialization and infrastructure development are progressing at an accelerated rate, which is driving up demand for explosion-proof circuit breakers. Businesses in hazardous environments including oil refineries, power plants, chemical plants, and mining activities need effective circuit protection solutions.

Technological developments: The market for explosion-proof circuit breakers has grown as a result of the development of sophisticated technologies in circuit protection, such as improved arc quenching mechanisms and improved insulating materials.These technical developments provide improved performance and dependability in risky circumstances.

Demand: The increased focus on safety in dangerous areas is predicted to drive up demand for explosion-proof circuit breakers. Explosion-proof circuit breakers are being adopted by industries across all sectors, including oil and gas, chemical, mining, and manufacturing, in order to adhere to safety laws and safeguard their operations.

Explosion-proof circuit breakers that meet the strict safety standards and regulations of diverse industries should be the primary focus of manufacturers and suppliers in this industry. To meet the changing needs of the market, they should also emphasise the strength, dependability, and simplicity of maintenance of their products.

Referrals to our Stringent datalytics, trade journals, and websites that focus on market reports are encouraged. These sources frequently include thorough research, market trends, growth projections, competition analysis, and other insightful information about this market.

You can investigate the availability of particular reports linked to this market by going to our website or getting in touch with us directly. We offer thorough and in-depth information that might be helpful for firms, investors, and individuals interested in this industry, but these reports frequently need to be purchased or subscribed to.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/explosion-proof-circuit-breaker-market/10057/

Market Segmentations:

Global Explosion-proof Circuit Breaker Market: By Company

• Phoenix Contract

• Connecticut Electric

• Murrelektronik

• Eaton

• Siemens

• ABB

• Culter-Hanmmer

• Westinghouse

• Schneider

• Blue Sea Systems

• IDEC

• Carling Technologies

• Bussman

• AudioPipe

• Buyers Products

• ITE

• Panduit

• Powerwerx

• Stinger

• Federal Pacific

• Murray Feiss

Global Explosion-proof Circuit Breaker Market: By Type

• High Voltage

• Medium Voltage

• Low Voltage

Global Explosion-proof Circuit Breaker Market: By Application

• Petrochemical

• Military Industry

• Others

Global Explosion-proof Circuit Breaker Market: Regional Analysis

The regional analysis of the global Explosion-proof Circuit Breaker market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Explosion-proof Circuit Breaker market report are as follows:

North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Explosion-proof Circuit Breaker in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product.

Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Explosion-proof Circuit Breaker in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors.

Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Explosion-proof Circuit Breaker in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction.

Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors.

South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Explosion-proof Circuit Breaker in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/explosion-proof-circuit-breaker-market/10057/

Reasons to Purchase Explosion-proof Circuit Breaker Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can assist companies in assessing market opportunities, such as those presented by possible new goods or services, emerging markets, and trends..

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Explosion-proof Circuit Breaker Market#Breakers#Market Dynamics#Safety Regulations#Equipment Protection#Industrial Automation#Oil and Gas Industry#Chemical Industry#Mining Sector#Process Industries#Electrical Infrastructure#Electrical Components#Risk Mitigation#Market Forecast#Industry Insights#Electrical Industry#Safety Standards#Electrical Systems#Power Distribution#Electrical Control#Circuit Breaker Technologies#global research market report

0 notes

Text

Cable Paper: The Hidden Hero Behind Reliable Electrical Connections

In the realm of electrical connections, there exists a silent hero, often overlooked but indispensable in ensuring uninterrupted power flow and reliable performance. Enter cable paper, the unsung champion that forms the backbone of secure electrical connections. Join us as we unveil the incredible story of Cable Paper and its vital role in maintaining the integrity of your electrical systems.

Reliability is the cornerstone of any electrical infrastructure, and behind every dependable connection lies cable paper. Developed through years of innovation and expertise, cable paper acts as a shield, protecting delicate electrical components from environmental factors such as moisture, temperature variations, and mechanical stress. As you explore the remarkable world of cable paper, you'll soon realize why it's a hidden hero deserving of recognition.

