#Linearmotorsingleaxisrobots

Explore tagged Tumblr posts

Text

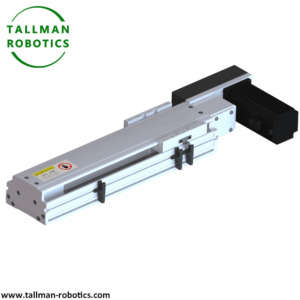

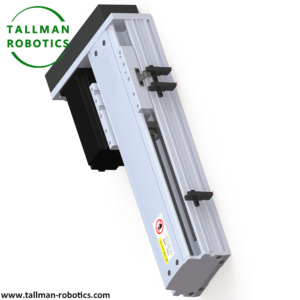

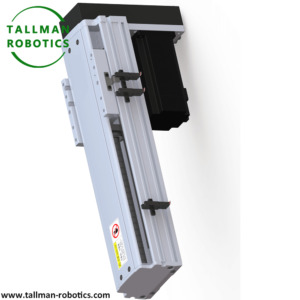

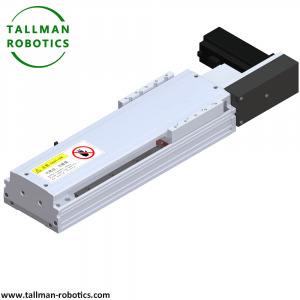

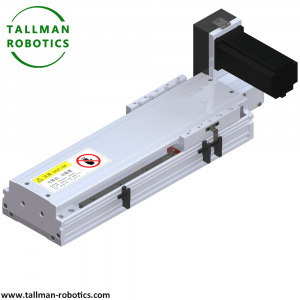

Linear Actuators Robots

Linear Actuators Robots are a pivotal technology in modern robotics due to their versatility, precision, and scalability. They have a broad range of applications in various fields. Here's an overview of how Linear Actuators Robots are integrated into robotic systems and their benefits: Classification and Mechanisms: Types: Linear Actuators Robots can be driven by different mechanisms including screw type, belt drives, and linear motors. Each mechanism offers unique advantages; for instance, screw-based actuators driven by stepping motors are highly suitable for precise positioning but may be underpowered for certain applications requiring servo motors. Motion and Force: These actuators provide both horizontal and vertical motion. They can handle travel distances up to 500 feet and speeds up to 600 inches per second, and manage loads up to 10,000 pounds, making them suitable for a variety of industrial applications. Applications: Manufacturing Automation: Linear Actuators Robots are prominently used in automation for repetitive, tedious, or dangerous tasks. They help in streamlining processes and maintaining high precision and consistency in manufacturing, greatly reducing production costs. Prosthetics: The introduction of micro linear actuators has revolutionized prosthetics, enabling more natural and powerful motions in prosthetic hands. These tiny actuators offer significant strength and precision, essential for driving individual fingers directly. Drones and Aerospace: In drones, actuators are used for functions such as camera gimbals, retractable landing gear, and arms for manipulating objects. They are also incorporated into aerospace applications, such as the International Space Station, demonstrating their reliability and precision in high-stakes environments. In conclusion, Linear Actuators Robots are vital components in the development of robotic systems, offering a broad spectrum of applications from industrial automation to advanced prosthetics and space exploration. Their adaptability, precision, and robustness make them indispensable in advancing robotics technology into the future. Here, we introduce our Screw drive linear modules by model TMS45 semi-closed type for general environment.

You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#ActuatorsinCartesianRobot#AutomationandRoboticswithElectricLinearActuator#Cartesianrobotic#Electriclinearactuators#IndustrialRobotslinearactuators#inearActuators#LinearActuator#Linearactuatorrobots#LinearActuatorsforRobotics#LinearMotionandActuatorsforSurgicalRobotics#Linearmotorsingleaxisrobots#LinearMotors&Actuators#Linearrobots#MicroLinearActuators#MultiStationBeltLinearActuator2AxisRobot#PrecisionLinearActuators#RobotActuators#RobotLinearActuators#RoboticArmwithLinearActuators#roboticslinearactuator#SingleAxisRobotLinearActuators#SingleAxisRobots#XYActuator(SingleRail)

0 notes

Text

Linear Motor Actuators Will be Delivered to Germany

Linear Motor and Actuators from Tallman Robotics Will be Delivered to Germany.

