#ElectricLinearActuators

Explore tagged Tumblr posts

Text

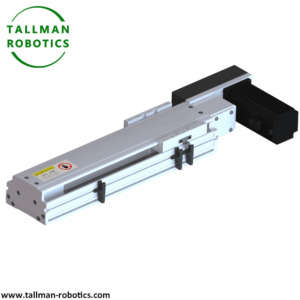

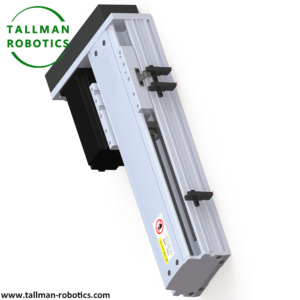

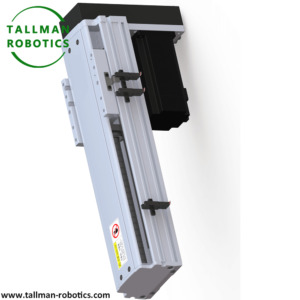

Linear Actuators Robots

Linear Actuators Robots are a pivotal technology in modern robotics due to their versatility, precision, and scalability. They have a broad range of applications in various fields. Here's an overview of how Linear Actuators Robots are integrated into robotic systems and their benefits: Classification and Mechanisms: Types: Linear Actuators Robots can be driven by different mechanisms including screw type, belt drives, and linear motors. Each mechanism offers unique advantages; for instance, screw-based actuators driven by stepping motors are highly suitable for precise positioning but may be underpowered for certain applications requiring servo motors. Motion and Force: These actuators provide both horizontal and vertical motion. They can handle travel distances up to 500 feet and speeds up to 600 inches per second, and manage loads up to 10,000 pounds, making them suitable for a variety of industrial applications. Applications: Manufacturing Automation: Linear Actuators Robots are prominently used in automation for repetitive, tedious, or dangerous tasks. They help in streamlining processes and maintaining high precision and consistency in manufacturing, greatly reducing production costs. Prosthetics: The introduction of micro linear actuators has revolutionized prosthetics, enabling more natural and powerful motions in prosthetic hands. These tiny actuators offer significant strength and precision, essential for driving individual fingers directly. Drones and Aerospace: In drones, actuators are used for functions such as camera gimbals, retractable landing gear, and arms for manipulating objects. They are also incorporated into aerospace applications, such as the International Space Station, demonstrating their reliability and precision in high-stakes environments. In conclusion, Linear Actuators Robots are vital components in the development of robotic systems, offering a broad spectrum of applications from industrial automation to advanced prosthetics and space exploration. Their adaptability, precision, and robustness make them indispensable in advancing robotics technology into the future. Here, we introduce our Screw drive linear modules by model TMS45 semi-closed type for general environment.

You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#ActuatorsinCartesianRobot#AutomationandRoboticswithElectricLinearActuator#Cartesianrobotic#Electriclinearactuators#IndustrialRobotslinearactuators#inearActuators#LinearActuator#Linearactuatorrobots#LinearActuatorsforRobotics#LinearMotionandActuatorsforSurgicalRobotics#Linearmotorsingleaxisrobots#LinearMotors&Actuators#Linearrobots#MicroLinearActuators#MultiStationBeltLinearActuator2AxisRobot#PrecisionLinearActuators#RobotActuators#RobotLinearActuators#RoboticArmwithLinearActuators#roboticslinearactuator#SingleAxisRobotLinearActuators#SingleAxisRobots#XYActuator(SingleRail)

0 notes

Text

Linear Motor Actuators Will be Delivered to Germany

Linear Motor and Actuators from Tallman Robotics Will be Delivered to Germany.