Moisture, the arch-nemesis of electrical systems, can wreak havoc on their performance and longevity. Cable paper, with its exceptional moisture resistance properties, acts as a barrier, preventing water intrusion and safeguarding your connections against corrosion and short circuits. This ensures your electrical infrastructure remains robust and reliable even in challenging environments.

Temperature fluctuations can pose significant risks to electrical connections, causing expansion and contraction that may compromise their integrity. However, cable paper's remarkable thermal insulation properties provide a vital defense against such temperature variations. By minimizing the effects of heat or cold, cable paper helps maintain consistent electrical performance, thereby enhancing the longevity of your systems.

The world is constantly in motion, and electrical connections often face the brunt of mechanical stress. Here, cable paper demonstrates its strength and resilience. Acting as a cushion, cable paper absorbs vibrations and shock, shielding delicate electrical components from damage and ensuring their longevity. This reliability is crucial, especially in applications such as automotive, aerospace, and industrial sectors, where high-stress environments are commonplace.

At OWCable you'll find a comprehensive range of cable paper products meticulously designed and engineered to meet the demands of modern electrical applications. With a commitment to quality, performance, and customer satisfaction, OWCable stands at the forefront of cable paper innovation. Their products not only meet industry standards but also surpass them, giving you peace of mind and the assurance of exceptional electrical connections.

Conclusion:

Next time you flick a switch or power up a device, remember the silent hero working tirelessly behind the scenes: cable paper. With its moisture resistance, thermal insulation, and mechanical protection properties, cable paper ensures the reliability and longevity of your electrical systems. Visit https://www.owcable.com/cable-paper-product/ to explore the remarkable world of cable paper and discover how it can elevate the performance of your electrical connections to new heights. Trust the hidden hero to keep your power flowing smoothly, consistently, and reliably.

0 notes

Text

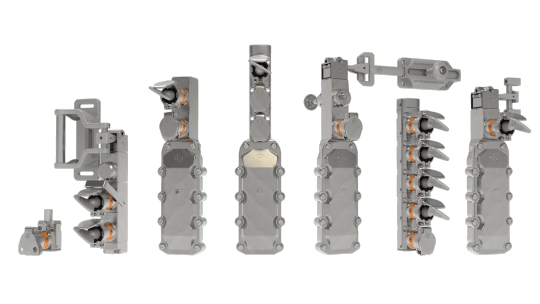

Powering the Future of Railways: A Comprehensive Guide to Connectors for Railway Traction

In the context of global advancements towards sustainable and efficient transportation alternatives, there is a notable resurgence in the prominence of railways. The utilisation of railways as a primary means of transportation for both passengers and freight is on the rise, mostly due to the advantageous environmental attributes and cost-efficiency associated with this method of transport. The complex technology that drives modern railway systems is crucial for their performance, with a key element being the connectors employed for railway propulsion. Reliability you can depend upon. Elevate your railway systems with premium railway traction connectors manufactured and supplied by Radiant Enterprises - one of the distinguished Railway Traction Connectors manufacturers in India!

This thorough guide aims to provide an in-depth analysis of railway traction connectors, examining their importance, various types, advantages, and potential prospects in the future. A comprehensive grasp of these connectors is imperative for individuals engaged in the railway sector, as they assume a crucial function in propelling the advancement of trains and cultivating an environmentally friendly transportation infrastructure.

The Importance of Railway Traction Connectors:

This thorough guide aims to provide an in-depth analysis of railway traction connectors, examining their importance, various types, advantages, and potential prospects in the future. A comprehensive grasp of these connectors is imperative for individuals engaged in the railway sector, as they assume a crucial function in propelling the advancement of trains and cultivating an environmentally friendly transportation infrastructure.

Types of Railway Traction Connectors:

· Pantographs:

Pantographs represent the prevailing form of connectors employed in electric trains. The pantographs, located on the train's roof, establish a connection with the overhead wires, facilitating the transfer of electrical power to the train. Contemporary pantographs are outfitted with advanced sensors and control systems, enabling them to adjust to fluctuating voltage levels and maintain a consistent power provision.