Here are some details about linear servo motor modules: 1. Types of Linear servo Motors: Linear motor modules can be categorized into different types based on their design and configuration: - Single-Axis Linear Motors: These actuators provide linear motion along a single axis. They are commonly used for applications that require linear positioning or pushing/pulling tasks. -Multi-Axis Linear Motors: These actuators consist of multiple linear motors combined in a coordinated manner to provide motion in multiple axes. They are used in applications that require precise and synchronized movements in different directions, such as robotics or multi-axis machining. - Planar Linear Motors: Planar linear motor modules are designed to provide motion in a two-dimensional plane. They can offer linear motion in both X and Y axes, making them suitable for applications such as gantry systems or XY tables. - Curved Linear servo Motors: Curved linear motor modules are designed to provide linear motion along a curved path. They are used in applications that require motion along curved surfaces or tracks, such as in packaging or material handling systems. 2. Feedback Systems: Linear motor actuators often incorporate feedback systems to provide accurate position control and feedback information. These feedback systems can include optical encoders, linear scales, or Hall effect sensors. The feedback signals are used by the control system to ensure precise positioning and closed-loop control of the actuator. 3. Control Options: Linear motor actuators can be controlled in various ways depending on the application requirements. They can be controlled manually using switches or buttons, or they can be integrated into automated control systems. Automated control options include using programmable logic controllers (PLCs), motion controllers, or computer-based control systems. These control systems allow for precise control of motion parameters such as speed, acceleration, deceleration, and position. 4. Environmental Considerations: Linear motors can be designed to meet specific environmental requirements. For example, they can be built to withstand harsh conditions such as extreme temperatures, humidity, or exposure to dust or chemicals. This makes them suitable for applications in industries such as automotive, aerospace, or manufacturing where environmental conditions can be challenging. 5. Integration with Other Systems: Linear motors can be easily integrated with other systems or components to create complete motion solutions. They can be combined with mechanical components such as guide rails, bearings, or couplings to ensure smooth and precise linear motion. Additionally, they can be integrated with control interfaces, communication protocols, or network systems to enable seamless integration into larger automation systems. 6. Safety Considerations: Safety features can be incorporated into linear motor actuators to ensure safe operation. These features may include emergency stop buttons, limit switches to prevent overtravel, position sensors for accurate positioning, or torque sensing to detect abnormal loads or obstructions. 7. Cost Considerations: The cost of linear motors can vary depending on factors such as the type of linear motor used, the size and load capacity of the actuator, the level of precision required, and additional features or customization. It is essential to consider the specific application requirements and balance them with the associated costs to determine the most suitable linear motor actuator solution. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#ElectricLinearActuators#LinearDCmotors#Linearmagneticmotorsandactuators#LinearMotorActuator#LinearMotorActuators#Linearmotorsingleaxisrobots#LinearMotors&Actuators#motorisedlinearactuator#StepperMotorLinearActuators#TubularLinearMotors

0 notes

Text

Single Axis Linear Robot Will Be Delivered To Singapore

Single Axis Linear Robot from Tallman Robotics Limited Will Be Delivered To Singapore.

