#Polymers

Explore tagged Tumblr posts

Text

The substances behind the slimy strings from okra and the gel from fenugreek seeds could trap microplastics better than a commonly used synthetic polymer. Previously, researchers proposed using these sticky natural polymers to clean up water. Now, they report in ACS Omega that okra and/or fenugreek extracts attracted and removed up to 90% of microplastics in ocean water, freshwater and groundwater. Rajani Srinivasan and colleagues have been exploring nontoxic, plant-based approaches to attract and remove contaminants from water. In one set of lab experiments, they found that polymers from okra, fenugreek and tamarind stick to microplastics, clumping together and sinking for easy separation from water.

Continue Reading.

#Science#Environment#Plants#Chemistry#Analytical Chemistry#Polymers#Microplastics#Okra#Fenugreek#Recycling

264 notes

·

View notes

Text

Engineer reinvents ceramics with origami-inspired 3D printing

In a breakthrough that blends ancient design with modern materials science, researchers at the University of Houston have developed a new class of ceramic structures that can bend under pressure—without breaking. Potential applications for this technology range from medical prosthetics to impact-resistant components in aerospace and robotics, where lightweight—but tough—materials are in high demand. Traditionally known for their brittleness, ceramics often shatter under stress, making them difficult to use in high-impact or adaptive applications. But that may soon change as a team of UH researchers, led by Maksud Rahman, assistant professor of mechanical and aerospace engineering, and Md Shajedul Hoque Thakur, postdoctoral fellow, has shown that origami-inspired shapes with a soft polymer coating can transform fragile ceramic materials into tough, flexible structures. Their work was recently published in Advanced Composites and Hybrid Materials.

Read more.

31 notes

·

View notes

Text

Illustration detail from a Bakelite Plastics promotional postcard - 1938.

#vintage illustration#vintage advertising#bakelite#bakelite plastics#plastics#plastic products#chemistry#bakelite company#molded plastics#resins#polymers#chemical companies#plastic manufacturers#union carbide#vinyl#union carbide and carbon corporation#deco design#art deco#vintage postcards#industry#science#product design#industrial design

18 notes

·

View notes

Text

What are the materials used in weapons manufacturing?

Materials used in weapons manufacturing are chosen based on their mechanical properties, durability, and suitability for specific applications. The materials used in weapons manufacturing are:

1. Alloys, including steel, aluminum, titanium, nickel, and cooper. 2. Composites, including carbon fiber, glass fiber, and kevlar. 3. Ceramics, including alumina, silicon carbide, and boron carbide. 4. Polymers, including polyamide, polycarbonate, and polyethylene. 5. Specialized Coatings and Treatments, including ceramic coatings, teflon coatings, and phosphate coatings. 6. Explosives and Propellants, including RDX (Cyclotrimethylenetrinitramine), TNT (Trinitrotoluene), and composite propellants. 7. Electronic and Semiconductor Materials, including silicon, and gallium nitride (GaN).

Alloys

High-Strength Steel - Commonly used in the manufacturing of

Barrels: The main component of a firearm, responsible for propelling projectiles.

Receivers: The housing for the firearm's action, holding essential components.

Slides (pistols): The moving part that houses the barrel and holds ammunition.

Frames (pistols): The base of the handgun, supporting other components.

Bolts and carriers (rifles): Components involved in the firing cycle.

Springs: Essential for firearm operation, providing recoil and return forces.

Steels like 4140, 4340, and maraging steel are known for their toughness, high yield strength, and resistance to wear.............

#science#metals#alloys#materials#materials science#materials science and engineering#composites#ceramics#polymers#engineering#firearm

11 notes

·

View notes

Text

Metamaterials are products of engineering wizardry. They are made from everyday polymers, ceramics, and metals. And when constructed precisely at the microscale, in intricate architectures, these ordinary materials can take on extraordinary properties.

With the help of computer simulations, engineers can play with any combination of microstructures to see how certain materials can transform, for instance, into sound-focusing acoustic lenses or lightweight, bulletproof films.