· Third Rail Collectors:

The utilisation of a third rail as a power source is observed in certain railway systems, where trains derive electrical energy from an additional rail positioned adjacent to the tracks. Third-rail collectors are dynamic connectors that establish an electrical connection by sliding and making contact with the third rail. This approach is commonly observed in specific urban transport networks owing to its straightforwardness and economical nature.

Benefits of Advanced Railway Traction Connectors:

· Enhanced Efficiency:

Contemporary connections utilised in railway traction systems are engineered with the objective of minimising power losses during gearbox, hence leading to enhanced energy efficiency. The achievement of efficient power transmission results in a decrease in energy consumption and a reduction in operating expenses for railway operators.

· Reliability and Safety:

The utilisation of premium materials and cutting-edge engineering in the production of connectors guarantees a dependable and secure electrical linkage, hence enhancing reliability and safety. This improves the dependability and security of railway operations, hence mitigating the likelihood of power disruptions and incidents.

· Reduced Maintenance:

Connector designs that are more advanced sometimes possess self-cleaning capabilities, hence aiding in the prevention of the accumulation of dirt, debris, and ice on the contact surfaces. The implementation of this self-cleaning technology results in a reduction in maintenance demands and a decrease in downtime, hence enhancing operational availability.

· Sustainability:

The utilisation of electric trains, which are fueled by renewable energy sources, plays a substantial role in mitigating greenhouse gas emissions and addressing the issue of climate change. The utilisation of high-quality traction connectors is of paramount importance in expediting the acceptance and implementation of sustainable transportation systems.

The Future of Railway Traction Connectors:

The ongoing progress of technology will inevitably lead to the further development of railway traction connectors. Transform railway electrification with the advanced Railway Traction Connectors supplied by Radiant Enterprises. Request a sample today!

· Smart Connectivity:

The integration of the Internet of Things (IoT) and Industry 4.0 has led to the expectation that railway traction connectors will contain intelligent functionalities. The utilisation of real-time data monitoring and analytics has the potential to facilitate predictive maintenance, hence enhancing the efficiency and durability of the connectors.

· Lightweight and Durable Materials:

The field of material science has the potential to facilitate the creation of connector materials that possess both lightweight properties and exceptional durability. This may potentially result in a reduction in the overall weight of trains, hence enhancing their energy efficiency.

· High-Speed Rail:

The global demand for high-speed rail networks is experiencing a notable increase. In order to facilitate the operation of faster trains while ensuring safety and efficiency, future traction connectors will be required to accommodate elevated levels of voltage and current.

· Wireless Charging:

Wireless charging technology is now being investigated by researchers as a potential solution for trains. Potential future connectors have the potential to integrate wireless charging capabilities, hence obviating the necessity for direct physical contact between the train and the power source.

Final Thoughts:

The railway industry is positioned to assume a crucial role in influencing the trajectory of sustainable transport in the future. In order to realise this vision, the utilisation of modern technology, such as railway traction connectors, will play a pivotal role. As we progress, allocating resources towards research and development in order to create inventive and dependable connector solutions will not only propel the future of railway systems but also make a significant contribution towards a more environmentally friendly and efficient global landscape. The ongoing advancement of connector technology holds promise for the development of a more environmentally sustainable and interconnected railway system that will benefit future generations. Explore the optimal solution for your railway projects. Explore a diverse range of railway traction connectors offered by Radiant Enterprises - one of the trusted Railway Traction Connectors manufacturers in India!

#Railway Traction Connectors Manufacturers in India#Railway traction connectors#electrical#business#electrical company#electrical industry#smart grid sensor#rail insulator#railway#railway technology companies#train operating companies#locomotive#tramways#third rail#cable connector

10 notes

·

View notes

Text

Pioneering excellence in cycloaliphatic epoxy insulators | radiantenterprises

Discover the epitome of reliability and innovation with Radiant Enterprises, India's foremost manufacturer of epoxy insulators. As leaders in the transmission and distribution sector, we specialize in crafting high-quality cycloaliphatic epoxy insulators tailored to meet the unique needs of India's energy infrastructure. With a commitment to excellence, Radiant Enterprises stands as the top choice for the best insulator solutions nationwide. Experience unmatched durability, performance, and reliability with our cutting-edge products, setting new standards in the industry.