A Single Axis Linear Robot is a type of robotic system that is designed to perform linear motion along a single axis. A single axis linear robot, also known as a linear actuator or cartesian robot, is an essential piece of machinery in numerous industrial applications. These robots provide precise, efficient, and highly customizable linear motion solutions, making them ideal for repetitive tasks or processes that require strict accuracy and control. Components: 1. Rigid frame: This provides the structural foundation for the robot's operation. Often made of metal such as aluminum extrusion or steel, the frame is responsible for maintaining rigidity and stability during movement. 2. Motorized drive system: This is the component responsible for generating and controlling the robot's motion. The drive system typically consists of an electric motor (stepper, servo or brushless DC motor) that converts electrical energy into linear motion via a mechanical translation system such as ball screws, linear motors, or belt and pulley systems. 3. Linear guide system: The linear guide ensures smooth, precise, and highly accurate movement along the single axis while also preventing undesired motion in other directions. Linear guides can include profiled rails with rolling bearings, linear bushings, or magnetic guidance systems. 4. End effector or tooling: This is the part of the robot that interacts with the workpiece or material. Depending on the specific application, the end effector could be a gripper, a vacuum cup, a welding tool, or even a small camera. 5. Control system: The control system manages and synchronizes the motion of the single-axis linear robot. The system typically consists of a programmable automation controller (PAC) or microcontroller, which receives input from sensors, user interfaces, or other devices and sends the desired motion commands to the motorized drive system. Applications: Among the various scenarios where single-axis linear robots are employed, these are some of the most common ones: 1. Assembly automation: Linear robots are essential in the assembly of electronic devices, automotive components, and various consumer products. They can quickly and accurately position parts for assembly or perform tasks such as screw tightening, adhesive dispensing, or press-fitting. 2. Material handling: Single-axis robots are frequently employed in conveyor systems and packaging lines to load/unload materials or transport goods between different stations. 3. Quality control and inspection: Attaching cameras or sensors to linear robots can automate inspection processes, thus ensuring consistent quality and production speed. This is particularly useful in industries like food processing, pharmaceuticals, and semiconductors. 4. Laboratory automation: In life sciences and clinical laboratories, single-axis linear robots can simplify tasks such as sample handling, tube sorting, and liquid dispensing. In conclusion, single-axis linear robots are fundamental tools in modern manufacturing, as they provide accurate, reliable, and customizable motion control. They help enhance the efficiency of various industrial tasks and enable businesses to maintain high standards of quality and productivity. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#1-axisrobot#AutomatedPickingSystems#Automatedsolderingrobot#ChinaSingleAxisRobotManufacturers#Linear&GantryRobots#LinearActuators#Linearmotorsingleaxisrobots#LinearStageAxisSingleLinearRobotArm#RoboticPicking#RoboticSystems#Singleaxisrobots#SingleAxisStages#Single-AxisRobotLinearModule

0 notes

Text

Single Axis Linear Actuator

Single Axis Linear Actuator You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects. Single Axis Linear Actuators, also named as Modular Linear Actuator, Linear Motion Module, Industrial Linear Motion, Linear Axis Actuator etc. TM by Tallman Robotics, as a famous producer to produce linear modules, supplies diverse TM Linear modules such as screw linear modules, belt linear modules, and semi closed and fully closed respectively for different environment application. TM Linear Modular Actuator Modules can run with world famous band motors by 50W,100W,200W/400W /750W/1000W or 42, 57,86 stepper motors or NMEA17, NMEA23, NMEA34 stepping motors in quality aluminum frame system to guarantee precise and speed requirement of various precision and common application projects. You can choose linear modules with brake or without brake. Tallman Robotics’s Single Axis Linear Actuator type TM135 with body with by 135mm have 5 series. Respectively,TM135 can be classified into screw driven semi closed, screw driven fully closed, and belt driven semi closed, belt driven fully closed. These Linear modules perform strokes from 0 mm up to 3500 mm, and payload from 6kg up to 110kgs. It could applied in laser marking, connection insert and pull test, components can be stitched by a condition of a certain thrust, parts from automobile undergo the second picking and positing.