But simulations can only take a design so far. To know for sure whether a metamaterial will stand up to expectation, physically testing them is a must. But there’s been no reliable way to push and pull on metamaterials at the microscale, and to know how they will respond, without contacting and physically damaging the structures in the process.

Now, a new laser-based technique offers a safe and fast solution that could speed up the discovery of promising metamaterials for real-world applications.

The technique, developed by MIT engineers, probes metamaterials with a system of two lasers — one to quickly zap a structure and the other to measure the ways in which it vibrates in response, much like striking a bell with a mallet and recording its reverb. In contrast to a mallet, the lasers make no physical contact. Yet they can produce vibrations throughout a metamaterial’s tiny beams and struts, as if the structure were being physically struck, stretched, or sheared.

The engineers can then use the resulting vibrations to calculate various dynamic properties of the material, such as how it would respond to impacts and how it would absorb or scatter sound. With an ultrafast laser pulse, they can excite and measure hundreds of miniature structures within minutes. The new technique offers a safe, reliable, and high-throughput way to dynamically characterize microscale metamaterials, for the first time.

“We need to find quicker ways of testing, optimizing, and tweaking these materials,” says Carlos Portela, the Brit and Alex d’Arbeloff Career Development Professor in Mechanical Engineering at MIT. “With this approach, we can accelerate the discovery of optimal materials, depending on the properties you want.”

Portela and his colleagues detail their new system, which they’ve named LIRAS (for laser-induced resonant acoustic spectroscopy) in a paper appearing today in Nature. His MIT co-authors include first author Yun Kai, Somayajulu Dhulipala, Rachel Sun, Jet Lem, and Thomas Pezeril, along with Washington DeLima at the U.S. Department of Energy’s Kansas City National Security Campus.

Keep reading.

Make sure to follow us on Tumblr!

19 notes

·

View notes

Text

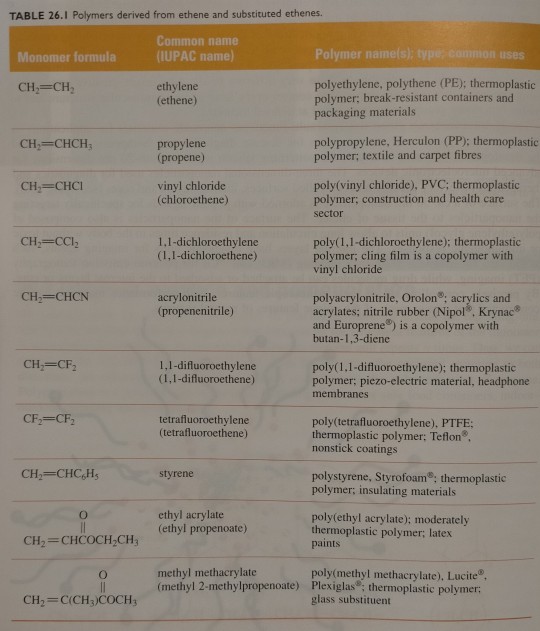

Table 26.1 gives some examples of polymers formed from compounds related to ethene, along with their common names and most important uses.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#polymers#ethene#ethylene#propene#propylene#chloroethene#vinyl chloride#dichloroethene#dichloroethylene#propenenitrile#acrylonitrile#difluoroethene#difluoroethylene#tetrafluoroethene#tetrafluoroethylene#styrene#ethyl propenoate#ethyl acrylate#methyl methylpropenoate#methyl methacrylate

2 notes

·

View notes

Text

god sometimes i wish i was a polymer, life would be so much easier if i was a polymer.

i would just have to carry your groceries and be so helpful to you, or i could play music for you on a second-hand record player, i could brush your teeth for you, i could be so useful as a polymer.

trust me i wouldn’t be like one of those nasty polymers. i wouldn’t be part of the great pacific garbage patch or disintegrate into microplastics in your oceans and in your food. not me sir no i’m not like the other polymers

#polymers#polymer#polymer chemistry#polymer manifesto#polymer posting#chemistry#chem posting#chem#just me#shower thoughts#based#microplastics#plastic#plastics

3 notes

·

View notes

Text

World’s first ice cream made from plastic

Reuters | 28 September 2023

The world’s first food made from plastic waste - according to its developer - is vanilla ice cream.