Here are some details about linear servo motor modules: 1. Types of Linear servo Motors: Linear motor modules can be categorized into different types based on their design and configuration: - Single-Axis Linear Motors: These actuators provide linear motion along a single axis. They are commonly used for applications that require linear positioning or pushing/pulling tasks. -Multi-Axis Linear Motors: These actuators consist of multiple linear motors combined in a coordinated manner to provide motion in multiple axes. They are used in applications that require precise and synchronized movements in different directions, such as robotics or multi-axis machining. - Planar Linear Motors: Planar linear motor modules are designed to provide motion in a two-dimensional plane. They can offer linear motion in both X and Y axes, making them suitable for applications such as gantry systems or XY tables. - Curved Linear servo Motors: Curved linear motor modules are designed to provide linear motion along a curved path. They are used in applications that require motion along curved surfaces or tracks, such as in packaging or material handling systems. 2. Feedback Systems: Linear motor actuators often incorporate feedback systems to provide accurate position control and feedback information. These feedback systems can include optical encoders, linear scales, or Hall effect sensors. The feedback signals are used by the control system to ensure precise positioning and closed-loop control of the actuator. 3. Control Options: Linear motor actuators can be controlled in various ways depending on the application requirements. They can be controlled manually using switches or buttons, or they can be integrated into automated control systems. Automated control options include using programmable logic controllers (PLCs), motion controllers, or computer-based control systems. These control systems allow for precise control of motion parameters such as speed, acceleration, deceleration, and position. 4. Environmental Considerations: Linear motors can be designed to meet specific environmental requirements. For example, they can be built to withstand harsh conditions such as extreme temperatures, humidity, or exposure to dust or chemicals. This makes them suitable for applications in industries such as automotive, aerospace, or manufacturing where environmental conditions can be challenging. 5. Integration with Other Systems: Linear motors can be easily integrated with other systems or components to create complete motion solutions. They can be combined with mechanical components such as guide rails, bearings, or couplings to ensure smooth and precise linear motion. Additionally, they can be integrated with control interfaces, communication protocols, or network systems to enable seamless integration into larger automation systems. 6. Safety Considerations: Safety features can be incorporated into linear motor actuators to ensure safe operation. These features may include emergency stop buttons, limit switches to prevent overtravel, position sensors for accurate positioning, or torque sensing to detect abnormal loads or obstructions. 7. Cost Considerations: The cost of linear motors can vary depending on factors such as the type of linear motor used, the size and load capacity of the actuator, the level of precision required, and additional features or customization. It is essential to consider the specific application requirements and balance them with the associated costs to determine the most suitable linear motor actuator solution. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#ElectricLinearActuators#LinearDCmotors#Linearmagneticmotorsandactuators#LinearMotorActuator#LinearMotorActuators#Linearmotorsingleaxisrobots#LinearMotors&Actuators#motorisedlinearactuator#StepperMotorLinearActuators#TubularLinearMotors

0 notes

Text

High Speed Linear Motors Are Ready For Delivery To UK

High Speed Linear Motors from Tallman Robotics Will be Transported To UK.

Can you provide examples of control algorithms commonly used for High Speed Linear Motors? Certainly! Here are a few examples of control algorithms commonly used for linear motors: 1. Proportional-Integral-Derivative (PID) Control: PID control is a widely used control algorithm for High Speed Linear Motors. It calculates the control signal based on the error between the desired position and the actual position feedback. The PID controller consists of three components: the proportional term, the integral term, and the derivative term. The proportional term provides immediate response to the position error, the integral term eliminates steady-state errors, and the derivative term improves stability and responsiveness by anticipating future error trends. 2. Model Predictive Control (MPC): MPC is an advanced control algorithm that uses a mathematical model of the system to predict its future behavior. It optimizes a cost function based on the predicted trajectory and control inputs to generate the control signal. MPC takes into account system dynamics, constraints, and future setpoints to achieve precise motion control. It is particularly effective in applications where there are constraints on the motor and system behavior, such as minimizing overshoot or avoiding collisions. 3. Sliding Mode Control (SMC): SMC is a robust control algorithm that aims to make the system track the desired trajectory regardless of uncertainties and disturbances. It creates a sliding surface that the system attempts to reach and maintain. SMC uses a switching control law that actively adjusts the control signal based on the position error and its rate of change. This algorithm is known for its ability to handle nonlinearities and external disturbances, making it suitable for applications with varying loads or changing environmental conditions. 4. Adaptive Control: Adaptive control algorithms continuously adjust the control parameters based on thesystem's characteristics and changes in the operating conditions. These algorithms use online estimation or identification techniques to adapt to varying system parameters, such as load variations or changes in friction. Adaptive control algorithms aim to maintain accurate motion control by continuously updating the control signal based on the estimated or identified system parameters. 5. Feedforward Control: Feedforward control algorithms compensate for known disturbances or feedforward signals to achieve precise motion control. These algorithms calculate and apply a control signal based on the expected disturbance or desired trajectory before the feedback is received. Feedforward control algorithms can improve the system's response time and reduce tracking errors by preemptively compensating for known disturbances or inputs. It's important to note that the selection of the control algorithm depends on the specific requirements of the application, the system dynamics, and the desired performance criteria. Often, a combination of these control algorithms may be used to achieve the best results. The implementation details and parameter tuning of these algorithms may also vary depending on the specific control system and High Speed Linear Motors setup. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#ElectricLinearActuators#Highspeedactuators#HighSpeedLinearModule#HighSpeedMotorizedLinearActuators#IronlessMotors#Linearmodules#LinearMotionActuators#LinearMotors#Sensorsforlinearmotors