Choose Radiant Enterprises for superior quality and unwavering dependability in every insulator.

#Epoxy insulator#Transmission and distribution manufacturers in India#Cycloaliphatic epoxy insulators manufacturer in India#Best insulator manufacturers in India#electrical company#electrical engineering#electrical industry#innovative insulators

4 notes

·

View notes

Text

5 Ways To Grow Your Electrical Business!

Ready to take your Electrical Business to unprecedented heights? This blog presents an enlightening piece that outlines 5 ways to dominate the Electrical Industry. Gain a competitive edge by focusing on customer retention and ensuring exceptional service delivery. Embrace business development tactics that foster long-term growth and profitability. Harness the power of marketing tips to enhance your brand visibility and appeal. This blog leaves no stone unturned, offering a holistic approach to fueling your Electrical Business's expansion. Elevate your market position, attract new opportunities, and thrive in the Electrical Industry with these 5 tried-and-tested growth techniques

1 note

·

View note

Text

Plastic Cone, Plastic Solid Cones Manufacturer in India

Manufacturer, Supplier and Exporter of Plastic Cone, Plastic Solid Cones for Textile Industry in Sangli, Maharashtra, India.

Plastic Cone, Plastic Solid Cones, Perforated Dye Tubes, Perforated Dye Cones, Plastic Yarn Carriers, Textile industry, Spinning, Twisting, Texturizing, Yarn Dyeing & Carpet Industry, Injection Moulded products, Corrugated Pipe Industry, Electrical Industry, Manufacturer, Supplier and Exporter, Sangli, Maharashtra, India.

#Plastic Cone#Plastic Solid Cones#Perforated Dye Tubes#Perforated Dye Cones#Plastic Yarn Carriers#Textile industry#Spinning#Twisting#Texturizing#Yarn Dyeing & Carpet Industry#Injection Moulded products#Corrugated Pipe Industry#Electrical Industry#Manufacturer#Supplier and Exporter#Sangli#Maharashtra#India

0 notes

Text

Unleashing the Potential of Oxygen-Free Copper: Revolutionizing High-Performance Applications

Oxygen-free high-conductivity copper is another name for oxygen-free copper. A class of wrought copper alloys known as oxygen-free copper is refined using an electrolytic process and exhibits excellent conductivity. In particular, electrolytic refining is required to reduce the oxygen concentration to or below 0.001%.

Makers are focused on item testing to make sure that production programs,…

View On WordPress

#advanced metal#aerospace industry#automotive applications#circuit boards#conductivity#copper alloys#corrosion resistance#electrical industry#Electronics#heat exchangers#high-performance materials#market trends#metal fabrication#oxygen-free copper#power transmission#reliability#renewable energy#telecommunications

0 notes

Text

What is Cable Gland?

A cable gland is a device used to secure and protect the end of an electrical cable or wire where it enters an enclosure or piece of equipment. The cable gland provides a seal around the cable, preventing the ingress of dust, dirt, moisture, and other contaminants into the enclosure or equipment.

Cable glands come in various sizes and materials, and are often made of metal, plastic, or rubber. They typically consist of a threaded cylinder that screws onto the outside of the enclosure or equipment, a compression ring that secures the cable, and a sealing element that provides the waterproof seal.

Usage of Cable Gland:

The main usage of a cable gland is to provide a secure and reliable method for routing and connecting electrical cables through an enclosure or piece of equipment. Here are some of the key uses of cable glands:

Protecting cables from environmental factors: Cable glands are used to protect cables from various environmental factors such as dust, dirt, water, and other contaminants. This helps to ensure the safe and reliable operation of the electrical system.

Providing strain relief: Cable glands provide strain relief to cables, which helps to prevent damage to the cable caused by pulling or twisting forces. This can help to extend the life of the cable and prevent premature failure.