Despite being locked in a freezer in London, she hopes it kickstarts a heated debate about the future of food and the plastic pollution crisis.

The ice cream is actually an art installation called ‘Guilty Flavours’ by artist and designer Eleanora Ortolani, 27, intended to challenge the way we think about plastic waste and what we are - and are not - prepared to eat.

"Guilty Flavours is what I believe is the first sample of ice cream made from plastic waste,” Ortolani told Reuters at Central Saint Martins, part of the University of the Arts London.

“It's coming from the same plastic as we can find in bottles, plastic bottles,” she said.

The process, developed by scientists in Edinburgh, harnesses the metabolic power of bacteria and enzymes to behave as eco-friendly factories to digest polyethylene terephthalate (PET) and turn it into vanillin, the molecule that gives vanilla its flavour.

“There are certain enzymes which do certain chemical reaction,” Dr Joanna Sadler, a biotechnologist at the University of Edinburgh, told Reuters.

“So if you plug those together, you can get through to lots of different chemical products," she said.

Plastic is made of a string of molecules bonded together into what are known as polymers.

Sadler broke those bonds with a hungry microbe, leaving her with molecules that were no longer plastic.

That former PET-soup was then easily processed by another bacteria into vanillin.

Sadler's research, published in the Journal Biochemist in December 2021, focuses on degrading and upcycling plastic and using it as feedstock for microbial growth.

She produced the specially engineered bugs for Ortolani's project but was at pains to point out that the student's ice cream is very much a research project.

It's not currently for human consumption.

"I've even had members of the public email me saying it's irresponsible to encourage people to eat plastic," Sadler said.

"It is really important that we take the safety side of it really, really seriously and we make it very clear that this has to go through exactly the same regulatory processes and food standard processes as any other food ingredient.

And only once it has been through all of those would it go anywhere near any kind of consumer product."

Ortolani, who is from Verona, Italy, said Guilty Flavours was inspired by her frustration with the failure of the recycling system to stop plastic polluting the environment.

It is locked away to highlight what she says is a looming global food crisis.

“We have the tools today to rethink the food system we're living in,” she said.

“This is ready now and today but nobody can really touch it or interact with it because it's not tested for safety yet."

Vanilla, sometimes called 'green gold', is the second most expensive spice in the world after saffron.

youtube

UK designer recycles plastic into vanilla ice cream

27 September 2023

Introducing the world's first food made from plastic waste... vanilla ice cream!

Named Guilty Flavours, the ice cream has been designed to provoke viewers into thinking about plastic waste.

The ice cream was developed by scientists in Edinburgh, who used bacteria and enzymes to digest PET plastic and turn it into vanillin -- the molecule that gives vanilla its flavour.

The ice cream is still in its research phase and currently not for human consumption.

#Guilty Flavours#vanillin#vanilla ice cream#ice cream#plastic waste#PET plastic#plastic pollution crisis#Youtube#Eleanora Ortolani#Central Saint Martins#University of the Arts London#polyethylene terephthalate (PET)#Dr Joanna Sadler#University of Edinburgh#plastic#polymers#Journal Biochemist#vanilla#green gold#biotechnology#recycle#upcycle

5 notes

·

View notes

Text

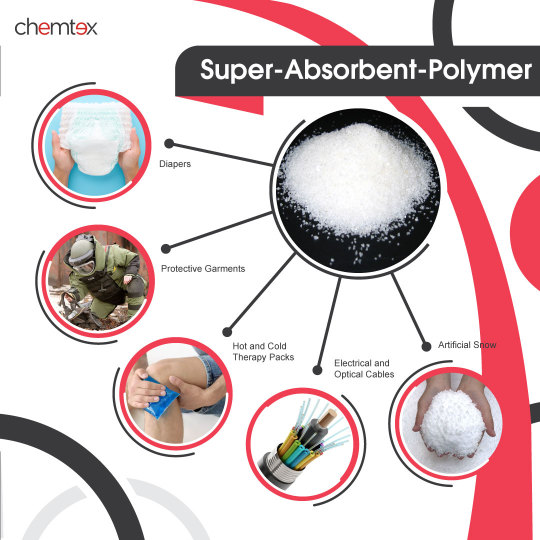

Super Absorbent Polymer Polyacrylate based | Chemtex Speciality Limited

Sodium Polyacrylate is a widely accepted super absorbent polymer, that finds extensive usage in various applications like ice gel packs, protective garments, baby diapers, etc., owing to its high water absorption capacity of about 300 – 400 times of its own weight.

