#Epoxy Floor Coating Manufacturers

Text

Trusted Epoxy Flooring Manufacturers of India

#Epoxy Flooring Manufacturers#epoxy floor coating#resin manufacturers#epoxy resin manufacturers#epoxy floor coating manufacturers#epoxy marble#epoxy over marble

0 notes

Text

Visit Protexion LLP for epoxy floor coating

Epoxy floor coating is a polymer coating made by mixing epoxy resin, polyurethane hardener, and other reinforcing materials. When it is not used as a floor coating, it is often used as a glue or adhesive.

These Epoxy floor coating are in great demand in the building and construction industries for stubborn and hard flooring solutions. When it is mixed in the right amount, it creates a chemical reaction that gives the floor a very hard surface and well-defined marks.

Protexion is committed to providing specialized solutions for industrial epoxy flooring in India. Protexion is a leading service provider of epoxy flooring and other commercial flooring solutions for industries across India. At Protection we offer epoxy flooring services that are composite, waterproof, hygienic and resistant to impact, chemicals, scratches, scuffs. Epoxy floors are a versatile solution for your needs.

For More Details Contact us: +919011958800

More about information for Epoxy floor coating then Visit our site - http://www.protexion.in/epoxy-floor-coating.php

#epoxy floor coating#epoxy floor coating manufacturers#epoxy floor coating suppliers#epoxy flooring services#epoxy flooring

0 notes

Text

Epoxy Self-Leveling is Ideal for Commercial & Industrial Flooring

Epoxy self-leveling, also known as epoxy self-flowing floor and epoxy ground, is made of epoxy resin as the main material, curing agent, diluents, solvents, dispersants, defoamers and some fillers and other mixed processing of epoxy floor coating, combined with a specific floor construction process, on-site ground decorative construction of a class of flooring. This process can be based on the unevenness of the ground downstream flow, the ground for automatic leveling, and rapid drying, after curing the ground will form a smooth, flat, seamless mirror effect surface layer. In addition, self-leveling also has moisture-proof, antibacterial, anti-corrosion and other characteristics.

Main characteristics of epoxy self-leveling

Epoxy self-leveling has chemical properties such as water resistance, oil resistance, acid and alkali resistance, salt spray corrosion resistance, and physical properties such as abrasion resistance, stamping resistance and scrub resistance. And the surface is bright, flat, beautiful, no joints, easy to clean, easy maintenance, durable, can meet the needs of modern industry on the floor, in the flooring materials occupy an important position, is the ideal long-lasting flooring materials for modern industry, and has been widely used in medicine, automobile, electronics, food, electricity, chemical industry and other industrial floor decoration.

Epoxy self-leveling composition

Epoxy self-leveling includes two parts: concrete base and epoxy self-leveling floor coating.

Concrete grass-roots level: The concrete with strength level not less than C25 is poured and moulded at one time, when the floor has the requirement of pressure resistance and impact resistance, the concrete grass-roots level can be processed by two-way reinforcing steel mesh.

Epoxy self-leveling floor coating: bottom coating, middle coating, putty layer, top coating.

The bottom coating is epoxy primer, using penetration and adhesion of epoxy primer, continuous and uniform coating film, no leakage, to enhance the adhesion of the grass-roots surface.

The middle coating is epoxy mortar layer, epoxy two-component add appropriate amount of 100 mesh quartz sand, enhance the smoothness of the coating surface and the strength of the coating.

Putty layer for epoxy putty layer, epoxy two-component add appropriate amount of putty powder, further leveling of the coating surface, to achieve a flat surface, smooth.

The top coating is coated with colour paint, and the self-leveling epoxy top coating is evenly troweled.

Epoxy self-leveling construction precautions

Epoxy self-leveling floor coating is a kind of epoxy resin, it is widely used in building construction, is a kind of environmentally friendly and harmless paint. It can ensure that the ground after the construction of non-skinning, as well as the flatness of the grass-roots level and surface strength, but also to fill the ground base of the original cuts or cracks, to ensure that the surface effect of self-leveling and anti-cracking. At the same time, the product can also be high-pressure washing of the grass-roots level to ensure that the ground clean.

However, epoxy self-leveling floor coating in the use of the process there are some precautions that must be observed, otherwise it will cause some irreparable damage to the building construction.

Construction temperature needs to be ≥5℃, if you want to construct in <5℃ need to choose special formula. Humidity is recommended for construction below 75%.

Construction to ensure air circulation, modulation of the amount of use, not more than 30 minutes.

Construction process to do a good job of maintenance, to avoid the intrusion of dust and debris, affecting the effect of paint.

After the construction is completed, it needs to be maintained for at least 7 days before being put into use. During the maintenance period, especially can not have water or all kinds of solution infiltration.