Basic Specification of TM135 series Model No TMS135-CM TMS135CR Drive solution Ball screw Sealed or not Semi closed Fully closed Motor power AC (W) 200/400W/750 Repeatability (mm) ±0.01/±0.005 Ball screw outer diameter (mm) 16/20 16/20 16 16/20 16 20 lead (mm) 5 10 16 20 32 40 Fastest speed Motor speed 3000 (rpm) 250 500 800 1000 1600 2000 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 95/110/110 75/110/110 44/68/90 35/50/80 13/30/60 10/15/25 Vertical 0.3G 27/35/35 18/25/35 7/18/25 6/14/20 -/8/10 - Rate Thrust (N) 683/1388/2100 341/694/1050 213/432/840 174/347/528 108/216/380 42/174/320 Linear guide (mm) 15*12.5-2 Origin sensor: Plug-in EE-SX674(NPN)EE-SX674P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Model No TMS135S-CM Drive solution Ball screw Sealed or not Semi closed Motor power AC (W) 200/400W/750 Repeatability (mm) ±0.01/±0.005 Ball screw outer diameter (mm) 16/20 16/20 16 16/20 16 20 lead (mm) 5 10 16 20 32 40 Fastest speed Motor speed 3000 (rpm) 250 500 800 1000 1600 2000 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 70/70/70 47/70/70 30/48/70 24/45/70 13/25/50 10/15/25 Vertical 0.3G 17/17/25 12/12/18 6/8/15 4/6/10 - - Rate Thrust (N) 683/1388/2100 341/694/1050 213/432/840 174/347/840 108/216/380 42/174/320 Linear guide (mm) 15*12.5-2 Origin sensor: Plug-in EE-SX672(NPN)EE-SX672P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Model No TMB135-CM TMB135-CR Drive solution Timing Belt Timing Belt Sealed or not Semi closed Fully closed Motor power AC (W) 200/400W Repeatability (mm) ±0.04 Reduction Ratio 1:1 1:2 lead (mm) 90 45 Fastest speed Motor speed 3000 (rpm) 4500 2250 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 10/21 22/42 Vertical 0.3G - - Rate Thrust (N) 45/91 90/182 Linear guide (mm) 15*12.5-2 Origin sensor: Plug-in EE-SX672(NPN)EE-SX672P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Related knowledge:Which industries are linear modules used for? How should it be classified? 1. Painting The linear module can be accurately positioned and stable operation 2. Image visual inspection device Utilizing the characteristics of high positioning accuracy and telling running stability of the linear slide module, it can be used to perform AOI inspection of appearance 3. Surface treatment Using the sliding table's constant speed and stable movement characteristics, the workpiece can be hung on the sliding table and immersed in the solvent, which can smoothly perform the surface treatment 4. Substrate printing Utilizing the sliding table's constant speed and stable movement characteristics, the substrate can be fixed on the sliding table's moving seat to perform the printing operation 5. Circuit board cutting Use the sliding table to move at a constant speed and stable, with the cutter mechanism to perform the cutting operation 6. Part assembly operations Utilize the characteristics of multi-point positioning and accurate positioning of the servo slide, which can smoothly perform the assembly of parts 7. Production line handling operations Utilize the module's high load and tellable running characteristics, it can be used to carry out the goods handling operation on the conveyor belt 8. Packing entire operation Utilizing the characteristics of high positioning accuracy of single-axis robots, it can be used for the entire movement on the conveyor belt 9. Large items pick and place operation Using the characteristics of high load and high positioning accuracy of the robot, it can be used to replace the manual execution of large items. 10. Machine tool processing pick and place operation Using the high positioning accuracy and high-speed stability of the linear module, it can be used with a machine tool to execute the pick-and-place mechanism for loading and unloading of processed parts 11. Print job Use the feature that the slide can move at the same speed and at the same distance to perform laser printing 12. Pick and place entire columns The linear module can be accurately moved, using a two-axis module sliding table, with a fixture or suction cup can be assembled into a pick and place mechanism 13. Automatic soldering operation Utilizing the characteristics of high positioning accuracy and high stability of the servo slide, it is possible to perform the soldering operation of complex circuit board parts 14. Large LCD glass substrate coating equipment Using the design method of gantry connection, the glue gun is fixed on the Z axis and can be used for high-speed glue application 15. Winding device The characteristics of sliding table can be moved with high precision and accurate and fixed speed operation Main products---electric slide (manipulator, actuator, linear module, electric cylinder) The electric slide table is widely used in precise positioning and moving animal materials, and can be basically used in the automation industry involved. Commonly used in the following industries: Electronics industry equipment: dispensers, placement machines, etc.: Battery equipment: power battery laminator, etc.; Laser equipment: laser welding machine, laser cutting machine, laser marking machine, etc.; Spraying equipment: spraying manipulator, etc.; Cutting equipment; plasma cutting machine, flame cutting machine, etc.; Die-casting machine, injection molding machine reclaiming manipulator, etc. Read the full article

#CurvedRailSystems#Electricaxes#LinearGuideRail#LinearGuideSystems#LinearmotionGuide#LinearMotionGuideModule#LinearMotionGuideRail#linearmotionsystems;linearslidesandcylindersandactuators#Linearmotorsingleaxisrobots#MiniatureLinearGuide#SingleAxis#SingleAxisLinearActuator#SmallLinearActuators

0 notes