0 notes

Text

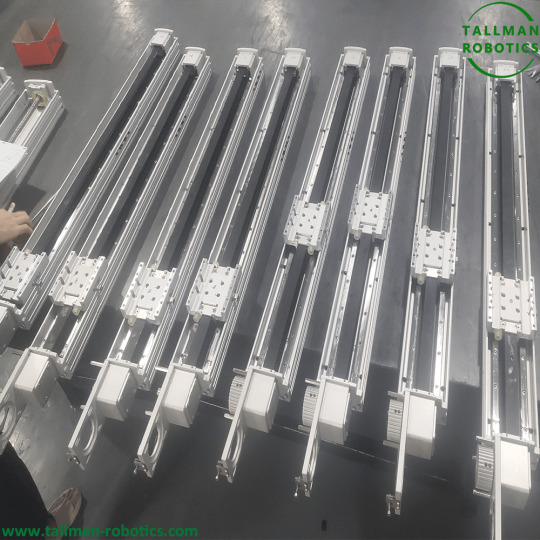

Belt Linear Actuators Will Be Finished for Clients from Russia

Belt linear actuators are a type of linear actuator that use a belt or a pulley system to convert rotational motion into linear motion. They are commonly used in automation and robotics applications to precisely control the linear movement of tools, parts or objects. Belt linear actuators offer a number of advantages including high speed, precision, repeatability and low maintenance requirements. They are also capable of handling heavy loads and high forces making them suitable for a variety of industrial and manufacturing applications.

You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Belt linear modules are widely used in applications such as robotics, manufacturing, and industrial automation, where precise control of motion is required. These actuators use a belt or pulley system to convert rotary motion into linear motion. The rotary motion is supplied by a brushless servo motor, which is attached to a timing belt. The belt is then connected to a carriage which moves along a linear guide rail. One of the main advantages of belt linear modules is their high speed and acceleration capabilities. They can achieve speeds of up to several meters per second, making them ideal for high-speed pick and place. Belt linear actuators can also accelerate and decelerate quickly, allowing for precise control of motion. Another advantage of belt linear modules is their precision and repeatability. With the use of encoders and other position feedback devices, they can achieve positional accuracy of fractions of a millimeter. This makes them ideal for applications such as CNC machines, where precise and accurate movements are required. Belt linear modulesare also relatively low maintenance compared to other types of linear actuators. The belt and pulley system eliminates the need for lubrication or other maintenance procedures, making them ideal for use in harsh environments. Finally, belt linear modules can handle heavy loads and high forces. They are capable of generating forces of several thousand newtons, making them ideal for applications such as material handling and lifting heavy objects. Read the full article

#BeltDrivenLinearActuator#beltdrivenlinearactuatorkit#BeltDrivenRotatingActuator#BeltDrivesforAutomationSystems#ElectricLinearActuators#HeavyLoadActuators#LinearActuator#linearactuatorkit

0 notes