Visit-

https://www.chemtexltd.com/products-and-solutions/performance-chemicals/general-chemicals/sodium-polyacrylate/

#polymers#polymer#polyacrylamide#absorbent#watergel#chemistry#polymerclay#manufacturing#chemicals#superabsorbentpolymer#waterabsorbent#sap#chemtexspecialitylimited

2 notes

·

View notes

Text

This one goes out to a post I found in which the OP made a Seinfeld skit where Jerry wished someone would make waffle makers out of polymers cuz he wanted to see how the waffles cook. 🧇

raise a glass to the posts you love that end up deleted. to the fanart and fanfics you lose track of and can't locate. to the blogs you used to look through that ended up unexpectedly disappearing. to the things you didn't archive because you always assumed they'd be there.

109K notes

·

View notes

Text

Degree in networking and I can't even write an email

0 notes

Text

What if there were a fabric that, like Superman, could take a bullet and self-heal? Such a super-dynamic, action-powered polymer might actually help protect real-life flyers in space. Material scientists at Texas A&M University have developed just such a polymer with a unique self-healing property never before seen at any scale. When struck by a projectile, this material stretches so much that when the projectile manages to pass through, it takes only a small amount of the polymer with it. As a result, the hole left behind is much smaller than the projectile itself. However, for now, this effect has only been observed under extreme temperatures and at the nanoscale.

Continue Reading.

83 notes

·

View notes

Text

Plants over plastics: Researchers create biodegradable cellulose-based packaging

Researchers at Virginia Tech have found a way to make biodegradable packaging stronger while using less energy in the process. The research team from the College of Agriculture and Life Sciences and the College of Natural Resources and Environment developed a low-pressure treatment that improves plant-based packaging materials. This discovery could help companies move away from plastic without sacrificing strength or durability. "Petroleum-based plastics have long been the mainstay of packaging applications," said Haibo Huang, associate professor in the Department of Food Science and Technology. "However, their persistence in the environment has led to increased concerns about 'white pollution.' Biodegradable packaging materials are gaining interest as alternatives, but they often struggle to match the performance properties of petroleum-based plastic."

Read more.

#Materials Science#Science#Plastics#Plants#Polymers#Cellulose#Biodegradable#Packaging#Virginia Tech#Biomaterials

40 notes

·

View notes

Text

Researchers Create Contact Lenses for Night Vision That Operate Even with Closed Eyes

Using safe polymers and nanoparticles, researchers developed night vision contact lenses that enable clear infrared vision even while the eyes are closed. Using nanoparticles to transform light into wavelengths, researchers at the University of Science and Technology in China have developed new night vision contact lenses that function even while the eyes are closed. The flexible nanoparticles are combined with polymers, which are non-toxic materials frequently found in contact lenses, to create the new kind of lenses. This was tested on people and mice to see how it functions.

0 notes

Text

Additive manufacturing, also known as 3-D printing, is a transformative approach to industrial production that is making lighter, stronger parts and systems a possibility.

This article will delve in the concept of additive manufacturing, its types, and the materials used in additive manufacturing.

What is the additive manufacturing?

Additive manufacturing is processes used to create a three-dimensional object by laying down successive layers of material under the control of a computer. Objects created can be of almost any shape or geometry and are created from digital model data. It is intended to construct a part from scratch but raw material, using digital data coming from a CAD file.

The familiar term of additive manufacturing is 3D printing. This is a popular type of additive manufacturing.

#science#materials science#engineering#materials science and engineering#materials#metals#polymers#composites#ceramics#biomaterials#3D printing#additivemanufacturing

2 notes

·

View notes