Creating a seal: Cable glands create a seal around the cable, preventing moisture, dust, and other contaminants from entering the enclosure or equipment. This can help to prevent corrosion, short circuits, and other issues that can affect the performance of the electrical system.

Meeting safety standards: Cable glands are often required to meet certain safety standards in order to ensure that the electrical system is safe and compliant with regulations. For example, explosion-proof cable glands are required in hazardous environments to prevent sparks or flames from escaping through the cable entry point.

Providing grounding: Some cable glands are designed to provide grounding for the cable, which can help to protect against electrical interference and reduce the risk of electrical shock.

Overall, cable glands are a critical component of many electrical systems, providing a secure, reliable, and safe method for routing and connecting cables through enclosures or equipment.

Types of Cable Glands?

PVC Gland: A PVC gland is a type of cable gland that is made from polyvinyl chloride (PVC) material. PVC glands are commonly used in indoor applications and provide good resistance to moisture, chemicals, and UV light. They are generally less expensive than other types of cable glands but may not be suitable for outdoor or harsh environments.

Nylon cable gland: Nylon cable glands are made from a type of thermoplastic material called nylon. They are lightweight, durable, and provide good resistance to chemicals, oil, and UV light. Nylon cable glands are commonly used in outdoor applications and are suitable for a wide range of cable sizes.

Polyamide cable gland: Polyamide cable glands are similar to nylon cable glands in terms of their material and properties. They are commonly used in harsh environments where there is exposure to extreme temperatures, chemicals, and UV light. Polyamide cable glands provide good mechanical strength and are available in a wide range of sizes.

Metallic cable gland: Metallic cable glands are made from materials such as brass, stainless steel, or aluminum. They provide good mechanical strength, resistance to corrosion, and are suitable for use in harsh environments. Metallic cable glands are commonly used in industrial applications and may be required in certain hazardous environments.

EMC cable gland: An EMC (electromagnetic compatibility) cable gland is designed to provide shielding against electromagnetic interference (EMI) and radio frequency interference (RFI). EMC cable glands provide a low-resistance electrical connection to the cable's shielding, which reduces the risk of EMI.

Nickel Plated cable gland: A nickel-plated cable gland is a type of metallic cable gland that has a coating of nickel on its surface. The nickel plating provides additional corrosion resistance and improves the durability of the gland. Nickel-plated cable glands are commonly used in outdoor and harsh environments.

Brass cable gland: A brass cable gland is a type of metallic cable gland that is made from brass material. Brass cable glands provide good mechanical strength, corrosion resistance, and are suitable for a wide range of applications. They are commonly used in industrial and outdoor applications.

Why choose Trinity Touch?

Trinity Touch is an Indian-based company that specializes in the manufacturing of cable glands and other related products. The company was established in 1993 and has since become a leading player in the Indian market. Here are some reasons why Trinity Touch may be considered one of the best cable gland companies in India:

Wide range of products: Trinity Touch offers a wide range of cable glands to suit various applications and cable types. They have products for standard cables, armoured cables, EMC cables, and more.

Quality and reliability: Trinity Touch has a reputation for producing high-quality products that are reliable and durable. They use advanced technology and rigorous quality control processes to ensure that their products meet the required standards.

Compliance with standards: Trinity Touch products are designed to comply with various national and international standards such as UL, CE, and ATEX. This ensures that their products meet the required safety and regulatory standards.

Customer service: Trinity Touch has a strong focus on customer service and support. They offer technical assistance, training, and product customization to meet the specific needs of their customers.

Industry recognition: Trinity Touch has received various industry awards and accolades for their products and services, which further highlights their position as a leading player in the market.

Overall, Trinity Touch's focus on quality, compliance, customer service, and innovation has helped them establish a strong position in the Indian cable gland market.

#cable glands#Cable Gland#cable glands brass#What is cable gland#Usage of cable gland#types of cable glands#tumblog#electrical industry#industrial manufacturing#Trinitytouch

1 note

·

View note