It is strictly prohibited to mix with other paints.

Must be strictly in accordance with the prescribed proportion of the addition of curing agent.

Keep the surface of the coated material clean, and the water content of the coated material must be less than 7%.

Keep the painting environment clean, it is strictly prohibited to construct in the environment with a lot of dust.

Epoxy self-leveling coating characteristics

Epoxy self-leveling coating is made of epoxy resin and special curing agent as main material, and is processed by adding various auxiliaries, pigments and fillers through strict proportioning. It not only has excellent chemical properties such as water resistance, oil resistance and chemical corrosion resistance, but also has the advantages of good adhesion, high mechanical strength, low shrinkage of paint film after curing, and can be coated into a thick film at a time, so it is widely used in modern industrial flooring.

The coating film is tough, wear-resistant, good chemical resistance, non-toxic and non-flammable.

The surface is smooth and clean, with good decorative properties, and can meet the requirements of class 100 cleanliness level.

It has high adhesion, strong mechanical strength, chemical resistance and good electrical properties.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#epoxy self-leveling#epoxy self-leveling flooring#epoxy self-leveling floor coating#self-leveling epoxy#epoxy coating

0 notes

Text

Honoring Strength, Courage, and Hope

On World Cancer Day, CAPA stands with warriors, survivors, and caregivers around the globe. Let's unite in the fight against cancer, spreading awareness, supporting research, and offering love and compassion to those affected.

Together, we can make a difference. Together, we can bring light to the darkness. Join us in honoring the resilience and determination of cancer fighters everywhere. #WorldCancerDay #CAPACares #StrengthInUnity

To know more tile adhesives and waterproofing floors, epoxy grouts visit: https://capaindia.in/product/capa-flex/, https://capaindia.in/product/capaproof-hybrid-w/

#best tile adhesive in india#top tile adhesive brands in india#top building materials companies in india#tile adhesive manufacturers#tile adhesives for fixing natural stones#high strength flooring mortars#tile adhesive companies in india#floor repairs mortars in india#tile adhesives for vitrified tiles#block jointing mortar manufacturers in india#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system#floor repairs mortars in India#best flooring solutions in india#best waterproofing mineral mortars in india#aliphatic polyurethane waterproofing coating#elastomeric waterproofing coating#flexible waterproofing mortar for crack bridging#waterproofing solutions for crack bridging#affordable waterproofing solutions

0 notes

Text

0 notes

Link

#Paint Manufacturers#Pool Paint Australia#Bg Pool Paint Australia#Buy Artist Paint Online#Swimming Pool Paint Suppliers#Paint Pro Brush Online#Shop Online Industrial Coatings#Wood Varnish Paint For Sale Australia#Epoxy Pool Paint#Acrylic Pool Paint Online#Buy Online Industrial Floor Paint#Fiberglass Pool Coating Kit#Heavy Duty Concrete Paint#buylocal#buyart#buyonline#paintsuppliers#poolbuilderbrisbane#brisbanepoolrenovation#brisbanepoolbuilder#BG Pool Paint#Brisbane Paints#Buy Brisbane Pool Paints online#Swimming Pool Paint Brisbane#Swimming Pool Epoxy Paint Suppliers#Acrylic Pool Paint Online Brisbane#Buy Online Brisbane Pool Paint#Brisbane Pool Paints#Brisbane Paints Colors

0 notes

Video

undefined

tumblr

Australia’s largest Swimming Pool Paint Manufacturers and suppliers. BG Pool Paint offers the ultimate coatings experience in pool paint systems. Buy online Bg Pool Paint Australia or visit store in Perth Now!

Contact Us:

Phone: 1300 894 994

Email: [email protected]

Location: U4/34 Truganina Rd, Malaga WA 6090, Australia.

#Paint Manufacturers and suppliers#Industrial Coatings#Artist Paint#Acrylic house Paint#Roof paint#Swimming Pool Paint#Australian Paints#Shop Online Industrial Coatings#BG house paint#Wall Paint#Paint suppliers#Paint manufacturers#OrderOnline#buy paint#bestprize#Acrylic Pool Paint#Fiberglass Pool Coating Kit#Heavy Duty Concrete Paint#Industrial Floor Paint#Epoxy Pool Paint Perth

0 notes

Text

#polyurea coatings#polyurea coating manufacturers#polyurea coating supplier#Drcipy#polyurethane paint#polysulphide sealants#industrial epoxy flooring

0 notes

Photo

Industrial epoxy flooring work by Jemkon. Epoxy flooring is beneficial for manufacturing industry as it is cost effectvice, durable and long lasting. Jemkon provides industrial epoxy flooring all across India , delhi , chennai ,bangalore, hyderabad, ahmedabad

#epoxy floor coating#industrial epoxy flooring#epoxy flooring manufacturer#delhi#india#chennai#bangalore#hyderabad#ahmedabad

0 notes

Text

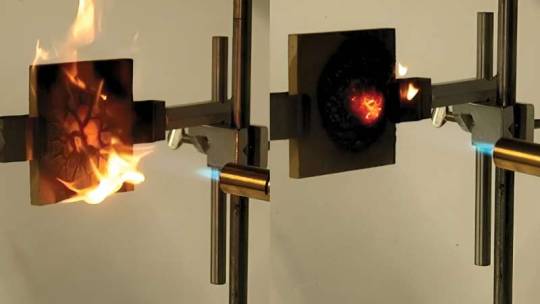

Recycling the non-recyclable: New epoxy resin resists flames and reduces waste

Empa researchers have developed an epoxy resin that can be repaired and recycled, in addition to being flame-retardant and mechanically strong. Potential applications range from coating for wooden flooring to composites in aerospace and railways.

Epoxy resins are tough and versatile polymers. In combination with glass or carbon fibers, they are used, for example, to manufacture components for aircraft, cars, trains, ships and wind turbines. Such epoxy-based fiber-reinforced polymers have excellent mechanical and thermal properties and are much lighter than metal. Their weakness: They are not recyclable—at least not yet.

Now Empa researchers led by Sabyasachi Gaan at Empa's Advanced Fibers laboratory have developed an epoxy resin-based plastic that is fully recyclable, repairable and also flame retardant—all while retaining the favorable thermomechanical properties of epoxy resins. They have published their findings in the Chemical Engineering Journal.

Read more.

#Materials Science#Science#Recycling#Epoxy#Resins#Flames#Waste#Flame retardants#Polymers#Thermosets#Vitrimers

11 notes

·

View notes

Text

When it comes to epoxy flooring coating, it is an important decision to choose among reputed Epoxy Flooring Manufacturers. A reputable Epoxy Floor Coating Manufacturer will have a proven track record of offering top-notch quality epoxy products that pass the test of durability and resistance.

#Epoxy Flooring Manufacturers#Epoxy Floor Coating Manufacturers#resin manufacturers#epoxy resin manufacturers#epoxy resin manufacturers in india#epoxy resin#Floor Coating#Epoxy flooring manufacturers in india#epoxy floor coating manufacturers in India

0 notes

Photo

Epoxy floor coating is a polymer coating made by mixing epoxy resin, polyurethane hardener, and other reinforcing materials. When it is not used as a floor coating, it is often used as a glue or adhesive.

#epoxy floor coating#epoxy floor coating manufacturers#epoxy floor coating suppliers#epoxy flooring services#epoxy flooring

0 notes

Text

EPOXY FLOOR GRINDING WORKS

Manycon Saudi is one of the best Epoxy Floor Grinding Contractors in Saudi Arabia & all GCC & India

In Saudi Arabia, Manycon Contracting Company offers professional epoxy floor coating application services in addition to a variety of other concrete flooring services for clients throughout Qatar, Saudi Arabia and India. Our flooring services epoxy floor paint application, concrete polishing, shot blasting and concrete grinding, concrete stain application, flooring and adhesive removal.. Our epoxy floor coating and concrete flooring services are ideal for commercial buildings and industrial plants.

The following are some of the main types of buildings, which would benefit from our epoxy coating and floor finishing services.

Aircraft Hangars

Chemical Plants

Manufacturing Plants

Warehouses & Distribution Facilities

Laboratories

Hospitals

Commercial and Residential Garages

Showrooms

Commercial Kitchens

Office Buildings

Retail Spaces & Mall

Athletic Facilities

2 notes

·

View notes

Text

Experience the Power of Aplicacer PU Flex

Designed for versatility, Aplicacer PU Flex offers unparalleled adhesive strength for a wide range of surfaces. Whether it's interior or exterior, dry or wet conditions, this multipurpose adhesive delivers superior performance every time. Say goodbye to challenges with its remarkable bonding ability on various substrates. Elevate your projects with Aplicacer PU Flex today! To know more about best waterproofing mineral mortars in india visit: https://capaindia.in/product/

#top tile adhesive brands in india#tile adhesive manufacturers#top building materials companies in india#best tile adhesive in india#tile adhesives for fixing natural stones#tile adhesives for vitrified tiles#high strength flooring mortars#block jointing mortar manufacturers in india#tile adhesive companies in india#floor repairs mortars in india#best waterproofing mineral mortars in india#elastomeric waterproofing coating#epoxy grouts in india#epoxy adhesive manufacturers#epoxy adhesives manufacturers#affordable waterproofing solutions#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system

0 notes